Patents

Literature

37results about How to "Avoid out-of-shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

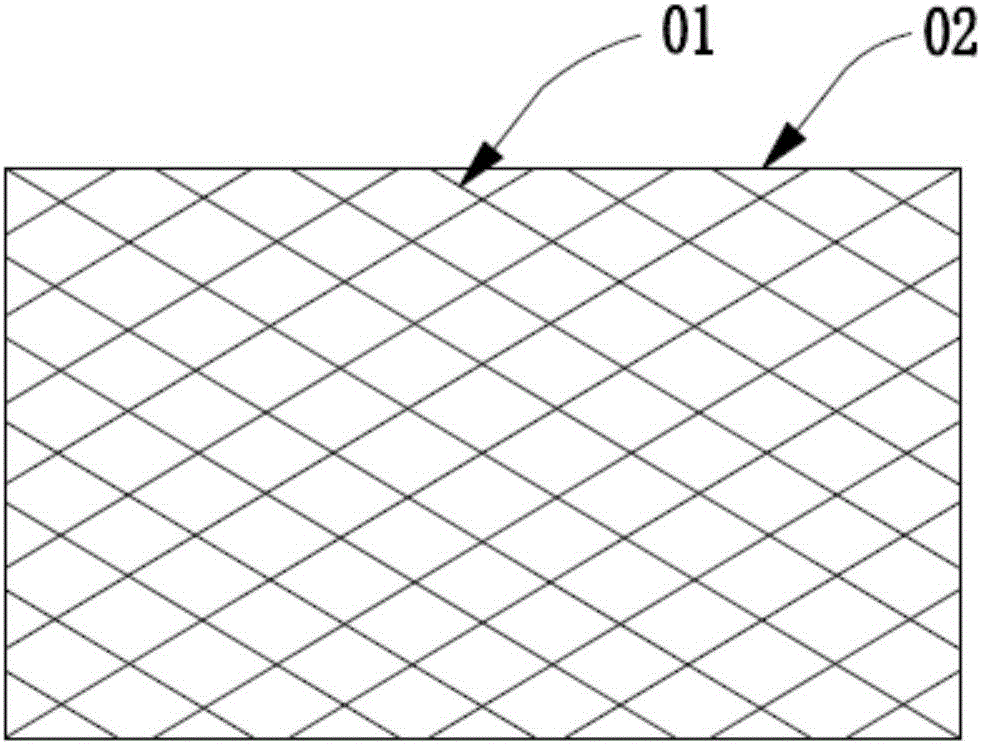

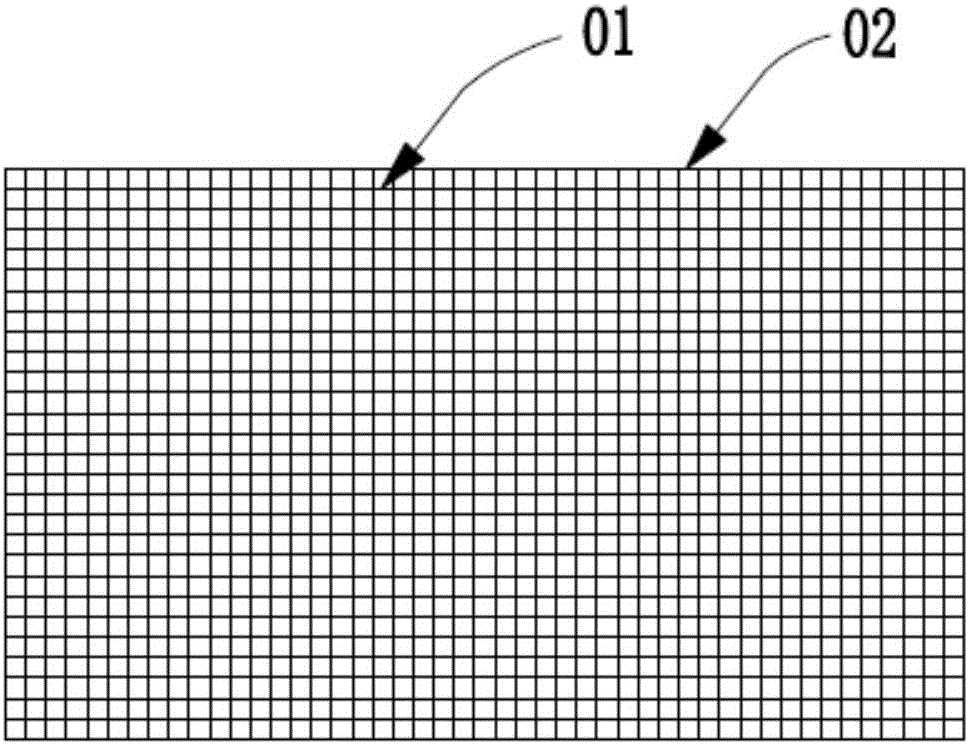

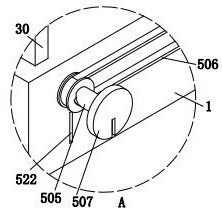

