Patents

Literature

76results about How to "Swing control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

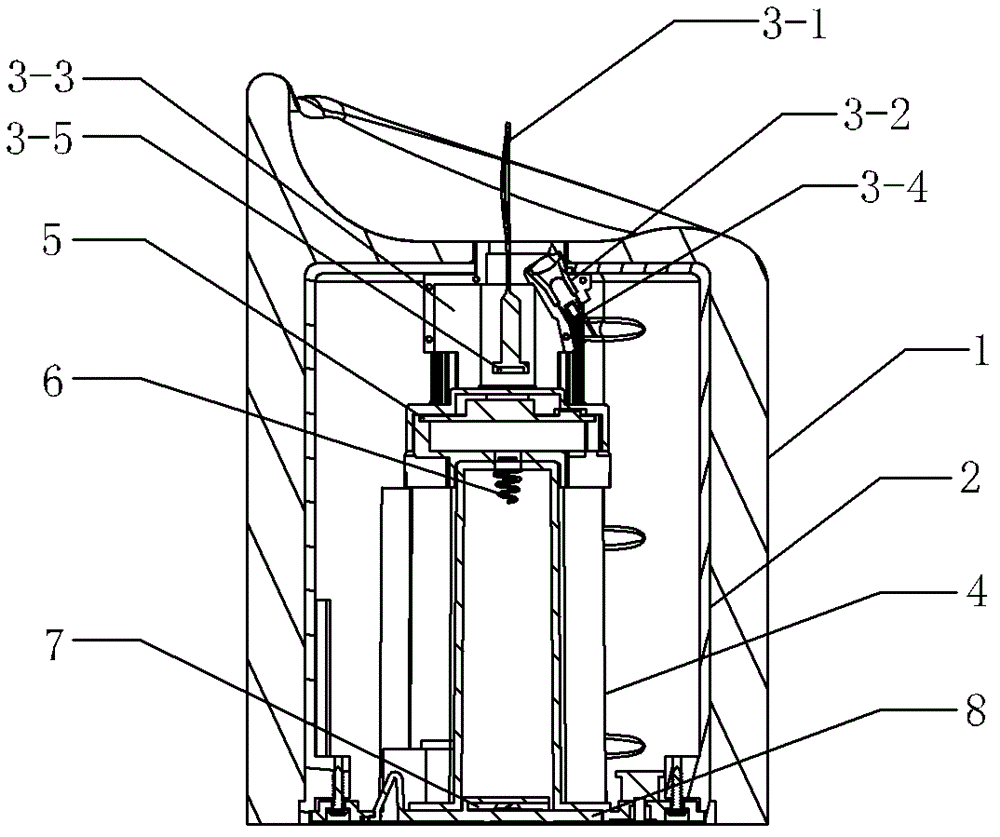

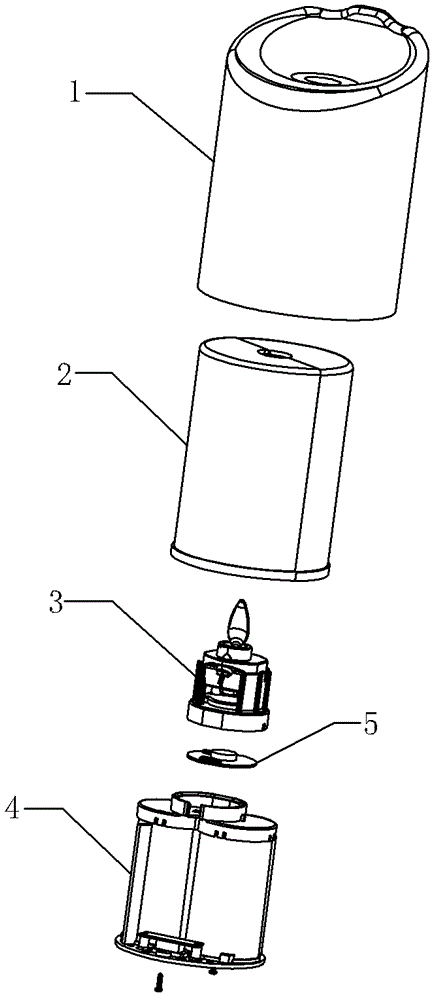

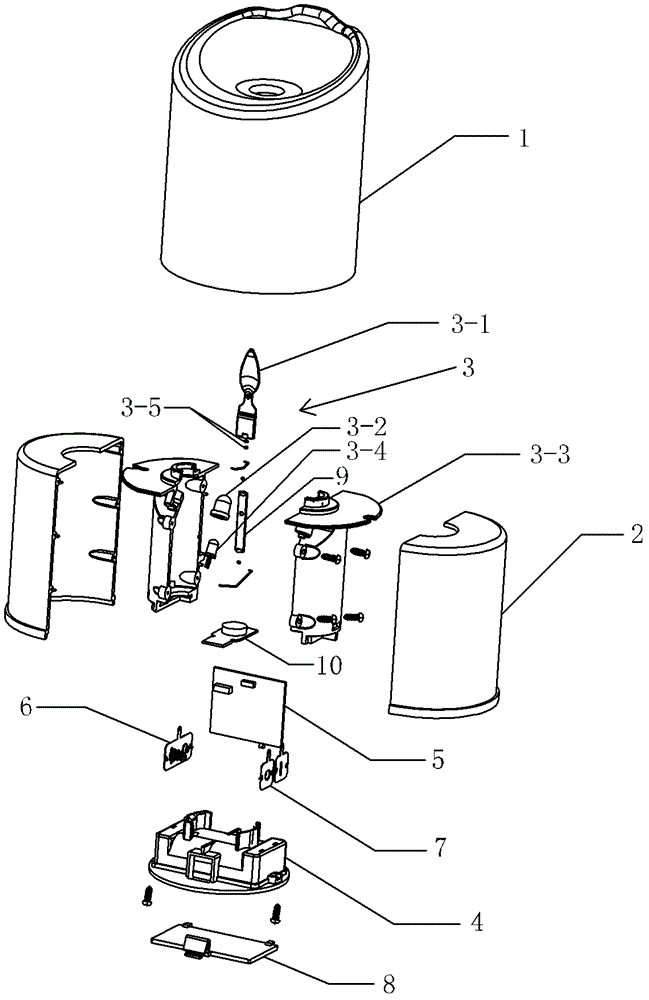

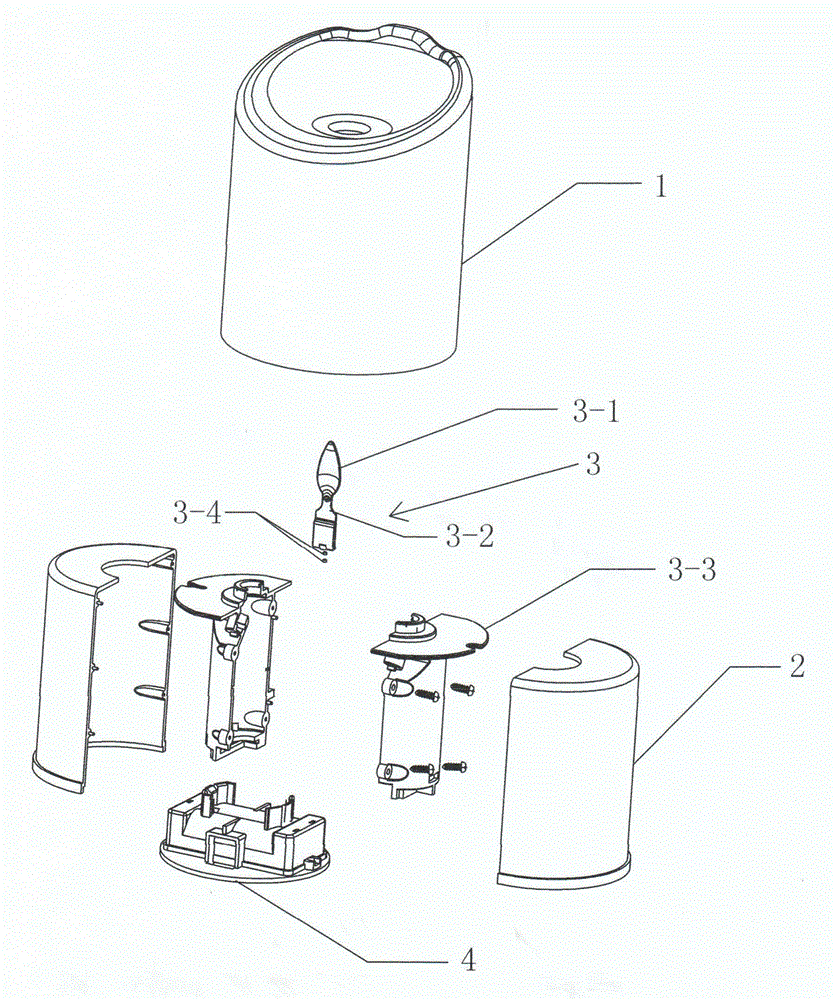

High-simulation light-emitting diode (LED) candle lamp

InactiveCN102748589AReduce power consumptionNo wastePoint-like light sourceElectric circuit arrangementsElectrical batteryElectrical polarity

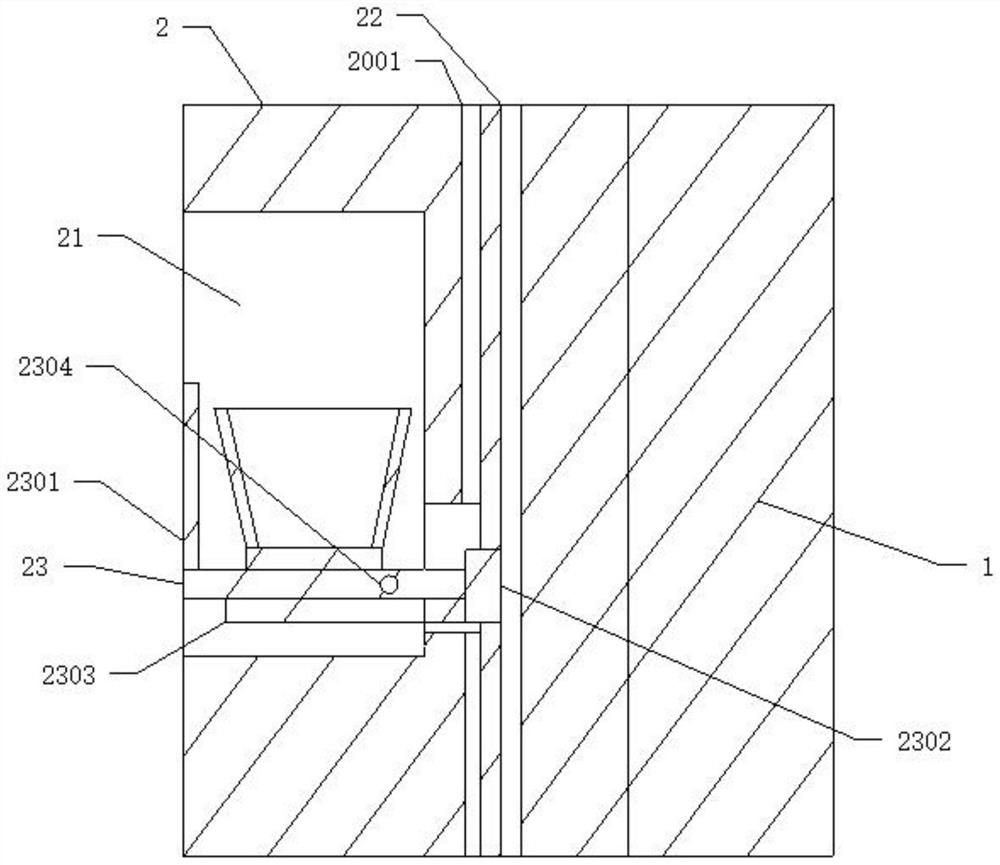

The invention discloses a light-emitting diode (LED) candle lamp and the swinging principle of a light-emitting sheet of the LED candle lamp. The LED candle lamp comprises a casing, a casing core arranged in the casing, a light-emitting assembly and a battery box arranged at the bottom of the casing. The light-emitting assembly comprises the light-emitting sheet, a lens and a support, wherein the support is fixed on the casing core, an LED chip is arranged on the lens, and a magnet is connected at the bottom of the light-emitting sheet. A power supply driving plate is arranged on a top cover of the battery box and is matched with the magnet of the light-emitting sheet through an electromagnet to form a flame swinging mechanism. The swinging principle in that: an electromagnetic coil is driven and led to generate a magnetic field with corresponding change, polarity of the direction of the magnetic field is identical to that of the direction of the magnet at the bottom of the light-emitting sheet, repulsive force changing along with square waves is generated, and the light-emitting sheet is led to swing randomly under effects of electromagnetic force and self gravity. The LED candle lamp is small in electricity consumption and generated heat, is completely free of potential safety hazard, cannot cause energy waste, achieves effect of environment protection, and is suitable for being widely used by people.

Owner:GUANGDONG TONGFANG LIGHTING

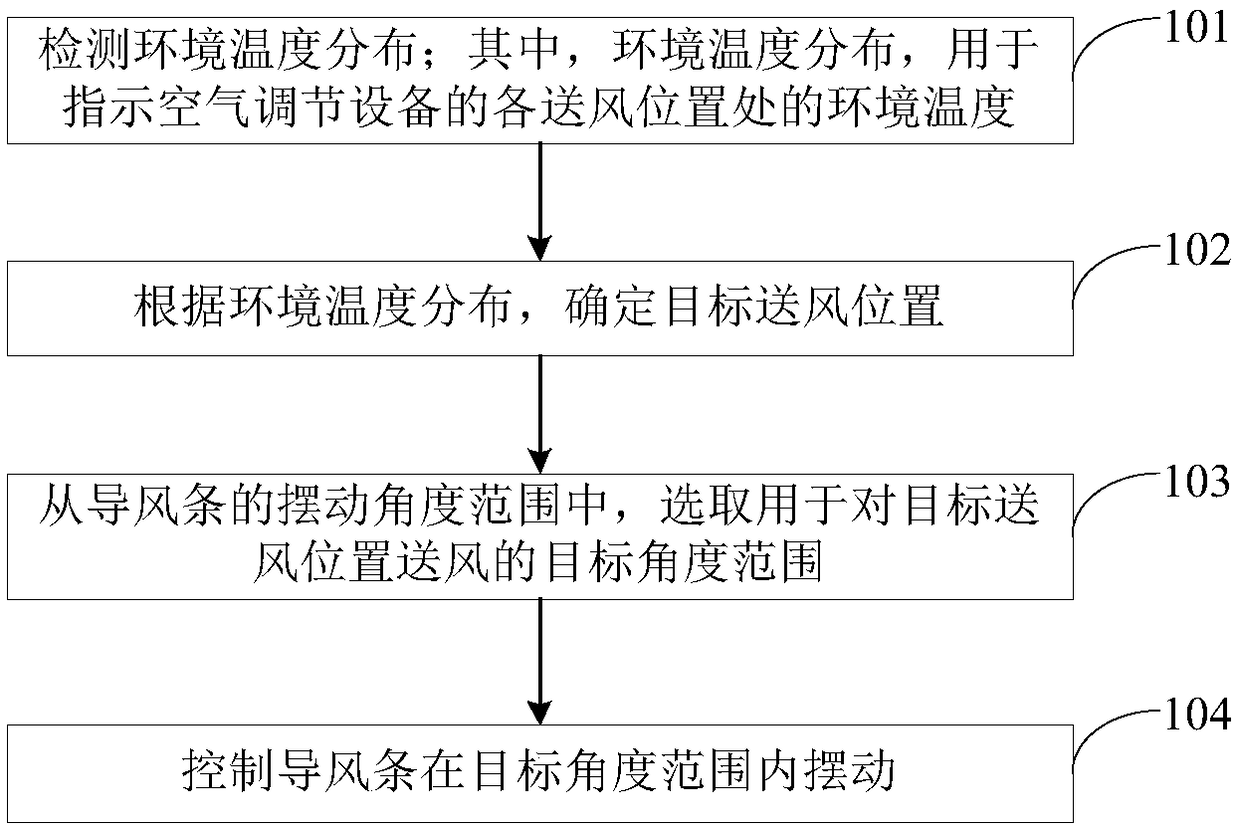

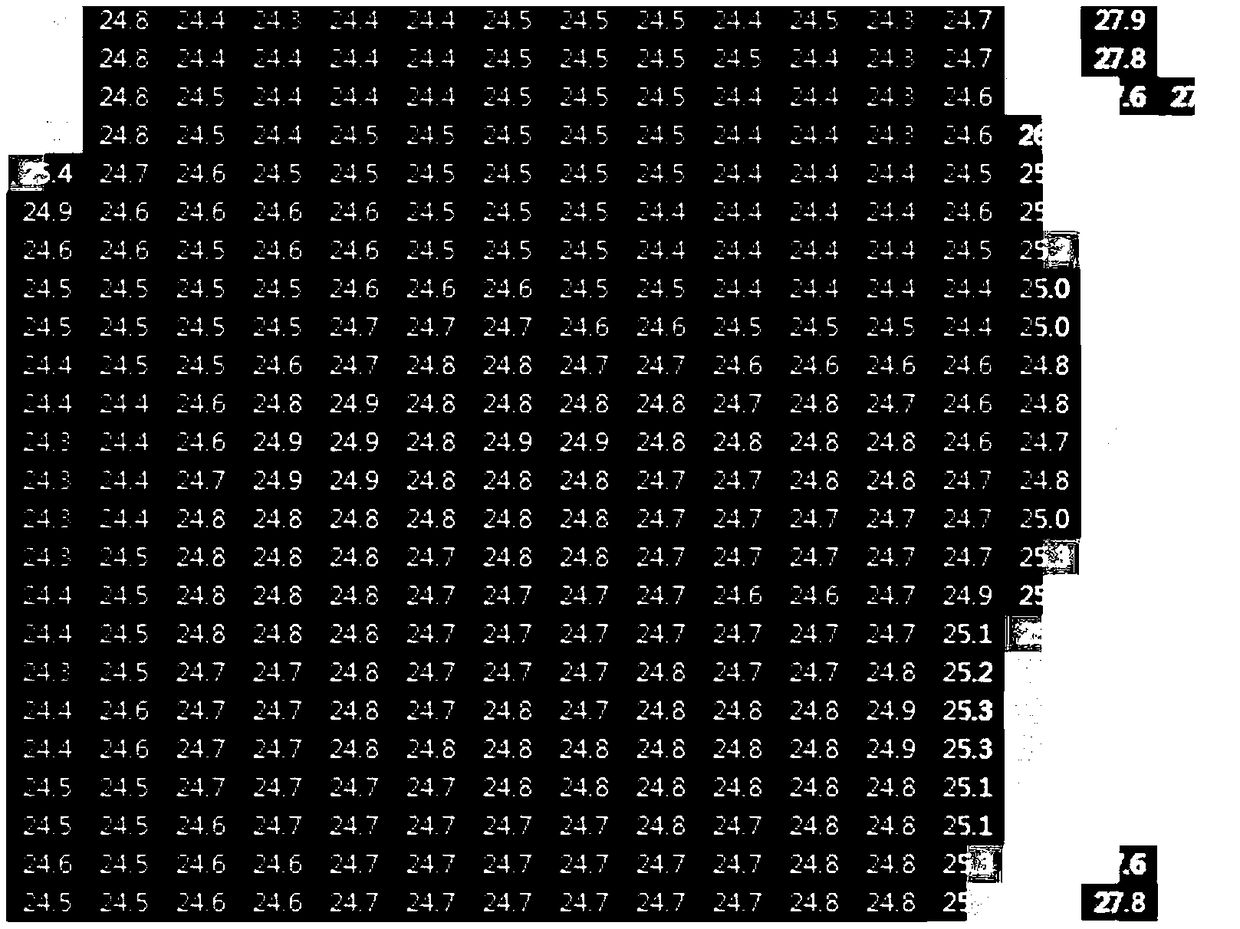

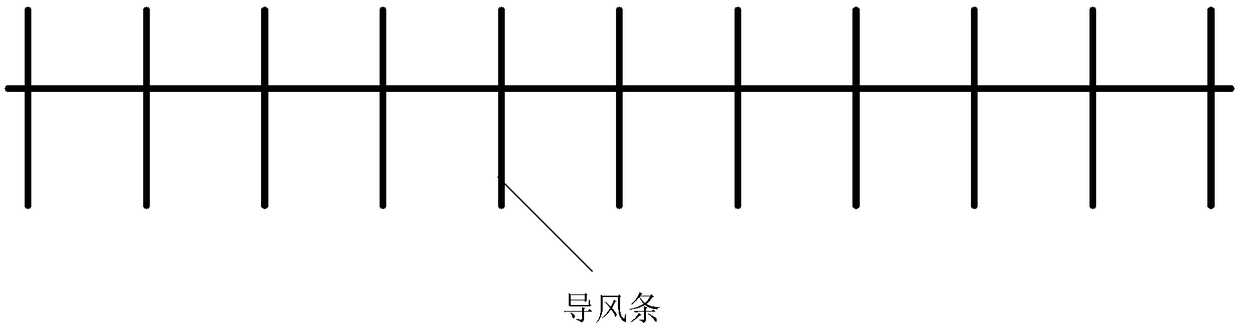

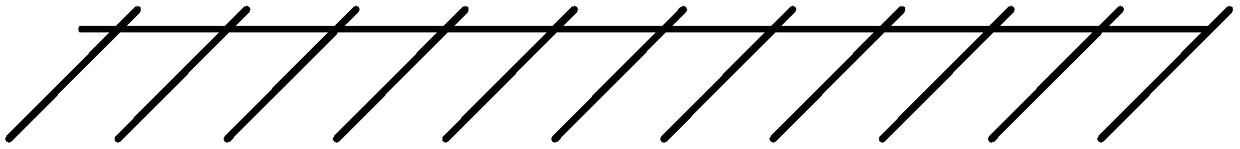

Air guide strip control method and device of air conditioning equipment and air conditioning equipment

InactiveCN108800469AImprove comfortUniform distribution of ambient temperatureMechanical apparatusLighting and heating apparatusEngineeringAir conditioning

The invention provides an air guide strip control method and device of air conditioning equipment and the air conditioning equipment. The method comprises the steps that environment temperature distribution is detected and is used for indicating the environment temperature of each air supply position of the air conditioning equipment; the target air supply position is determined according to environment temperature distribution; the target angle range used for supplying air to the target air supply position is selected from the swing angle range of an air guide strip; and then the air guide strip is controlled to swing within the target angle range. In the method, the swing angle range of the air guide strip can be controlled according to environment temperature distribution, and thereforethe aim that the environment temperature in the space where the air conditioning equipment is located is distributed uniformly is achieved, and user comfort is improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

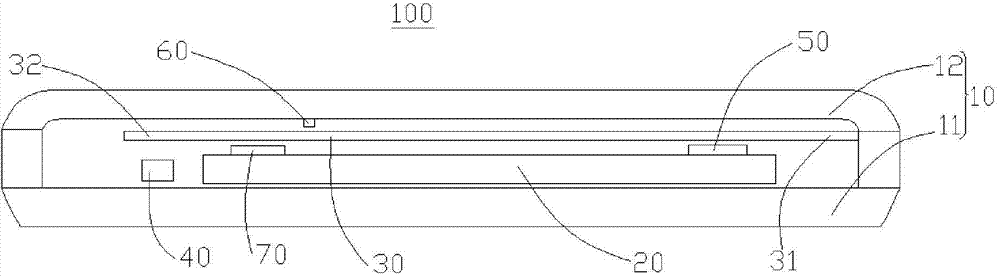

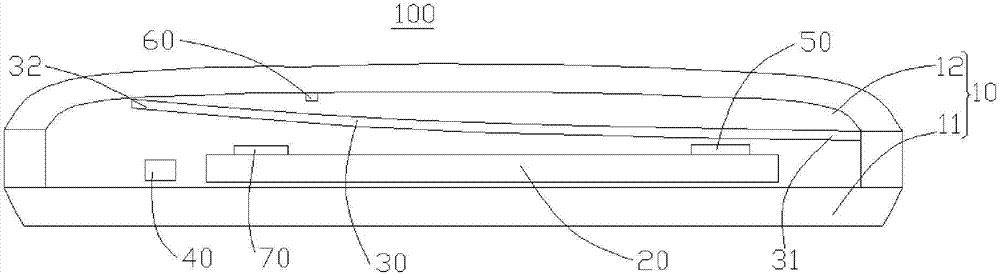

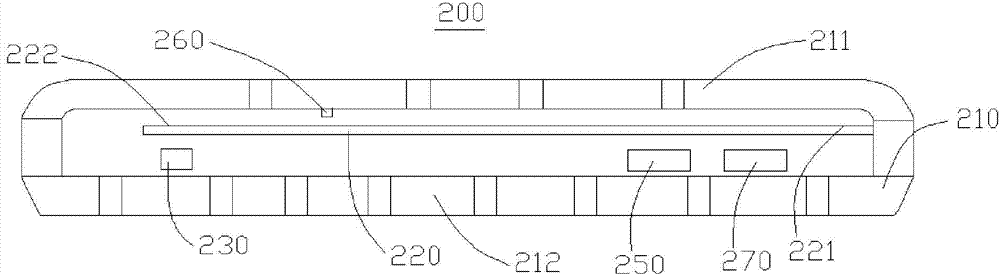

Electronic equipment and air flow accelerating device

ActiveCN104853562AImprove cooling efficiencySpeed up distributionCooling/ventilation/heating modificationsMetallic materialsElectric equipment

The invention discloses electronic equipment and an air flow accelerating device. The electronic equipment comprises a housing, an electronic device, a vibration sheet and an electromagnet. The housing comprises a front housing and a rear housing arranged opposite to the front housing. The rear housing is made of a memory metal material. The electronic device is arranged between front housing and the rear housing. The vibration sheet is arranged between electronic device and the rear housing. The vibration sheet comprises a fixed part and a free end. The fixed part is relatively fixed to the front housing. The vibration sheet is made of material capable of being absorbed by a magnetic piece. The electromagnet is arranged between the front housing and the rear housing. When the heat radiated by the electronic device enables the temperature of the rear housing to reach a preset value, the rear housing deforms, the space between the rear housing and the front housing is increased, the electromagnet is power-on, and the free end of the vibration sheet is capable of swinging in the space under the magnetic force of the electromagnet, so that the heat radiation speed is increased.

