Patents

Literature

161results about How to "Wide range of control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

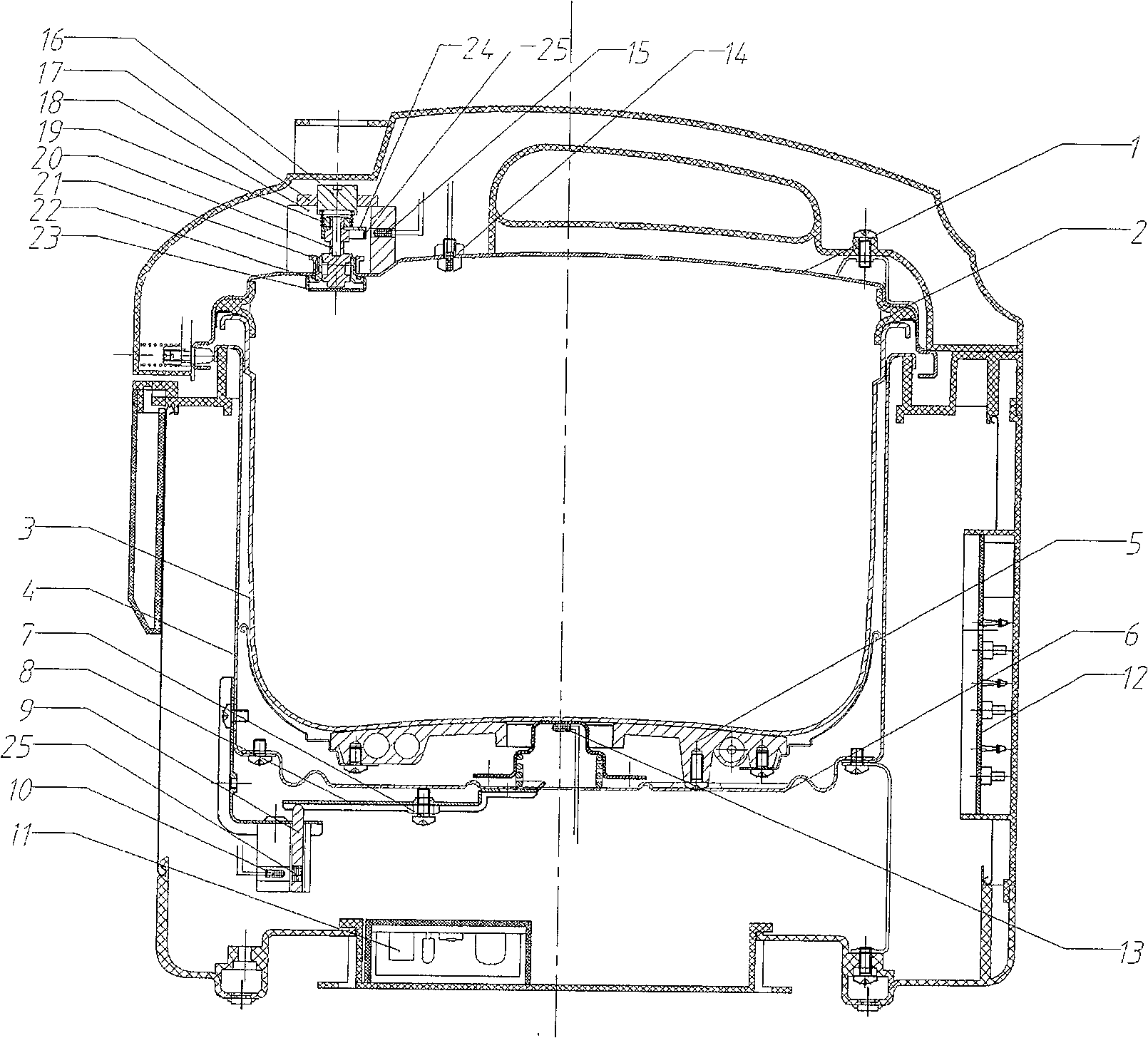

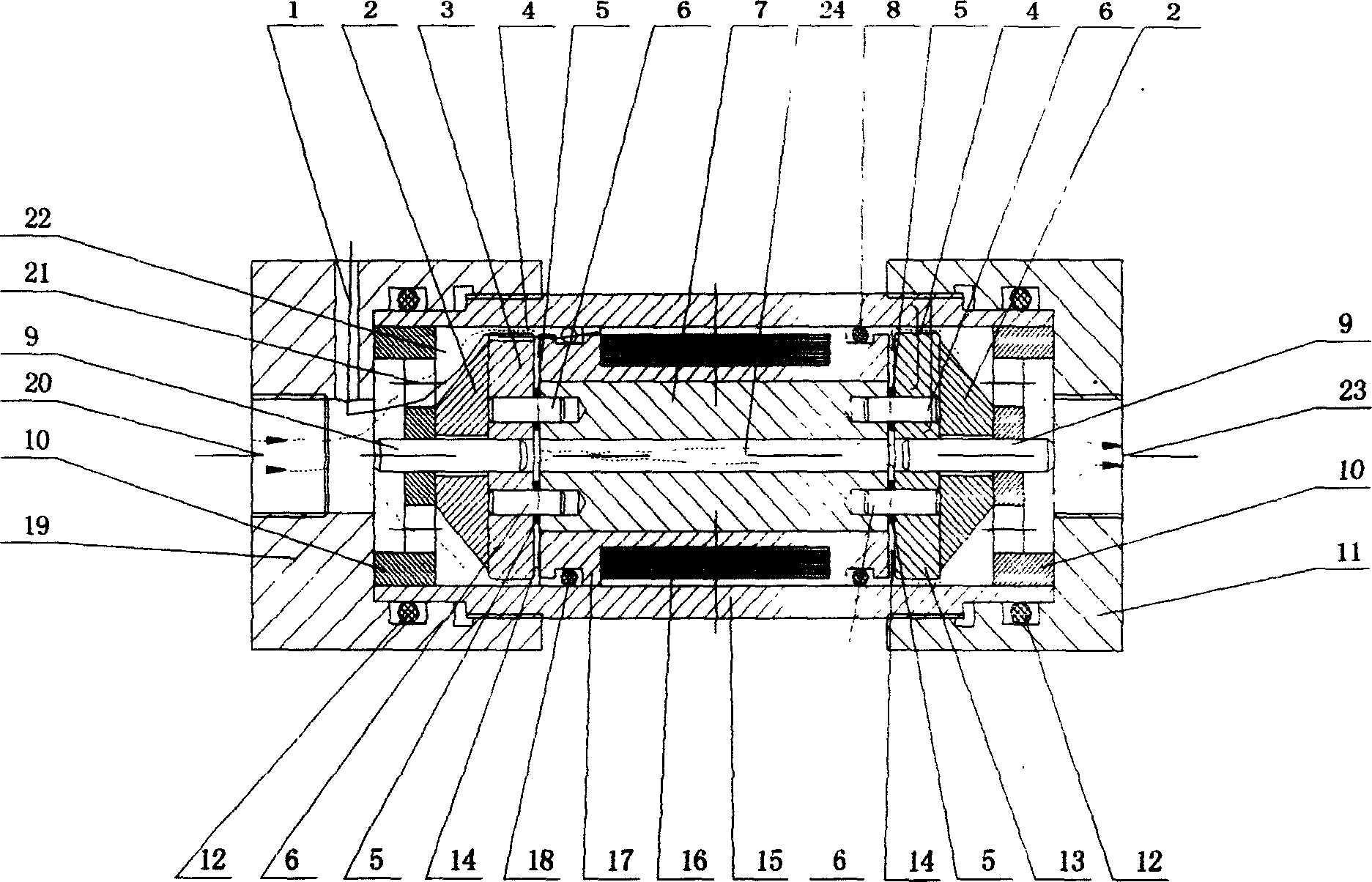

Electronic sensing type electric pressure cooker

InactiveCN100534363CSimple structureImprove performancePressure-cookersInternal pressureAutomatic control

Owner:李寿民 +1

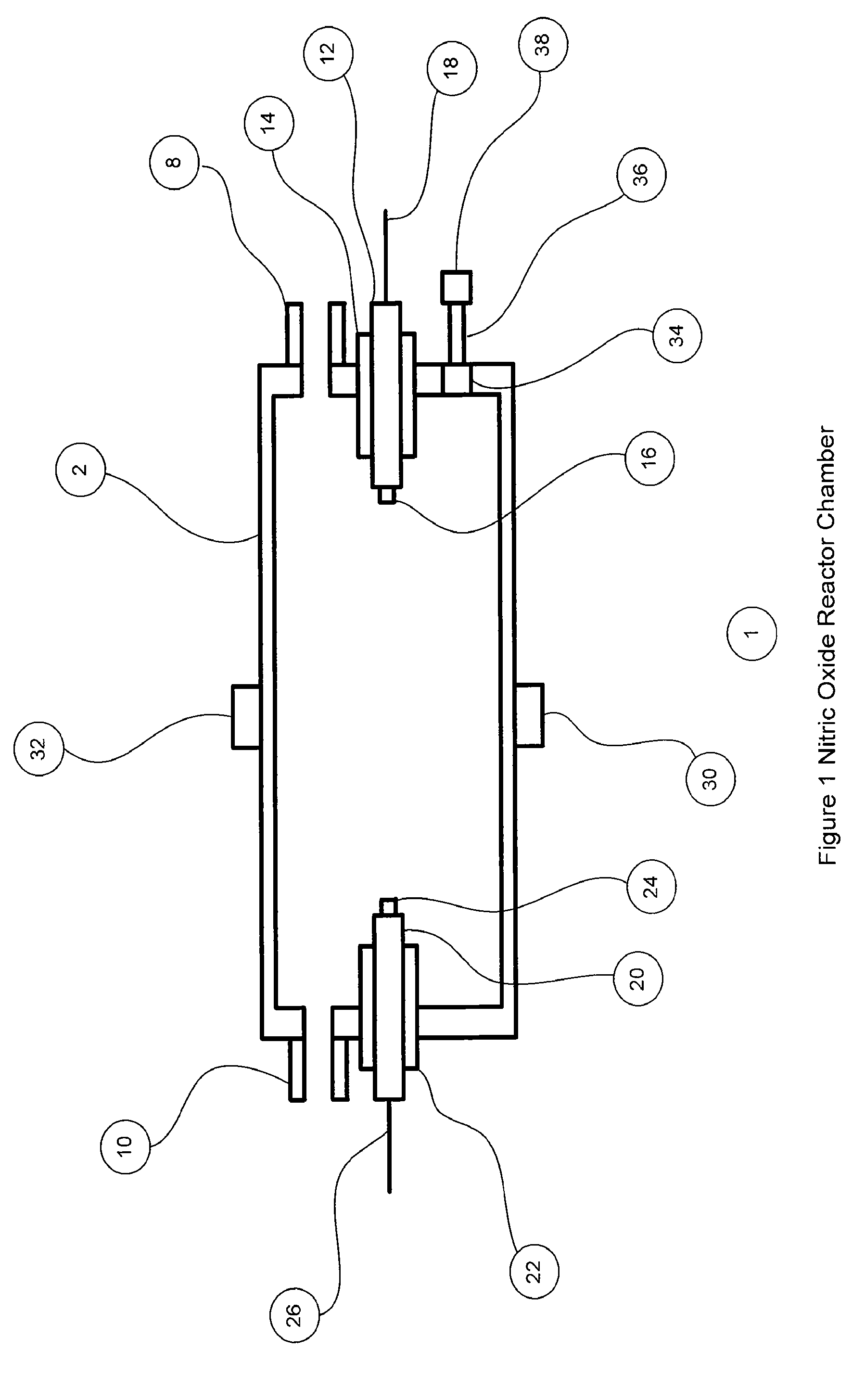

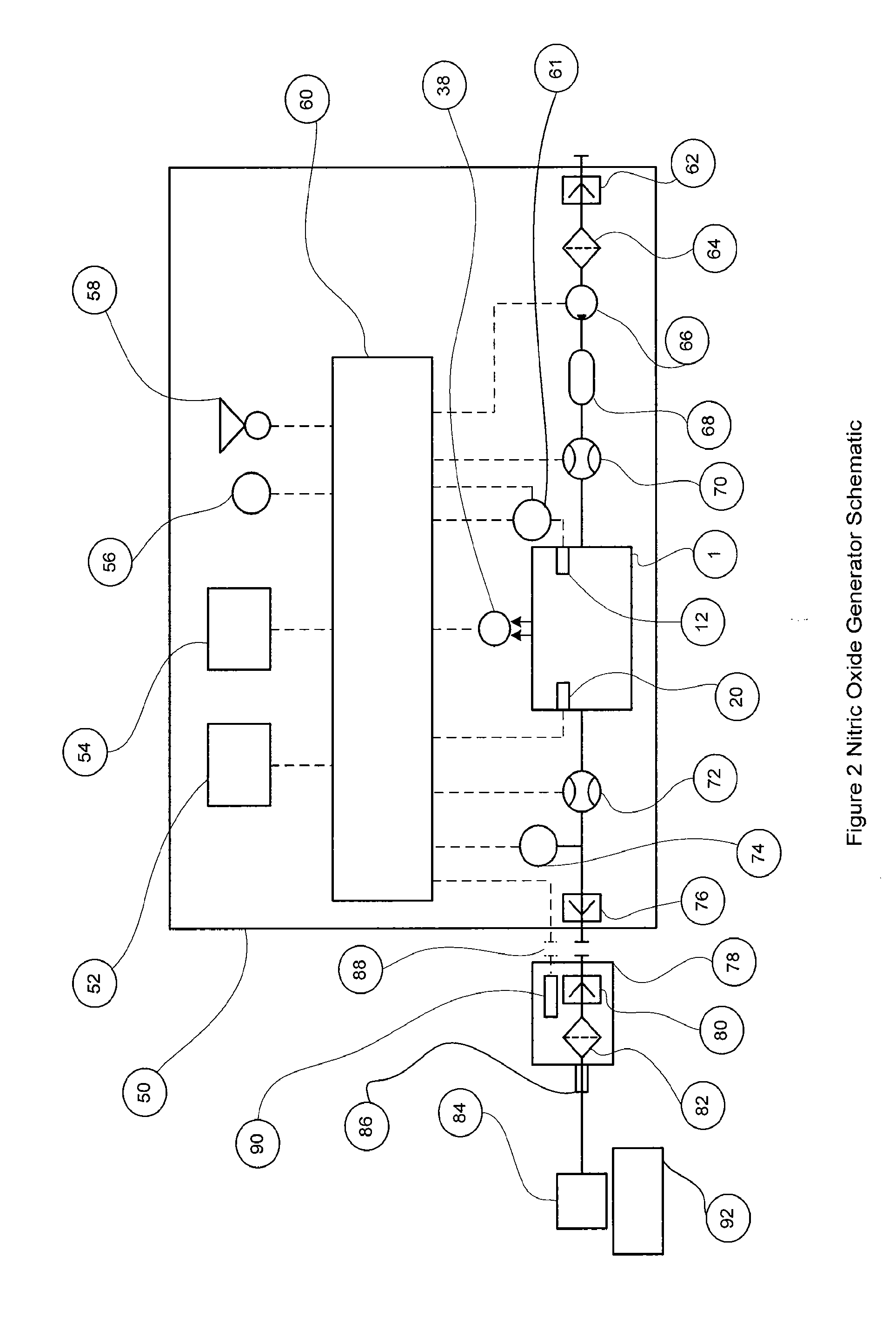

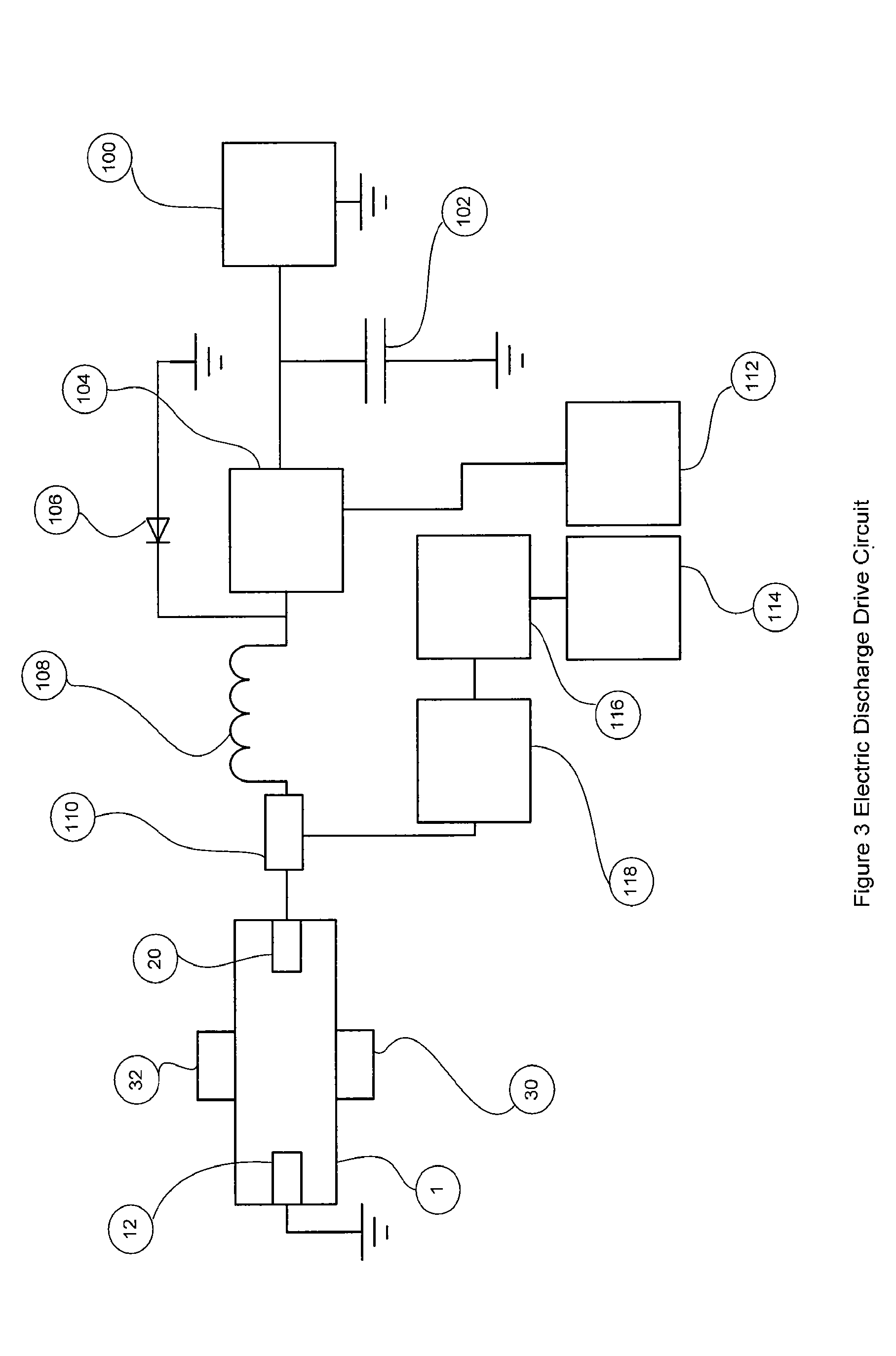

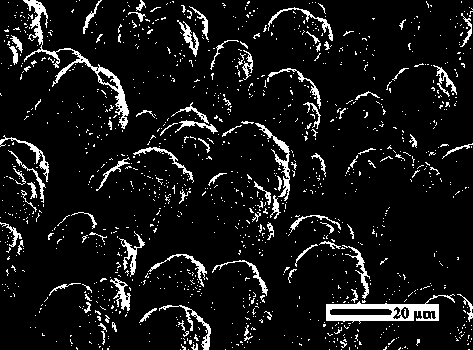

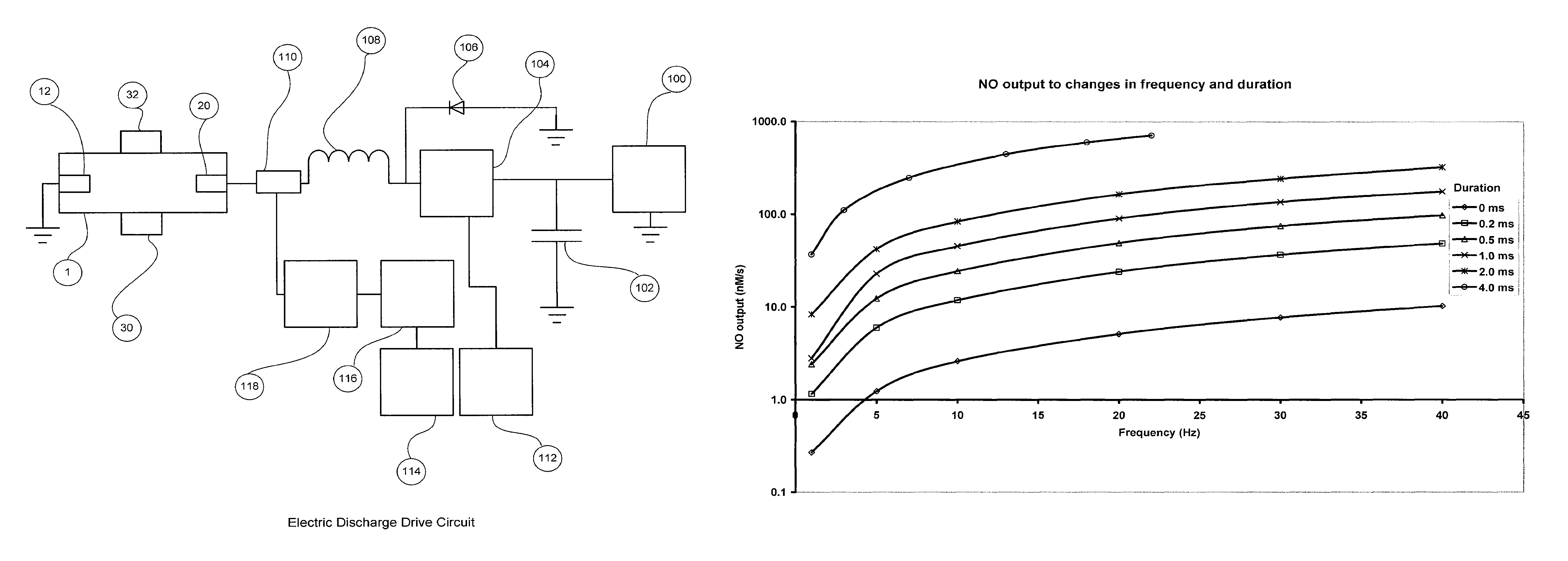

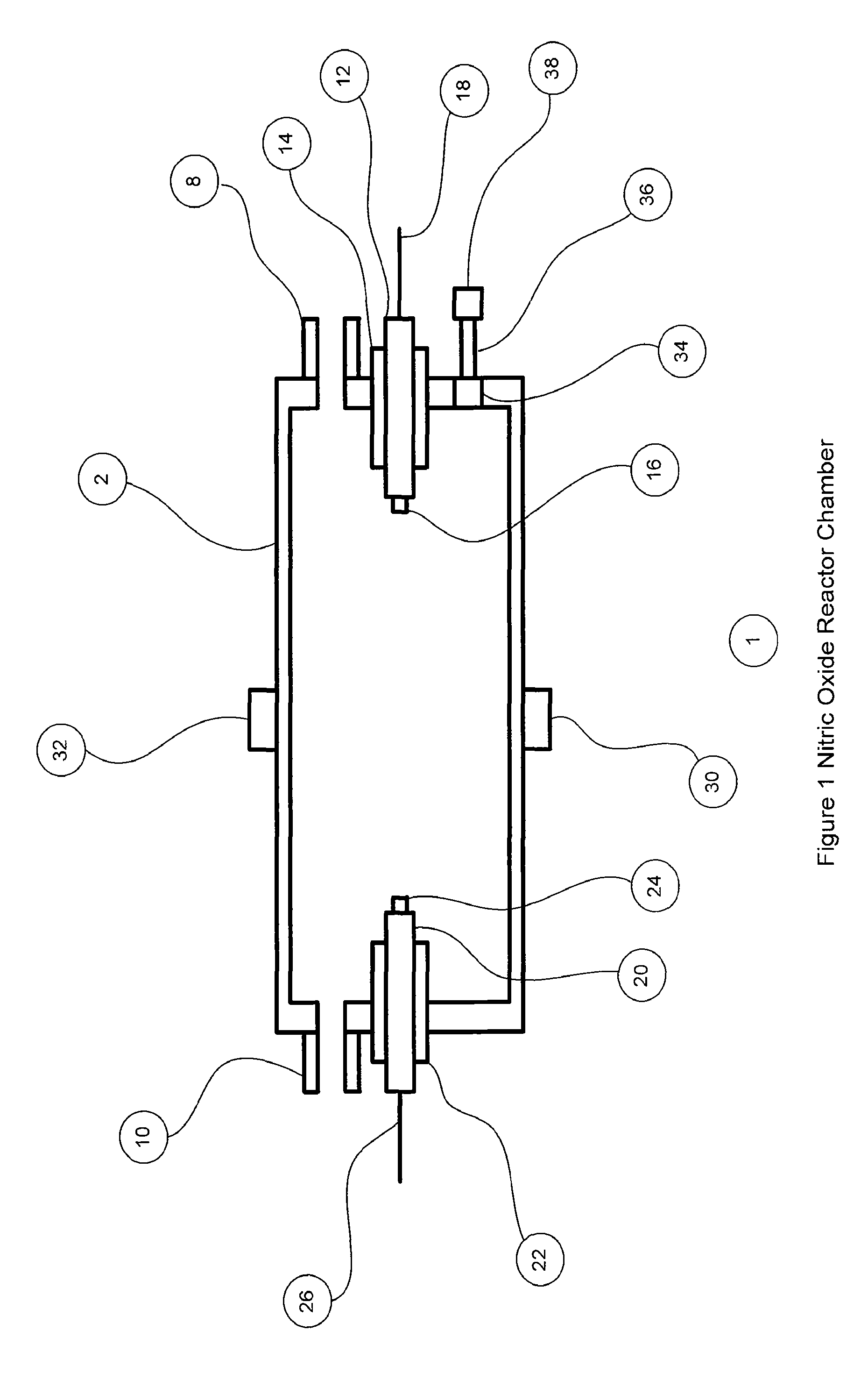

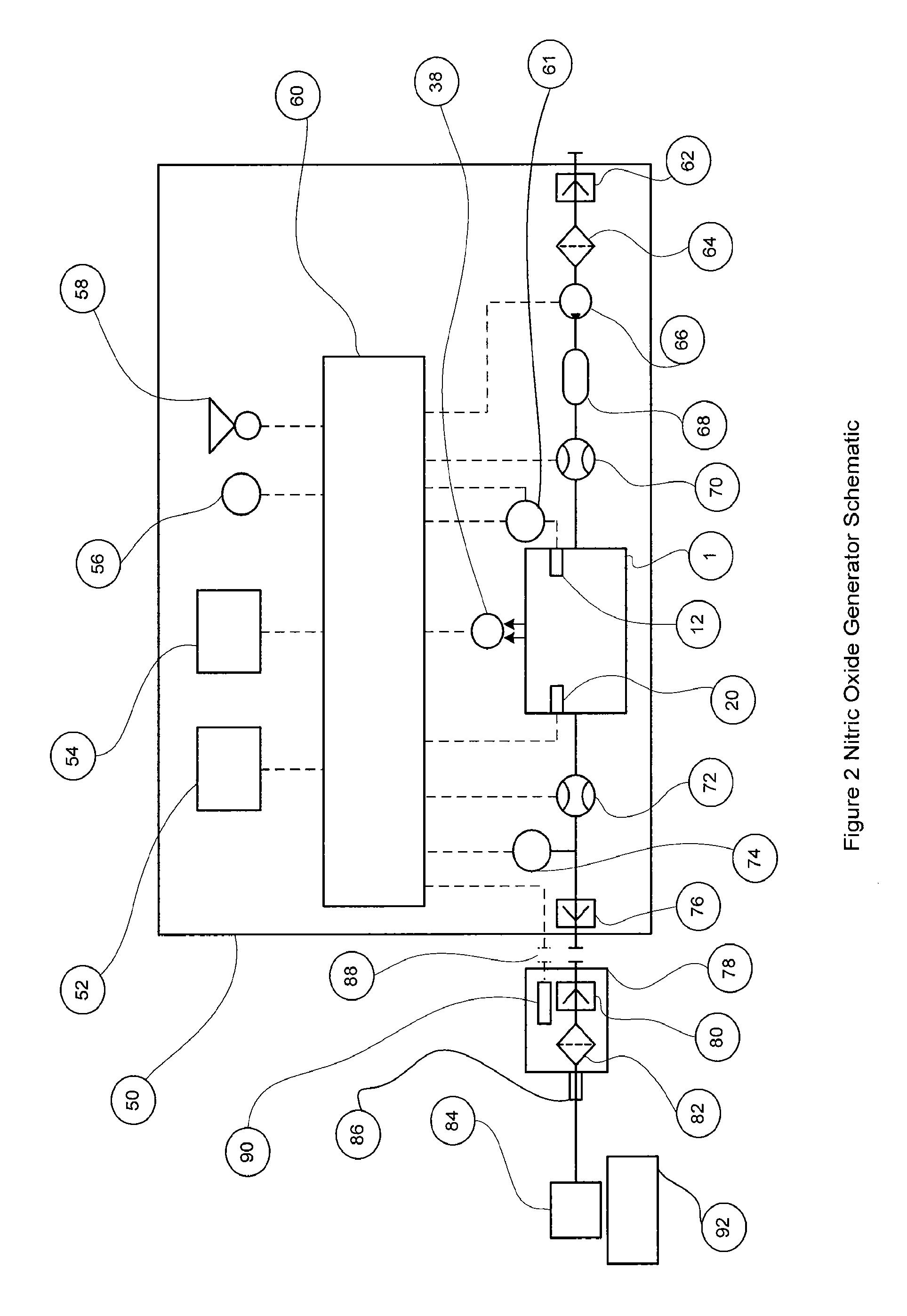

Apparatus and method for generating nitric oxide in controlled and accurate amounts

ActiveUS20140251787A1Remove adulterantAccurate representationCombination devicesAuxillary pretreatmentNitrogenNitric oxide

A nitric oxide generator generates nitric oxide from a mixture of nitrogen and oxygen such as air treated by a pulsating electrical discharge. The desired concentration of nitric oxide is obtained by controlling at least one of a frequency of the pulsating electrical discharge and duration of each electrical discharge pulse.

