Patents

Literature

58results about How to "Wear control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

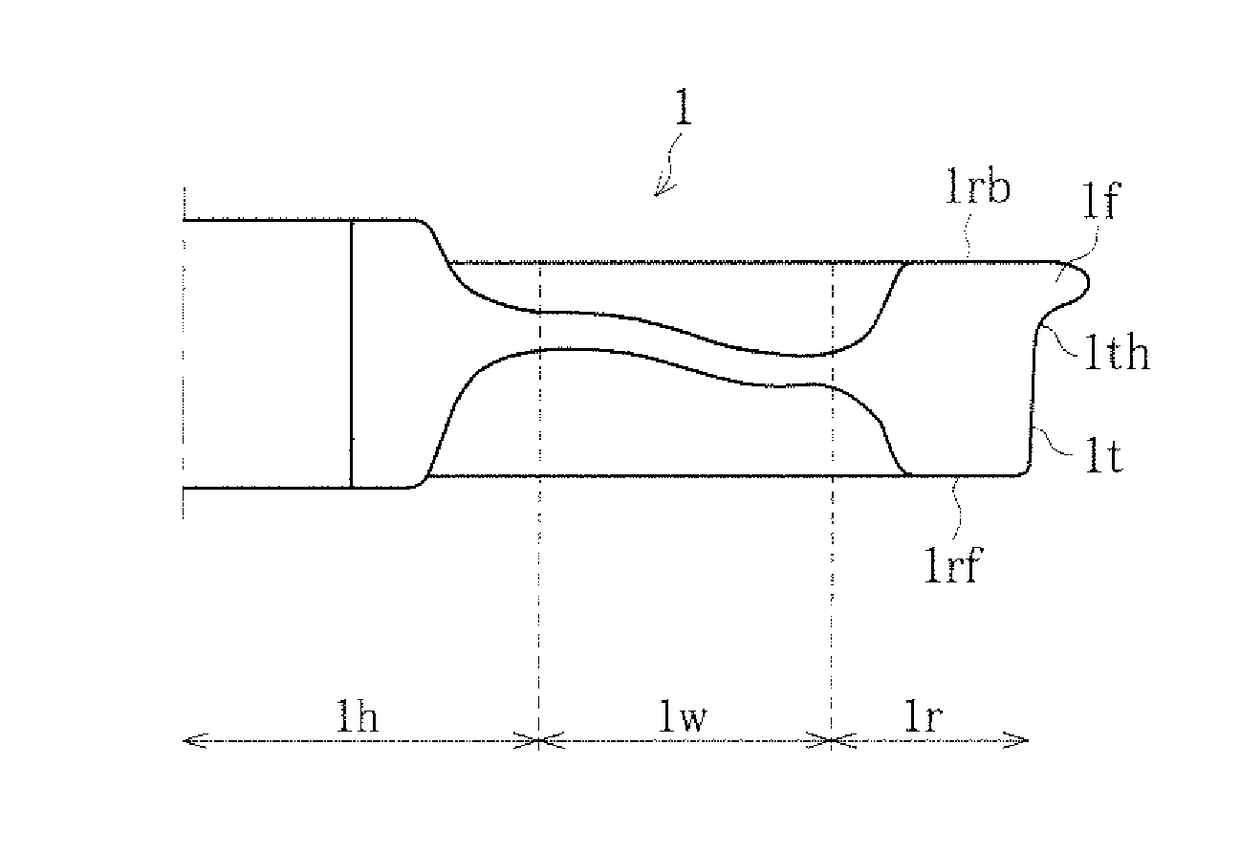

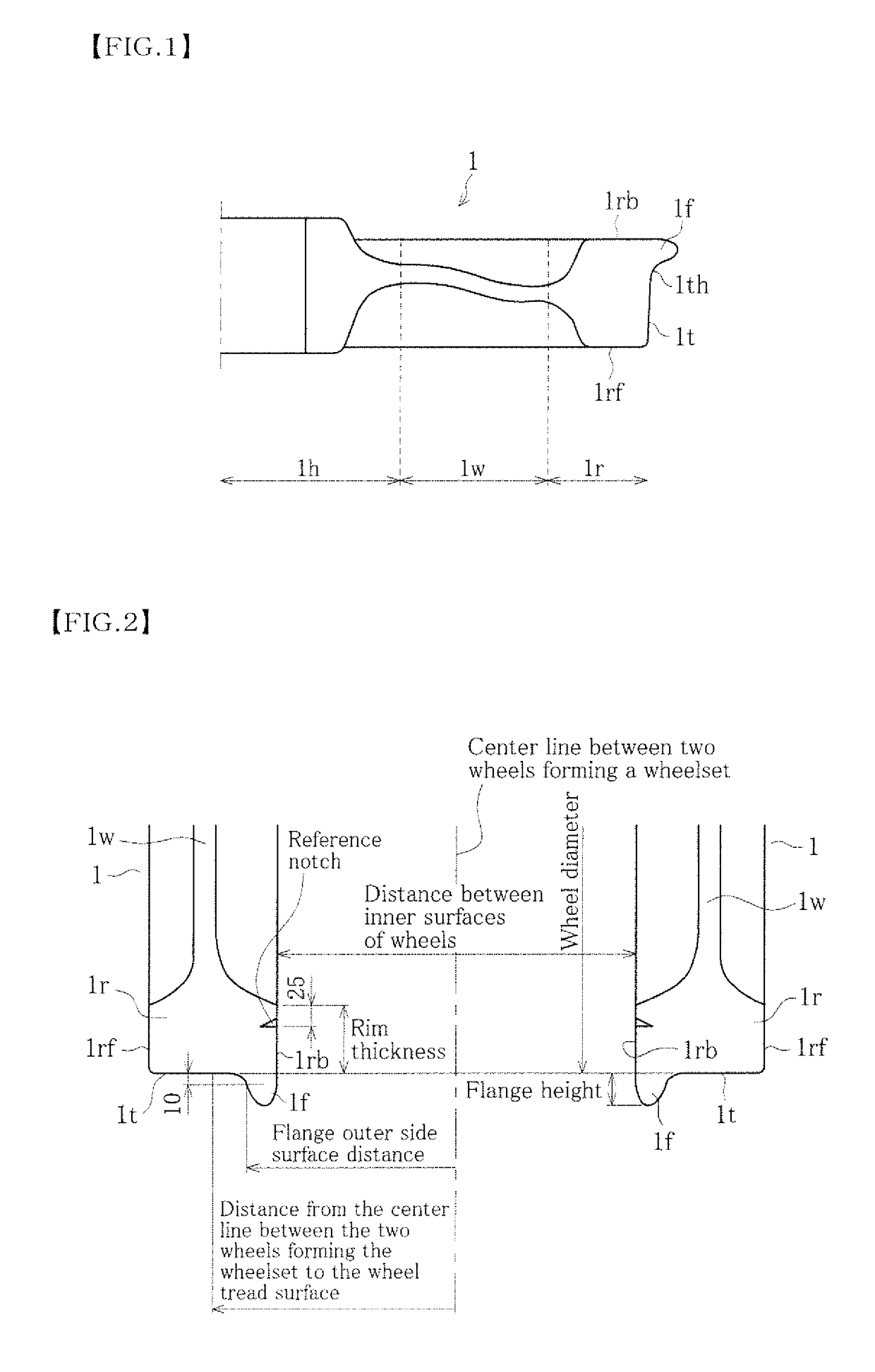

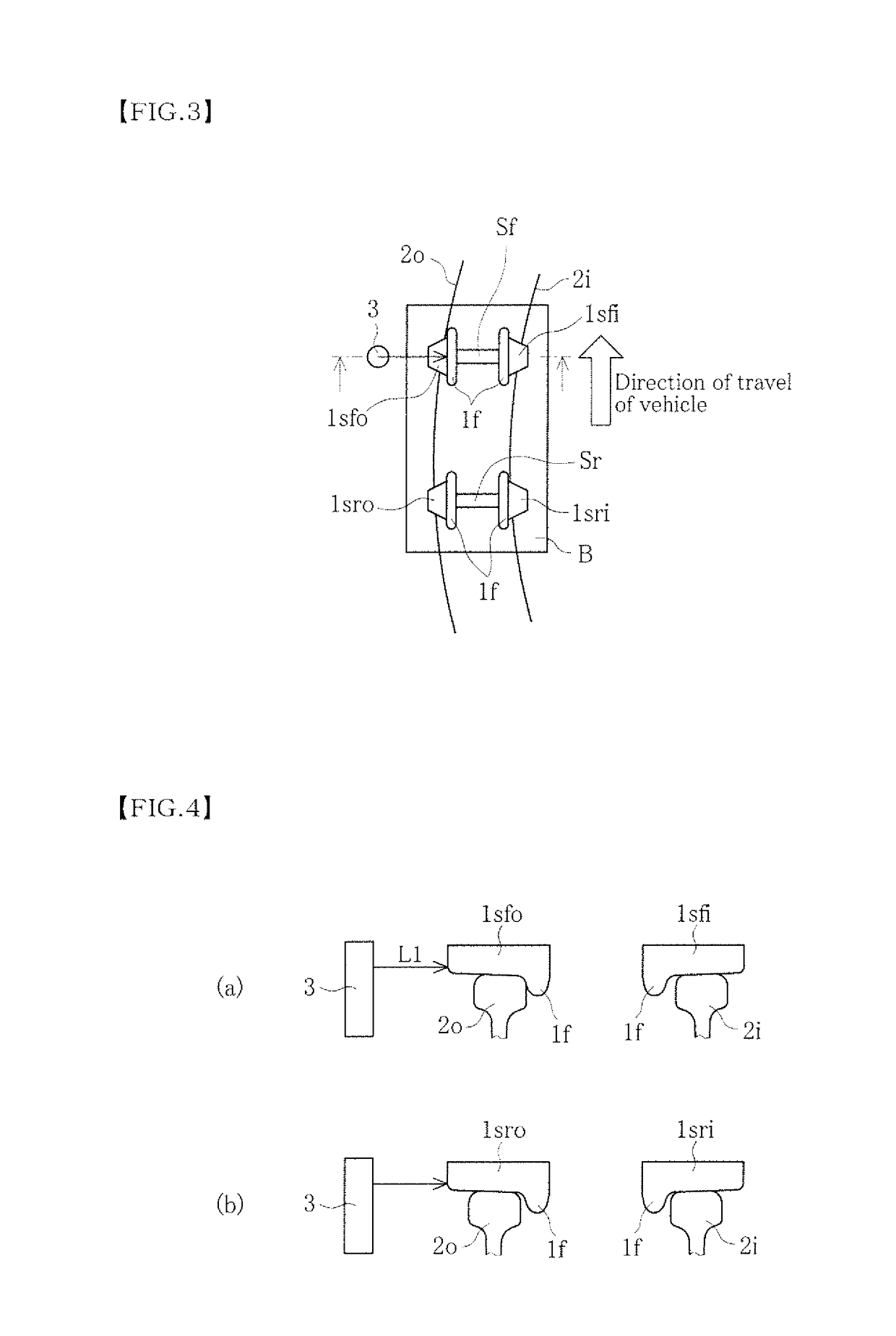

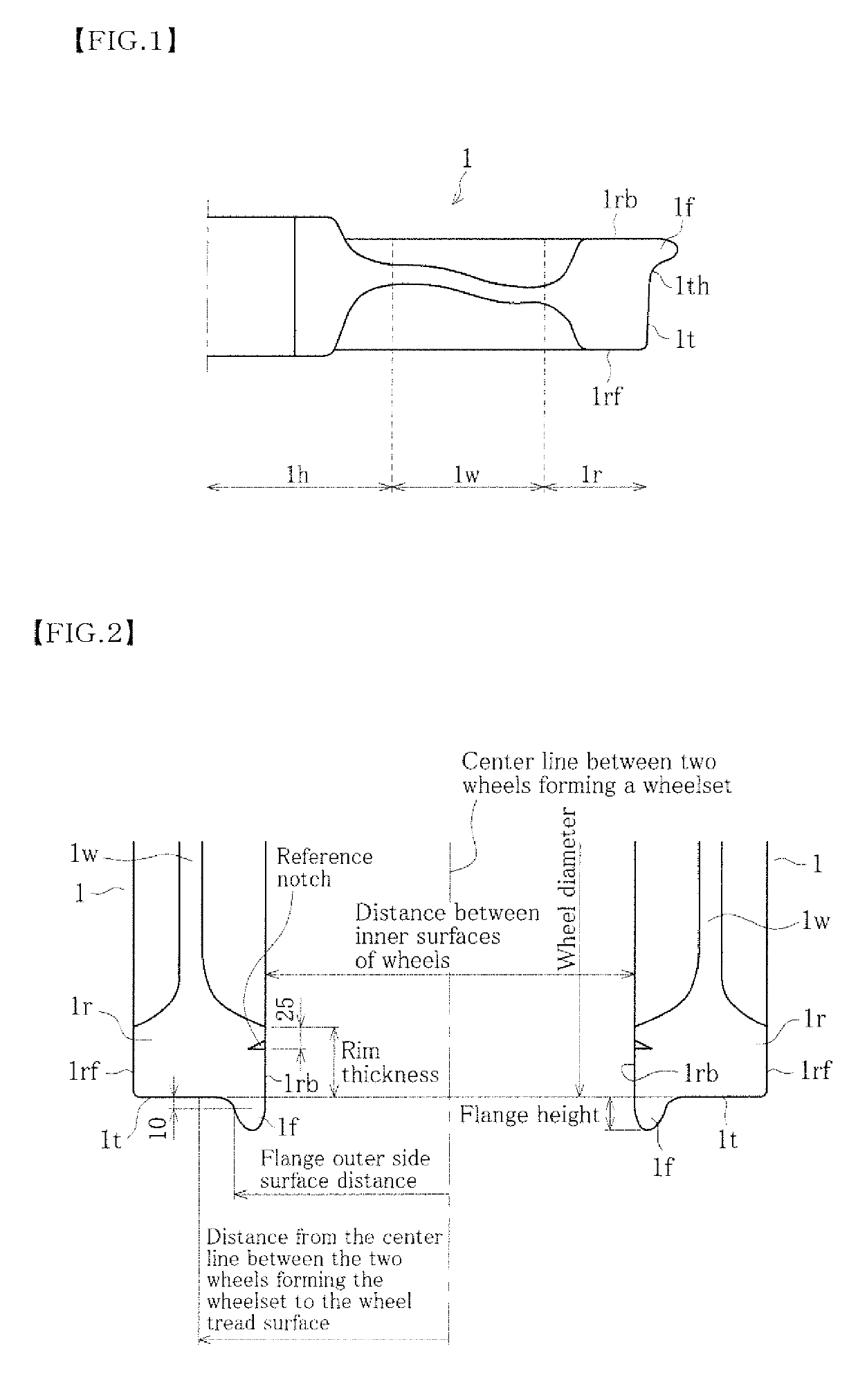

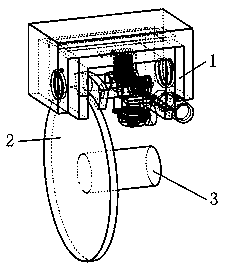

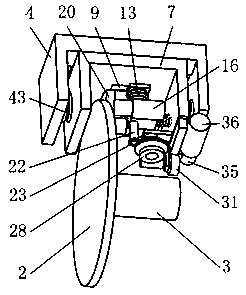

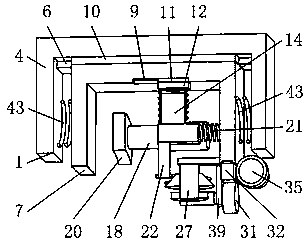

Method for measuring wear of railroad vehicle wheel flange

InactiveUS20170336293A1Quick wearExceeded control rangeWheel-rims surveying/measuringRailway traffic control systemsBogieLaser rangefinder

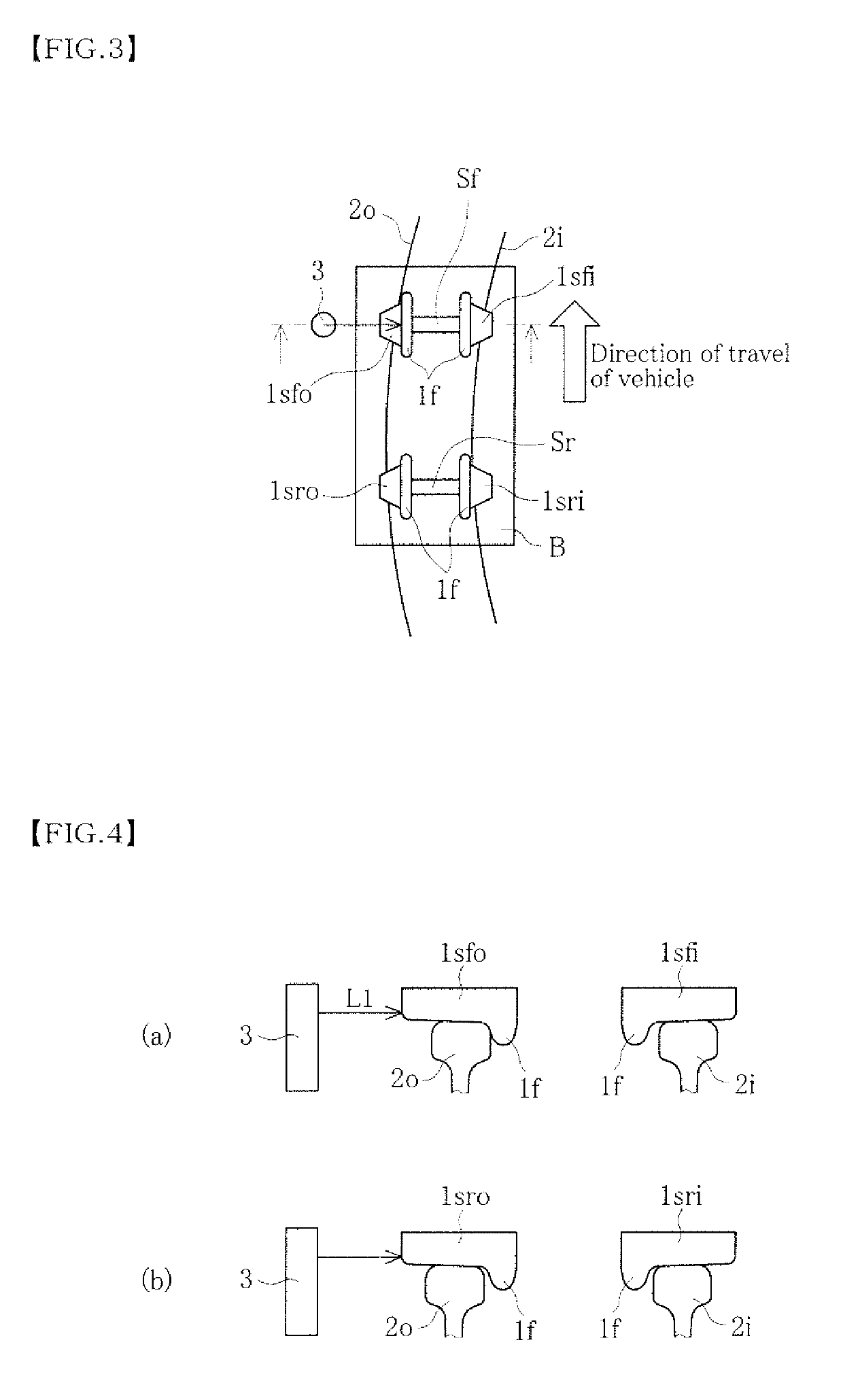

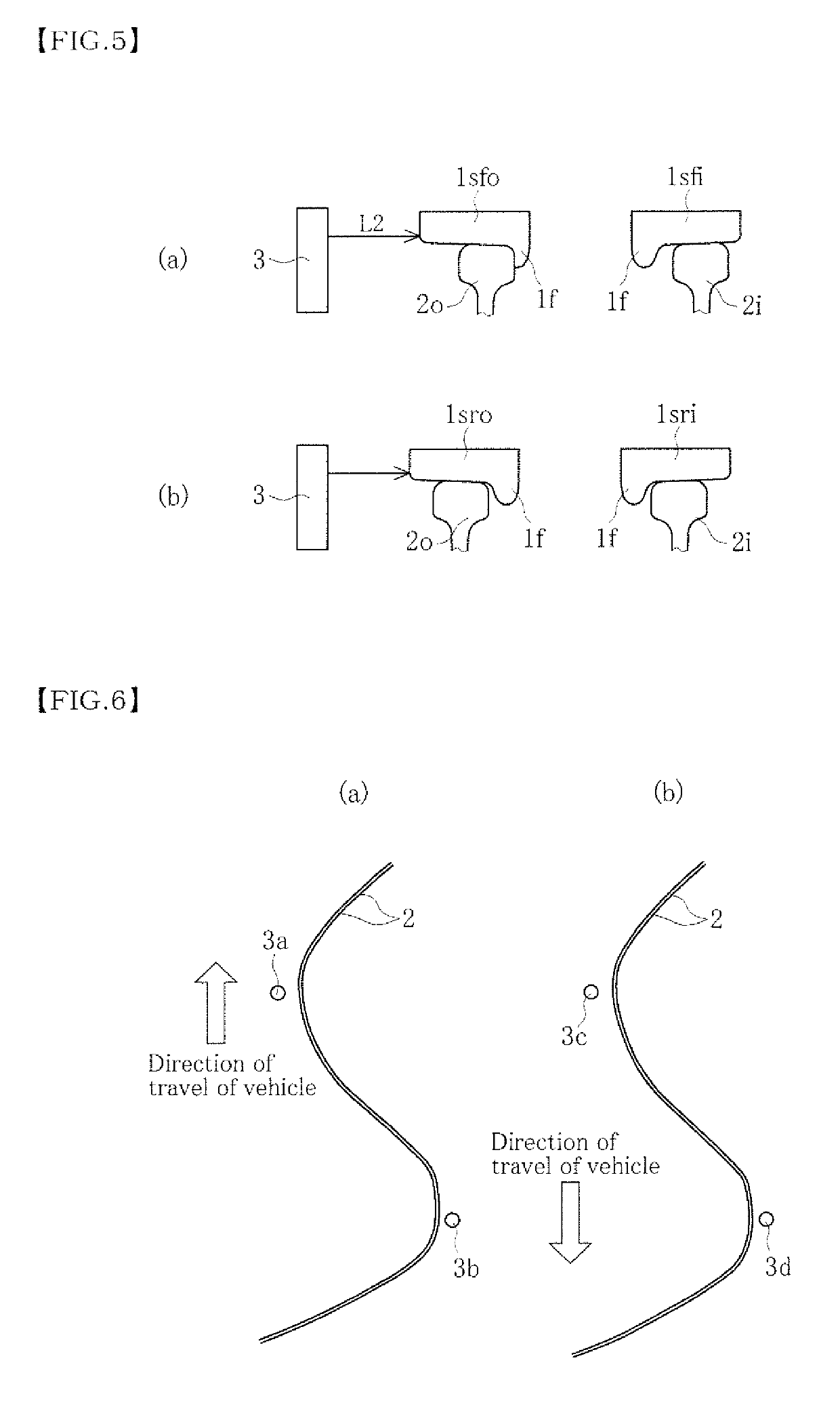

An amount of wear of a railroad vehicle wheel flange online while traveling in a curved section is directly measured. A laser rangefinder 3 is installed on an outer track side in a rounded curve section of a railroad track. When a railroad vehicle travels through the rounded curve section, the laser rangefinder 3 measures a distance to a front rim surface of a wheel on an outer track side of a wheelset in a forward direction of travel of a bogie forming a vehicle. The amount of wheel flange wear is obtained by comparing this measured distance with a previous measurement of the measured distance. It is then possible to control the amount of wheel flange wear when traveling in a curved section, thus making it possible to quickly find wheels having flange wear that has exceeded a control range and ensure safety during travel of the railroad vehicle.

Owner:NIPPON STEEL CORP

Method for measuring wear of railroad vehicle wheel flange

InactiveUS10352831B2Wear controlQuick wearWheel-rims surveying/measuringRailway traffic control systemsBogieEngineering

An amount of wear of a railroad vehicle wheel flange online while traveling in a curved section is directly measured. A laser rangefinder 3 is installed on an outer track side in a rounded curve section of a railroad track. When a railroad vehicle travels through the rounded curve section, the laser rangefinder 3 measures a distance to a front rim surface of a wheel on an outer track side of a wheelset in a forward direction of travel of a bogie forming a vehicle. The amount of wheel flange wear is obtained by comparing this measured distance with a previous measurement of the measured distance. It is then possible to control the amount of wheel flange wear when traveling in a curved section, thus making it possible to quickly find wheels having flange wear that has exceeded a control range and ensure safety during travel of the railroad vehicle.

