Sand-paving machine simultaneously having sieving sand pressure-reducing sand-guide functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1 common type

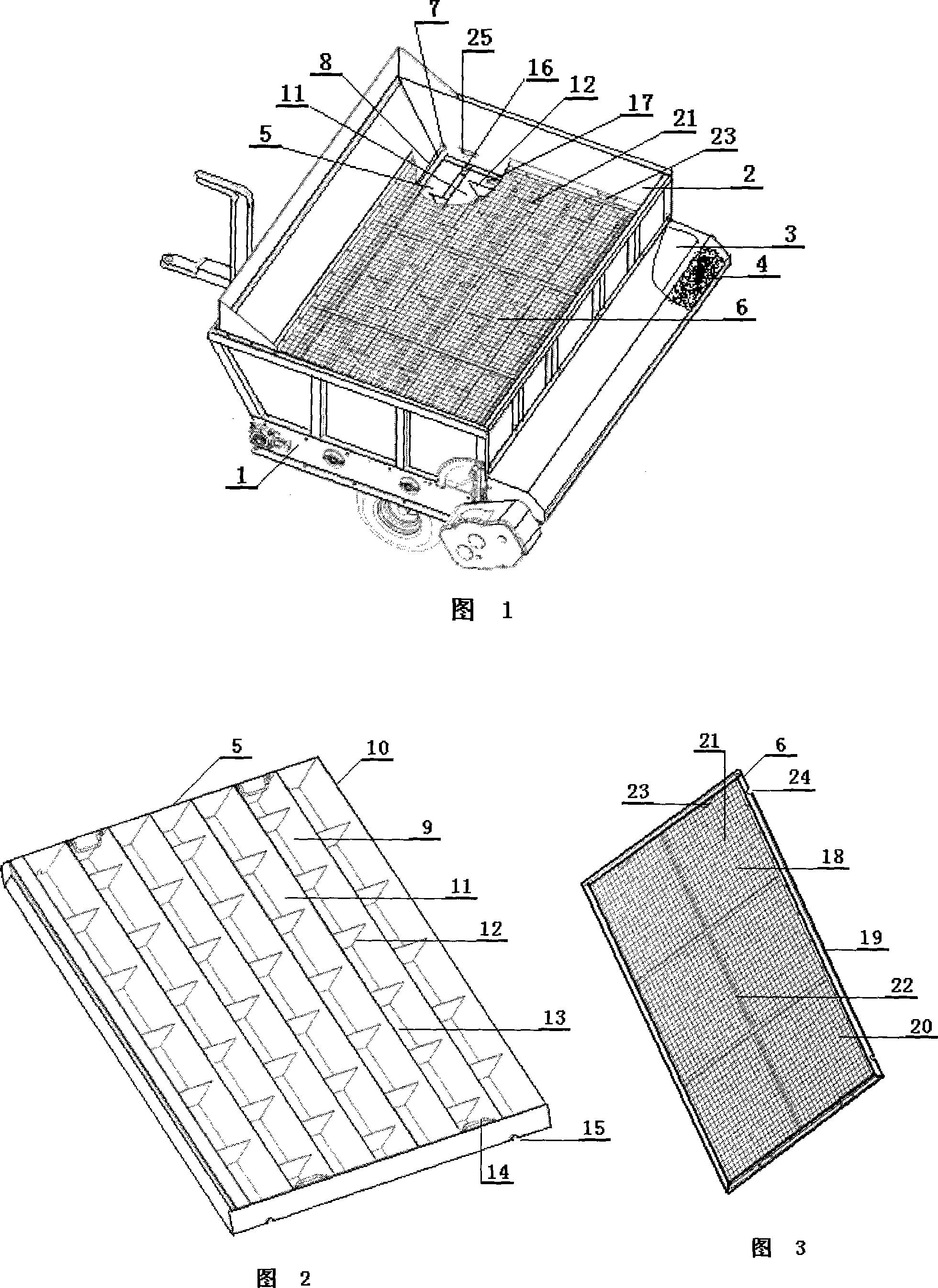

[0023] In Fig. 1, Fig. 2 and Fig. 3, the main body of the topdressing machine with the functions of sand screening and decompression and sand guiding of the present invention is composed of a frame 1, a sandbox 2 that takes out the sand mouth, a conveyor belt 3 driven by power and Composed of roller brushes 4, the conveyor belt 3 passes through and is arranged on the bottom of the sandbox 2, and the roller brushes 4 are arranged closely below the sand outlet. Pressure sand guide grid plate 5 and a sand screening grid plate 6 composed of the middle main surface 16 and the surrounding frame 17, wherein: the decompression sand guide grid plate 5 is horizontally arranged near the bottom of the box 2 above the conveyor belt 3 In terms of position, the middle main board 7 is connected by a number of small grids 11 composed of front and rear unidirectional inclined sides 9 and reinforcing ribs 10 arranged between the front and rear unidirectional inc...