Owner:NITRICGEN

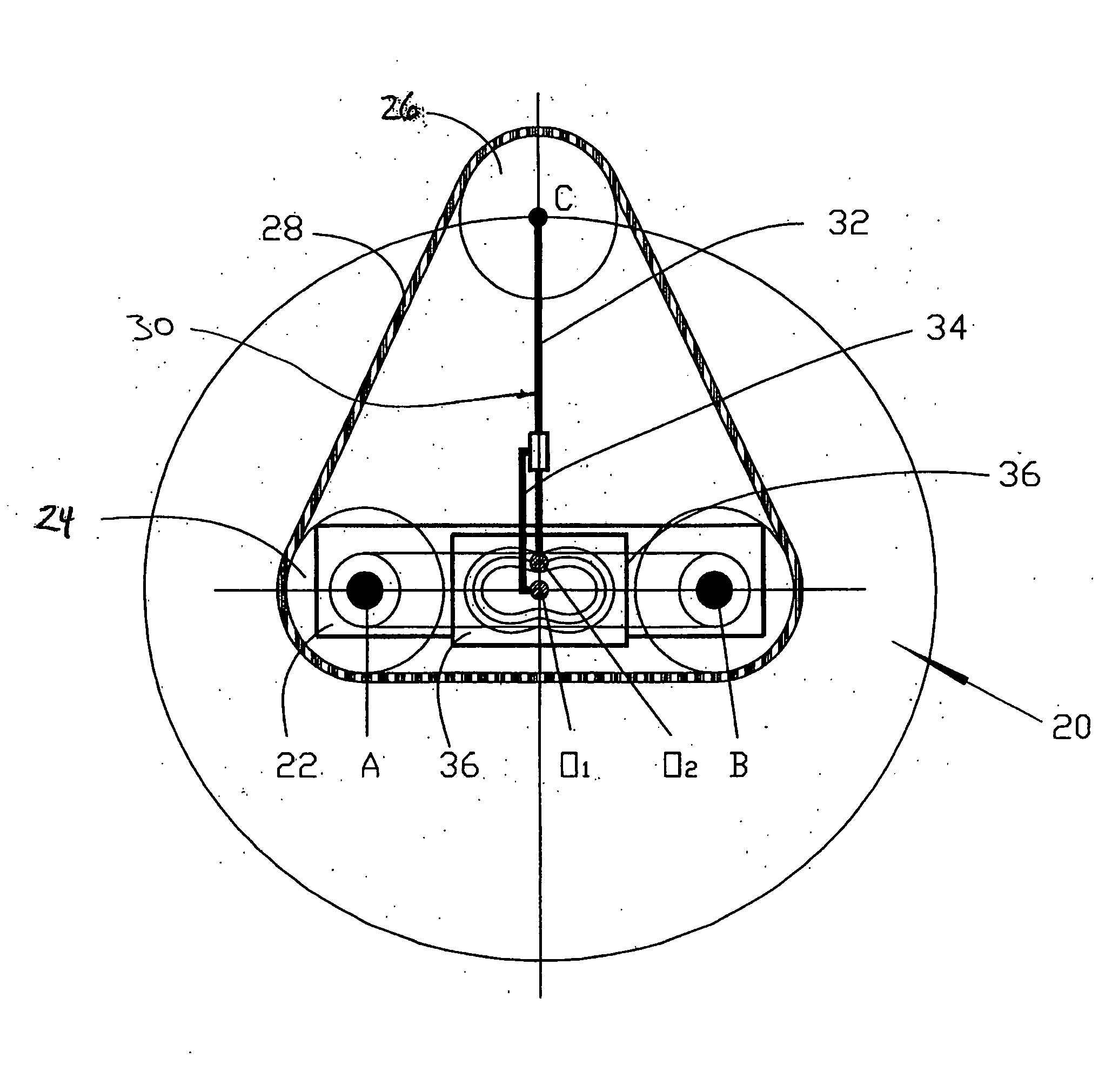

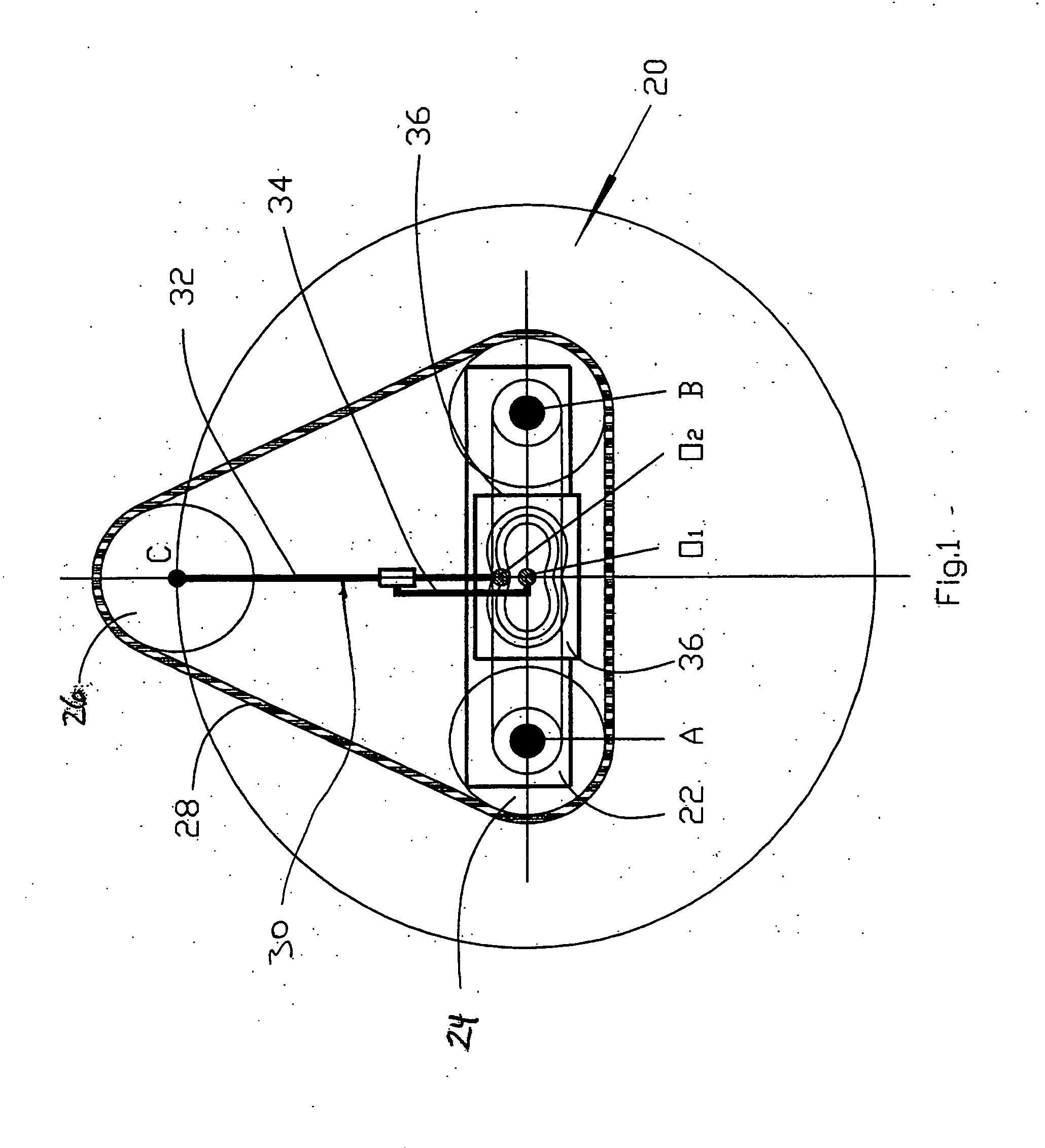

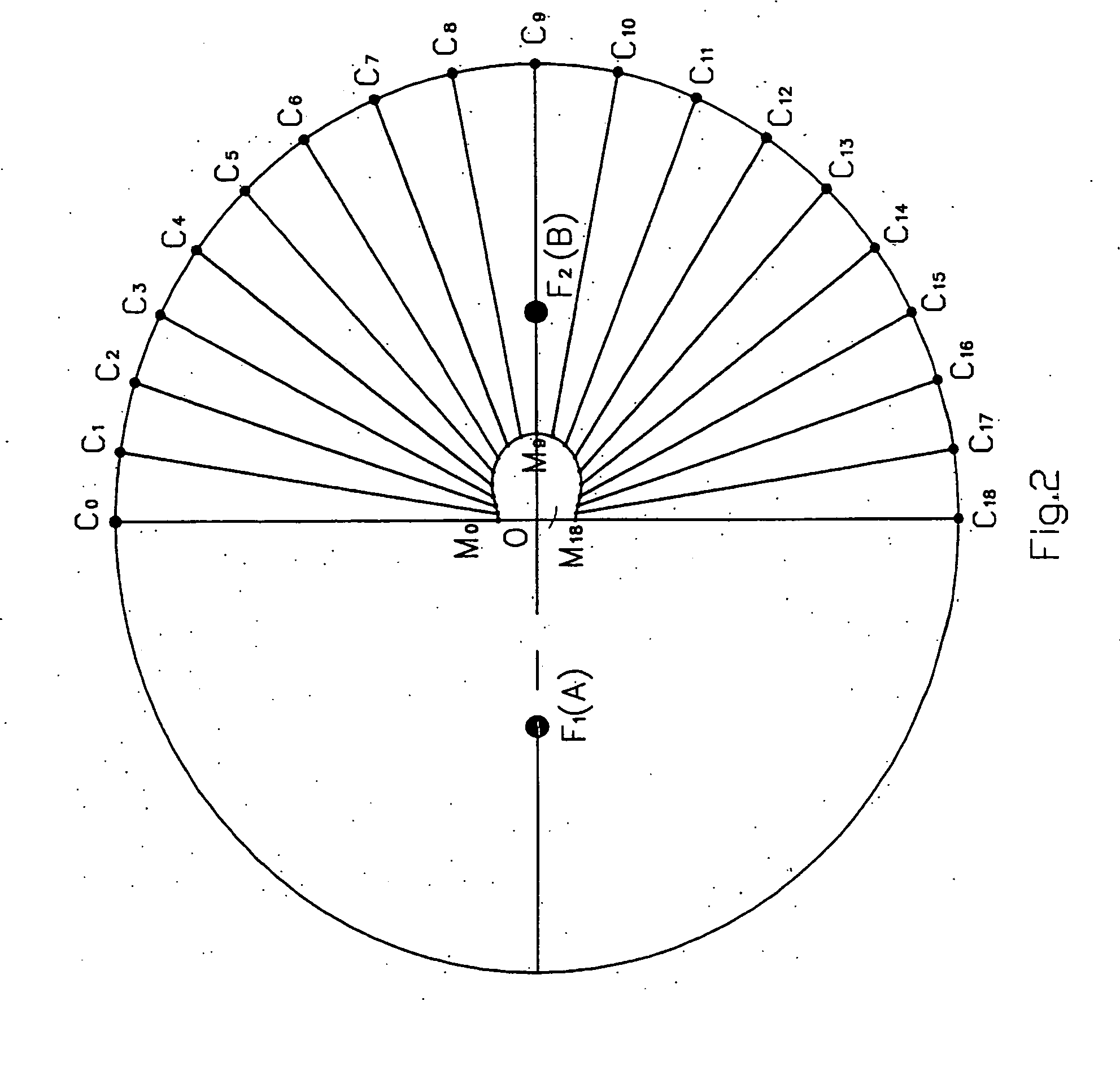

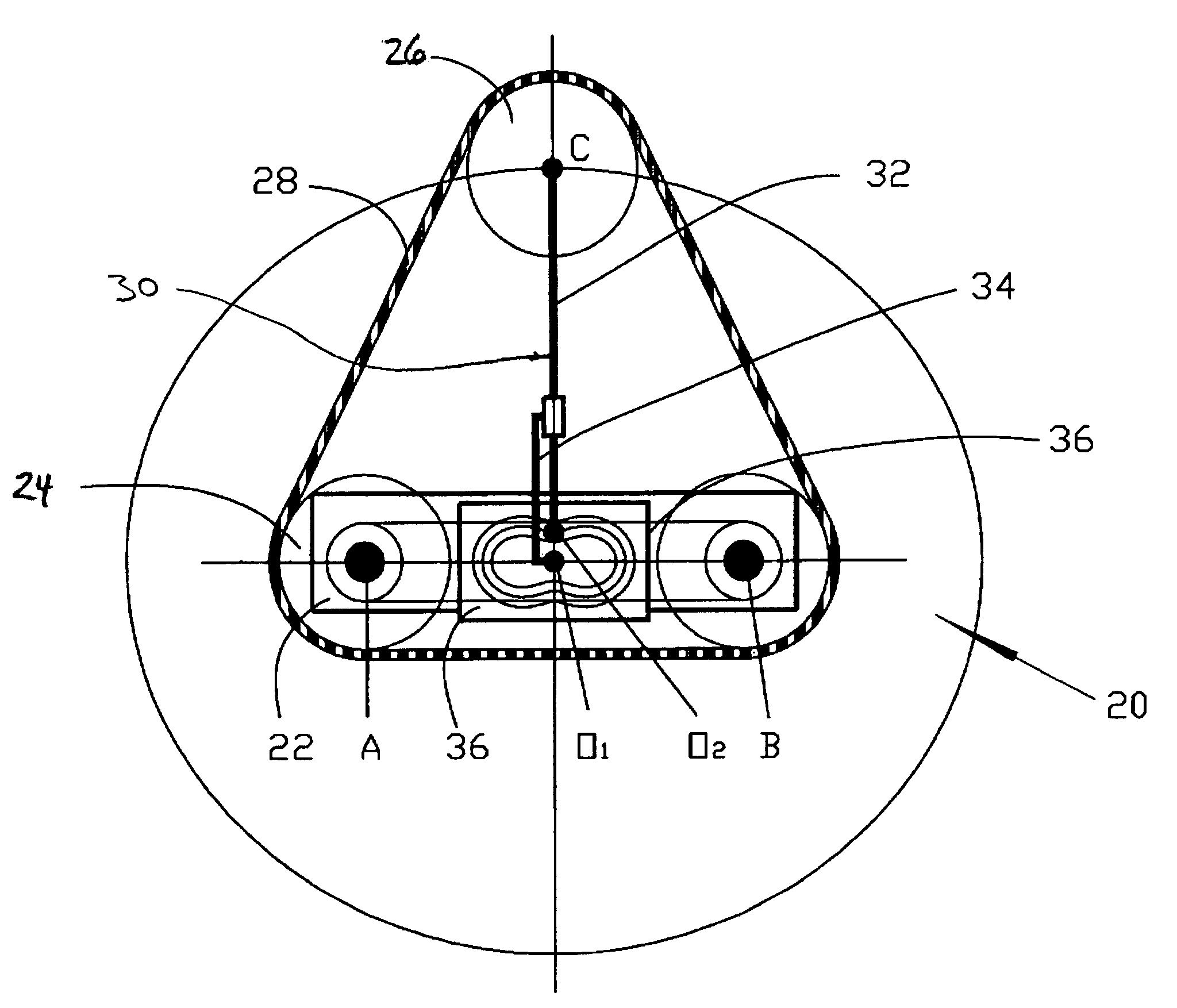

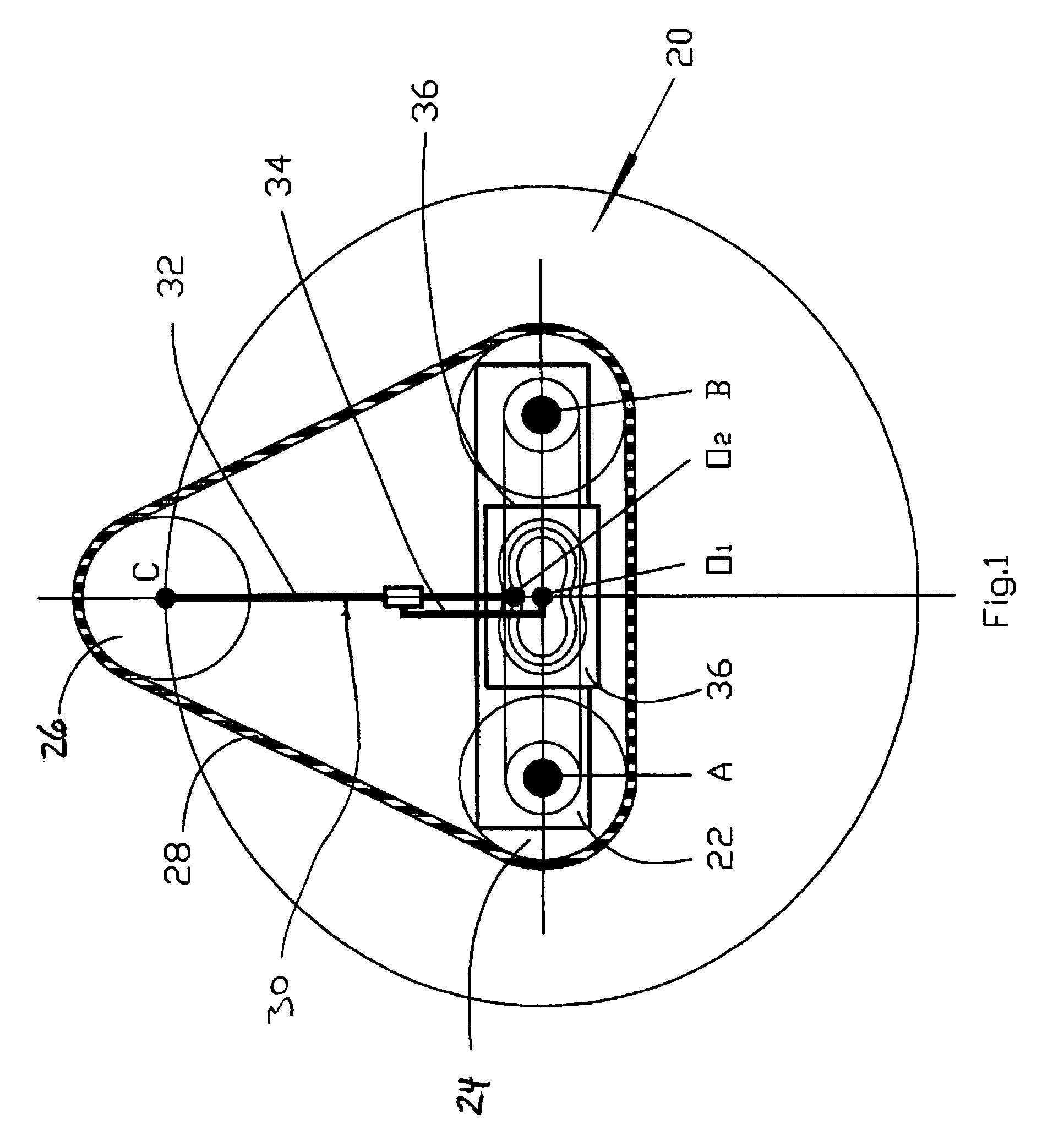

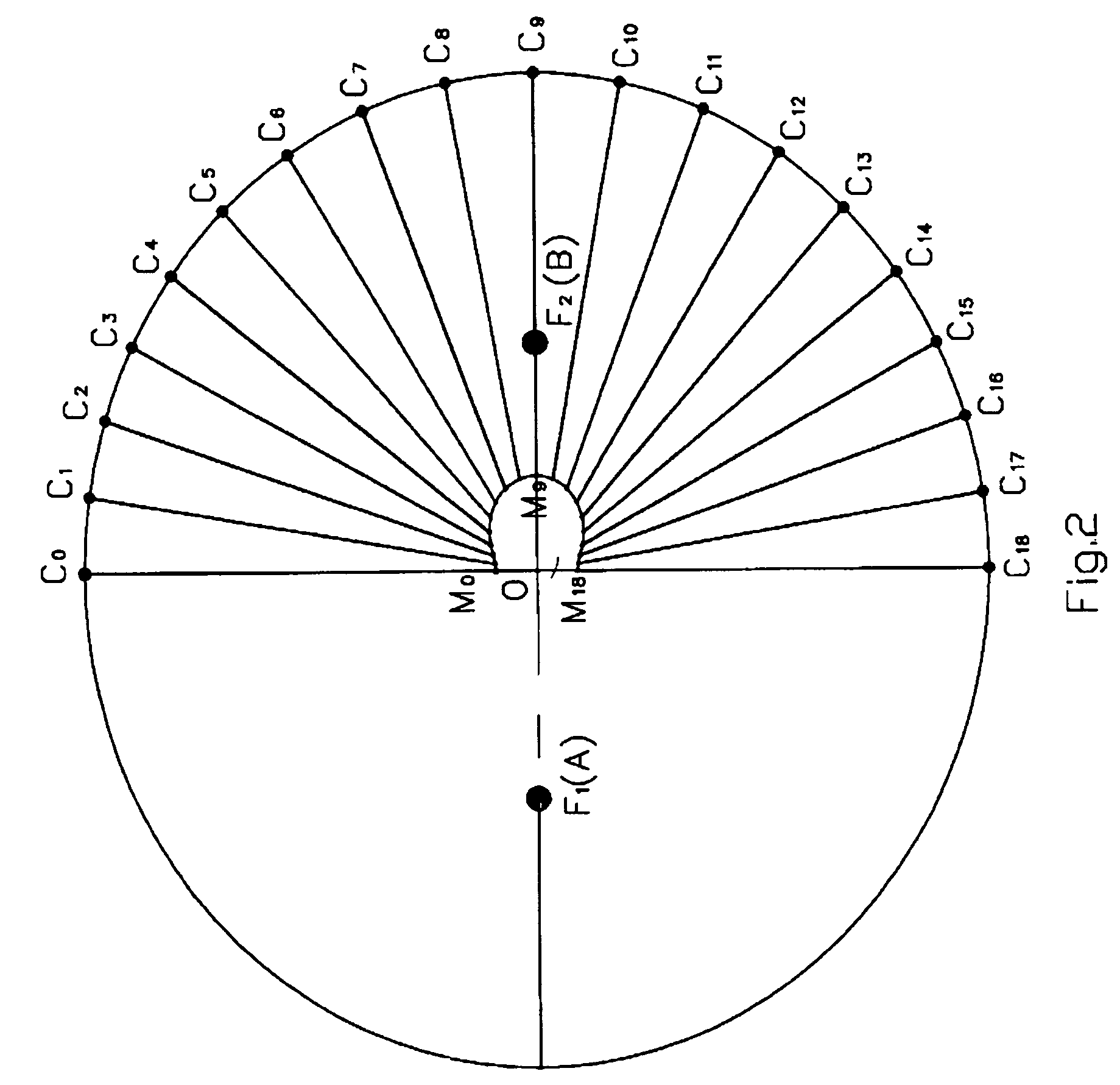

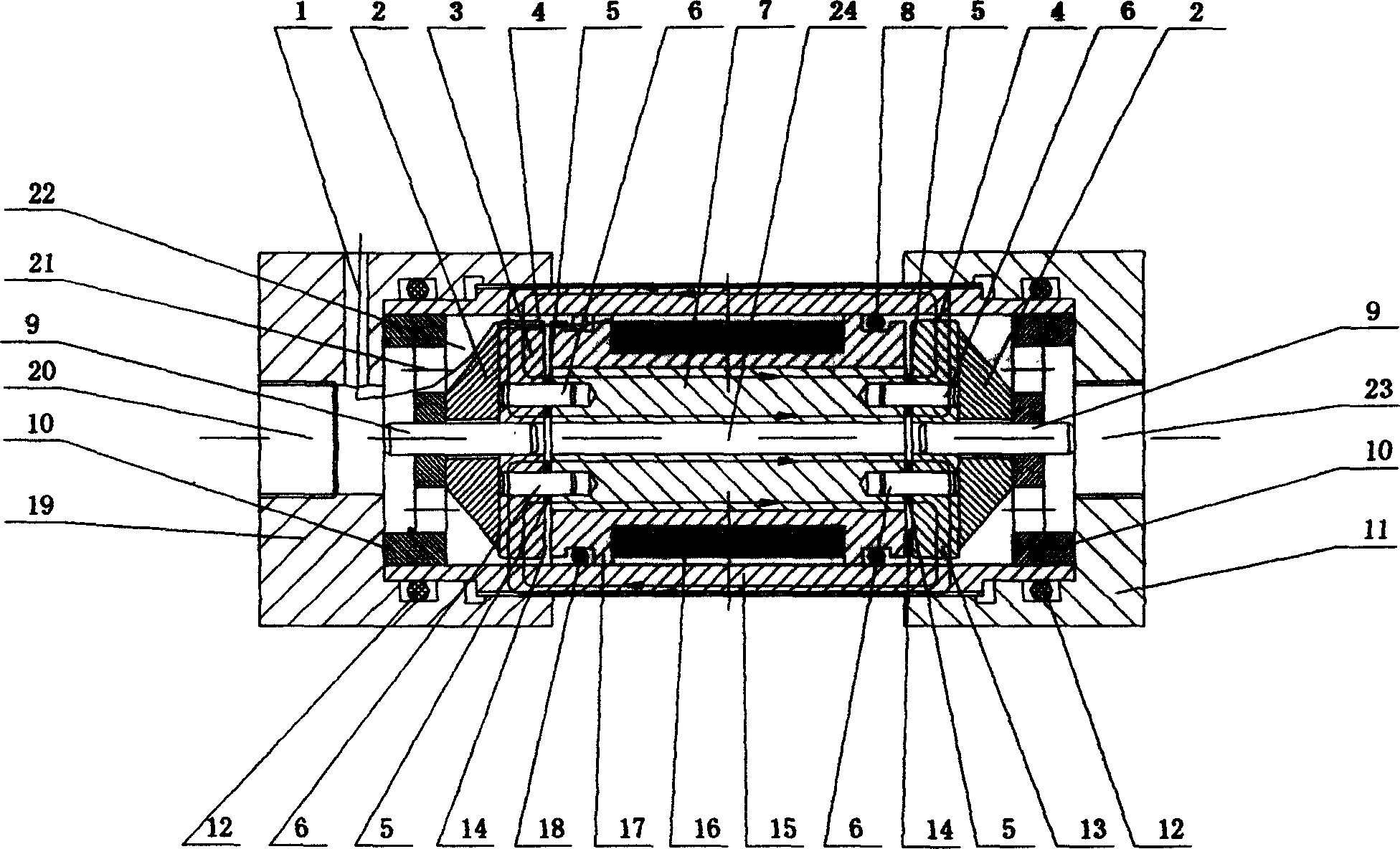

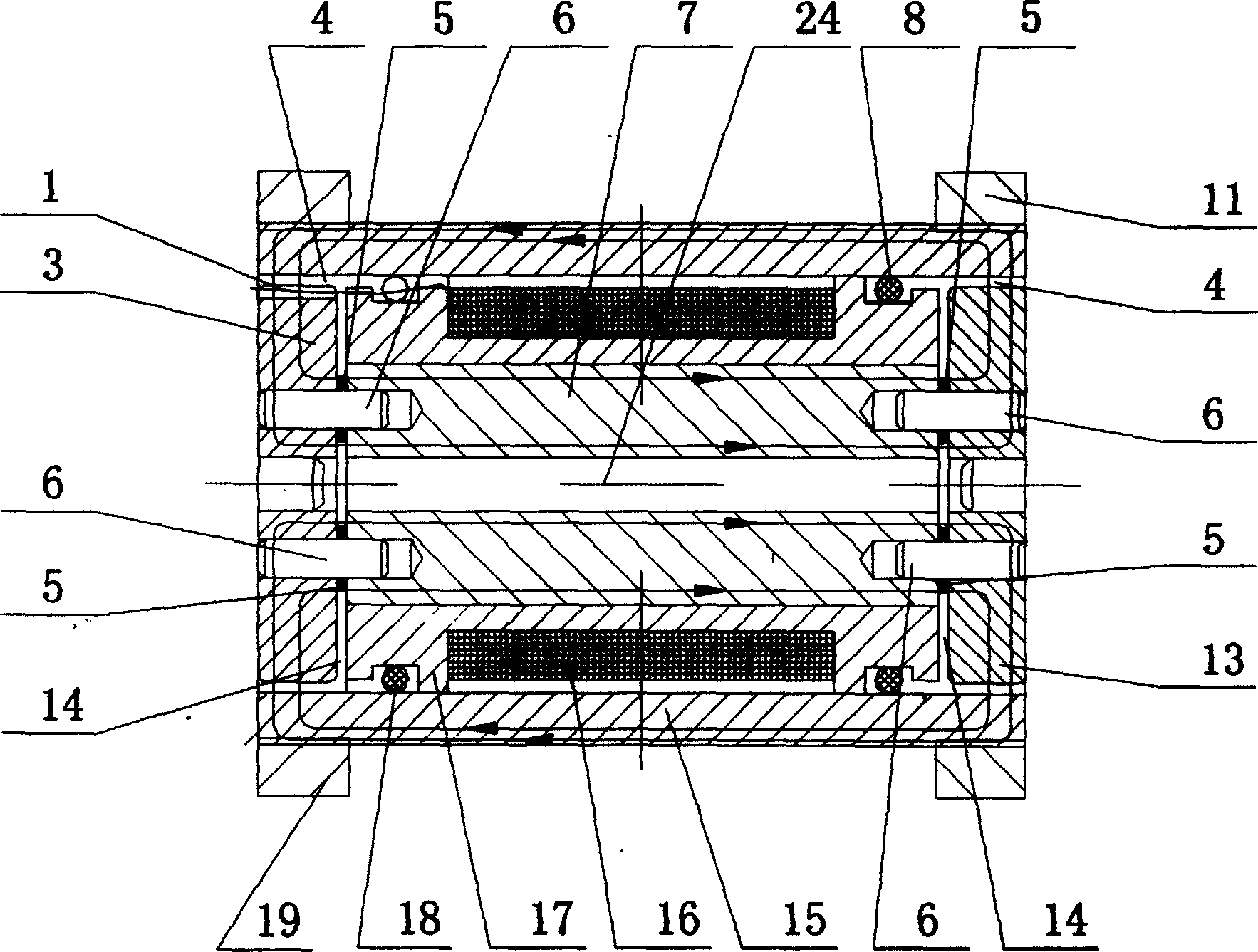

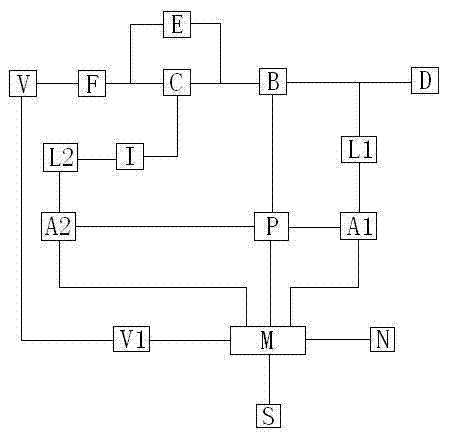

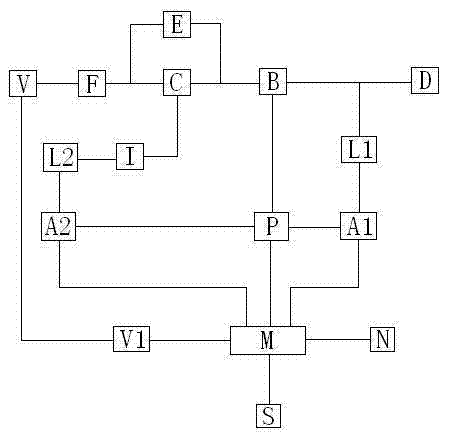

Variable configuration articulated tracked vehicle

ActiveUS20070193790A1Wide range of controlEasy to assembleCarriage/perambulator accessoriesEndless track vehiclesEngineeringDrive motor

A variable configuration articulated tracked vehicle comprises a chassis, a pair of right and left drive pulleys, a right and left planetary wheel, a right and left track, a right and left arm mechanism, and a right and left drive motor. The drive pulleys are rotatably attached to the chassis and each pair of drive pulleys is in the same plane. The planetary wheels are movable relative to the chassis such that each planetary wheel is in the same plane as its respective drive pulleys. The tracks extend around the pair of drive pulleys and the planetary wheel on the respective sides. The arm mechanisms connect the respective planetary wheel to the chassis. Each arm mechanism is rotatably attached to the chassis with a cam. The cam defines a motion path of one end of the arm whereby the motion of the planetary wheel provides a path for the planetary wheel such that the track path defined by the respective drive pulleys and the planetary wheel is a constant track length. The motors are each operably connected to the respective pair of drive pulleys for driving the track.