Owner:NIPPON STEEL CORP

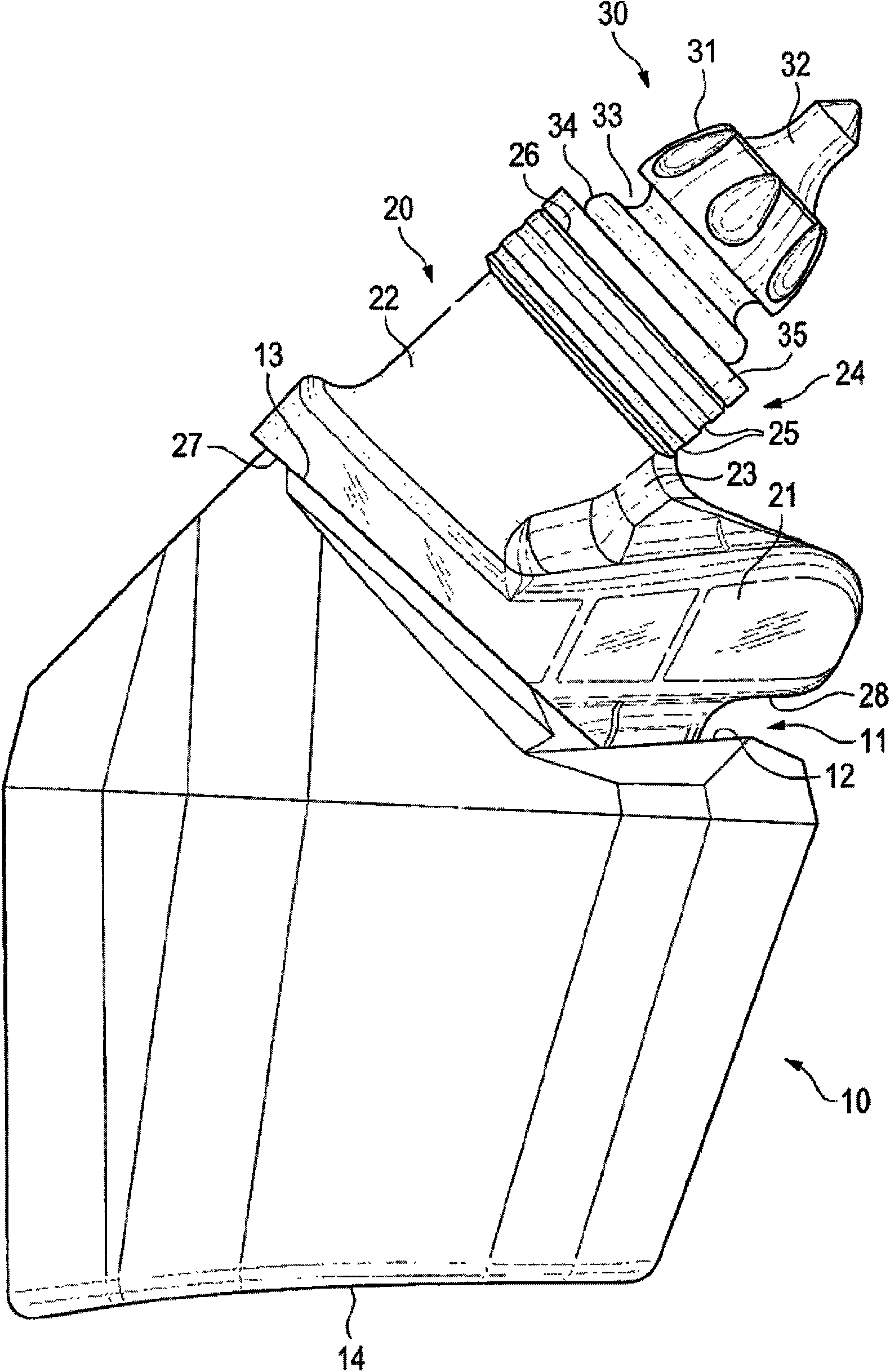

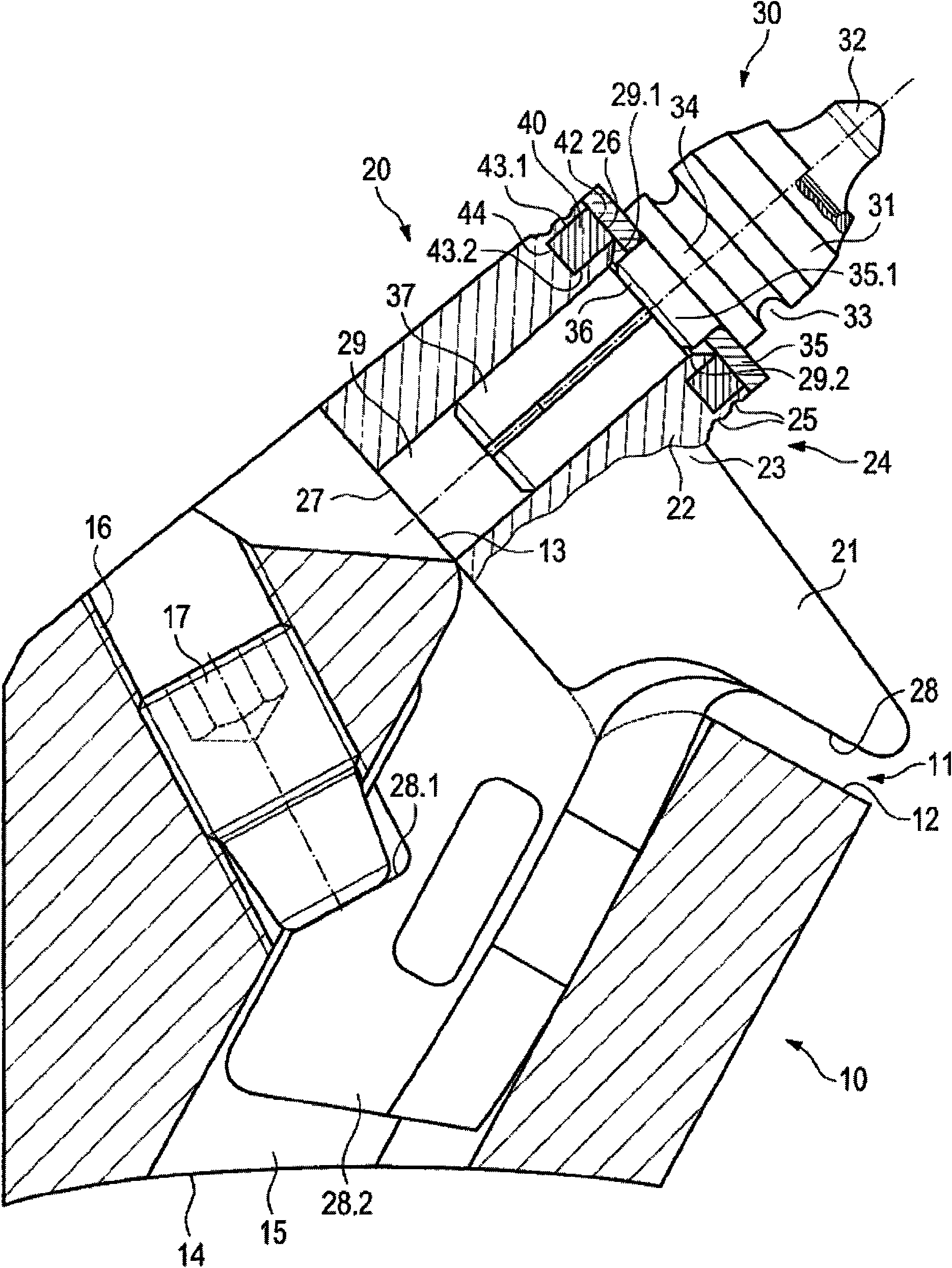

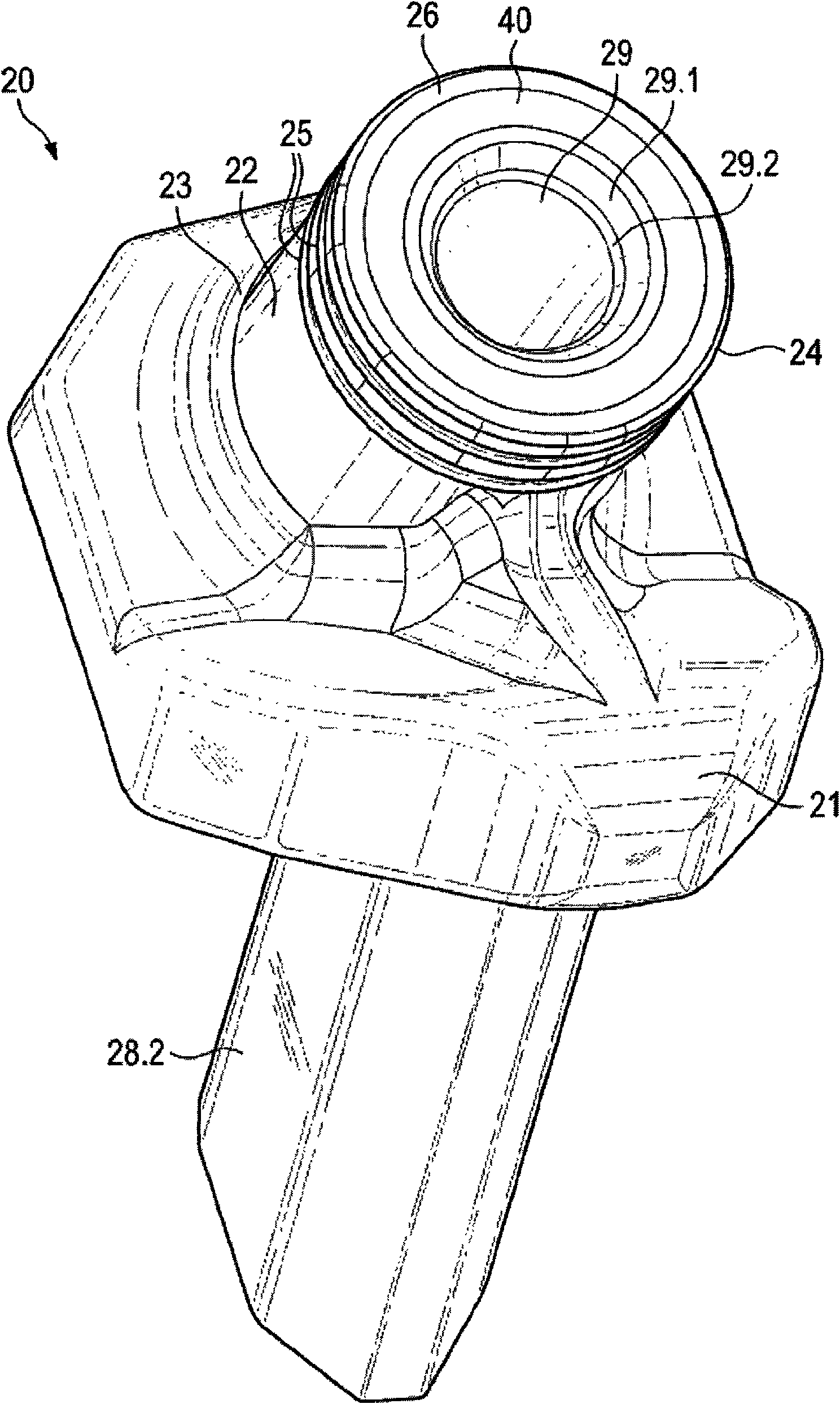

Chisel holder

ActiveCN101666229AConstant wear resistanceReliable arrangementSlitting machinesCutting machinesChiselSupport surface

The invention relates to a chisel holder for a cutting machine, road milling machine, surface miner, or the like, having a chisel receptacle, which comprises an insertion opening, and having a chiselsupporting surface, wherein at least one wear protection element is arranged in an area associated with the chisel supporting surface. In order to bring about effective wear protection in such a chisel holder at low cost, it is provided that the at least one wear protection element is designed as a weld and is arranged at least in areas in at least one opening.

