A fan control circuit for prolonging the life of fan DC carbon brush motor

A fan motor and fan control technology, applied in pump control, emergency protection circuit devices, electrical components, etc., can solve the problems of accelerated wear of the motor working current carbon brush, arcing, carbon deposition in the commutator slot, etc., to eliminate the motor Unstable working phenomenon, eliminating the effect of increasing the working current of the motor and prolonging the life of the fan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

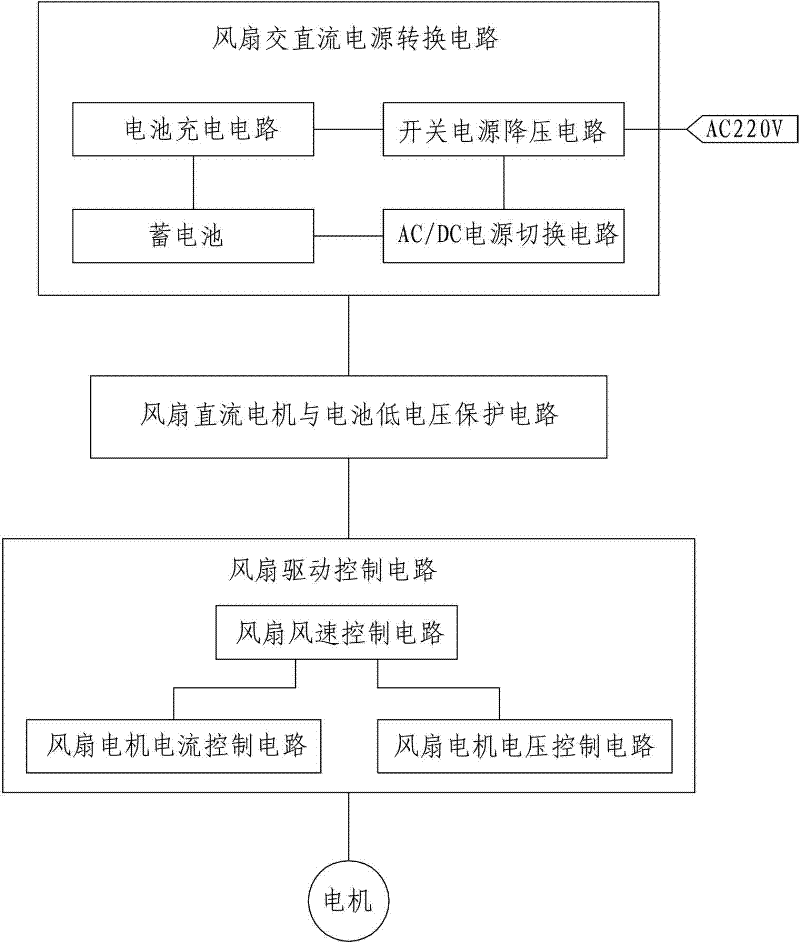

[0024] see figure 1 and Figure 5 , The invention discloses a fan control circuit for prolonging the service life of a fan DC carbon brush motor, which includes three major circuits including a fan AC-DC power conversion circuit, a fan DC motor and battery low-voltage protection circuit, and a fan drive control circuit.

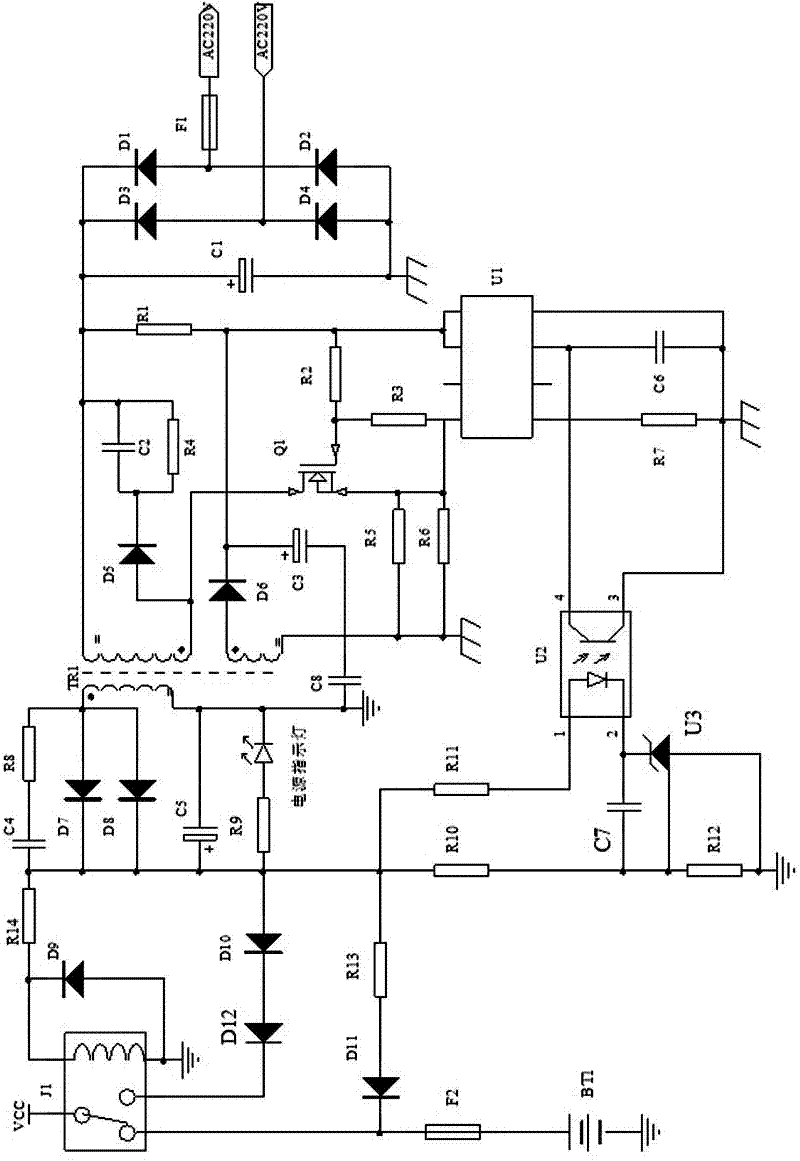

[0025] Among them, the fan AC-DC power conversion circuit can realize two kinds of power supply: industrial frequency AC power supply and DC power supply (rechargeable battery). The circuit schematic diagram is as follows: figure 2 shown. This circuit is divided into three parts: the first is the switching power supply step-down circuit, which consists of D1, D2, D3, D4, D5, D6, D7, D8, D9, R1, R2, R3, R4, R5, R6, R7, R8, R9 , R10, R11, R12, Q1, TR1, U1, U2, U3, C1, C2, C3, C4, C5, C6, C7, C8, F1 form a switching power supply step-down circuit, which converts the mains power into a DC carbon brush motor The required low-voltage direct current, in which U1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com