Owner:CHINA SUPERROBOTICS LTD

High plastic-strain ratio galvanized steel sheet and production method

InactiveCN101255529ALower recrystallization temperaturePromotes secondary phase formationHot-dipping/immersion processesMetal rolling arrangementsChemical compositionSheet steel

The invention relates to a hot galvanizing sedan plate and the production method thereof, which solves the following problems: P and S in steel are difficult to control because of being lowly required; as to a horizontal Sendzimir hot galvanizing machine, the recrystallization temperature of a steel plate is slightly high, and the plastic strain ratio and extension are low. The high-plastic-strain-ratio galvanizing plate is composed of no more than 0.004% by weight of C, no more than 0.020% by weight of Si, 0.05% to 0.20% by weight of Mn, no more than 0.016% by weight of 0.016, no more than 0.015% by weight of S, 0.04% to 0.07% by weight of Ti, 0.02% to 0.06% by weight of Als, no more than 0.003% by weight of N, and the balance Fe and unavoidable impurity. The production steps are as follows: smelting by hot metal desulphurization and secondary refining process; hot rolling; cold rolling with a total reduction of 80%; and galvanizing. The invention has the characteristics that the method is pure Ti processing; the control scopes of S and P are wide; the plastic strain ratio is r90 DEG C >=2.5, the extension A80mm is 45% to 50%; and the current process route and equipment is unchanged.

Owner:武钢集团有限公司

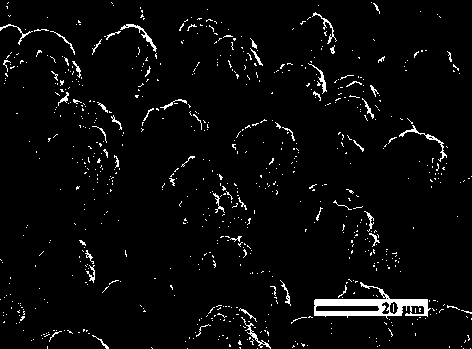

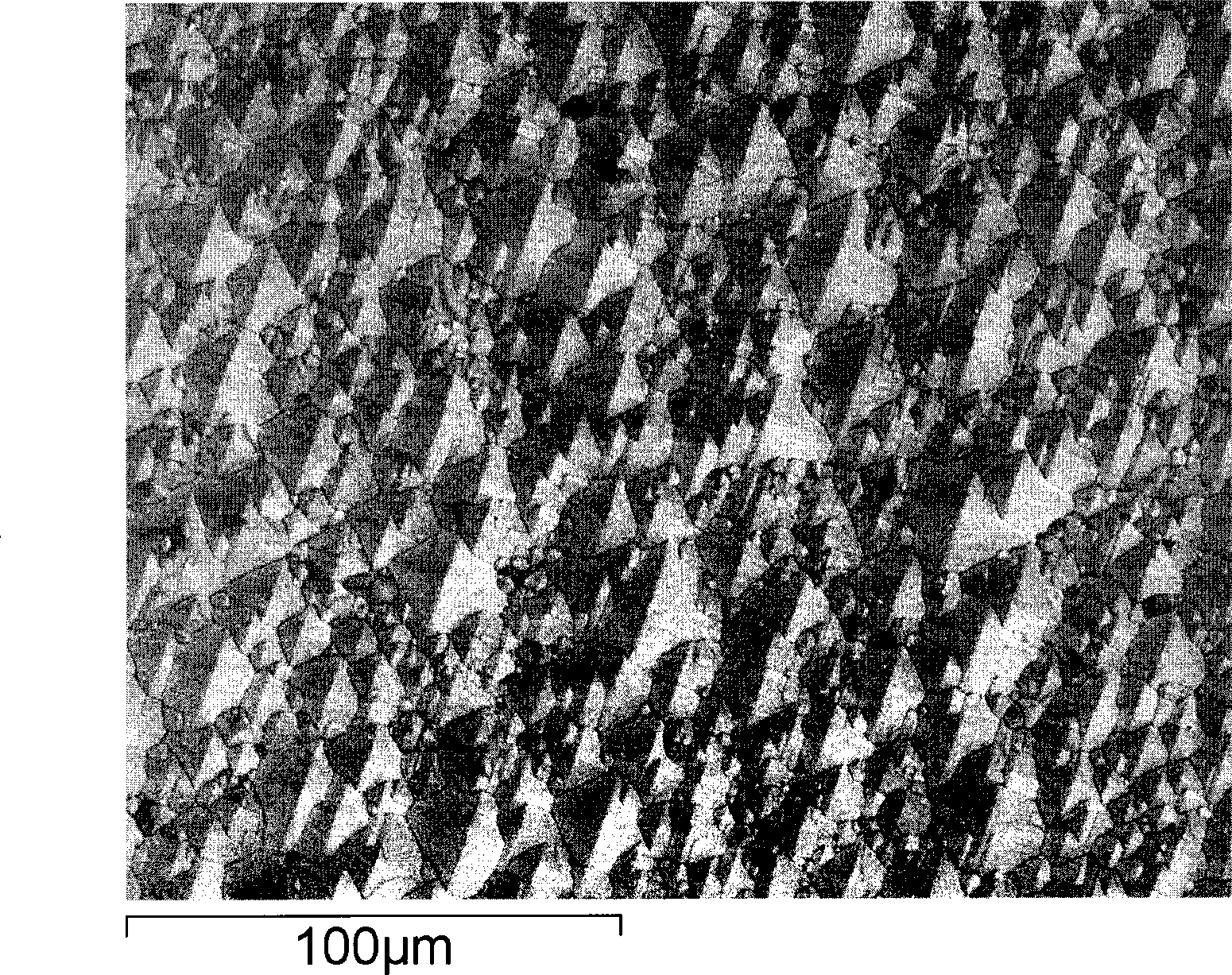

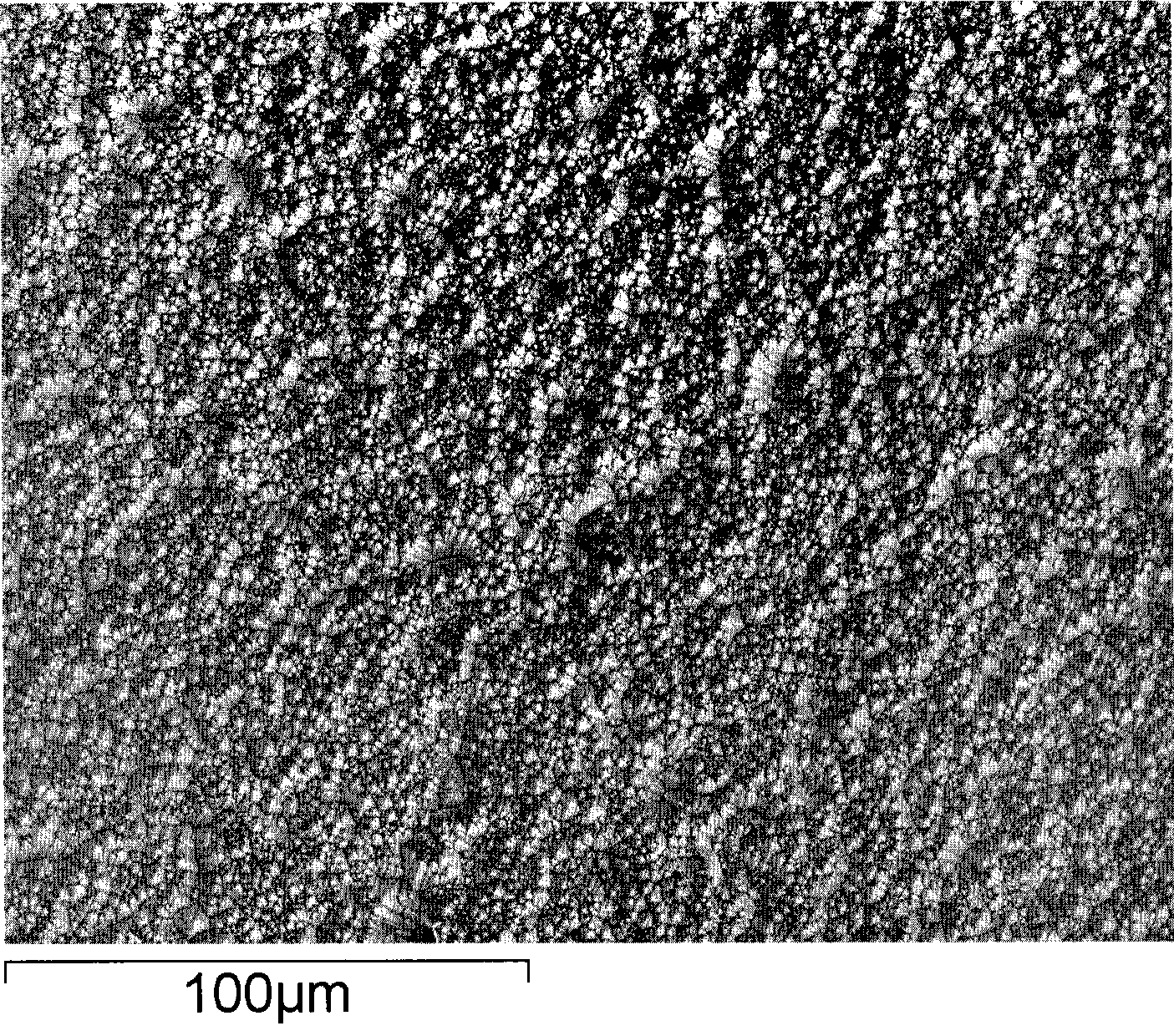

Single crystal silicon texture-making additive and single crystal silicon texture-making technology

InactiveCN102115915AIncrease productivityIncrease production capacityAfter-treatment detailsFinal product manufactureActive agentPotassium hydroxide

The invention relates to a single crystal silicon texture-making additive and a single crystal silicon texture-making technology. The single crystal silicon texture-making additive consists of a wetting agent and a defoaming agent. The additive is characterized in that the wetting agent is a nonionic surfactant. The single crystal silicon texture-making technology comprises the following steps: heating deionized water to 70-80 DEG C, adding sodium hydroxide or potassium hydroxide to obtain a single crystal silicon texture-making corrosive liquid, wherein the mass percentage of sodium hydroxide or potassium hydroxide is 1%-2%; adding the single crystal silicon texture-making additive in the single crystal silicon texture-making corrosive liquid to obtain a mixed solution, wherein the volume percentage of the additive is 0.3%-2%; and placing a precleaned raw silicon chip in the mixed solution for 600-1200s for texture-making. By adopting the additive and technology in the invention, the texture-making quality can be greatly increased, the cost is greatly reduced, the technological operation can be easier and the automatic solution preparation can be realized.

Owner:百力达太阳能股份有限公司

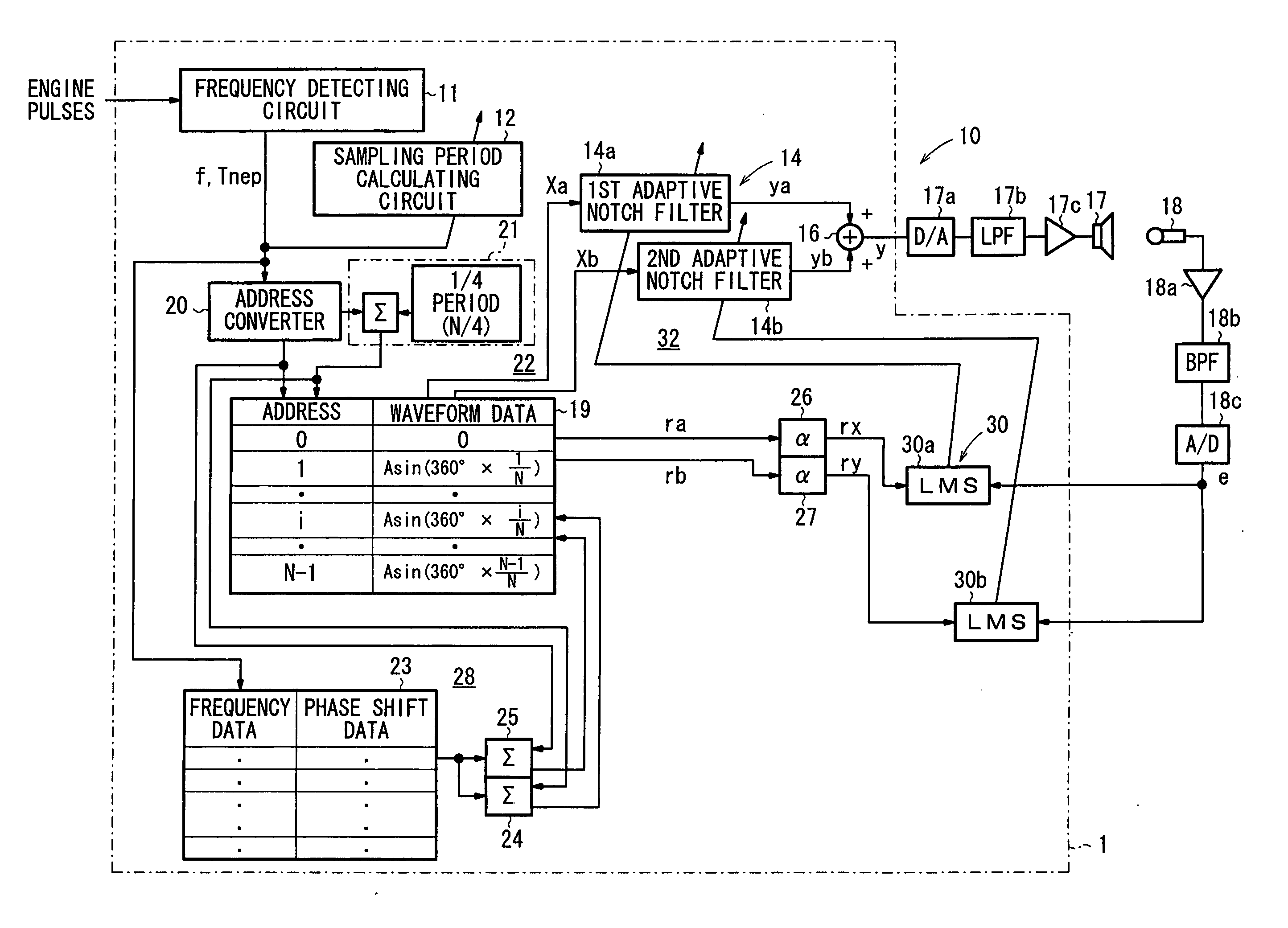

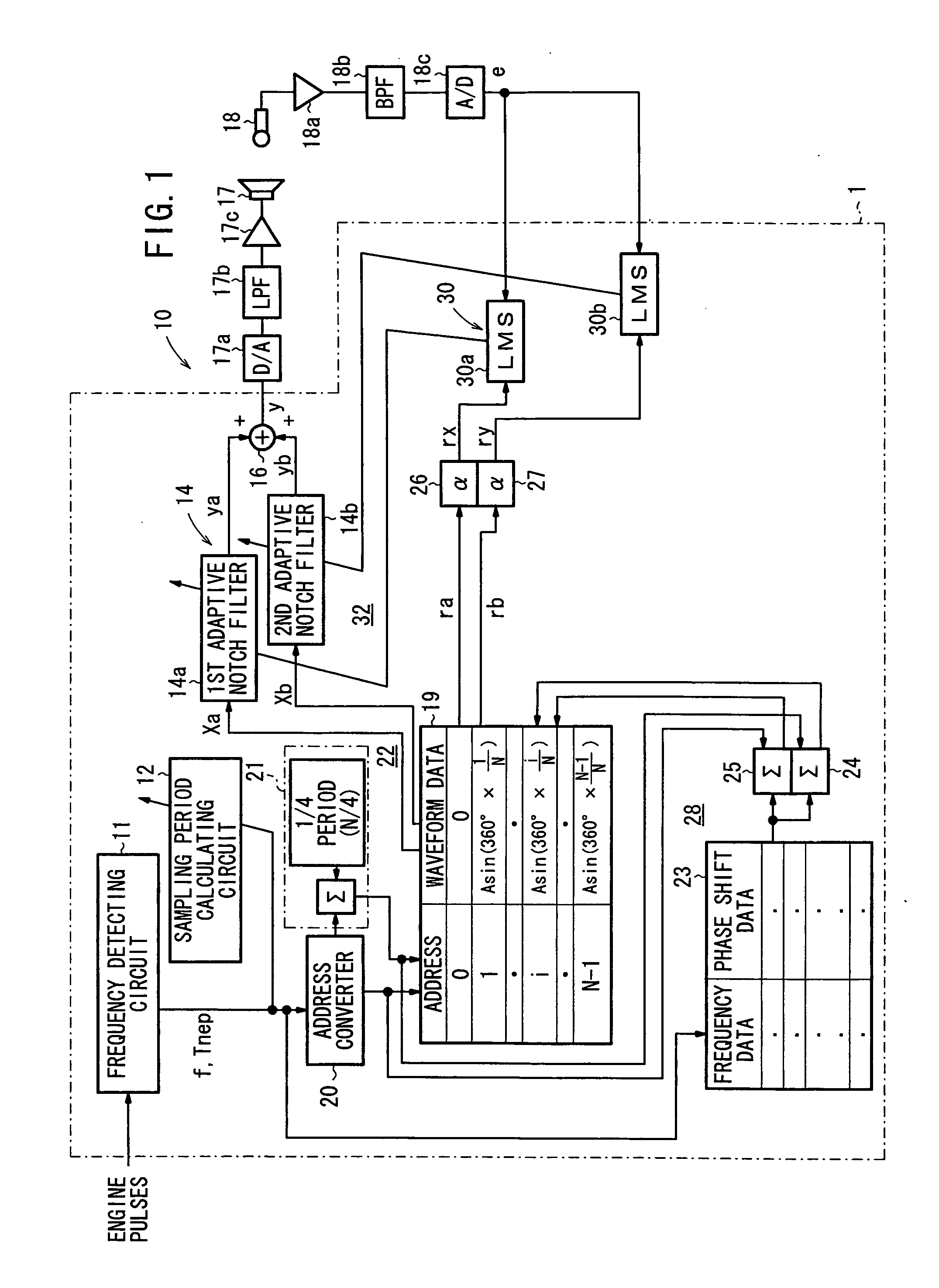

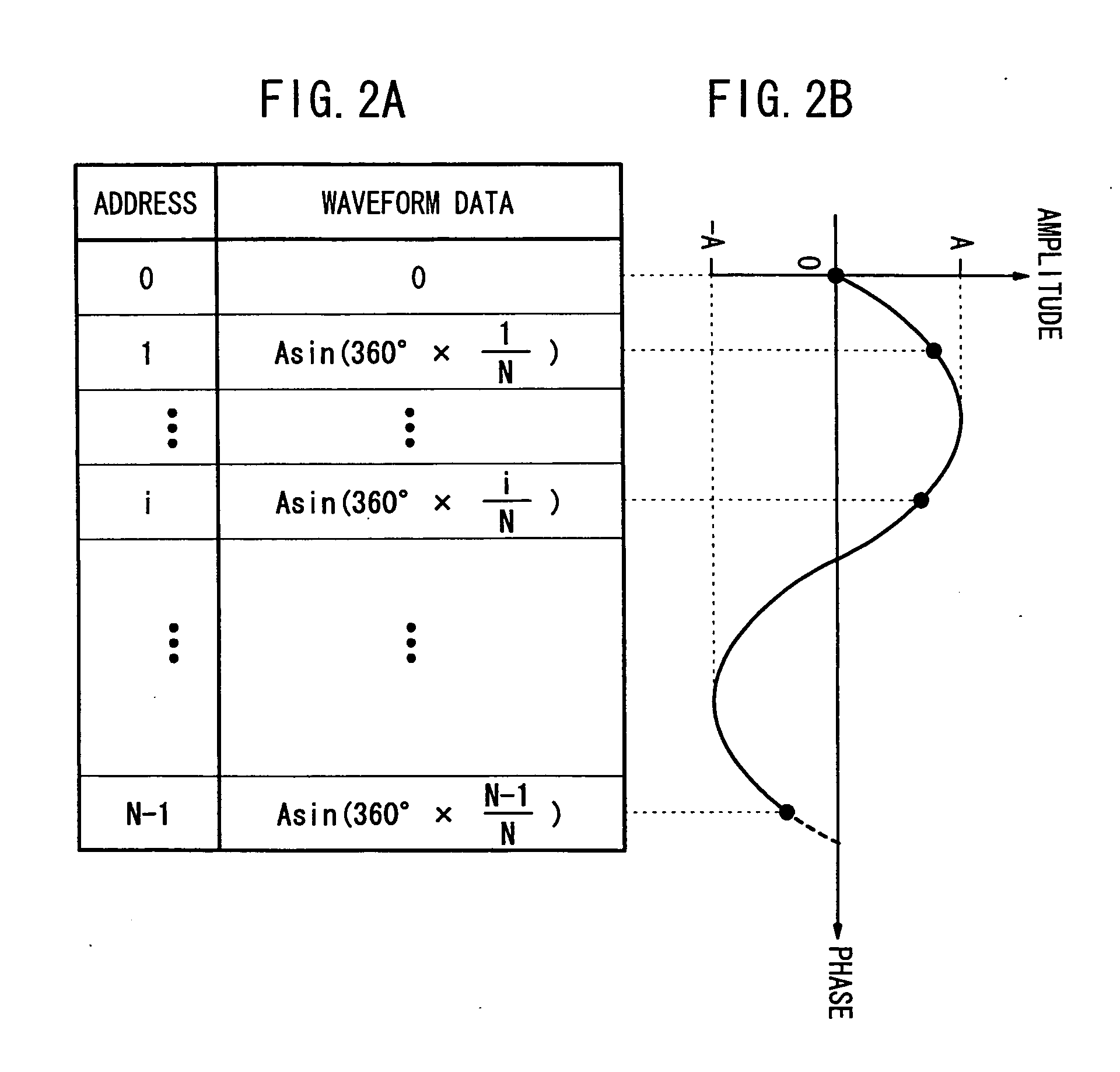

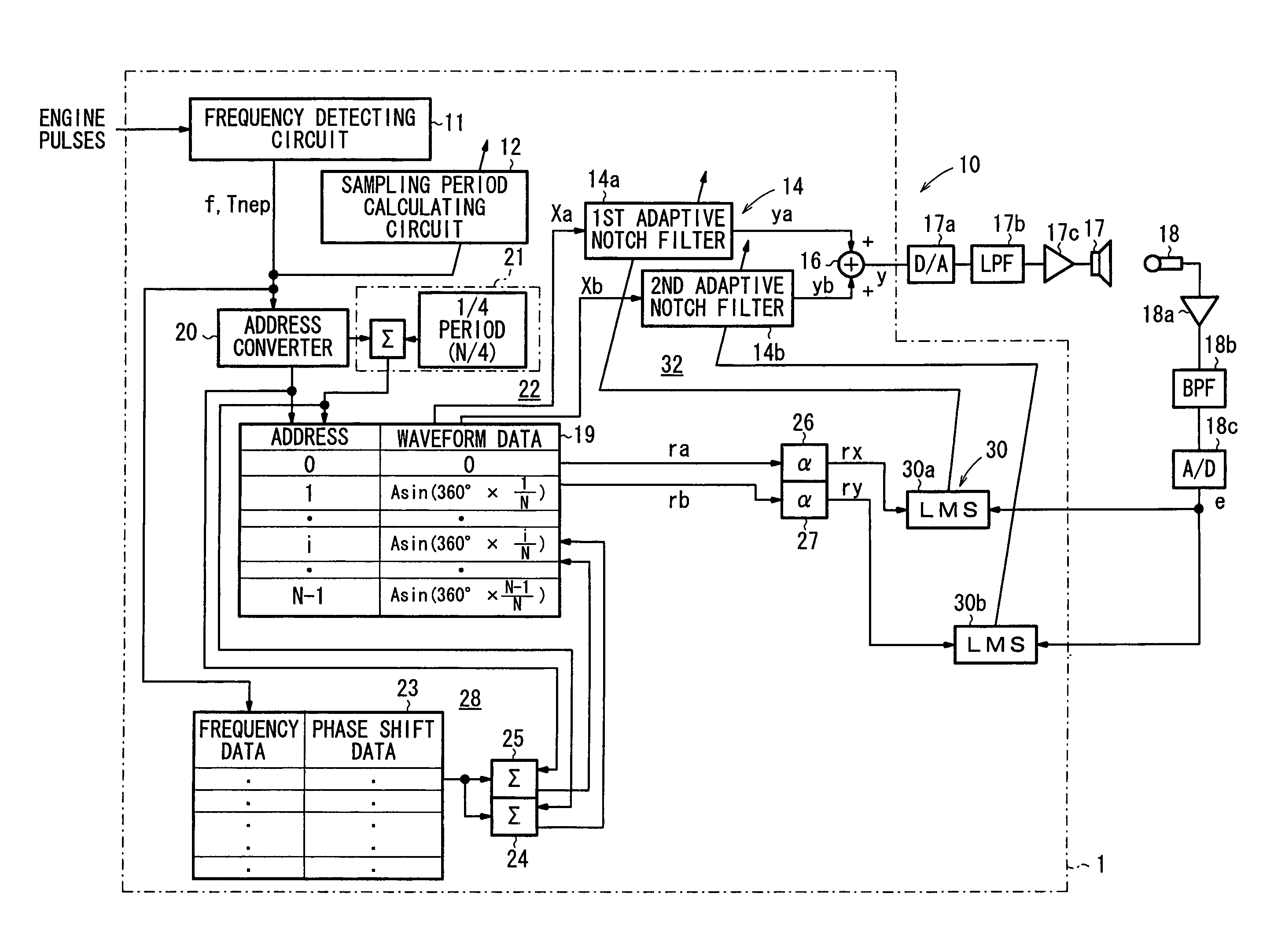

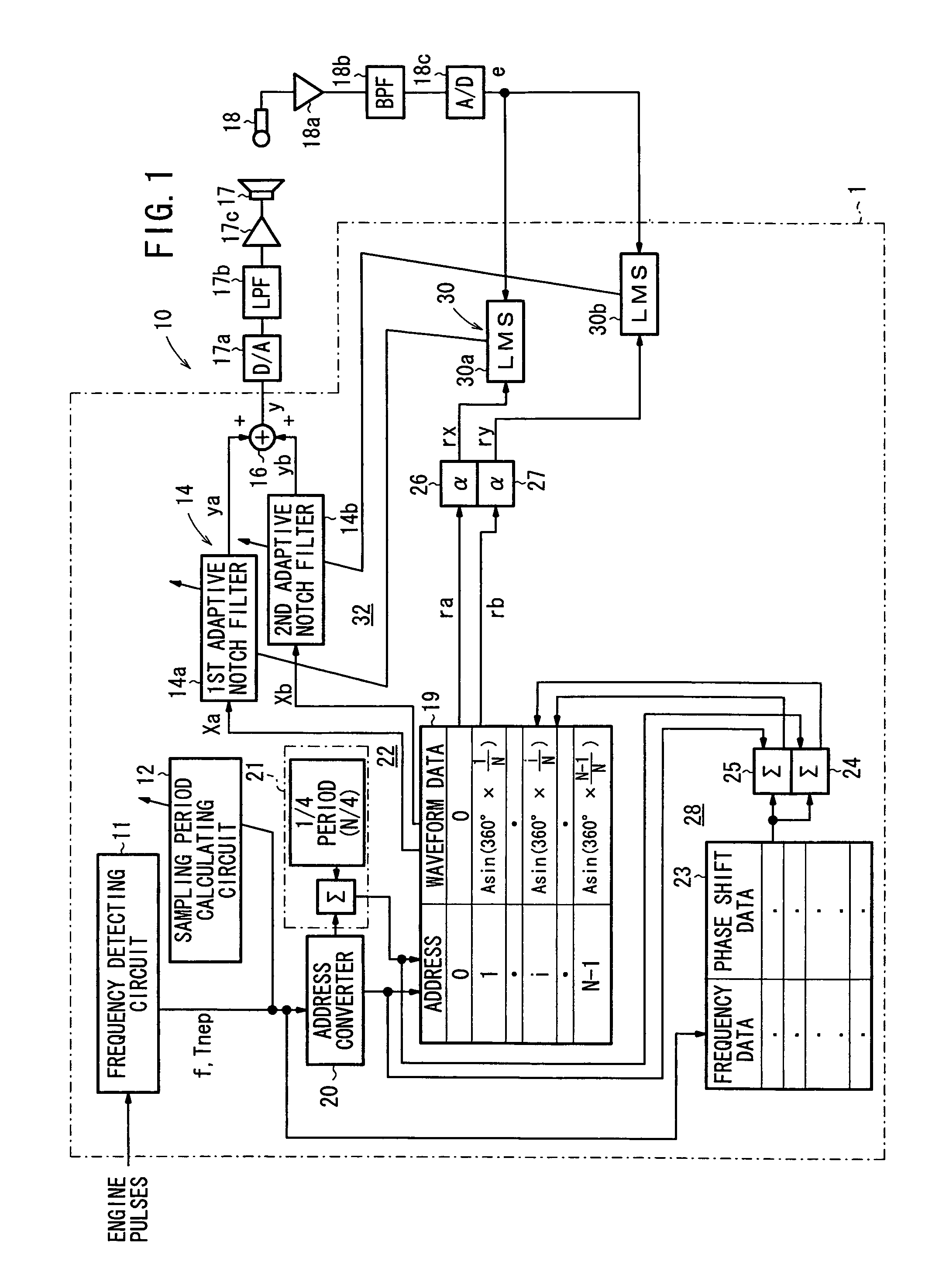

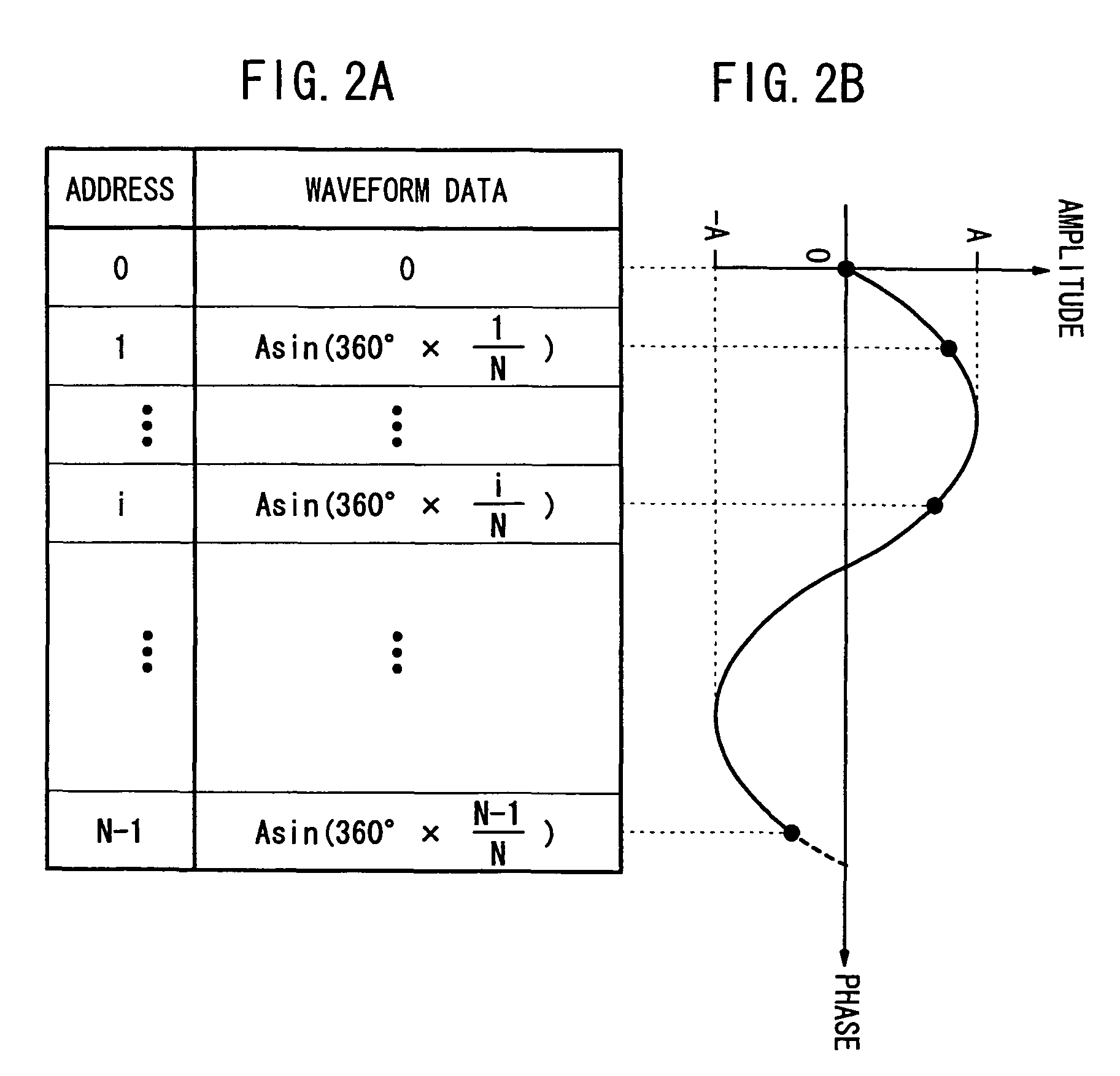

Active vibrational noise control apparatus

ActiveUS20070140503A1Increase freedomProcess controlEar treatmentNoise generationHysteresisNoise control

While a vehicle incorporating an active vibration noise control apparatus is decelerating, hysteresis is given if an operating point moves from an operating point on a sampling period characteristic curve to an operating point on another sampling period characteristic curve. Even if a base period detected depending on noise contains fluctuations, a smooth noise control process is performed. Since a division number produced when the base period is divided by a sampling period is a real number, the freedom of design is widened. Less strict limits are posed on the processing capability of a CPU of the active vibration noise control apparatus to provide a wider control range.