Owner:WIRTGEN GMBH

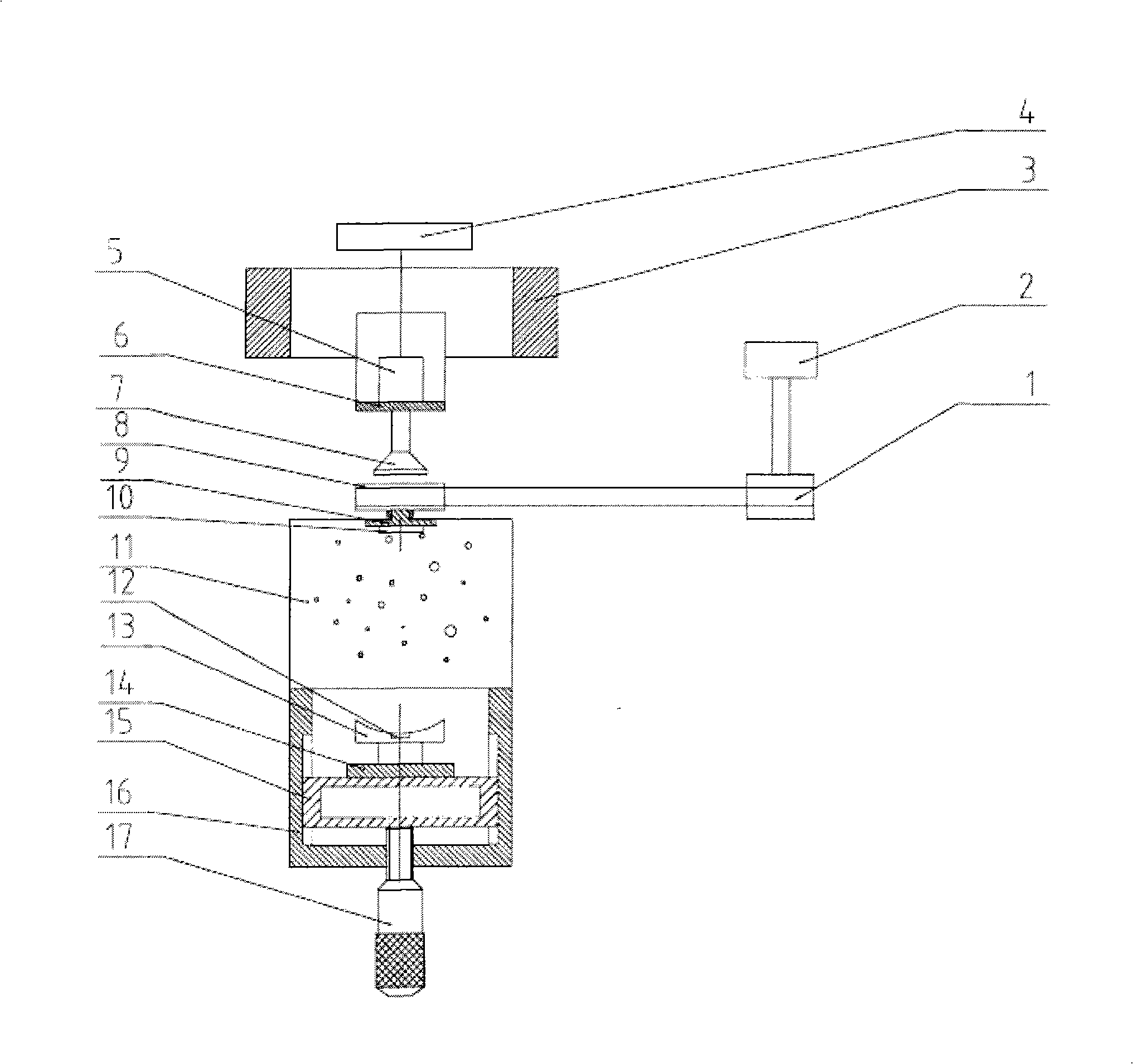

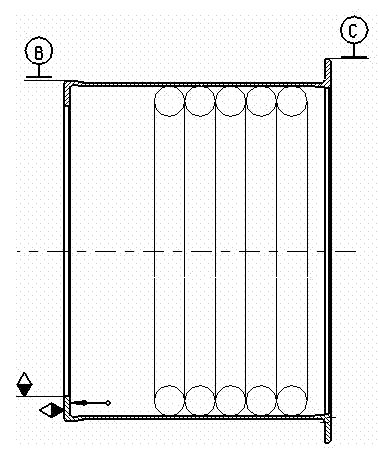

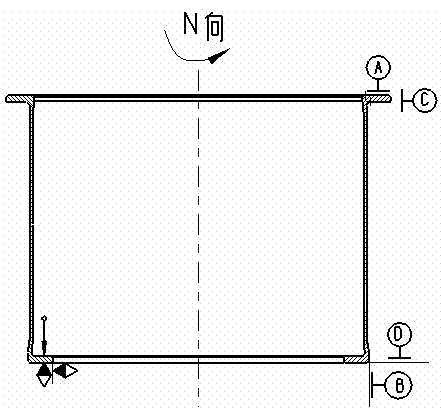

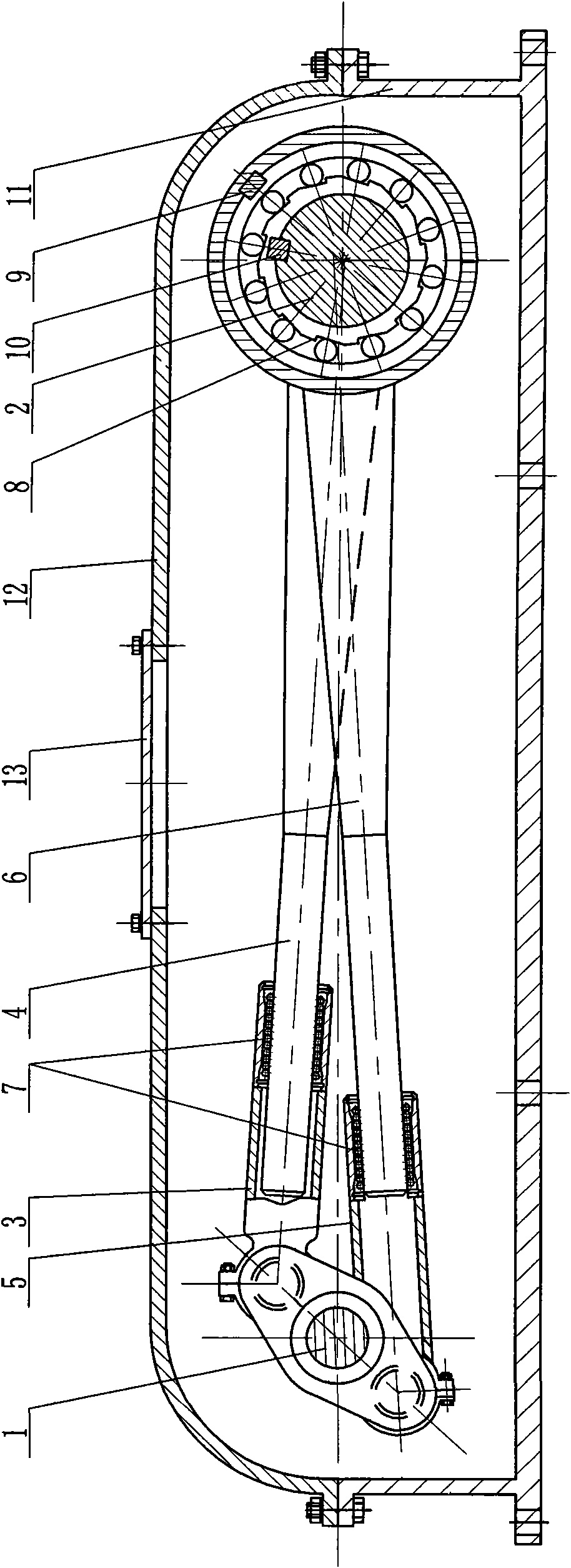

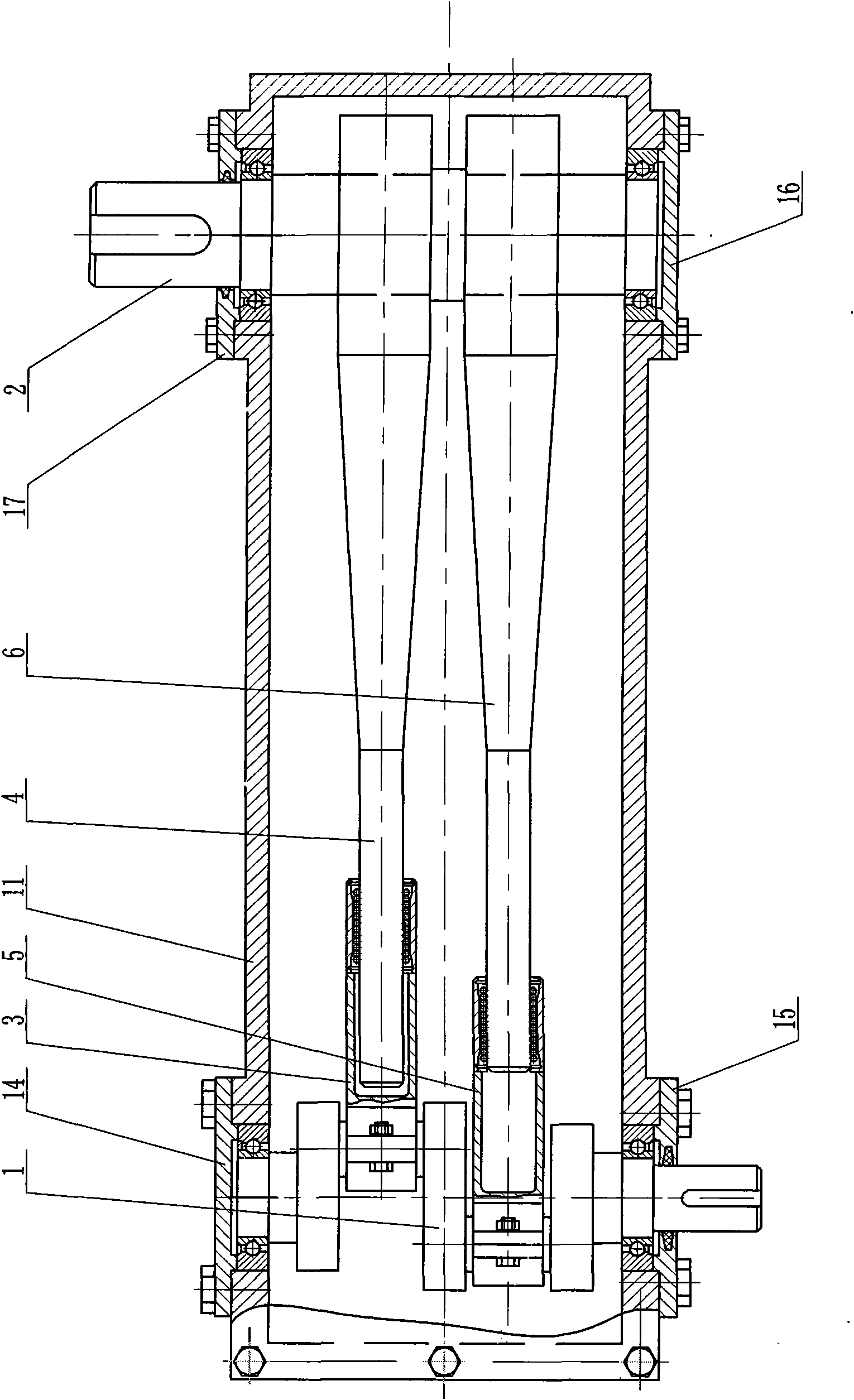

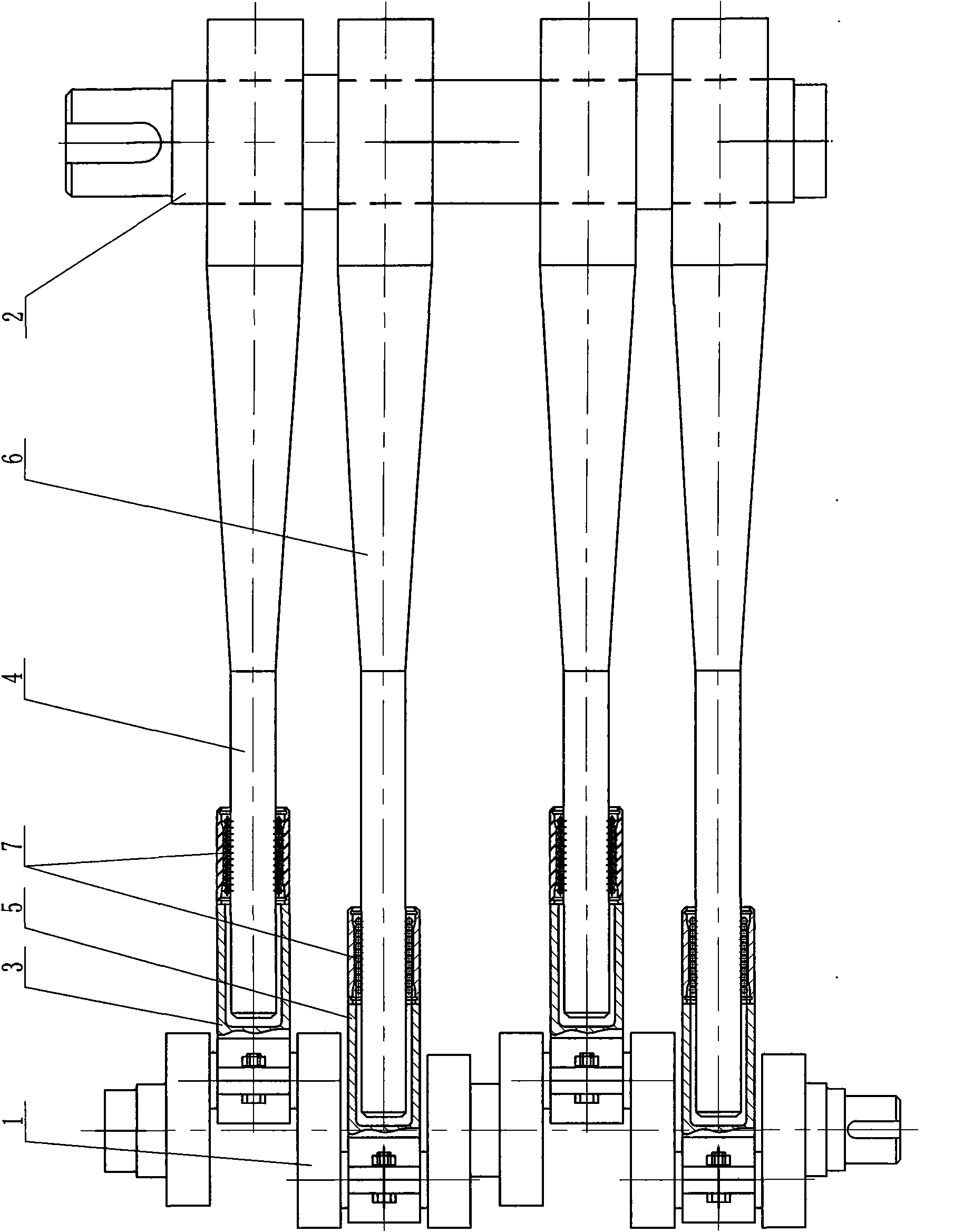

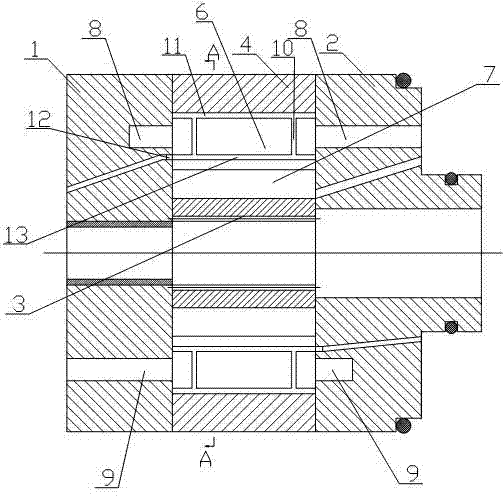

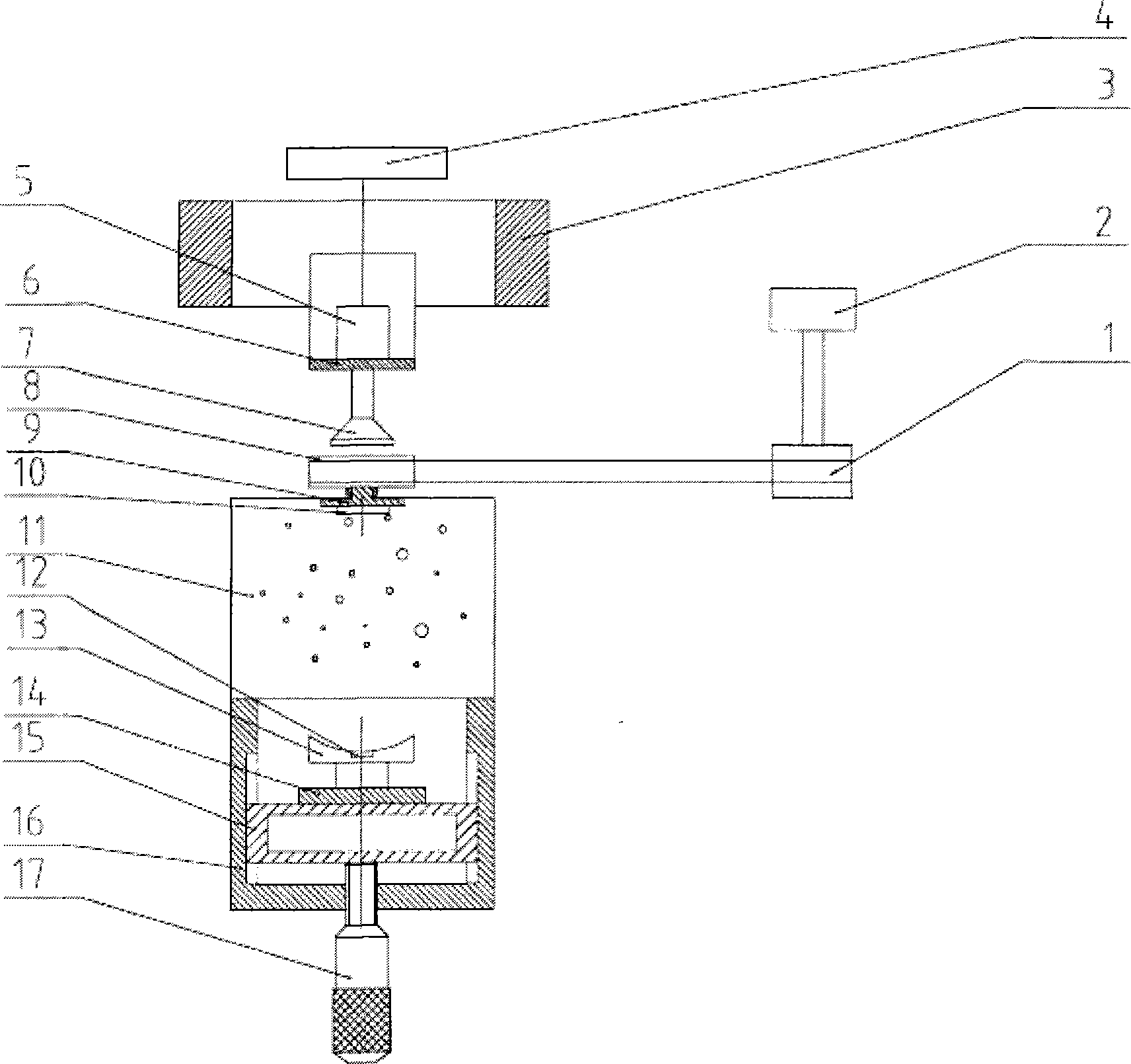

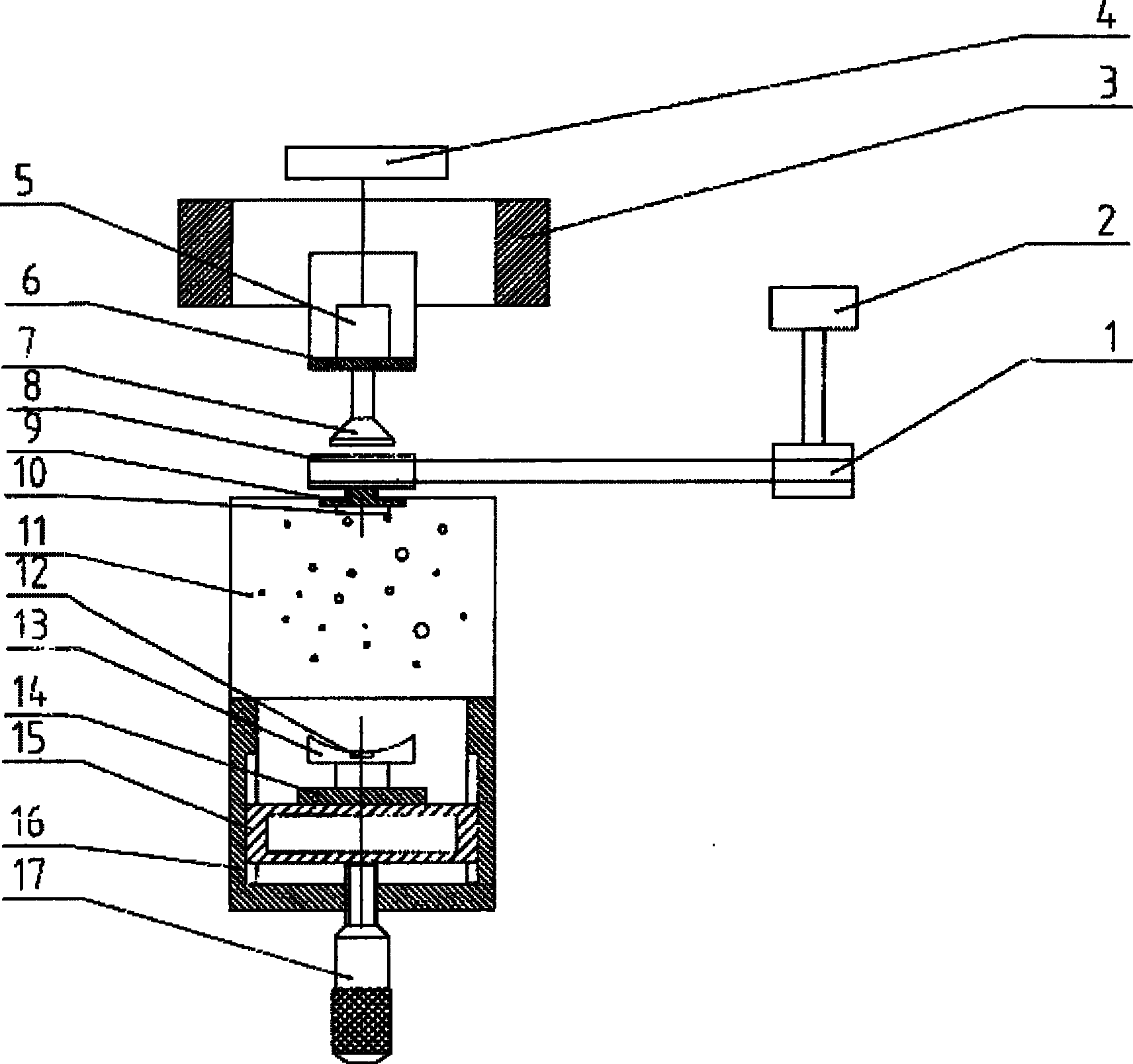

Sound suspending polissoir for nanometer mechanics characterization sample

InactiveCN101344468AAchieve removalGood dispersionPreparing sample for investigationUltrasonic sensorTest sample

The invention discloses an acoustic levitation polishing machine of mechanically representing nano test samples and comprises a machine frame, a pulse power source, a holding fixture that is used for clamping a working piece to be processed, an ultrasonic energy transducer, a container that is used for storing polishing liquid, an ultrasonic reflecting end, and a tuning mechanism that is used for adjusting the distance between the ultrasonic reflecting end and the ultrasonic energy transducer. The ultrasonic energy transducer, the container and the tuning mechanism are all arranged above the machine frame, the pulse power source is connected with the ultrasonic energy transducer, the container is arranged under the ultrasonic energy transducer, the holding fixture is arranged above the container and is connected with a belt wheel actuating mechanism, and the ultrasonic reflecting end is arranged under the container, coordinated with the ultrasonic energy transducer and connected with the tuning mechanism. The invention provides an acoustic levitation polishing machine of the mechanically representing nano test samples with good applicability and well polishing effect.

Owner:ZHEJIANG UNIV OF TECH

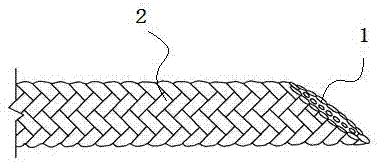

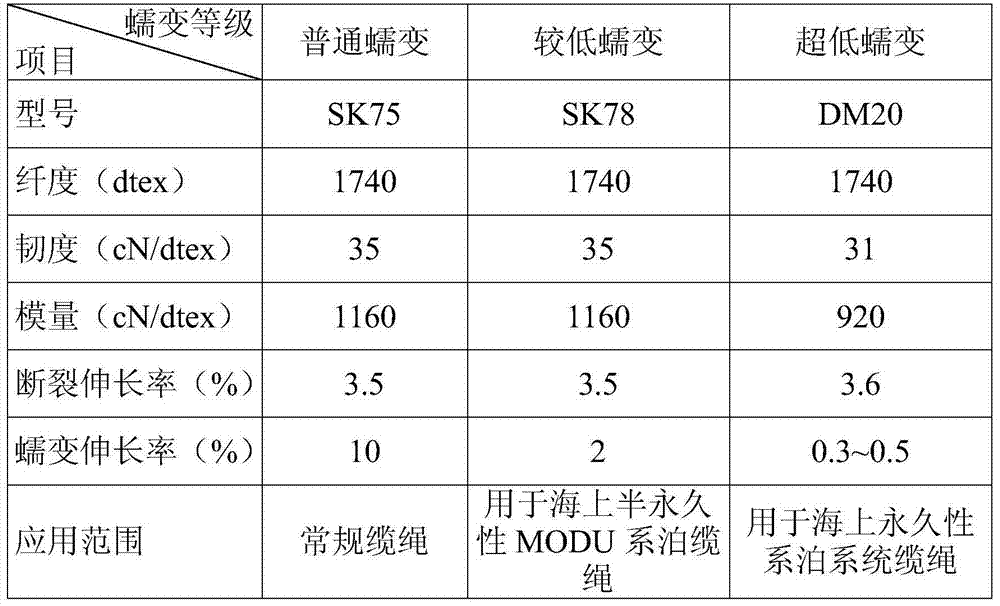

Offshore underwater component device mooring cable and manufacturing method thereof

The invention relates to an offshore underwater component device mooring cable. The offshore underwater component device mooring cable is characterized by being of a sheath-core composite double-layer structure, an inner core is of a eight-strand structure made of DM20 ultra-high molecular weight polyethylene, an outer layer is a fixing sheath formed by weaving wear-proof high-strength polyester fibers, the inner core is formed according to the steps of manufacturing rough yarn, manufacturing rope yarn, manufacturing strands, weaving ropes, soaking the inner core in resin, prestretching the inner core and drying the inner core, and the fixing sheath is formed according to the steps of splicing threads, twisting the threads, manufacturing strands and weaving the 32 strands around the inner core into the fixing sheath in a one-off mode through a double-layer weaving machine.

Owner:TAIZHOU HONG DA ROPE & NET

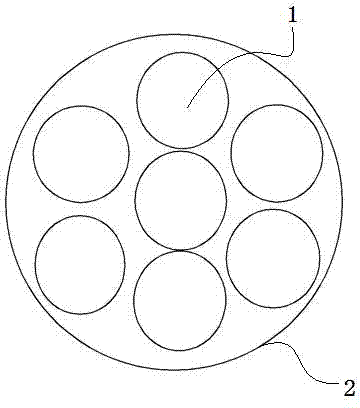

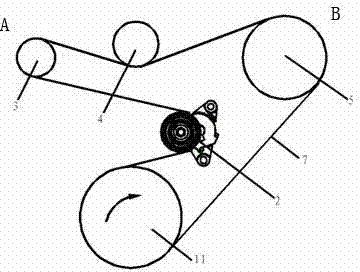

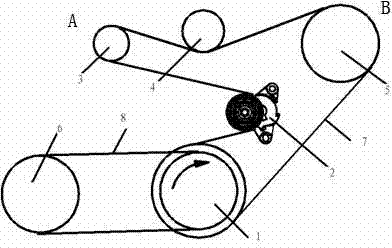

A kind of automobile engine front end accessory wheel train system

A front-end accessory wheel train system of an automobile engine comprises a crankshaft pulley with double-layer pulleys, an automatic tensioner pulley, an alternator pulley, an idler pulley, a water pump pulley, an air conditioner compressor pulley and two V-belts. The system is divided into two layers of accessory gear trains; the first layer is connected by the first V-ribbed belt clockwise to the crankshaft pulley, the first layer of the crankshaft pulley, the automatic tensioner, the alternator pulley, the idler pulley and the water pump pulley. Composition; the second layer is formed by connecting the second layer of the crankshaft pulley and the pulley of the air conditioner compressor sequentially by the second V-ribbed belt along the clockwise direction of the crankshaft pulley. Also, the alternator pulley is on the intake manifold side, and the water pump pulley is on the exhaust manifold side. The invention uses the automatic tensioning wheel and the elastic belt to solve the problems that the V-ribbed belt is easy to loosen when the V-ribbed belt is extended during the after-sales use of the front-end accessory wheel system of the engine, resulting in abnormal slipping noise and wear, and at the same time, it also takes into account the switching of the whole vehicle The air conditioner compressor is convenient and fast, and at the same time, it also considers the beauty of the engine and avoids the heat damage of the generator.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Automobile brake device

ActiveCN109050497AAvoid damageReduce replacement cycleBraking element arrangementsBraking action transmissionFriction forceBraking system

The invention belongs to the automobile brake field, in particular to an automobile brake device, which comprises a brake mechanism, a brake disc and a wheel axle, wherein the brake disc is mounted onone end of the wheel axle of the automobile; The brake mechanism is fixedly installed on the vehicle body, and the brake mechanism is matched with the brake disc; During the braking process, the contact area between the brake pads and the brake discs increases, which decreases the friction force per unit area on the friction surface between the brake pads and the brake discs, effectively controlsthe wear of the brake pads and the brake discs, and further prolongs the service life of the brake pads and the brake discs. During the braking process, two brake pads of the two brake pad mechanismsrespectively contact with two end faces of the brake disc and generate friction, so that the forces on the two end faces of the brake disc are balanced, the damage of the brake disc caused by long-term unilateral force is avoided, the brake disc replacement cycle is delayed, and the maintenance cost of the brake system of the automobile is reduced.

Owner:上海八幡五金有限公司

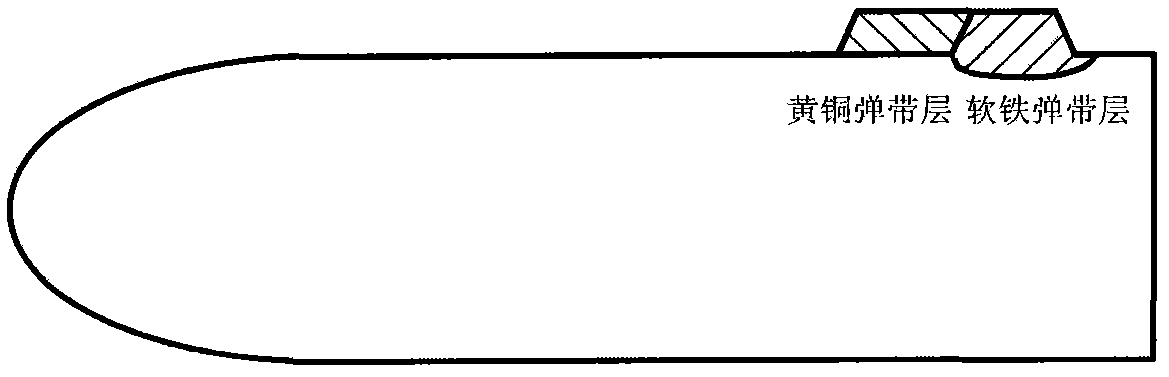

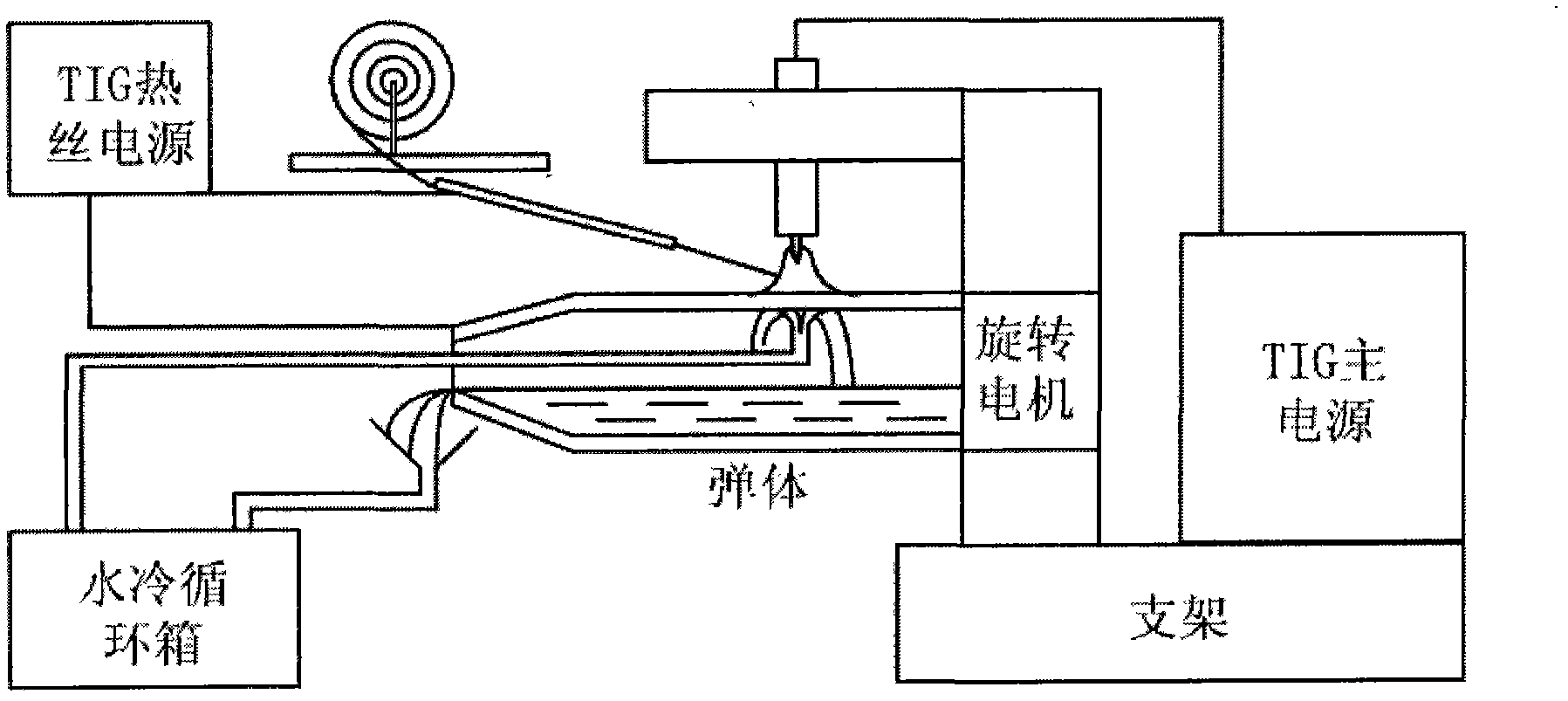

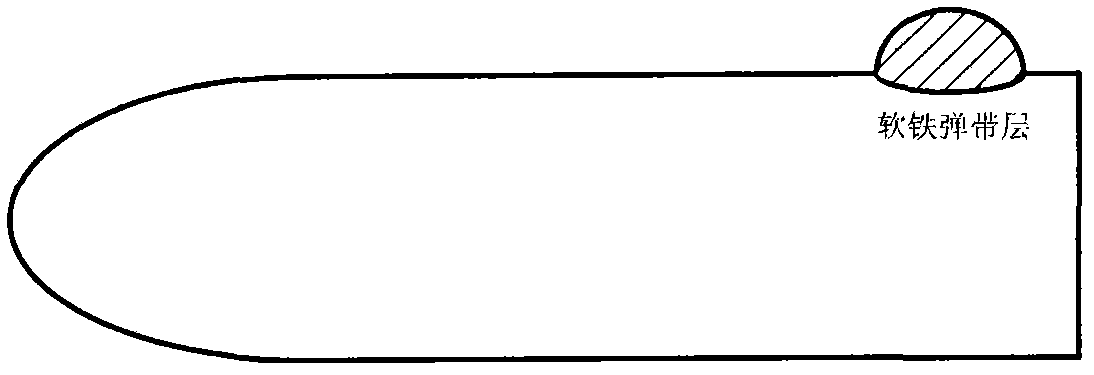

Soft iron-brass composite band structure and welding method thereof

InactiveCN102636084AHigh strengthIncrease stiffnessAmmunition projectilesArc welding apparatusHardnessUltimate tensile strength

The invention provides a soft iron-brass composite band structure and a welding method thereof. The soft iron-brass composite band structure uses two materials of soft iron and brass to overlay on the surface of an elastic body; the soft iron is located at the back of a band; and a brass part is located at the front part of the band. The welding method comprises the following steps of: firstly, welding a soft iron part; overlaying the brass part after cutting and machining to be flat; and finally, secondarily machining to form the entire band meeting design requirements. According to the soft iron-brass composite band structure and the welding method thereof provided by the invention, the properties and functions of the band can be improved by using own characteristics of the brass and the soft iron to complement the advantages of the brass and the soft iron. The characteristic of good air closeness of a soft iron band is maintained by using the composite band, so as to achieve a wider cannonball firing range. Compared with a brass band, the composite band only has the advantage that a half amount of the brass is used, so that the manufacturing cost is lowered. The composite band has the advantage of larger flexibility. Compared with the brass band, the soft iron band has the advantages of high strength, high rigidity and better air closeness. The rigidity, air closeness and the like of the band can be adjusted by adjusting the ratio of the soft iron and the brass in the band.