Owner:LENOVO (BEIJING) CO LTD

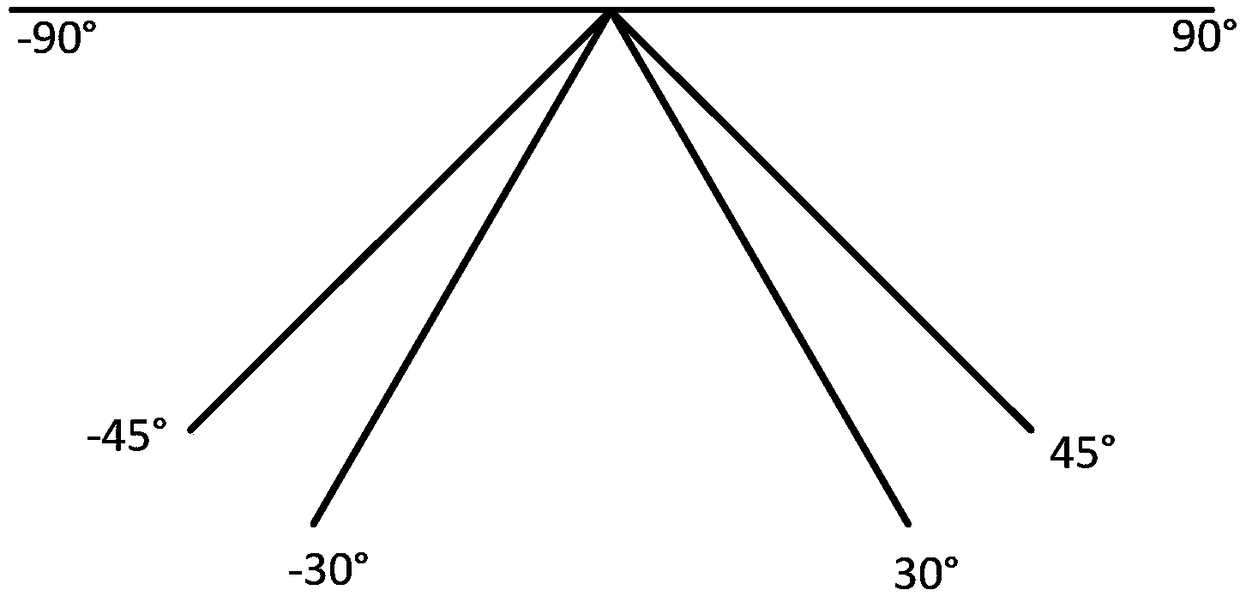

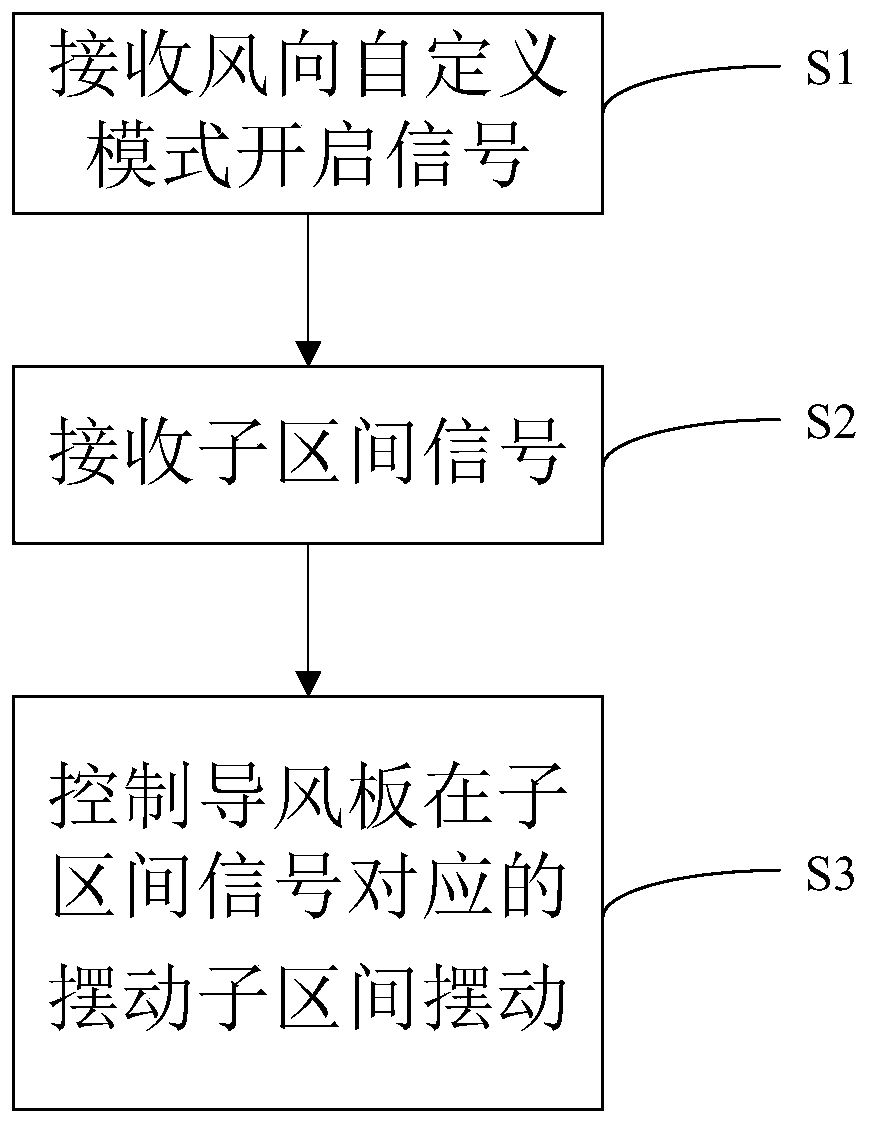

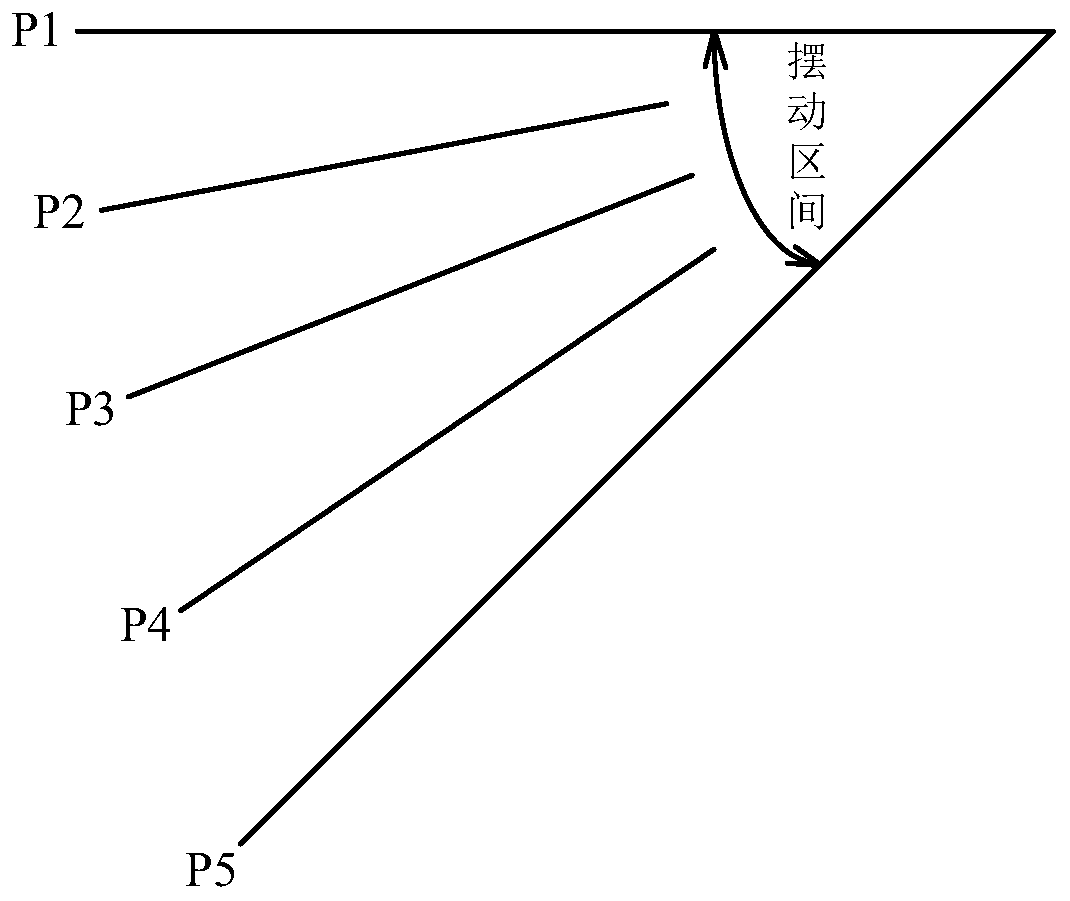

Wind deflector multidirectional swing control method and control device and air conditioner

ActiveCN110608506AWide range of controlSolve the wind blowingMechanical apparatusSpace heating and ventilation safety systemsRemote controlEngineering

The invention provides a wind deflector multidirectional swing control method, a wind deflector multidirectional swing control device and an air conditioner, and relates to the air conditioning technology field. The wind deflector multidirectional swing control method includes: when receiving a wind direction custom mode starting signal, entering a wind direction custom mode, wherein the wind direction custom mode includes a plurality of preset positions set in a wind deflector swing range, the plurality of the preset positions are all located in the wind deflector swing range, a wind deflector is suitable for swinging between two arbitrary preset positions, an interval between each two adjacent preset positions is used as a swing subrange, and the different swing subranges correspond to different subrange signals; and when receiving each subrange signal sent by a remote control device, controlling the wind deflector to swing in the corresponding swing subrange according to each received subrange signal. The wind deflector multidirectional swing control method, the wind deflector multidirectional swing control device and the air conditioner are wide in wind swing direction controlrange, and suitable for customers to voluntarily set wind directions of swing wind according to scenes, solves the problems that discharged wind directly blows and temperature is slow to balance, andis humanized.

Owner:NINGBO AUX ELECTRIC +1

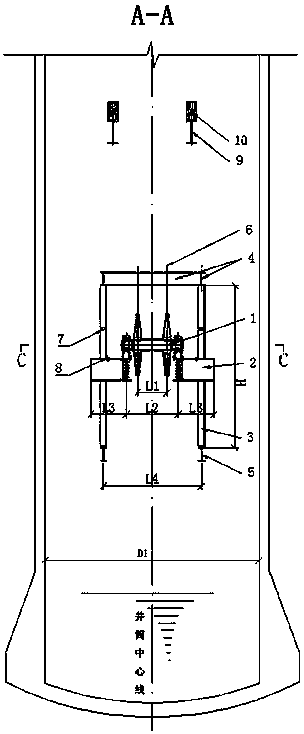

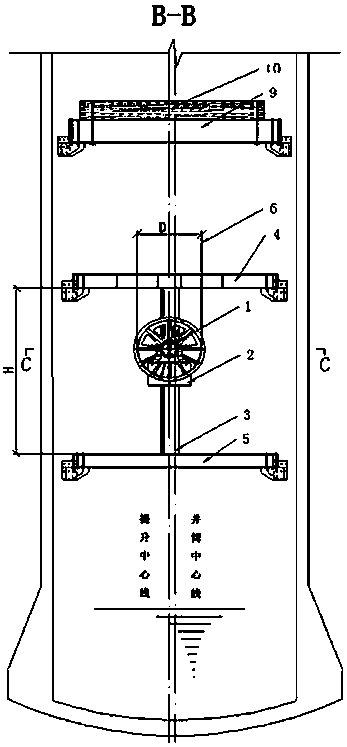

Tail rope tensioning device for vertical shaft hoisting container

The invention discloses a tail rope tensioning device for a shaft hoisting container, which comprises a tail rope tension beam (5), on which two guide columns (3) are arranged, and a movable guide wheel support (2) Placed between two guide columns (3), the movable guide wheel support (2) is connected with the guide wheel mechanism (1), the upper end of the guide column (3) is connected with the anti-kink beam (4), and the guide column ( 3) There is a vertical limit block (7) on the top, and a horizontal limit block (8) is set on the movable guide wheel support (2). Compared with the traditional anti-kink device and method for the tail rope of the shaft hoisting container, the present invention has the advantages of improving the smooth operation of the hoisting container, effectively preventing the kink of the tail rope of the hoisting container, and reducing the wear and tear of the tail rope, and more importantly, it essentially solves the kink of the tail rope security issues.

