Alkali etch solution and method for preparing monocrystalline silicon pile fabrics

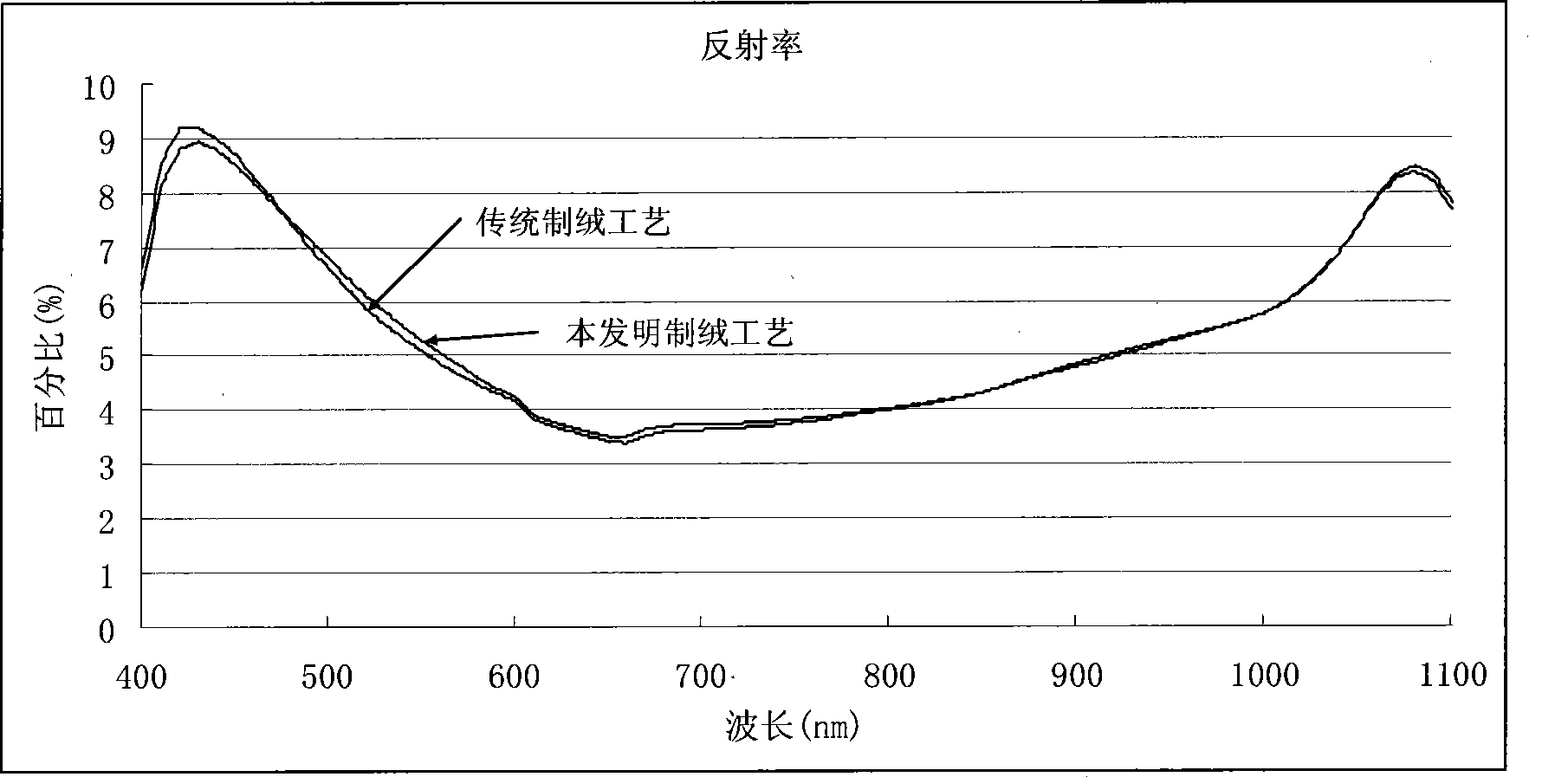

A technology of alkali corrosion and alkali solution, which is applied in the fields of final product manufacturing, sustainable manufacturing/processing, photovoltaic power generation, etc., can solve the problem of changing the frequency of solution, increasing the rework rate of suede preparation, affecting the conversion efficiency of solar cells, and increasing the fragmentation of cells Incidence rate and other issues, to achieve the effect of stable texturing process, wide control range and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