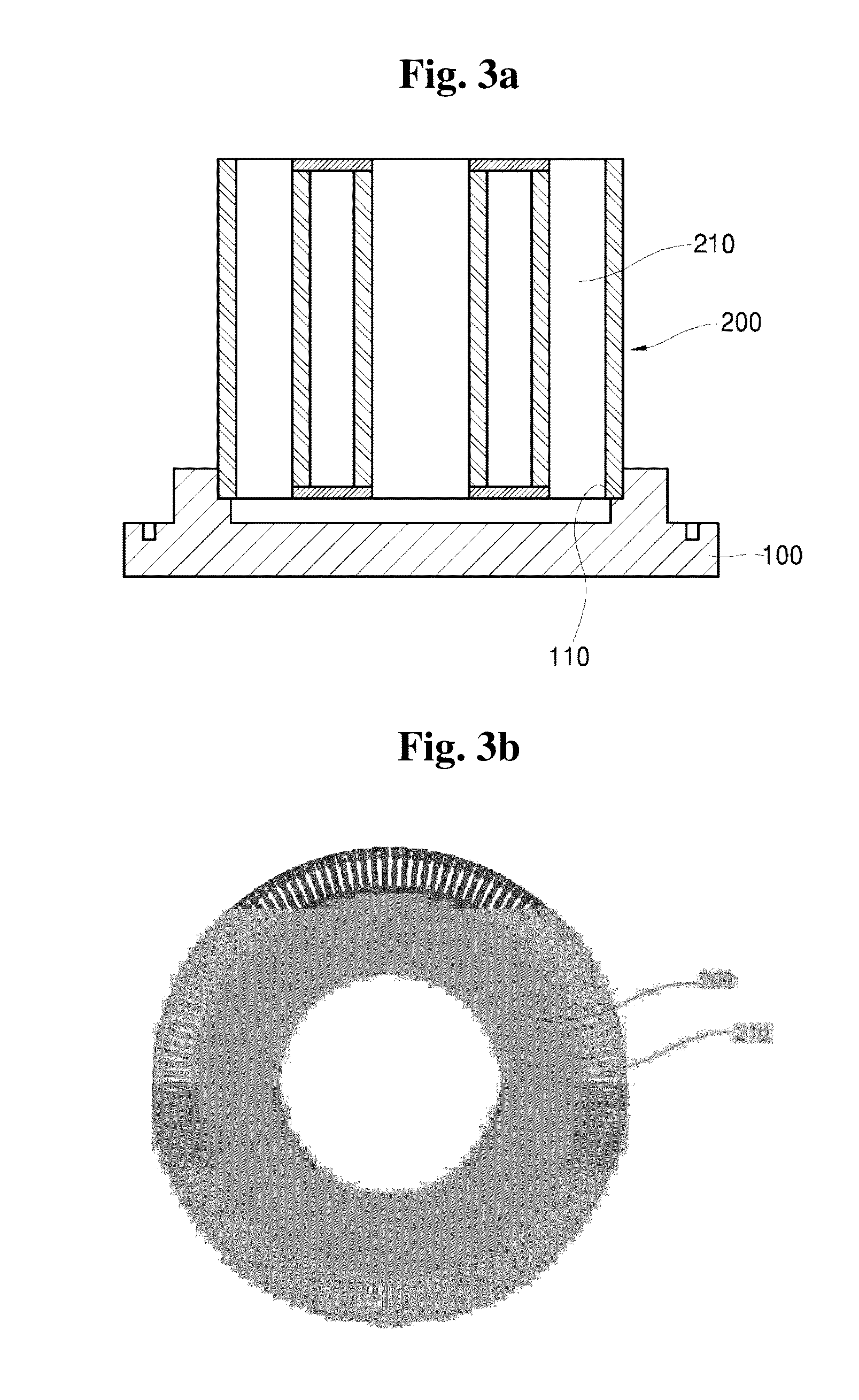

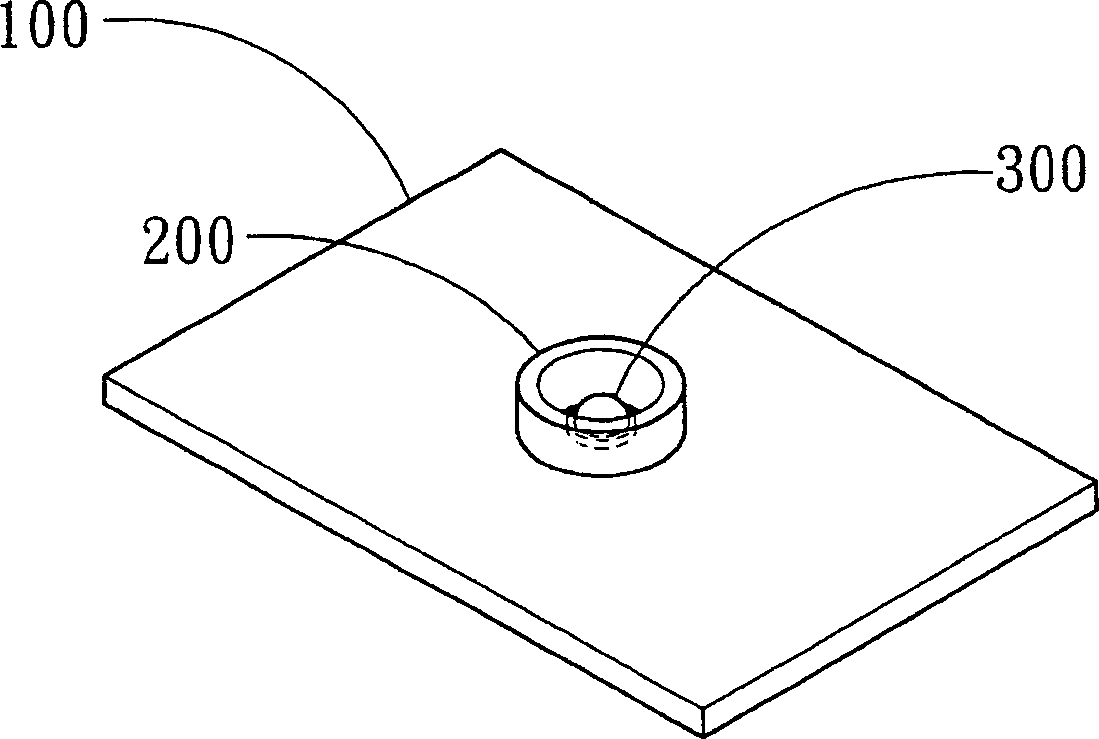

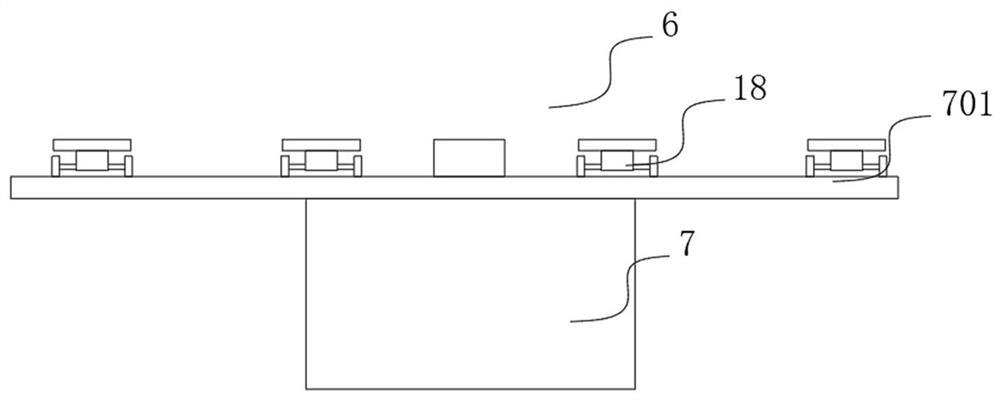

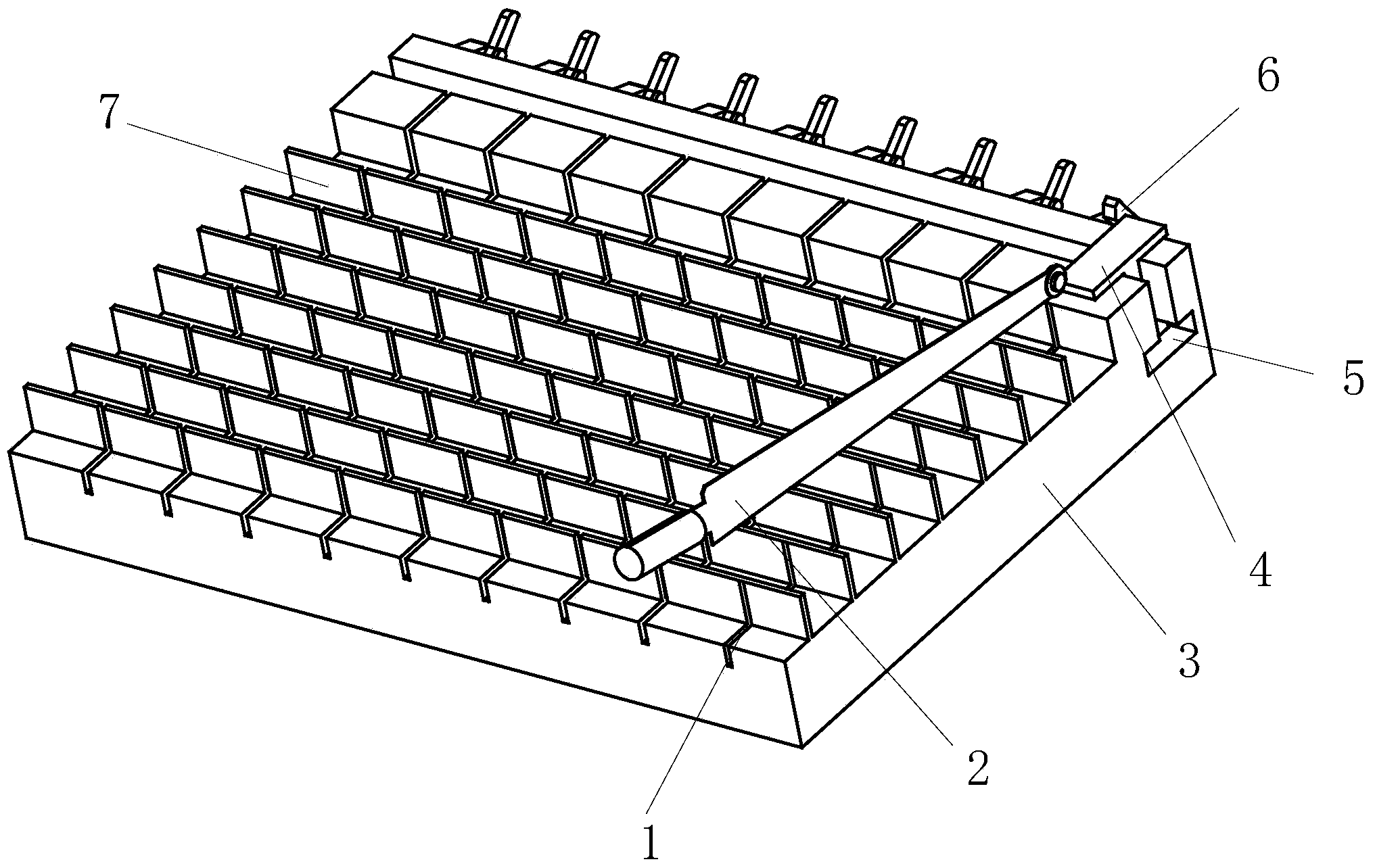

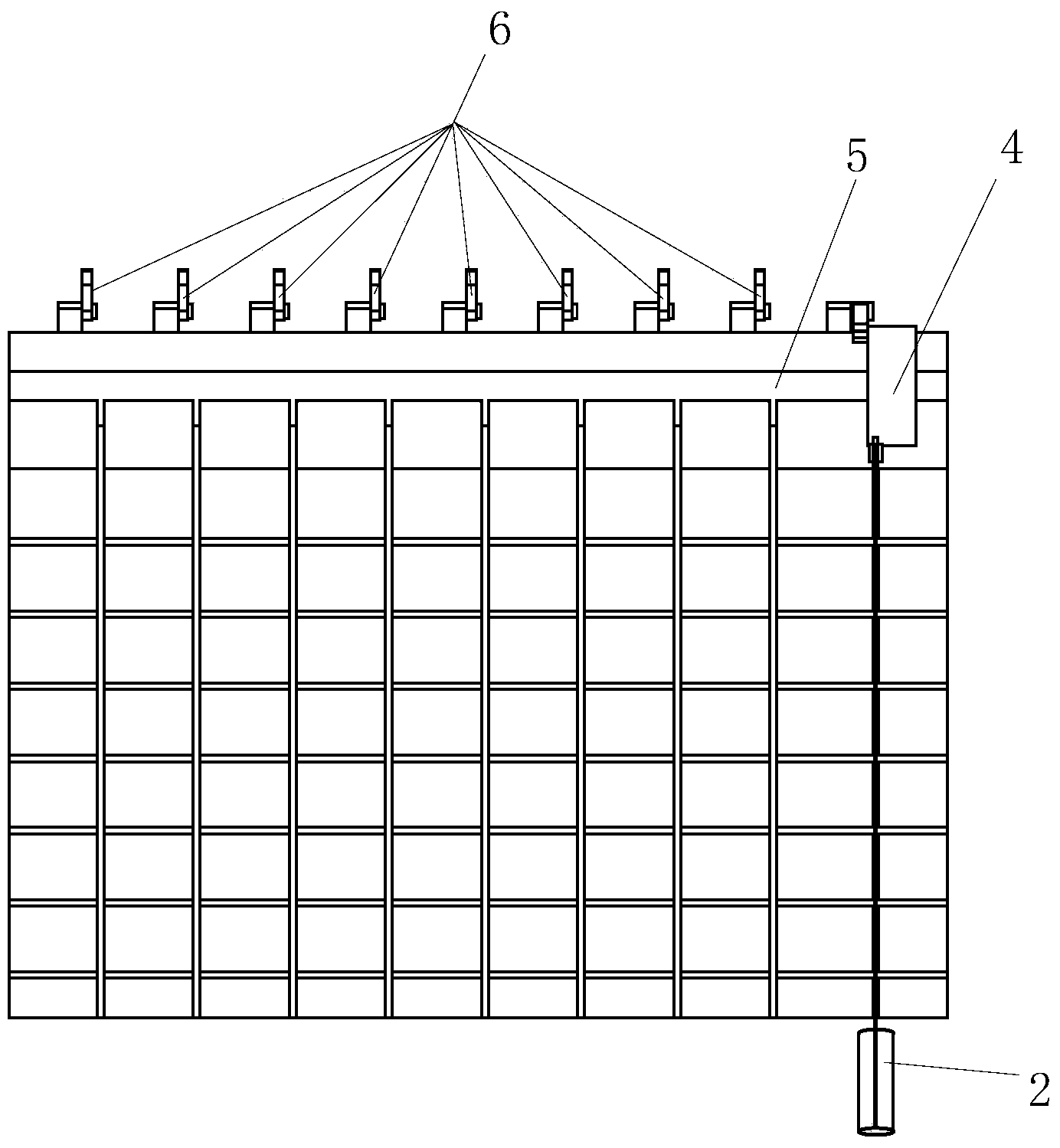

