High-strength and high-toughness two skew-roll piercing method for 2219 aluminum alloy pipe

A technology for cross-rolling piercing and aluminum alloy tubes, which is applied in metal rolling, metal rolling, metal rolling stands, etc., can solve the problems of limited grain refinement effect, small overall deformation of the billet, and uneven wall thickness of the tube. , to control the wear of the nose of the plug, improve the uniformity of wall thickness, and achieve excellent mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

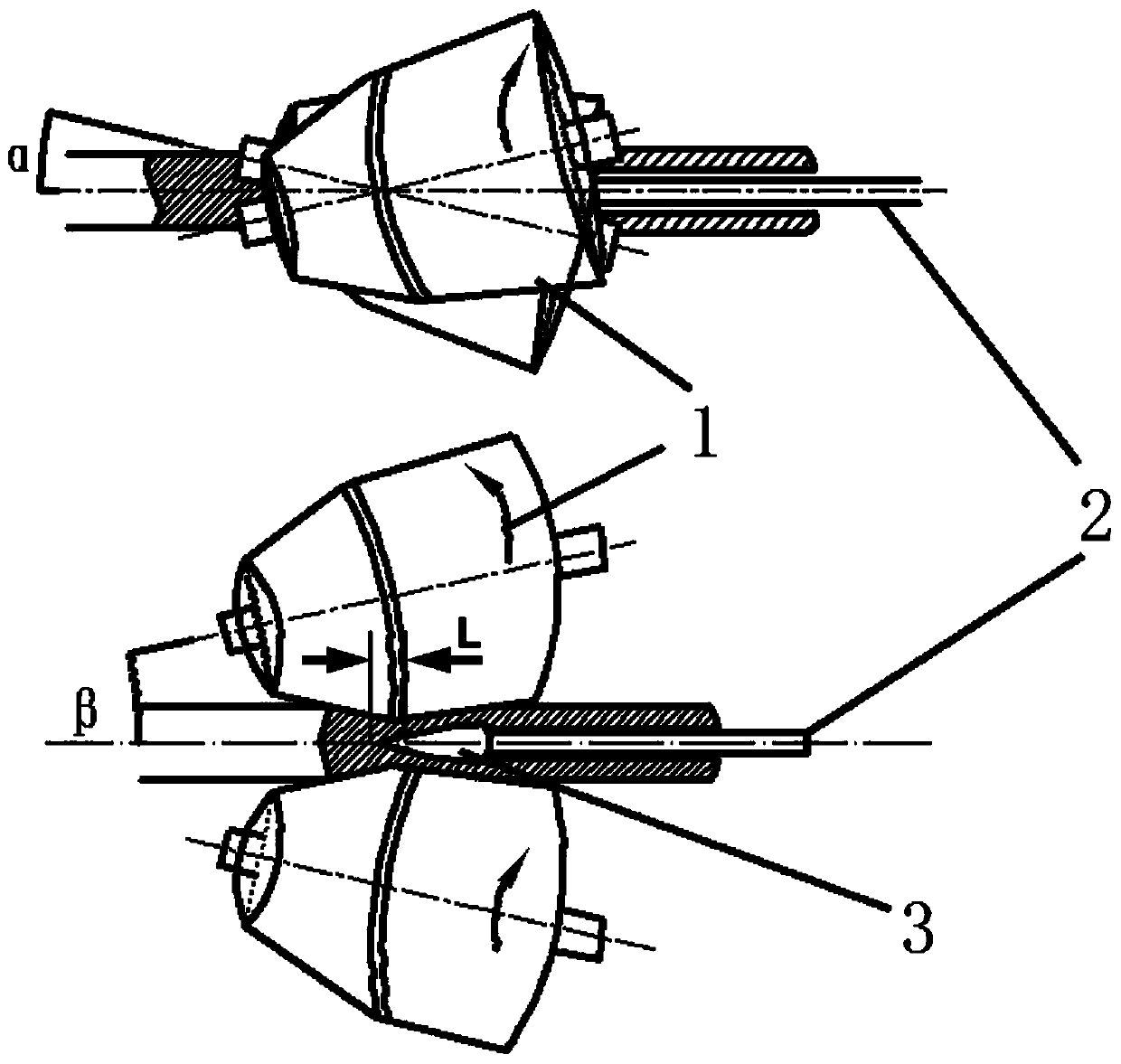

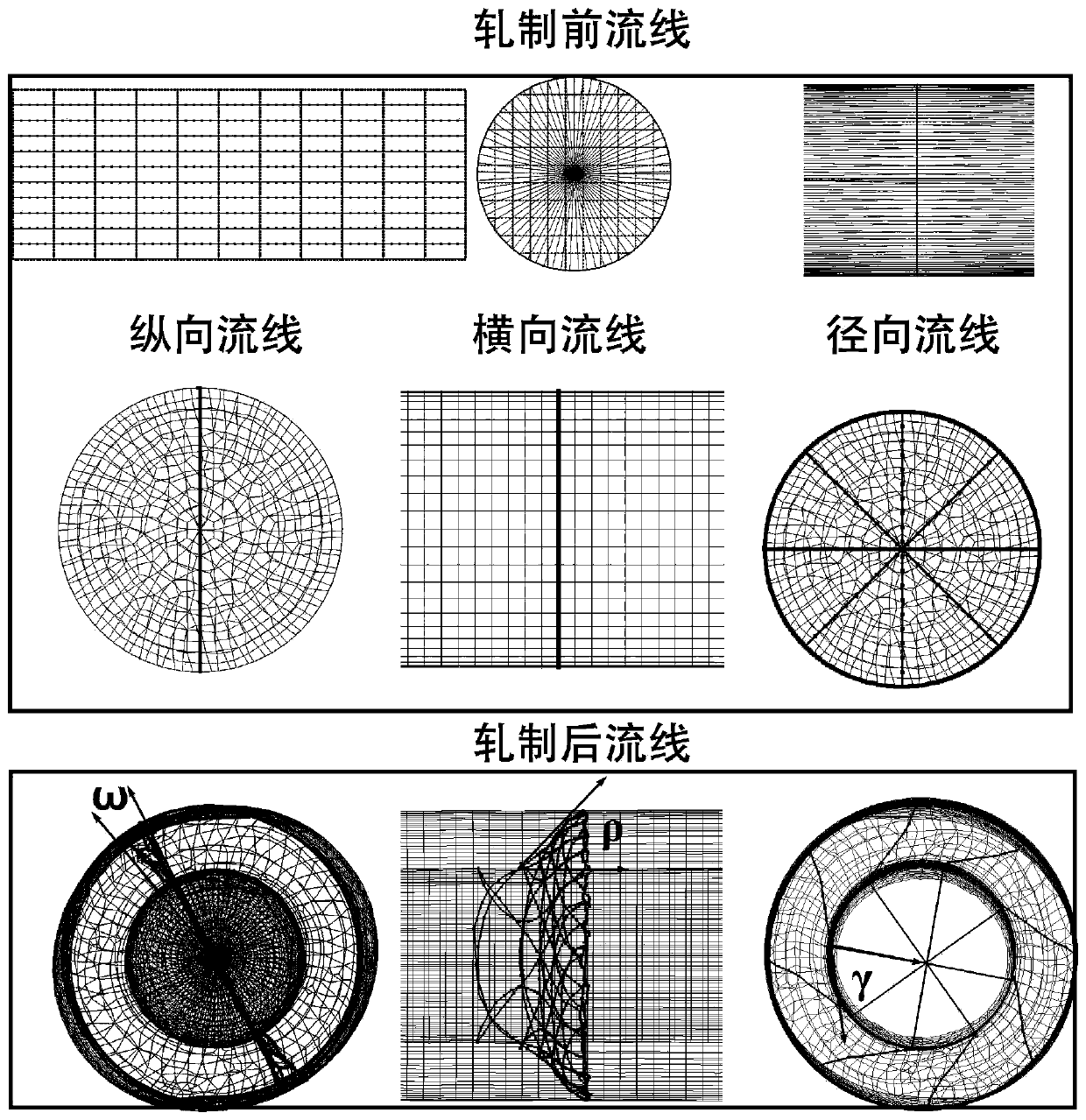

[0038] Take the production of 2219 aluminum alloy tubes with specifications of φ170×Φ100×595mm as an example, such as Figure 1-2 As shown, the production process of a high-strength two-roll cross-rolling piercing method for a 2219 aluminum alloy tube provided in this embodiment is as follows:

[0039] The 2219 aluminum alloy is smelted, forged and machined in a vacuum consumable electric arc furnace. The size of the cylindrical blank is Φ150×500mm, and the quality meets the requirements of cross-rolling and piercing.

[0040] (1) Heating

[0041] The above-mentioned 2219 aluminum alloy cylindrical billet was placed in a heating furnace for heating. The heating method was a warm-loaded furnace, the heating temperature was 450°C, and the holding time was 100 minutes.

[0042] (2) cross rolling piercing

[0043] Transfer the heated 2219 aluminum alloy cylindrical billet from the heating furnace to the guide groove of the skew rolling piercer, and the transfer time does not exc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com