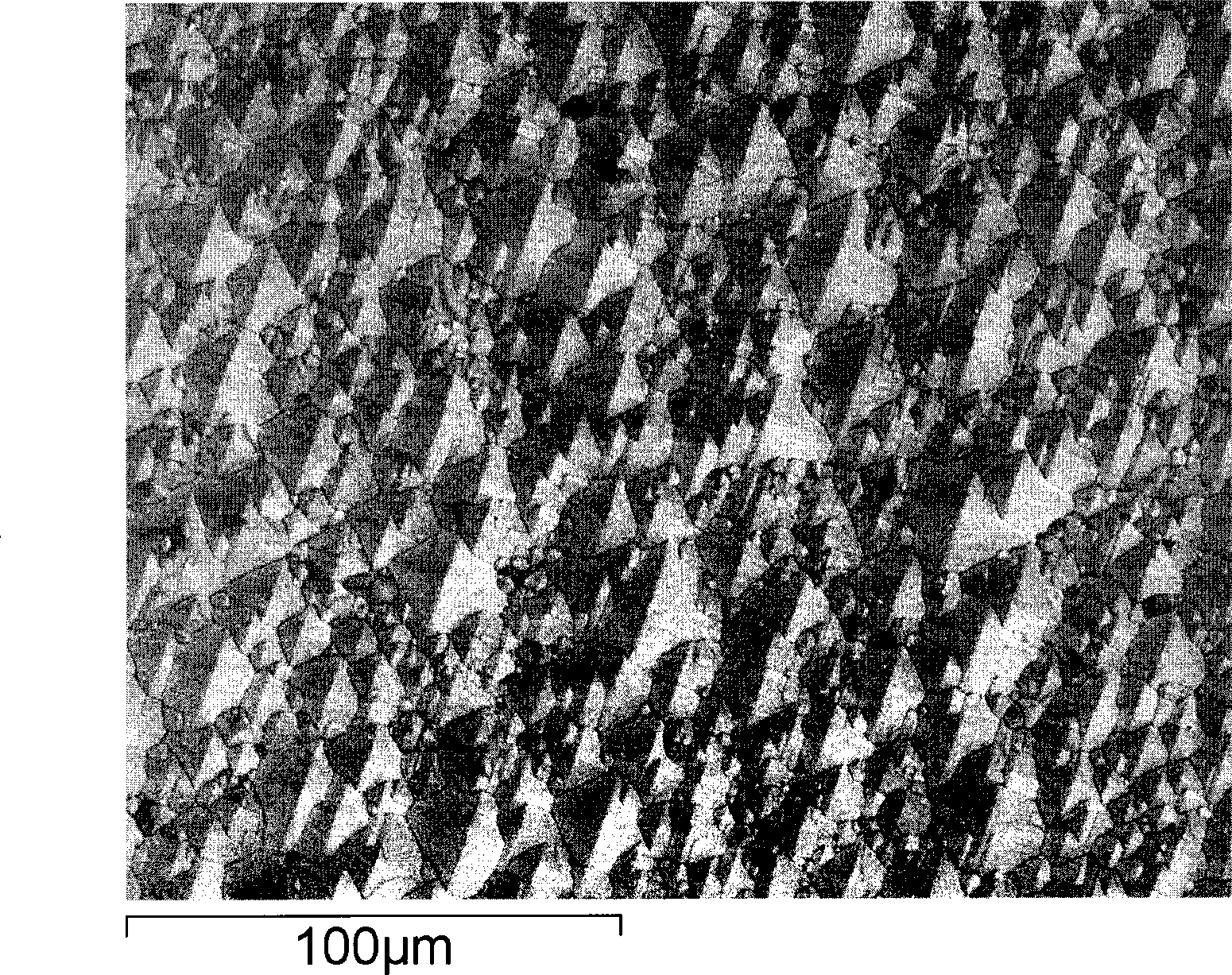

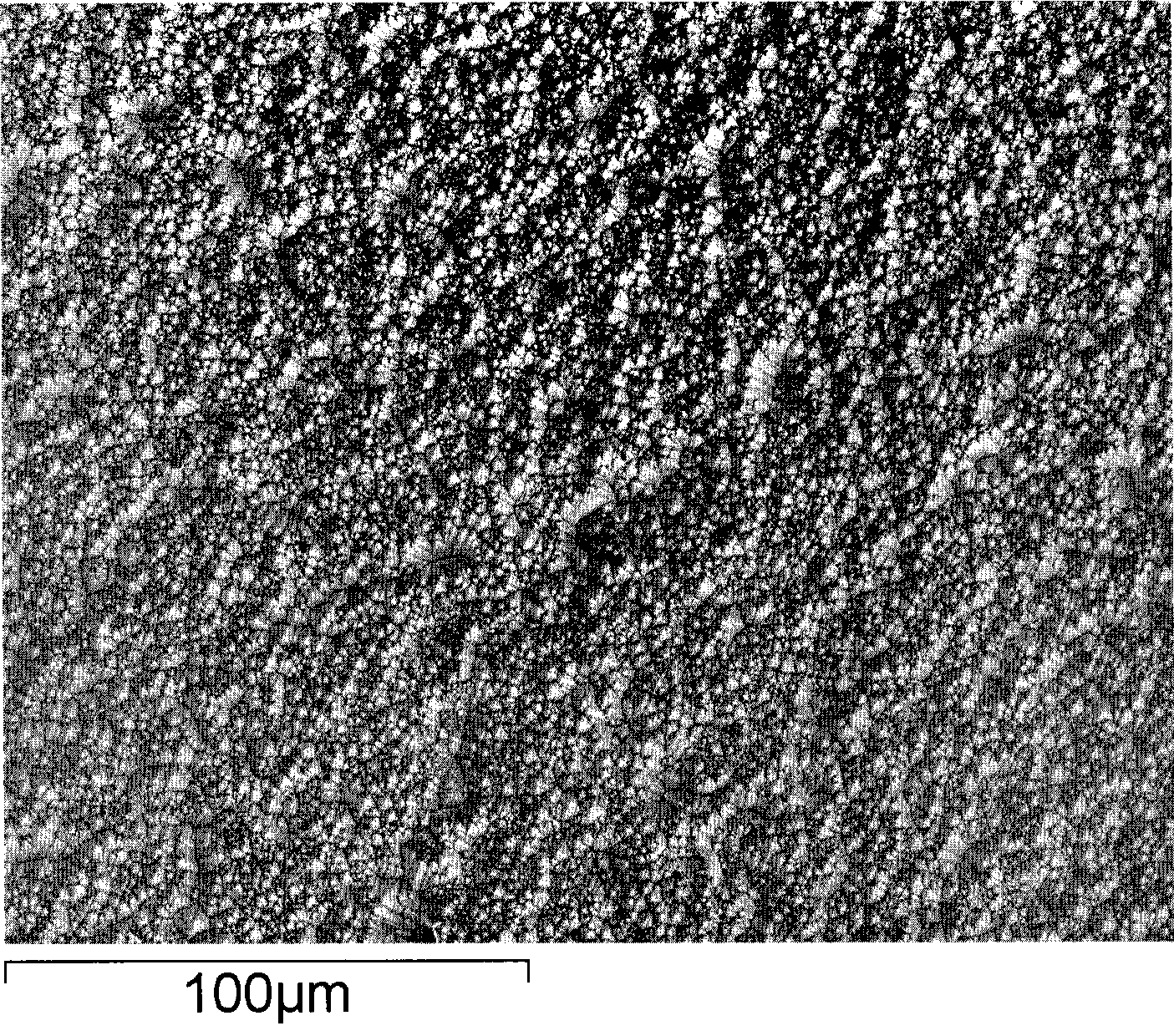

[0025] The percentage by weight of NaOH solution is 2% in the present embodiment, and the percentage by weight of Virahol is 6%, and NaOH solution 2 SiO 3 The weight percentage is 0.5%, Pb(NO 3 ) 2 The weight percentage is 0.05‰. The temperature of the alkali etching solution is 80° C., the alkali etching time of the monocrystalline silicon wafer is 20 minutes, and the measured result of the size of the prepared textured pyramid is 0.9 μm.

Embodiment 2

[0027] The percentage by weight of NaOH solution is 3% in the present embodiment, and the percentage by weight of Virahol is 5%, and NaOH solution 2 SiO 3 The weight percentage is 1%, Pb(NO 3 ) 2 The weight percentage is 0.02‰. The temperature of the alkali etching solution is 85° C., the alkali etching time of the monocrystalline silicon wafer is 28 minutes, and the measured result of the size of the prepared textured pyramid is 1.5 μm.

Embodiment 3

[0029] The percentage by weight of NaOH solution is 1.5% in the present embodiment, and the percentage by weight of Virahol is 7%, and NaOH solution 2 SiO 3 The weight percentage is 0.2%, Pb(NO 3 ) 2 The weight percentage is 0.1‰. The temperature of the alkali etching solution is 82° C., the alkali etching time of the monocrystalline silicon wafer is 25 minutes, and the measured size of the prepared textured pyramid is 0.7 μm.

[0030] In the above examples, NaOH solution can be replaced by the same amount of KOH solution, Pb(NO 3 ) 2 It can be replaced by the same amount of Pb.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com