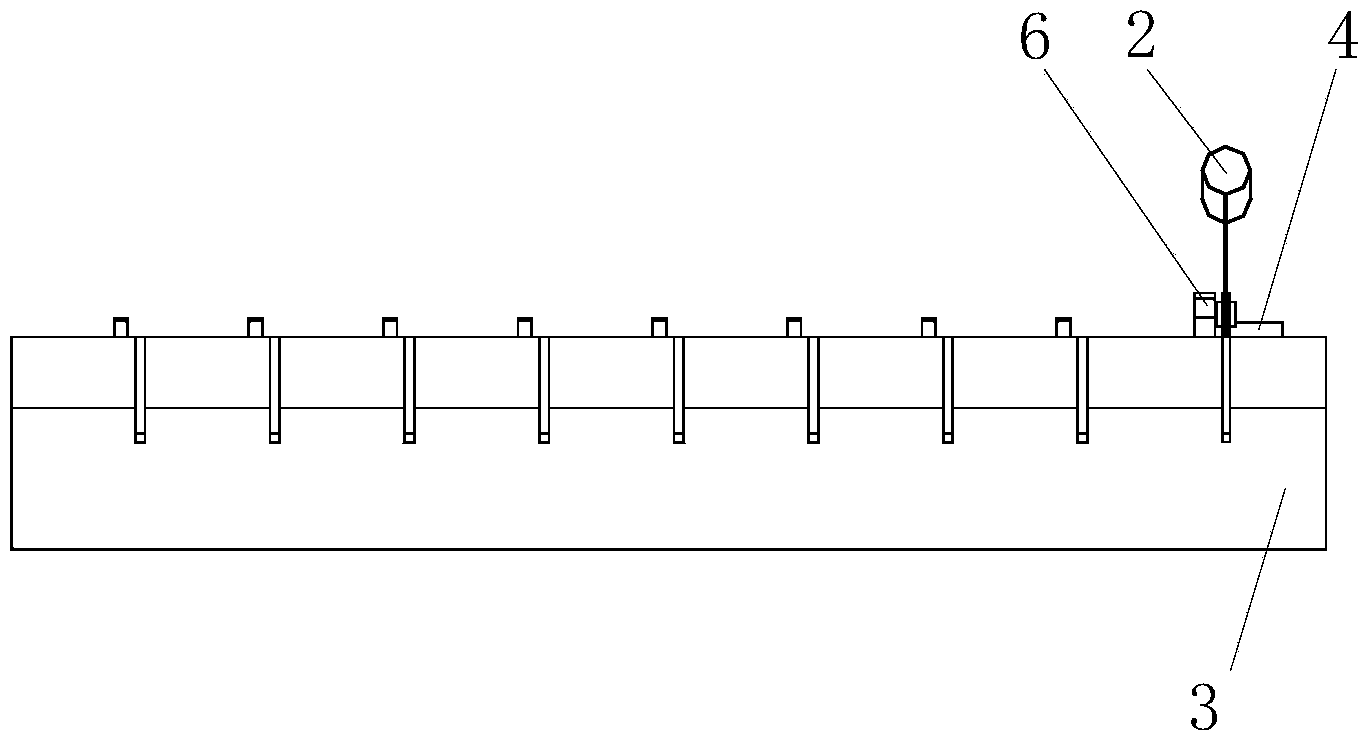

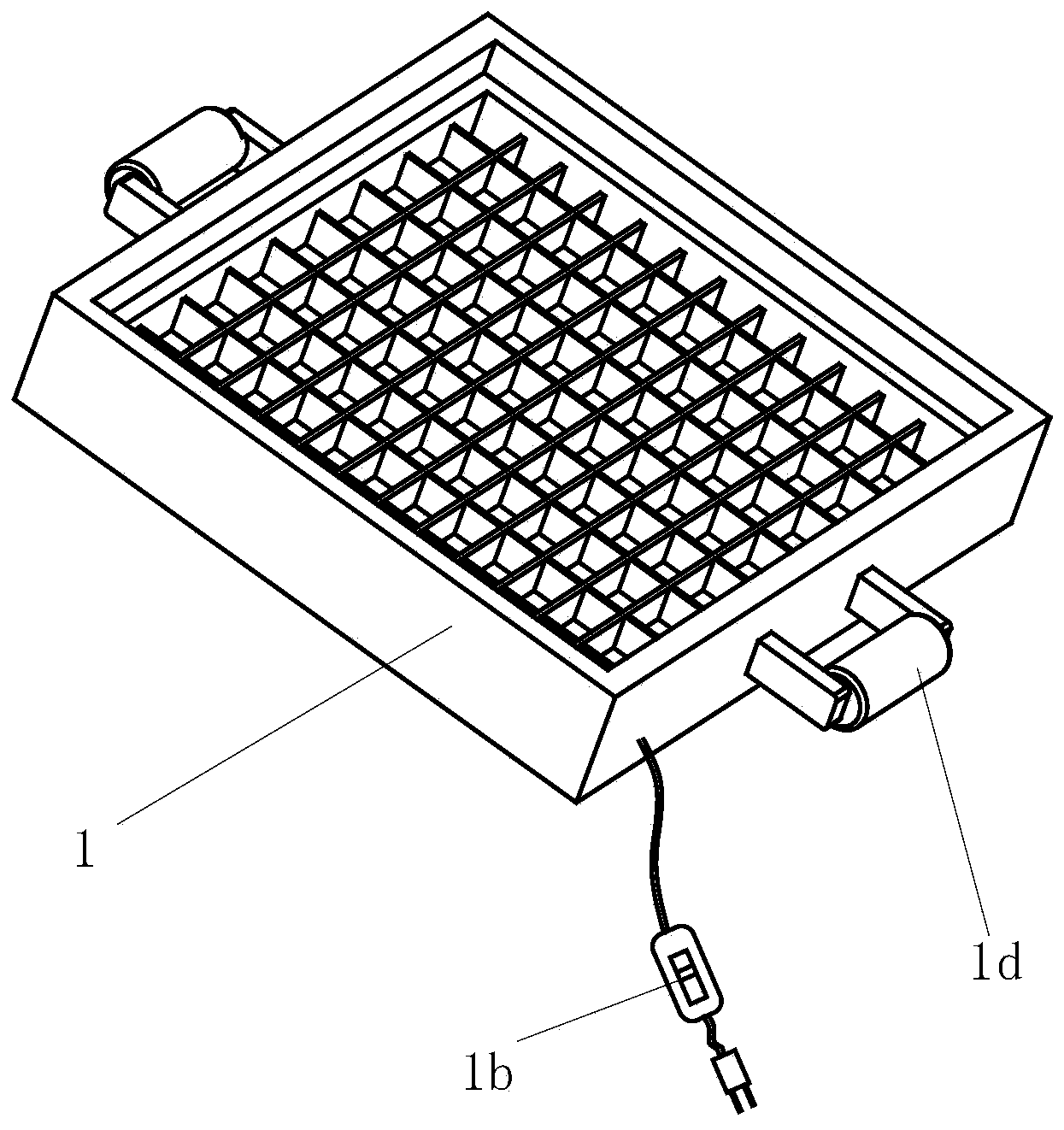

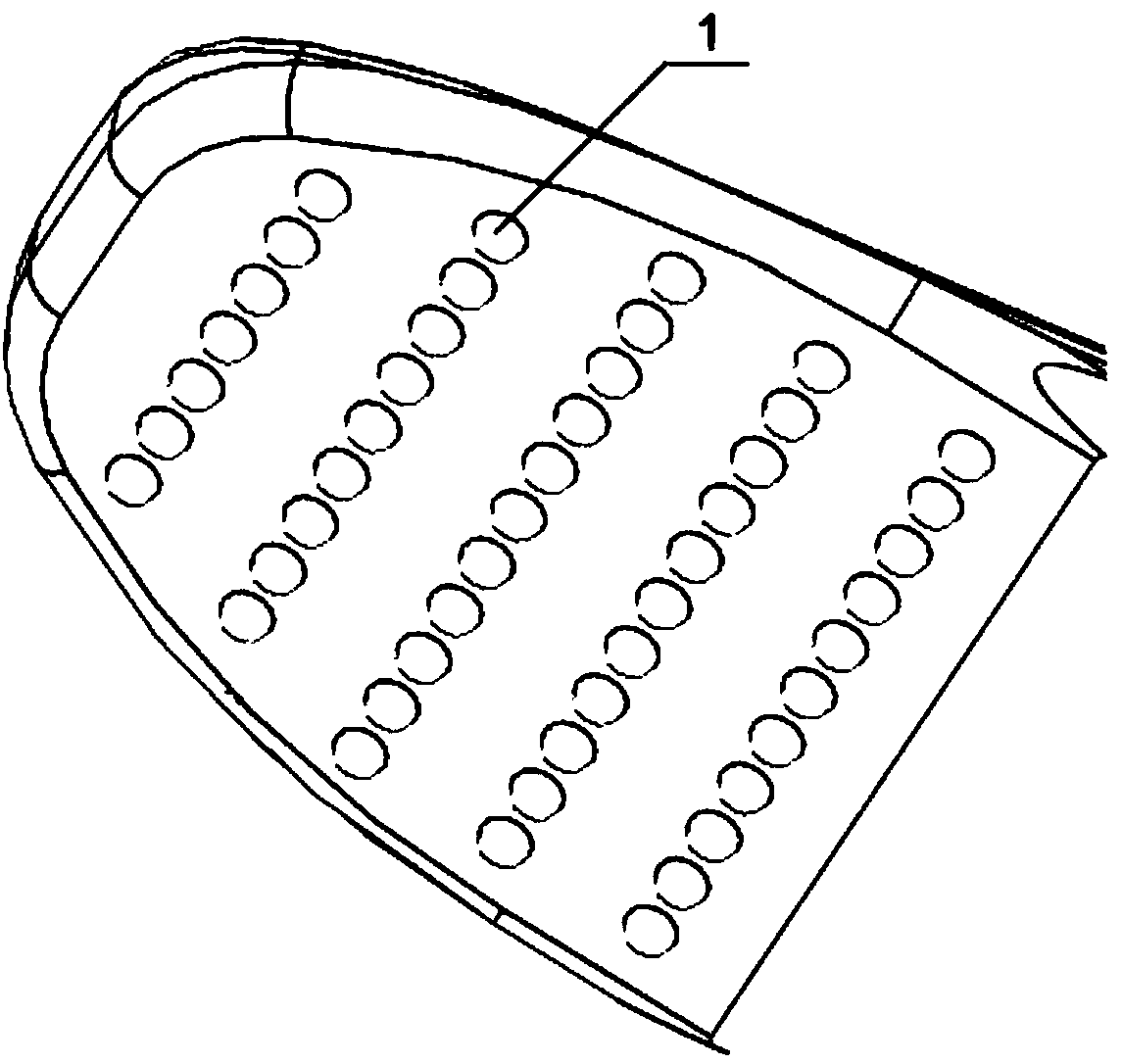

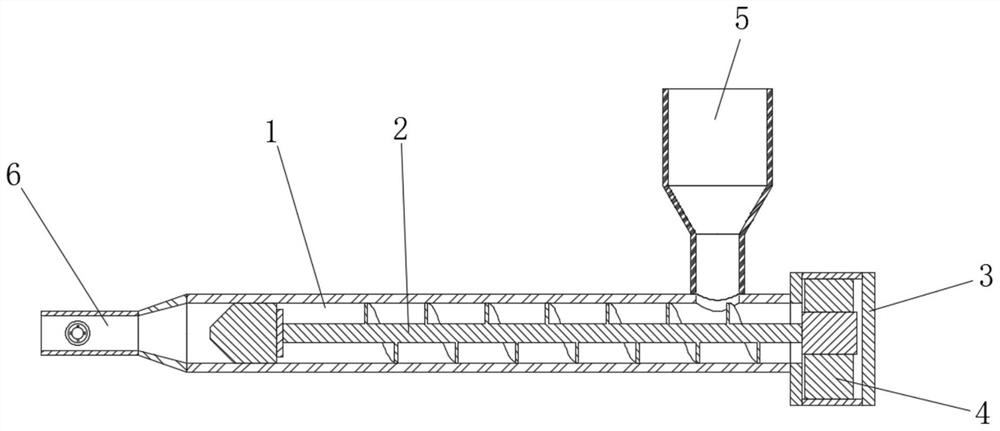

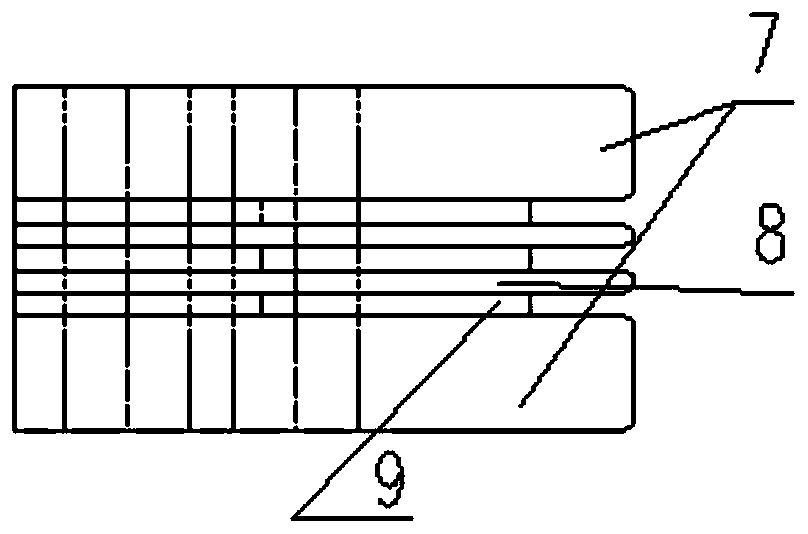

Preparation process for imitation full-body tile and grid provided with square lattices and used for preparation process

ActiveCN107520950AAvoid cross mixingAvoid out of shapeFeeding arrangmentsAuxillary shaping apparatusSurface layerBrick