Owner:HONDA MOTOR CO LTD

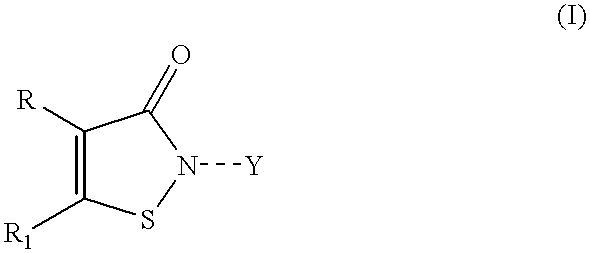

Controlled release compositions

InactiveUS6676954B2Low water solubilityControl releaseOrganic active ingredientsBiocideControlled releaseSolubility

Solid compositions containing low water solubility 3-isothiazolone compounds and carbon-based adsorbents that do not rapidly release the 3-isothiazolone when added to a locus to be protected are disclosed. In particular, methods of controlling or inhibiting the growth of marine organisms using the controlled release solid compositions in paints and coatings for marine structures is disclosed.

Owner:ROHM & HAAS CO

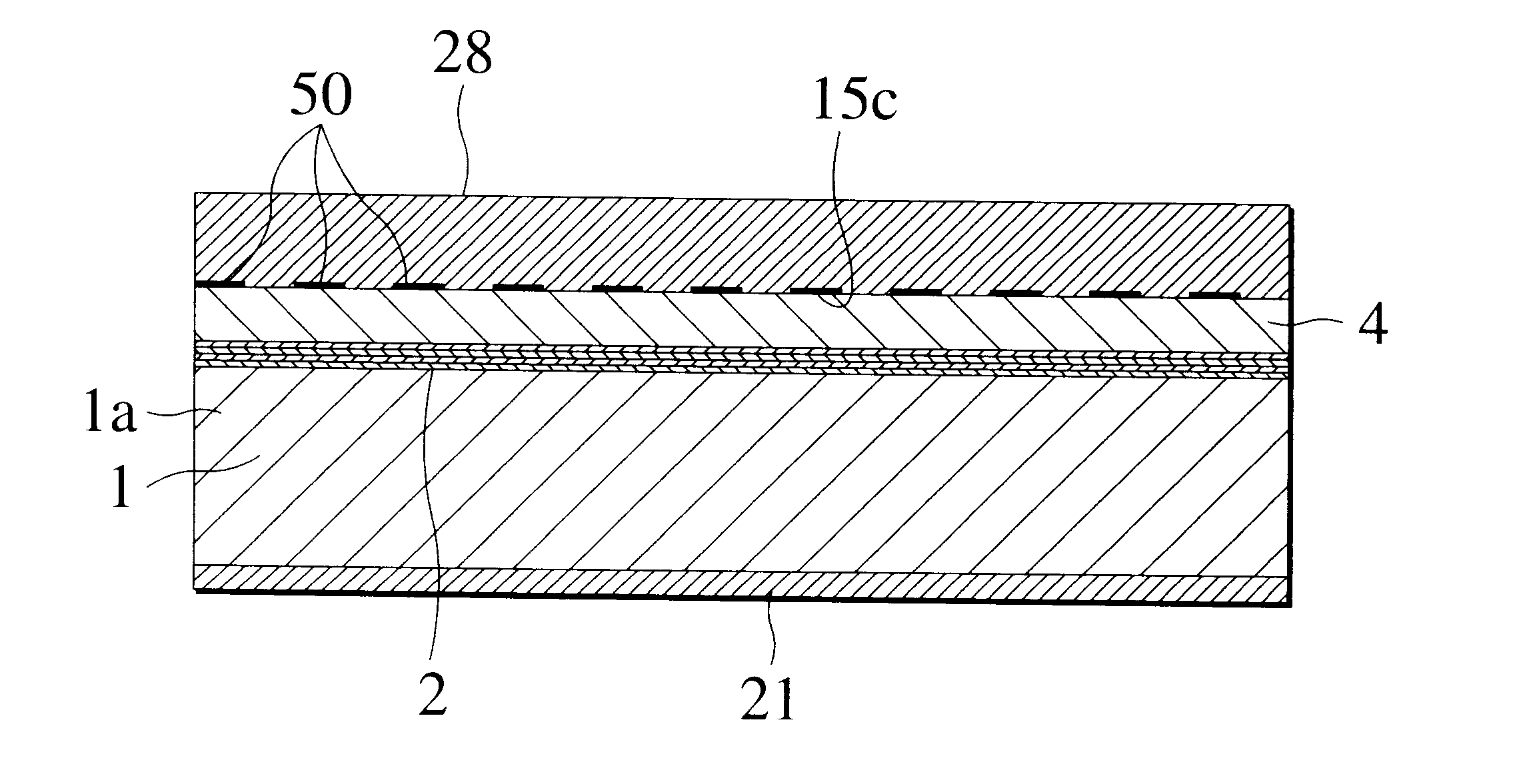

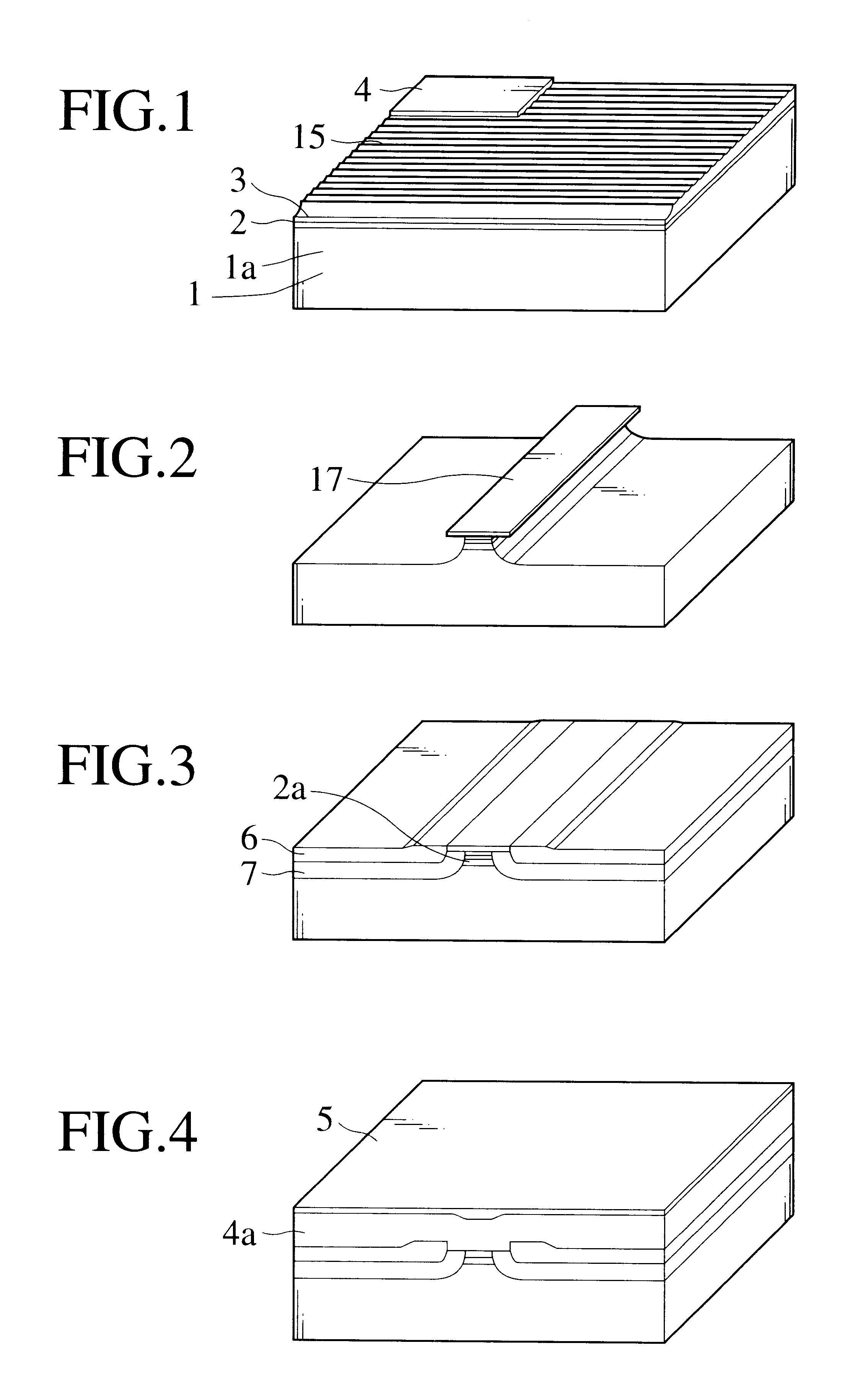

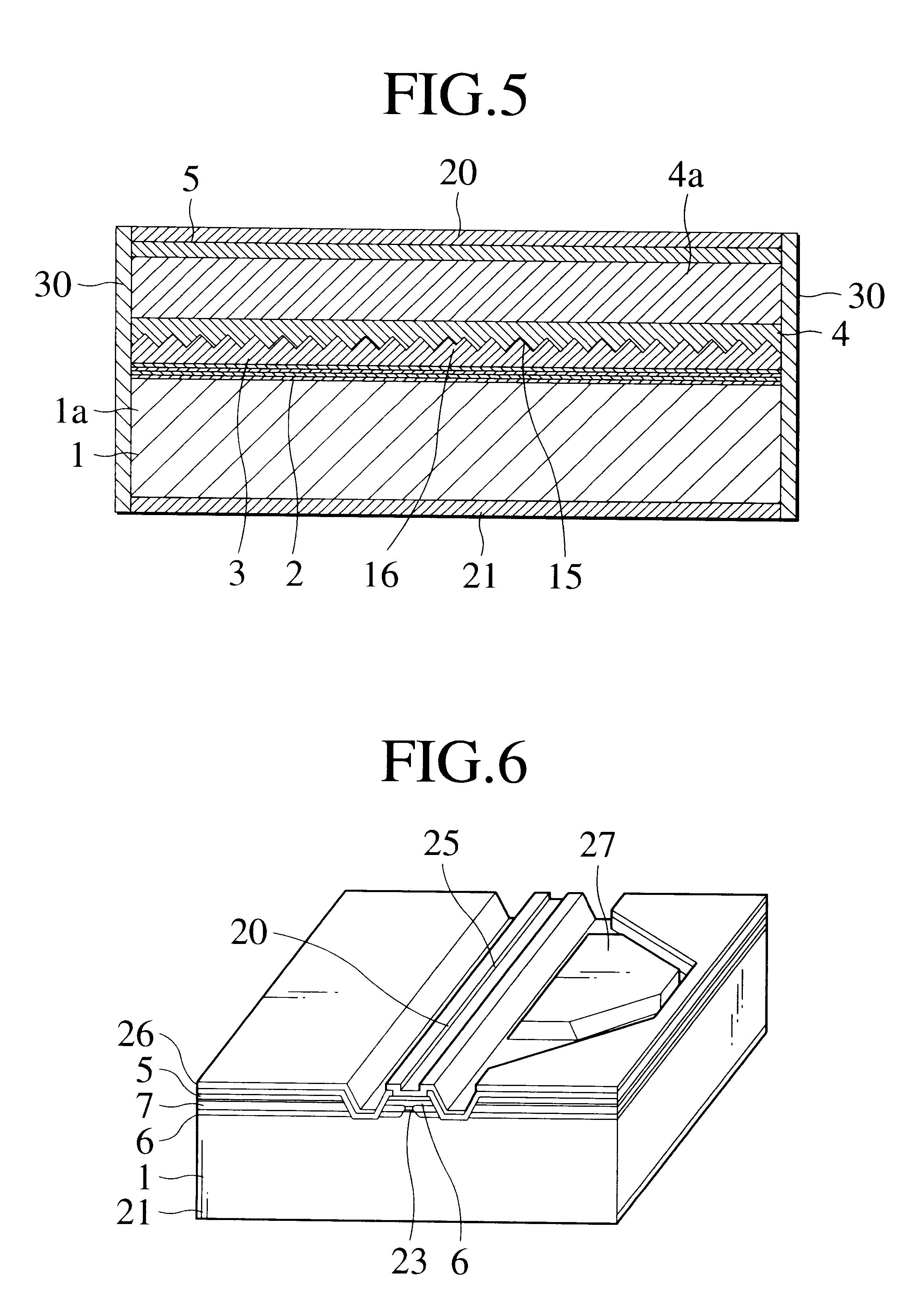

Optoelectronic device and laser diode

InactiveUS6327413B1Simple configurationReduce manufacturing stepsLaser detailsLaser optical resonator constructionWaveguideElectric field

Both an electric energy applying mechanism and an optical waveguide mechanism can be provided to an ITO layer (transparent electrode) by constituting an optical waveguide so as that the guided mode profile spread into the ITO layer. Also a bonding pad is provided to supply a power and apply an electric field onto the ITO layer. Accordingly, a device structure can be simplified and thus improvement in yield of the optoelectronic device having an optical waveguide and improvement in parameters of the optoelectronic device can be achieved.

Owner:KK TOSHIBA

Method for controlling size and distribution of metal surface micro-nanostructure

ActiveCN103433618AThe production process is simpleIncrease productivityLaser beam welding apparatusMicro nanoAngle of incidence

The invention discloses a method for controlling the size and distribution of a metal surface micro-nanostructure. In order to implement the invention, plasma filaments induced by ultrashort pulse laser with the pulse width of 15fs-5ps are utilized to directly irradiate a metal surface, by controlling the ultrashort pulse laser parameters and the scanning speed and scanning spacing to the metal surface of the filaments, control of the plasma filaments on the size and distribution of the metal surface induced micro-nanostructure is realized; by changing the incidence angle of the laser induced plasma filaments, the orientation of the micro-nanostructure is changed; the control on the shape of the micro-nanostructure is realized by changing the polarizing character of the laser. The invention provides a method used for designing parts such as a solar absorber in an optimized manner.

Owner:CHANGCHUN UNIV OF SCI & TECH

Apparatus and method for generating nitric oxide in controlled and accurate amounts

ActiveUS9573110B2Easy to controlLow impurity contentDispersed particle filtrationInorganic active ingredientsNitrogenEngineering

A nitric oxide generator generates nitric oxide from a mixture of nitrogen and oxygen such as air treated by a pulsating electrical discharge. The desired concentration of nitric oxide is obtained by controlling at least one of a frequency of the pulsating electrical discharge and duration of each electrical discharge pulse.

Owner:NITRICGEN

Active vibrational noise control apparatus

ActiveUS7773760B2Increase freedomProcess controlEar treatmentNoise generationHysteresisNoise control

Owner:HONDA MOTOR CO LTD

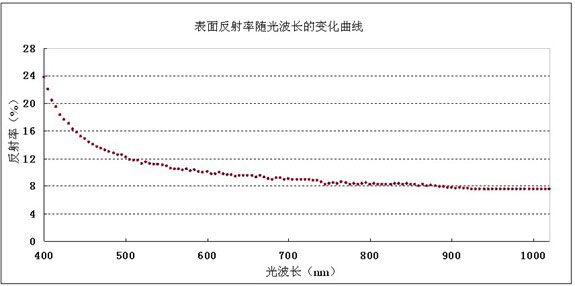

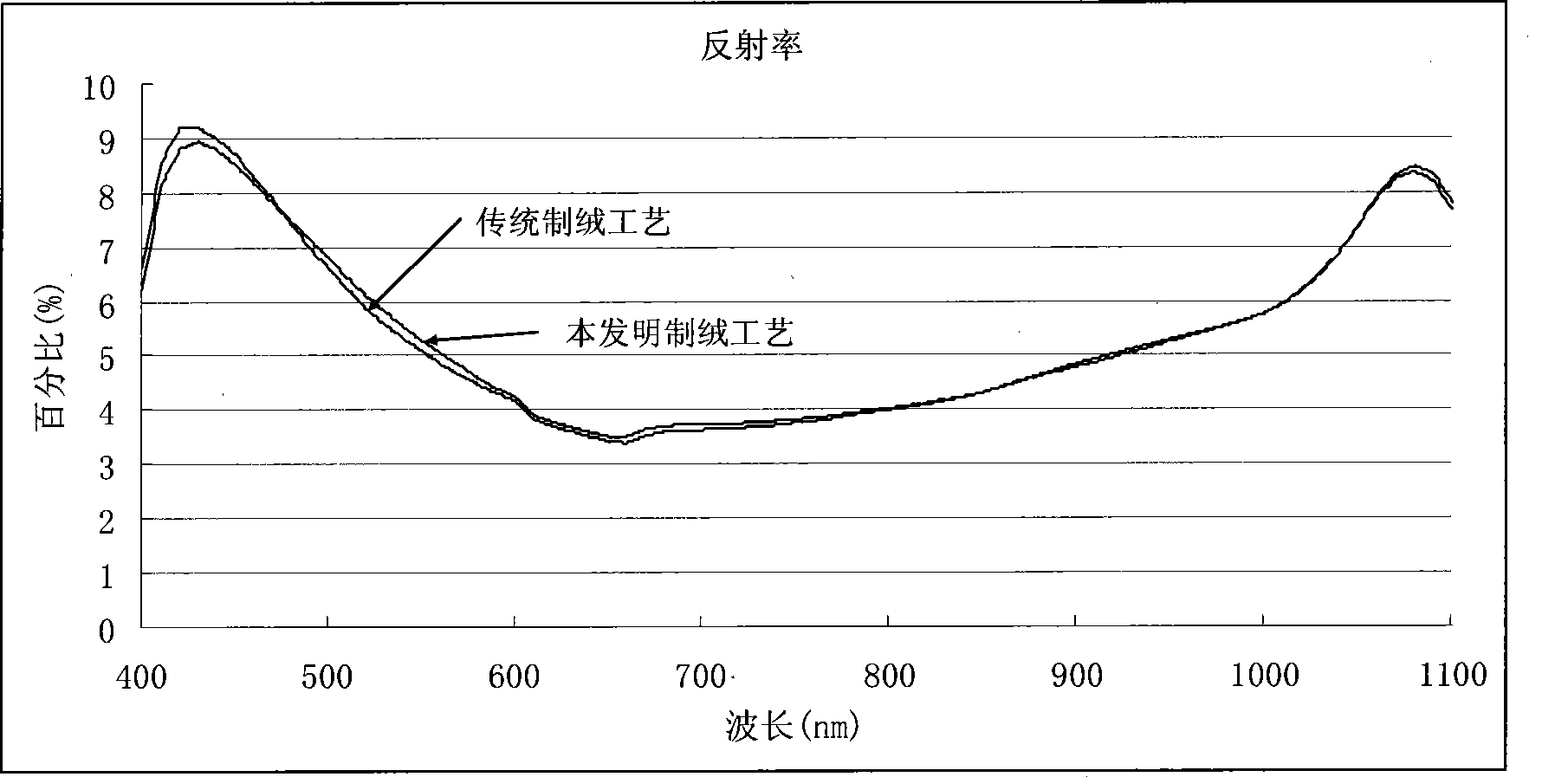

Alkali etch solution and method for preparing monocrystalline silicon pile fabrics

InactiveCN101423942AReduce dosageImprove conversion efficiencyFinal product manufacturePhotovoltaic energy generationCorrosion reactionSolar cell

The invention belongs to the field of monocrystalline silicon solar battery production and discloses an alkaline corrosion solution and a method for preparing monocrystalline silicon texture. The solution is a mixed liquor of an alkaline solution, isopropanol and Na2SiO3, and is structurally characterized in containing 0.002 to 0.01 weight percent of Pb(NO3)2 or Pb. The weigh percentage of the alkaline solution is 1 to 3.5 percent, the weight percentage of the isopropanol is 5 to 7 percent, and the weight percentage of Na2SiO3 is 0.2 to 2 percent. The method is to soak a monocrystalline silicon piece in the alkaline solution to perform a corrosion reaction for 20 to 30 minutes under a condition that the alkaline corrosion solution is at a temperature of between 75 and 80 DEG C. The alkaline corrosion solution and the method have the advantages of reducing surface reflectivity of the monocrystalline silicon piece, preparing a fine texturing 'pyramid', along with low cost, simple operation and stable and effective preparation of the monocrystalline silicon texture.

Owner:蒋冬 +1

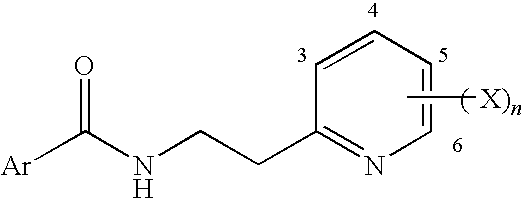

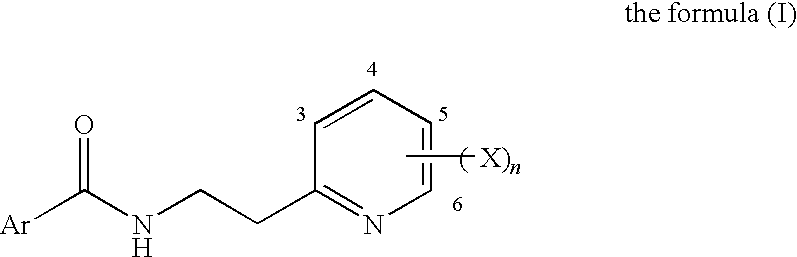

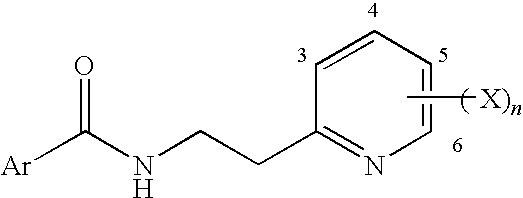

Nematicidal agent composition and method of using the same

ActiveUS20100048647A1Reduce the impactBroad nematode control spectrumBiocideOrganic chemistryPhenyl groupControl effect

The present invention provides a nematocide containing, as an active ingredient, an N-2-(pyridyl)ethylcarboxamide derivative represented by the formula (I):wherein Ar is a substituted phenyl group having one or more, the same or different substituents selected from a halogen atom, a (C1-C6)alkyl group, a halo(C1-C6)alkyl group, a (C1-C6)alkylthio group, a halo(C1-C6)alkylthio group, a (C1-C6)alkoxy group and a halo(C1-C6)alkoxy group, and the like, X may be the same or different, and is a hydrogen atom, a halogen atom, a (C1-C6)alkyl group, a halo(C1-C6)alkyl group, and the like, and n is the integer 0 to 4, or a salt thereof, and a method of controlling nematodes, including applying the above compound. The present invention can provide a nematocide or a method of controlling nematodes that exerts a reduced impact on the global environment, exhibits a broad nematode control spectrum at low application rates, and has an excellent nematode control effect.

Owner:NIHON NOHYAKU CO LTD

Variable configuration articulated tracked vehicle

InactiveUS7493976B2Wide range of controlEasy to assembleEndless track vehiclesEngineeringDrive motor

