Method for smelting low-aluminum high-vanadium iron

A smelting method and high-ferro-vanadium technology, applied in the direction of improving process efficiency, etc., can solve the problems of limited use, difficult reaction, low recovery rate, etc., and achieve the effects of wide product control range, reaction control, and easy reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

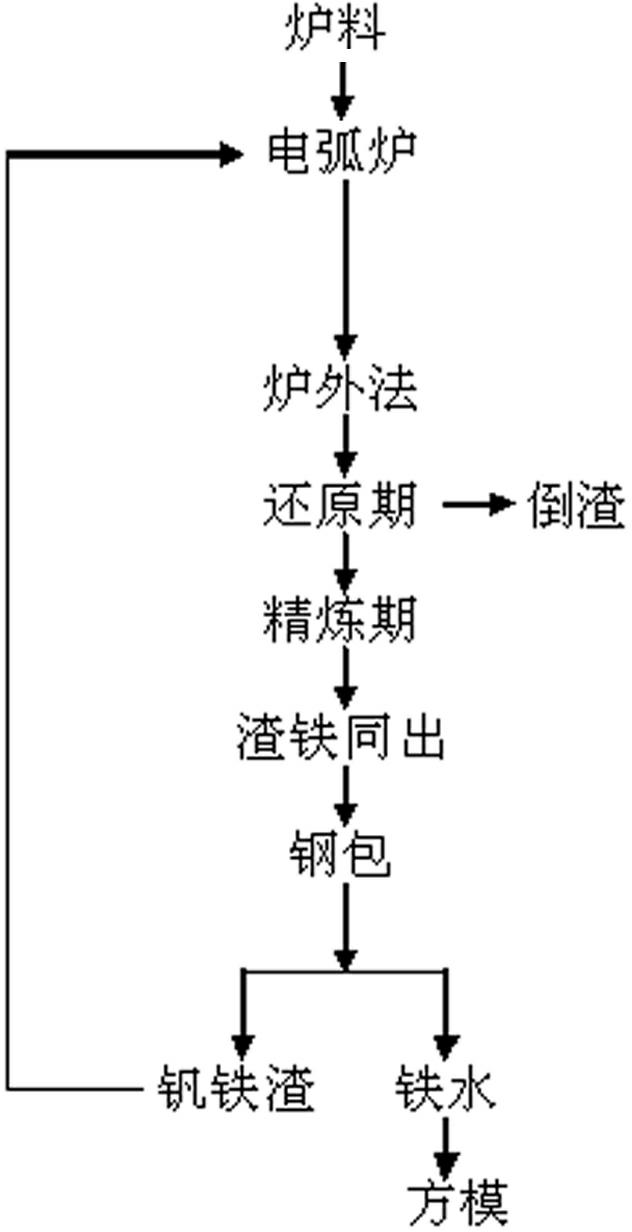

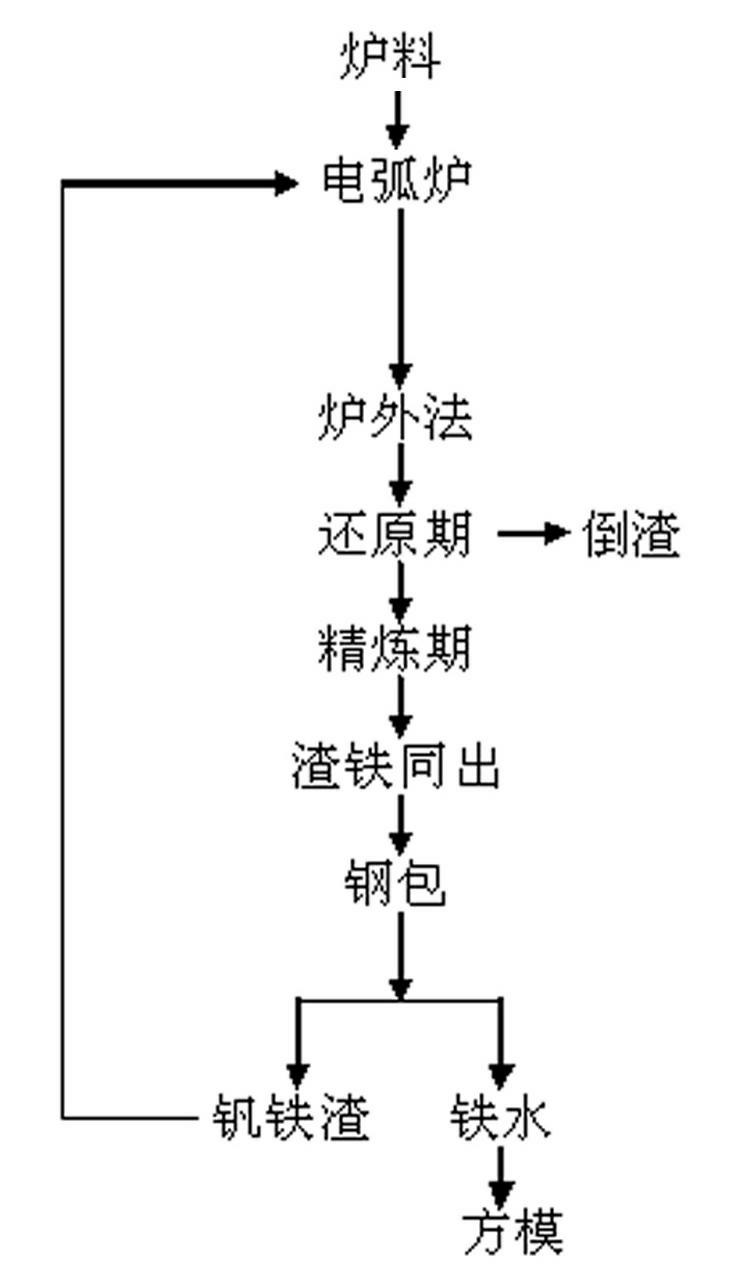

Image

Examples

Embodiment 1

[0013] 1. First, the smelting operation outside the furnace. Mix 300 kg of vanadium pentoxide, 120 kg of aluminum powder, and 100 kg of vanadium iron slag as a mixture and put it on the operation table in front of the furnace, and put 18 kg of scrap steel into the electric arc furnace. Take 150 kilograms of the mixture from outside the furnace and spread it on the bottom of the electric arc furnace, and ignite it with an open flame of 1 kilogram of potassium chlorate and magnesium.

[0014] 2. Manually add the remaining materials outside the furnace for further reaction. After the reaction is completed, high-vanadium iron and slag are generated, and the slag is not discharged.

[0015] 3. The operation steps of the reduction period are lowering the electrode, feeding the electricity, melting and reducing, sampling and dumping the slag.

[0016] Feeding electricity: Take 340 kg of vanadium pentoxide and 630 kg of lime and mix them as the materials for the reduction period and go down ...

Embodiment 2

[0022] 1. Firstly, the smelting operation outside the furnace. Mix 270 kg of vanadium pentoxide, 135 kg of aluminum powder, and 130 kg of vanadium iron slag as a mixture and put it on the operation table in front of the furnace, and put 24 kg of scrap steel into the electric arc furnace. Take 150 kilograms of the mixture from outside the furnace and spread it on the bottom of the electric arc furnace, and ignite it with an open flame of 1 kilogram of potassium chlorate and magnesium.