Owner:HARBIN INST OF TECH

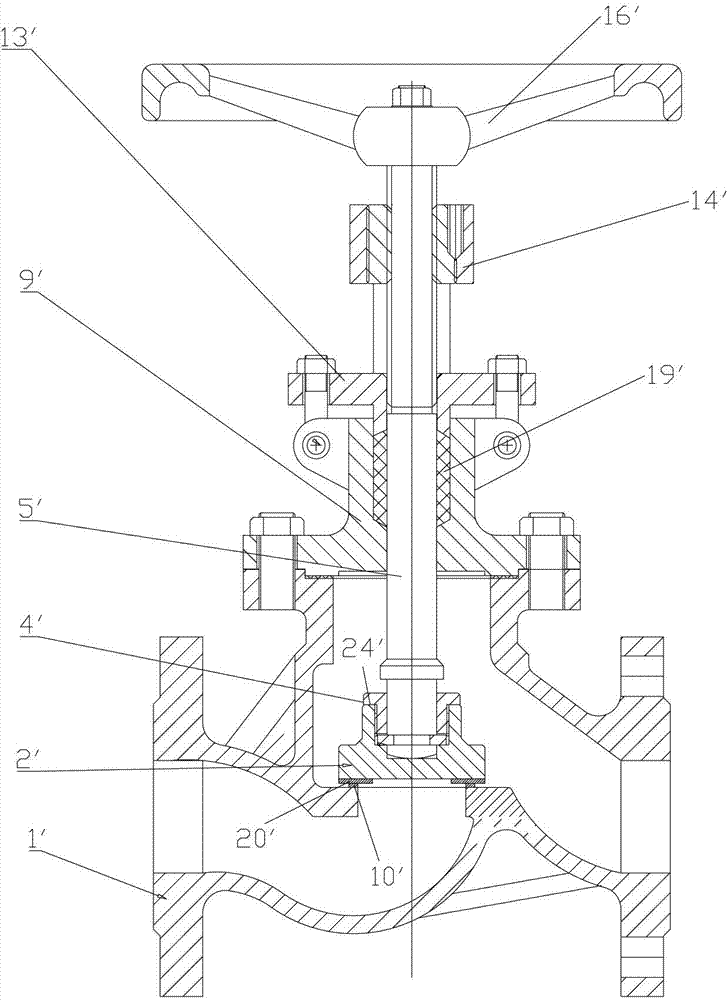

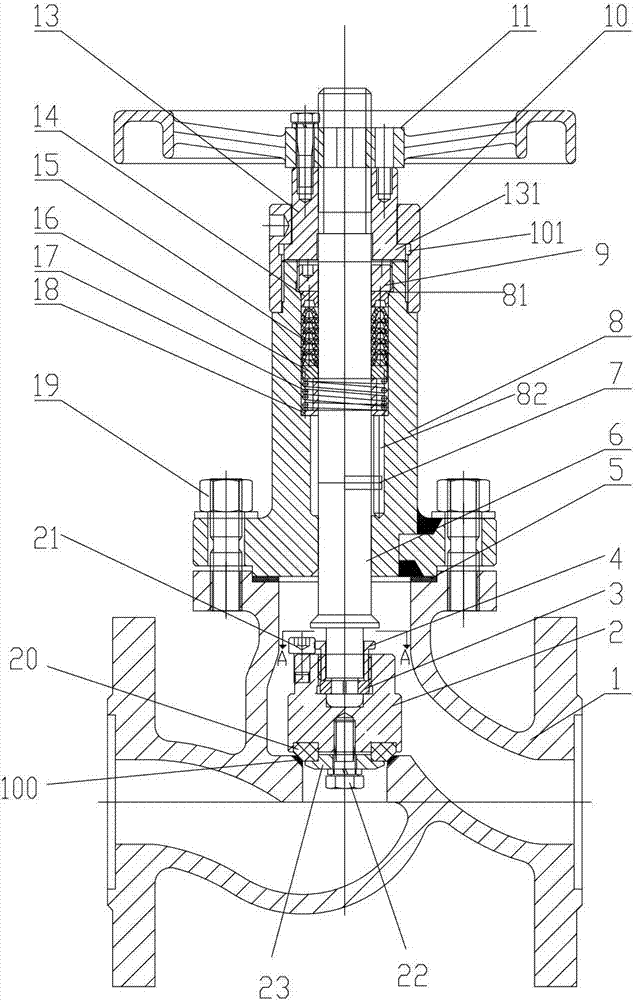

Stop valve

The invention provides a stop valve, which is provided with a valve body, a valve cover is fixedly arranged on the valve body and is internally provided with sealing filler, a valve-stem nut is arranged above the valve cover, a valve stem penetrates through the valve-stem nut, the sealing filler and the valve cover, and extends into the valve body, the lower tail end of the valve stem is connected with a valve clack, and a valve clack sealing surface of the valve clack is matched with a valve seat sealing surface in the valve body. The stop valve is characterized in that the upper end of the valve cover is fixedly connected with a valve-stem nut stopper which is provided with a circular groove, an annular protruded wall of the valve-stem nut is embedded into the circular groove, the valve-stem nut is capable of rotating, external threads of the valve stem are in screw arrangement with internal threads of the valve-stem nut, the inner wall of the valve cover is provided with a guide groove, and a locating pin, extending towards the lateral direction, of the valve stem extends into the guide groove to cause the valve stem to perform axial movement. The stop valve, disclosed by the invention, is long in service life, good in sealing performance and low in cost.

Owner:ZIGONG HUAXI PUMP & VALVE MFR

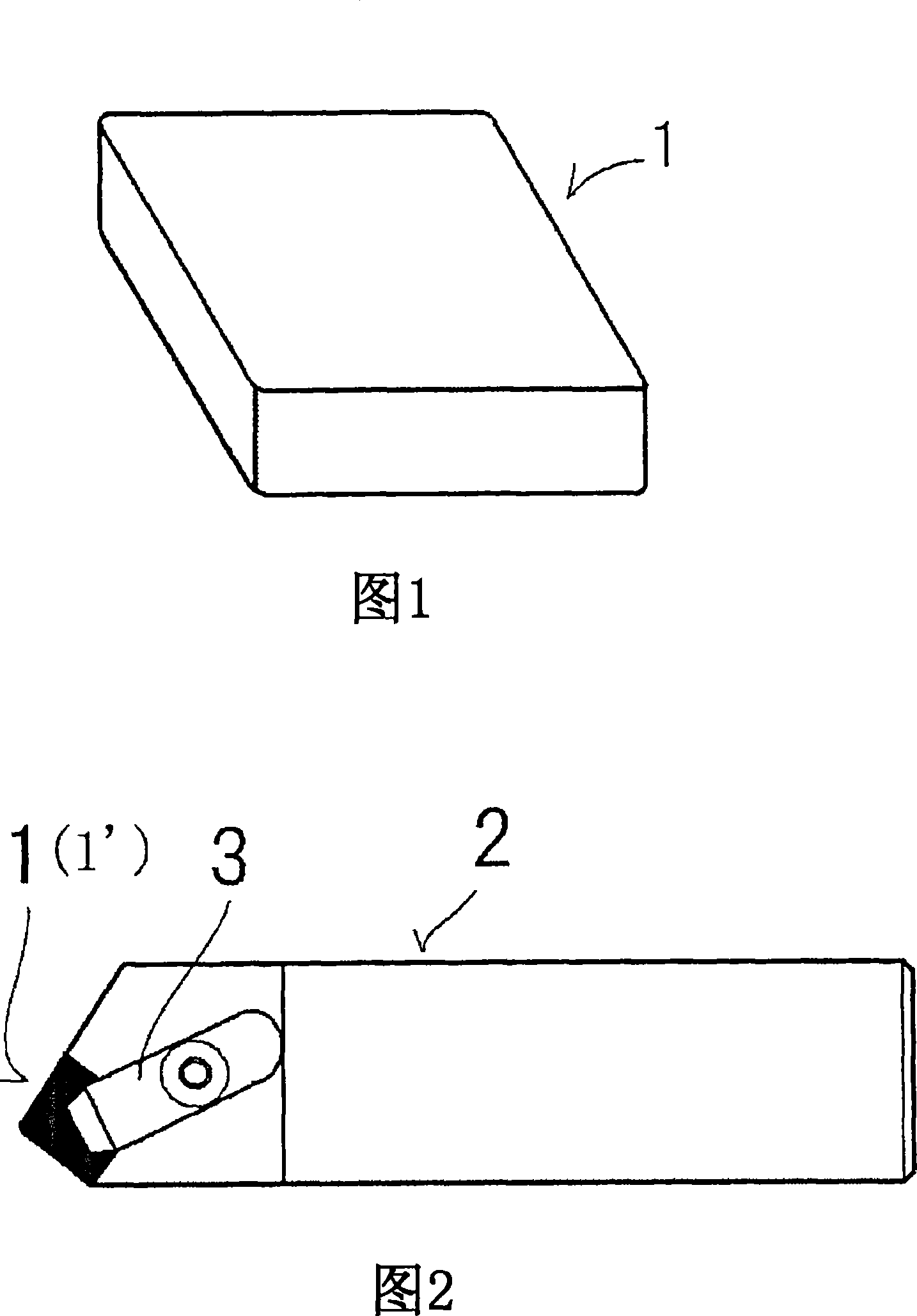

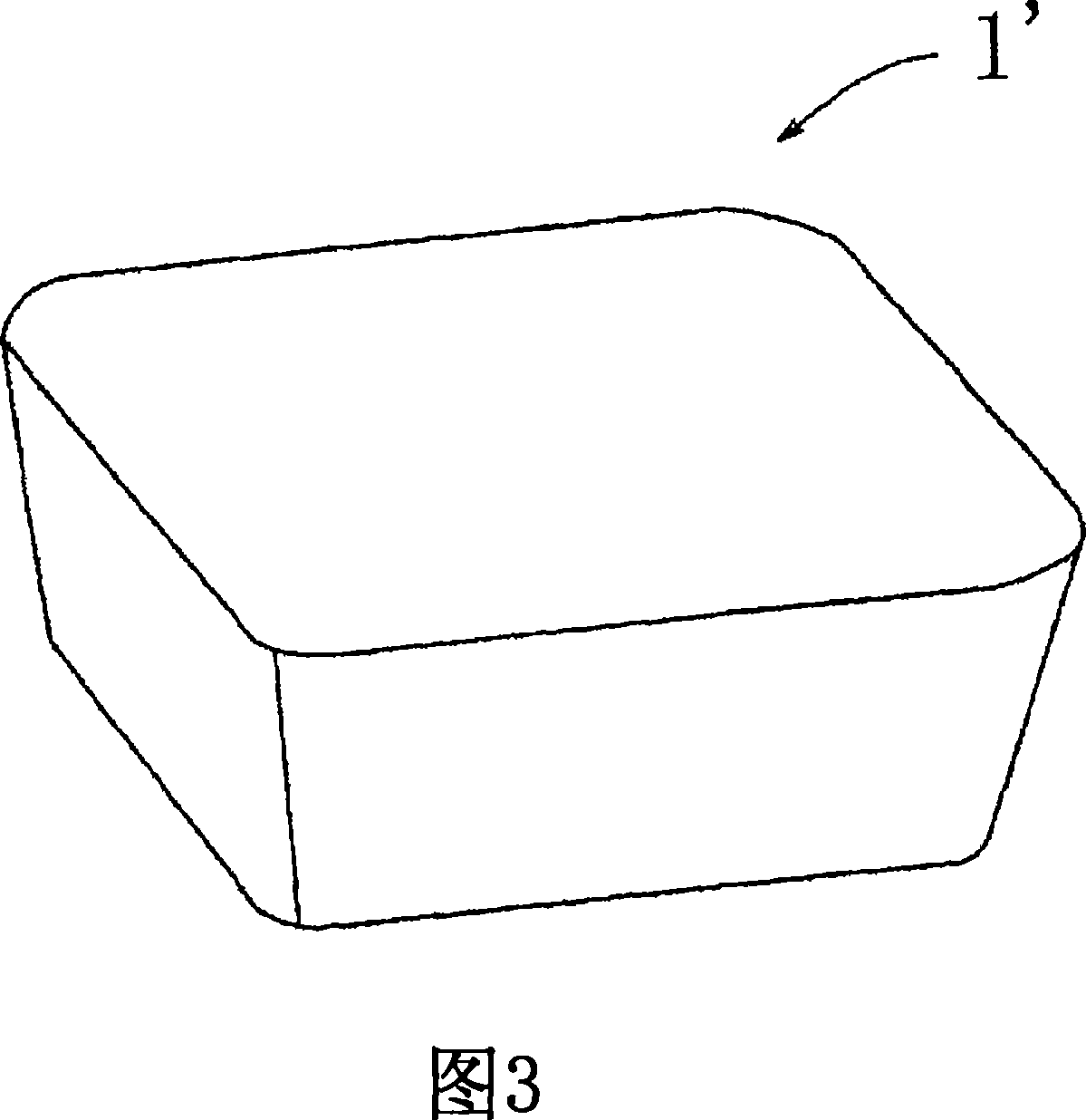

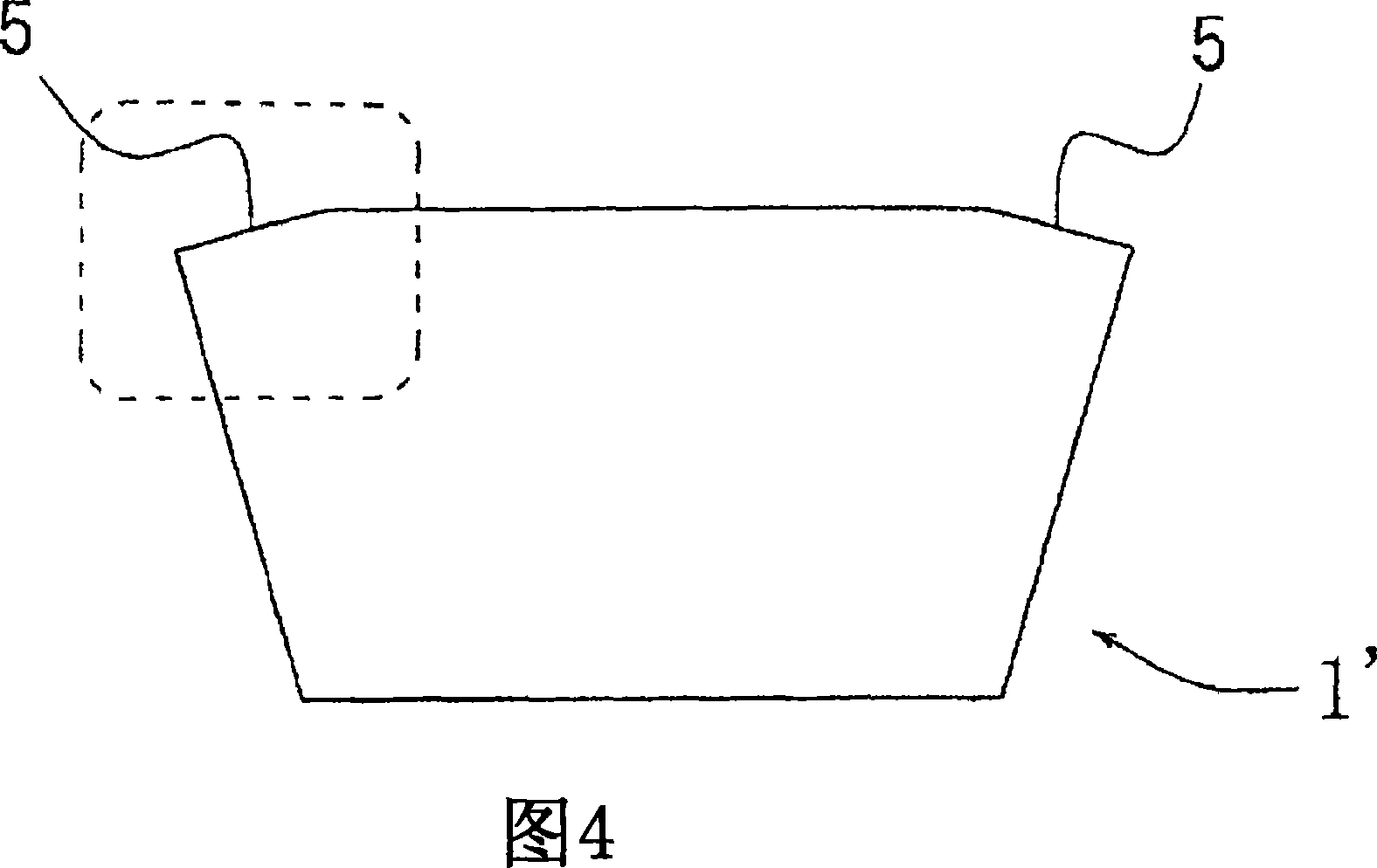

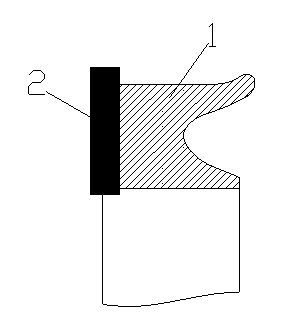

Sialon ceramic blade and cutting tool equipped therewith

ActiveCN101087670AHigh strengthExtended service lifeMilling cuttersCutting insertsCeramic sinteringBeta phase

This invention provides a long-life Sialon insert, the cutting edge of which is resistant to wear and hard to fracture, and a cutting tool equipped with the Sialon insert. Provided are a Sialon insert made of a Sialon sintered body including a Sialon phase comprising an alpha-phase Sialon and a beta-phase Sialon, and at least one element, originating from a sintering aid, selected from the group consisting of Sc, Y, Dy, Yb, and Lu in an amount of 0.5 to 5 mol% in terms of an oxide thereof, wherein an alpha value, which shows the proportion of the alpha-phase Sialon in the Sialon phase, is from 10% to 40%; the betal Sialon has a value of Z from 0.2 to 0.7 wherein Z is a variable of the formula Si 6-Z Al Z O Z N 8-Z and within a range: 0 / K or less at temperatures of room temperature to 1000 DEG C, and a thermal conductivity of 10 W / m*K or more at temperatures of room temperature to 1000 DEG C, and a cutting tool comprising a holder equipped with the Sialon insert.

Owner:NTK CUTTING TOOLS CO LTD

Pile foundation hole forming construction process under large-particle-size cobble sandy soil and severe water seepage geological condition

InactiveCN105970918AReduce porosityImprove on-site construction efficiencyBulkheads/pilesSlagSteel bar

The invention discloses a pile foundation hole forming construction process under the large-particle-size cobble sandy soil and severe water seepage geological condition. Holes are formed through a follow-up process that rotary drilling rig drilling is matched with a steel casing. The pile foundation hole forming construction process comprises the specific construction steps that 1, site formation is conducted, specifically, site formation of a pioneer road and site formation within a construction area range are conducted; 2, pile position lofting is conducted, specifically, on the basis of technical disclosure data, surveying and setting out are conducted through a total station, the specific position of a pile is determined, and a marker is made in the center of the pile in the mode of coating a short steel bar with paint; and 3, outer-side steel casing inserting and beating are conducted, specifically, an outer-side steel casing is inserted and beat to the position 4-6 m under the river bed ground with a crawler crane being matched with a hydraulic vibration hammer, the wall thickness of the outer-side steel casing is not less than 10 mm, and the diameter of the outer-side steel casing is 40 cm larger than that of the actual drilled pile. According to the pile foundation hole forming construction process under the large-particle-size cobble sandy soil and severe water seepage geological condition, the problem that drilling is difficult due to the fact that a rotary drilling rig encounters large-particle-size cobbles during construction is solved, the amount of drill slag after the holes are formed is decreased, the problem that the holes are not cleaned thoroughly is solved, accordingly, the drilling time is shortened, and the formed hole quality is improved.

Owner:STEEL STRUCTURE CONSTR CO LTD OF CHINA TIESUU CIVIL ENG GRP

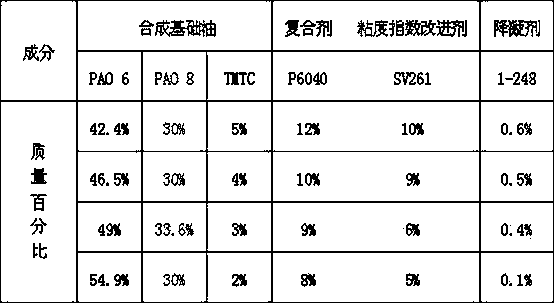

Formula and production process for special lubricating oil for turbosupercharged engine

InactiveCN104109573ASmooth runningSolve the problem of carbon depositionLubricant compositionOil additiveProcess engineering

The invention relates to a formula and a production process for special lubricating oil for a turbosupercharged engine. The formula is characterized in that the lubricating oil comprises base oil and additives, wherein the base oil employs imported synthesized base oil PAO6 and PAO8 and polyol ester TMTC synthesized base oil, the additives comprise a complexing agent P6040, a viscosity index improver SV261 and a pour-point depressant 1-248, and the base oil and the additives are mixed according to a certain ratio. According to the invention, high performance dynamic cleaning and dispersion technology is used, the interior of the engine can be cleaned, aggregation of carbon microspheres can be avoided, accumulation of greasy filth and generation of carbon deposit can be prevented, the engine is cleaner, and the problem of carbon deposit of turbine engines can be effectively overcome; the lubricating oil has long-term antioxidation capability and high temperature resistance, can effectively control increase of viscosity of an oil product, protects the engine from wearing, reduces noise produced by the engine, protects the engine running at high load under the driving conditions of frequent starting and braking, increases pressure for turbines and improves protection of multi-air valve engines.

Owner:山东力牌石油化学有限公司

Cold hot stamping film production technology

InactiveCN106965610AExcellent peelabilityImprove trimming effectWax coatingsDecorative surface effectsHot stampingProcess quality

The invention relates to a cold hot stamping film production technology. A PET base film is included. A release layer, a colored layer, a vacuum aluminum coated layer and a gum layer are sequentially arranged on the PET base film from interior to exterior. The cold hot stamping film production technology sequentially includes the following steps of coating mixing of the release layer, coating of the release layer, coating mixing of the colored layer, coating of the colored layer, die pressing, vacuum aluminum coating, coating mixing of the gum layer, coating of the gum layer, slitting and quality checking. The cold hot stamping film production technology has the beneficial effects that the cold hot stamping film manufactured through the production processes of coating mixing of the release layer, coating of the release layer, coating mixing of the colored layer, coating of the colored layer, die pressing, vacuum aluminum coating, coating mixing of the gum layer, coating of the gum layer, slitting and quality checking has the beneficial effects that the stripping performance is good, the edge cutting performance is good, and definition is high; a gradually-changing effect can be perfectly shown, the layering sense is high, normal-temperature transferring can be achieved, heating is not needed, energy is saved, the production efficiency is high, and the machining cost is low; and the produced cold hot stamping film can replace a traditional technology for positioning cleaning of aluminum products, and the production qualification rate is high.

Owner:ZHEJIANG YAXIN PACKAGE MATERIAL

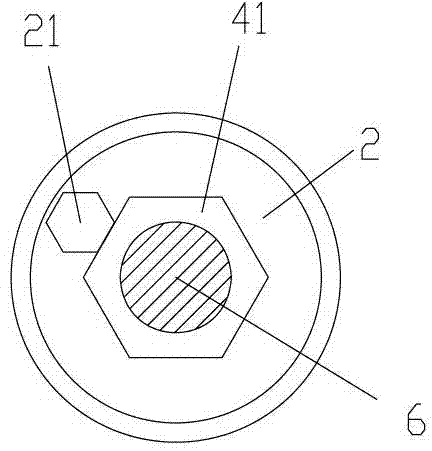

Automobile brake calliper

ActiveCN109050496AWear controlAvoid damageBraking element arrangementsAxially engaging brakesCalipersFriction force

The invention belongs to the automobile brake field, in particular to an automobile brake caliper, which comprises a caliper mechanism, a brake disc and an axle, wherein the brake disc is mounted on one end of the axle of the automobile; The caliper mechanism is fixedly installed on the vehicle body, and the caliper mechanism is matched with the brake disc; During the braking process, the contactarea between the brake pads and the brake discs increases, which decreases the friction force per unit area on the friction surface between the brake pads and the brake discs, effectively controls thewear of the brake pads and the brake discs, and further prolongs the service life of the brake pads and the brake discs. During the braking process, while the brake pads are in contact with the brakediscs, the sides of the second cut-out on the equalizer block are in contact with and rub against the brake discs, so that the forces on the two end faces of the brake discs are balanced, damage to the brake discs due to long-term unilateral force is avoided, the brake disc replacement cycle is delayed, and the maintenance cost of the brake system of the automobile is reduced.