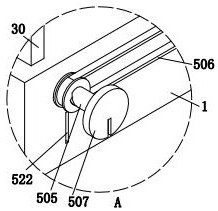

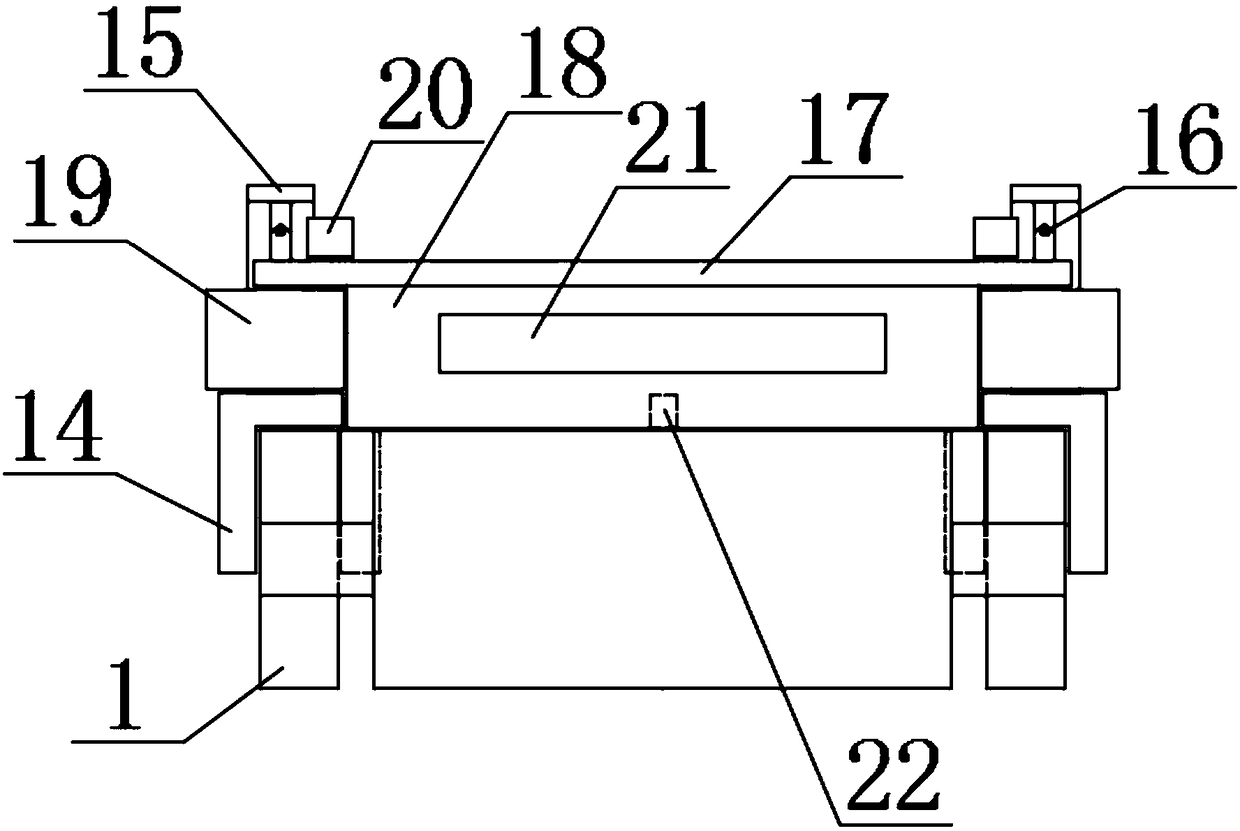

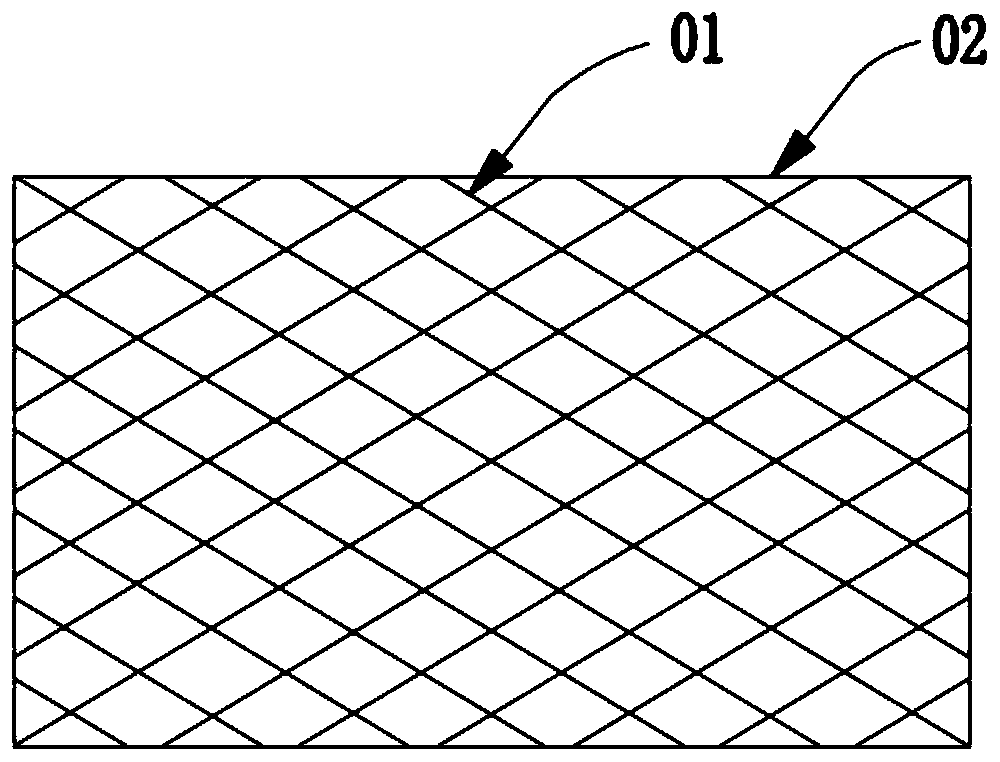

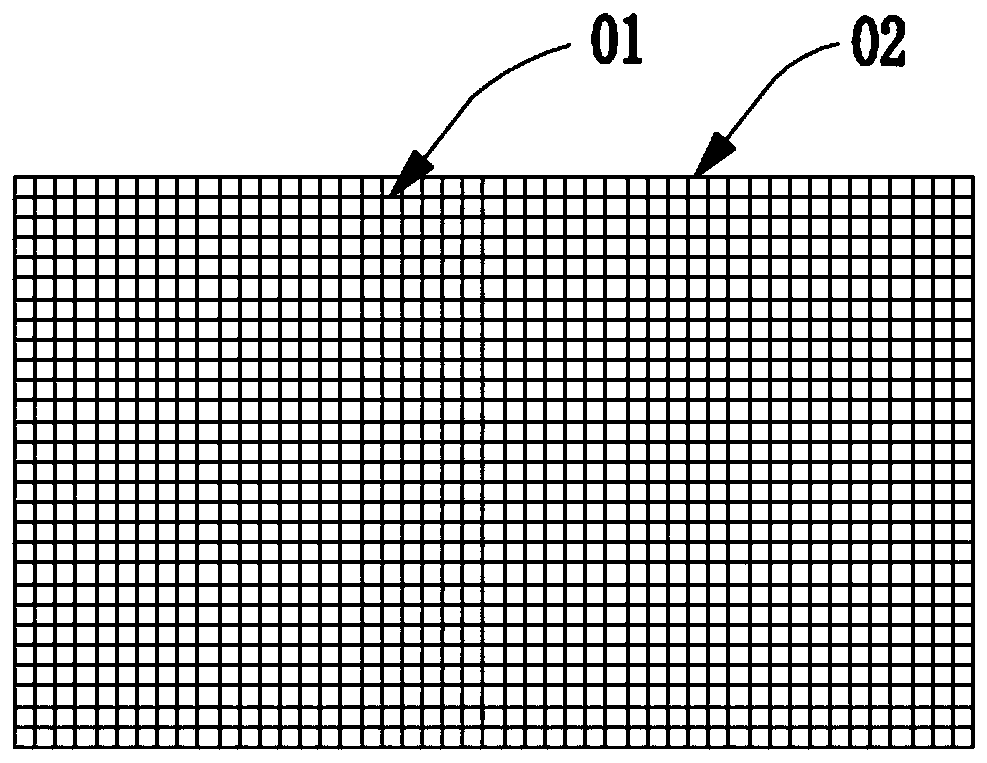

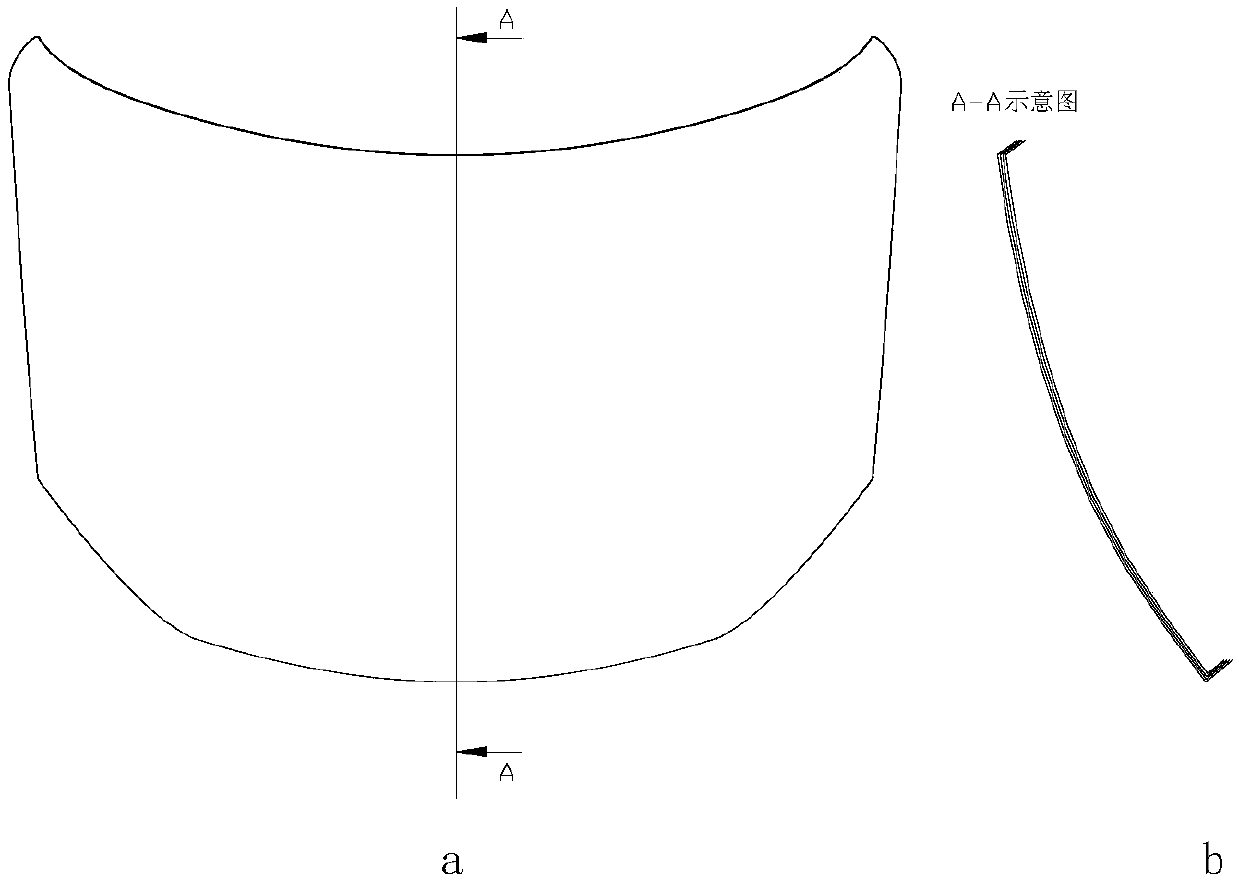

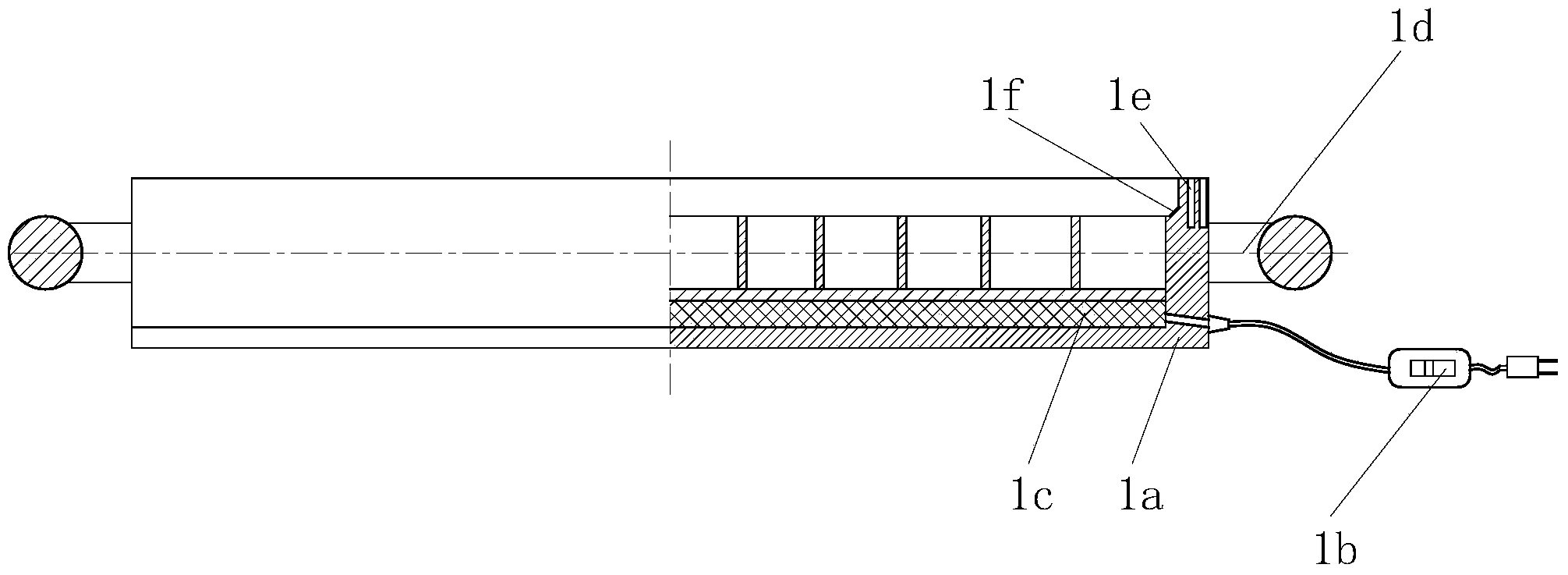

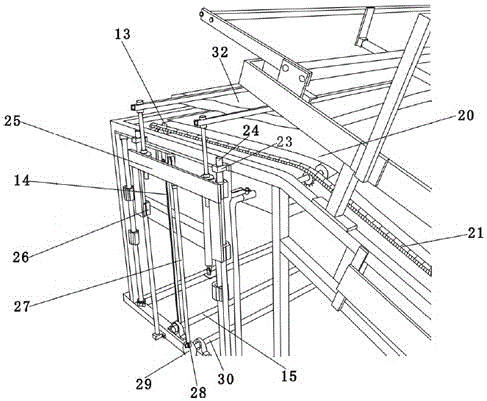

The invention provides a preparation process for an imitation full-body tile and a grid provided with square lattices and used for the preparation process. The preparation process comprises the following steps that firstly, the grid with the square lattices is arranged on a material distribution platform; secondly, material distribution is conducted, and a preset textured pattern is formed; thirdly, a secondary color mist spray material is applied into the lattices not applied with a main color mist spray material in the grid; fourthly, press forming is conducted after a layer of fabric is applied; and fifthly, the processes such as marking are conducted on green bricks according to the corresponding codes of the bottom material textures distributed by a press, and the imitation full-body tile with the consistent decoration textures in the fabric layer and the bottom material layer are obtained. According to the preparation process for the imitation full-body tile and the grid with the square lattices, even slotting of the imitation full-body tile is conducted, the textures in a slot of the imitation full-body tile can be perfectly in joint with infiltrating textures of the surface layer, and no segmented offset or breakage phenomenon exists. The invention further provides the grid provided with the square lattices and used in the preparation process for the imitation full-body tile, and deformation of the textures in the powder crossed mixing and material push processes after material distribution can be avoided.