Owner:GUIYANG AL-MG DESIGN & RES INST

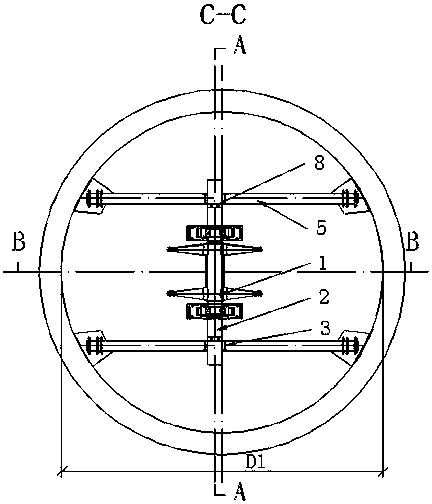

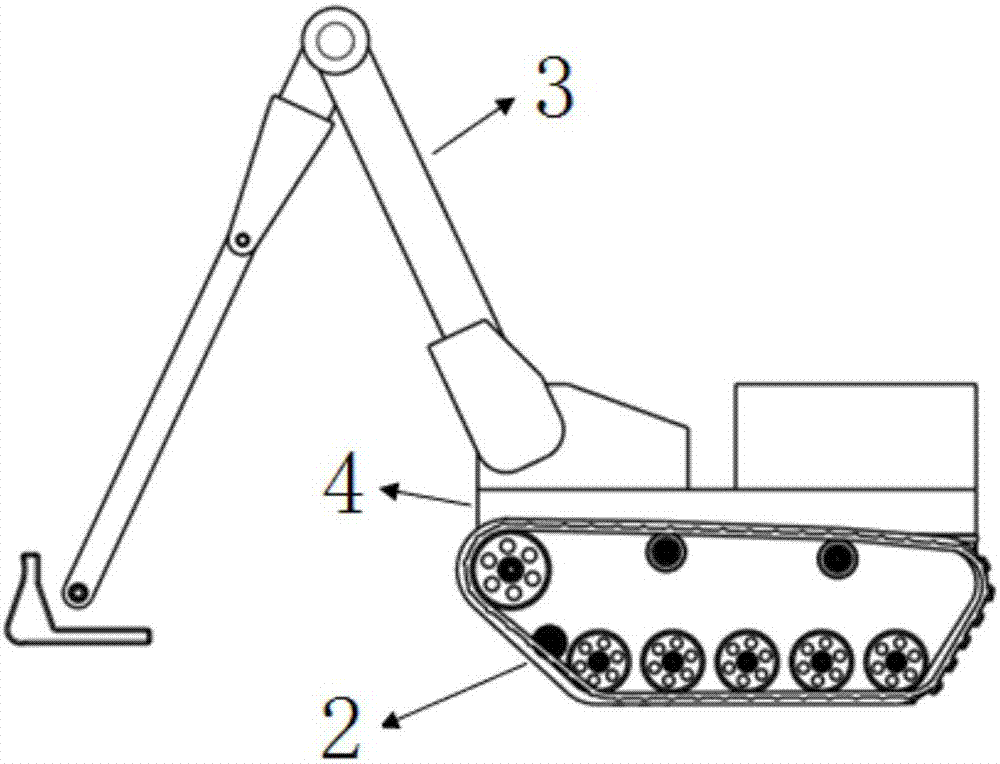

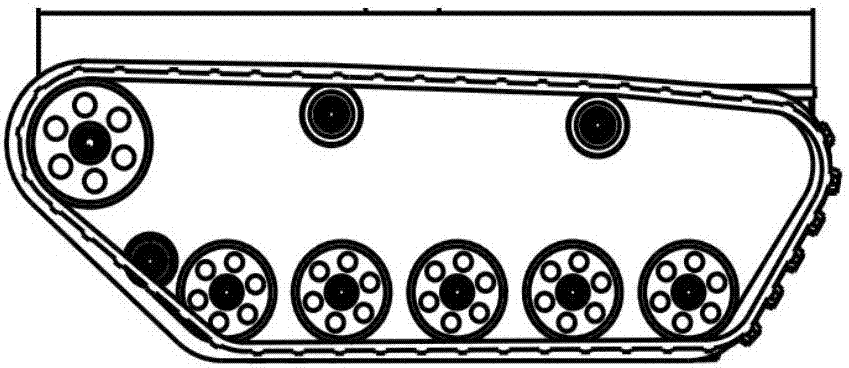

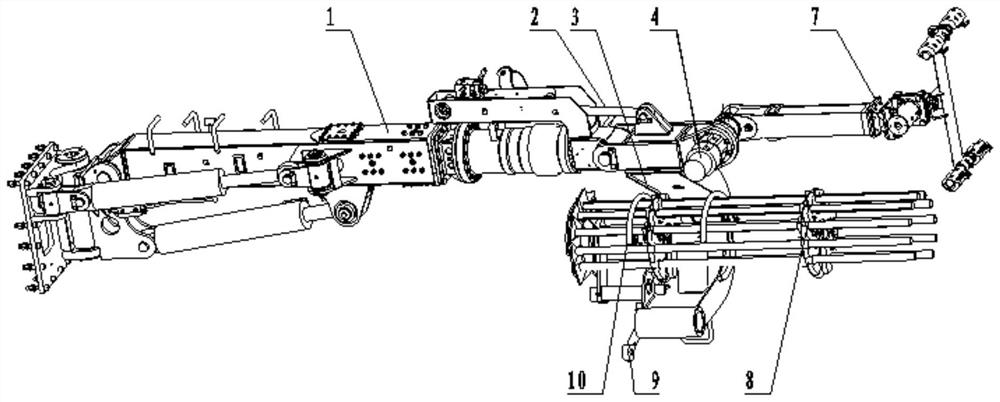

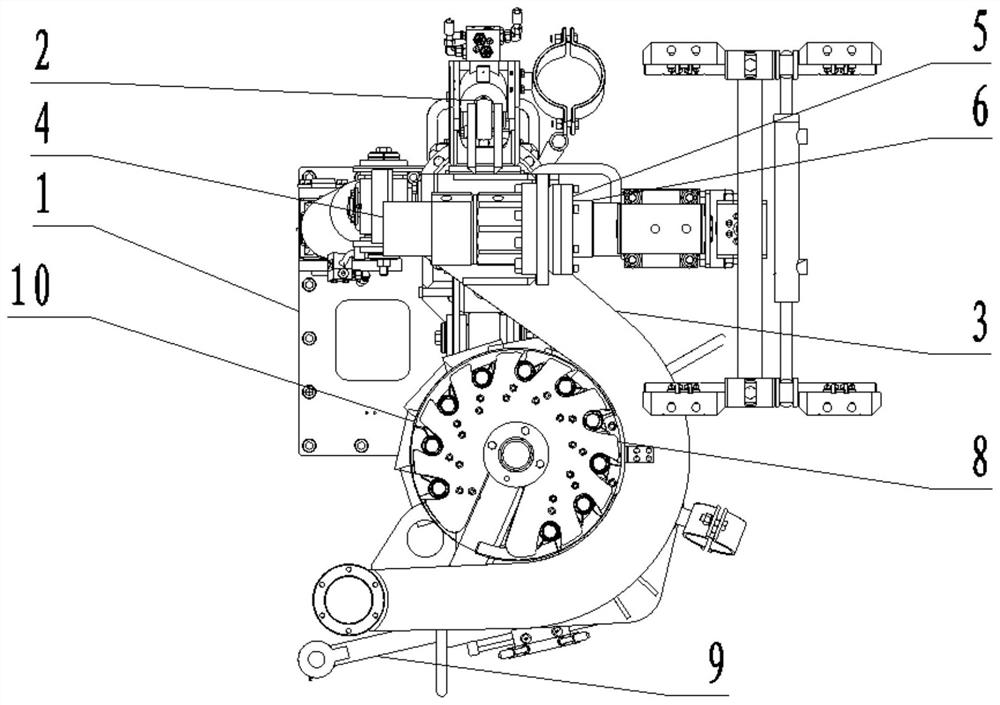

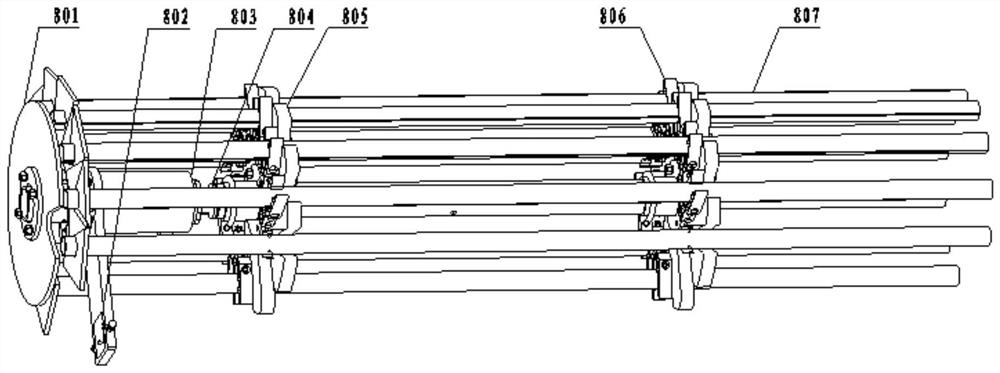

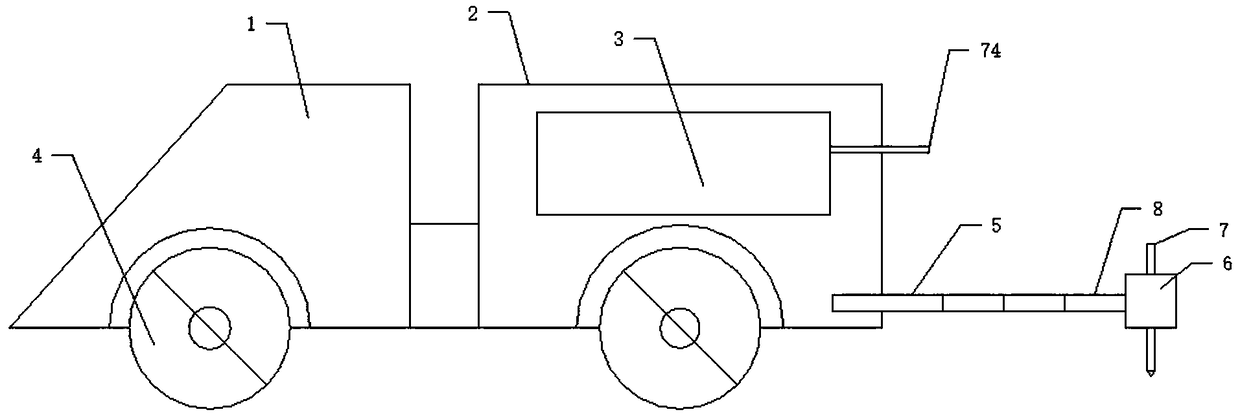

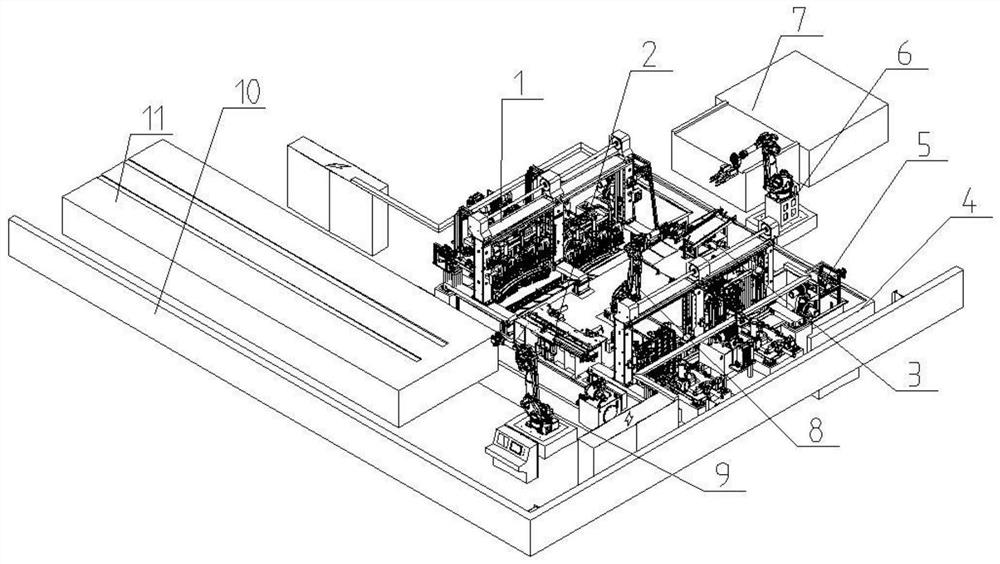

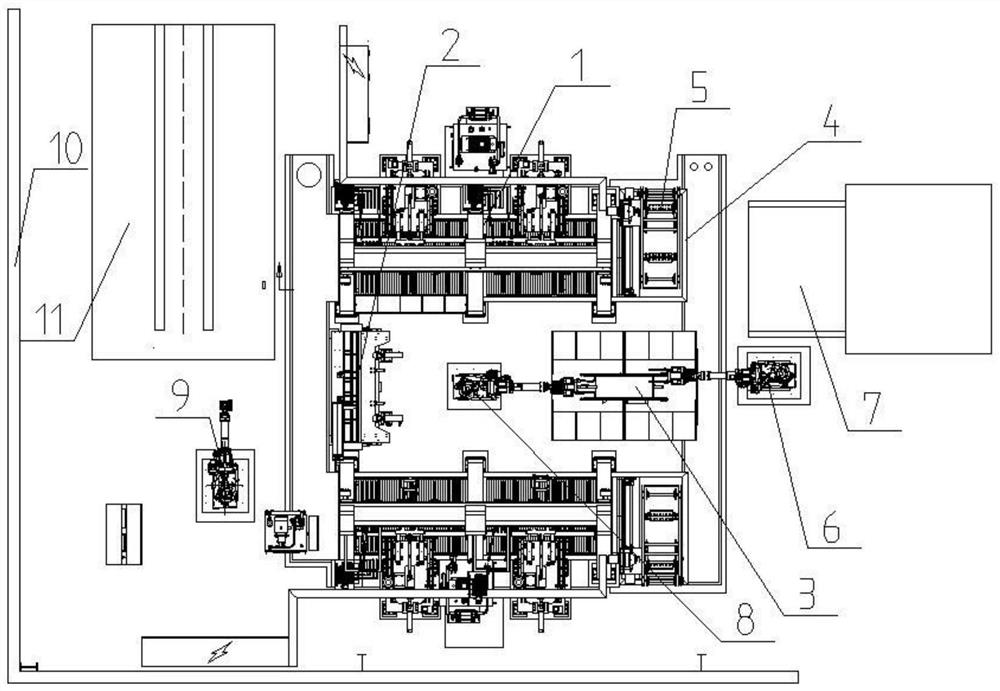

Autonomous type mine detection robot system and mine detection method

InactiveCN107328308AReasonable path planningImprove operational efficiencyDefence devicesPosition/course control in two dimensionsRobotic systemsControl system

The invention discloses an autonomous type mine detection robot system and a mine detection method. The autonomous type mine detection robot system comprises a vehicle body. A moving chassis system 2, a mechanical arm detection system 3 and a coating system 4 are arranged on the vehicle body. The moving chassis system 2 is connected with the mechanical arm detection system 3 and the coating system 4. The moving chassis system 2 comprises a moving platform system 5, a power system 6 and a control system 7. The mechanical arm detection system 3 comprises a mechanical arm movement system 8 and a detection system 9. The power system 6 is installed at the back end of the movement platform system 5, provides the power source for the whole device and is used as a counter weight. The control system 7 is connected with the power system 6 and the detection system 9. The detection system 9 is arranged at the front end of the mechanical arm movement system 8. The autonomous type mine detection robot system can intelligently, accurately and efficiently detect and mark mine points of a mine area in a non-destructive manner, and therefore the safe and reliable guarantee is provided for follow-up mine removal. The autonomous type mine detection robot system conducts mine detection and marking and is long in service life.

Owner:上海圭目机器人有限公司

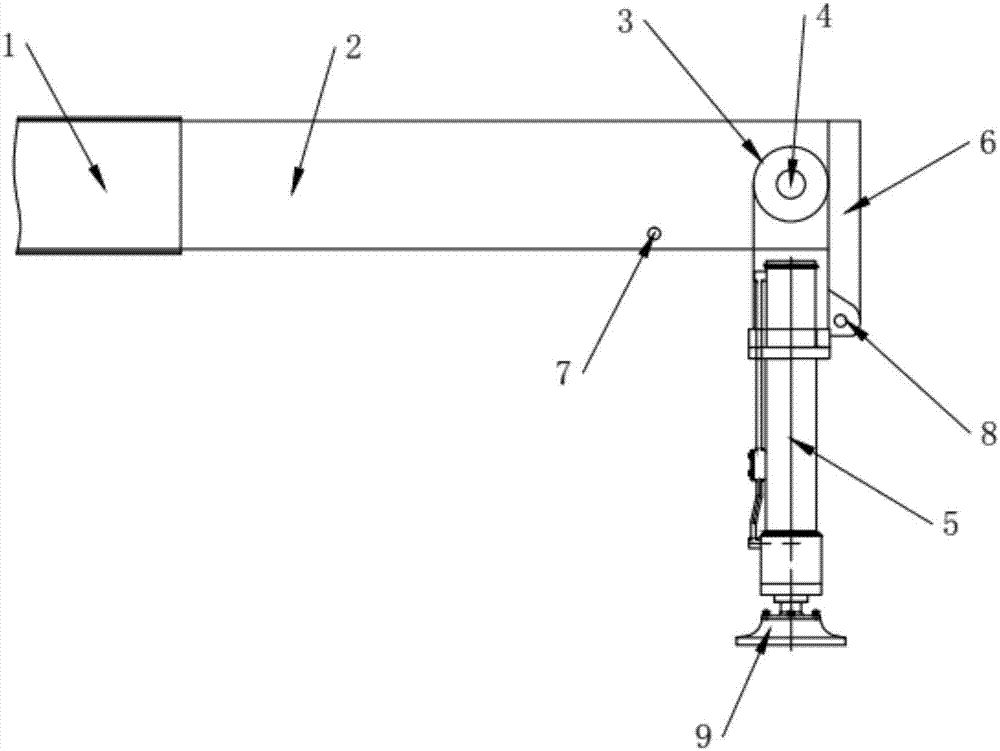

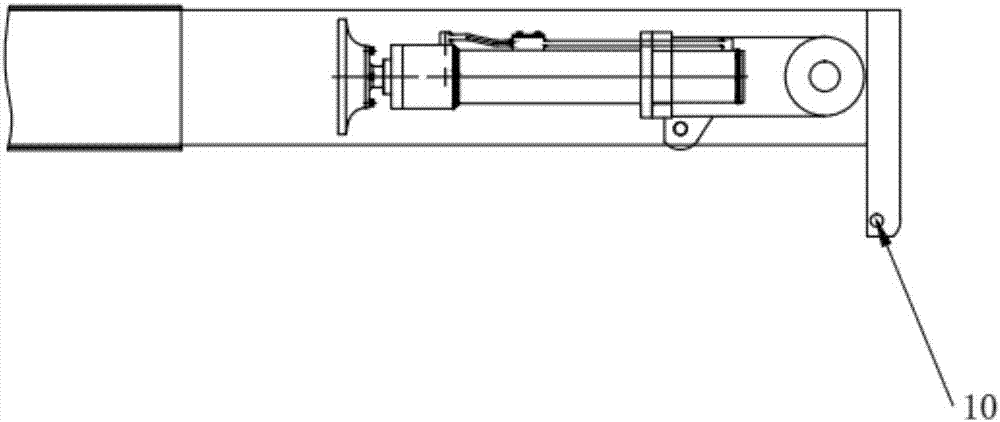

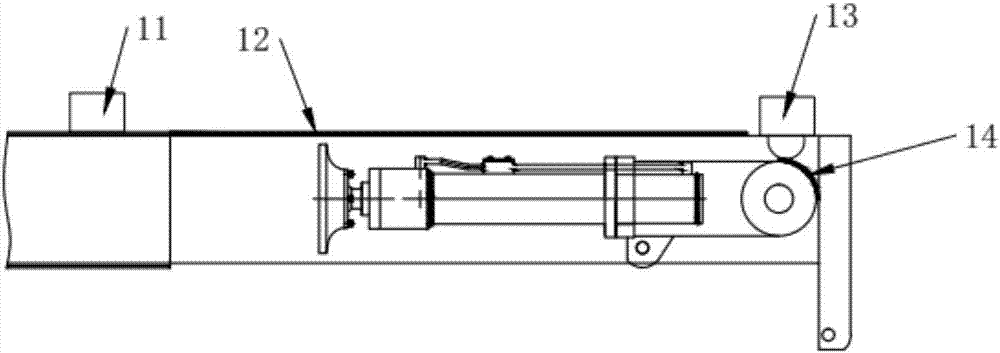

Foldable supporting leg and engineering car with same

InactiveCN107953867AOvercoming the small ground clearanceOptimized designVehicle fittings for liftingMechanical engineeringHydraulic cylinder

The invention discloses a foldable supporting leg and an engineering car with the same, and relates to the technical field of supporting devices. The foldable supporting leg comprises a car body, a mounting seat, a sliding sleeve and a hydraulic cylinder, the mounting seat is mounted on the car body, one end of the sliding sleeve is slidably mounted in the mounting seat in a reciprocating manner,the sliding direction of the sliding sleeve is parallel to axes of wheels on the car body, an opening is formed in the lower surface of the sliding sleeve, hiding space is formed in the sliding sleeveby the aid of the opening, the hydraulic cylinder is hinged into the hiding space, a hinging position approaches to the other end of the sliding sleeve, the swinging direction of the hydraulic cylinder and the sliding direction of the sliding sleeve are in the same plane, and a supporting seat is mounted at the end of the telescopic pole of the hydraulic cylinder. The foldable supporting leg hasthe advantage that the foldable supporting leg is simple in structure, foldable and convenient to use.

Owner:CHANGDE KEJIAN MACHINERY MFG CO LTD

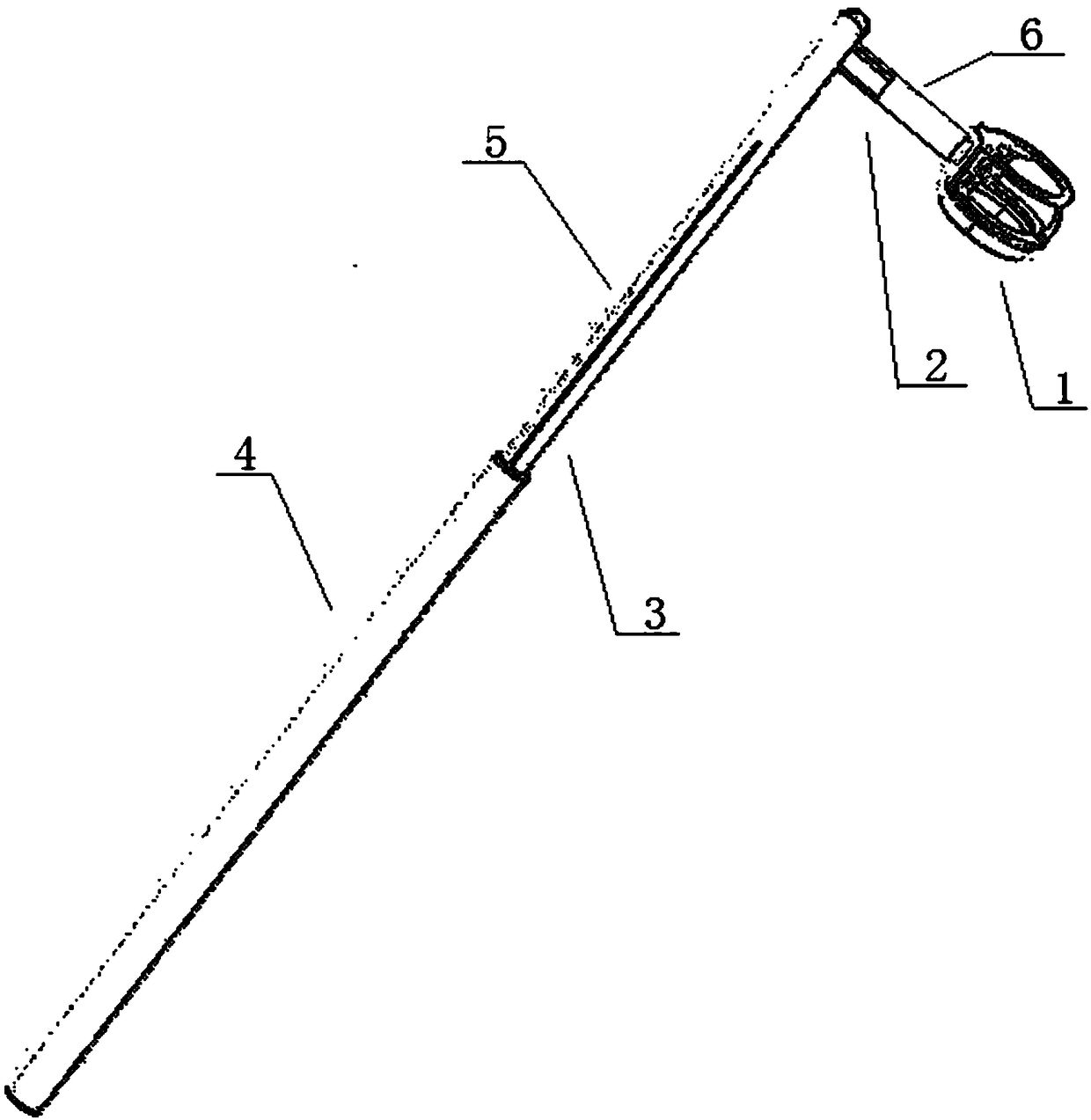

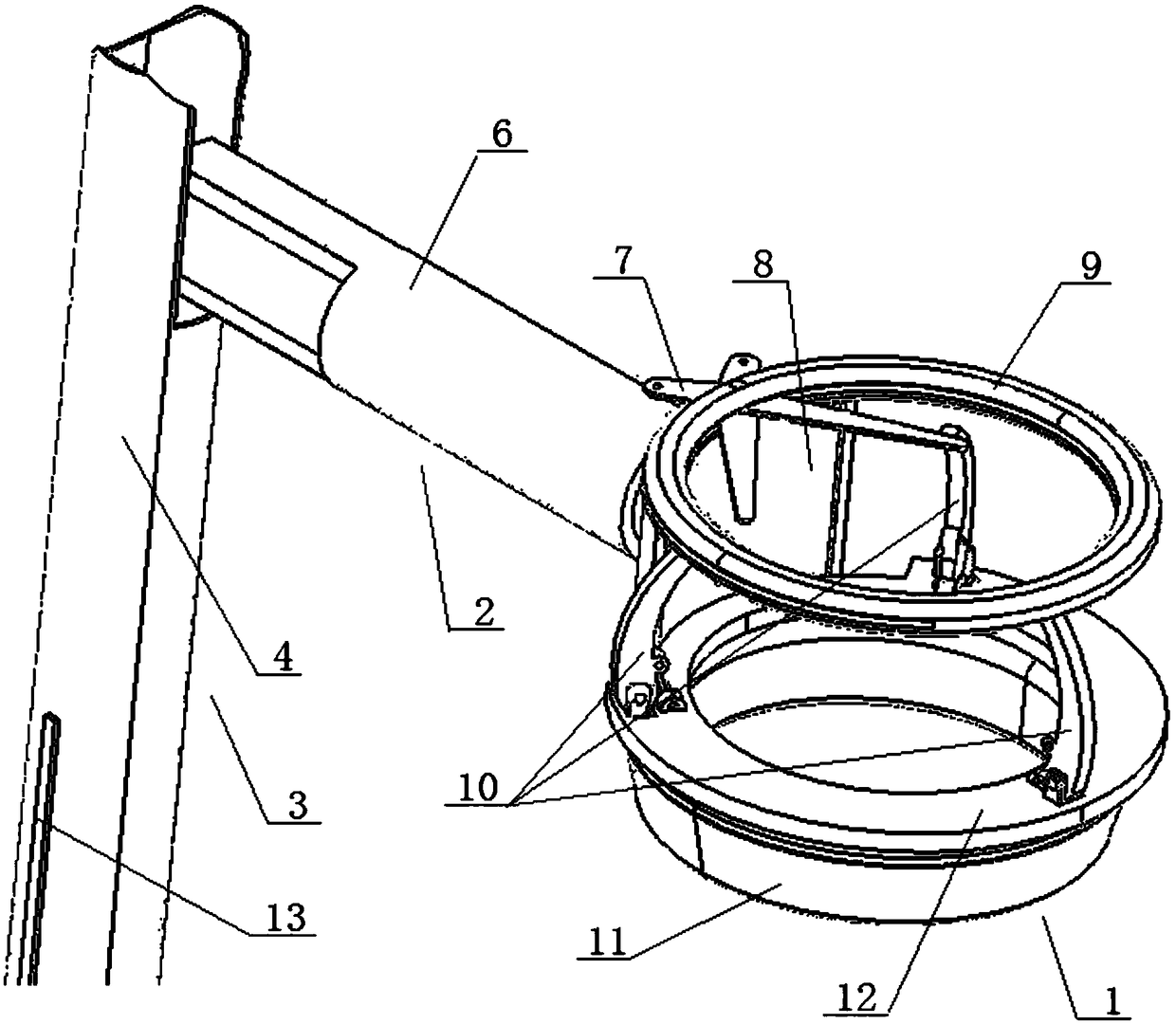

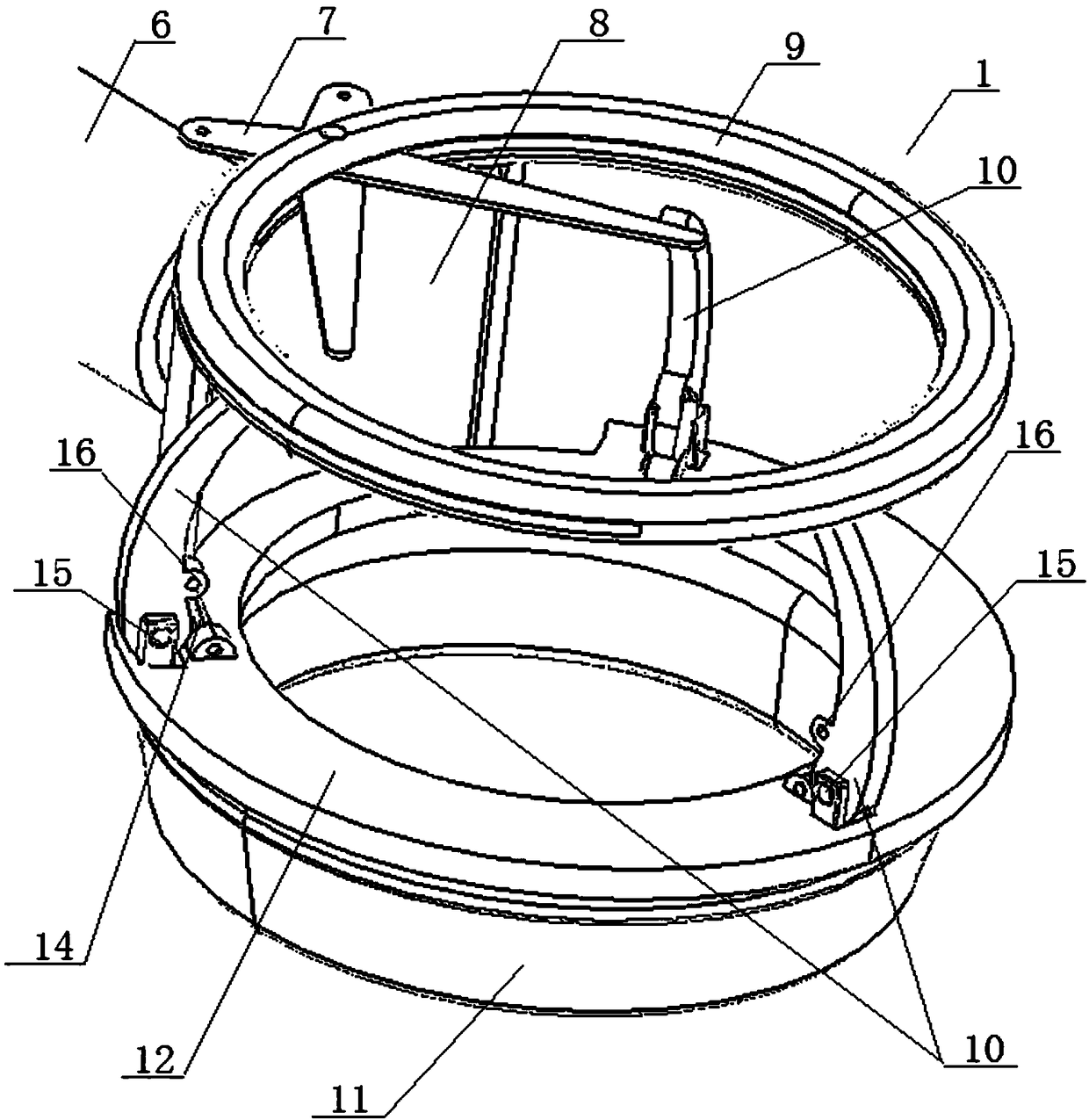

Electric telescopic self-sensing tree fruit picker

PendingCN108633476AMeet the needs of picking fruitReduce volumePicking devicesFruit treeSelf sensing

The invention provides an electric telescopic self-sensing tree fruit picker. The electric telescopic self-sensing tree fruit picker comprises a collecting bag and a buffer and is characterized by also comprising a telescopic rod, a swing rod and a tail end executor, wherein the swing rod is arranged at the top end of the telescopic rod, one end of the swing rod is fixedly connected with the telescopic rod, the other end of the swing rod is fixedly connected with the tail end executor, the control end of the swing rod is arranged at the lower portion of the telescopic rod and is fixedly connected, the collecting bag is arranged below the tail end executor and is fixedly connected with the tail end executor, and the buffer is arranged in the collecting bag and located under the tail end executor. The working process is that the height of the telescopic rod is roughly adjusted according to the height of each fruit tree; the swing rod is adjusted to make the tail end executor reach a fruit position; fruits are captured; the fruits are picked; resetting is performed; the fruits are collected.

