Sealing material used between coke oven protecting plate and oven door frame and preparation method

A technology of sealing materials and protective plates, which is applied in the field of materials science, can solve the problems of poor sealing effect of sealing materials and complicated manufacturing process, and achieve the effects of improving high temperature volume stability, good thermal shock resistance, and good air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

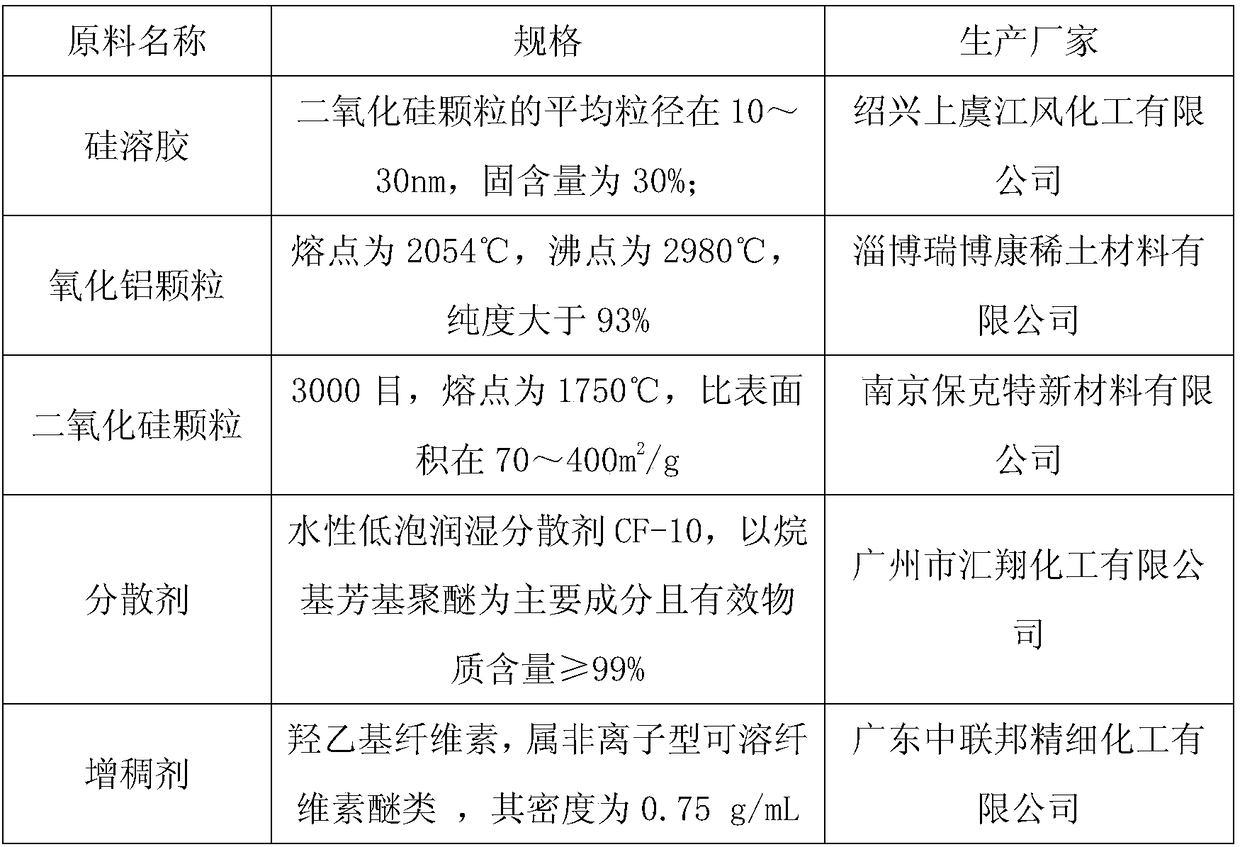

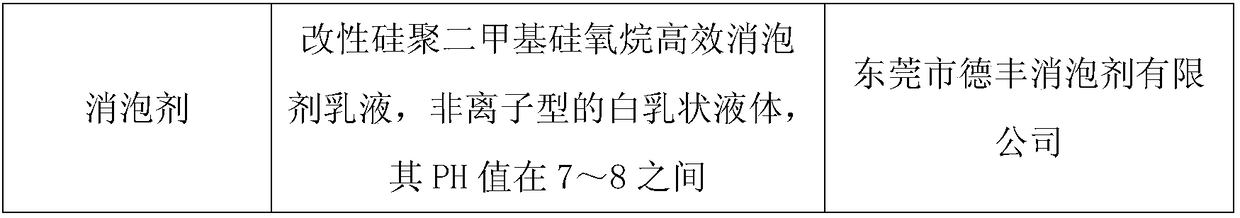

[0062] A sealing material used between a coke oven protection plate and an oven door frame, characterized in that, in parts by weight, its raw material composition and content are as follows:

[0063] 100 parts of silica sol solution;

[0064] 130 parts of aggregate;

[0065] 15 parts of additives;

[0066] The silica sol solution is a dispersion of nano-scale silica particles in water, the average particle diameter of the silica particles is 10-30 nm, and the solid content is 30%;

[0067] The aggregate is a mixture of alumina particles, silica particles and talcum powder, the amount of alumina particles, silica particles and talcum powder in the mixture is calculated by mass percentage, alumina particles: silica Granules: Talc as 45%:30%:25%;

[0068] Wherein, the melting point of the alumina particles is 2054°C, the boiling point is 2980°C, and the purity is greater than 93%;

[0069] The silica particles are 3000-10000 mesh, and their melting point is 1750°C;

[0070]...

Embodiment 2

[0083] A sealing material used between a coke oven protection plate and an oven door frame, characterized in that, in parts by weight, its raw material composition and content are as follows:

[0084] 100 parts of silica sol solution;

[0085] 180 parts of aggregate;

[0086] 17 parts of additives;

[0087] The silica sol solution is a dispersion of nano-scale silica particles in water, the average particle diameter of the silica particles is 10-30nm, and the solid content is 30%;

[0088] The aggregate is a mixture of alumina particles, silica particles and talcum powder, the amount of alumina particles, silica particles and talcum powder in the mixture is calculated by mass percentage, alumina particles: silica Granules: Talc as 60%:30%:10%;

[0089] Wherein, the melting point of the alumina particles is 2054°C, the boiling point is 2980°C, and the purity is greater than 93%;

[0090] The silica particles are 3000-10000 mesh, and their melting point is 1750°C;

[0091] ...

Embodiment 3

[0104] A sealing material used between a coke oven protective plate and an oven door frame, characterized in that, in parts by weight, its raw material composition and content are as follows:

[0105]100 parts of silica sol solution;

[0106] 155 parts of aggregate;

[0107] 16 parts of additives;

[0108] The silica sol solution is a dispersion of nano-scale silica particles in water, the average particle diameter of the silica particles is 10-30nm, and the solid content is 30%;

[0109] The aggregate is a mixture of alumina particles, silica particles and talcum powder, the amount of alumina particles, silica particles and talcum powder in the mixture is calculated by mass percentage, alumina particles: silica Granules: Talc as 50%:25%:25%;

[0110] Wherein, the melting point of the alumina particles is 2054°C, the boiling point is 2980°C, and the purity is greater than 93%;

[0111] The silica particles are 3000-10000 mesh, and their melting point is 1750°C;

[0112] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com