Owner:CHINA SUPERROBOTICS LTD

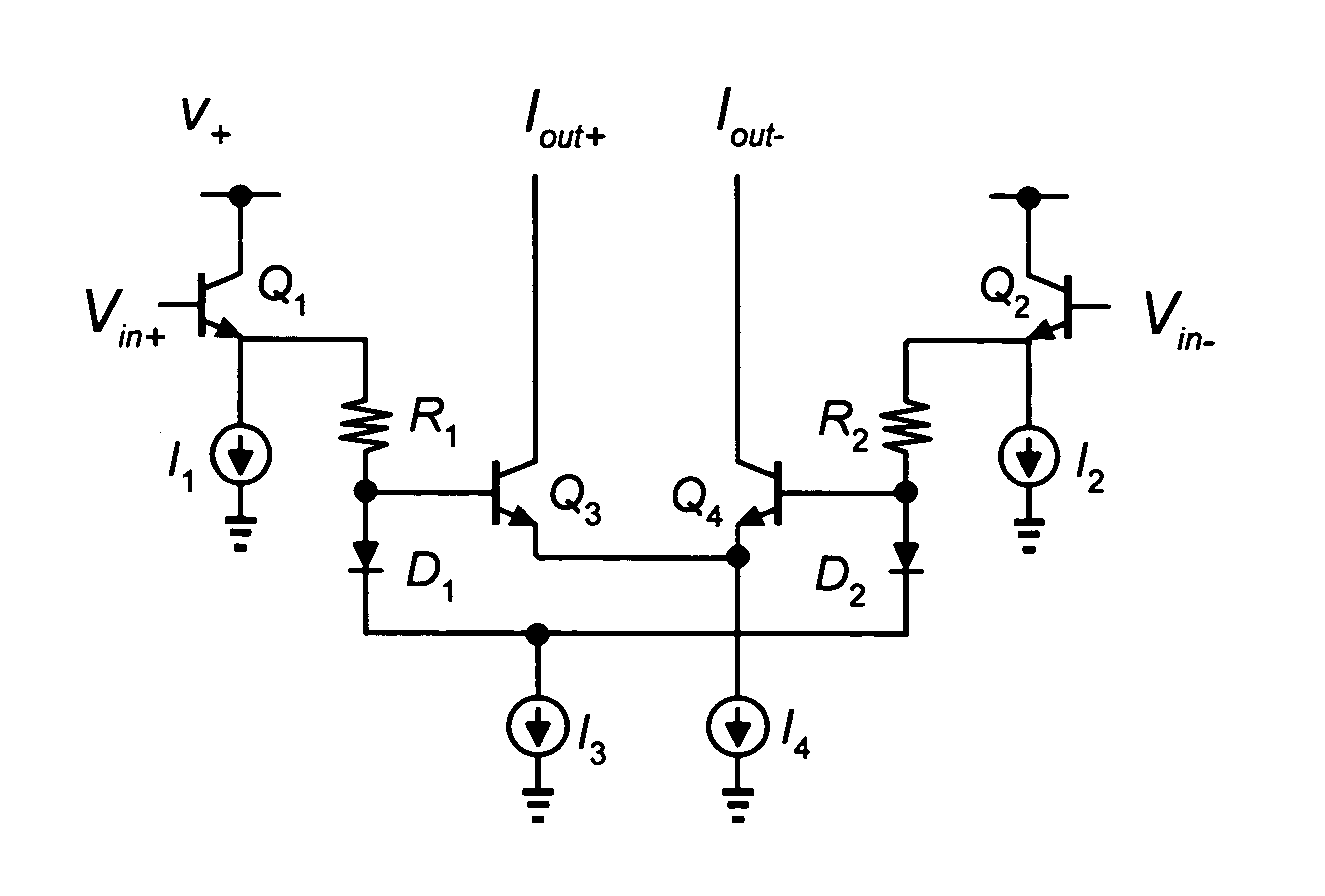

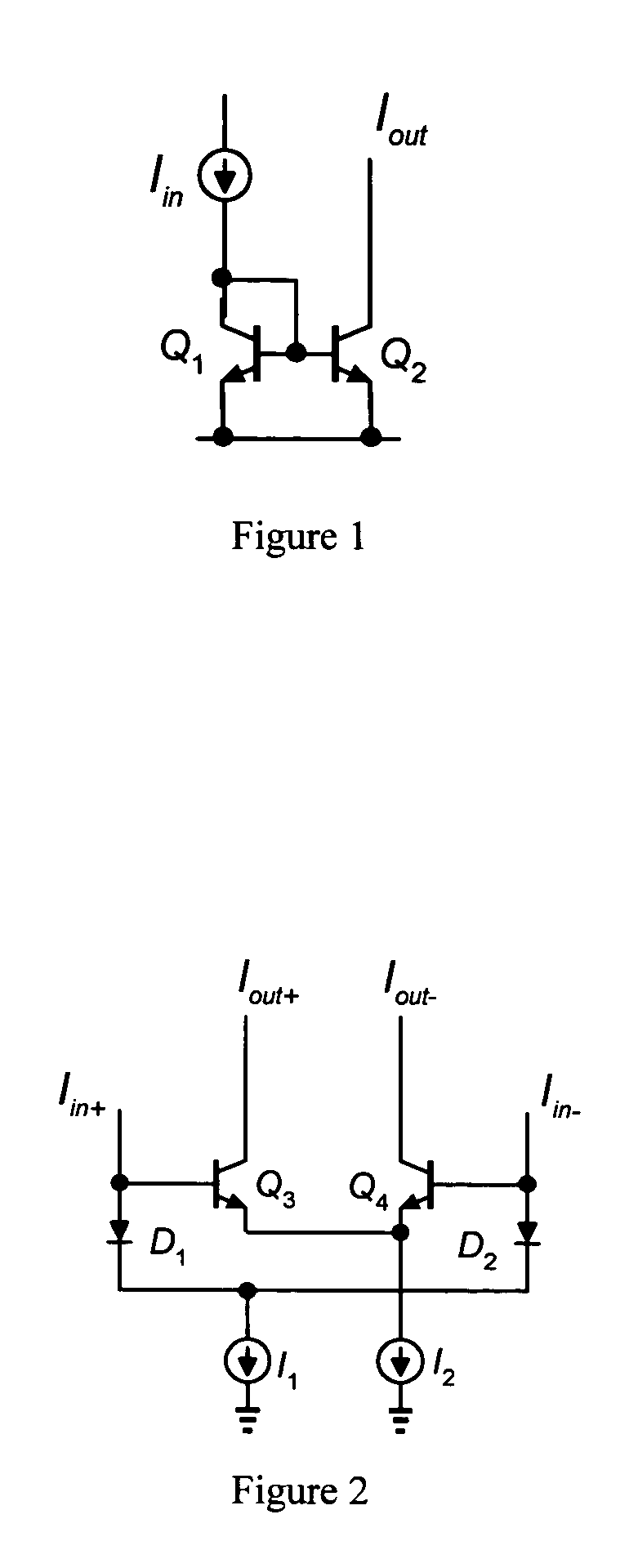

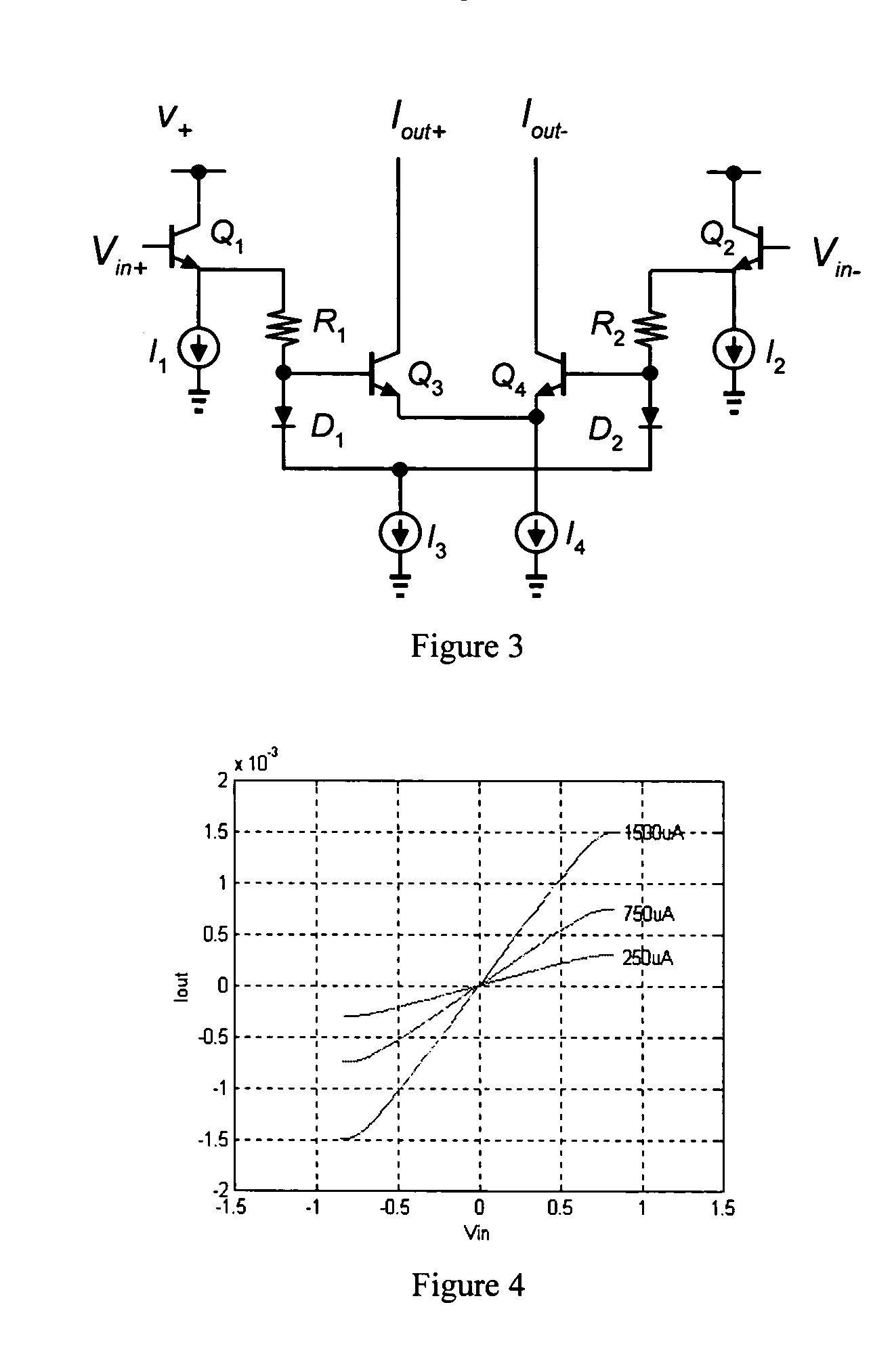

Translinear variable gain amplifier

InactiveUS20050099232A1Wide range of controlCascade easilyDifferential amplifiersPower conversion systemsAudio power amplifierVariable-gain amplifier

A translinear variable-gain amplifier. The translinear variable gain amplifier receives a differential input voltage and produces a differential output current having a selected gain. The amplifier comprises a buffer amplifier that receives the differential input voltage and produces a differential input current. The amplifier further comprises a translinear gain cell coupled to receive the differential input current and produce the differential output current. The gain cell includes a first adjustable bias source that operates to set a linear input range of the gain cell, and a second adjustable bias source that operates to set a gain value of the gain cell.

Owner:III HLDG 6

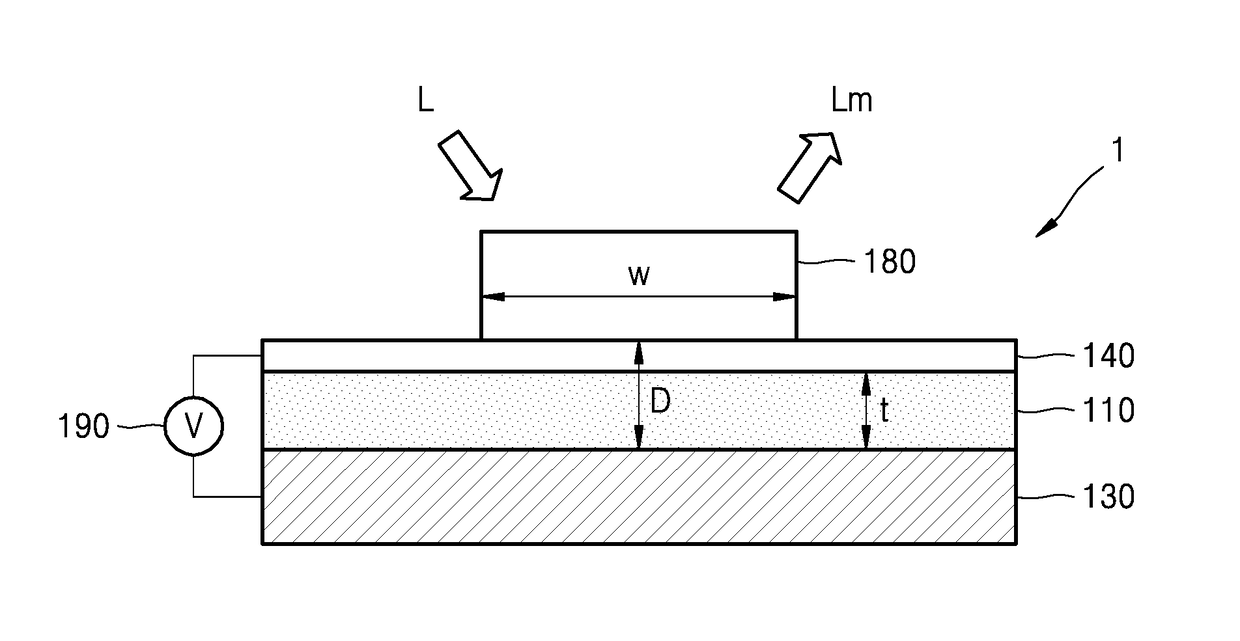

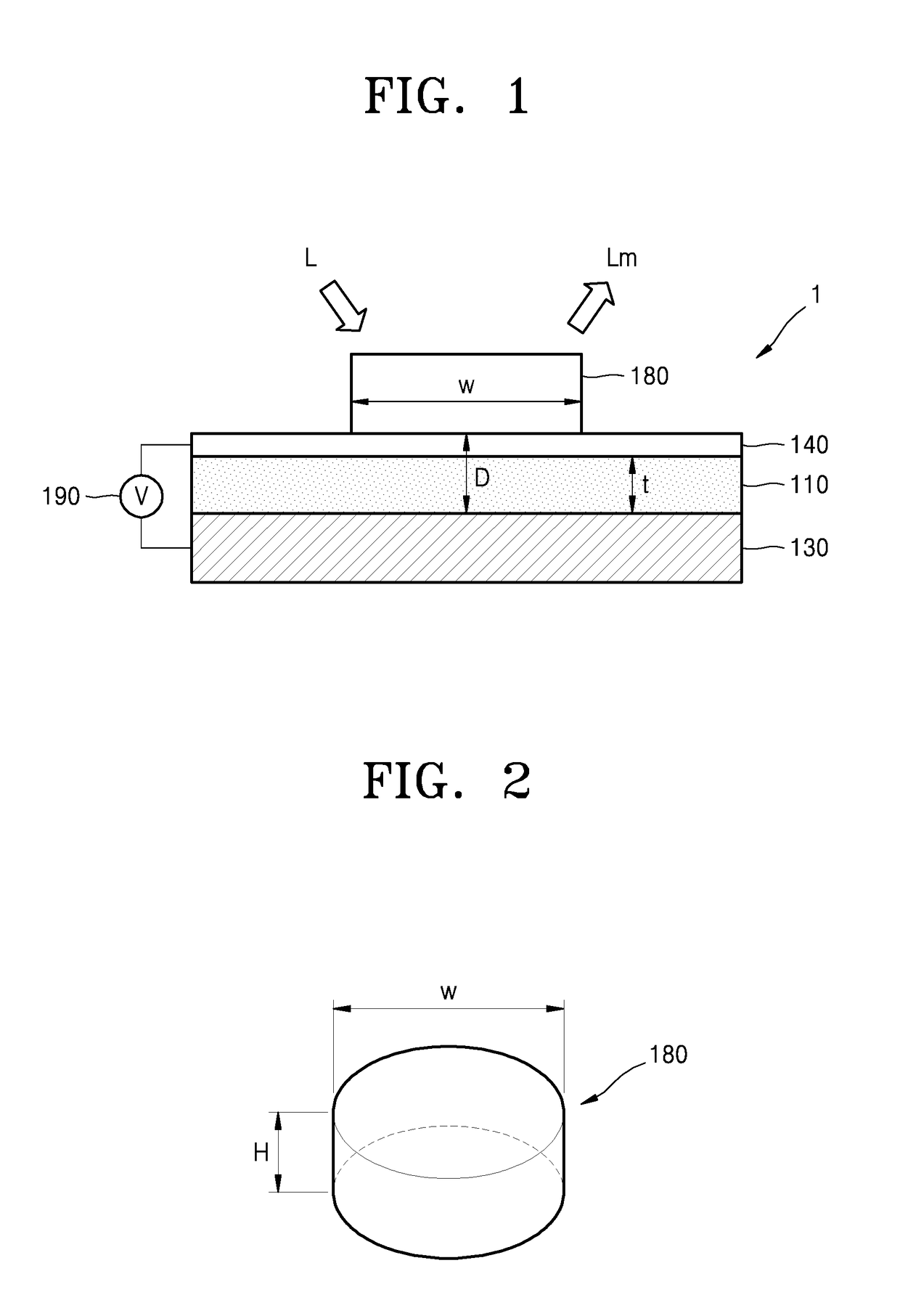

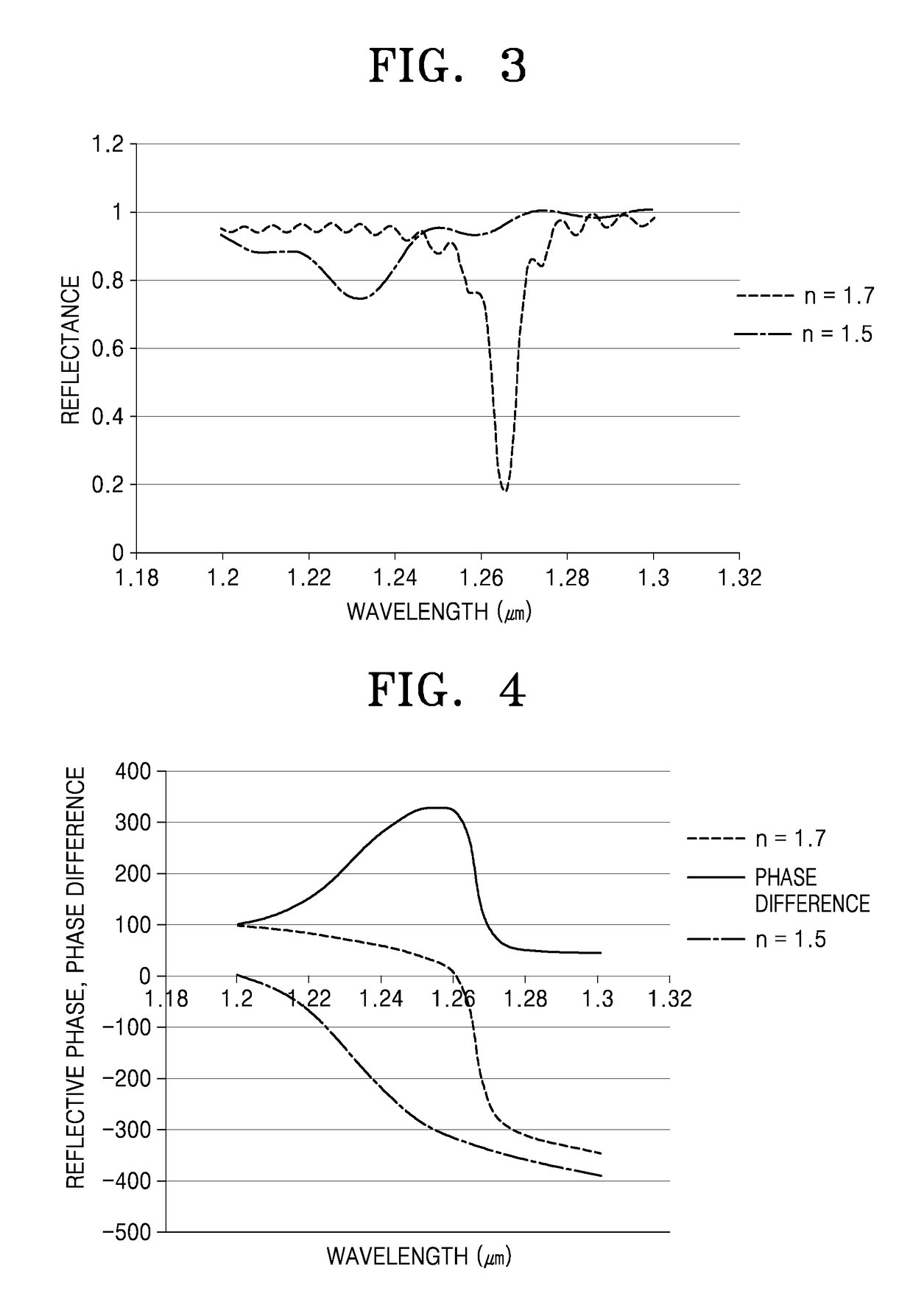

Light modulation device including dielectric antenna

ActiveUS20170176651A1Light loss is smallWide range of controlNon-linear opticsOptical elementsDielectricElectricity

A light modulation device includes a dielectric antenna and a refractive-index-variable layer which faces the dielectric antenna and comprises a material having a refractive index that changes according to a signal. A light may be modulated, since resonance characteristics of the dielectric antenna are controlled according to a refractive-index change of the refractive-index-variable layer.

Owner:SAMSUNG ELECTRONICS CO LTD

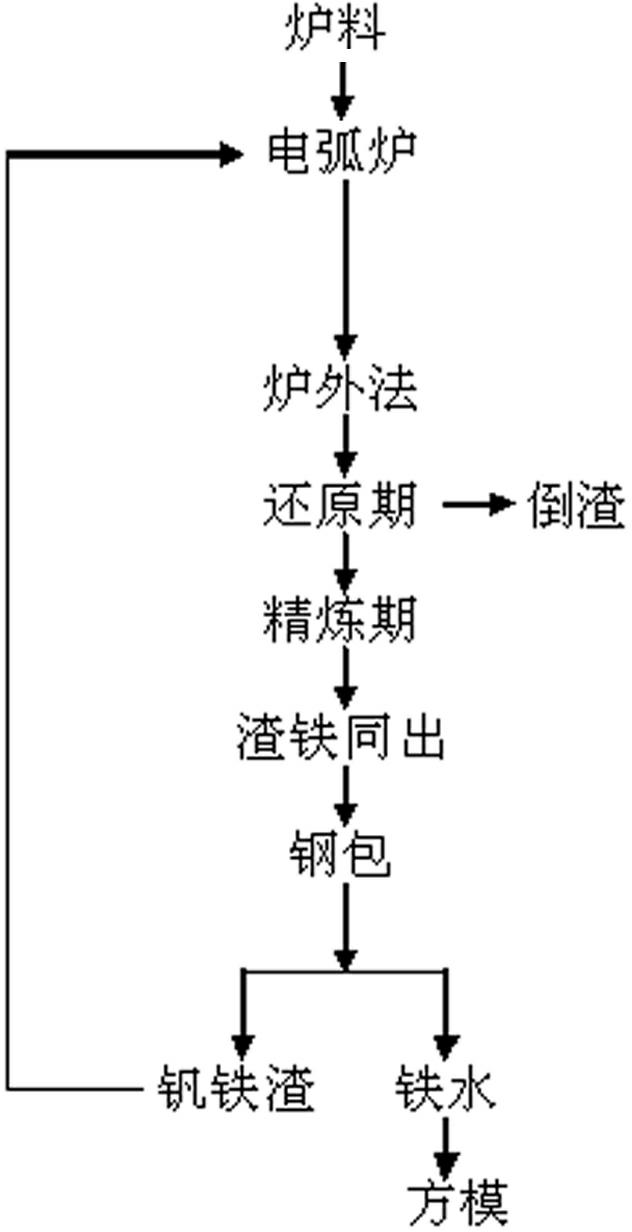

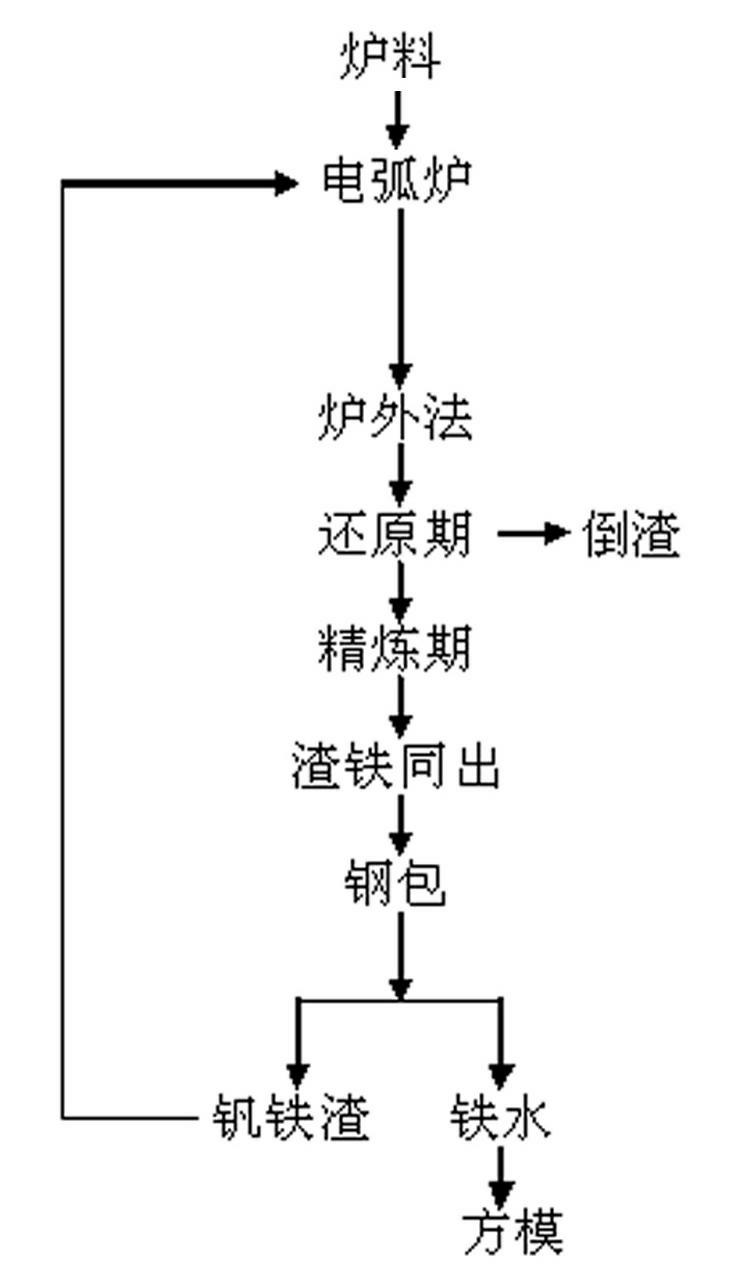

Method for smelting low-aluminum high-vanadium iron

ActiveCN102146527AReaction is easy to controlWide range of controlProcess efficiency improvementMolten stateElectric arc furnace

The invention discloses a method for smelting low-aluminum high-vanadium iron. The method comprises the following steps of: 1, smelting by adopting an outside furnace process, mixing vanadium pentoxide, aluminum powder, scrap steel, vanadium iron slag or lime, igniting and reacting to generate high-vanadium iron and furnace slag; and 2, uniformly mixing vanadium pentoxide and lime at a reducing stage by adopting an electric furnace process, putting the mixture into an electric arc furnace, adding scrap steel, adding industrial silicon and ferro-silico aluminum depleted furnace slag after the material is in a molten state, deslagging when the vanadium content of the furnace slag is below 0.5 percent, extracting an alloy sample and analyzing vanadium and silicon for monitoring before deslagging, putting vanadium pentoxide and lime into the furnace at a refining stage, electrifying to refine and pouring with a ladle after qualification is determined. The method has the advantages that aluminothermic process smelting is integrated with electro-silicothermic process smelting, chemical reaction heat of vanadium pentoxide and aluminum is fully utilized, furnace slag with high vanadium content is depleted, reduced and refined in a three-phase electric arc furnace to obtain high-vanadium low-aluminum qualified high-vanadium iron, the vanadium content of discharged furnace slag is lower than 0.5 percent, and the smelting yield is over 95 percent.

Owner:锦州钒业有限责任公司

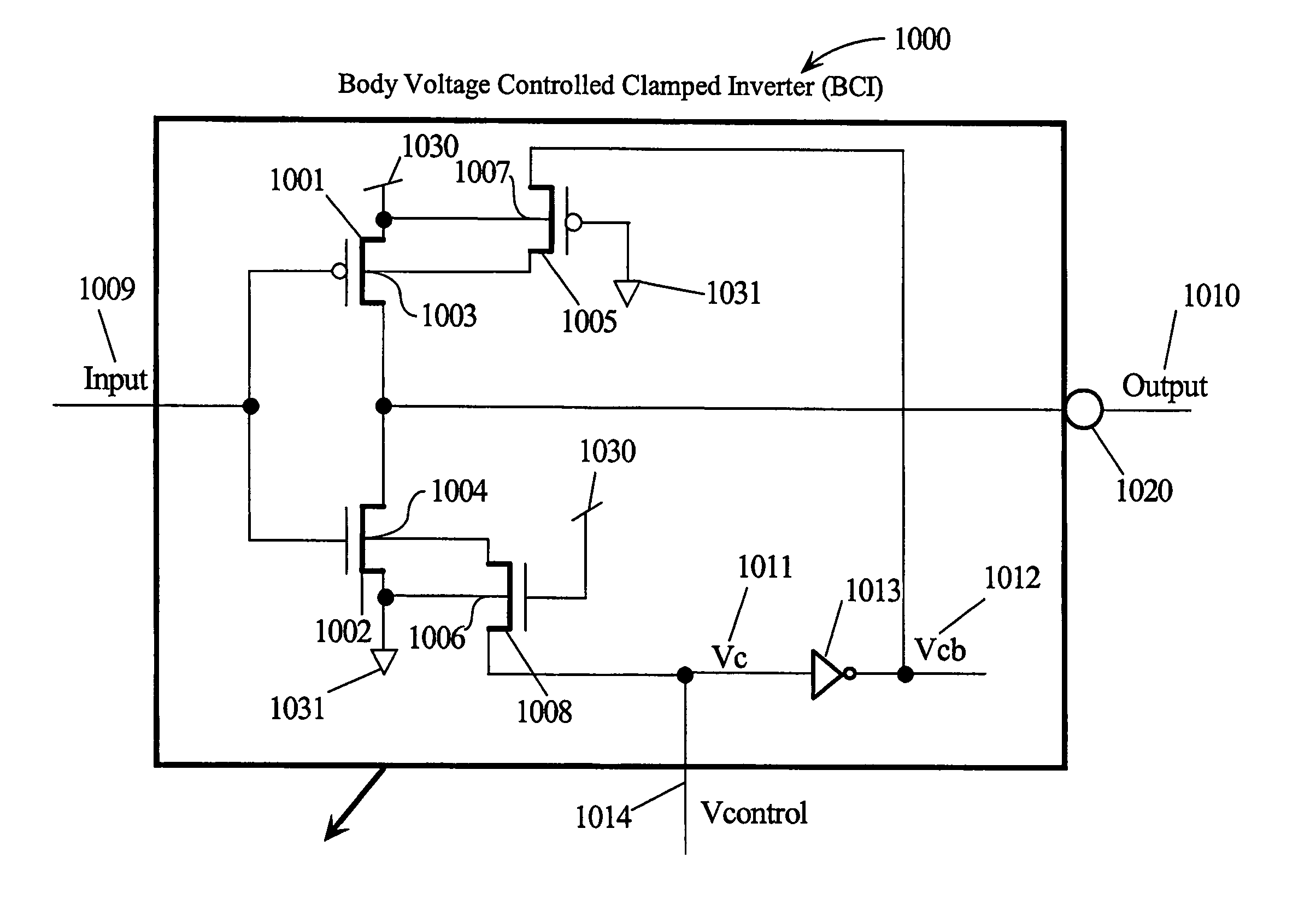

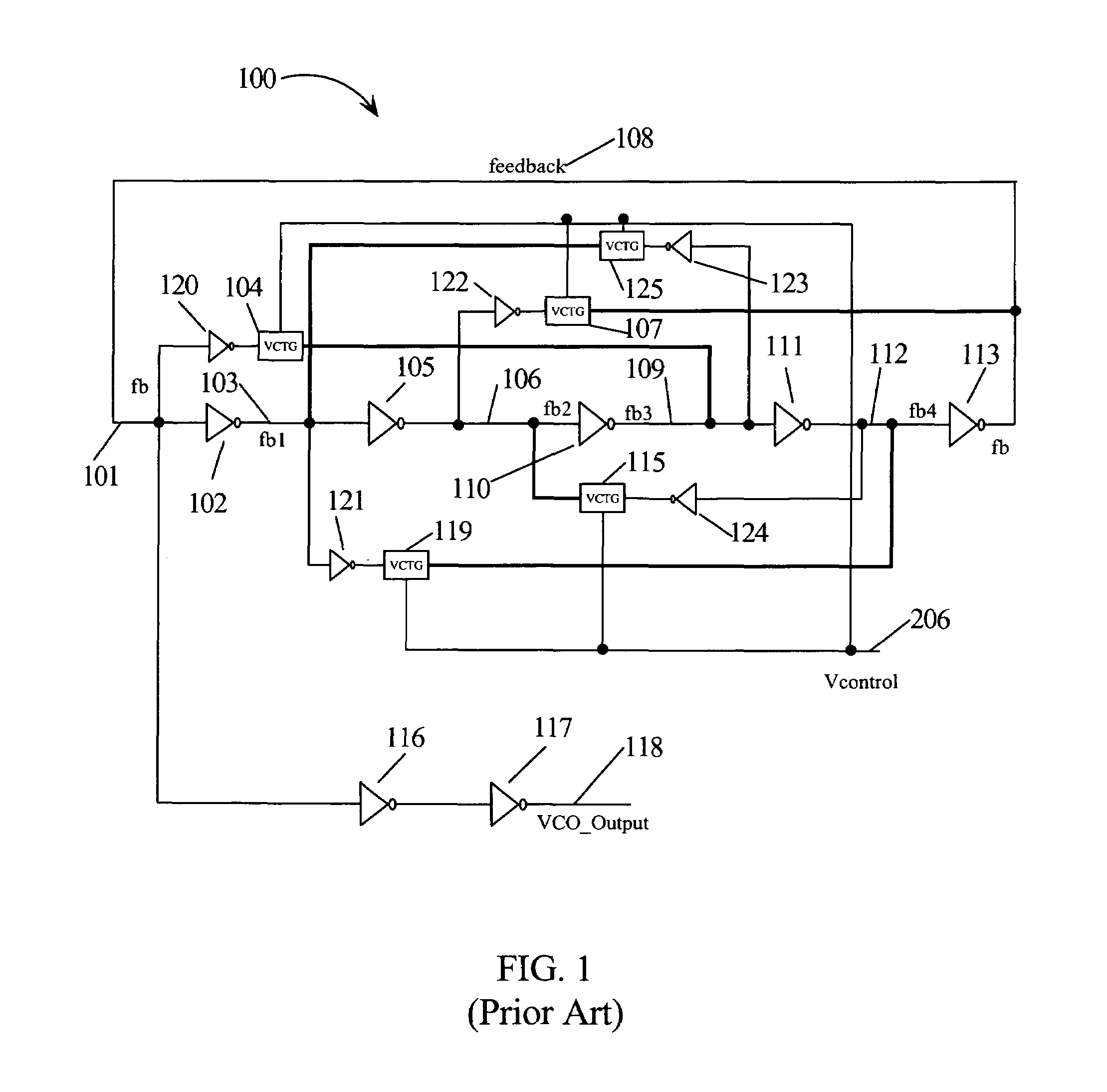

Interleaved VCO with body voltage frequency range control

InactiveUS7002420B2Wide range of controlPulse generation by logic circuitsPath switchingVoltage control