Owner:FOSHAN DONGPENG CERAMIC +2

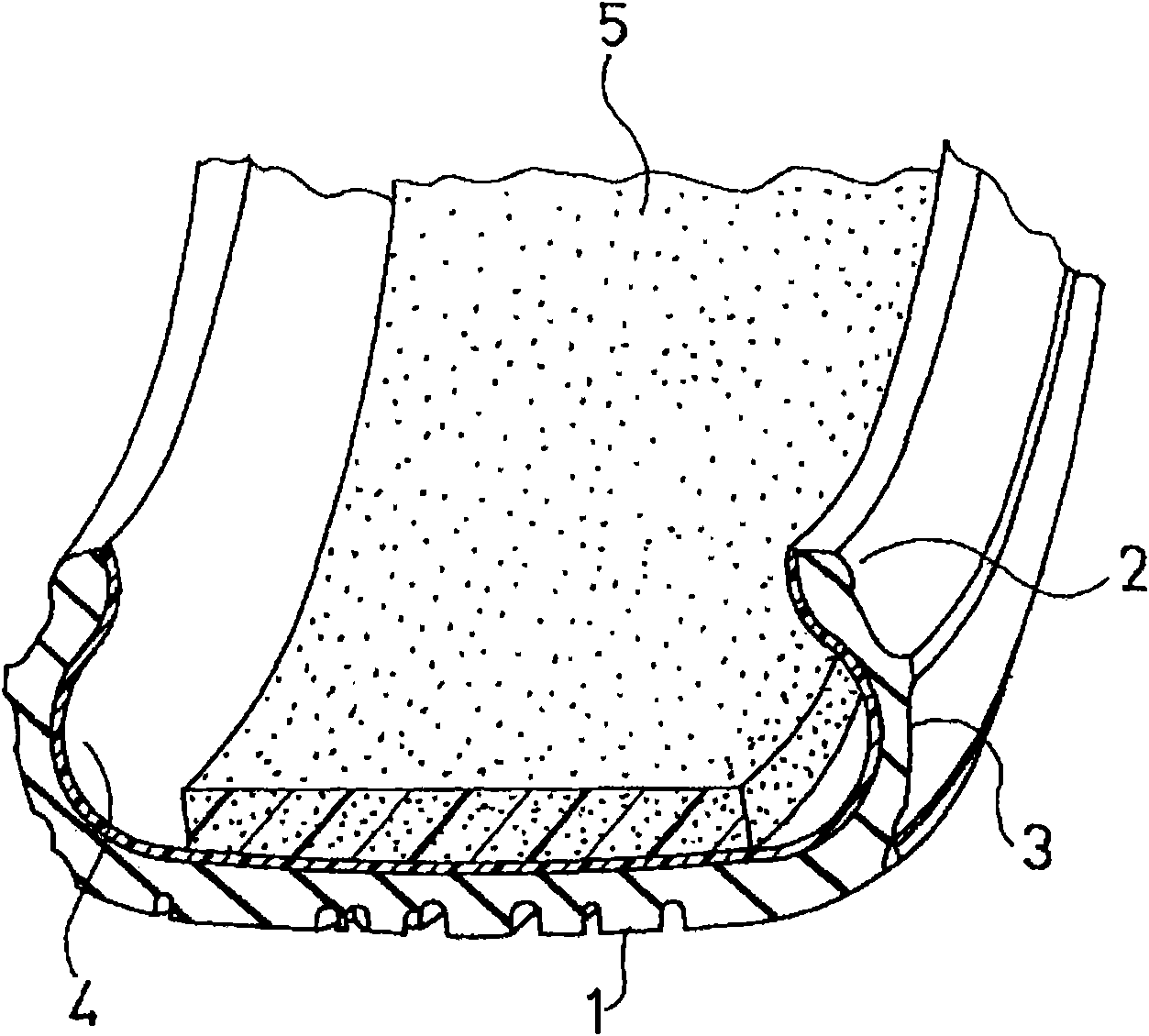

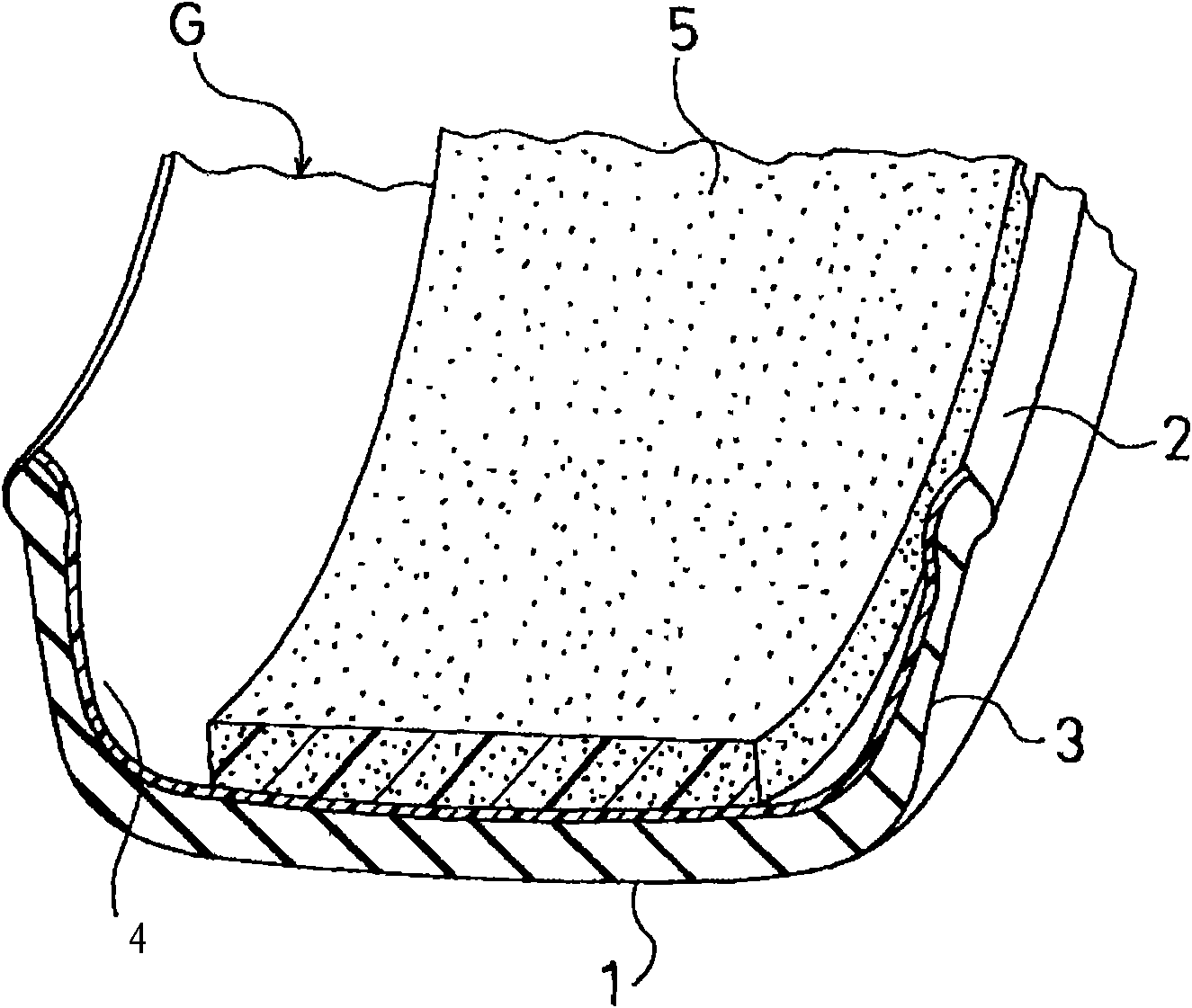

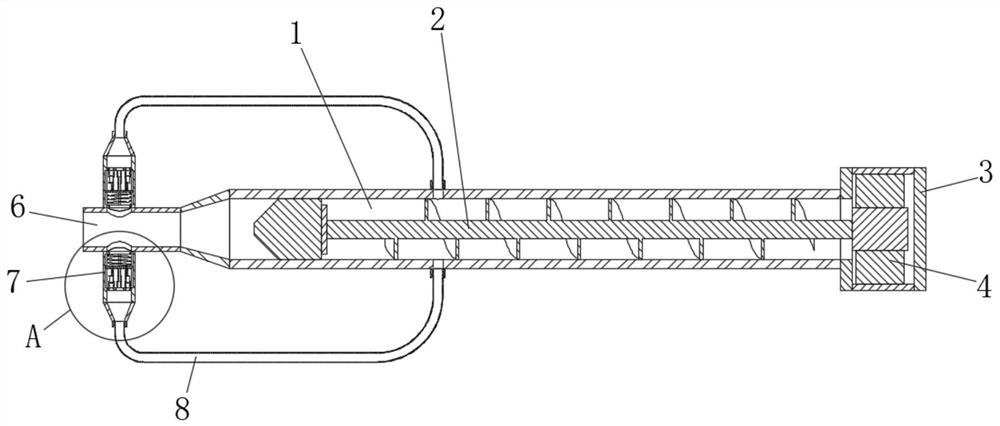

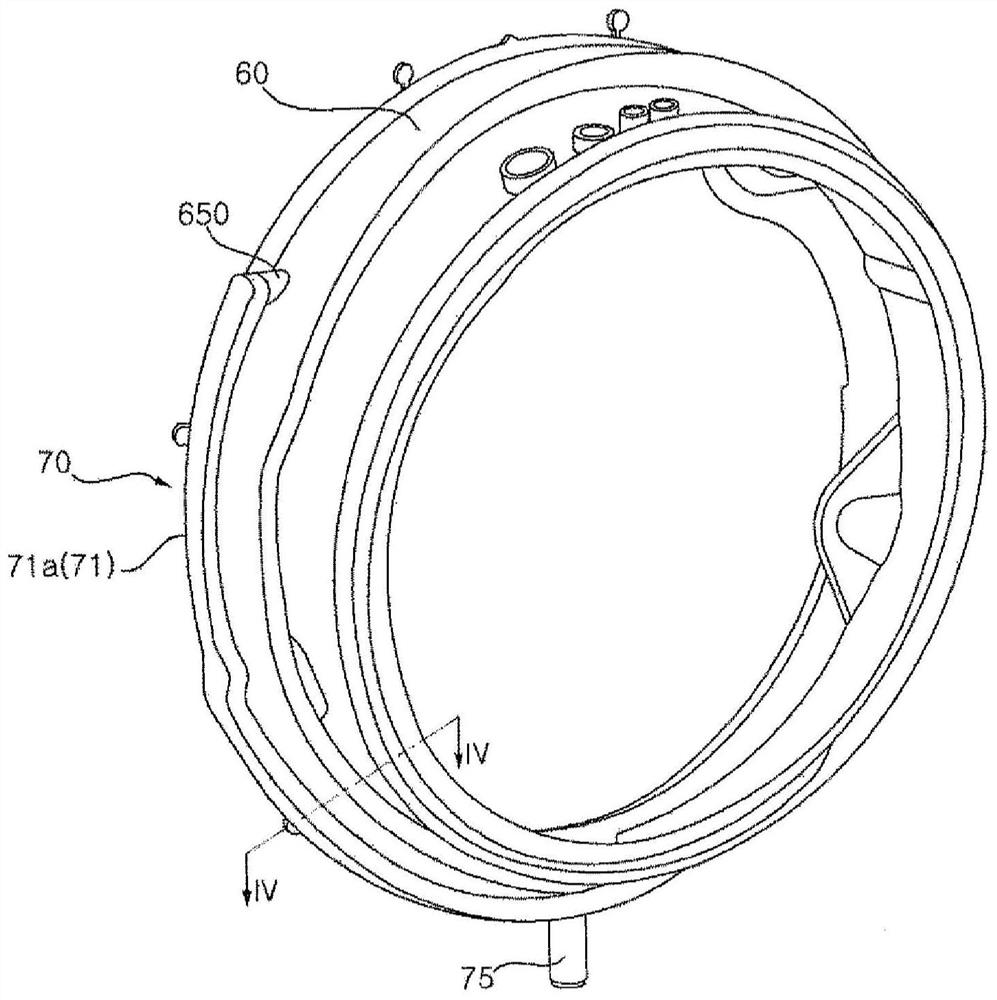

Method for manufacturing pneumatic tire

The present invention provides a method for manufacturing a pneumatic tire, the method enabling a sound-absorbing member to be easily mounted on the tire with an improved fixation of the sound-absorbing member onto an inner surface of the tire. The method for manufacturing a pneumatic tire of the present invention includes the steps of: forming a green tire including an inner liner layer and a sound-absorbing member, the inner liner layer disposed in an inner surface of the tire and made of any one of a thermoplastic resin and a thermoplastic elastomer composition obtained by dispersing an elastomer in a thermoplastic resin, the sound-absorbing member fixed onto the inner liner layer and made of a porous material; and thereafter curing the green tire.

