Automatic quenching device for automobile plate spring

A technology of quenching device and automobile plate, which is applied in the field of leaf spring rolling mills, can solve the problems of many operators, large floor space, and high labor intensity, and achieve the requirements of improving product quality, production efficiency, stability and precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with embodiment.

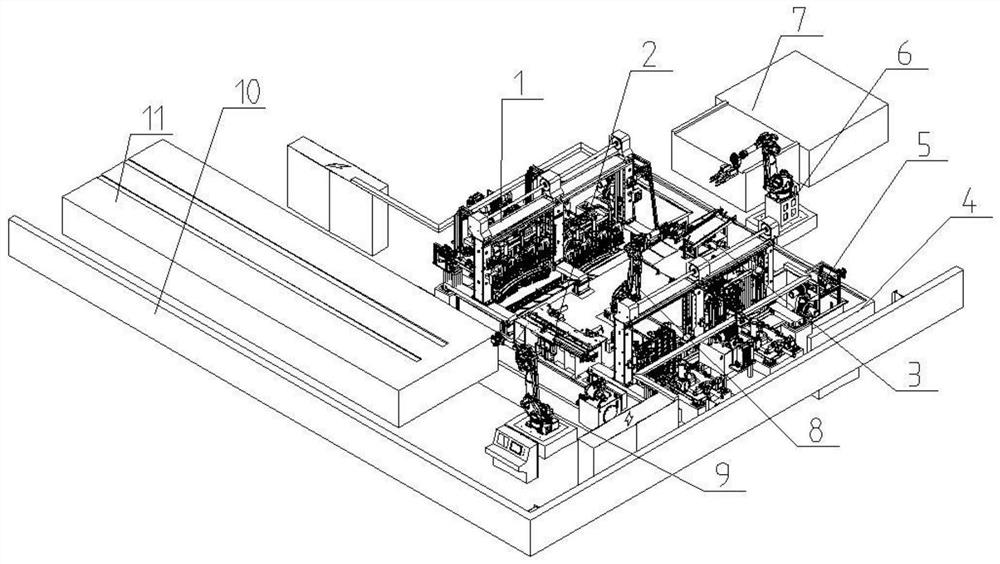

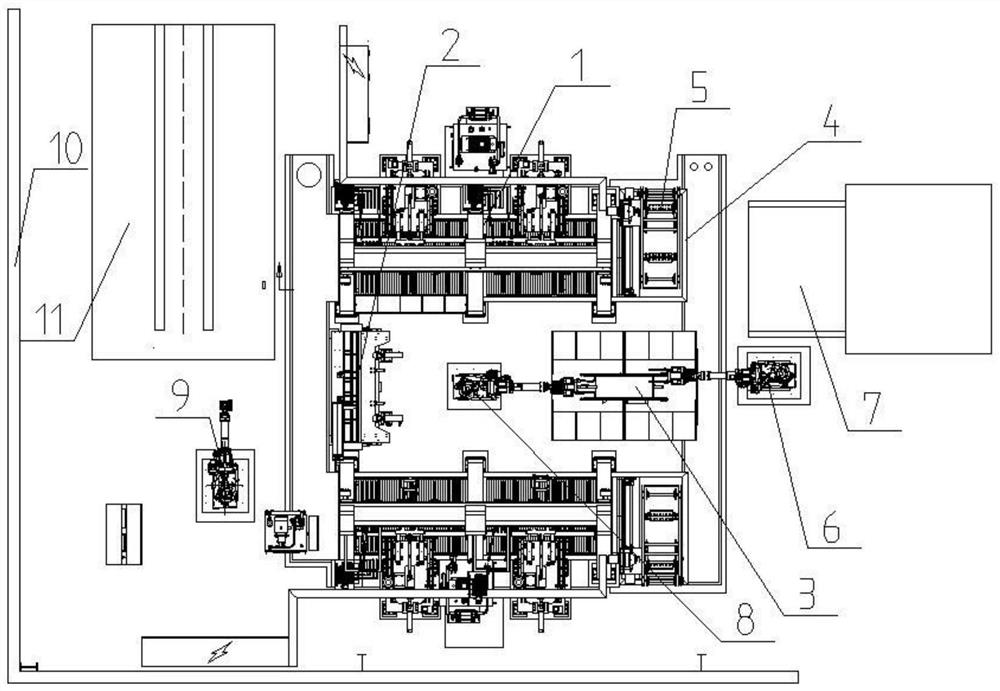

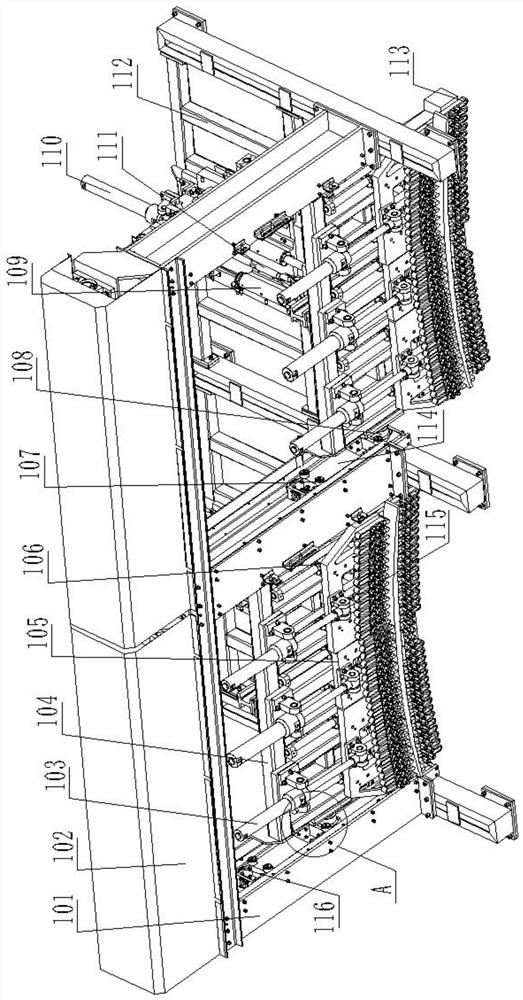

[0048] Such as Figure 1 to Figure 25 As shown, the present invention is an automatic quenching device for an automobile leaf spring, comprising a quenching oil pool 4, the top of the quenching oil pool 4 is provided with a fully automatic frame-type swinging lifting quenching machine 1, and the two ends of the quenching oil pool 4 are respectively provided with a quenching furnace 11 and The tempering furnace 7 and the side of the quenching oil pool 4 are equipped with a draining oil conveying device 3 and a heat straightening machine 2, and the discharge end of the quenching furnace 11 is provided with a robot 9 that transports the leaf spring from the quenching furnace 11 to the heat straightening machine 2 One end of the draining oil conveying device 3 is provided with a robot 2 8 that transfers the leaf spring from the heat straightening machine 2 to the fully automatic frame ty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com