Owner:INT BUSINESS MASCH CORP

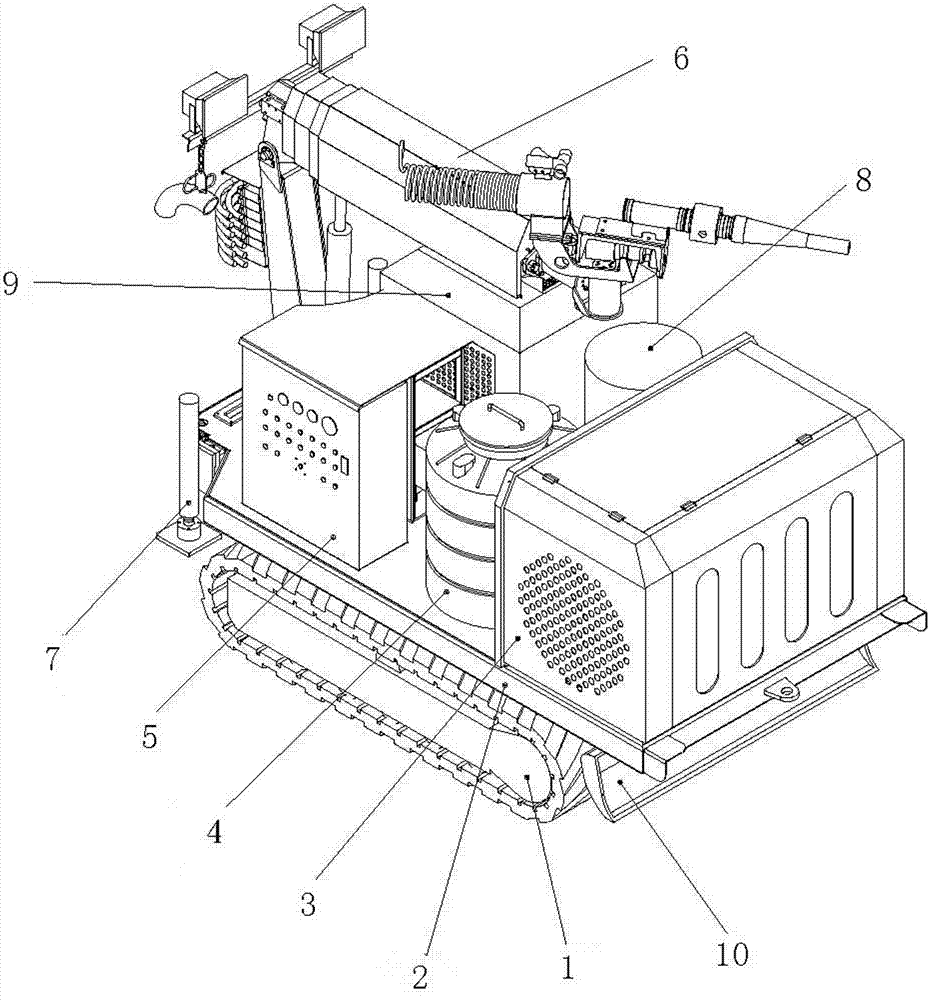

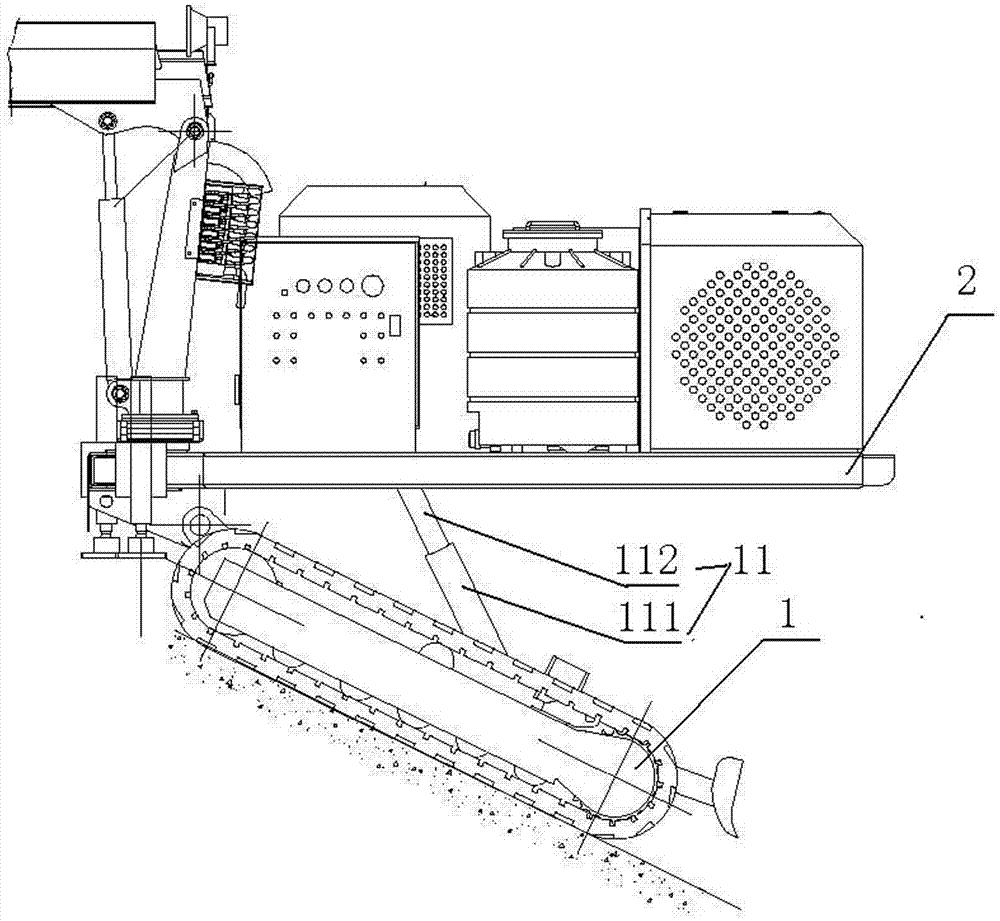

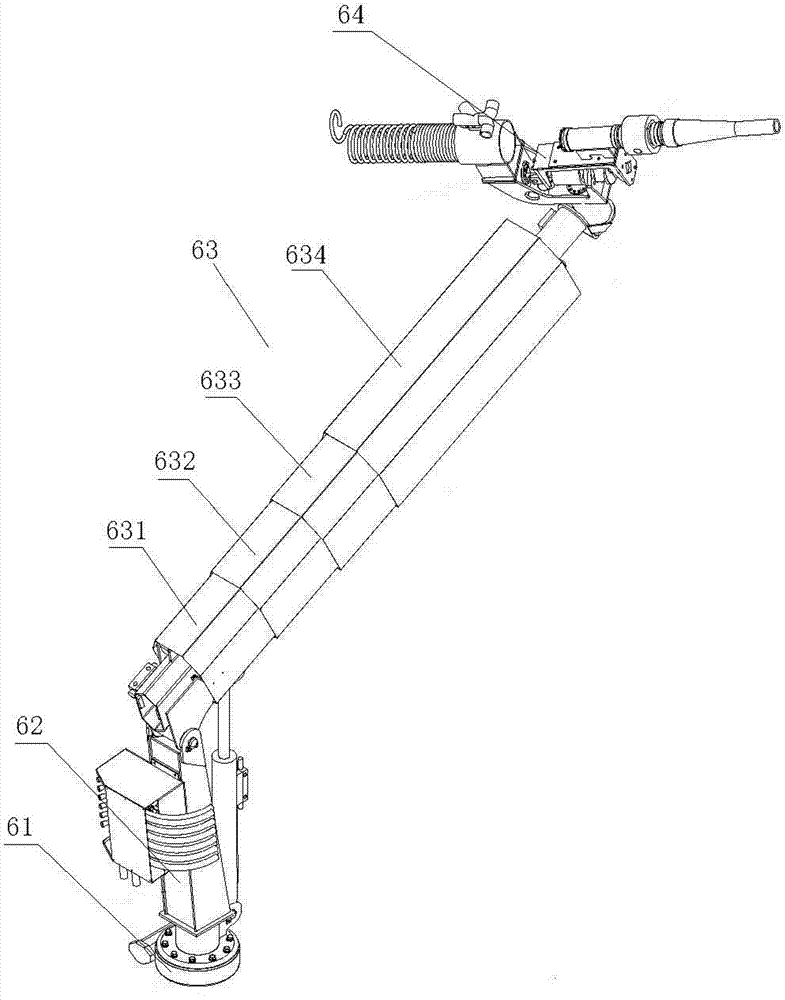

Concrete spraying mechanical arm

ActiveCN103498686ANo wet spray performance impactWith leveling functionProgramme-controlled manipulatorUnderground chambersRobotic armFrequency conversion

A concrete spraying mechanical arm only has the function of spraying concrete and does not have the function of concrete pumping. Crawler belt chassis are adopted for the mechanical arm and used for crawling. Leveling hydraulic air cylinders are arranged between a frame and the chassis, so that the mechanism arm performs construction on a ramp, wherein the gradient of the ramp is smaller than 30 degrees, and wet spraying performance is not affected. Hydraulic control is adopted for a multi-stage telescopic arm of a mechanical arm frame and can be freely operated in a narrow and long tunnel, a combination of manual speed adjustment and frequency conversion speed adjustment is adopted for the quantity of flows of additives, so that the control range of the quantity of flows of the additives is larger, and stepless adjustment is achieved. The mechanical arm can smoothly finish the concrete wet spraying operation in a narrow and small construction site and has the advantages of being small in size, light in weight, low in energy consumption and low in cost.

Owner:CHANGSHA KEDA INTELLIGENT EQUIP INC CO

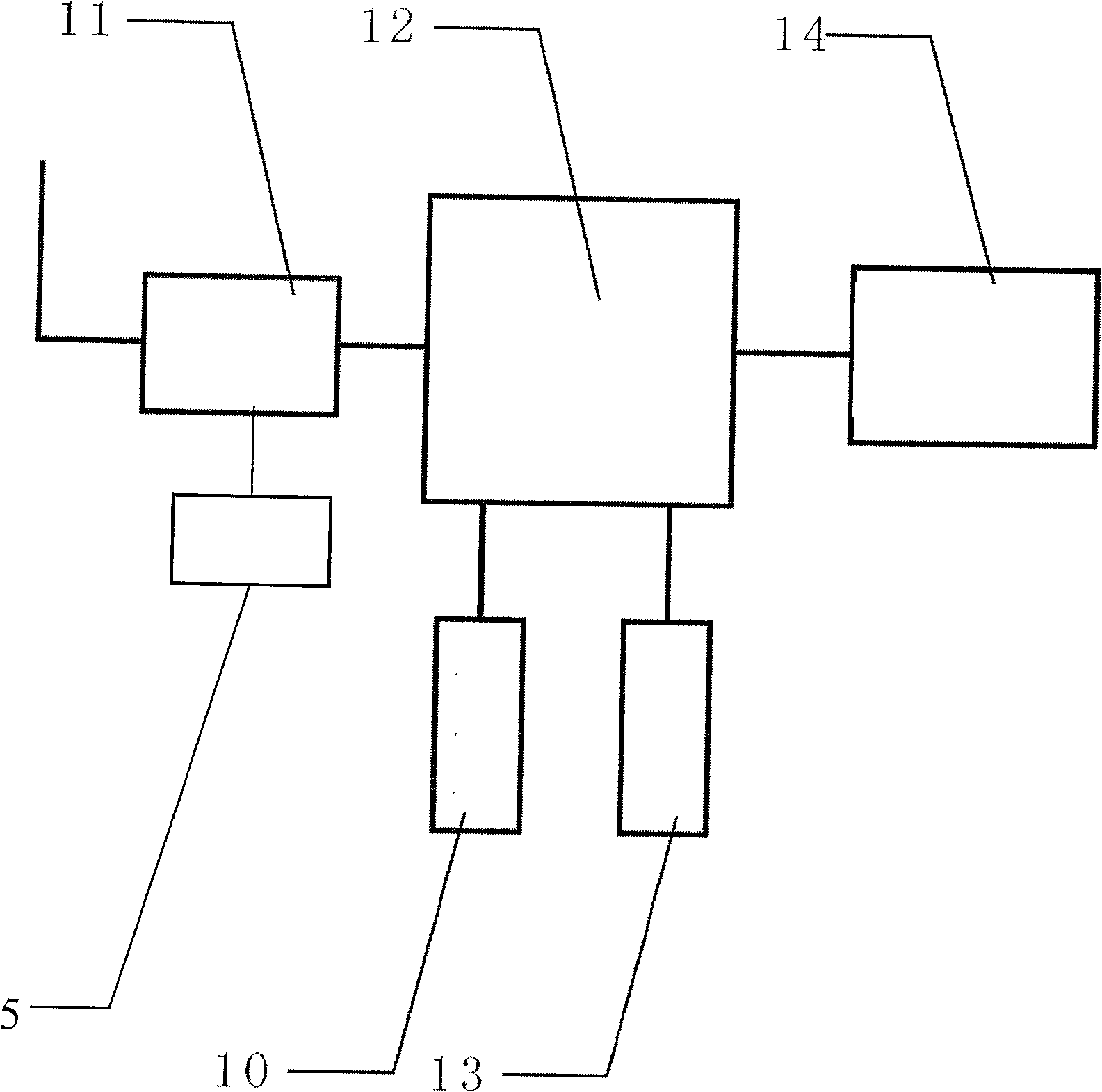

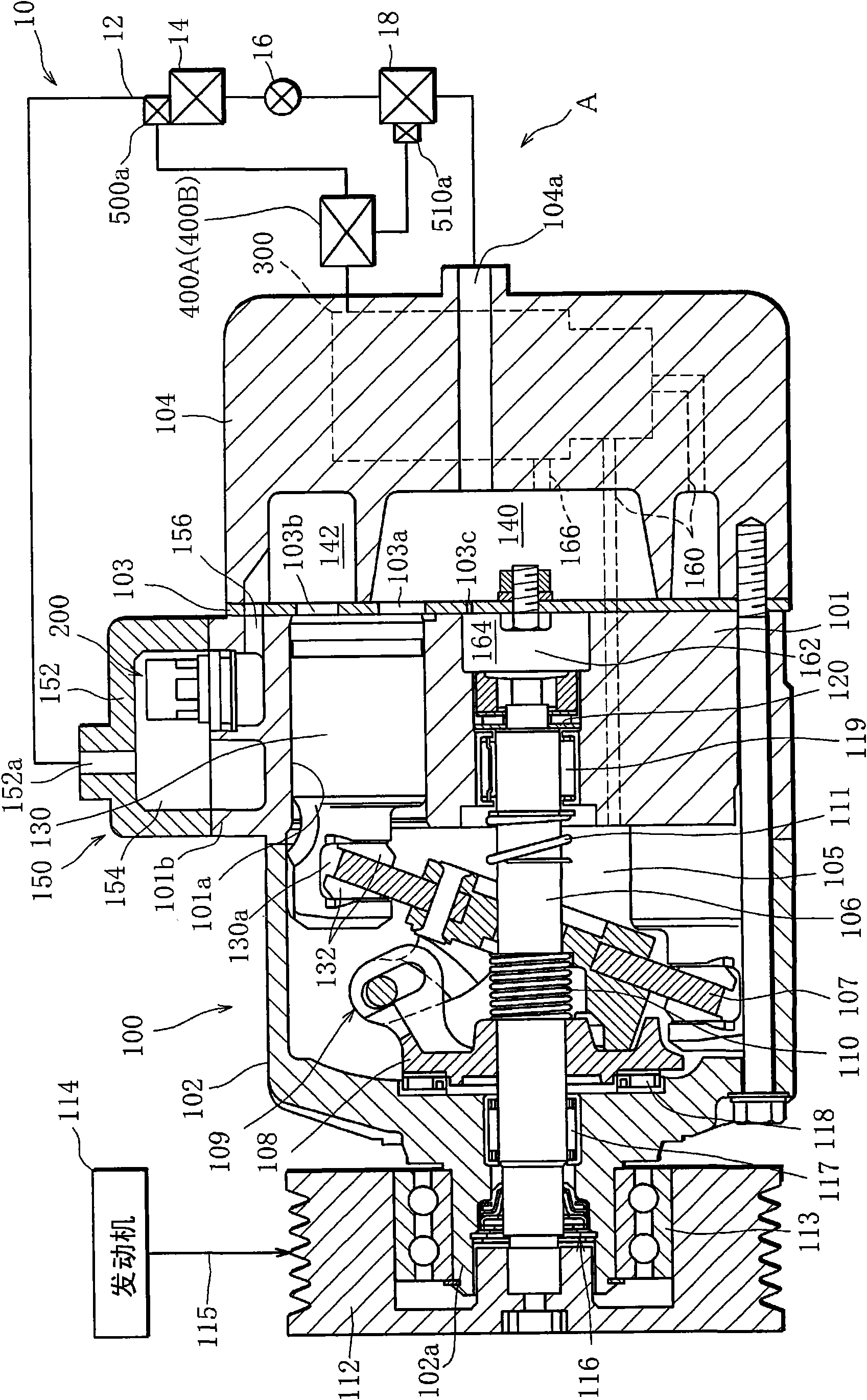

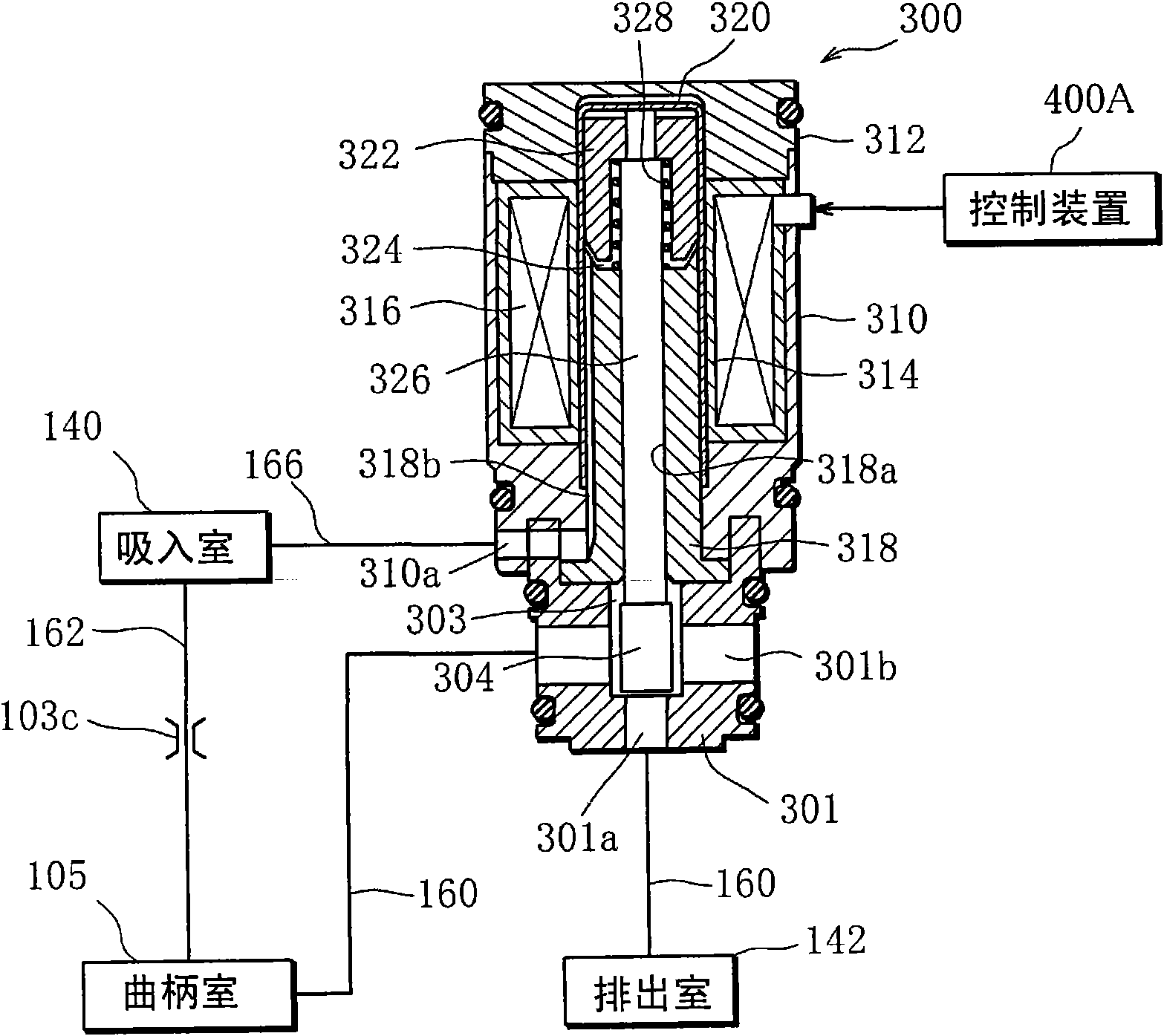

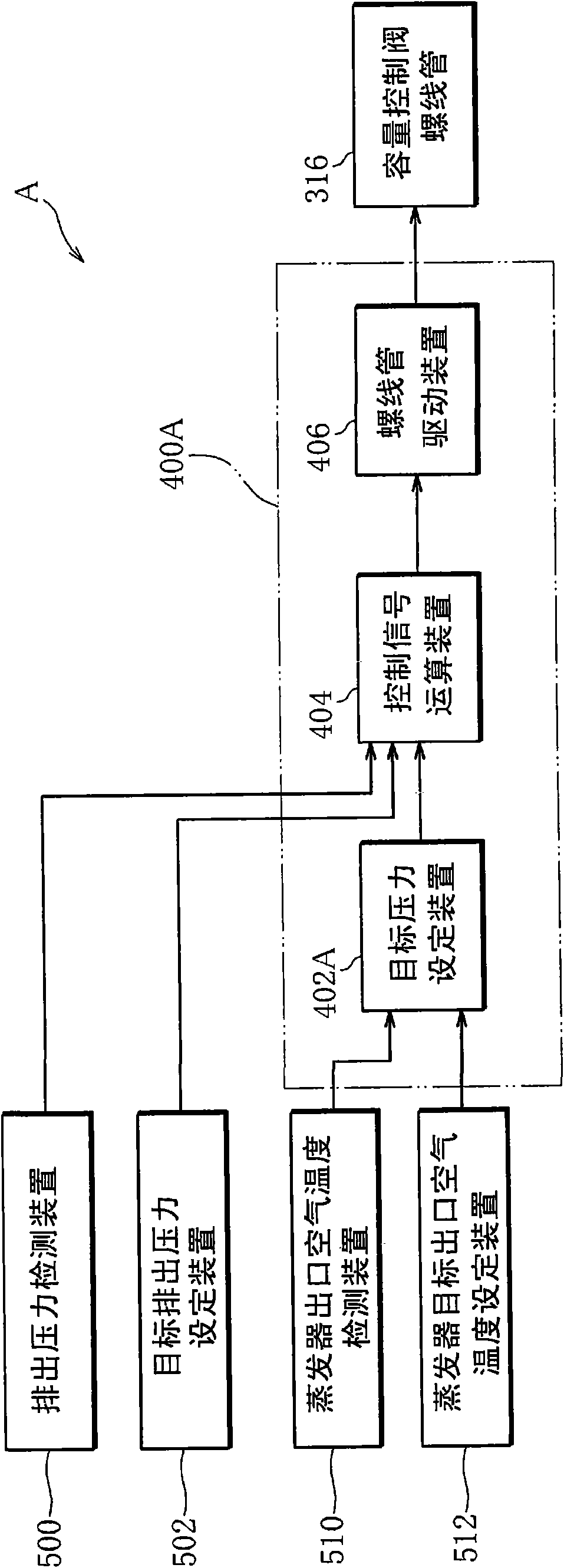

Displacement control system for variable displacement compressor

ActiveCN101605990AComfort adjustment stateOptimum Discharge Capacity ControlAir-treating devicesCompression machines with non-reversible cycleControl systemEngineering

A discharge displacement control system (A) of a variable displacement compressor has target pressure setting means (402A), discharge pressure detection means (500), and electric current regulation means (404, 406). The target pressure setting means (402A) sets a target of either the pressure in a suction chamber or the pressure in a crank chamber based on a target air temperature at the evaporator exit detected by means (510) for detecting the air temperature at the evaporator exit and on a target air temperature at the evaporator exit set by means (512) for setting a target air temperature at the evaporator exit. The discharge pressure detection means (500) detects the pressure of refrigerant in a high-pressure region. The electric current regulation means (404, 406) regulate, based on both the pressure of the refrigerant in the high-pressure region detected by the discharge pressure detection means (500) and the target pressure set by the target pressure setting means (402A), electric current supplied to a solenoid (316) of a displacement control valve.

Owner:SANDEN CO LTD

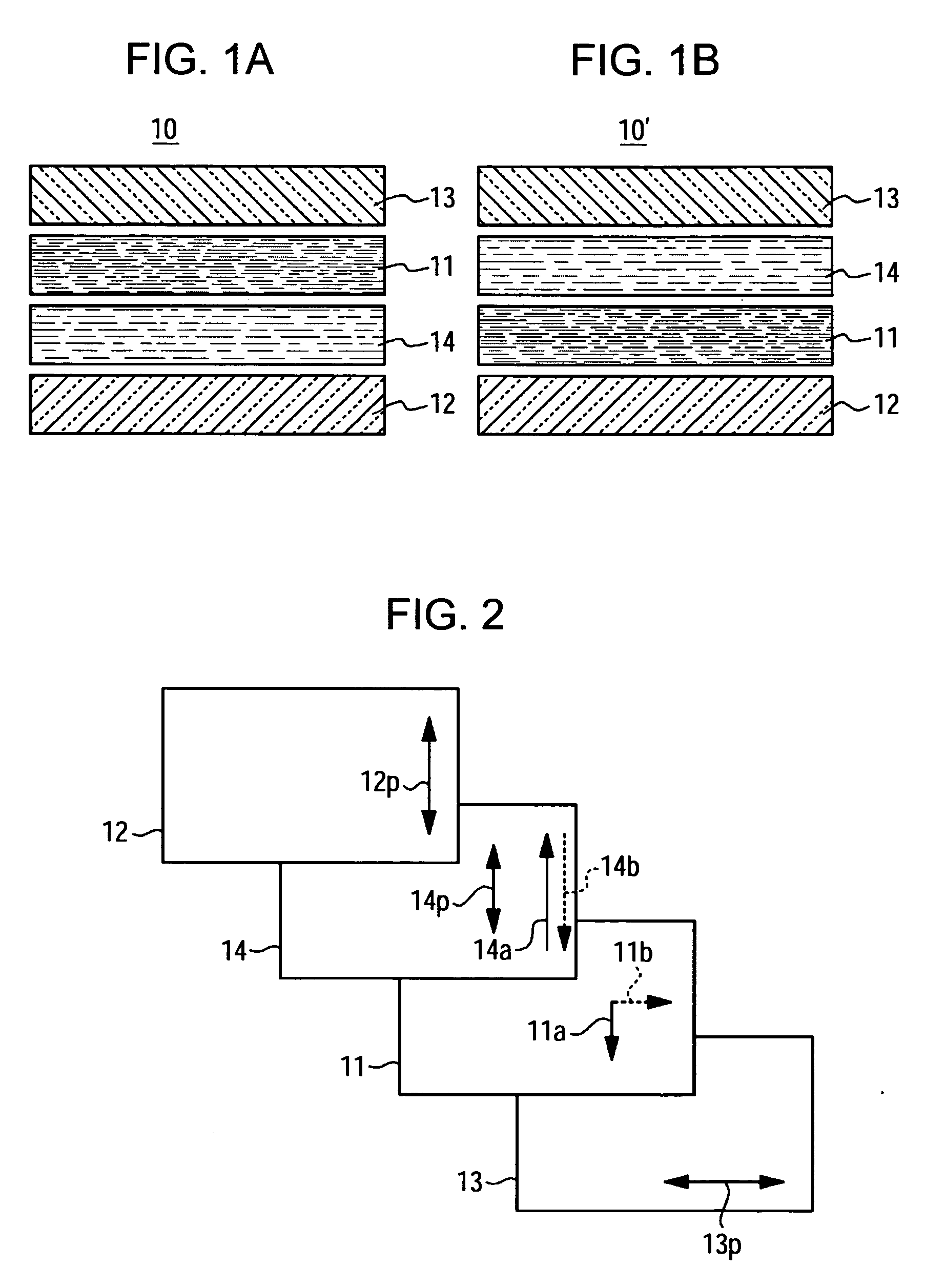

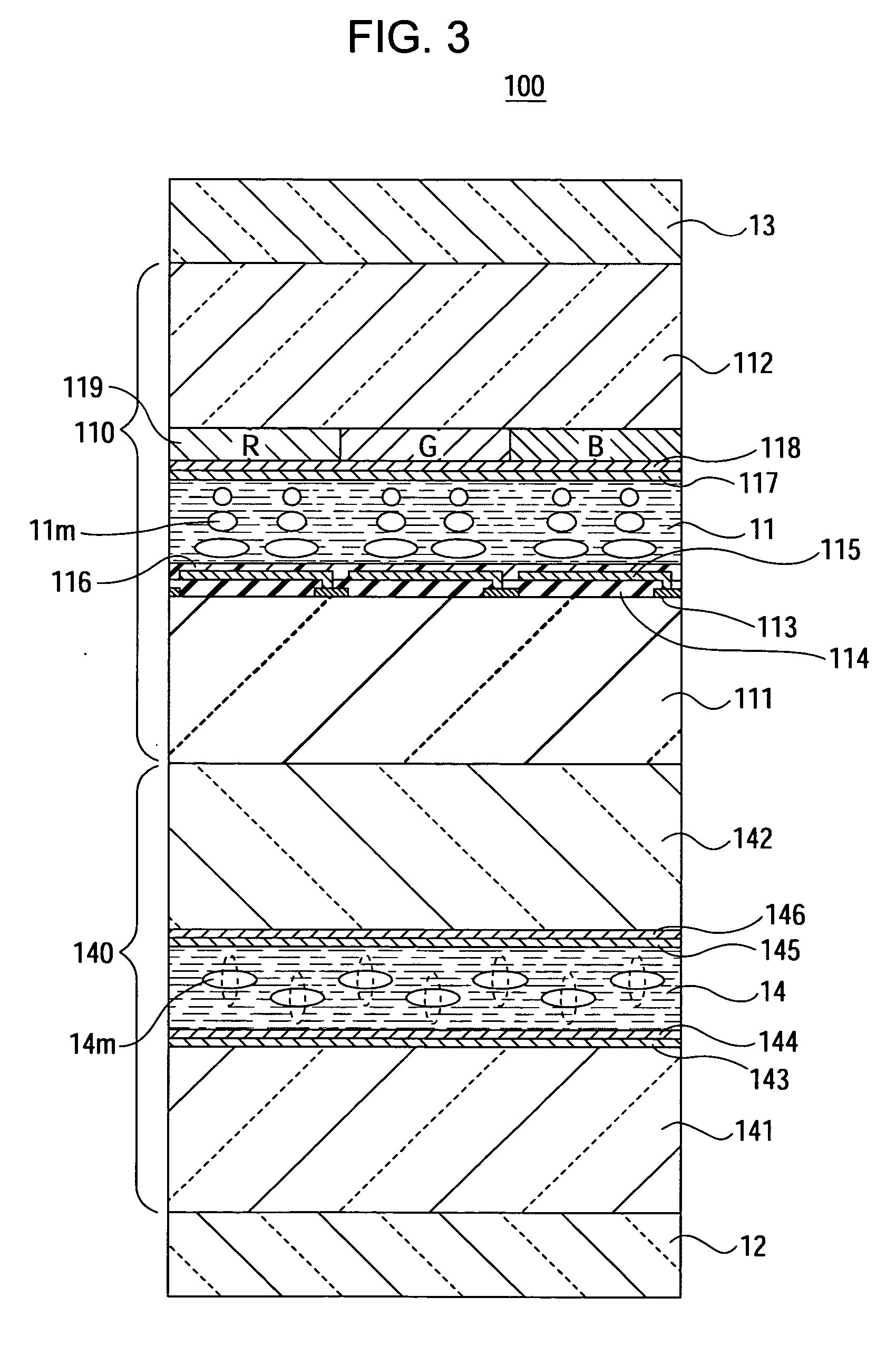

Liquid crystal display apparatus and electronic apparatus

ActiveUS20060158590A1Wide viewing angle controlling rangeLow efficiencyNon-linear opticsStrainersLiquid-crystal displayDisplay device

A liquid crystal display apparatus includes a viewing-angle controlling liquid crystal layer that, when in a horizontal alignment state, exhibits a slow axis that is parallel to a polarized-light transmitting or absorbing axis of a polarizing layer that is disposed opposite to the displaying liquid crystal layer from the viewing-angle controlling liquid crystal layer.

