Burnt-out polar fleece fabric and production method thereof

A production method and technology of polar fleece, applied in textile decoration, textile and papermaking, weft knitting and other directions, can solve the problems of complex process control, excessive ablation of fabric holes, etc., to expand economic benefits, ensure quality, The effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

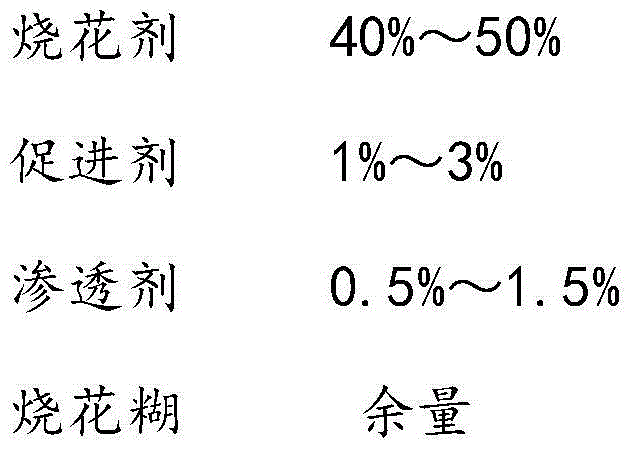

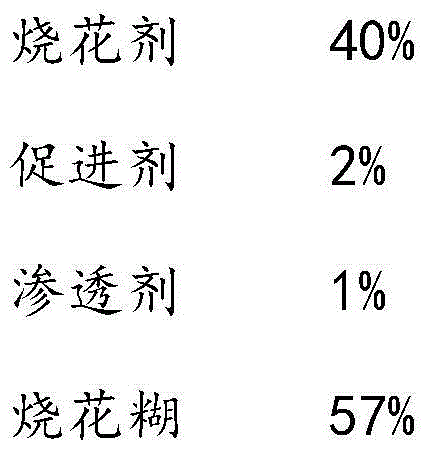

[0024] A burnt-out polar fleece fabric, the fabric is made through a burnt-out process, the fabric includes a veil and a bottom yarn, an alkaline burn-out auxiliary agent is used in the burnt-out process, the veil is polyester fiber, and the bottom yarn It is a viscose fiber blended yarn, which contains the following raw materials in mass percentages:

[0025] Cotton 15%

[0026] Viscose 55%

[0027] Nylon fiber 30%

[0028] Using the viscose fiber blended yarn with this composition, the blended yarn has the best thermal insulation and heat generation properties, and at the same time, the blended yarn has the best processability. The blended yarn has better alkali resistance. , will not ablate holes.

[0029] The above-mentioned burned-out polar fleece fabric is produced in the following manner: the mixed yarn of the above-mentioned polyester fiber and the above-mentioned viscose fiber is woven into a gray cloth on a large circular machine, and the gray cloth is passed thro...

Embodiment 2

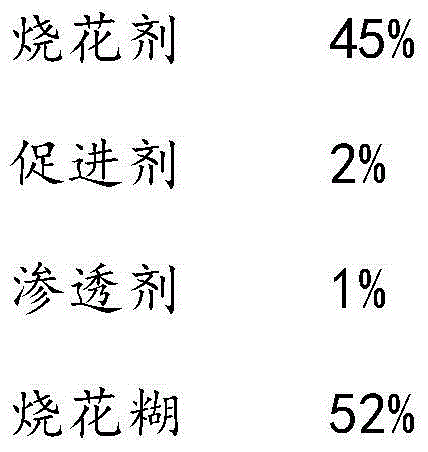

[0037] A burnt-out polar fleece fabric, the fabric is made through a burnt-out process, and the fabric includes a veil and a bottom yarn, an alkaline burn-out auxiliary agent is used in the burnt-out process, the veil is polyester fiber, and the bottom yarn It is a viscose fiber blended yarn, which contains the following raw materials in mass percentages:

[0038] Cotton 15%

[0039] Viscose 60%

[0040] Nylon fiber 25%

[0041] The above-mentioned burnt-out polar fleece fabric is produced in the following manner: the mixed yarn of the above-mentioned polyester fiber and the above-mentioned viscose fiber is woven into a gray cloth on a large circular machine, and the gray cloth is passed through the cutting process, the brushing process, the first carding process, the first The second shearing process, the pre-setting process, the burning process, the steaming process, the washing process, the dyeing process, the vat plus fluffing agent process, the dehydration and drying pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com