Owner:秦皇岛科泰工业有限公司

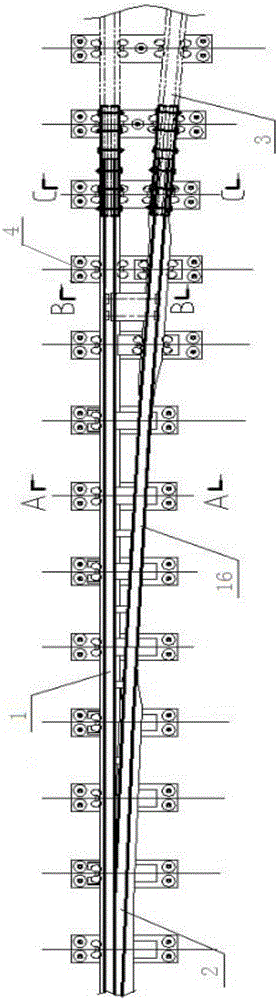

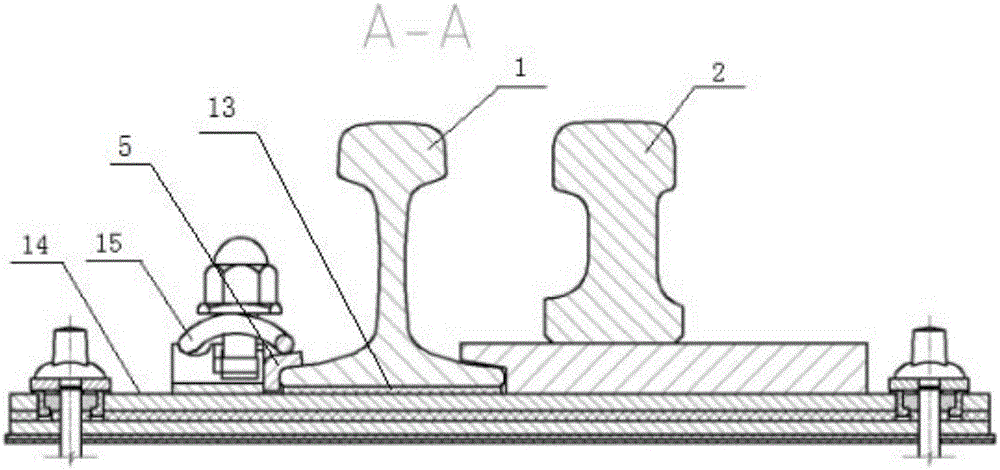

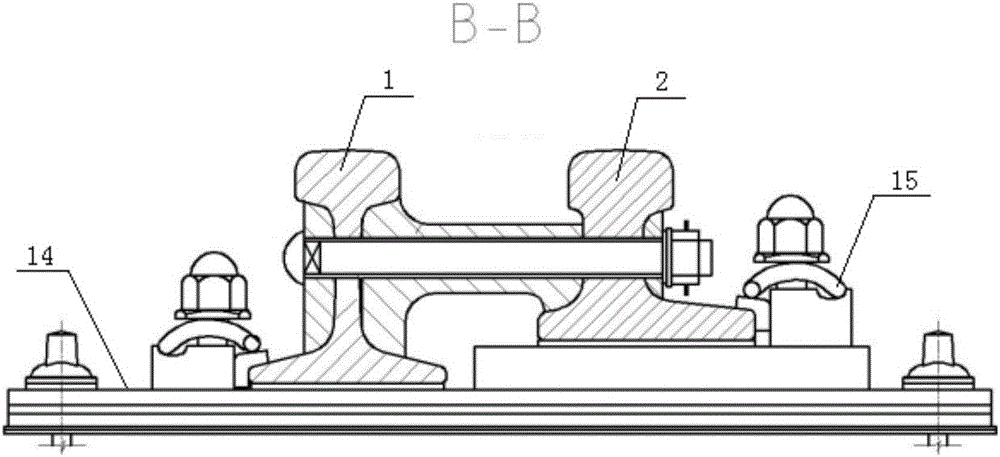

Urban railway transport vibration attenuation turnout structure

ActiveCN105862522AImprove pullout resistanceIncrease the installation heightRail switchesVibration attenuationEngineering

Disclosed is an urban railway transport vibration attenuation turnout structure. The urban railway transport vibration attenuation turnout structure comprises stock rails, switch rails and guide rails. The stock rails, the switch rails and the guide rails are mounted on a track bed through vibration attenuation fastener systems; the heel ends of the switch rails are provided with elastic bendable sections; the width of rail limbs of the working sides of the elastic bendable section is smaller than that of rail limbs of the working sides of the other sections of the switch rails; the stock rails, the heel ends of the switch rails and joints of the guide rails are connected through vibration attenuation joint clamping plates and common joint clamping plates, the vibration attenuation joint clamping plates are mounted on the non-working sides, and the common joint clamping plates are disposed on the working sides; and the top end faces of the vibration attenuation joint clamping plates are higher than the rail top faces of connected steel rails, and the top end faces of the vibration attenuation joint clamping plates have inclination consistent with that of wheel treads, so that the wheel treads operate on the top end faces of the vibration attenuation clamping plates when a train passes through joints. By means of the urban railway transport vibration attenuation turnout structure, vibration and noise caused by mutual impact of wheels and rails are reduced, the service life of turnout parts is prolonged, moreover, turnout construction is convenient, and less daily maintaining is needed.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP +1

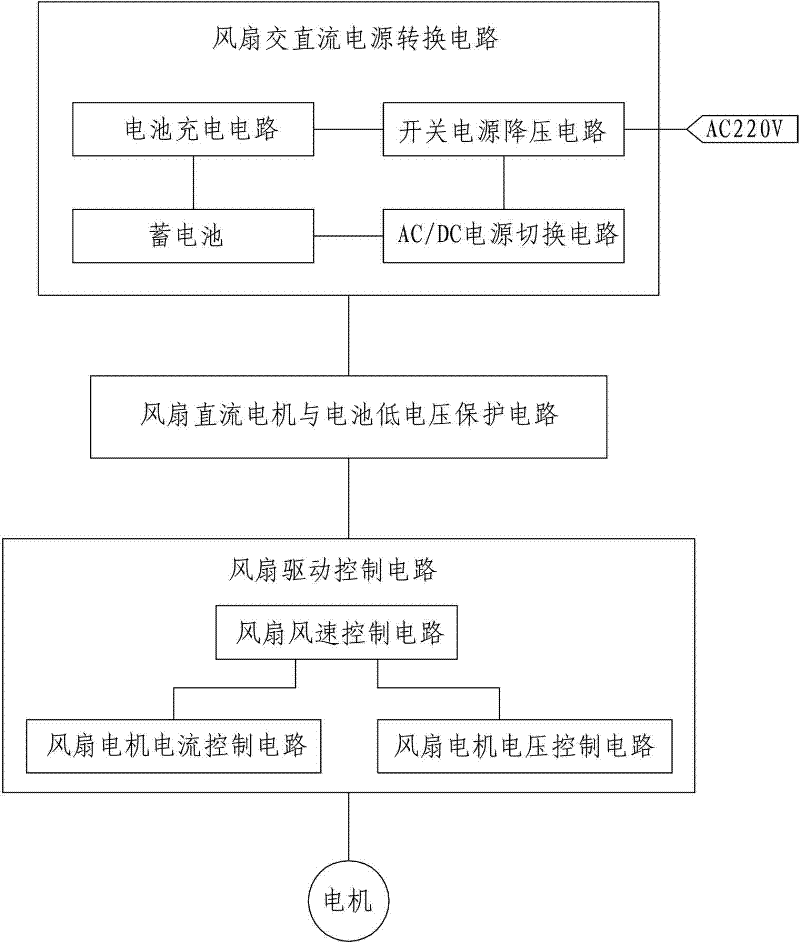

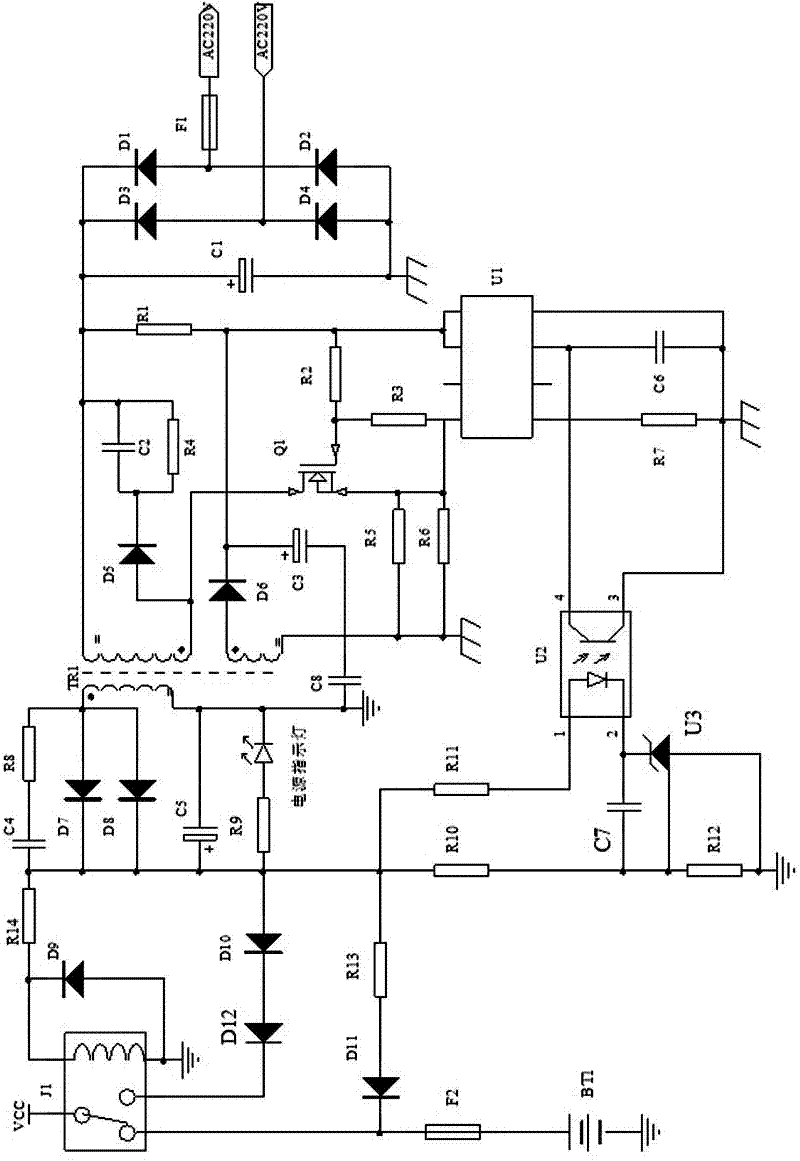

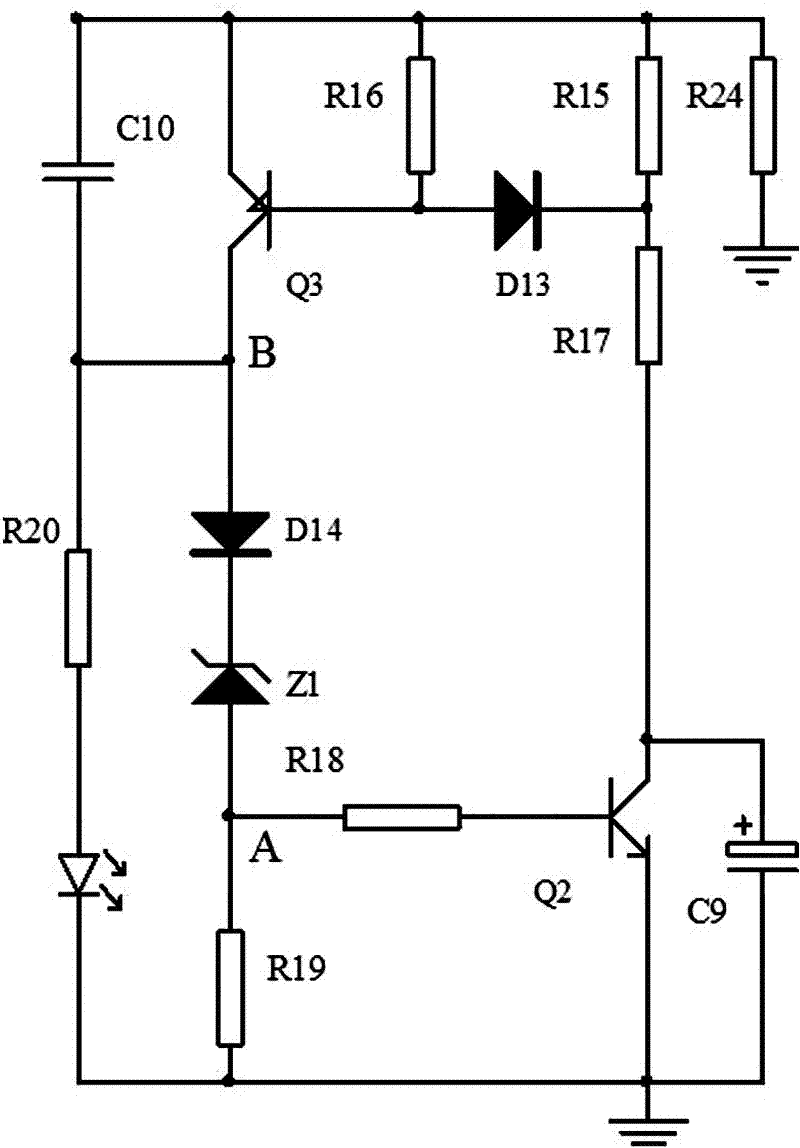

A fan control circuit for prolonging the life of fan DC carbon brush motor

ActiveCN102297148AAvoid burning phenomenonAvoid the phenomenon of burning, but also avoid the phenomenon of battery dischargeEmergency protective circuit arrangementsPump controlBrushless motorsLow voltage

The invention discloses a fan control circuit for prolonging the service life of a direct current carbon brush motor of a fan, which comprises an alternating and direct current power supply conversion circuit of the fan, a direct current motor of the fan, a battery low-voltage protective circuit and a driving control circuit of the fan; wherein the alternating and direct current power supply conversion circuit of the fan comprises a rechargeable storage battery, a switch power voltage reduction circuit, a battery charging circuit and an alternating current / direct current (AC / DC) power supply switching circuit; and the driving control circuit of the fan comprises an air speed control circuit of the fan, a motor current control circuit of the fan and a motor voltage control circuit of the fan. The fan control circuit can prevent the motor and the battery form being harmed due to too low power voltage, can stabilize the working current of the direct current carbon brush motor of the fan at a rated working current value, simultaneously controls the voltage at the lower limit of the rated working voltage of the motor and eliminates the phenomenon that the motor does not work stably dueto the fluctuated power voltage, so that the service life of the household alternative and direct current dual purpose fan is prolonged.

Owner:KENNEDE ELECTRIONICS MFG CO LTD

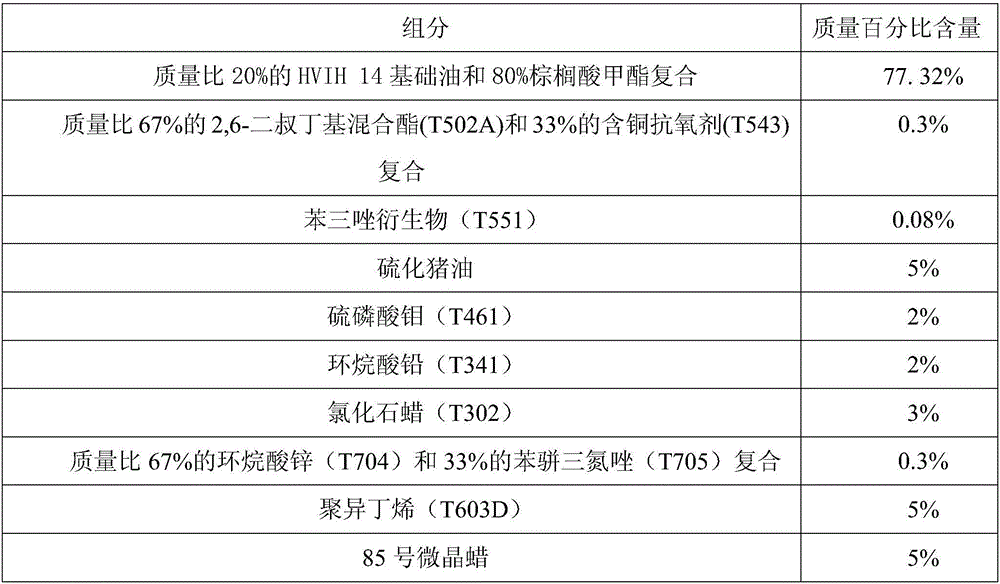

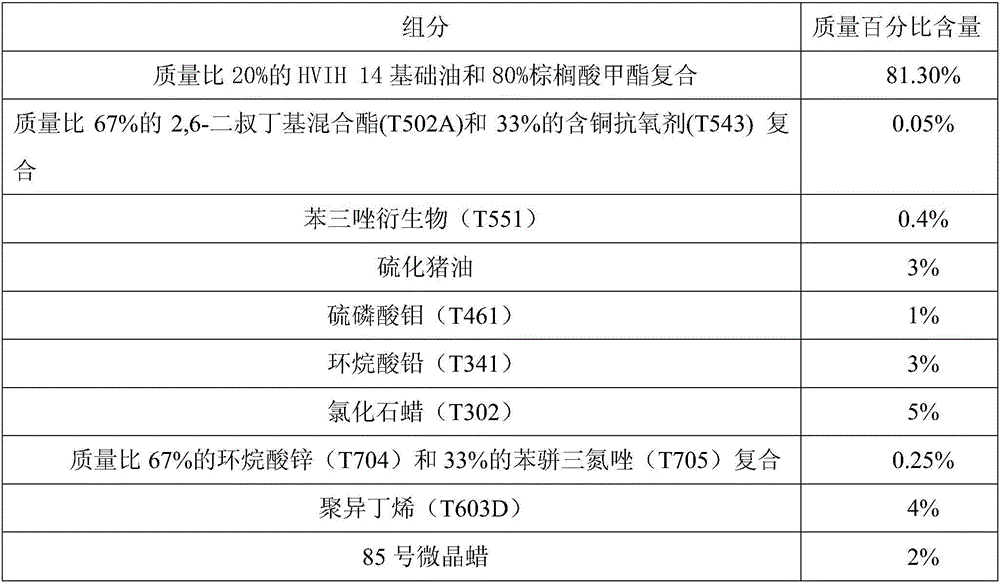

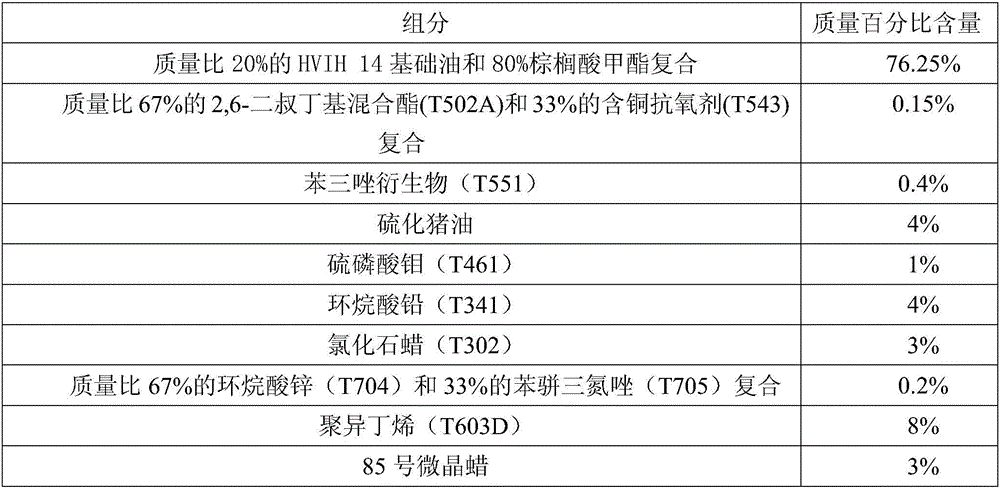

Lubricating agent composition for white alloy cold drawing machining

The invention discloses a lubricating agent composition for white alloy cold drawing machining. A compound of HVIH14 and methyl palmitate is adopted as basic oil and cooperates with various composite additives. The lubricating agent composition includes antioxidant, a metal passivator, an oiliness agent, antiwear agent, an extreme pressure agent, a friction improver, a viscosity index improver, a filling agent, antirust agent and others. The composition has the advantages that the number of machined workpieces and molds needing to be rubbed, lubricated and cooled is reduced, power consumption is lowered, and deformation is uniform; the service life of a tool is prolonged, and abrasion of workpiece materials is controlled; the quality of the surface of machined metal is improved, and the tolerance of the surface of the machined metal is reduced; temperature is controlled, and machining deformation is reduced; new and old surfaces of the machined metal are kept oxidized or passivated; using is safe, and toxins do not exist; residues do not affect machining and operating, and cleaning is convenient.