Owner:JILIN AGRI SCI & TECH COLLEGE

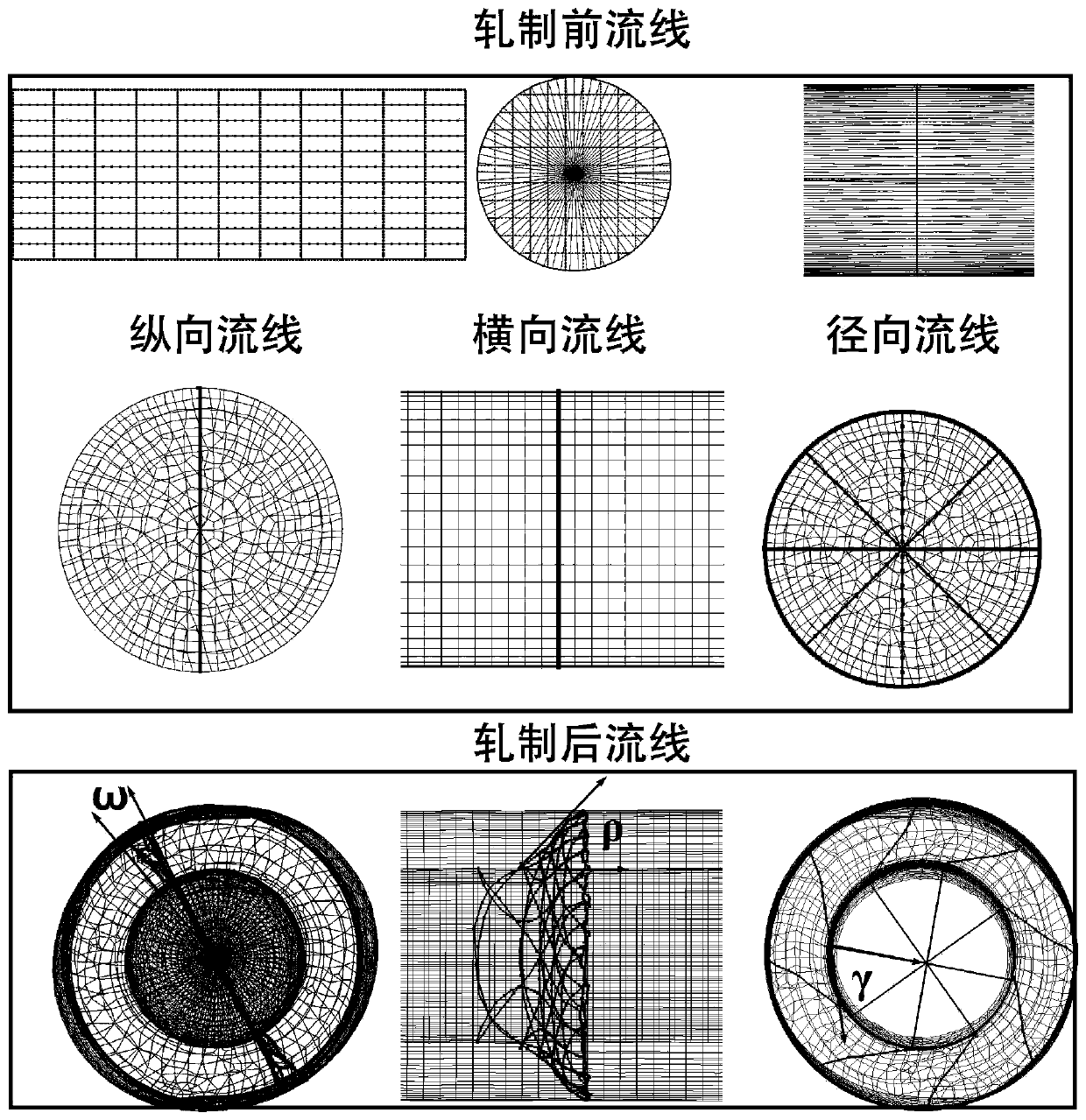

High-strength and high-toughness two skew-roll piercing method for 2219 aluminum alloy pipe

ActiveCN111589869AReduce resistanceWear controlMetal rolling stand detailsMetal rolling arrangementsTemperature controlHeating furnace

The invention discloses a high-strength and high-toughness two skew-roll piercing method for a 2219 aluminum alloy pipe, and relates to the technical field of aluminum alloy pipe machining. The methodcomprises the following steps that skew-roll piercing is conducted by adopting a perforating machine with a double-spiral conical roller; the plug advance is set to be 5-25 mm, the feeding angle of the two skew-roll perforating machine is set to be 6-21 degrees, the rolling angle is set to be 8-15 degrees, the reduction rate is set to be 5%-10%, the rotating speed of the roller is set to be 20-35r / min, and a aluminum alloy cylindrical blank is heated to 440-460 DEG C by adopting a heating furnace; the heated aluminum alloy cylindrical blank is moved to a guide chute of the two skew-roll perforating machine from the heating furnace; and the aluminum alloy cylindrical blank penetrates through a plug under the action of the roller, and the temperature of a rod blank is controlled to be 350-500 DEG C in a rolling process. According to the high-strength and high-toughness two skew-roll piercing method, three-dimensional pressing-twisting composite deformation of the aluminum alloy in thetwo-roller skew-roll piercing process is achieved, and finally the high-strength and high-toughness 2219 aluminum alloy pipe is obtained through the two-roller skew-roll piercing method.

Owner:安徽汉正轴承科技有限公司

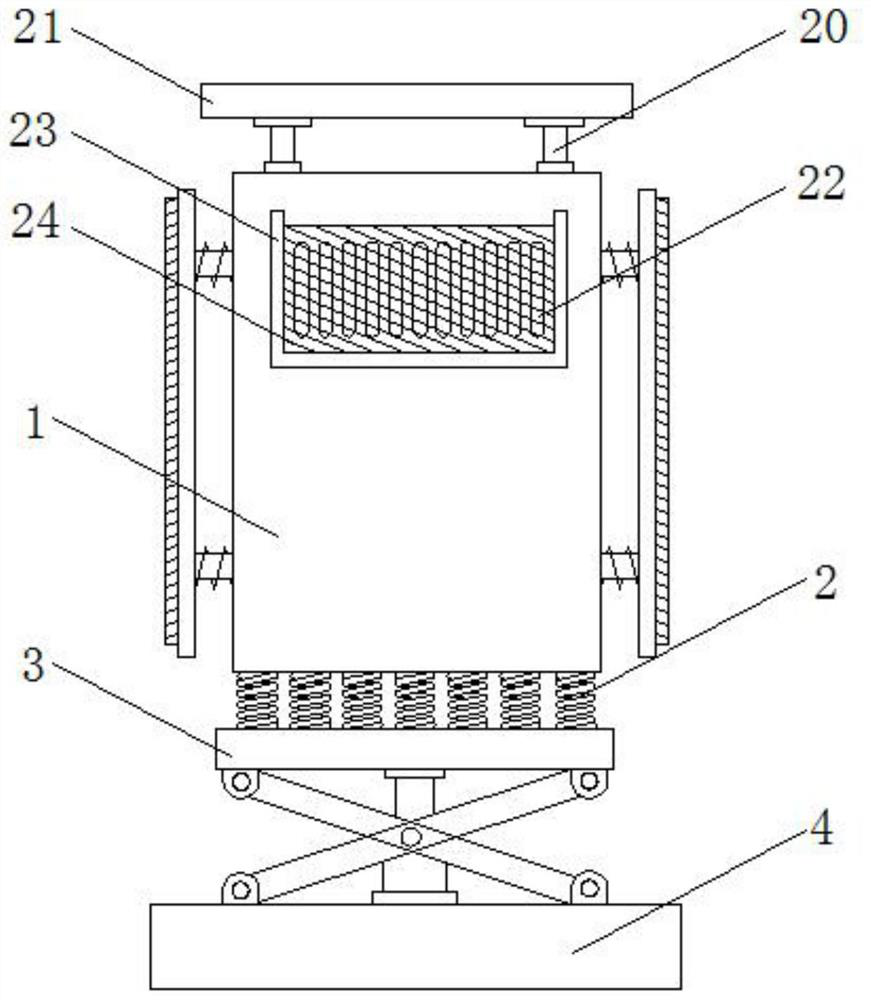

Arm frame mechanism for anchor net trolley

PendingCN112943328AImprove work efficiencyImprove adaptabilityUnderground chambersTunnel liningArchitectural engineeringMesh reinforcement

Owner:CHINA RAILWAY CONSTR HEAVY IND

Flange plate grinding device

InactiveCN108214129AEasy to processReduce processing costsRevolution surface grinding machinesGrinding work supportsFlangeEngineering

The invention belongs to the field of grinding devices, and particularly relates to a flange plate grinding device. The flange plate grinding device comprises a machine frame and a grinding knife, wherein the machine frame is provided with a positioning spigot, a rotating shaft is arranged on the machine frame in a penetrating mode, one end of the rotating shaft is located in the positioning spigot, and the other end of the rotating shaft is connected with a motor; fan blades are further arranged on the rotating shaft, and an air collecting opening is formed in one side of one fan blade; a knife placing groove for allowing the grinding knife to rotate is further formed in one side of the positioning spigot, a cavity is formed in the grinding knife, and a vent pipe is arranged in the bottomof the knife placing groove and penetrates through the machine frame; one end of the vent pipe communicates with the cavity of the grinding knife, and the other end of the vent pipe communicates withthe air collecting opening; air holes are further formed in the grinding knife, a first air cylinder is further fixedly connected to the machine frame, and an output rod of the first air cylinder isfixedly connected with a rack; and a gear way is arranged on the machine frame, a gear is arranged between the rack and the gear way in a meshed mode, and the grinding knife is rigidly connected withthe gear. According to the scheme, the flange plate grinding device can be used for machining a flange plate with a taper, and is mostly used for machining the flange plate with the taper.

Owner:重庆市乐珐机电有限责任公司

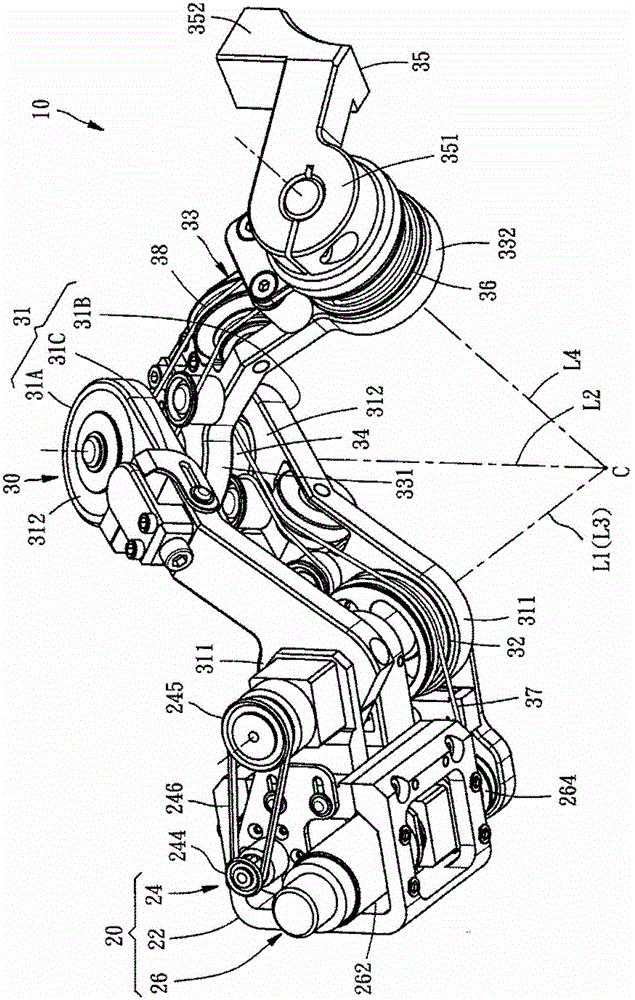

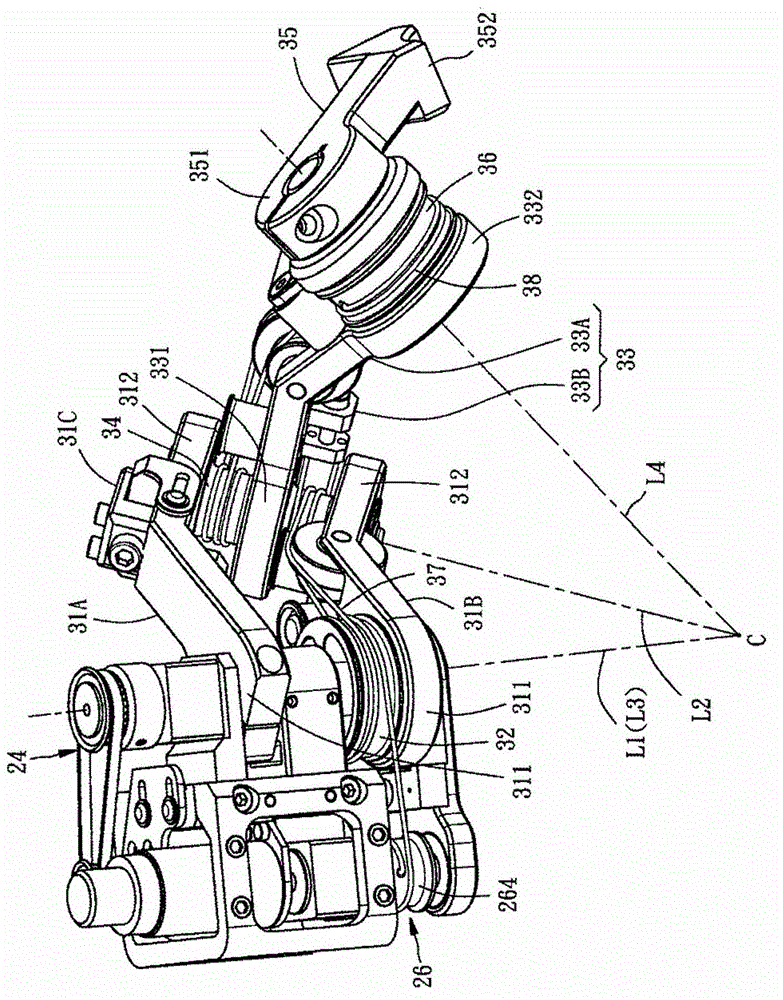

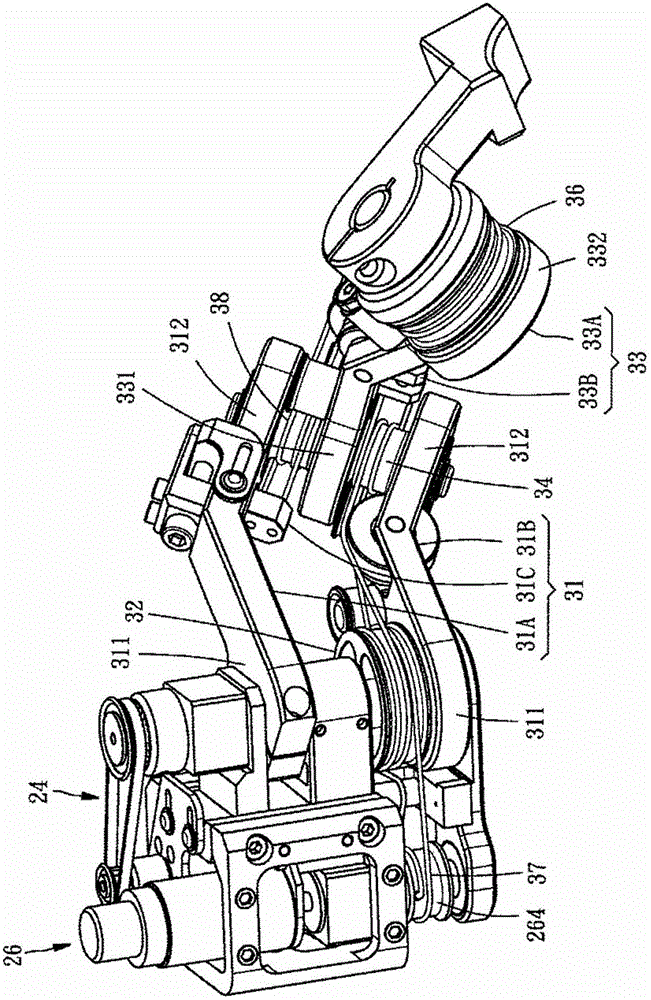

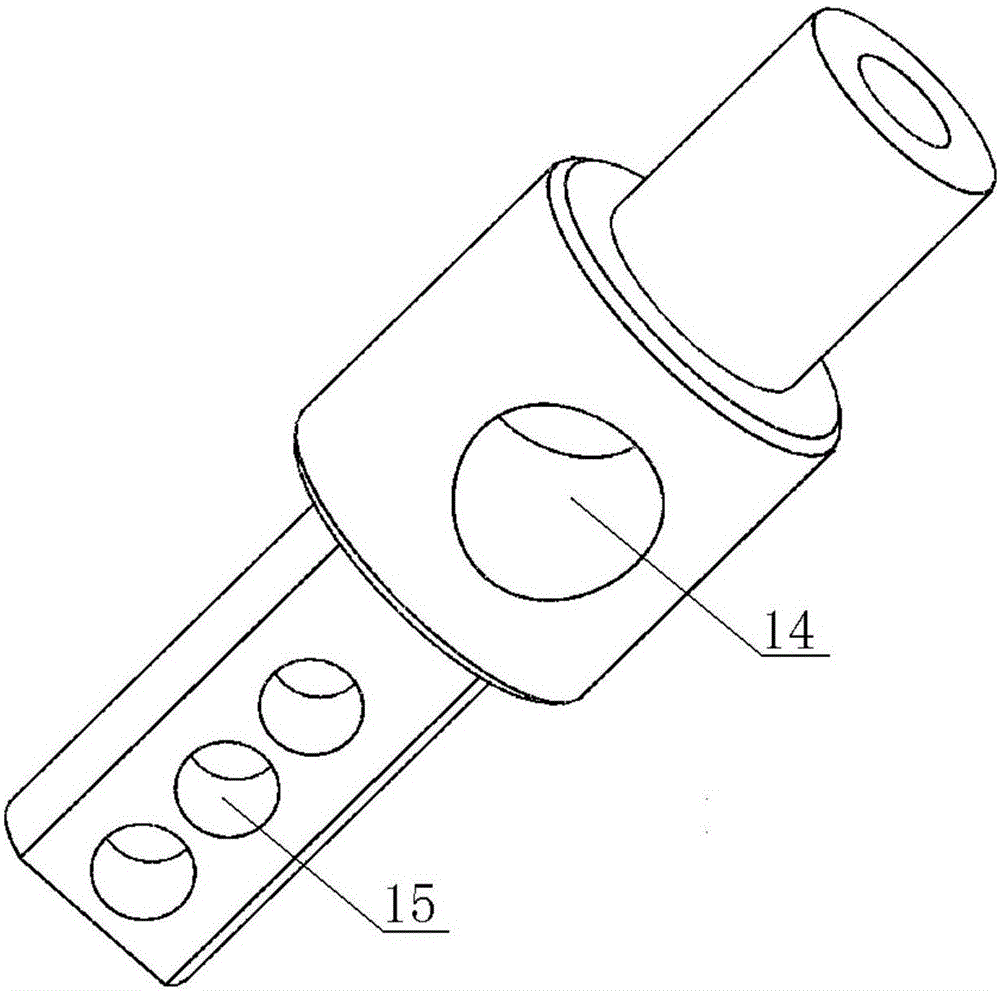

Spherical connecting rod type mechanical arm

ActiveCN104802158ALess number of bent barsSwing controlProgramme-controlled manipulatorArmsRobotic armMechanical engineering

The utility model discloses a spherical connecting rod type mechanical arm. The spherical connecting rod type mechanical arm comprises first and second bent rods, an appliance rod, first, second and third proportion wheels and first and second flexible ropes, which are pivoted with one another in sequence, wherein first to fourth hypothetical axes crossed at a spherical rotating centre can be defined; the first bent rod and the first proportion wheel are respectively driven to rotate through utilizing the first and third hypothetical axes as centers; the first flexible rope winds around the first and second proportion wheels and is used for the second bent rod; moreover, when the first proportion wheel is rotating, the first flexible rope drives the second proportion wheel and the second bent rod to rotate by utilizing the second hypothetical axis as the center; the second flexible rope winds around the second and third proportion wheels and is fixed at the first bent rod; when the second proportion wheel is rotating, the second flexible rope drives the third proportion wheel and the appliance rod to rotate through utilizing the fourth hypothetical axis as the center. The mechanical arm has small volume; operators can act the mechanical arm without any hindrance and the working area is relatively big.