Embodiment 2

[0025] Embodiment 2 vibration type

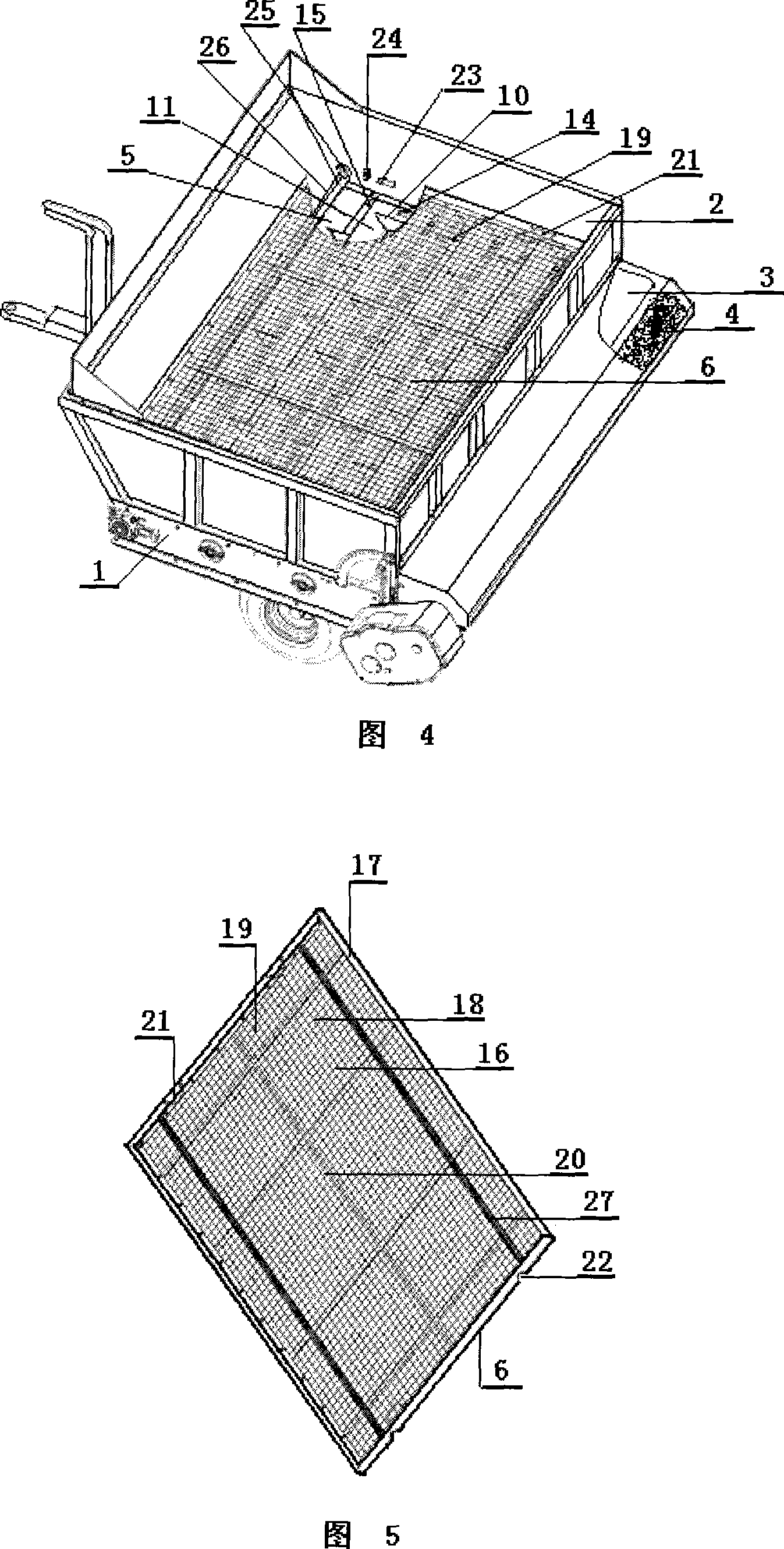

[0026]In Fig. 4 and Fig. 5, the main body of the sand topdressing machine with the functions of sand screening and decompression and sand guiding of the present invention is composed of a frame 1, a sand box 2 that is brought out of the sand mouth, a powered conveyor belt 3 and a roller brush 4 Composition, the conveyor belt 3 passes through and is set on the bottom of the sand box 2, and the roller brush 4 is placed close to the bottom of the sand outlet. It is characterized in that a decompression sand guide composed of a middle main board 7 and a surrounding frame 8 is arranged horizontally in the cavity of the sand box 2. Grid plate 5, a sand screening grid plate 6 made of the middle main surface 16 and the surrounding frame 17 and an upper band with a vibrating shaft 26 that drives the eccentric protrusion 25 of the sand screening grid plate 6 to vibrate, wherein: the The decompression and sand guide grid plate 5 is horizontally arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com