Owner:GUANGXI UNIV

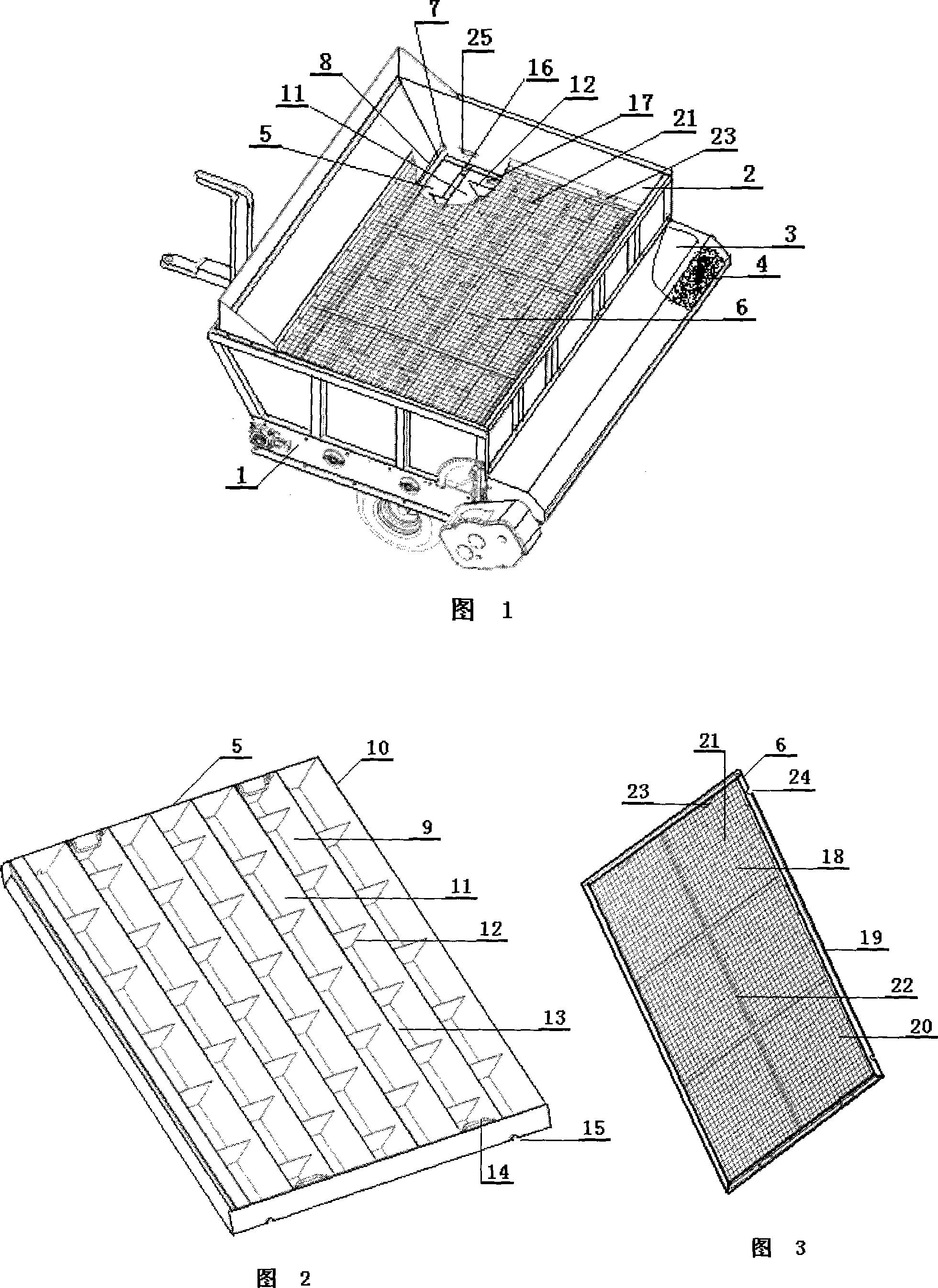

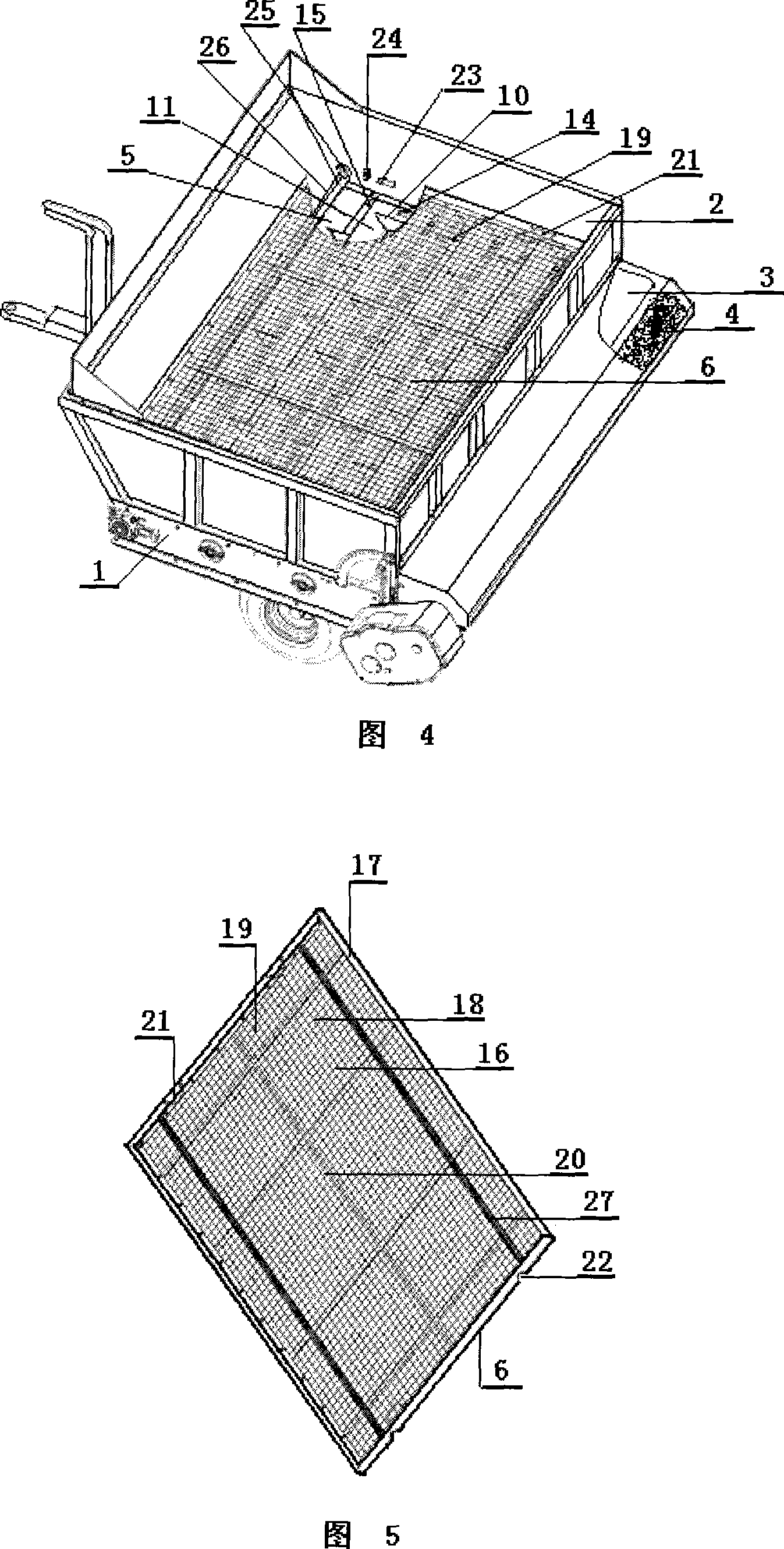

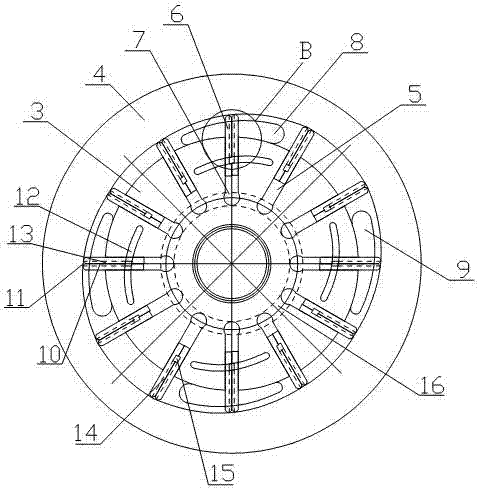

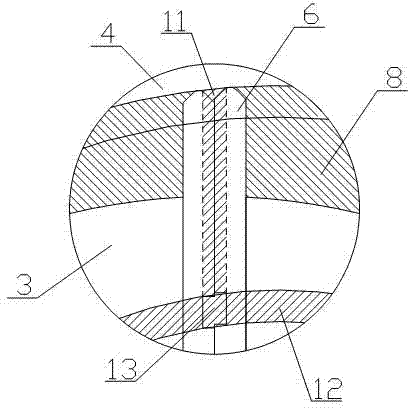

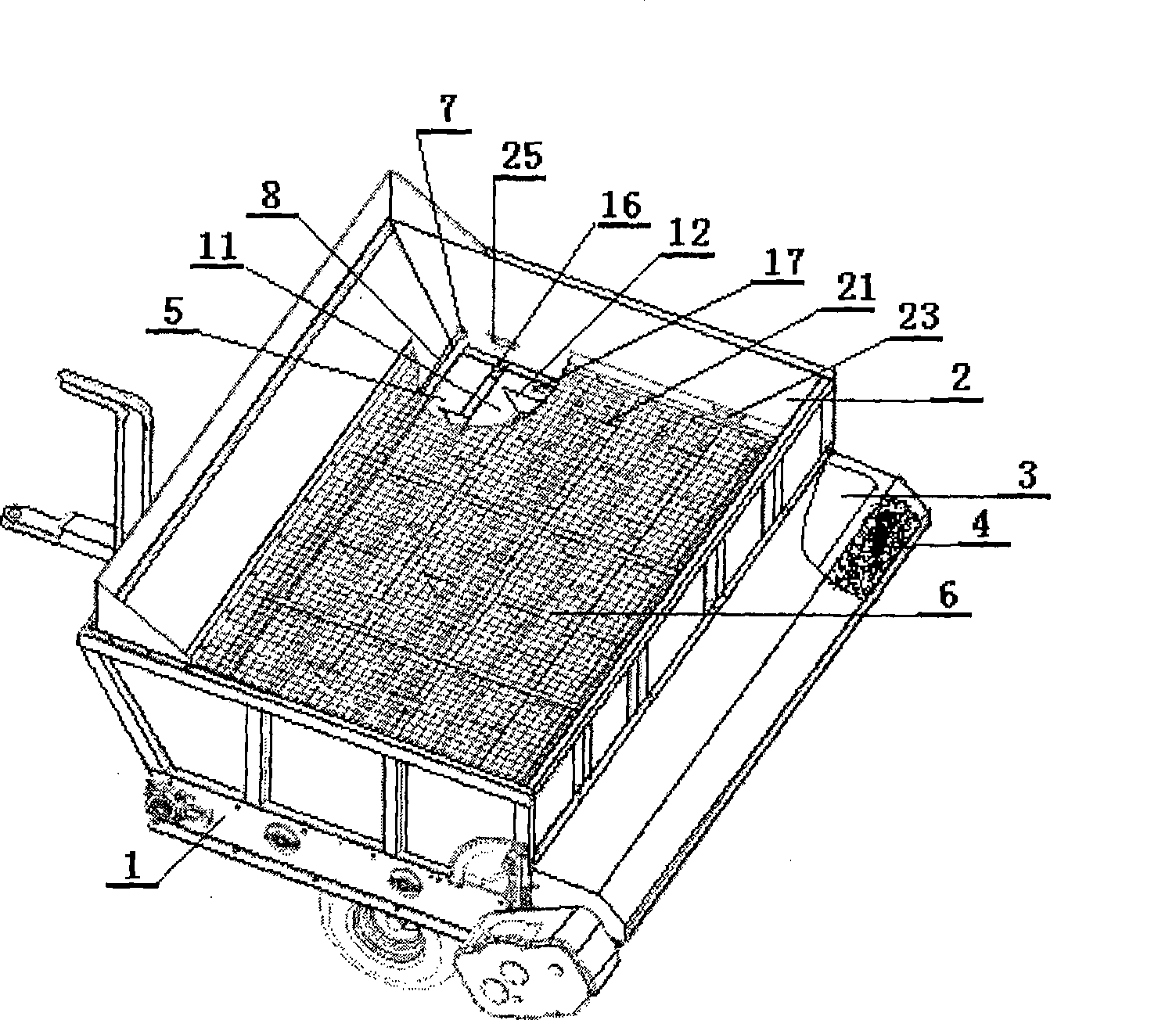

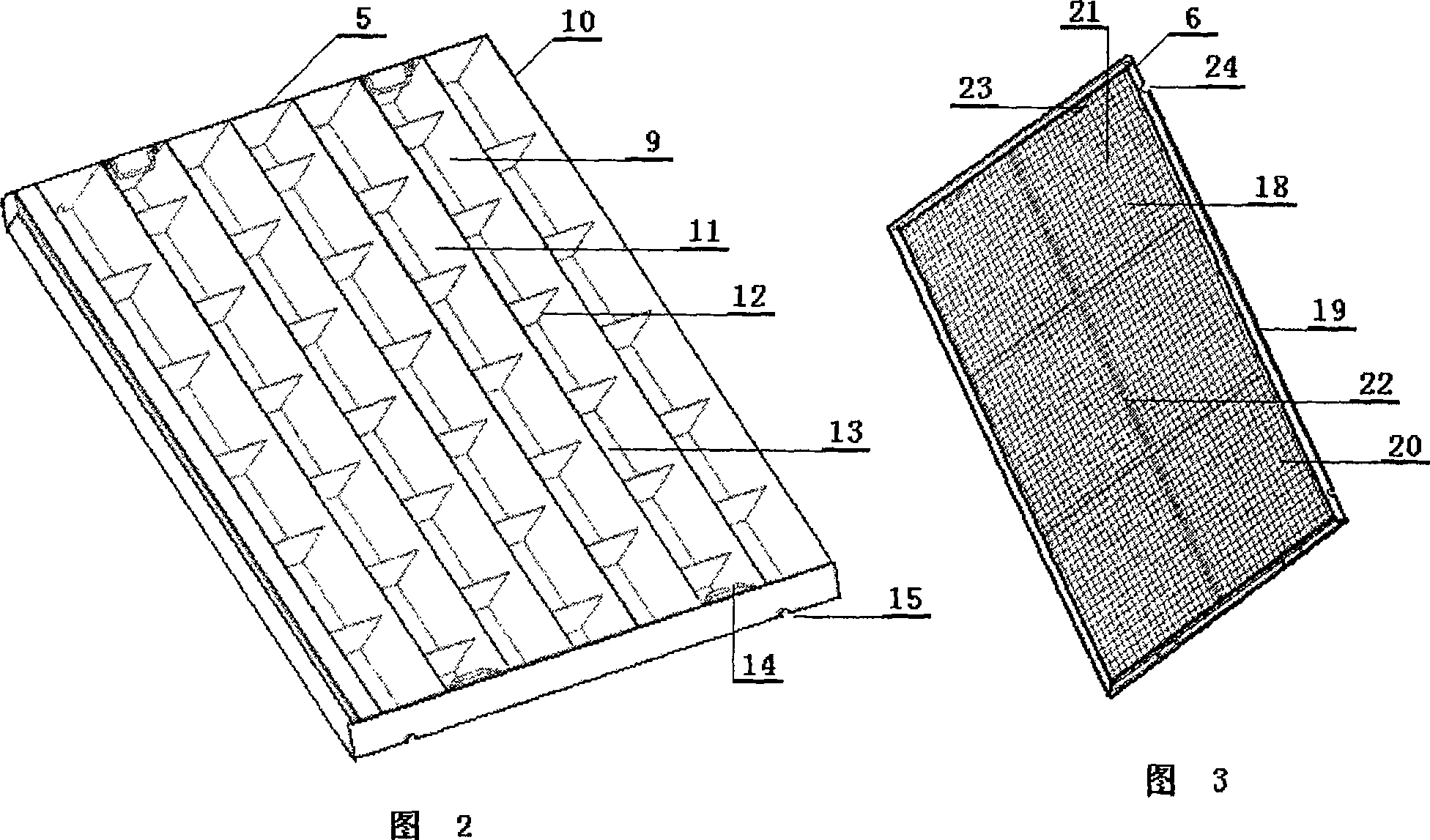

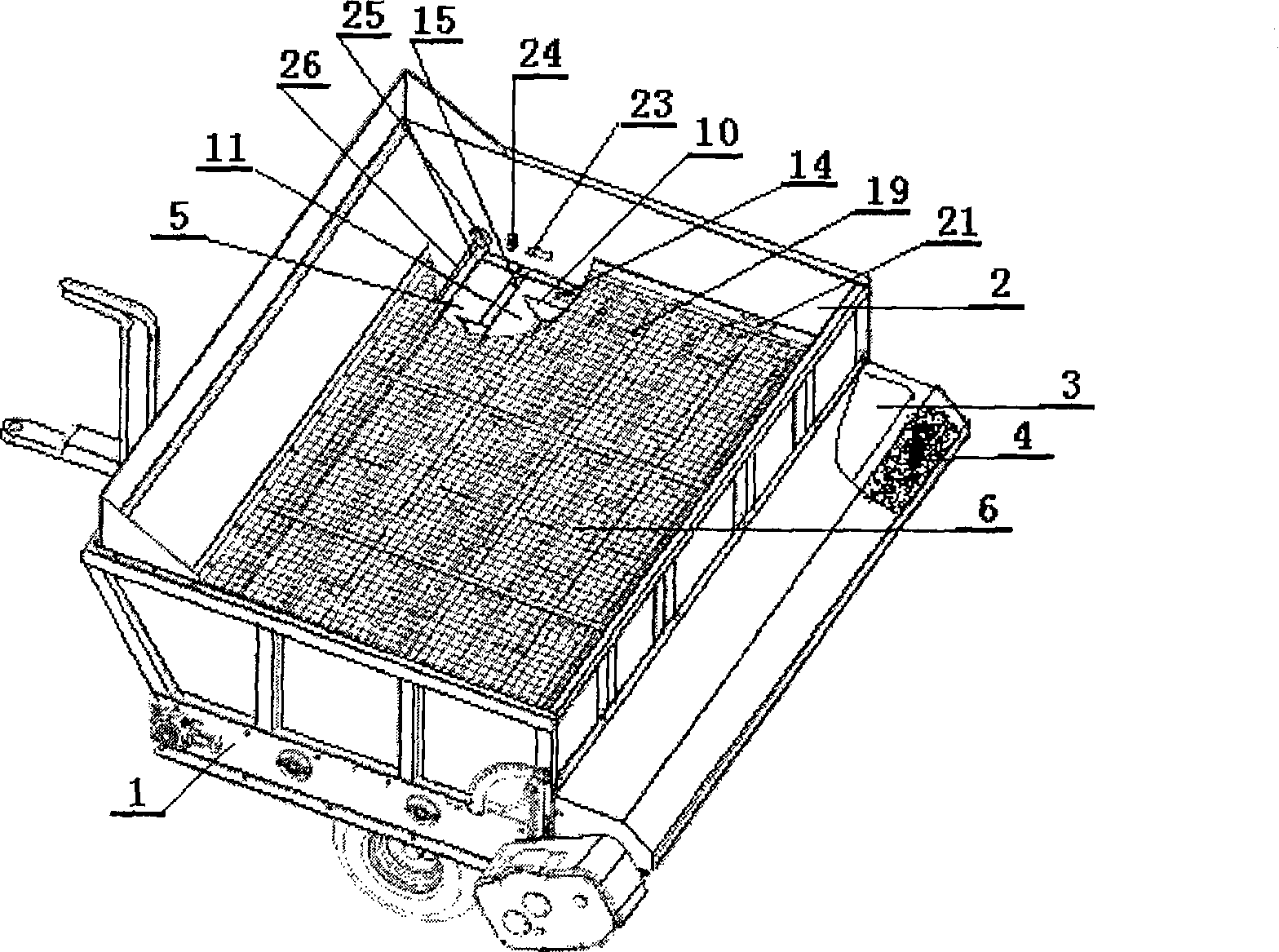

Sand-paving machine simultaneously having sieving sand pressure-reducing sand-guide functions

InactiveCN101070692AAffect the sand production rateAffect wearRoads maintainenceEngineeringMechanical engineering

This invention involves a kind spread sand machine have both siftings leads the sand function and the reduced pressure, which is composed by the rack, the sandbox, the conveyer belt and rolls brushes. The conveyer belt passes through establishment in the sandbox base, rolls brushes clings establishes underneath the sand mouth, near the sandbox cavity bottom is equipped with the reduced pressure to lead the sand grid overlay, upside establised siftings the grid overlay and the belt eccentric tappet vibration revolution axis, the reduced pressure leads on the sand grid overlay to be equipped with the small grid which, the handle and the spacing concave buckle around certain belts the unidirectional inclined shape side and the stiffener constitute, siftings on the grid overlay to be equipped with by the belt specification mesh strainer, vertically and horizontally the overlapping stiffener, the handle and the spacing saw notch, in the sandbox cavityNear base and upside on the sidewall establishes separately has the spacing to hold the block. When work, the sand falls directly in siftings on the grid overlay, after sieving filters the whereabouts, the reduced pressure to lead the sand grid overlay leads the sand on the conveyer belt obtains with the sand, withstanding compared to carries less pressures than the sands quantity, it is advantageous in raises the overall working efficiency, the construction quality and the extension conveyer belt service life, has the very strong usability.

Owner:李明

Method for machining rotor spindle of high pressure turbine

ActiveCN103753130AGuaranteed shot peening strengthAvoid deformationAircraft componentsEngineeringHigh pressure

The invention belongs to the technical field of machining and relates to a method for machining a rotor spindle of a high pressure turbine. Finish turning process is performed by using a rubber belt to wind parts, so that deformation of thin-walled workpieces is avoided. Spot facing machining tests cutting parameters, tool wear is controlled, and tool changing points are determined. Intensity check is performed on simulation test sheets through shot blasting so as to guarantee shot blasting intensity of the parts. The parts are subjected to static balance detection and superposition projection detection after processing. The method for machining the rotor spindle of the high pressure turbine includes the following steps of rear end positioning, front end half finish turning, front end positioning, rear end half finish turning, rear end positioning, front end finish turning, front end positioning, rear end finish turning, end face hole and fan-shaped groove machining, shot blasting, spigot finish turning, static balance detection, and superposition projection detection.

Owner:西安西航集团莱特航空制造技术有限公司

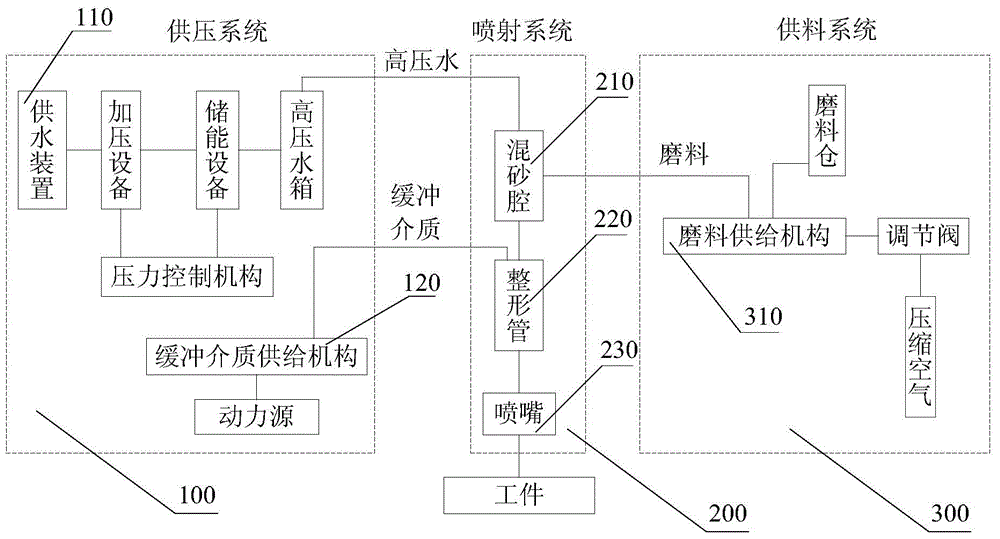

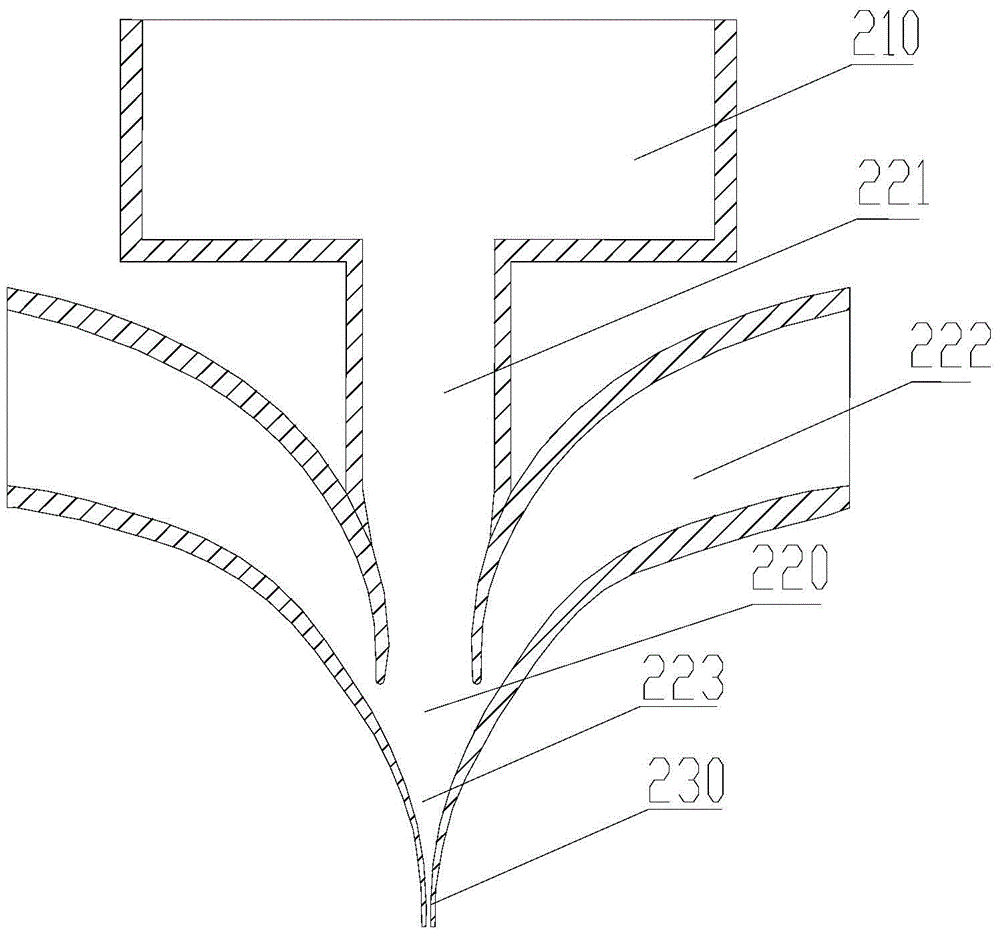

Water-jet machining device

InactiveCN105081982AAvoid direct contactReduce wearAbrasive machine appurtenancesAbrasive blasting machinesLow speedEngineering

Provided is a water jet machining device, comprising a pressure provision system, a jet system, and a feed provision system. The pressure provision system and the feed provision system are separately connected to the jet system. The jet system comprises a sand-mixing chamber and a nozzle. High-pressure water and an abrasive are mixed to form a mixture in the sand-mixing chamber. The jet system also comprises a shaping tube. A first inlet of the shaping tube is in communication with the exit of the sand-mixing chamber. The exit of the shaping tube is in communication with the nozzle. The mixture is injected into the shaping tube from the exit of the sand-mixing chamber at a low speed, forming a central water jet. The pressure provision system also comprises a buffering medium provision mechanism. The buffering medium provision mechanism is in communication with a second inlet of the shaping tube. The buffering medium provision mechanism injects the buffering medium into the shaping tube. The buffering medium sleeves the central water jet. The central water jet sleeved in the buffering medium is ejected out of the nozzle and works on the component to be machined. The water jet machining device of the present invention lowers the wear rate of the nozzle and the sand-mixing chamber, thereby reducing maintenance costs.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Y-type sealing ring

The invention discloses a Y-type sealing ring. The Y-type sealing ring comprises an annular body, wherein a Y-type sealing structure is arranged on one side, communicated with high-pressure oil, of the annular body; an abrasion-proof ring structure is additionally arranged on one end, not communicated with the high-pressure oil, of the annular body; and the abrasion-proof ring and the annular body are molded into a whole through a vulcanizing gluing process. The invention discloses the Y-type sealing ring, the Y-type sealing ring is unique in structural design, the abrasion-proof ring structure is additionally arranged on the annular body, and due to the structure, the abrasion resistance of the sealing ring is effectively improved and the service life of the sealing ring is improved; and meanwhile, due to the structure, an upper oil trapping area and a lower trapping area are formed by the sealing ring during a working process, so that abrasion losses of an upper lip and the lower lip of the sealing ring are effectively controlled, and the sealing performance is more excellent and the working state is more stable.