Owner:HIWIN TECH

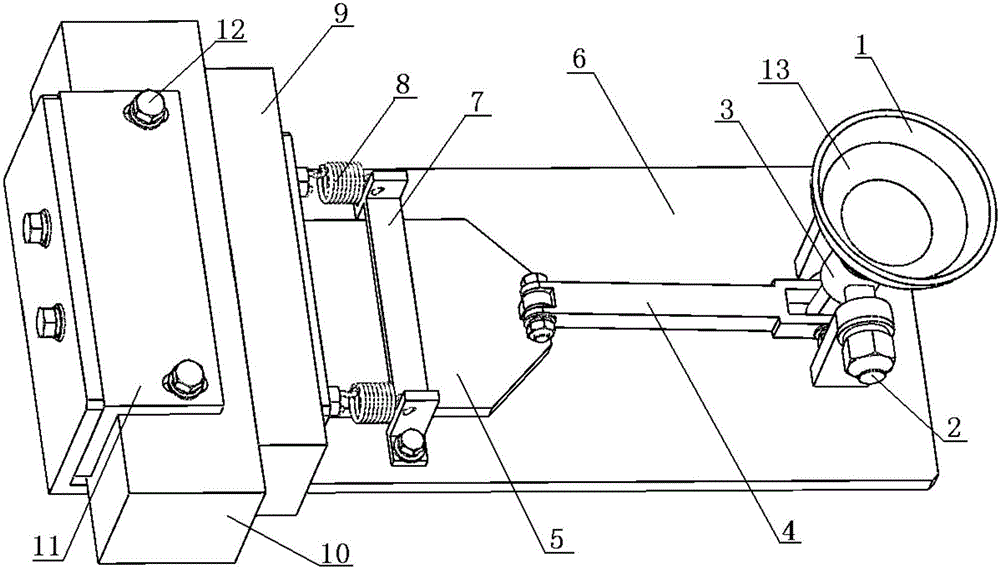

Limiting mechanism for cable transferring

The invention discloses a limiting mechanism for cable transferring. A portal frame is fixedly connected to a base, and a central through hole is formed in an upper beam plate of the portal frame. A lower limiting block is fixedly connected to the base, and an upper limiting block is coaxially arranged above the lower limiting block. A through groove parallel to the cable transferring direction isformed in the bottom of the upper limiting block, and an upper limiting groove parallel to the cable transferring direction is formed in the groove bottom of the through groove. A lower limiting groove parallel to the upper limiting groove is formed in the upper end of the lower limiting block, and the lower limiting block can be arranged in the through groove in an inlaid mode to enable the upper limiting groove and the lower limiting groove to be in butt joint to form a limiting through hole. A plurality of first springs are arranged between the other surfaces, except the through groove, ofthe bottom end face of the upper limiting block and the base. A driving mechanism for driving a vertical rod to vertically move is connected to the upper end of the vertical rod, and the lower end ofthe vertical rod stretches into a space defined by the portal frame through the central through hole and can make contact with the upper limiting block. The limiting mechanism can effectively controlswing in the cable transferring process.

Owner:WUHU HANGTIAN SPECIAL CABLE FACTORY

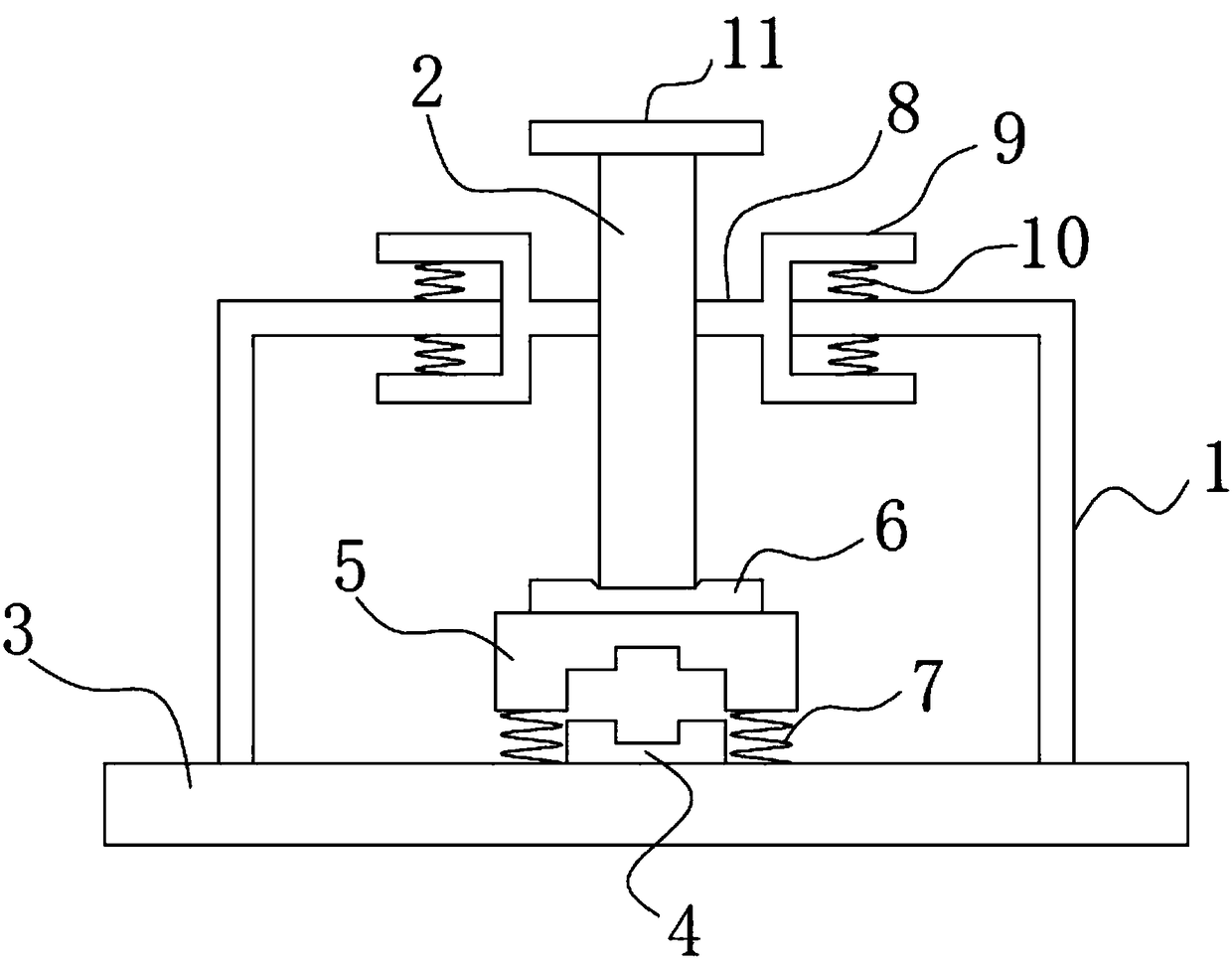

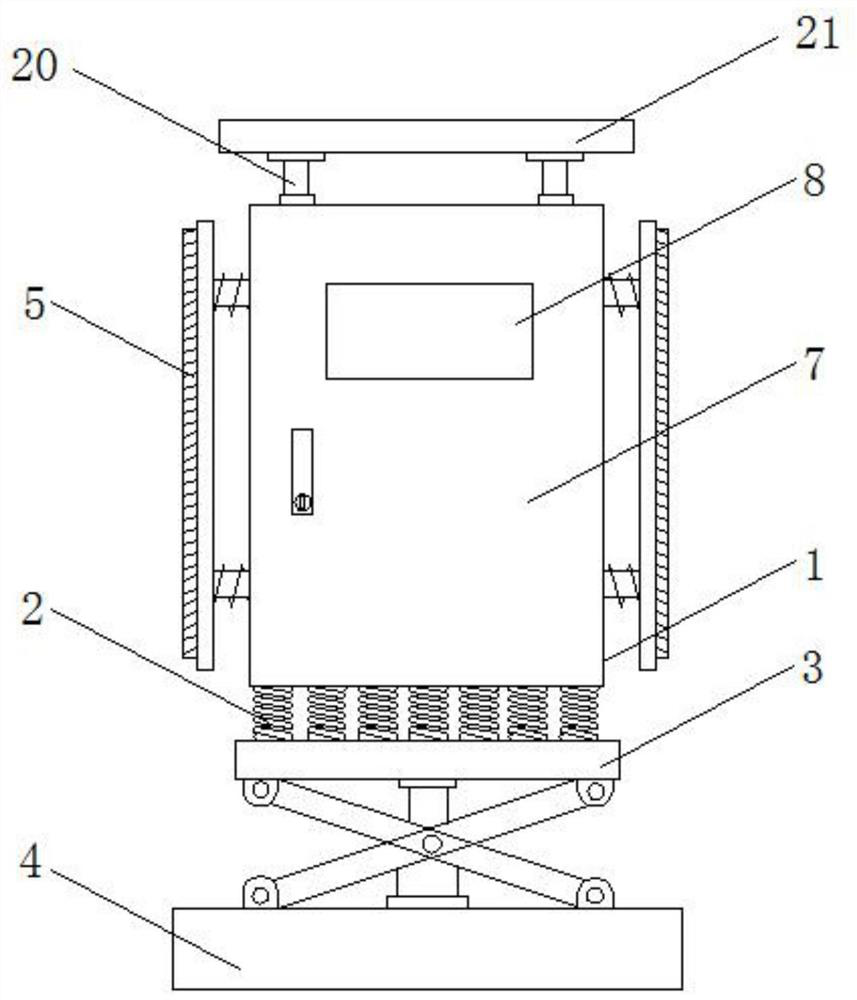

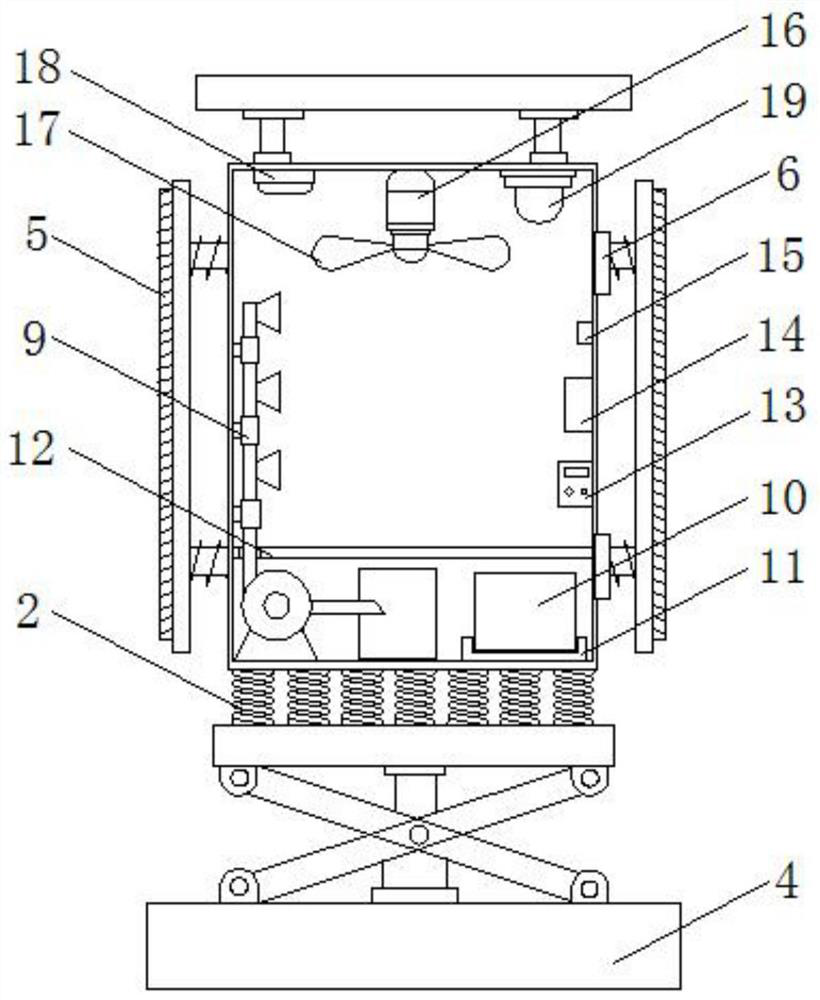

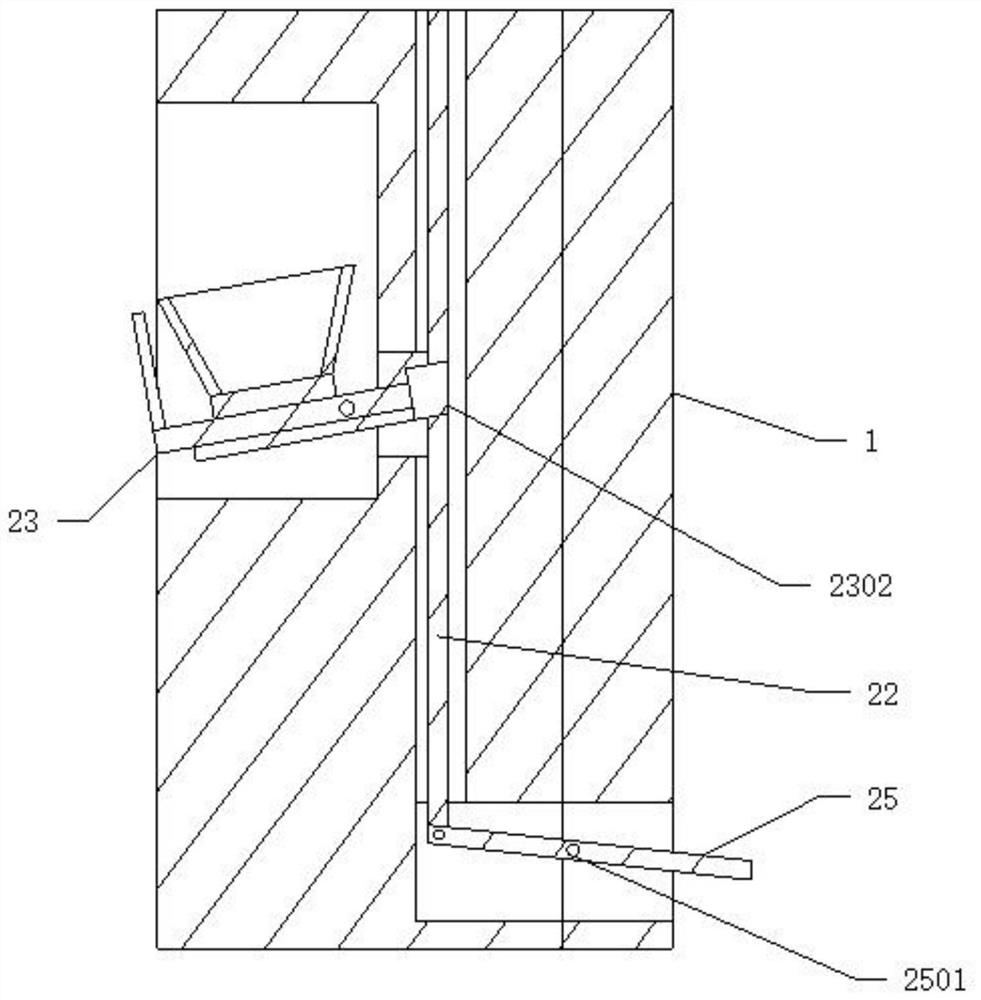

Low-voltage power distribution cabinet convenient to clean internal dust

InactiveCN113328348AEasy to cleanImprove dust removal effectBatteries circuit arrangementsDispersed particle filtrationElectric machineDust control

The invention discloses a low-voltage power distribution cabinet convenient to clean internal dust, which comprises a low-voltage power distribution cabinet body, protection mechanisms, a dust removal mechanism, a controller, a motor, an illuminating lamp, a solar photovoltaic panel and heat dissipation holes. Damping springs are arranged at the bottom of the low-voltage power distribution cabinet body, and the protection mechanisms are arranged on two sides of the low-voltage power distribution cabinet body. The dust removal mechanism is arranged in the low-voltage power distribution cabinet body, the partition plate is arranged above the storage battery, the controller is arranged above the electric leakage detector, the motor is arranged below the top end in the low-voltage power distribution cabinet body, and the illuminating lamp is arranged on one side of the cooling fan. The solar photovoltaic panel is arranged above the top end of the low-voltage power distribution cabinet body, and the heat dissipation holes are formed in the rear side of the low-voltage power distribution cabinet body. According to the low-voltage power distribution cabinet convenient to clean internal dust, the lifting mechanism and the dust removal mechanism are arranged, the height of the low-voltage power distribution cabinet can be conveniently adjusted through telescoping of the lifting mechanism, and dust in the low-voltage power distribution cabinet can be conveniently cleaned through work of the dust removal mechanism.

Owner:徐州华通电气科技有限公司

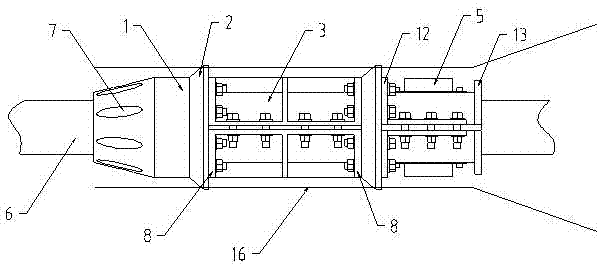

Submarine cable center positioning and protection device

ActiveCN105449618AStrong penetrating powerSwing controlCable installations in underground tubesApparatus for laying cablesFatigue damageEngineering

Owner:ZHONGTIAN TECH SUBMARINE CABLE CO LTD

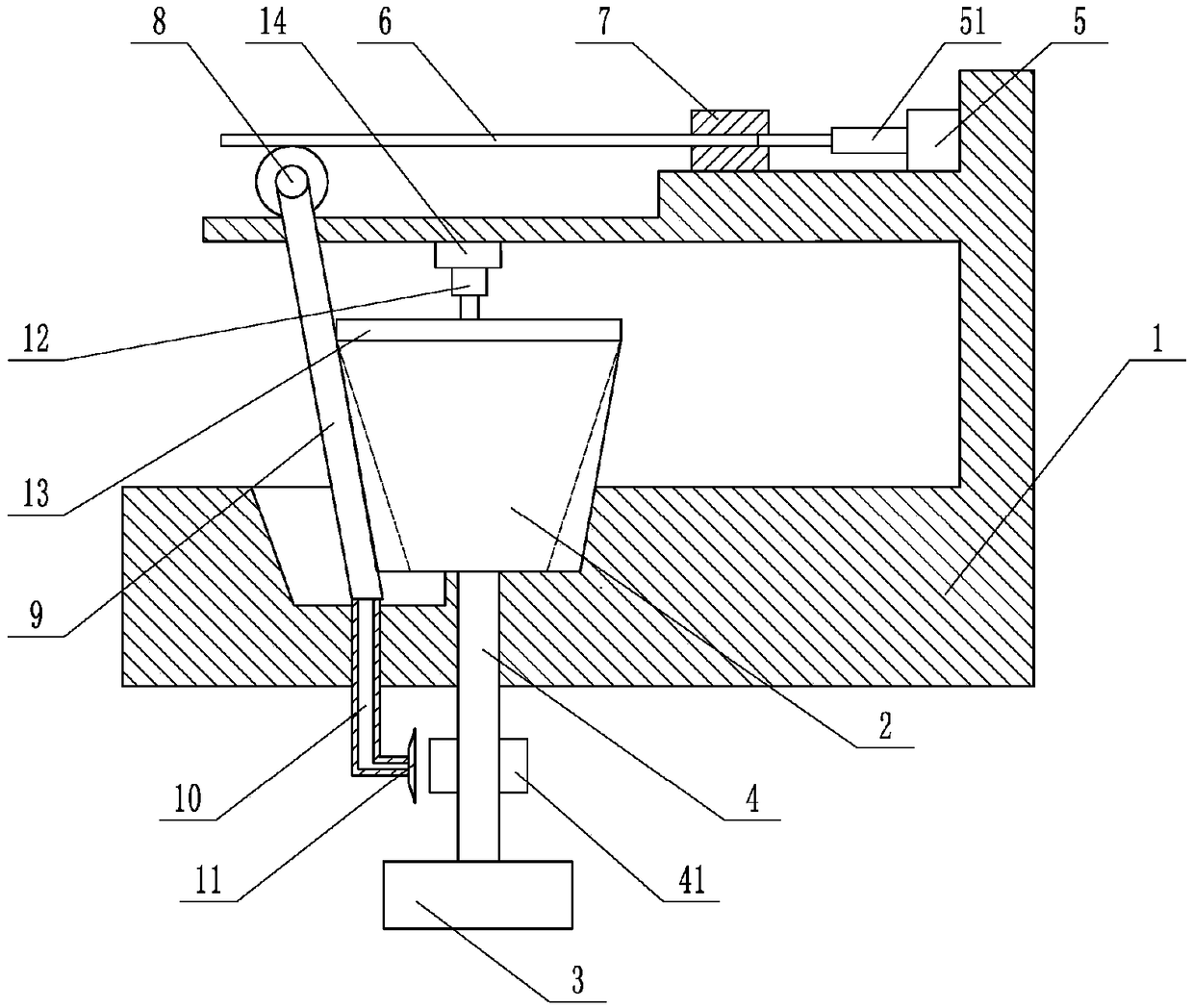

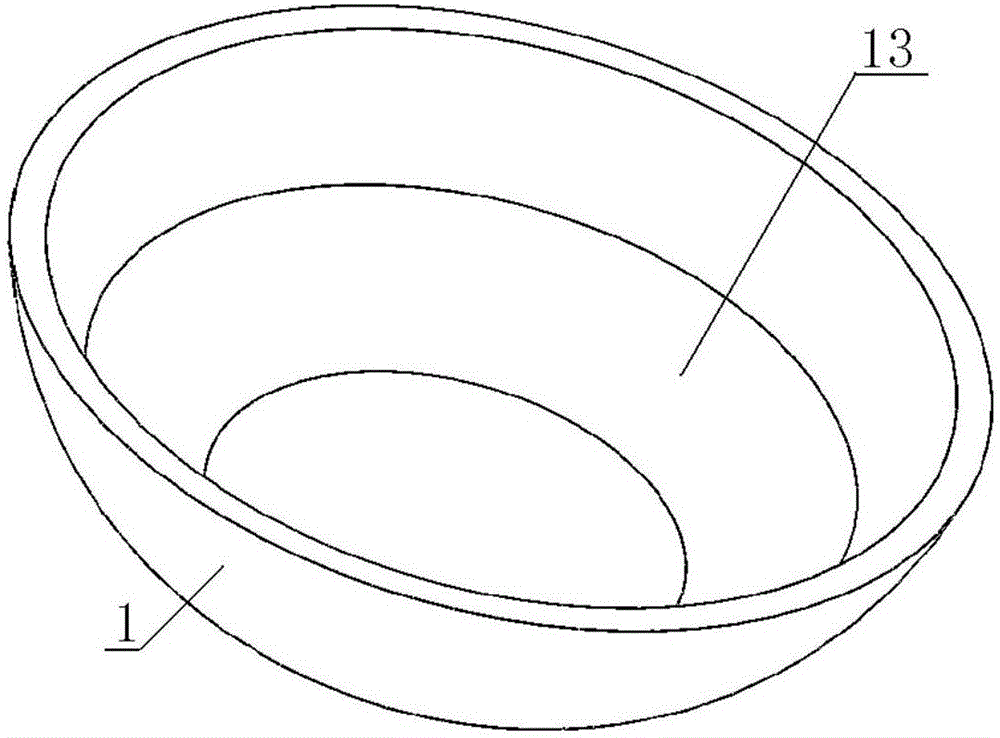

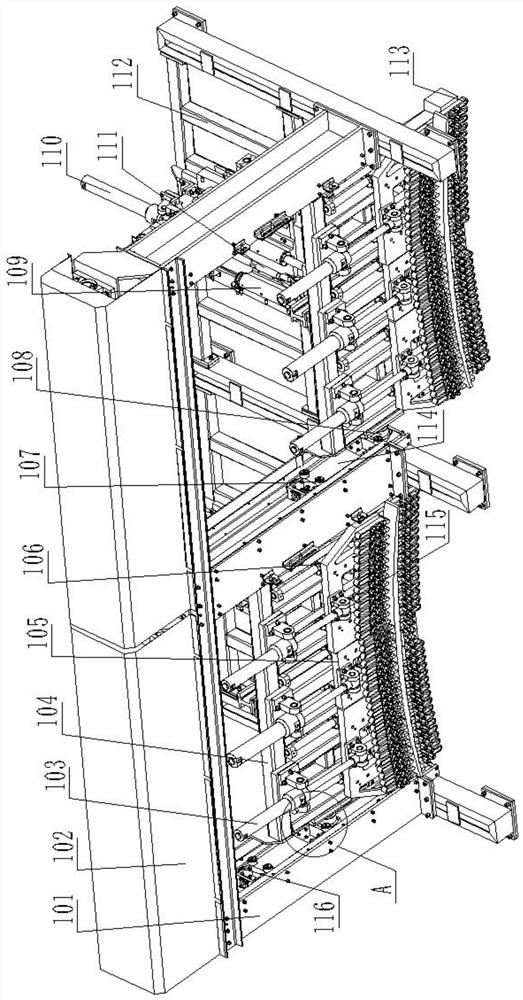

Circular slice material conveying equipment

ActiveCN103303679AEasy to collectRealize the whole columnBulk conveyorsConveyor partsEngineeringFunnel shape

The invention discloses circular slice material conveying equipment which comprises a feeding device and vibrating arraying devices, wherein the feeding device is installed on a machine frame and is used for conveying circular slice materials; the vibrating arraying devices are used for horizontally placing the circular slice materials and distributing the circular slice materials in an arrayed manner. The feeding device comprises a first vibrating component, a material box is installed on the first vibrating component, a cavity part corresponding to a lower box body is funnel-shaped, a blanking tube of which the two ends are open is vertically arranged in the center of the bottom of the lower box body in a penetrating manner, a plurality of air inlets are formed in the inner wall of the lower box body, a material guiding inclined plane is formed at the top of an upper box body, is positioned in the cavity and faces to the blanking tube, and an air outlet is formed in the upper box body; the vibrating arraying devices are arranged below the feeding device; each vibrating arraying device comprises a second vibrating component; a charging barrel of which one end is provided with a flaring is vertically installed on the second vibrating component; the flaring end of the charging barrel is connected with the blanking tube. The circular slice material conveying equipment solves the technical difficulty that the circular slice materials cannot be arrayed and conveyed.

