Method for machining rotor spindle of high pressure turbine

A technology of machining and high-pressure turbine, applied in the field of machining, can solve the problems of lengthy process, low pass rate of static balance superimposed projection detection, etc., and achieve the effect of ensuring shot peening strength and avoiding deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

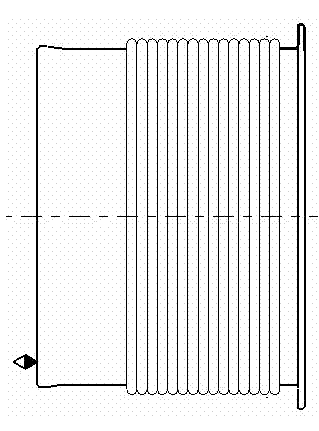

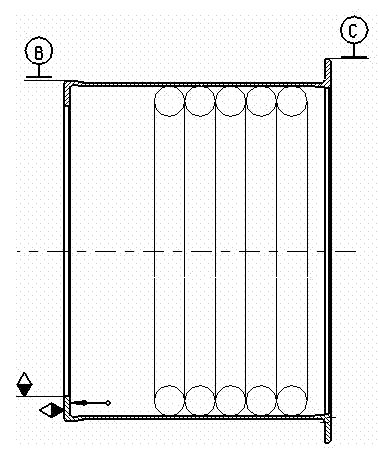

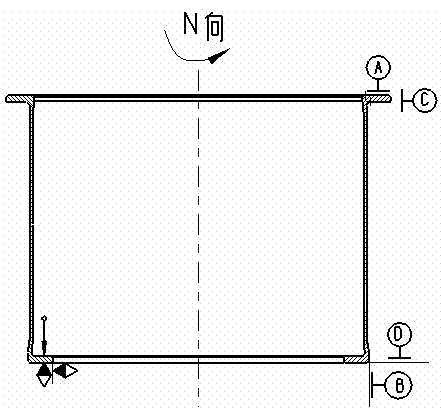

Image

Examples

Embodiment Construction

[0023] The processing route of the high-pressure turbine rotor shaft of the present invention: rear end positioning, semi-finishing front-end positioning, semi-finishing rear-rear positioning, finishing front-front positioning, finishing rear-processing end face, sector Groove - shot peening - finish turning seam - static balance - superimposed projection detection.

[0024] The rear end positioning described above, the front end of the semi-finishing car: the rough machining front adopts a ceramic knife with a large cutting capacity of 1.2mm-2mm, a high cutting speed of 180-208min / m and a large feed rate of 0.2-0.3mm / r to remove the allowance;

[0025] The front end positioning described above, the rear end of the semi-finishing car: the rough machining rear end also adopts ceramic knives with a large cutting amount of 1.2mm-2mm, a high cutting speed of 180-208min / m and a large feed rate of 0.2-0.3mm / r to remove excess quantity;

[0026] Directly carry out semi-finishing mac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

| Circularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com