Owner:常熟市董浜镇徐市盛峰液压配件厂

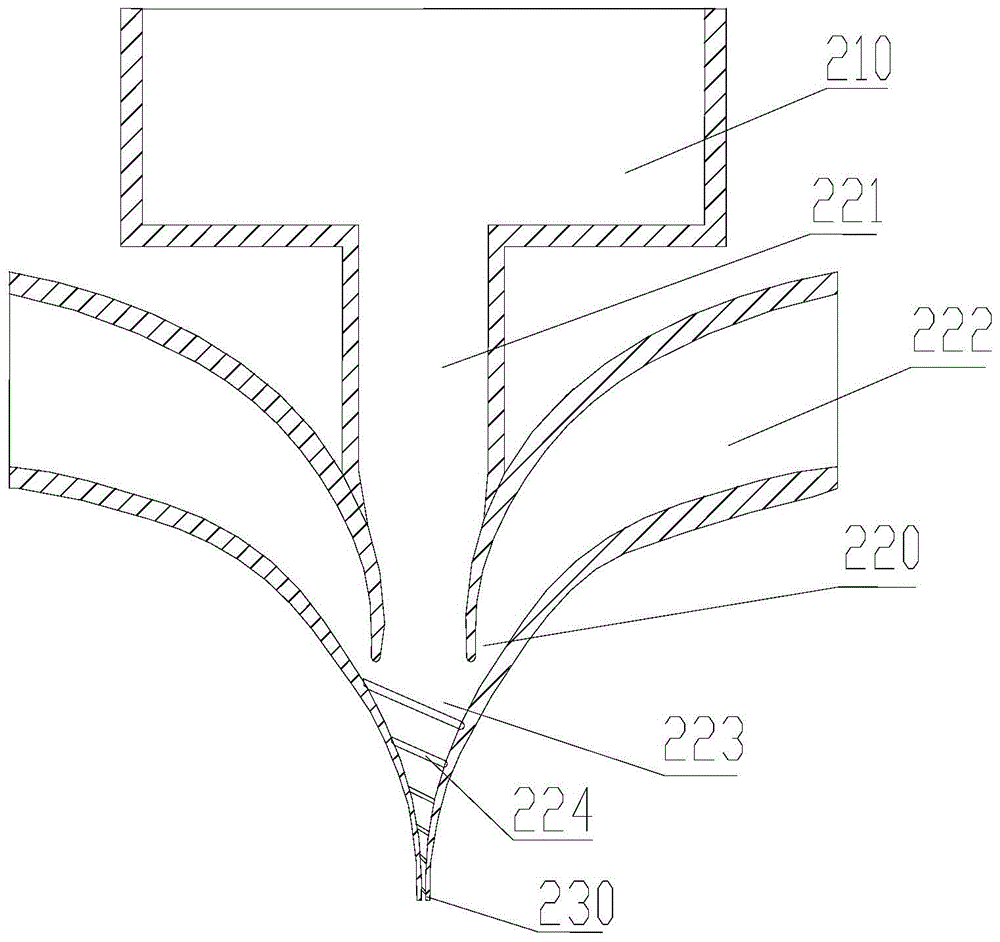

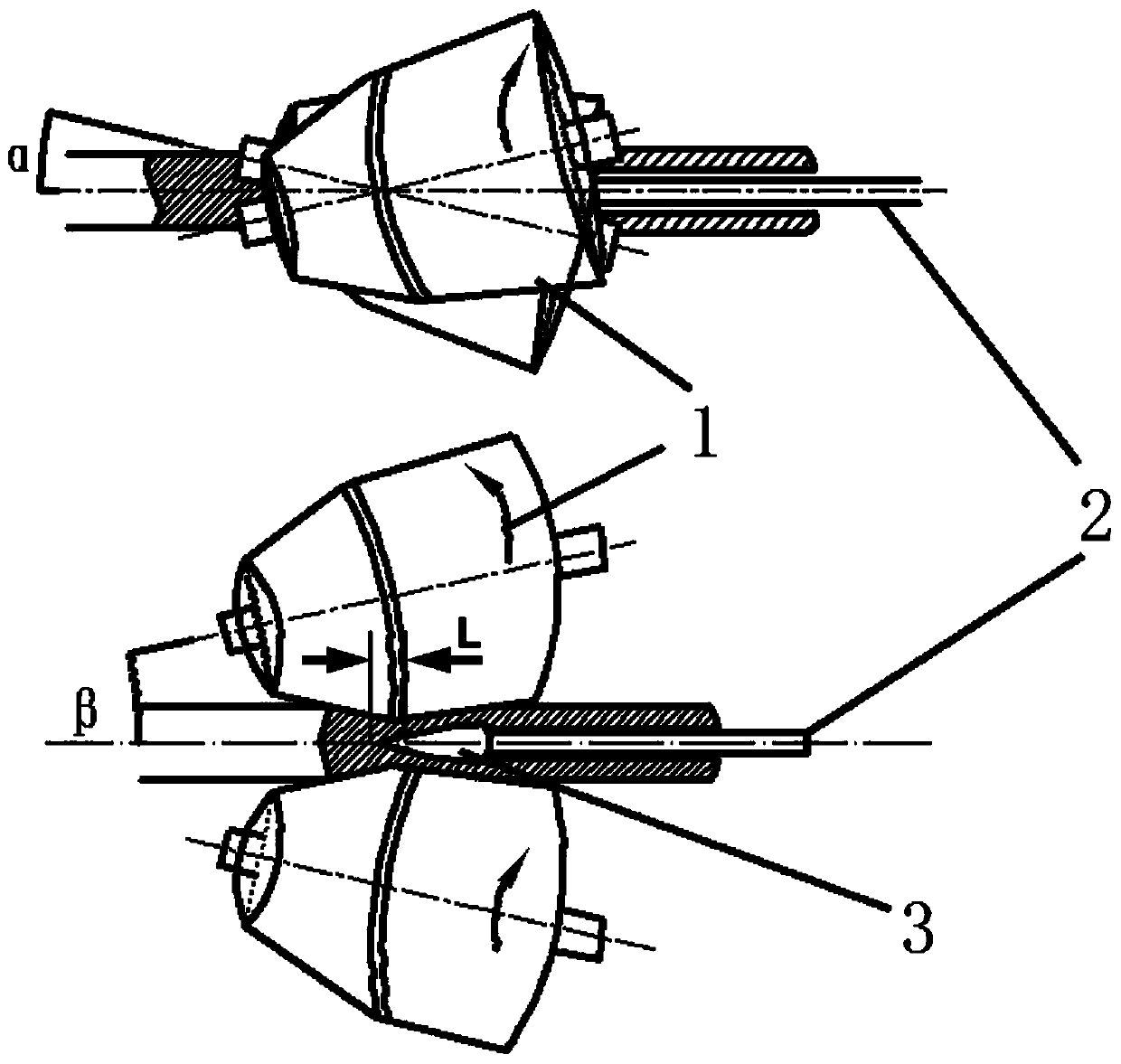

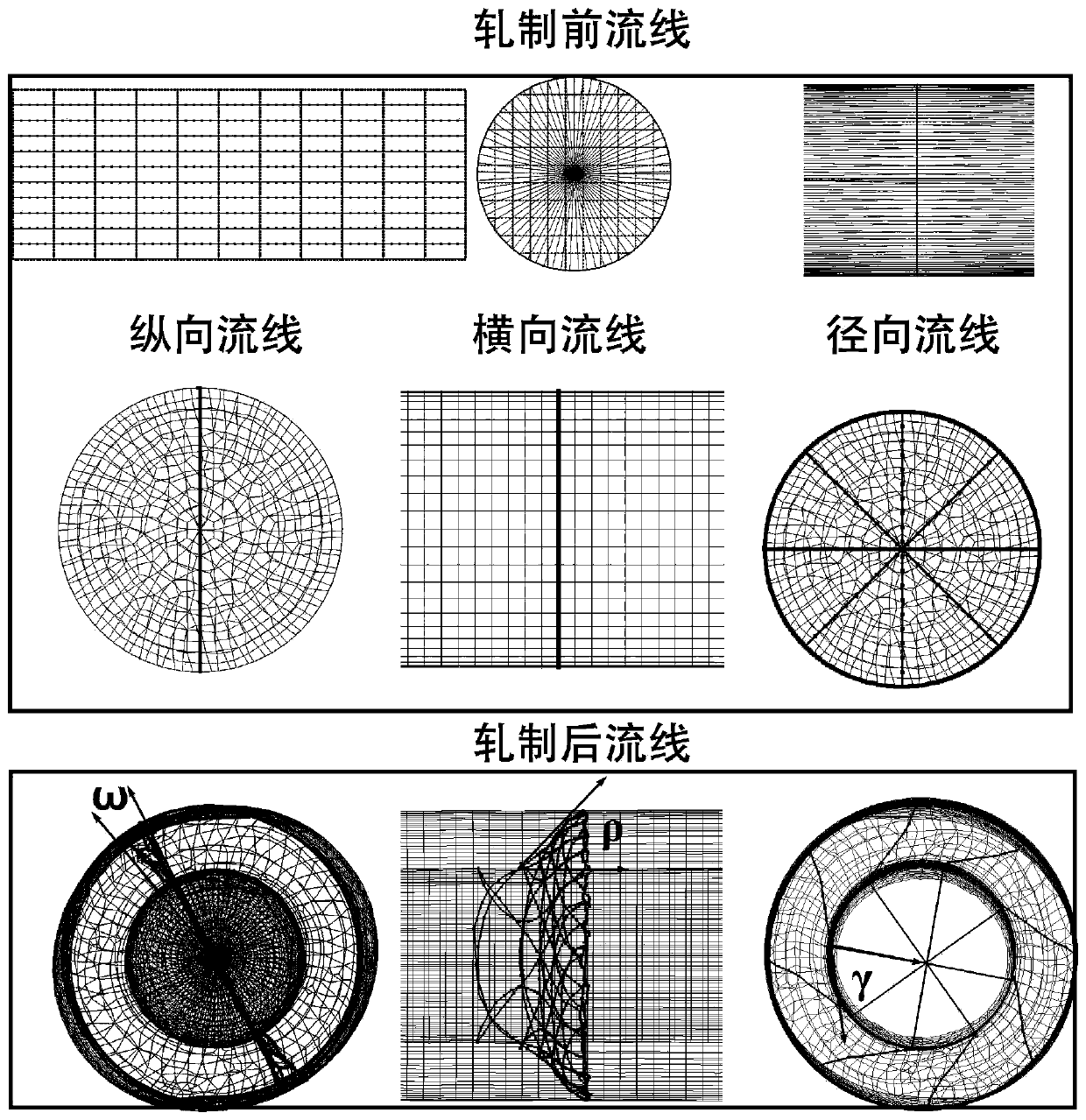

High-strength and high-toughness two skew-roll piercing method for 2219 aluminum alloy pipe

ActiveCN111589869AReduce resistanceWear controlMetal rolling stand detailsMetal rolling arrangementsTemperature controlHeating furnace

The invention discloses a high-strength and high-toughness two skew-roll piercing method for a 2219 aluminum alloy pipe, and relates to the technical field of aluminum alloy pipe machining. The methodcomprises the following steps that skew-roll piercing is conducted by adopting a perforating machine with a double-spiral conical roller; the plug advance is set to be 5-25 mm, the feeding angle of the two skew-roll perforating machine is set to be 6-21 degrees, the rolling angle is set to be 8-15 degrees, the reduction rate is set to be 5%-10%, the rotating speed of the roller is set to be 20-35r / min, and a aluminum alloy cylindrical blank is heated to 440-460 DEG C by adopting a heating furnace; the heated aluminum alloy cylindrical blank is moved to a guide chute of the two skew-roll perforating machine from the heating furnace; and the aluminum alloy cylindrical blank penetrates through a plug under the action of the roller, and the temperature of a rod blank is controlled to be 350-500 DEG C in a rolling process. According to the high-strength and high-toughness two skew-roll piercing method, three-dimensional pressing-twisting composite deformation of the aluminum alloy in thetwo-roller skew-roll piercing process is achieved, and finally the high-strength and high-toughness 2219 aluminum alloy pipe is obtained through the two-roller skew-roll piercing method.

Owner:安徽汉正轴承科技有限公司

Crankshaft rocker type speed reducer

The invention discloses a crankshaft rocker type speed reducer. An input shaft and an output shaft are supported on a box body through bearings; the input shaft is a crankshaft; one to three groups of bell cranks are arranged on the crankshaft along the axial direction; the number of each group of bell cranks is two; an alternate angle between the two bell cranks is 180 degrees in the same group; the first bell crank is connected with one end of a first rocker through a first connecting rod in the same group, and the other end of the first bell crank is sleeved on the output shaft through an isolator; the second bell crank is connected with one end of a second rocker through a second connecting rod in the same group, and the outer end of the second rocker is also sleeved on the output shaft through an isolator. The invention not only adopts a linear bearing movement mode with high precision at a high-speed end to effectively control the transmission noise, the abrasion, and the like of the crankshaft rocker type speed reducer, but also adopts the isolator capable of bearing the high pulling torque at a low-speed end to improve the transmission efficiency. Because the volume of the whole device is reduced by adopting the crankshaft, the connecting rods, the rocker, the isolators and other structural modes, the production cost is also reduced.

Owner:杨智勇

Production process for positioning stamping film

PendingCN108608752AHigh technical contentStrong confidentialityDuplicating/marking methodsPattern printingVisual observationZinc sulfide

The invention relates to a production process for a positioning stamping film comprising a PET base film; the PET base film is successively provided with a release layer, a coloring layer, a vacuum aluminum plating layer and a back glue layer from inside to outside. The production process comprises the following steps successively: mixing of a release layer coating, coating of a release layer, mixing of a coloring layer coating, coating of a coloring layer, mold pressing, vacuum aluminizing, aluminum washing, zinc sulfide coating, mixing of a back glue layer coating, back glue layer coating, slitting, and quality inspection. The production process has the advantages that the positioning stamping film produced by the steps has the advantages of high technical content and strong secrecy, isnon-duplicated, and can give consumers direct visual observation discrimination of authenticity before purchasing in goods anti-counterfeiting aspect, the packaging is prevented from being reused by counterfeiters, and the anti-counterfeiting performance and commercial benefits are improved; the produced positioning stamping film eliminates the gradual accumulation of stamping accuracy error in astamping process, and an independent pattern stamping foil needs a positioning cursor to correct the error of holographic patterns at intervals in time.

Owner:ZHEJIANG YAXIN PACKAGE MATERIAL

Vane-type hydraulic machine

ActiveCN103114994AAvoid Fatigue Failure DamageEasy to processRotary piston pumpsRotary piston liquid enginesHydraulic machineryEngineering

The invention discloses a vane-type hydraulic machine. The vane-type hydraulic machine comprises an oil inlet side plate, an oil outlet side plate, a rotor, a stator and a vane which is arranged inside a rotor groove, wherein the vane and the bottom of the rotor groove form a bottom cavity, a high-pressure port and a lower-pressure port are respectively formed on the oil inlet side plate and the oil outlet side plate, a fluid passageway is arranged on the vane, the end part of the vane is provided with a vane top groove which is communicated with the fluid passageway, the top of the vane and the contact line of the inner surface of the stator are respectively arranged on the two sides of the vane top groove, fluid channels corresponding to the fluid passageway are respectively arranged on the oil outlet side plate and the oil inlet side plate, and the fluid passageway, the vane top groove and the fluid channel form a vane control chamber. The vane-type hydraulic machine is simple and convenient to machine and has low cost; the accuracy of the vane-type hydraulic machine is ensured; the reliable contact between the vane and the inner surface of the stator is ensured; the abrasion is also controlled; the working pressure is increased; the product performance is improved; and the service life is prolonged.