Owner:BOE TECH GRP CO LTD

Magnetic flow liquid variable controllnig valve with two liquid flow resistance channels

InactiveCN1584347AReduce volumeSimple structureServomotorsFluid-pressure actuator componentsCircular discEngineering

A valve is used for continuous regulating and / or cutting-off magnetic rheological fluid. It has an annular drag channel and a circular drag channel. The external magnetic path is formed by a cylinder, a magnet-conducting disc and the said both channels. The core of the said valve is used as the internal magnetic path. The gap of the annular drag channel depends on precise transition fit of the cylinder and the positioning block, which is connected with the magnet-conducting disc by a pin. The thickness of the circular drag channel depends on cushions on a connecting pin of the said core. Neither pin nor cushions are of magnet-conducting material. A strong resistance of flow can be generated by a little electric current. The valve has a larger range of control, little energy consumption, small size and is light and simple, easy to mass production.

Owner:CHONGQING UNIV

Double-closed-loop feedback-control module

InactiveCN102315043AOptimal control of motion characteristicsImprove performance indicatorsRelaysIntegral actionClosed loop feedback

The invention relates to a double-closed-loop feedback-control module, wherein two closed-loop control loops are formed in the starting process and the holding stage of a contactor to directly and accurately control the coil current of the contactor, so that the optimizing control for the integral action characteristic of the contactor can be carried out, and the integral performance index of the contactor is comprehensively improved. The double-closed-loop feedback-control module has low hardware cost, the voltage-adjusting rate of a system can be improved, the transient response speed of the system is increased, and the stability of the system is enhanced.

Owner:FUZHOU UNIV

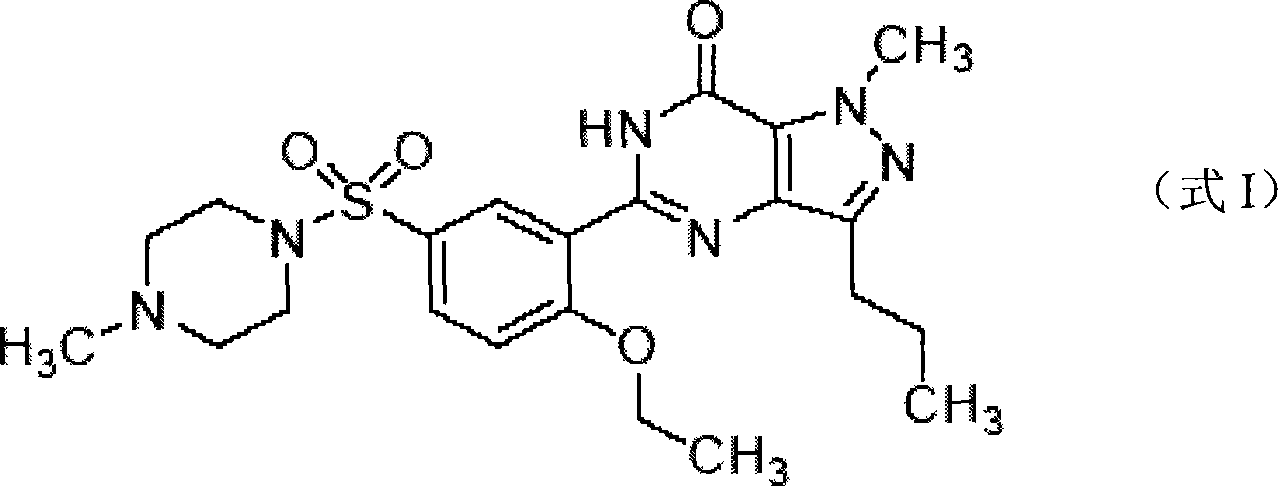

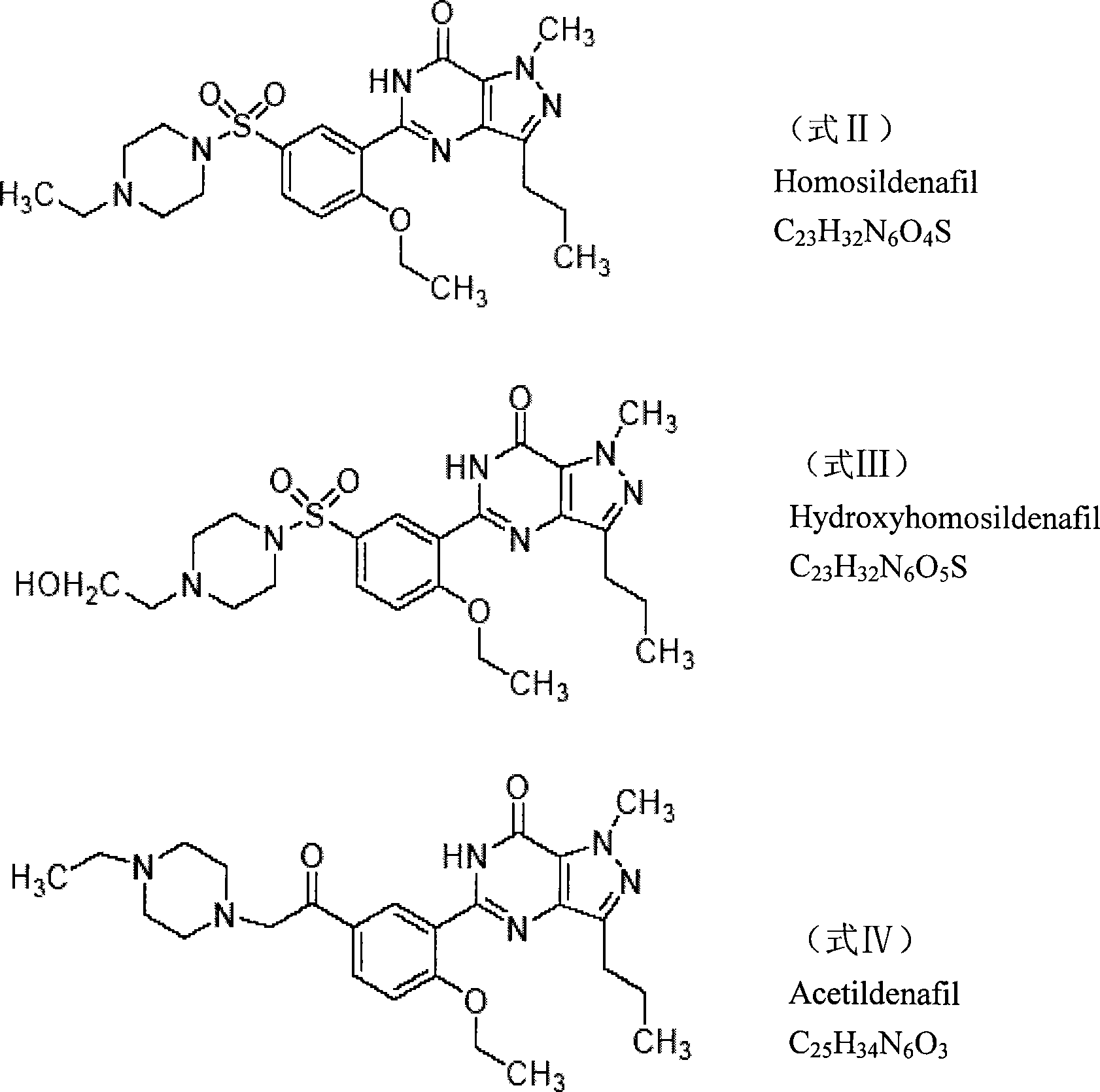

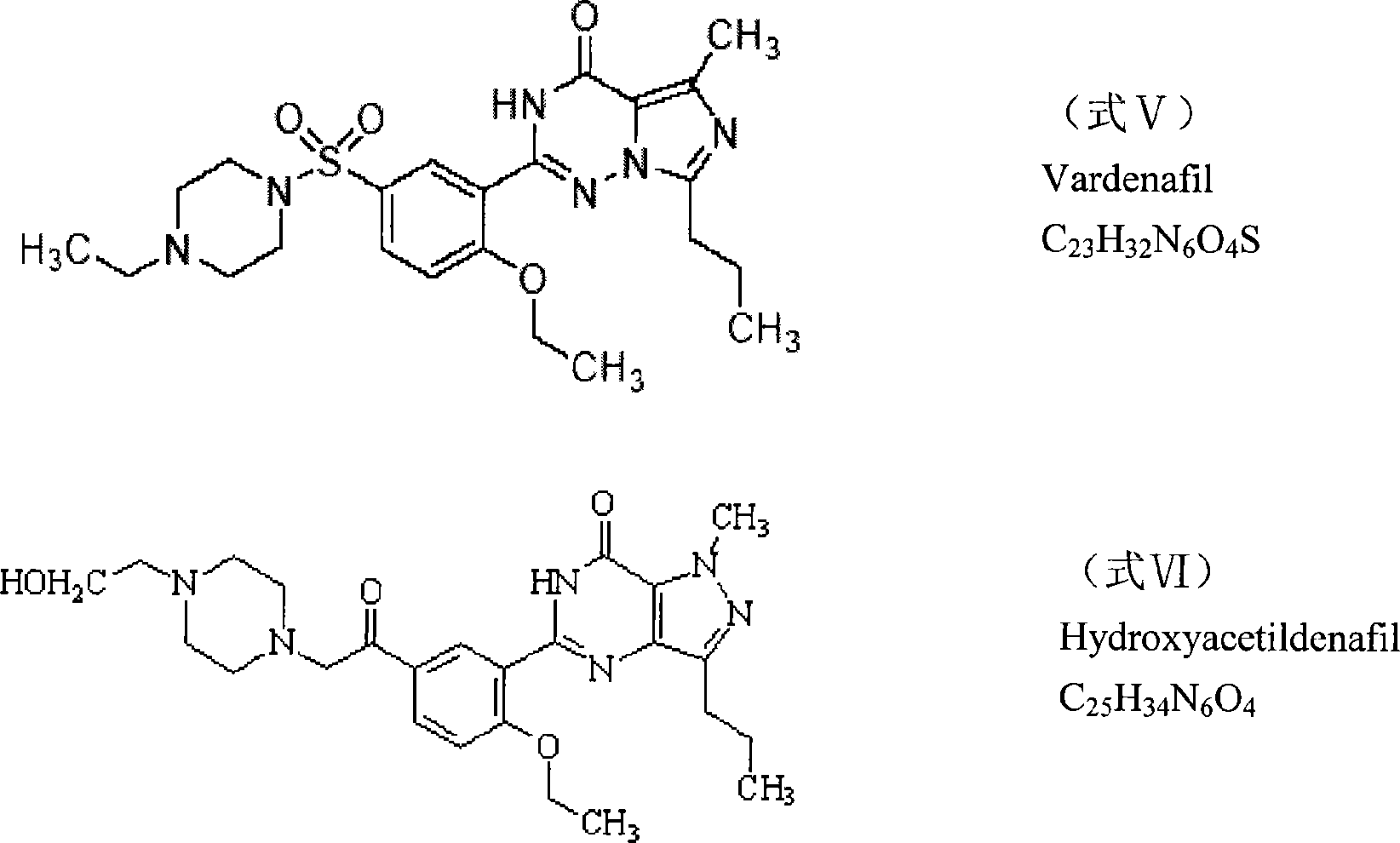

Method for assaying cedinafei and derivative thereof

ActiveCN101021479ANo interference detectedStrong specificityMaterial analysis by observing effect on chemical indicatorPreparing sample for investigationCITRATE ESTERTest sample

The invention discloses a method to test Sildenafil citrate and its ramifications. It contains steps: (1) Color reaction. Make color reaction of test sample with bismuth potassium iodide, silico-tungstic acid and Hager's reagent to observe result. (2) Result estimation. If above three color reactions appear deposit, there are Sildenafil citrate and its ramifications in test samples. If just one, two or none color reaction appear deposit, there is no Sildenafil citrate and its ramifications in test samples. The method has merits of quick, simple, strong property, high accuracy, extensive application and testing range.

Owner:BEIJING INST FOR DRUG CONTROL

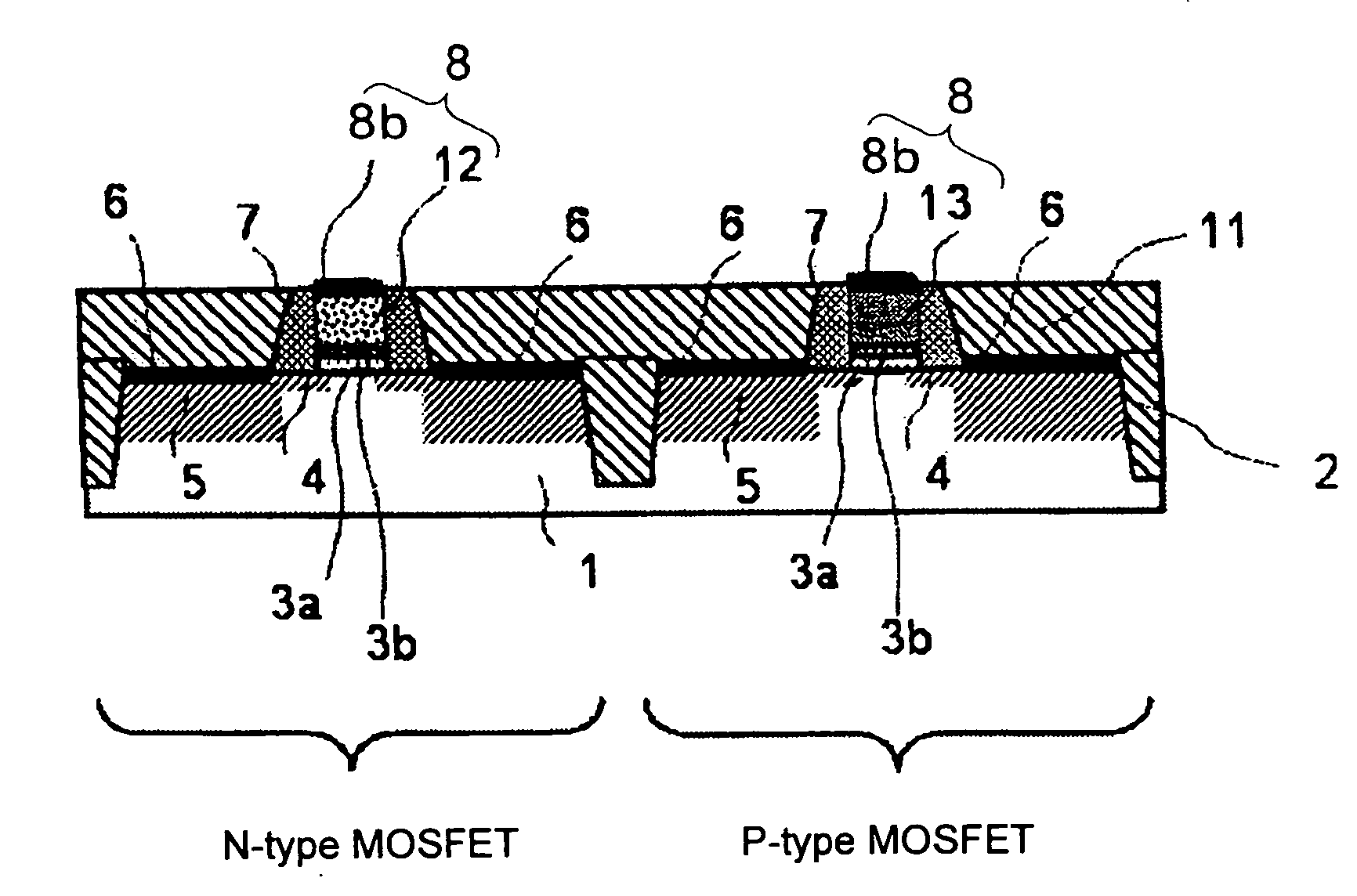

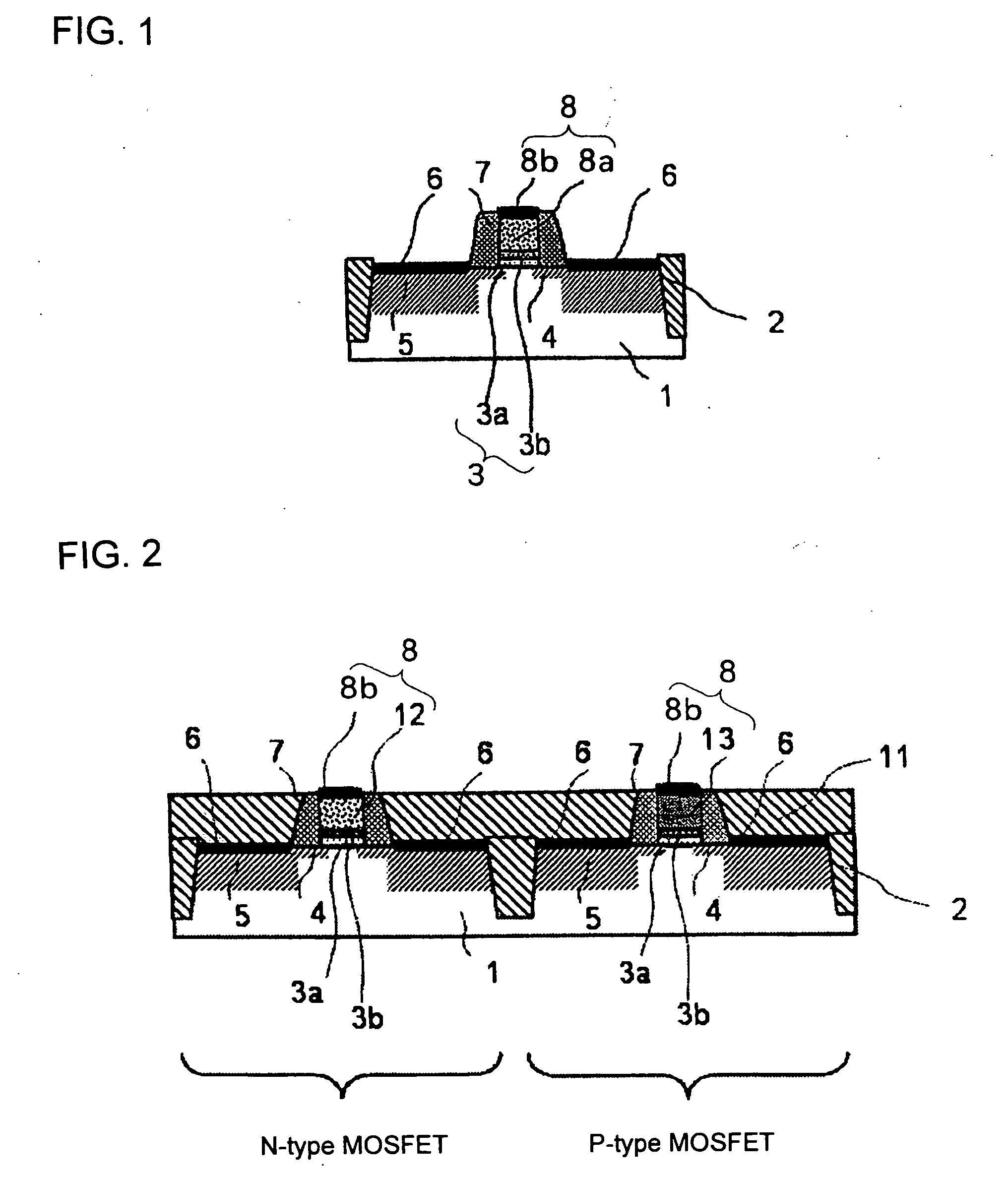

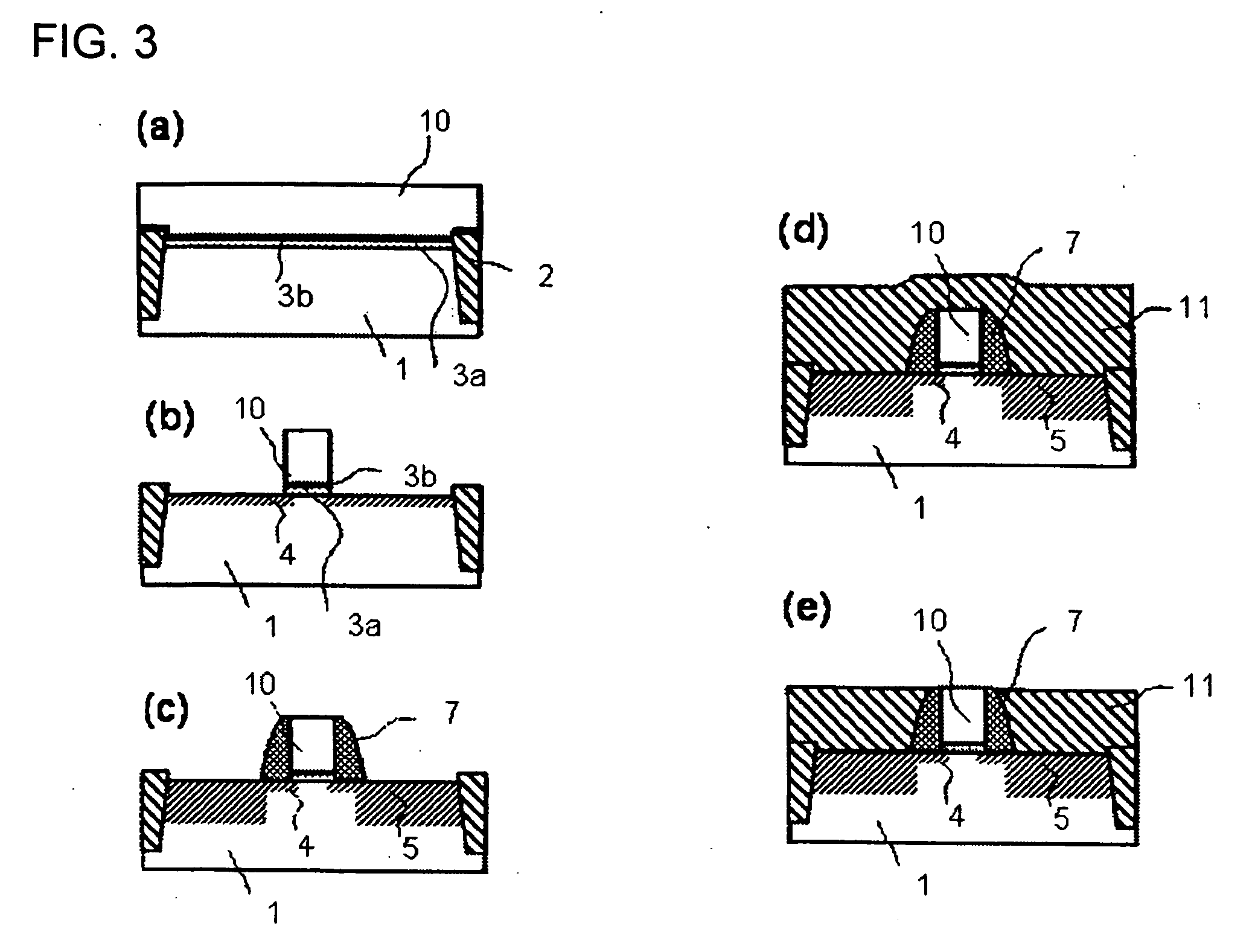

Semiconductor Device and Manufacturing Method Thereof

InactiveUS20090045469A1High speedReduce power consumptionTransistorSemiconductor/solid-state device manufacturingSemiconductorMetal

A semiconductor device including a silicon substrate; a gate insulating film on the silicon substrate; a gate electrode on the gate insulating film; and source / drain regions formed in the substrate on both sides of the gate electrode, wherein the gate electrode includes a first silicide layered region formed of a silicide of a metal M1; and a second silicide layered region on the first silicide layered region, the second silicide layered region being formed of a silicide of the same metal as the metal M1 and being lower in resistivity than the first silicide layered region.

Owner:NEC CORP

Method of electrodepositing silicon

A process for electrodeposition of silicon belongs to the electroanalysis and electrophoresis technology field and used forone-step electrodeposition of silicon from SiO2 by using molten salt as medium and adoping direct current. Said process is characterized as follows: using a 3-constituent element composed of NaCl, KCl and NaF as medium, wherein the mol ratio thereof is 1:1:0.5-1:1:4.5, and adding powdery SiO2 which mass is 10% of the fused-salt medium mass therein; after pre-electrolysis impurities removing, electrodepositing pure silicon with electrodeposition temperature of 800 -950 DEG C, electrodeposit time of 0.5 -3 hours and ampere density of 500-1000 A / m2.The present invention is characterized as follows: 1, the constituent elements forming molten salt are usual and cheap pharma-ceutical products which are easy to obtain, then the cost is low and the consumption is small; 2, the manufacturing technique is simple and the process is easy to control. Said process in accordance with the present invention possesses excellent applications foreground in semi-conductor devices fabricating.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