[0023] 2. Manually add the remaining materials outside the furnace for further reaction, reflecting that the slag will not be discharged after the end.

[0024] 3. The operation steps of the reduction period are lowering the electrode, feeding the electricity, melting and reducing, sampling and dumping the slag.

[0025] Feeding of electricity: Take 350 kg of vanadium pentoxide and 750 kg of lime and mix them as materials in the reduction period and put them into the electric arc furnace, and add 30 kg...

Embodiment 3

[0031] 1. First, the smelting operation outside the furnace. Put 300 kg of vanadium pentoxide, 180 kg of aluminum powder, and 130 kg of vanadium iron slag on the operation table in front of the furnace. Put 24 kg of scrap steel into the electric arc furnace and take it out of the furnace. 150 kilograms of the French mixture was spread on the bottom of the electric arc furnace and ignited with an open flame of 1 kilogram of potassium chlorate and magnesium.

[0032] 2. Manually add the remaining materials outside the furnace for further reaction, reflecting that the slag will not be discharged after the end.

[0033] 3. The operation steps in the reduction period are feeding electricity, melting reduction, sampling and dumping.

[0034] Feeding of electricity: Take 300 kg of vanadium pentoxide and 700 kg of lime and mix them as materials for the reduction period and go down to the electric arc furnace, and add 28 kg of scrap steel.

[0035] Melting reduction: With the input of the mixt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com