Owner:GOERTEK INC

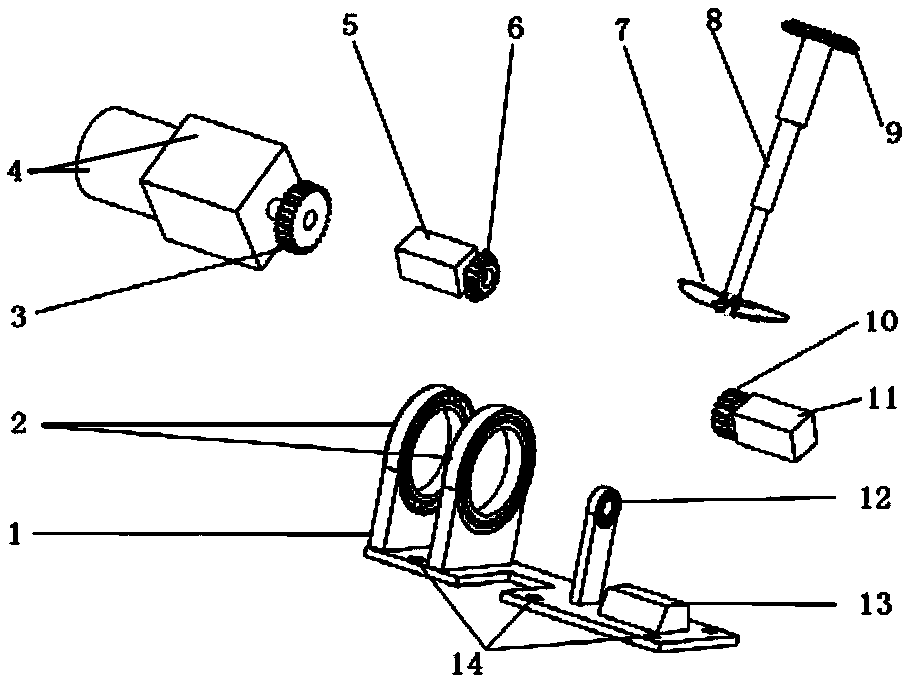

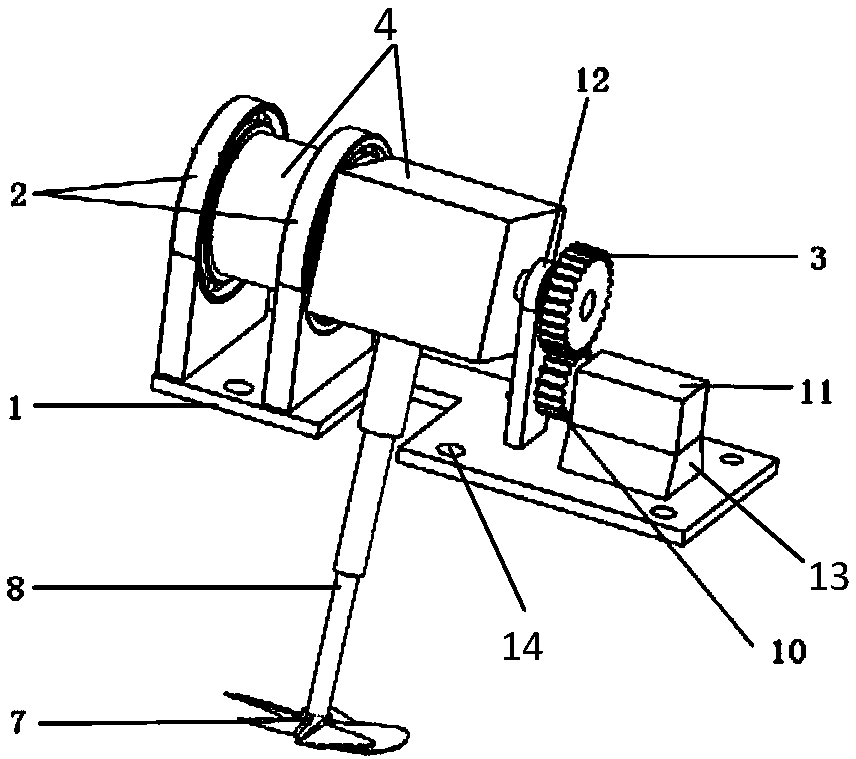

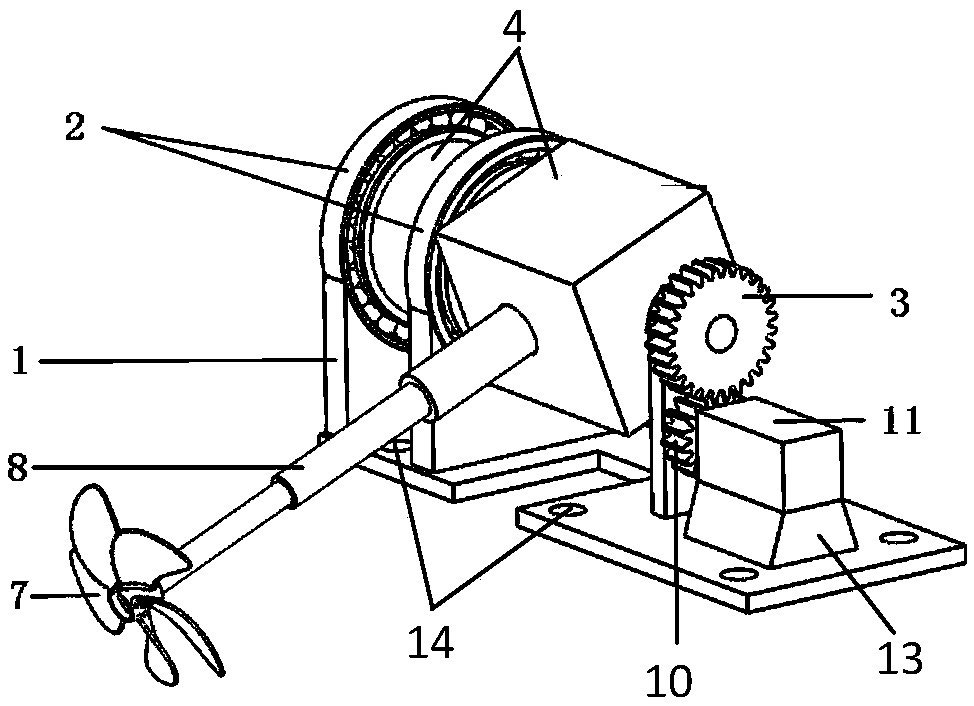

A rocking telescopic arm anti-rolling device for ship anti-rolling

ActiveCN109094750AEasy to assemble and disassembleDoes not impede fast sailingVessel movement reduction by foilsPropellerArchitectural engineering

The utility model relates to a rocking telescopic arm anti-rolling device for ship anti-rolling, which relates to a anti-rolling technology of a yacht. A base, a bearing group, a telescopic arm, a propeller self-rotating transmission chain, a telescopic arm rocking transmission chain, a bearing, a motor support and a base bolt hole are arranged; The base is fixedly connected with the bearing group, the motor support and the bearing, and the base is provided with a base bolt hole fixed with the hull deck; The propeller self-rotating transmission chain is provided with a self-rotating motor, a motor bevel gear, a propeller and a telescopic arm bevel gear, wherein the motor bevel gear is fixed on the self-rotating motor, the propeller and the telescopic arm bevel gear are fixed on the telescopic arm, and the self-rotating motor is vertically arranged with the telescopic arm; The telescopic arm rocking transmission chain is provided with a shell spur gear, a rotating body shell, a motor spur gear and a rocking motor, wherein the shell spur gear is fixedly connected with the rotating body shell, the motor spur gear is fixedly connected with the rocking motor, and the spin motor is fixedin the rotating body shell.

Owner:SHENZHEN RES INST OF XIAMEN UNIV +1

Microsphere coated diamond-like film rolling oscillation device

ActiveCN106381475ASwing controlAdapt to high temperature conditionsVacuum evaporation coatingSputtering coatingMicrosphereGas phase

The invention discloses a microsphere coated diamond-like film rolling oscillation device and belongs to the technical field of physical vapor deposition coating preparation. The microsphere coated diamond-like film rolling oscillation device is uniform in coating, and can reduce the surface roughness of microspheres. According to the technical scheme, the microsphere coated diamond-like film rolling oscillation device comprises a microsphere disc, a connector, a connecting part, a base and an electromagnetic relay; a support is arranged on the base, and the connector is installed on the support through a supporting rod and can swing around the supporting rod; and one end of the connector is connected with the microsphere disc, an arc-shaped protrusion protruding inwards is arranged on the microsphere disc, the other end of the connector is in drive connection with the electromagnetic relay through the connecting part, and the connecting part or the connector or the disc is further provided with an elastic part enabling the disc to be reset after the disc swings. By adjusting the inclination angle of the microsphere disc and the attraction frequency of the electromagnetic relay, the motion rail of the microspheres is optimized, the microspheres are dispersed, and then a diamond-like film is more uniformly coated with the microspheres.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

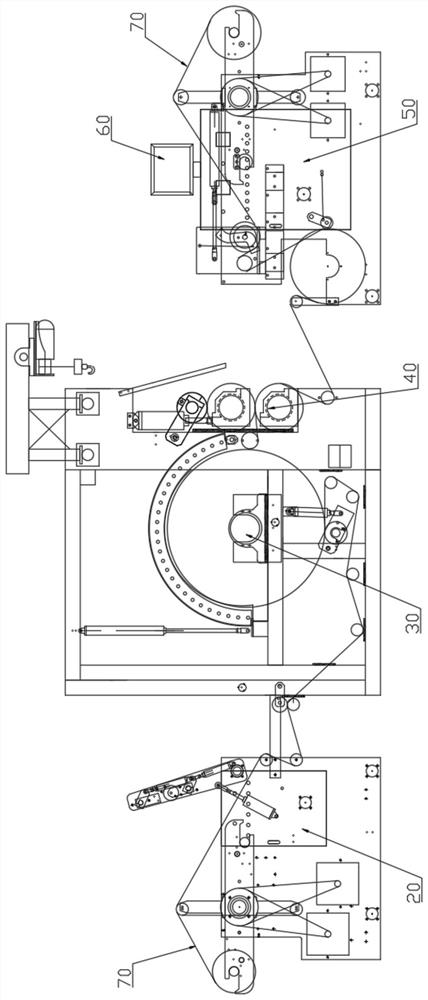

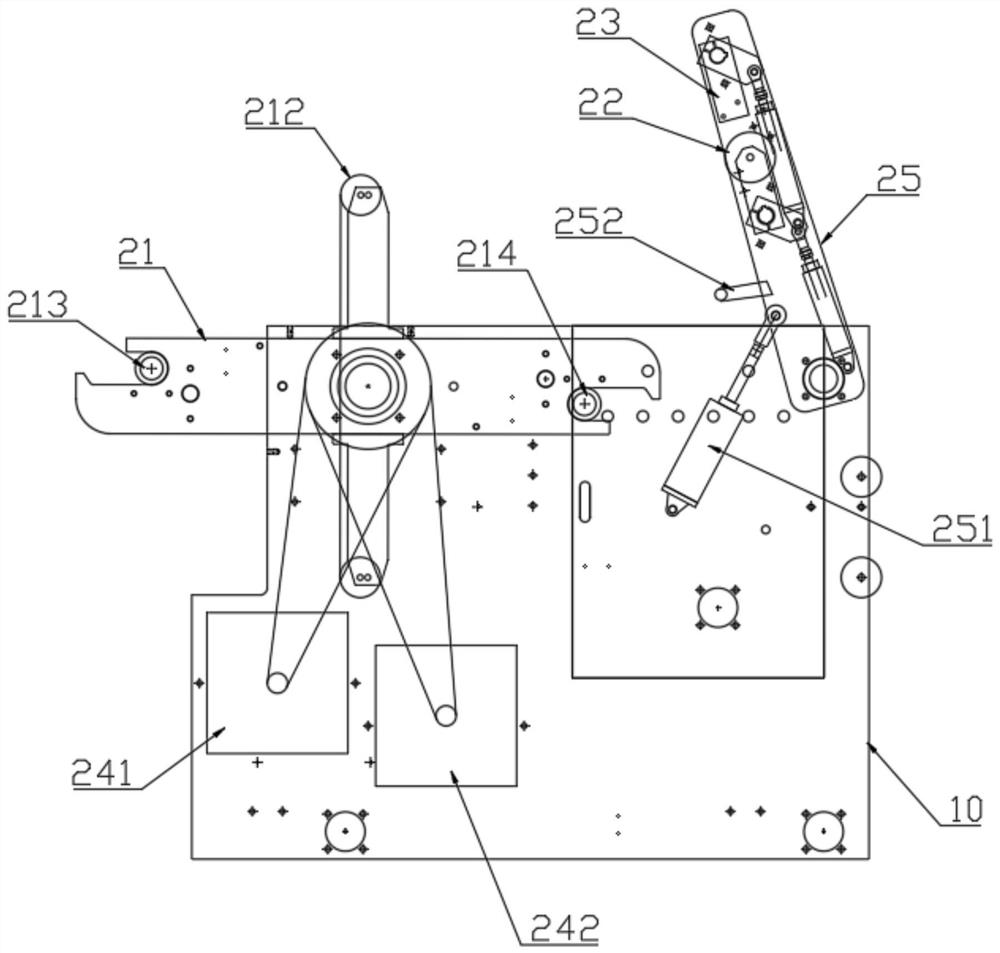

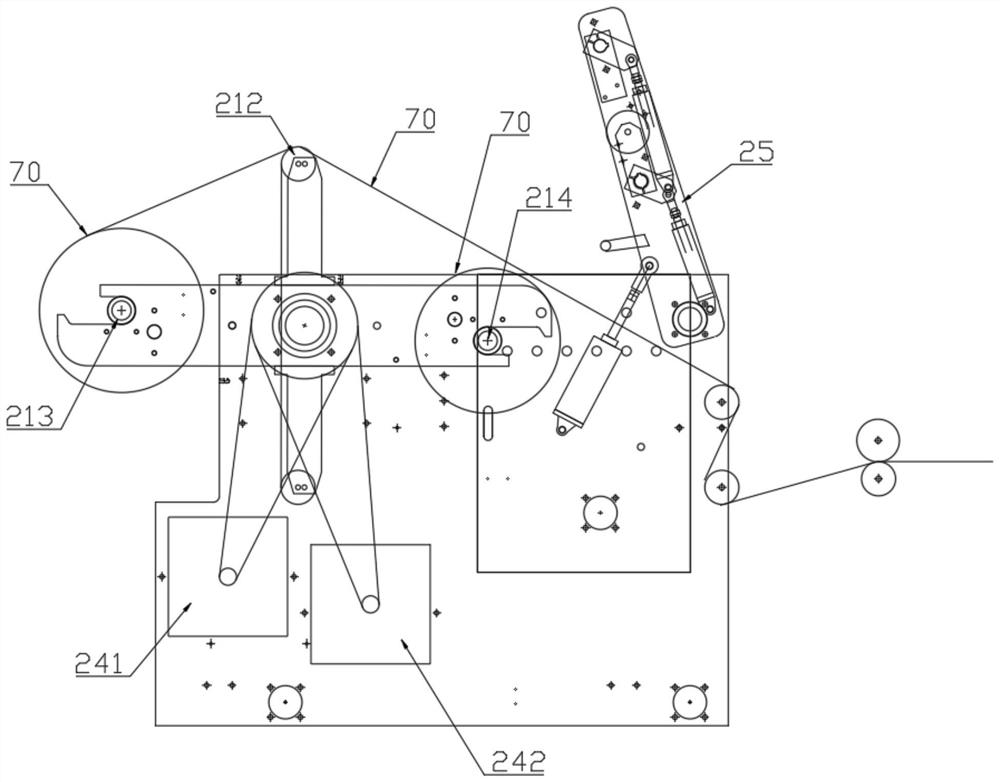

Embossing machine

InactiveCN113119527AAchieve embossingRealize intelligent operationBag making operationsFinal product manufactureAssembly disassemblyEngineering

The invention relates to an embossing machine. The embossing machine comprises a support, a double-station roller feeding mechanism, a heating device, an embossing device and a double-station roller receiving mechanism. By arranging a feeding bearing frame and a receiving bearing frame, double-station work of the feeding mechanism and the receiving mechanism can be achieved, switching of coiled materials can be achieved without stopping the machine for feeding or receiving, the working efficiency of the machine is greatly improved, the structure is ingenious, intelligent operation of switching of the coiled materials is achieved, and manpower and material resources are saved; and the double-station roller feeding mechanism, the heating device, the embossing device and the double-station roller receiving mechanism can be independently installed and arranged, assembly, disassembly or maintenance and replacement are convenient, and transportation is convenient.