Owner:胡阳

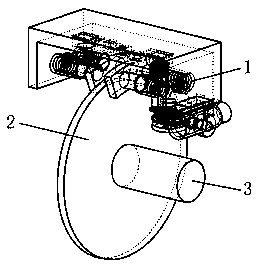

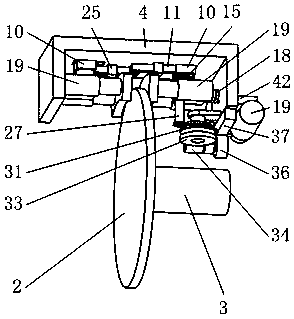

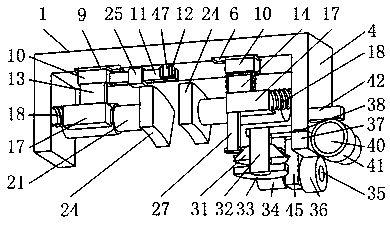

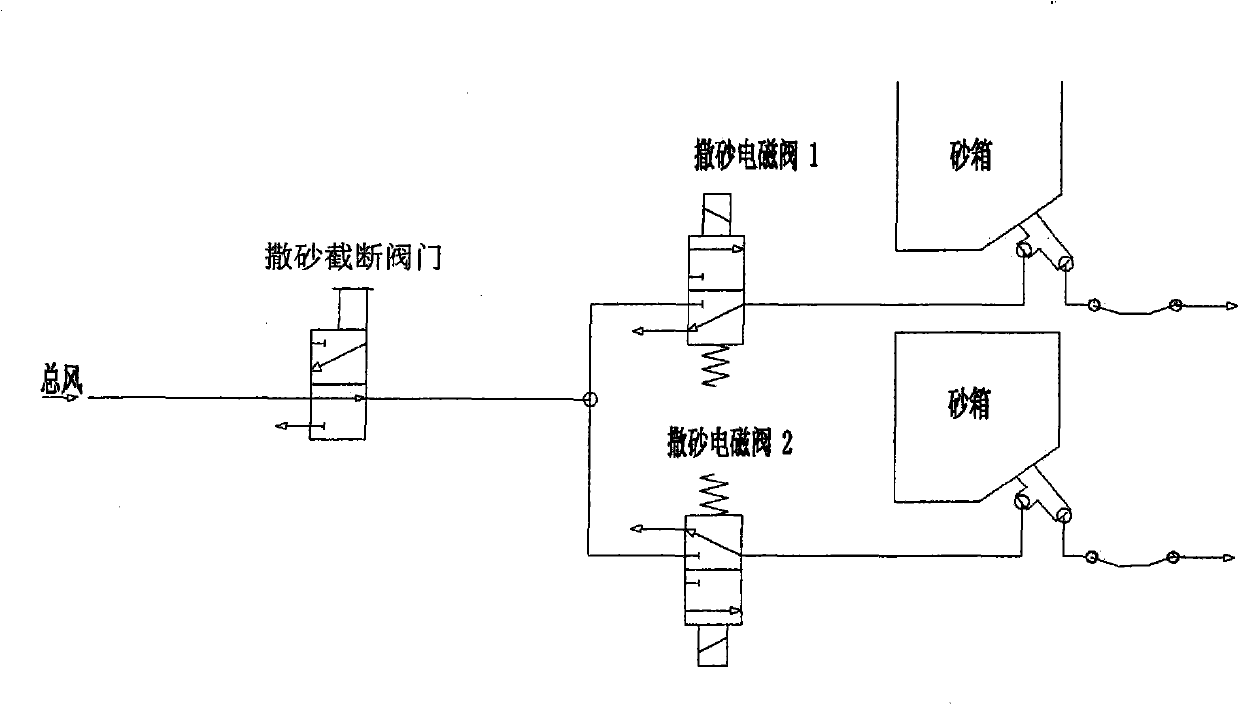

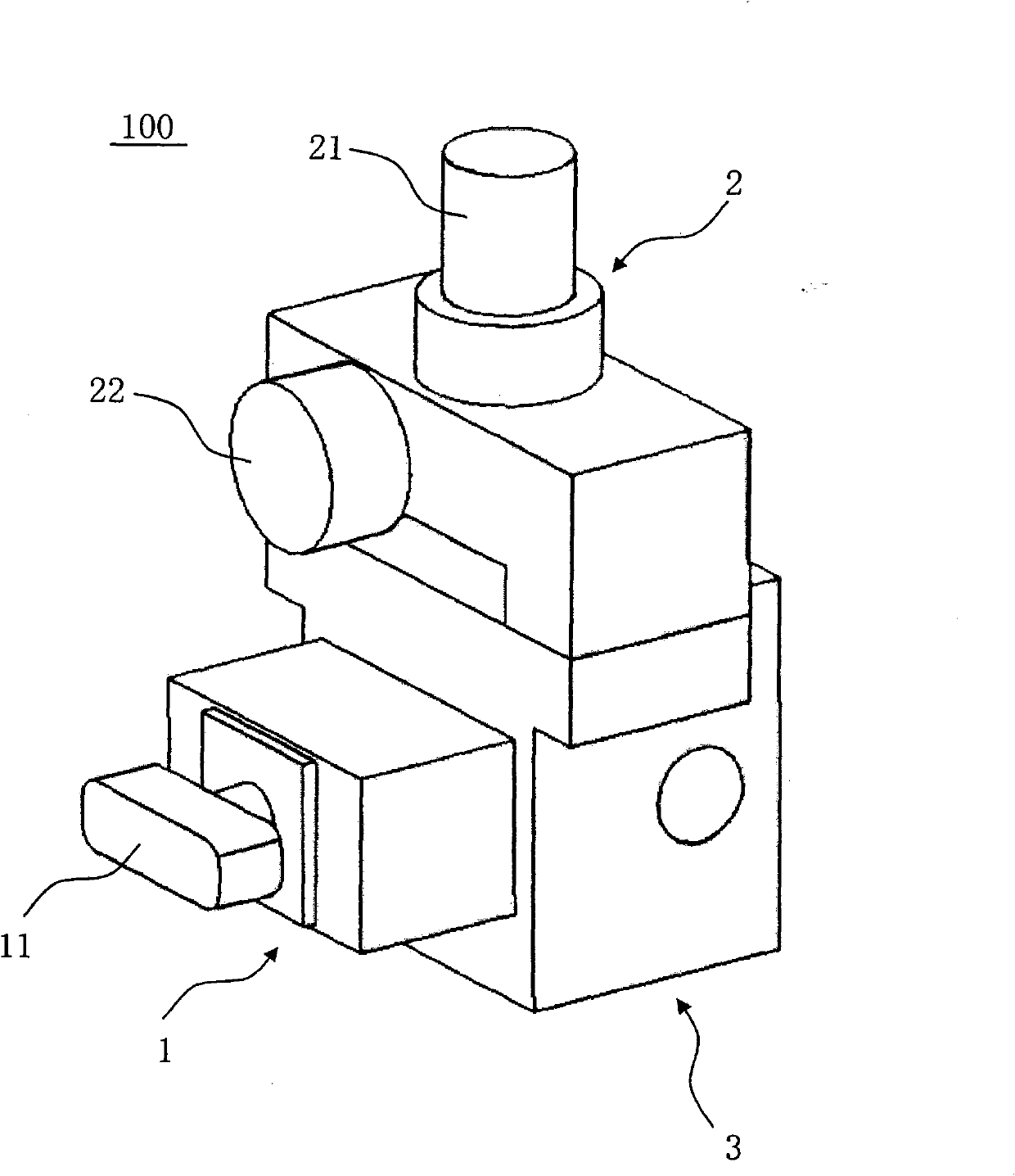

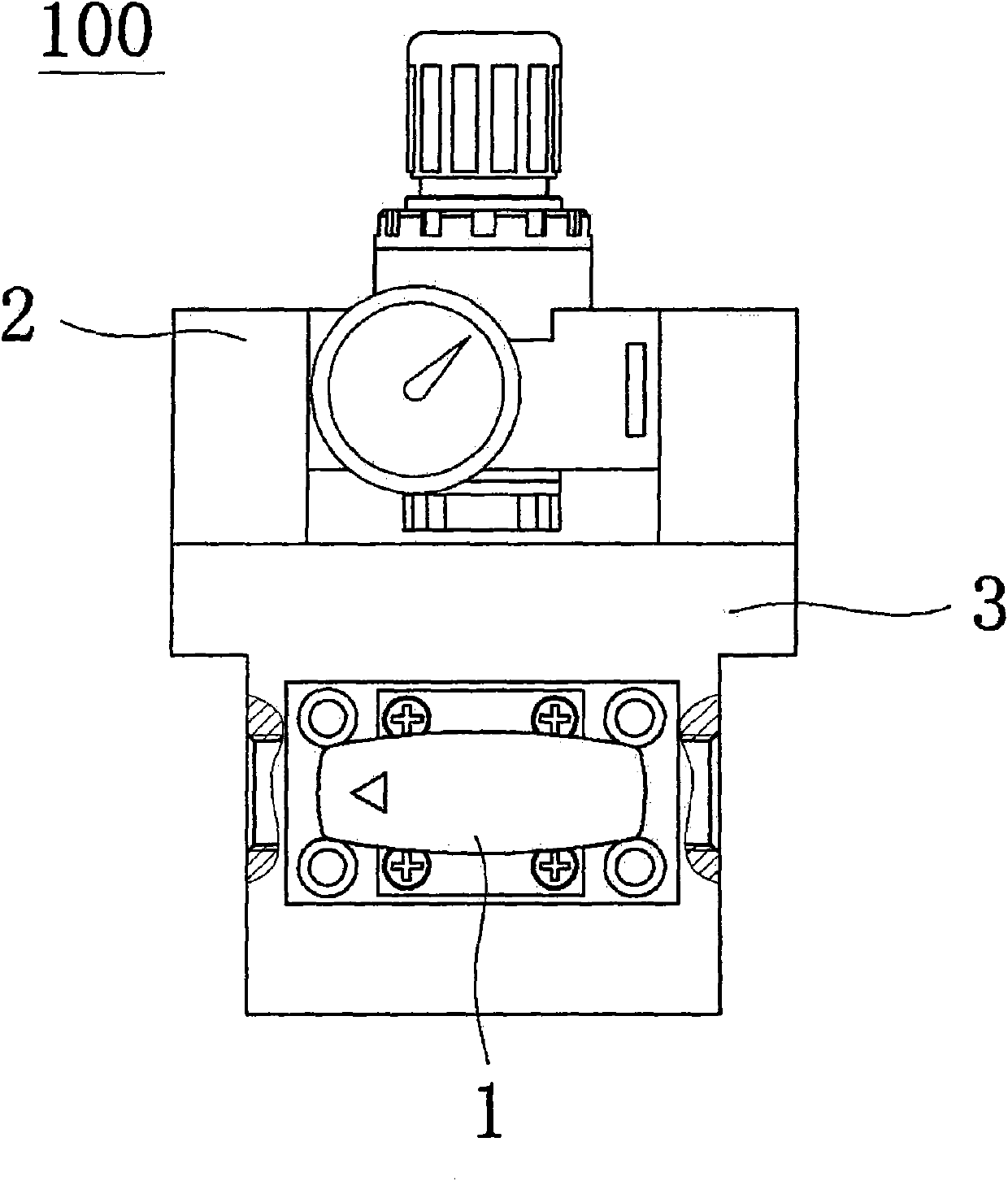

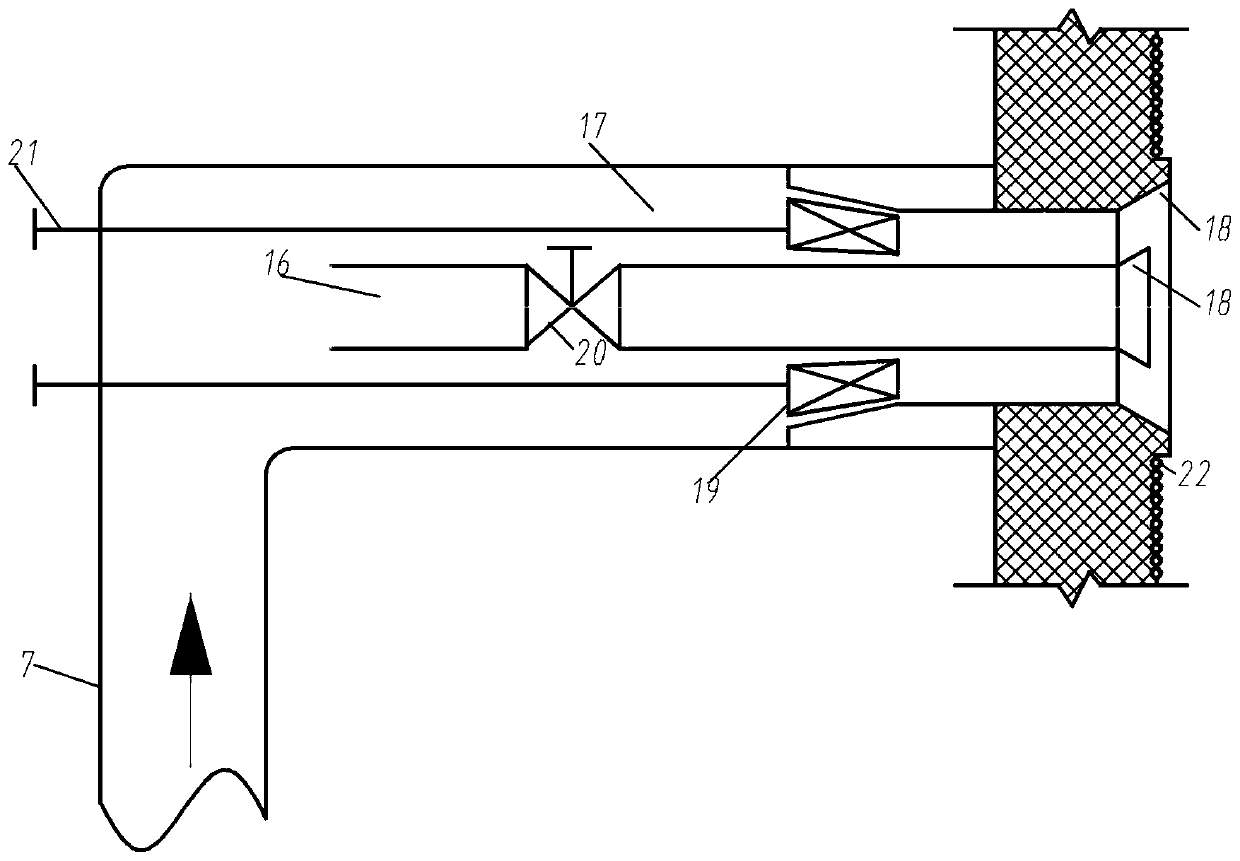

Sanding pressure control regulator

The present invention discloses a sanding pressure control regulator which is arranged in a sanding air passage and comprises an air passage plate, a blocking cock and a pressure regulator The air passage plate has a main air inlet and a main air outlet and is connected to the sanding air passage through the main air inlet and the main air outlet. A plurality of airways are provided inside the air passage plat. The blocking cock is fixed on the air passage plate and can be opened and closed for conducting or blocking compressed air in the air passage. The pressure regulator is fixed on the air passage plate and can adjust the pressure of the compressed air in the air passage to allow the pressure of the compressed air flowing through the pressure regulator to accord with the requirement of the sanding process. The blocking cock and the pressure regulator are connected in series through the air passage. With double functions of adjusting the pressure of the compressed air and controlling and blocking the compressed air, the sanding pressure control regulator of the present invention is applicable to blocking and adjusting the sanding pipeline pressure of locomotives of various types and enables to protect a sanding valve of the locomotives and to prolong the service life of the locomotives.

Owner:DATONG ELECTRIC LOCOMOTIVE OF NCR

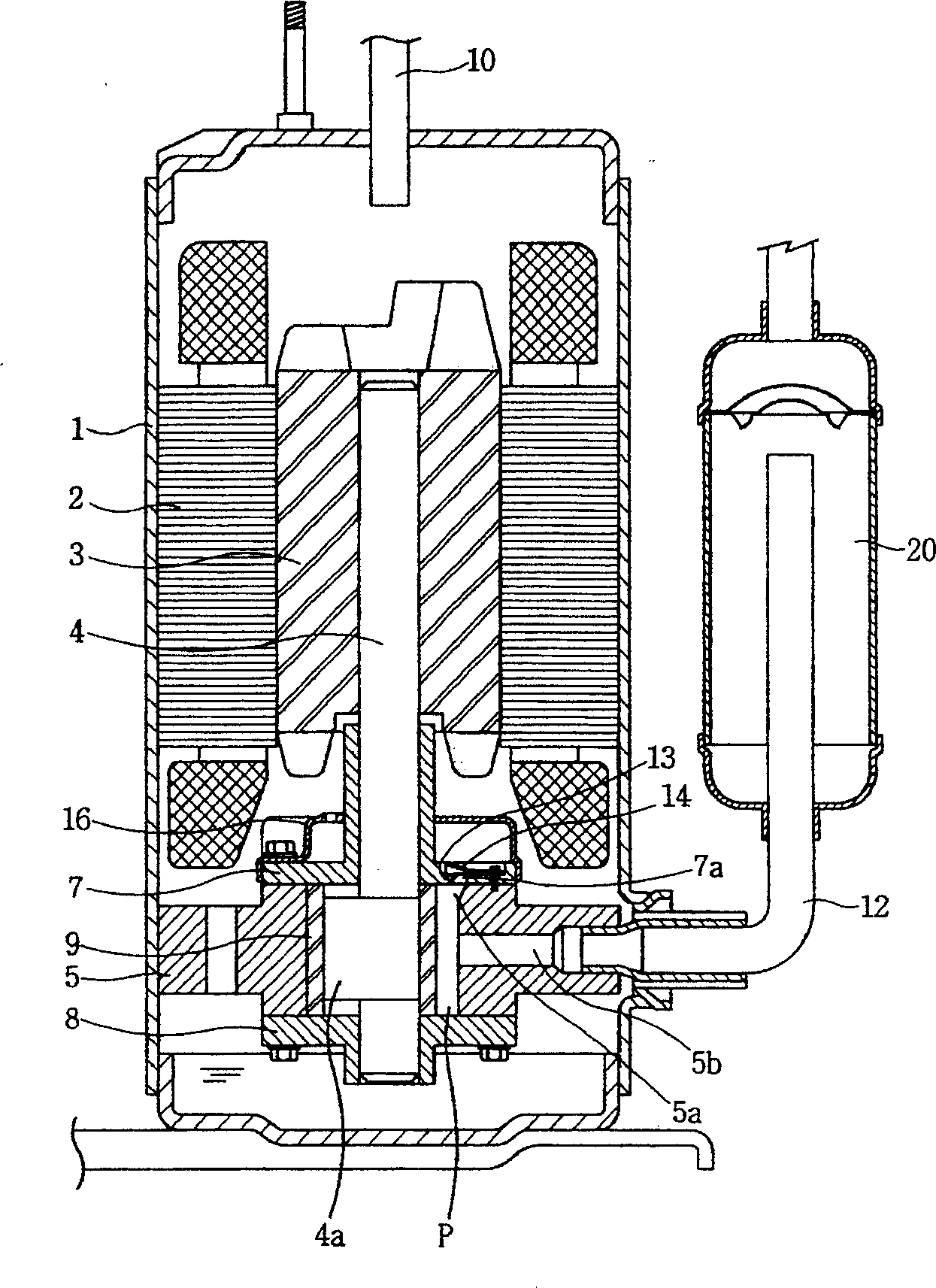

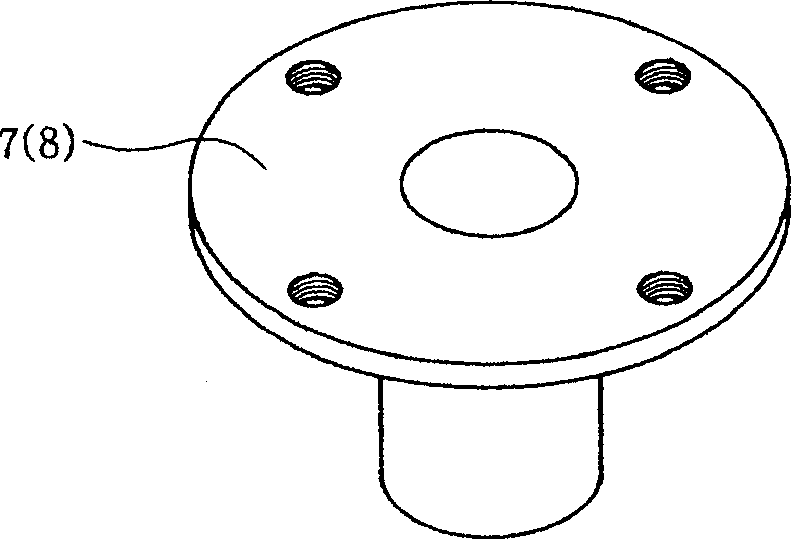

Structure for lowering load of rotary compressor

InactiveCN1427163AReduced mechanical propertiesReduce loadRotary piston pumpsRotary piston liquid enginesMechanical engineeringPiston

A structure for decreasing load of vortex-type compressor is composed of rolling piston, primary bearing and secondary bearing, and features that a recess is made on at least surface of them to decrease the contact area, so reducing friction and load.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Sound suspending polishing device for nanometer mechanics characterization sample

InactiveCN101344468BAchieve removalGood dispersionPreparing sample for investigationUltrasonic sensorTest sample

The invention discloses an acoustic levitation polishing machine of mechanically representing nano test samples and comprises a machine frame, a pulse power source, a holding fixture that is used for clamping a working piece to be processed, an ultrasonic energy transducer, a container that is used for storing polishing liquid, an ultrasonic reflecting end, and a tuning mechanism that is used foradjusting the distance between the ultrasonic reflecting end and the ultrasonic energy transducer. The ultrasonic energy transducer, the container and the tuning mechanism are all arranged above the machine frame, the pulse power source is connected with the ultrasonic energy transducer, the container is arranged under the ultrasonic energy transducer, the holding fixture is arranged above the container and is connected with a belt wheel actuating mechanism, and the ultrasonic reflecting end is arranged under the container, coordinated with the ultrasonic energy transducer and connected with the tuning mechanism. The invention provides an acoustic levitation polishing machine of the mechanically representing nano test samples with good applicability and well polishing effect.

Owner:ZHEJIANG UNIV OF TECH

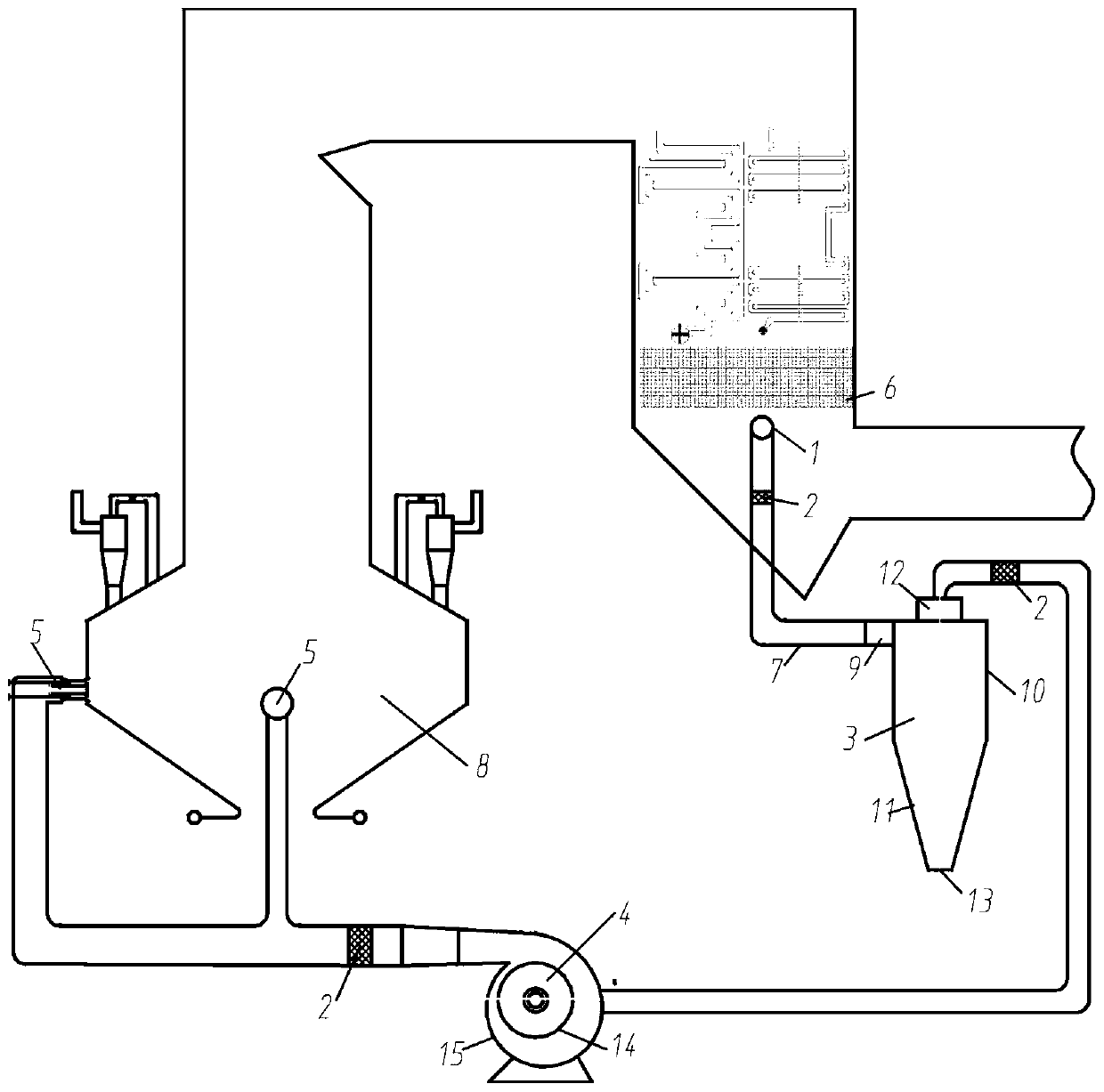

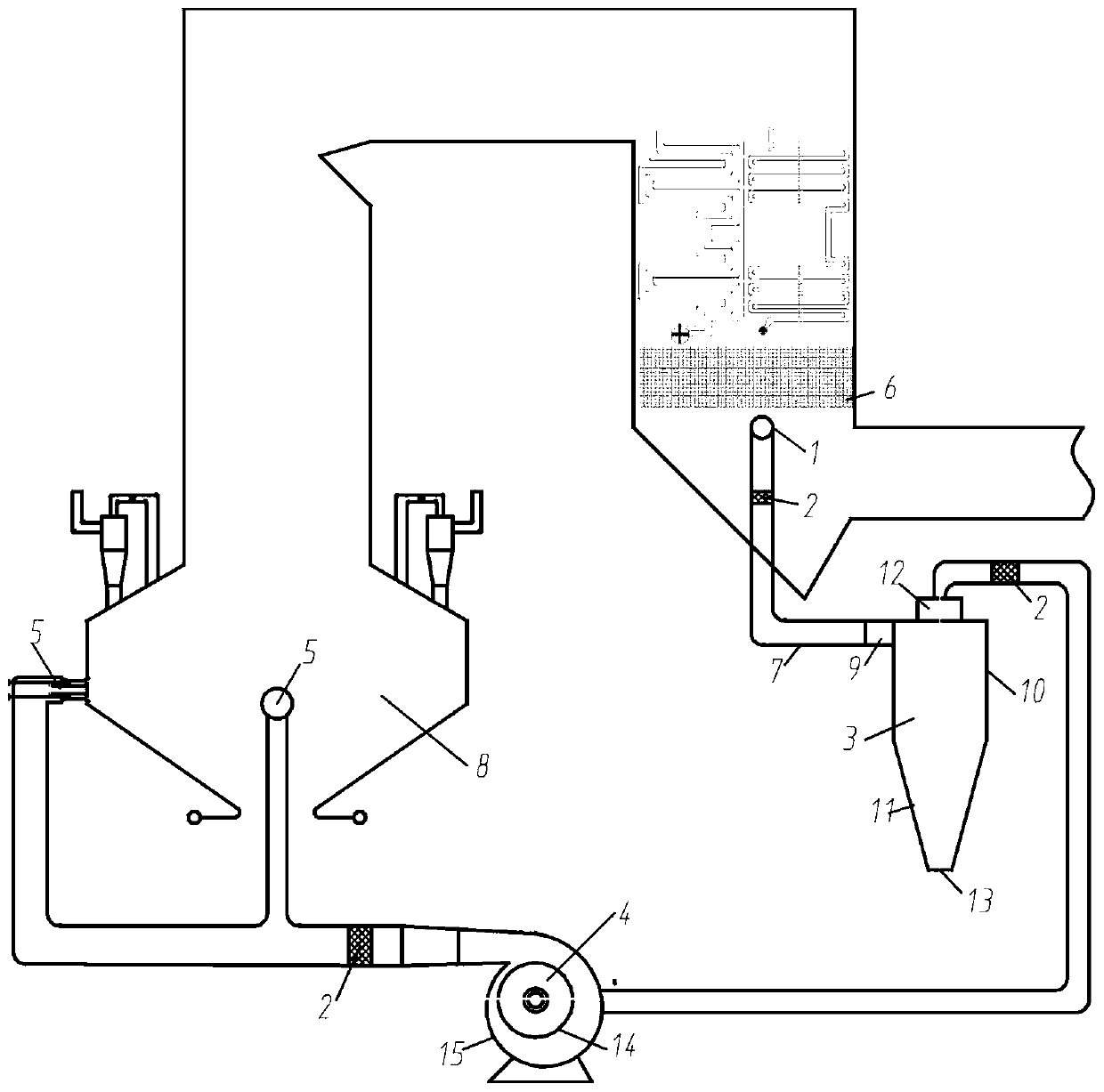

Flue gas recirculating system for low-nitrogen combustion and slag-bonding prevention of W-flame boiler

PendingCN111121007AReduce the temperatureControl generationCombustion apparatusAir preheaterBoiler furnace

The invention relates to a flue gas recirculating system for low-nitrogen combustion and slag-bonding prevention of a W-flame boiler. The flue gas recycling system comprises a boiler smoke exhaustingopening, a cyclone dust collector and a recirculating flue gas distributor, the boiler smoke exhausting opening communicates with a gas inlet of the cyclone dust collector, the cyclone dust collectoris connected with a recirculating fan through a boiler smoke pipeline, the recirculating fan is connected with the recirculating flue gas distributor, the recirculating flue gas distributor comprisesan inner annular channel and an outer annular channel, the inner annular channel is formed in the outer annular channel, a plurality of hydrocyclones are arranged on the outer annular channel, and anelectric regulating valve is arranged on the inner annular channel. High-temperature flue gas of the system is taken from the lower part of an economizer at the tail of the boiler, the temperature is10 DEG C-20 DEG C higher than the temperature of hot primary air and hot secondary air at an outlet of an air preheater, the flue gas is introduced into an under-arch area of a hearth of the boiler, the amount of the flue gas in the boiler can be increased, the main steam temperature and the reheat steam temperature are increased, the NOx generation amount is controlled, slag-bonding of a water-cooling wall of the under-arch area of the boiler is prevented, and the flue gas recirculating rate is controlled at 10%-20%.

Owner:XIAN THERMAL POWER RES INST CO LTD

Sand-paving machine simultaneously having sand-sieving and pressure-reducing sand-guiding functions

InactiveCN100464022CAvoid affecting topdressing qualityIncreased load-bearing capacityRoads maintainenceEngineeringMechanical engineering

This invention involves a kind spread sand machine have both siftings leads the sand function and the reduced pressure, which is composed by the rack, the sandbox, the conveyer belt and rolls brushes. The conveyer belt passes through establishment in the sandbox base, rolls brushes clings establishes underneath the sand mouth, near the sandbox cavity bottom is equipped with the reduced pressure to lead the sand grid overlay, upside establised siftings the grid overlay and the belt eccentric tappet vibration revolution axis, the reduced pressure leads on the sand grid overlay to be equipped with the small grid which, the handle and the spacing concave buckle around certain belts the unidirectional inclined shape side and the stiffener constitute, siftings on the grid overlay to be equipped with by the belt specification mesh strainer, vertically and horizontally the overlapping stiffener, the handle and the spacing saw notch, in the sandbox cavityNear base and upside on the sidewall establishes separately has the spacing to hold the block. When work, the sand falls directly in siftings on the grid overlay, after sieving filters the whereabouts, the reduced pressure to lead the sand grid overlay leads the sand on the conveyer belt obtains with the sand, withstanding compared to carries less pressures than the sands quantity, it is advantageous in raises the overall working efficiency, the construction quality and the extension conveyer belt service life, has the very strong usability.

Owner:李明

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com