Drill chuck

A technology for drill chucks and flanges, applied in the direction of tool joints, etc., which can solve problems such as insufficient clamping force, inaccurate centering, and slippage of drill bits, so as to achieve good centering, improve production quality and efficiency, and increase clamping force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention is described below in conjunction with accompanying drawing.

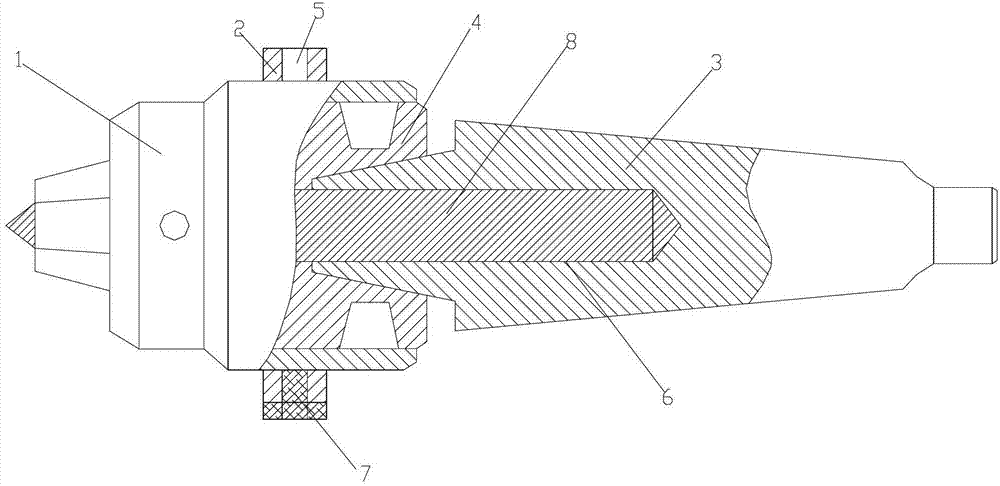

[0011] attached figure 1 The drill chuck according to the present invention includes a drill chuck body 1, a flange 2, and a taper shank 3; the flange 2 is fixedly sleeved on the outer diameter of the drill chuck body 1 through bolts 7; the method A through hole 5 is provided on the outer circle of the flange 2; a lock sleeve 4 is provided inside the drill chuck body 1; one end of the taper handle 3 is connected in the lock sleeve 4; a mounting hole 6 is provided inside the taper handle 3; A flange 2 is socketed on the drill chuck body 1, and a through hole 5 is provided on the outer circle of the flange 2, and then a straight handle wrench is inserted into the through hole 5 to pull the drill chuck body 1 to realize the rapid drilling of the drill chuck. Clamping or loosening improves the clamping force on the drill bit; through the installation hole 6 in the tapered shank 3, the dril...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com