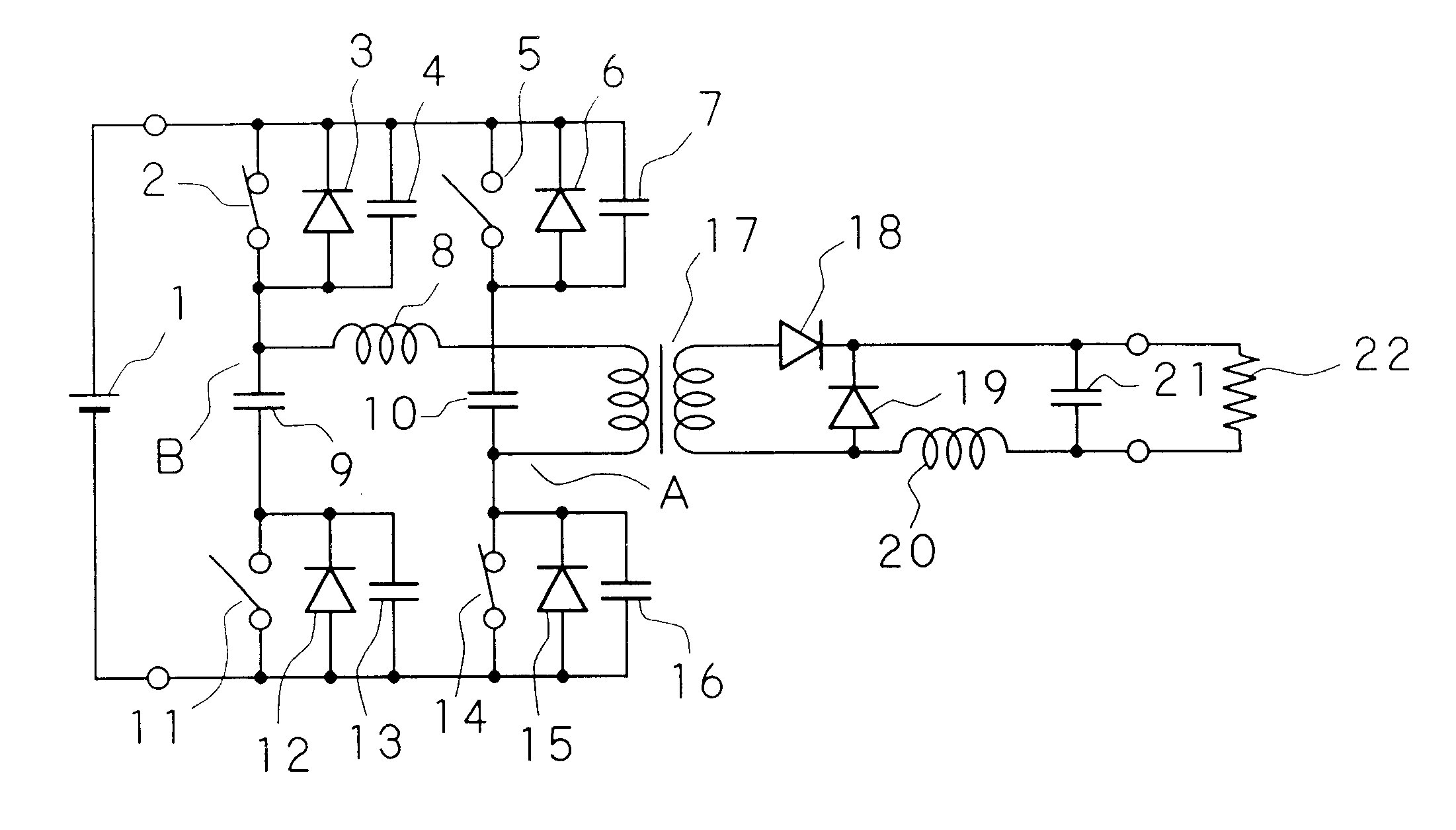

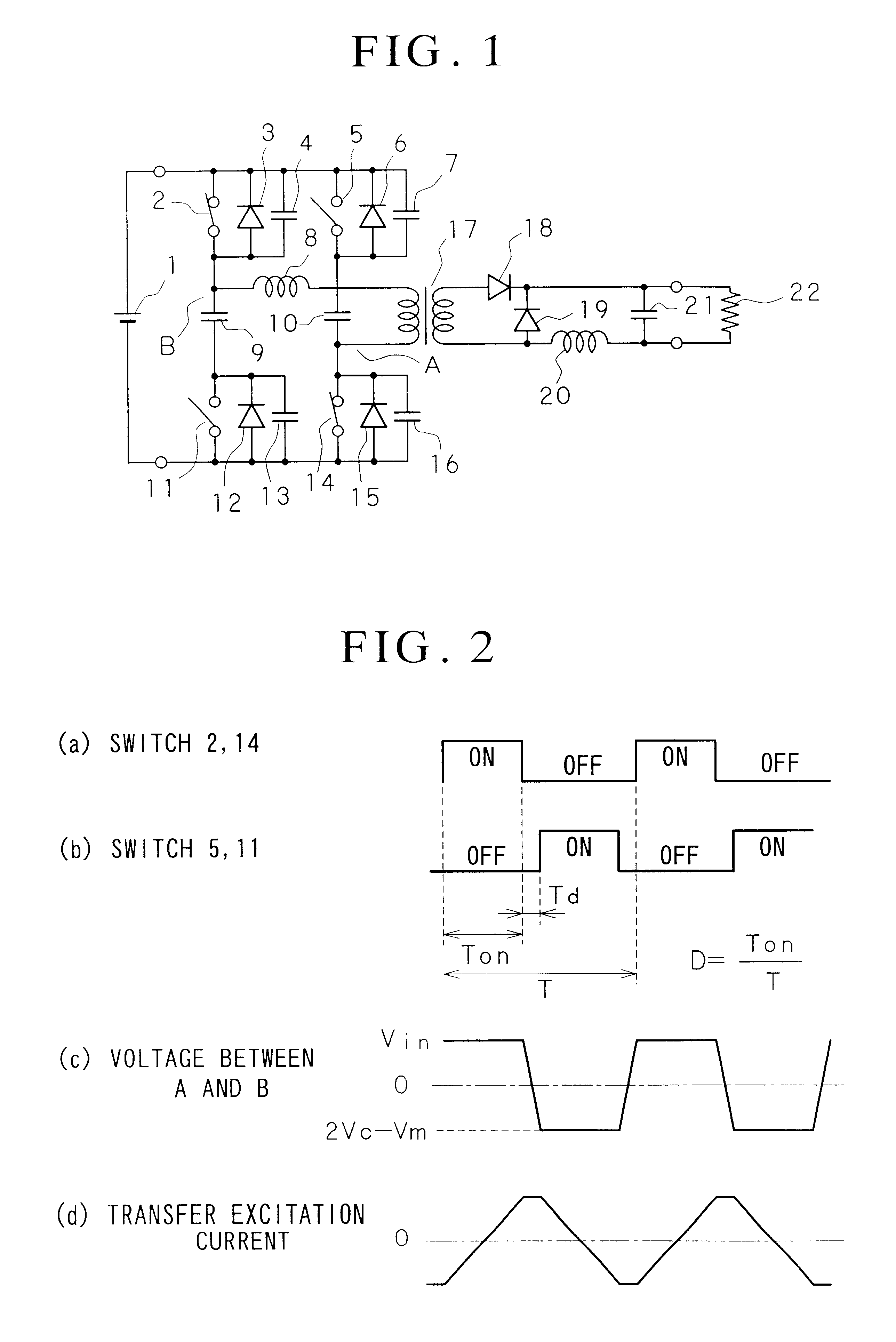

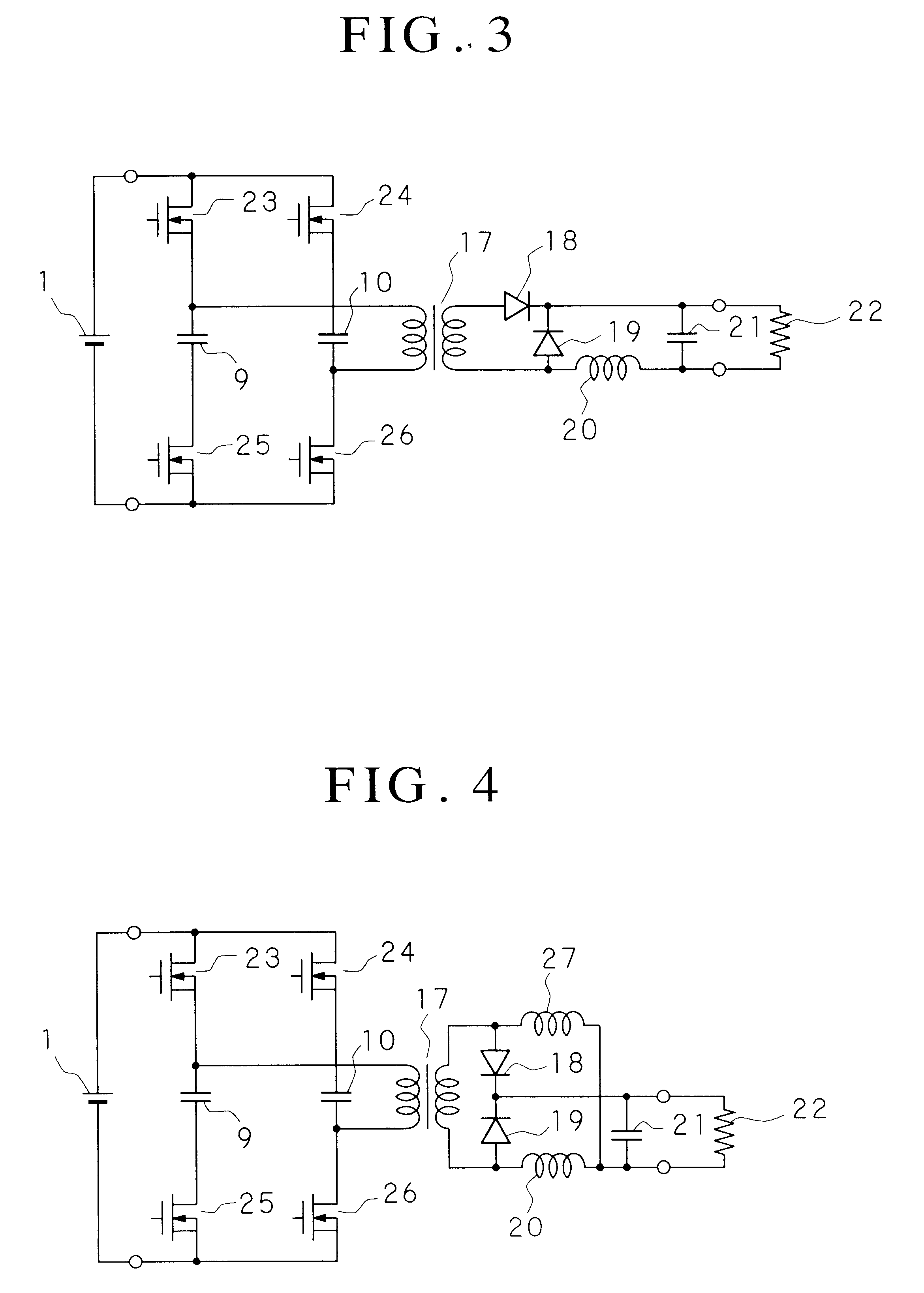

Active clamping for zero current zero voltage forward conversion

InactiveUS6396714B2Reduce withstand voltageReduce switching lossesEfficient power electronics conversionEmergency protective circuit arrangementsClamp capacitorActive clamp

Owner:NEC CORP

Method for preparing tungsten from WO3

The invention relates to a method for preparing tungsten from WO3, belonging to the technical field of electrolysis and electrophoresis. The method is used for realizing one-step electrodeposition to obtain WO3 from with fused salt as medium under the action of pulse direct current. The method is characterized in that a component comprising NaCl, KCl and NaWO4 is used as medium, wherein the molar ratio of NaCl to KCl to NaWO4 is 2:2:(0.01-2):2:0.05, and the powdered WO3 which is 10-20 wt% of the fused salt medium is added; and after impurity removal by pre-electrolysis, pure tungsten is obtained by electrodeposition at an electrodeposition temperature of 650-750 DEG C, electrodeposition time of 1-3 hours and current density of 300-600 A / m2. The method provided by the invention has the following characteristics: (1) the component of the fused salt is common cheap agent, is easily-accessible and has low cost and less consumption; (2) the production technology has short process and wide parameter control range, and is easy to operate and implement; (3) the electrodeposition temperature is low, so that the fused salt does not volatilize; and (4) the component of the fused salt can be ensured to not to change with the prolongation of the electrodeposition time, so as to ensure the stability of electrodeposition process. The method has good prospect in tungsten production and applications.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

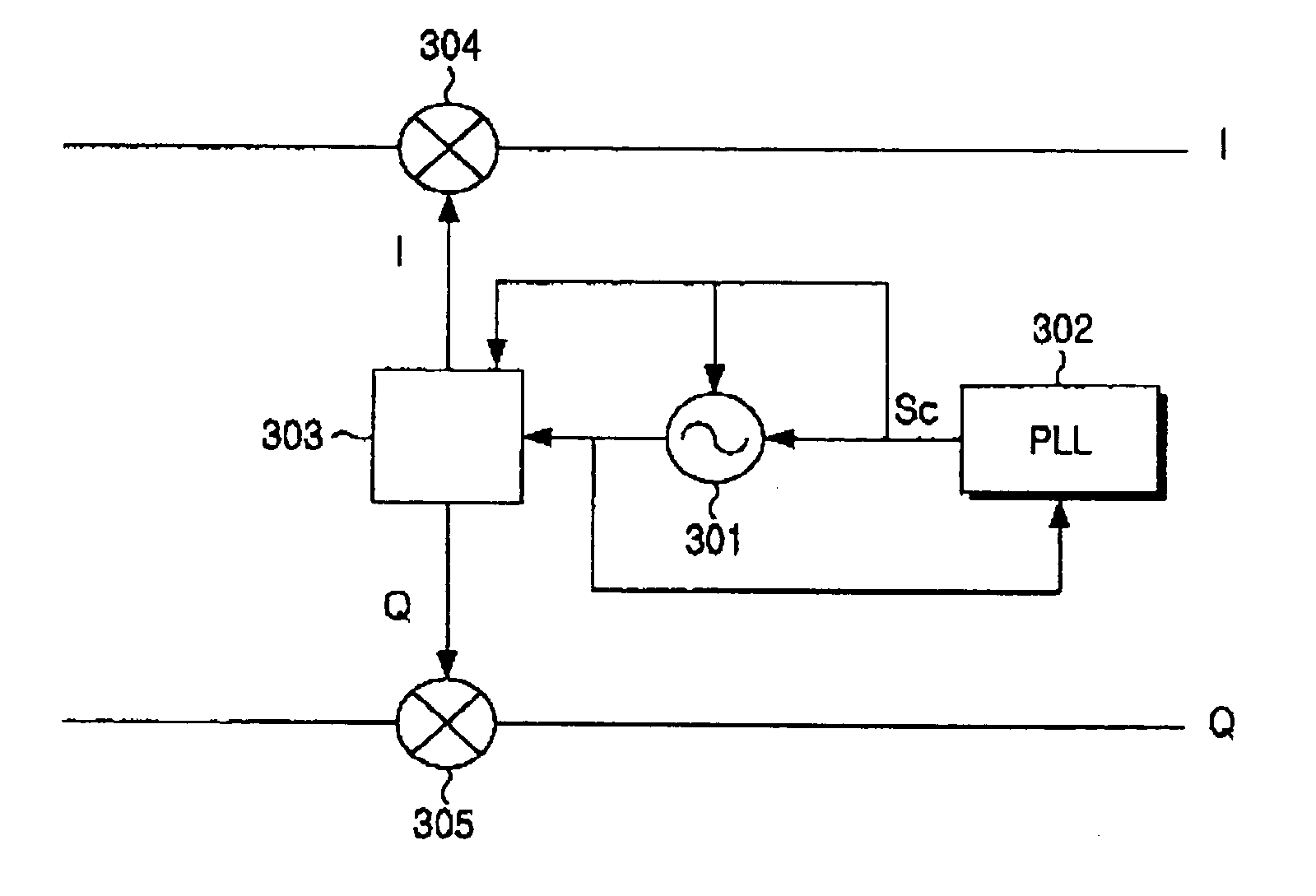

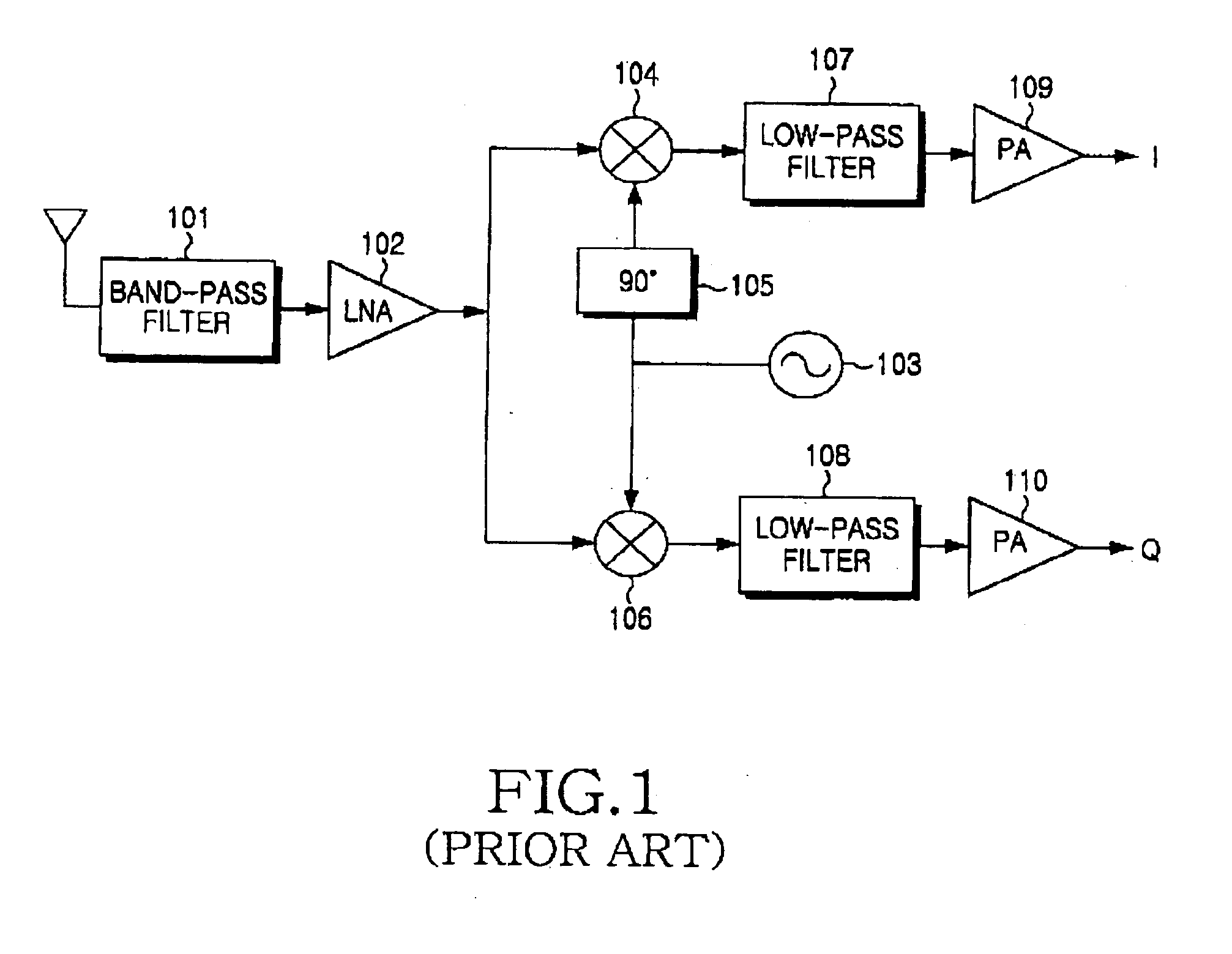

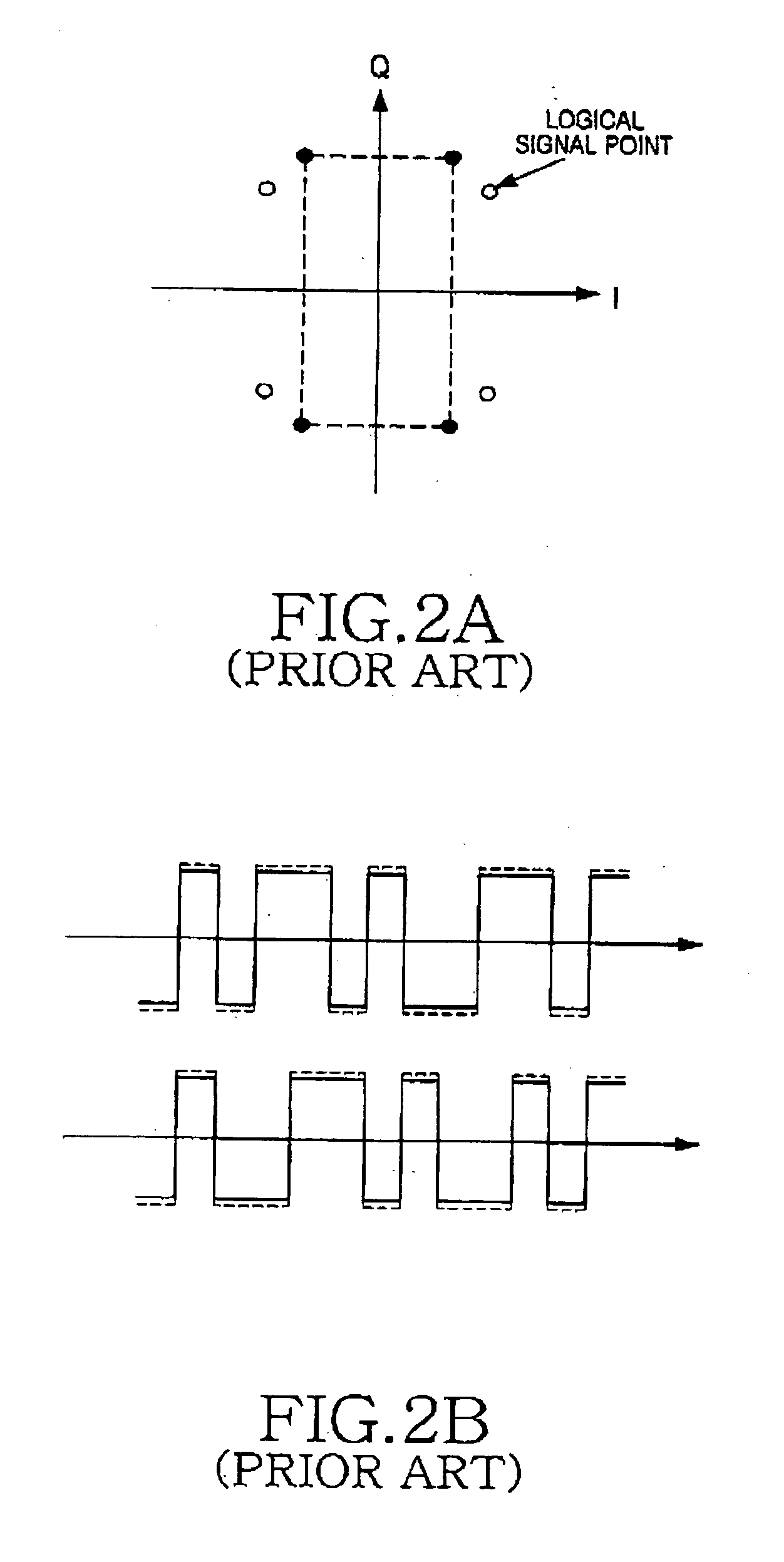

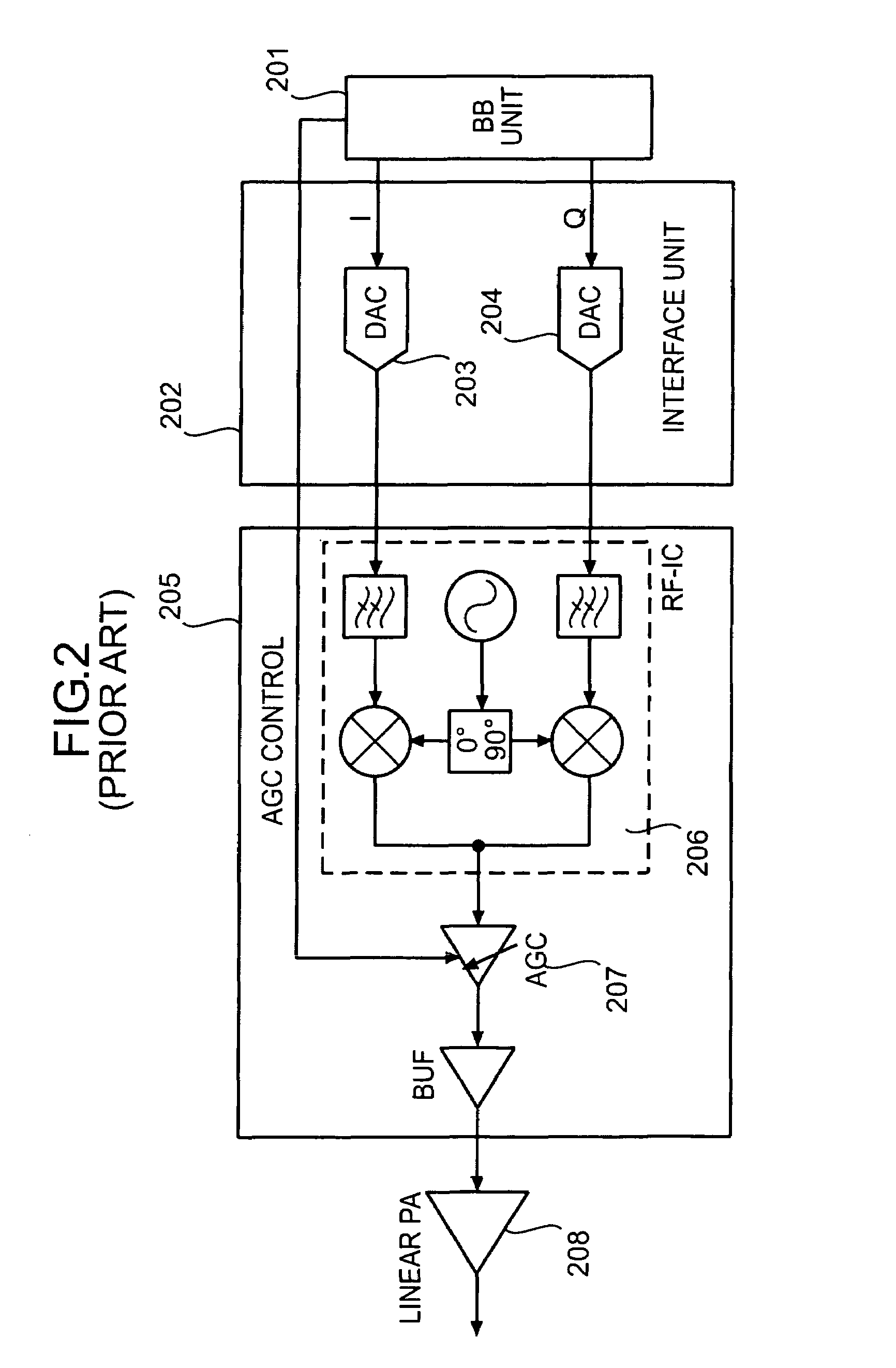

Wideband I/Q signal generation device

ActiveUS20050245225A1Wide range of controlInhibit deteriorationMultiple-port networksTransmission noise suppressionTransceiverWireless transceiver

An apparatus for generating an in-phase / quadrature-phase (I / Q) signal in a wireless transceiver is disclosed, including a local oscillator for generating a local oscillation signal, and first and second mixers for mixing the oscillation signal with a transmission / reception signal to convert the transmission / reception signal into a baseband or high-frequency signal. The apparatus includes a phase locked circuit for controlling the local oscillator, and a polyphase filter installed between the local oscillator and the mixers, for separating the oscillation signal from the local oscillator into an I signal and a Q signal depending on a control signal from the phase locked circuit, and outputting the separated I and Q signals to the first and second mixers, respectively.

Owner:SAMSUNG ELECTRONICS CO LTD +1

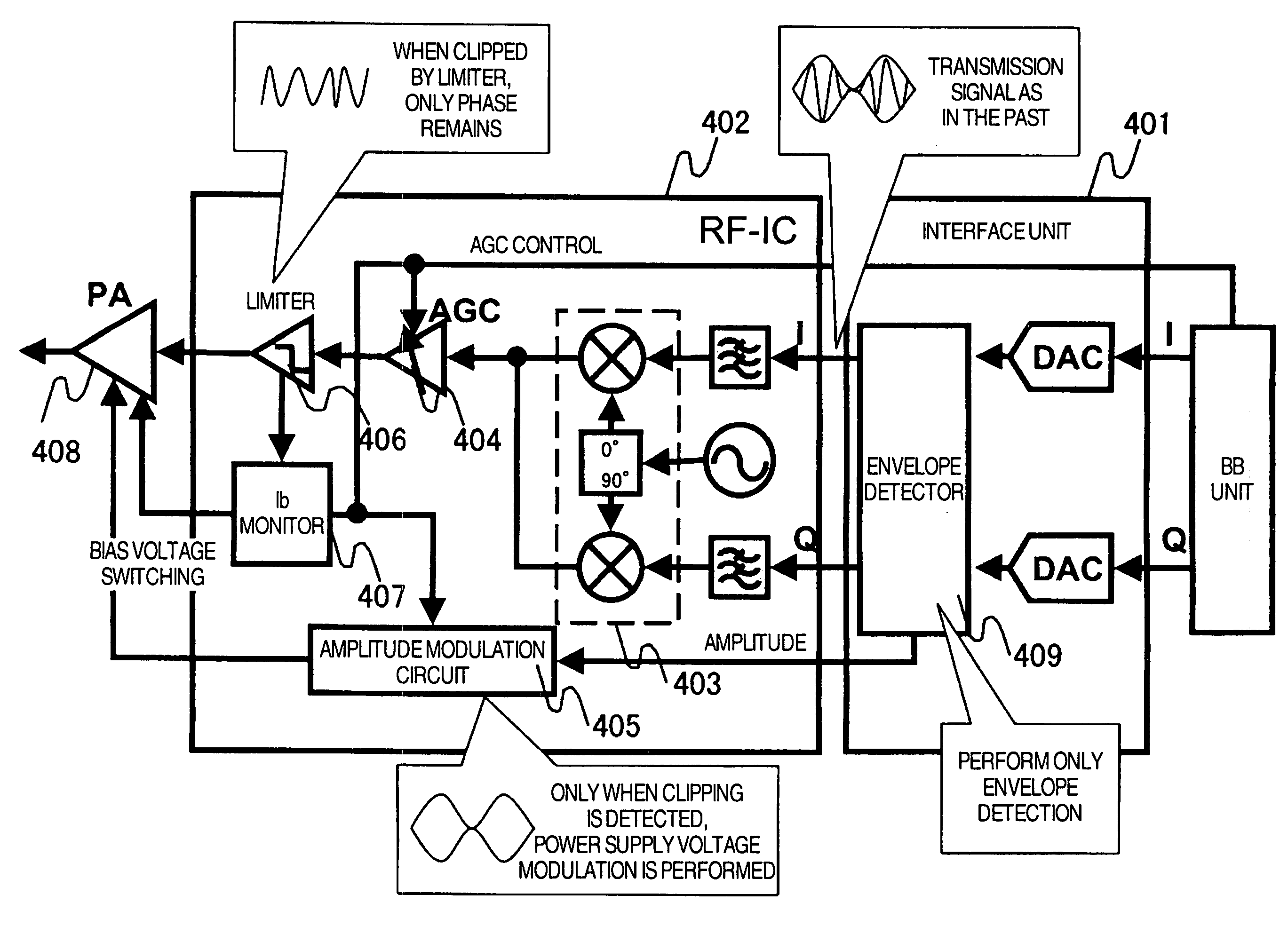

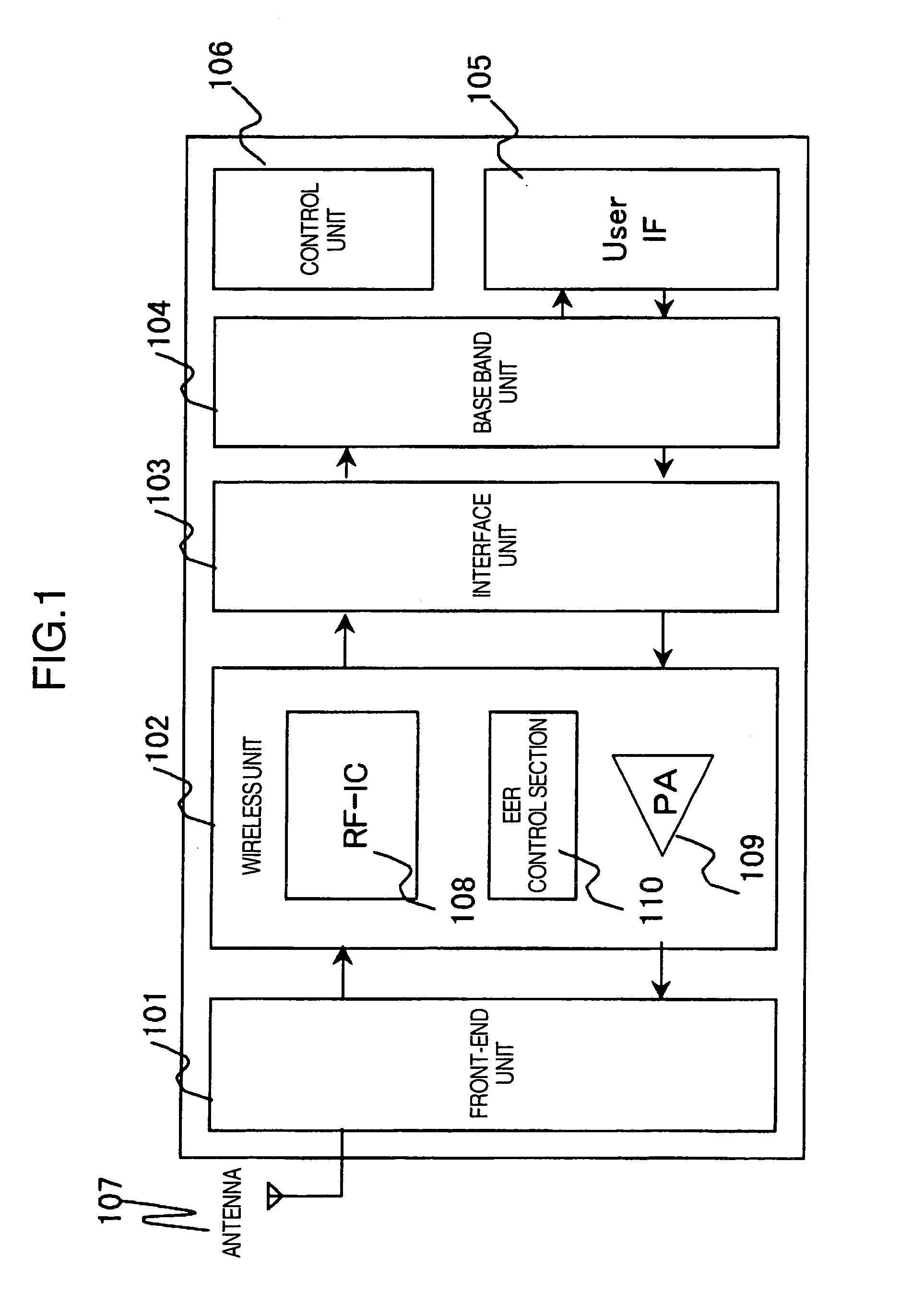

Wireless communication apparatus

InactiveUS7184491B2Wide range of controlImprove responsivenessEnergy efficient ICTPower amplifiersLinear controlAudio power amplifier

A linear system and an EER system are used in combination such that the EER system can also be used in a cellular phone with a wide output dynamic range. In the EER system, linear control of an amplifier becomes difficult in a low output range. Thus, use of the EER system is limited to a high output range, and the linear system is used in the low output range as in the past. A power efficiency is improved while requirements of linearity are satisfied by this structure. An effective circuit structure is proposed for a switching control system for two systems. In addition, an up-converter is constituted in combination with a step-down element with high responsiveness, whereby a power supply voltage control circuit for the EER system with a wide control range and high responsiveness is provided.

Owner:HITACHI LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com