Microwave preparing method for nanometer silver or gold

A nano-silver and microwave technology, which is applied in the field of microwave preparation of nano-silver or gold, can solve the problems such as the microwave preparation method of nano-silver or gold that has not been seen, and achieves a uniform particle shape, narrow particle size distribution, and controllable reaction process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add 0.01 mol / L silver nitrate or chloroauric acid solution and 0.5% sodium carboxymethyl cellulose solution in the reactor at a ratio of 1:1, add an appropriate amount of twice distilled water to the reaction system to be 200 ml; put the reactor Put it into the microwave reaction chamber and fix it, turn on a magnetic stirrer with a rotating speed of 100 rpm, set the microwave power to 0.3 kW, and react for 7 hours; after the reaction, the solution is dried by airflow, or vacuum freeze-dried, or spray-dried to prepare nano silver or Gold powder, or nano-silver or gold colloid concentrated to the desired concentration by vacuum.

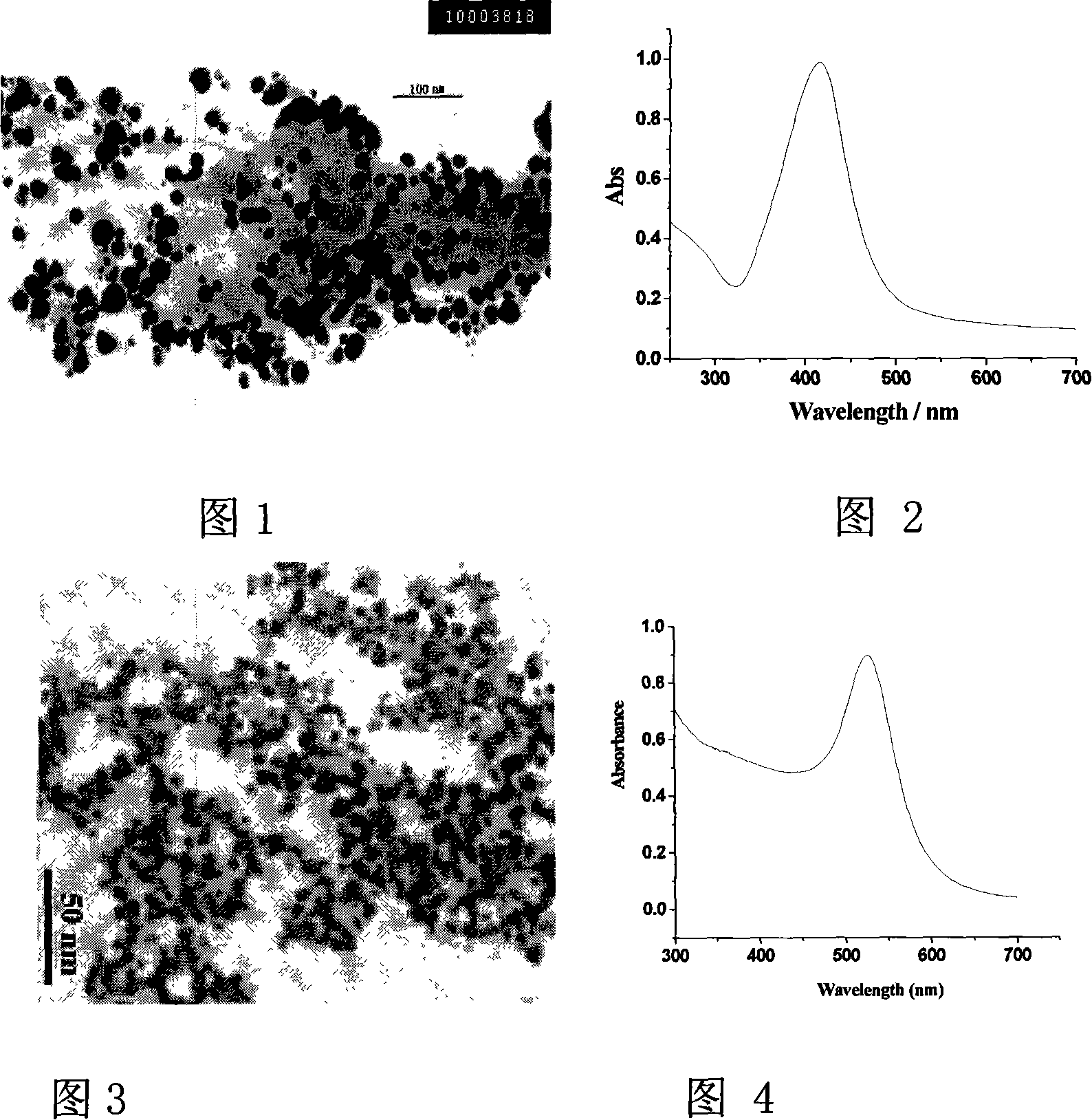

[0024] The electron micrographs and ultraviolet spectra of the nano silver or gold are shown in Figures 1, 2, 3, and 4.

Embodiment 2

[0026] Add 0.01mol / L silver nitrate or chloroauric acid solution and 1% starch solution in the reactor at a ratio of 1:1, add an appropriate amount of twice distilled water to the reaction system to reach 200ml, and add 1ml 0.01mol / L ammonia as a catalyst; Place the reactor in a microwave reaction chamber and fix it, turn on a magnetic stirrer with a rotating speed of 100 rpm, set the microwave power to 0.3 kW, and react for 1 hour. After the reaction, adjust the pH of the solution to neutral; after the reaction, the solution is dried by airflow. Or vacuum freeze-drying, or spray drying to prepare nano-silver or gold powder, or vacuum concentration to a desired concentration of nano-silver or gold colloid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com