Owner:中山市中伟机械设备有限公司

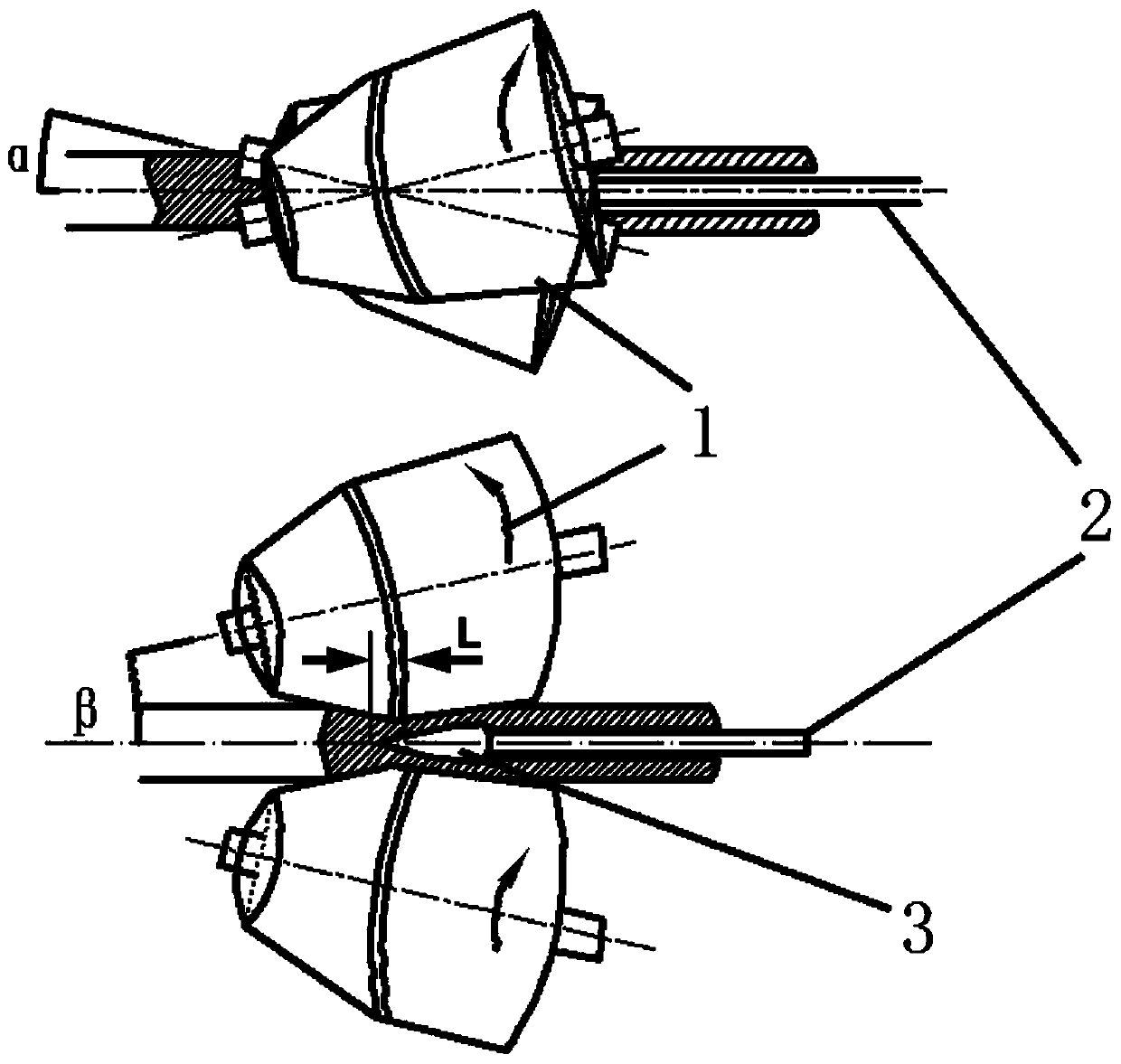

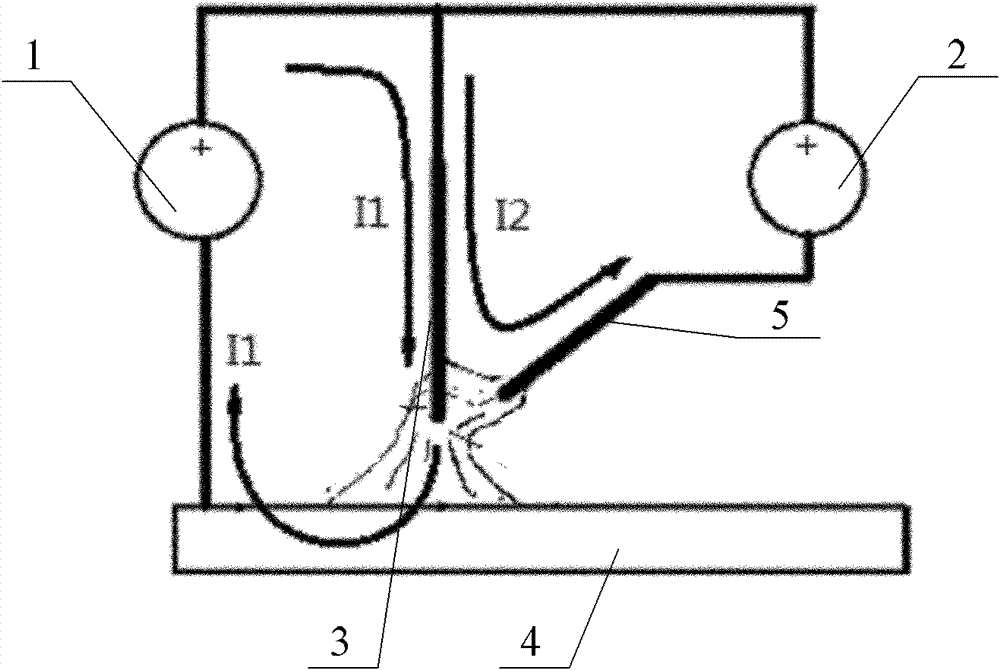

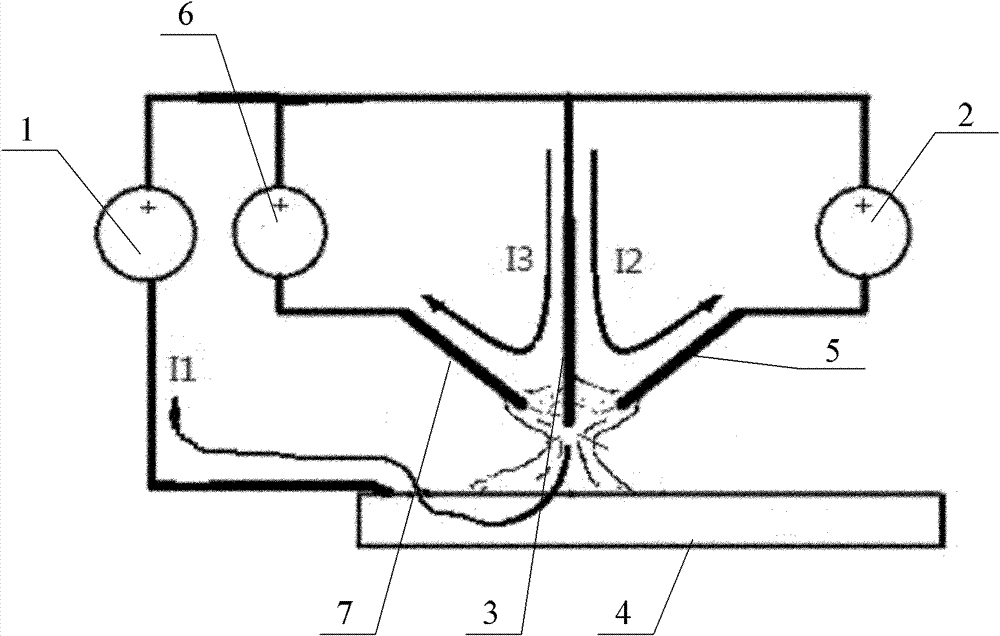

Compound electric arc welding method

ActiveCN101972879BFast meltingReduce welding heat inputArc welding apparatusAuxiliary electrodeEngineering

The invention relates to an electric arc welding method with high welding wire melting speed and low welding heat input, belonging to the technical field of welding. The electric arc welding method solves the problem of the mutual contradiction between improving the melting speed of a welding wire and reducing the welding heat input in the consumable electrode electric arc welding method. The electric arc welding method is characterized in that: the homopolar output ends of a main power supply and an auxiliary power supply are connected with the head end of a main consumable electrode, and the other electrode output end of the main power supply is connected with a workpiece to be welded, and the other electrode output end of the auxiliary power supply is connected with the head end of an auxiliary electrode. The welding method comprises the following steps of: enabling the tail end of the main consumable electrode to be close to the part to be welded, of the workpiece to be welded, and forming a main electric arc between the tail end of the main consumable electrode and the surface to be welded, of the workpiece to be welded under the action of the main power supply; enabling the tail end of the auxiliary electrode to be close to the tail end of the main consumable electrode, forming an auxiliary electrode arc between the tail end of the main consumable electrode and the tail end of the auxiliary electrode under the action of the auxiliary power supply, and forming a composite electric arc between the main electric arc and the auxiliary electric arc so as to realize the welding. The invention is used as an electric arc welding method.

Owner:HARBIN INST OF TECH

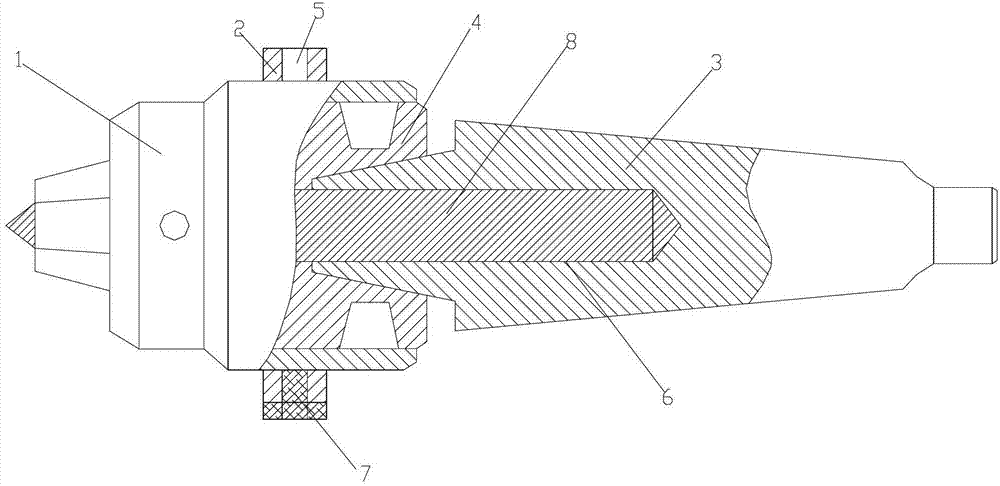

Drill chuck

The invention discloses a drill chuck. The drill chuck comprises a drill chuck body, a flange and a taper shank, wherein the flange is fixedly sleeved on the outer diameter of the drill chuck body through a bolt; a through hole is formed on the outer circle of the flange; a locking sleeve is arranged inside the drill chuck body; one end of the taper shank is connected to the inside of the locking sleeve; and a mounting hole is formed in the taper shank. According to the drill chuck, the flange is sleeved on the drill chuck body, the through hole is formed on the outer circle of the flange, and a straight spanner is inserted into the through hole to wrench the drill chuck body to ensure that the drill chuck can be quickly clamped or loosened, so that clamping force to a drill bit is improved; and the mounting hole is formed in the taper shank, and the handle part of the drill bit is inserted into the mounting hole, so that the oscillation of the drill bit can be effectively controlled, the drill bit is well centered, and the production quality and efficiency are improved.

Owner:SUZHOU DONGLI MACHINERY

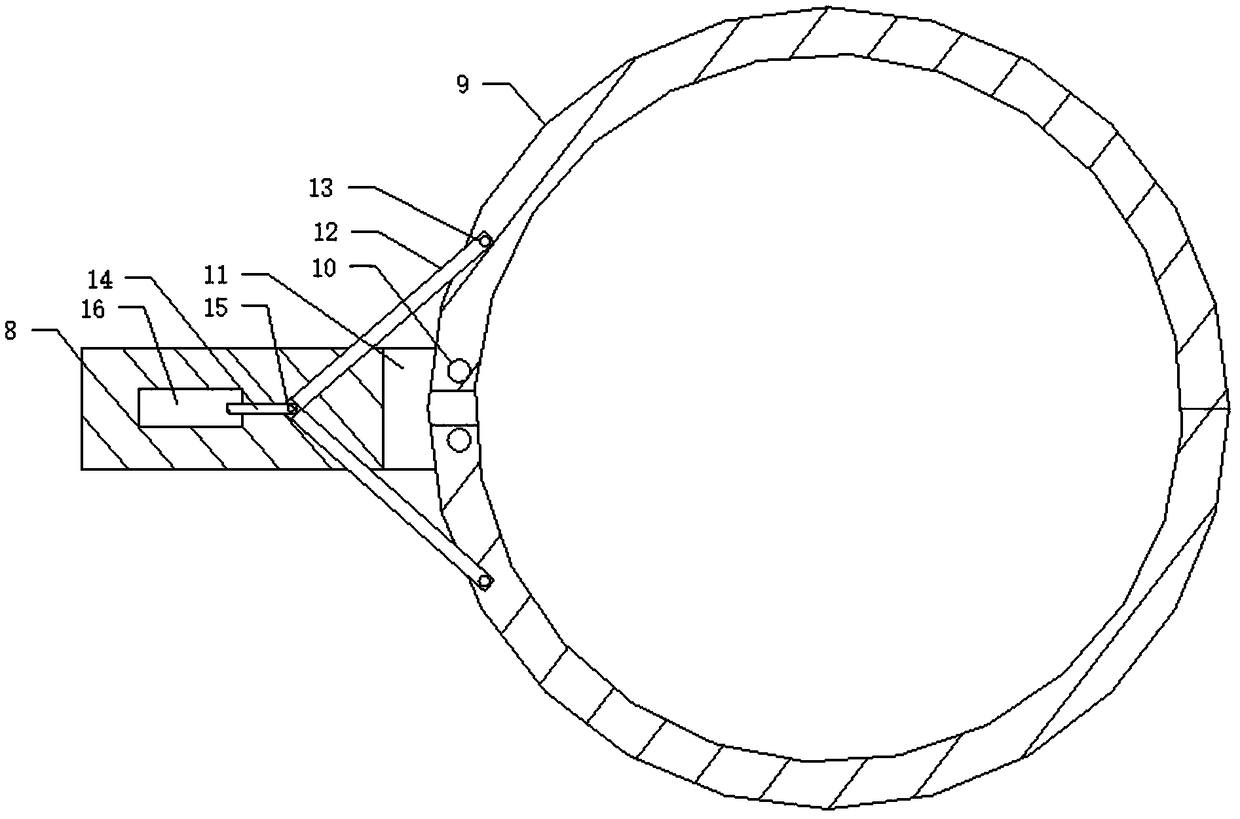

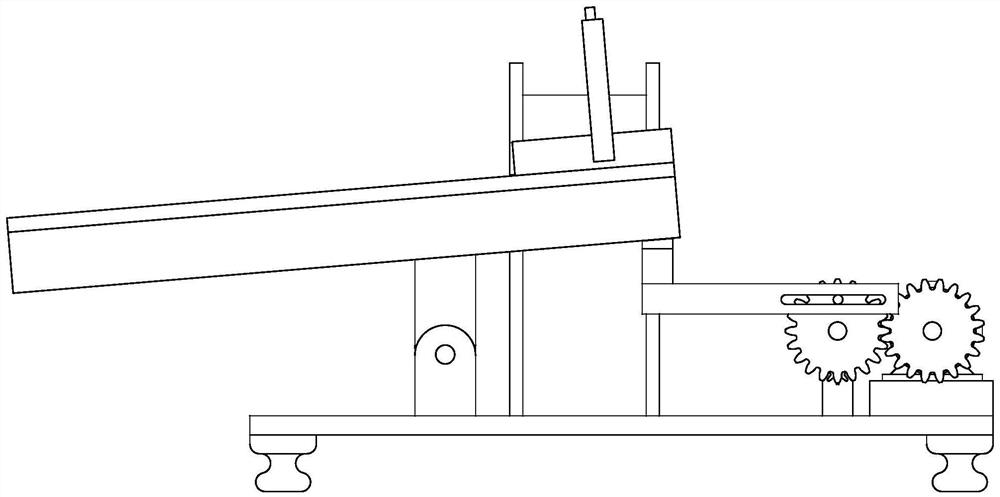

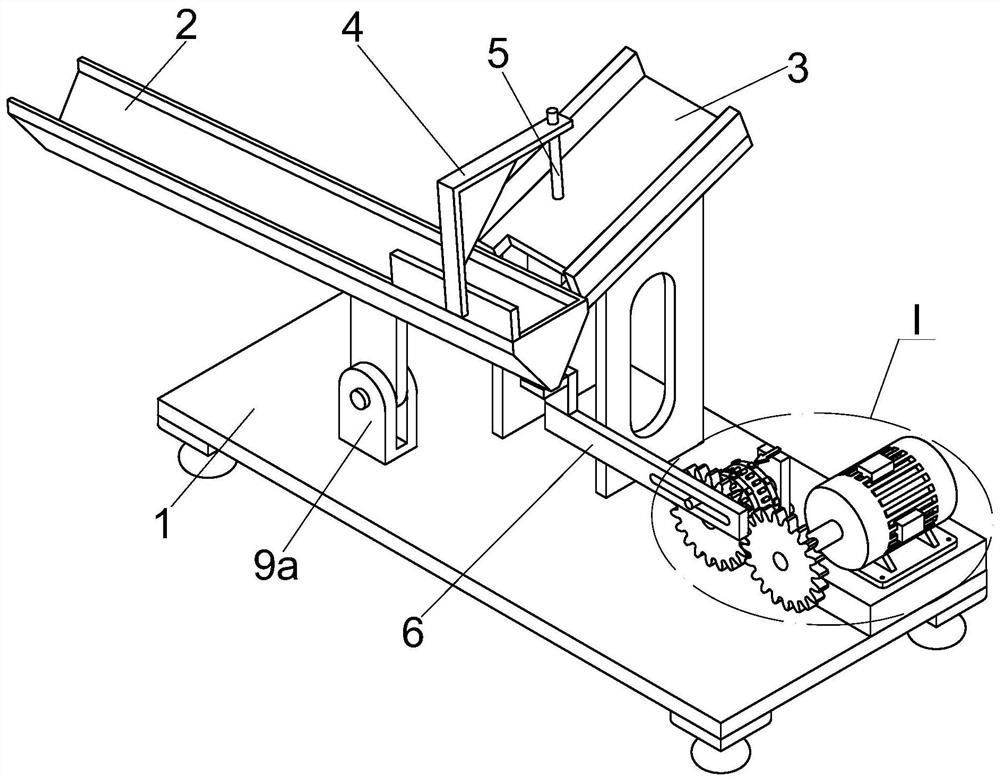

Garden management fertilizer conveyor using riverway sludge as fertilizer

ActiveCN109089506ASwing controlControl drillingPlantingDirect liquid fertiliser deliveryFertilizerDrill hole

The invention discloses a garden management fertilizer conveyor using riverway sludge as a fertilizer. The garden management fertilizer conveyor includes a compartment body, a compartment inner tank is disposed in the compartment body, the compartment body is provided with a plurality of first supporting frames, the plurality of first supporting frames are rotatably connected side by side, the endof each first supporting frame is connected with a rotatable second supporting frame, the second supporting frame is provided with two swinging supporting slideways, and the two supporting slidewaysare annularly arranged after being clamped correspondingly. The second supporting frame is also provided with a pulling machine for controlling the supporting slideways to swing, each supporting slideway is provided with a slidable sliding machine body, a slidable rotating disc is disposed in the sliding machine body, the rotating disc conveys a screw rod, a hole can be further drilled in the ground through the rotation of a conveying screw, so that sludge can be further conveyed to the drilled hole, and thus the goal of further using the sludge as the fertilizer can be achieved.

Owner:诸暨市暨东机电维修有限公司

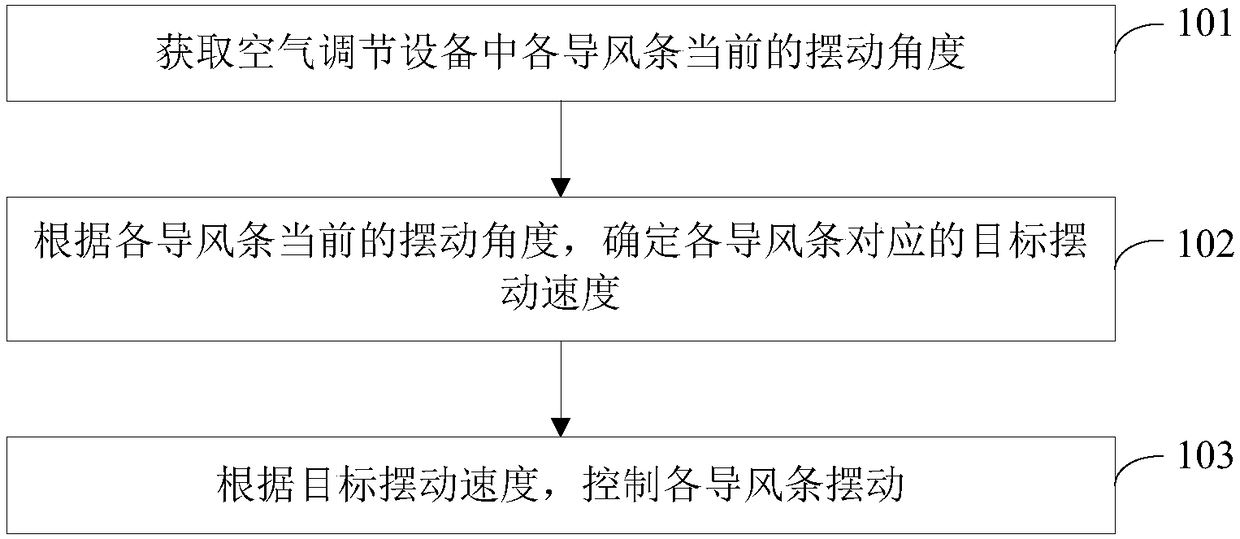

Air conditioning equipment air guide strip control method and device and storage medium

PendingCN109028504AUniform air supplyUniform temperature distributionMechanical apparatusEngineeringTemperature difference

The invention discloses an air conditioning equipment air guide strip control method and device and a storage medium. The air conditioning equipment air guide strip control method comprises the following steps that current swinging angles of air guide strips in the air conditioning equipment are obtained; the target swinging speed of the air guide strips is determined based on the swinging anglesof the air guide strips; and swinging of the air guide strips is controlled based on the target swinging speed. According to the air conditioning equipment air guide strip control method, the swingingspeed of the air guide strips is determined based on the swinging angles of the air guide strips, and therefore air output volume of the air guide strips of the air conditioning equipment is as uniform as possible in all directions, temperature difference between two side areas and the middle area of the air conditioning equipment is lowered, and temperature distribution in a room is more uniform.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

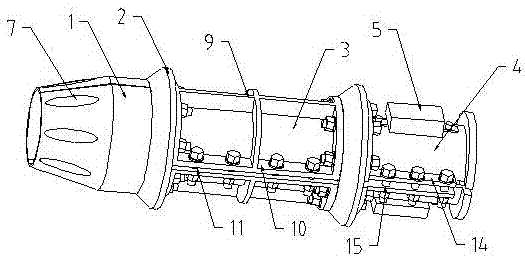

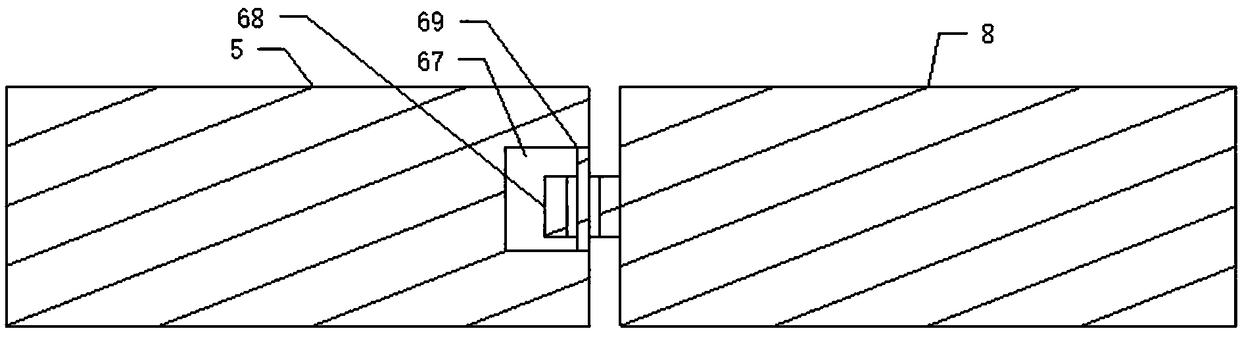

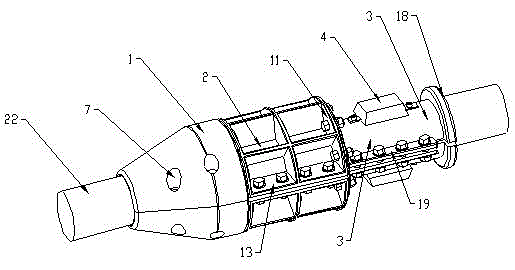

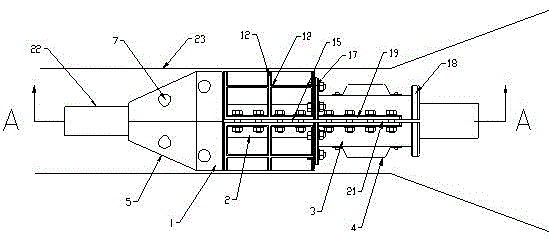

Centralized positioning protection device for submarine cable

ActiveCN105470906AAvoid fatigue damageEffective control of swingCable installations in underground tubesApparatus for laying cablesFatigue damageEngineering

The invention discloses a centralized positioning protection device for a submarine cable. The device comprises a guiding awl, a positioning shaft, and a connecting shaft, wherein the three parts are successively connected. The guiding awl is formed by two symmetric parts and the head has a tapered structure; a guiding central hole is formed inside the guiding awl; a mounting groove is formed in the tail; and a bolt hole is formed in the side surface. The positioning shaft is formed by two symmetric parts; a central through hole is formed inside the positioning shaft; a mounting protrusion is arranged at the head of the positioning shaft; and the mounting protrusion and the mounting rove of the tail of the guiding awl in matched occlusion connection. The connecting shaft has the two symmetric parts; a central hole is formed inside the connecting shaft; a connecting flange is arranged at the head of the connecting shaft; and a connection protrusion is arranged at the tail of the connecting shaft. According to the invention, with the protection device, a cable at the lower port segment of the protection tube can be limited at the center of the protection tube, so that swinging of the submarine cable in the protection tube can be effectively controlled, collision with the rigid protection tube can be prevented, and fatigue damages of the submarine cable under the long-term effect of the ocean current can be avoided. Meanwhile, the provided device has advantages of simple structure, convenient installation, high reliability, and long service life.

Owner:ZHONGTIAN TECH SUBMARINE CABLE CO LTD

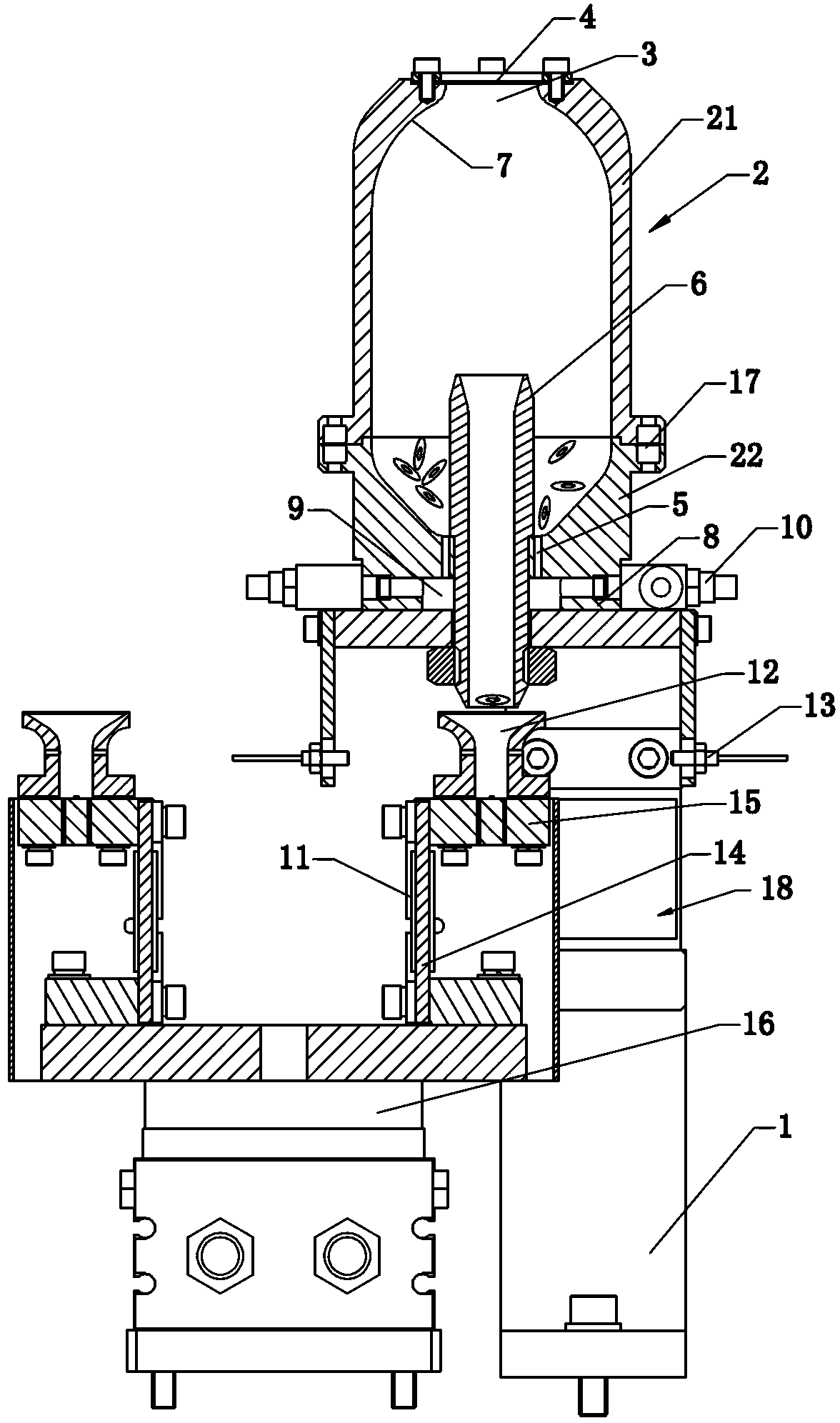

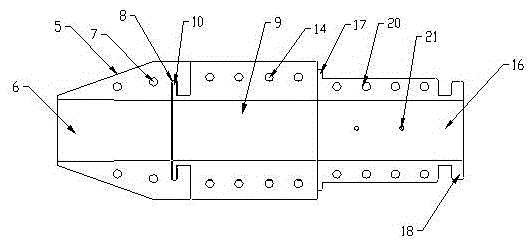

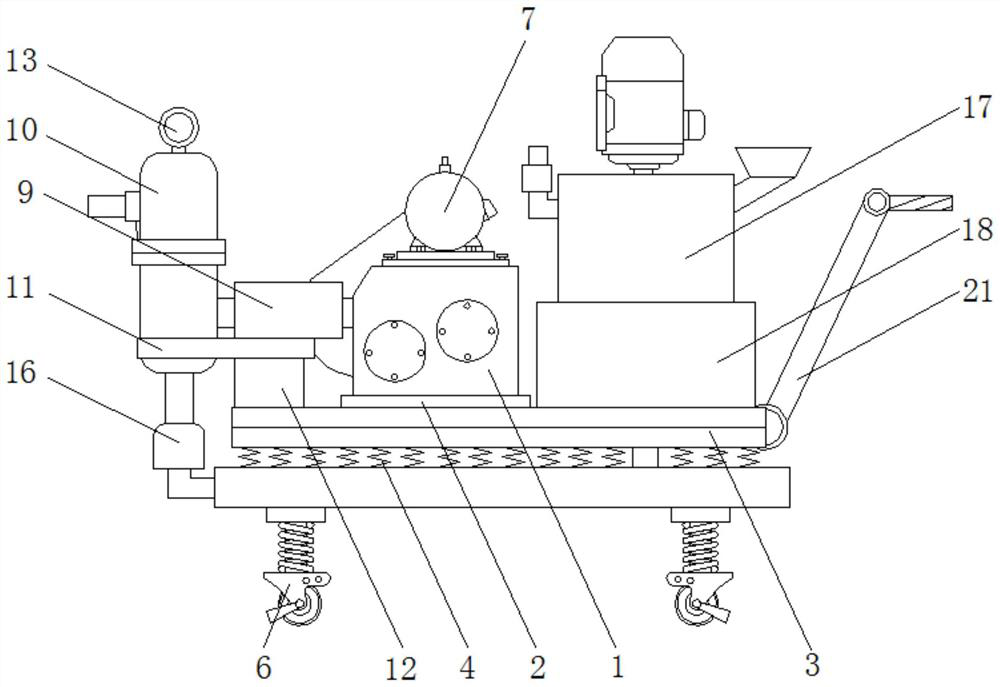

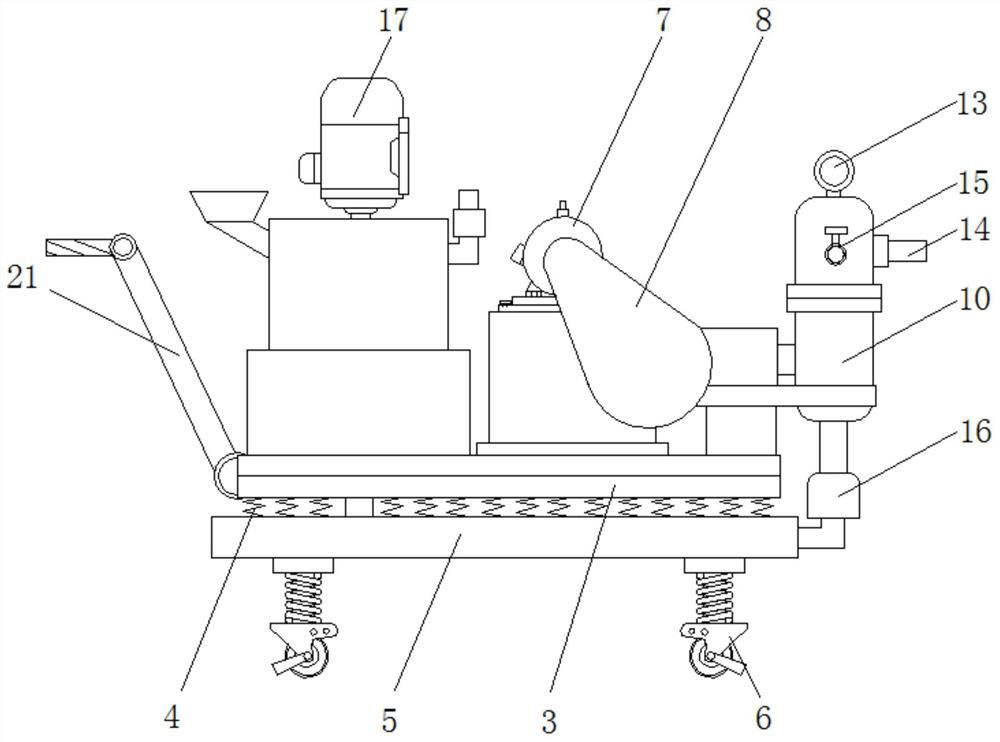

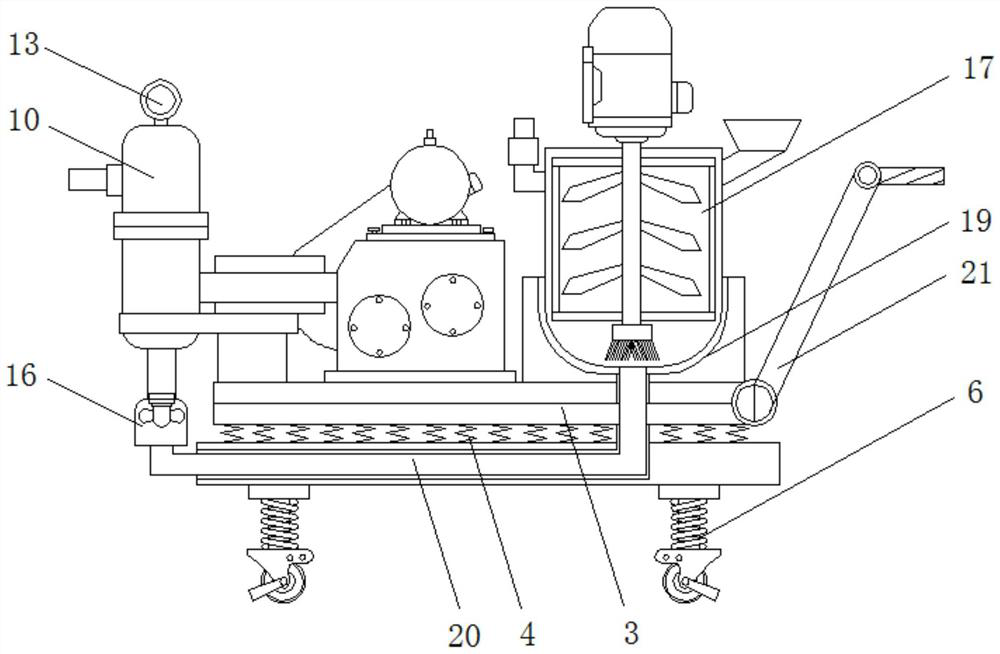

Movable grouting pump with stirring function

InactiveCN113232162AAvoid unstable working conditionsReduce vibrationPositive displacement pump componentsUnderground chambersClassical mechanicsElectric machinery

The invention discloses a movable grouting pump with the stirring function. The movable grouting pump comprises a grouting pump body, a pure copper motor, a grouting cylinder, a fixing block, a pressure gauge, a stirring mechanism, a containing groove, a discharging pipe and an adjusting mechanism, wherein the grouting pump body is fixedly connected with a damping plate through a fixing plate, and the damping plate is fixedly connected with a bottom plate through a first damping spring; the pure copper motor is arranged above the grouting pump body; one side of the grouting cylinder is fixedly connected with the grouting pump body through a piston material cylinder; the fixing block is arranged above one side of the damping plate; the pressure gauge is arranged at the top end of the grouting cylinder; a pressure relief valve is arranged on the other side of the grouting cylinder; the stirring mechanism is arranged on one side of the grouting pump body; and the containing groove is formed in a containing platform. According to the movable grouting pump with the stirring function, a moving mechanism and a stirring mechanism are arranged, the moving mechanism conveniently drives the grouting pump body to move through rolling wheels, the stirring mechanism conveniently and evenly stirs cement mortar, and grouting of the grouting pump is facilitated.

Owner:XUZHOU BOAN TECH DEV +1

Crushing device for blueberry processing

The invention discloses a crushing device for blueberry processing. The crushing device for blueberry processing comprises a device body, and two crushing rollers are arranged in the device body; a connection rod is fixed to the middle portion of one side of each crushing roller; one end of each connection rod is rotationally connected with the device body, and a transmission shaft is fixed to themiddle portion of the other side of each crushing roller; one end of each transmission shaft extends to the exterior of the device body and is fixedly provided with a driven belt wheel; a servo motoris installed on one side of the device body, and is located between the two transmission shafts; an output shaft of the servo motor is fixedly provide with a driving belt wheel; the exteriors of thedriving belt wheel and the driven belt wheels are sleeved with a belt; and the inner walls of the two sides of the device body are each fixedly provided with a U-shaped support. The crushing device for blueberry processing is ingenious in design, reasonable in structure and easy to operate, the two crushing rollers can be used for crushing blueberries conveniently, and practicability is high; andmeanwhile, a filtering plate can be controlled to swing, blueberry juice and blueberry pulp obtained after crushing can be conveniently collected separately, flexibility is high, and using and popularizing are facilitated.

Owner:MAJIANG RUILIN BLUEBERRY CO LTD

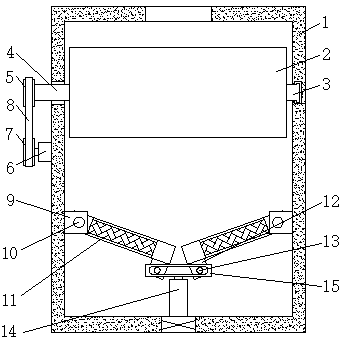

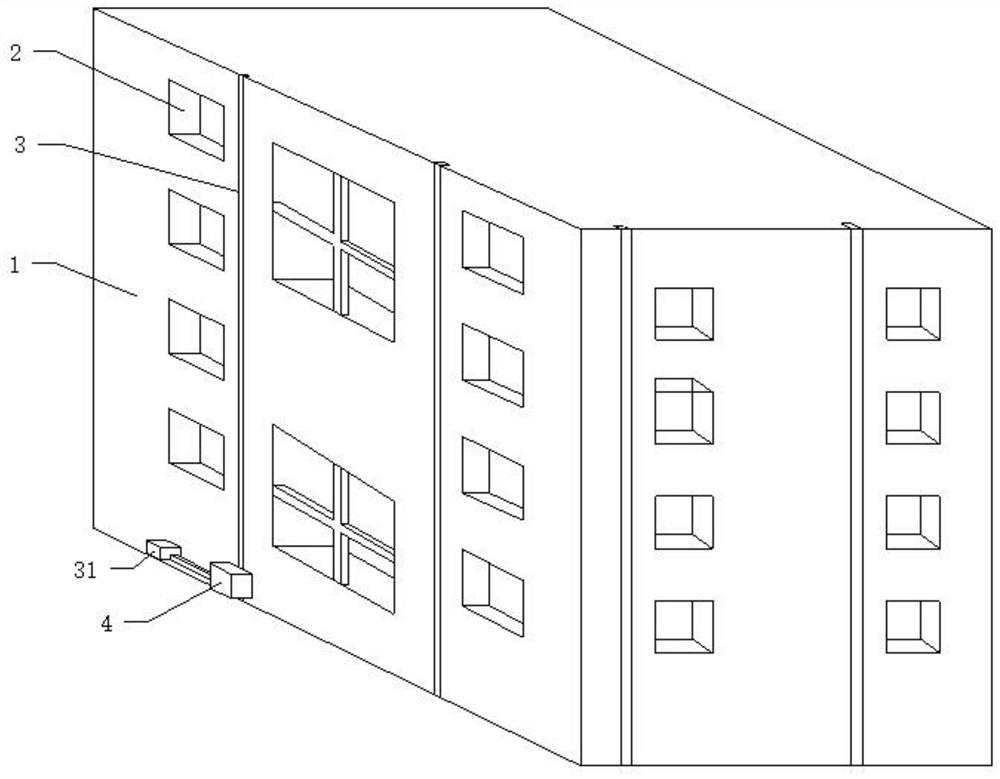

Intelligent green building body

InactiveCN111820032ASwing controlControl scalingCuttersCutting implementsAgricultural engineeringStructural engineering

The invention discloses an intelligent green building body. The intelligent green building body comprises a building body, wherein a window is arranged on the building body; the building body comprises a plant maintenance device and a pruning robot; the plant maintenance device comprises a fixing module, fixing bottom plates, baffles, connecting mechanisms, control bases, control rods and flowerpots, and the fixing module is provided with a row of storage grooves; the fixing bottom plates swing in the storage grooves; the control bases are arranged on the fixing bottom plates respectively; thebaffles are arranged at the ends of the corresponding fixing bottom plates and swing on the corresponding fixing bottom plates; the connecting mechanisms are arranged on the corresponding fixing bottom plates; and the control rods slide in the fixing module. The control rods control the connecting mechanisms to swing, the flowerpots are arranged on the fixing bottom plates, swing of the fixing bases can be controlled through sliding of the control rods, and then swing of the flowerpots is controlled, so that the flowerpots are exposed out of a wall, and the purpose of beautifying a building is achieved.

Owner:山东贝克特智能科技有限公司

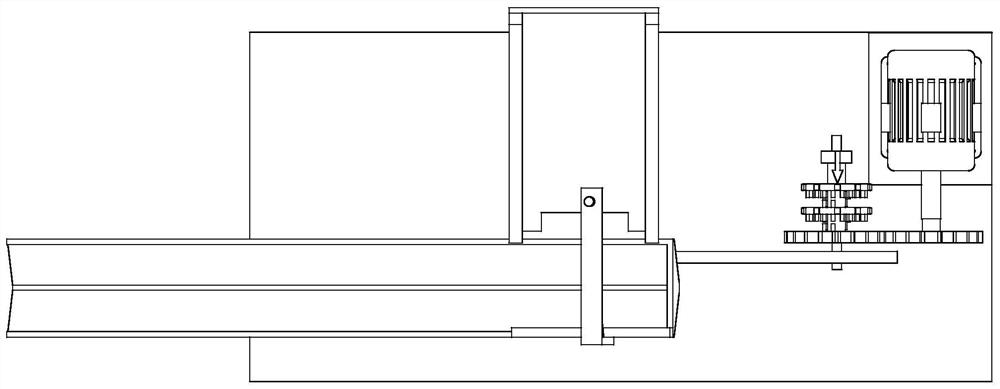

Counting type supply device for flexible mineral insulated cable product connectors

ActiveCN112693804AHigh degree of automationPracticalConveyorsControl devices for conveyorsControl theoryElectric cables

The invention relates to a counting type supply device for flexible mineral insulated cable product connectors. The counting type supply device comprises a base and a supply slideway installed on the upper left side of the base in a hinged mode. An inclined supply material passageway is installed on the rear part of the base, and the front end of the inclined supply material passageway abuts against the rear side wall of the right part of the supply slideway. A linkage block is installed at the right end of the supply slideway. The linkage block is connected with a swing driving assembly. The swing driving assembly is matched with a counting assembly. The counting type supply device is high in automation degree, and the supply slidingway can be controlled to swing to control the cable product connectors to be fed one by one; and during each time of feeding, the feeding counting function can be achieved through the manner of controlling a first rotating wheel to rotate and controlling a second rotating wheel to rotate in a carry mode, and practicability is high.

Owner:ANHUI STAR CABLE

Automatic quenching device for automobile plate spring

InactiveCN112301198AEasy to collectEasy to changeFurnace typesHeat treatment furnacesMachineFully automated

The invention relates to an automatic quenching device for an automobile plate spring. The automatic quenching device comprises a quenching oil pool, wherein a full-automatic frame type swinging lifting quenching machine is arranged at the top of the quenching oil pool; a quenching furnace and a tempering furnace are respectively arranged at two ends of the quenching oil pool; an oil draining conveying device and a hot straightening machine are arranged on one side of the quenching oil pool; a robot I for carrying the plate spring from the quenching furnace to the hot straightening machine isarranged at the discharging end of the quenching furnace; a robot II for carrying the plate spring from the hot straightening machine to the full-automatic frame type swinging lifting quenching machine and then carrying the plate spring to the oil draining conveying device after the plate spring is quenched is arranged at one end of the oil draining conveying device; and a robot III for carrying the plate spring from the oil draining conveying device to the tempering furnace is arranged at the other end of the oil draining conveying device. The automatic quenching device is small in occupied area, oil smoke is conveniently collected and purified, and the production efficiency is greatly improved. The robots are adopted for feeding and discharging, so that the labor intensity is greatly reduced, the yield is improved, the positioning precision can be guaranteed, and the product quality is improved.

Owner:山东中元自动化设备有限公司 +1

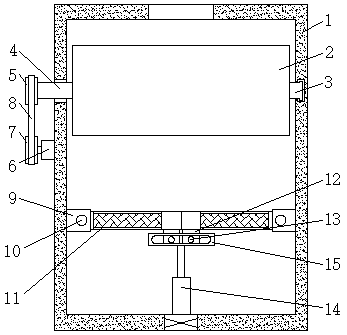

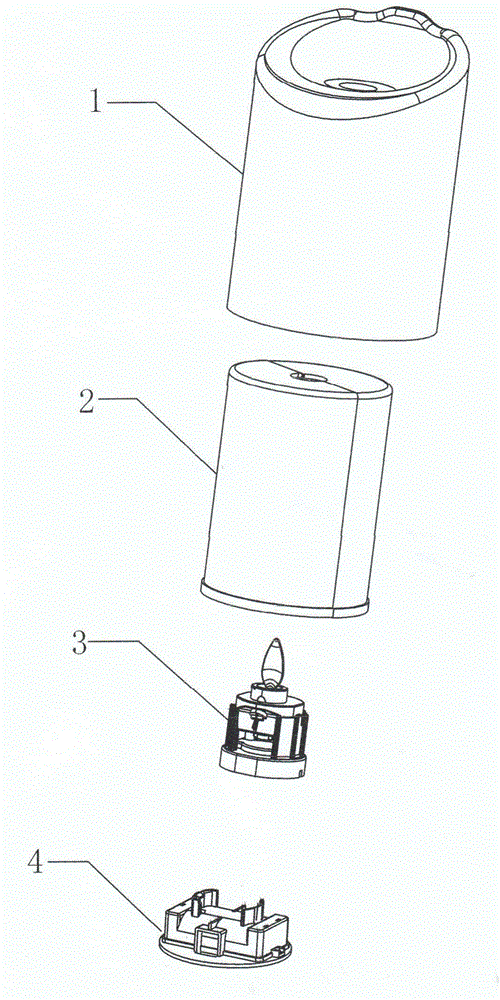

Simulated candle lamp based on electromagnetic principle

InactiveCN104976580ANo wasteReduce heatPoint-like light sourceElectric circuit arrangementsEngineeringCandle

The invention discloses a simulated candle lamp based on the electromagnetic principle. The simulated candle lamp based on the electromagnetic principle comprises a shell, a shell core, a light-emitting component and a power driving panel, wherein the shell core and the light-emitting component are arranged in the shell, and the power driving panel is arranged at the bottom of the shell. The light-emitting component comprises a light-emitting piece, an LED chip and a support. The support is fixed to the shell core. According to the simulated candle lamp based on the electromagnetic principle, power consumption is low, the amount of generated heat is small, potential safety hazards are completely avoided, energy waste is avoided, and the environmental friendliness effect is achieved; the simulated candle lamp based on the electromagnetic principle is suitable for being widely used by people.

Owner:罗周连

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com