Owner:THE YOKOHAMA RUBBER CO LTD

Stamping part production process

The invention discloses a stamping part production process. The stamping part production process comprises the following steps that (1) separation is carried out, specifically, blanking is carried outfirstly, stamping is carried out through a stamping die along a closed curve, the portion stamped off is a part which is used for manufacturing flat plate parts in various shapes, stamping is carriedout through the stamping die along the closed curve, the portion stamped off is scraps, then trimming is carried out, the edge of the formed part is trimmed to be regular or to be in a certain shape,and stamping is carried out through the stamping die along a non-closed curve to generate separation; and (2) molding is carried out, specifically, a plate blank is made into various opening hollow parts, the edge of a plate or a semi-finished product is made to be vertical along a certain curve at certain curvature, and the size precision of the molded part is improved or small corner radius isobtained in a shaping mode. Various measures are taken for defects, the quality of stamping parts is ensured, and the problem that due to the defects of cracking, stacking, waving, galling, deformation, burrs, material lack, unqualified size and the like of stamping parts produced by an existing stamping technology, the quality of the stamping parts is affected is solved.

Owner:温州天一五金制造有限公司

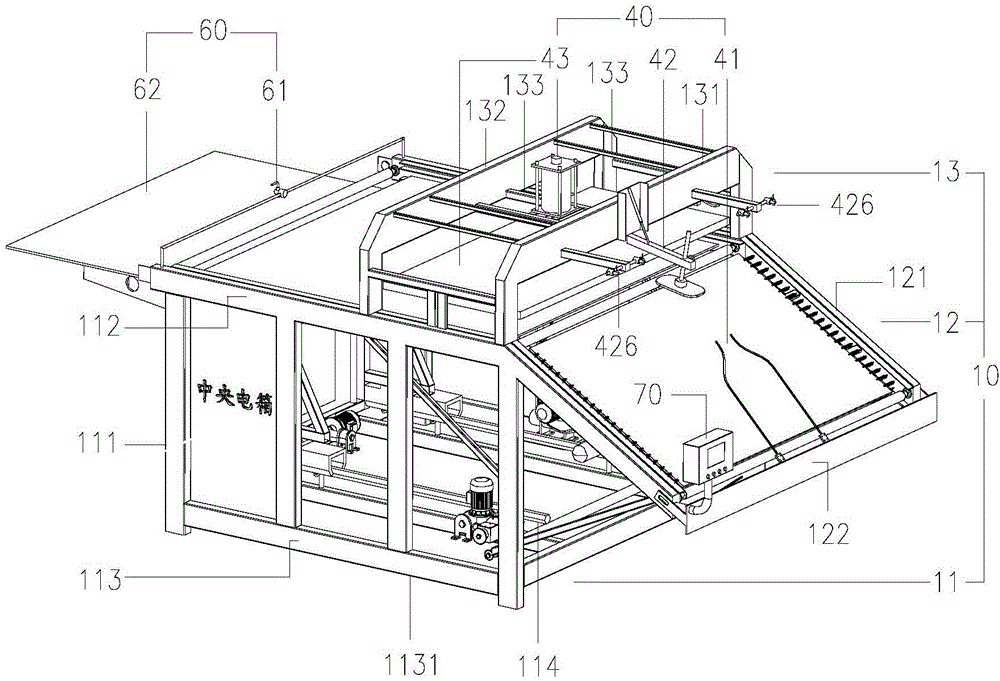

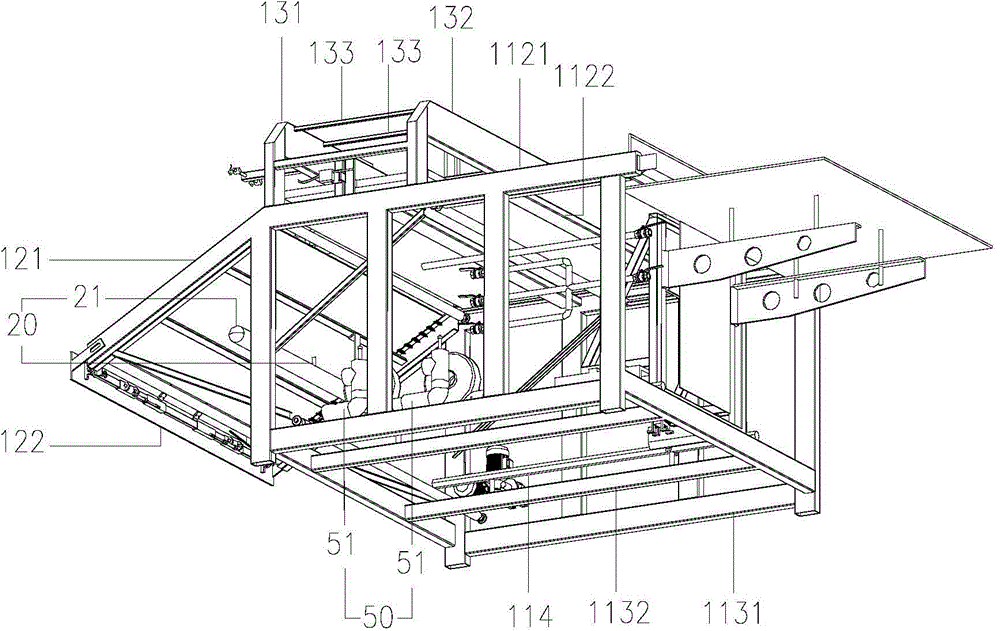

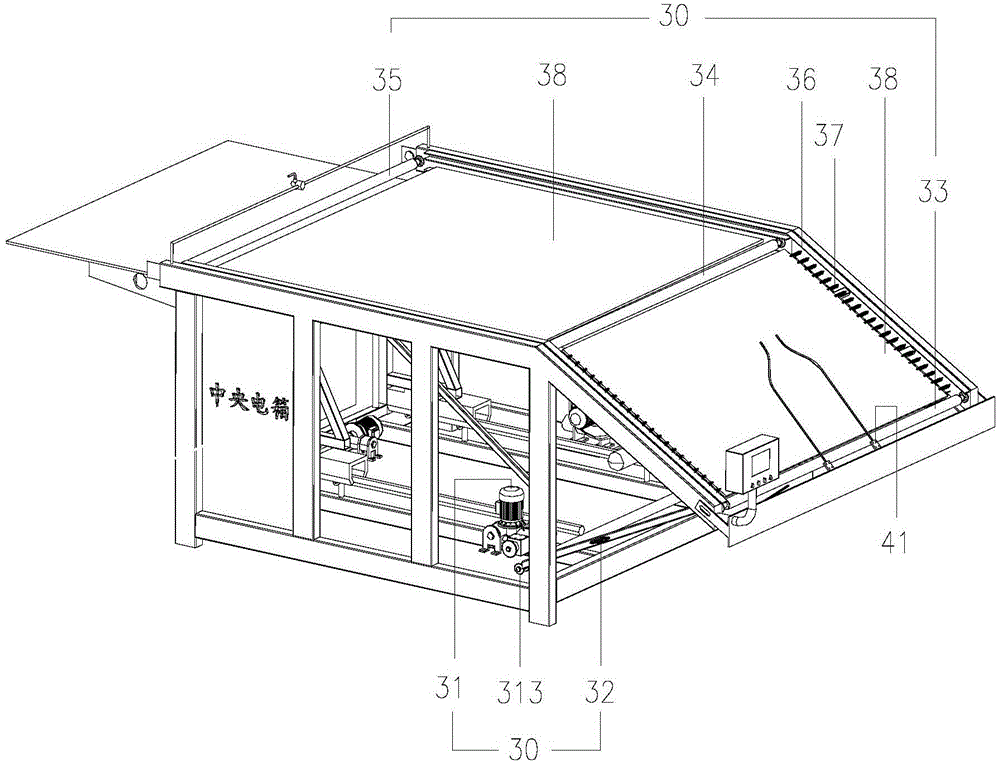

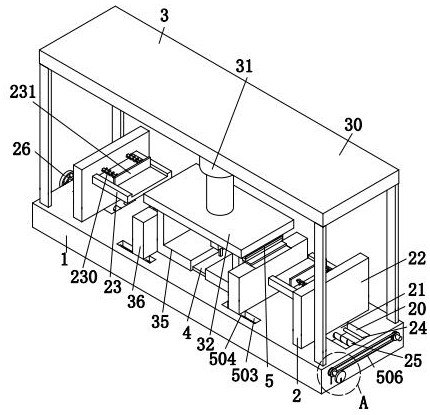

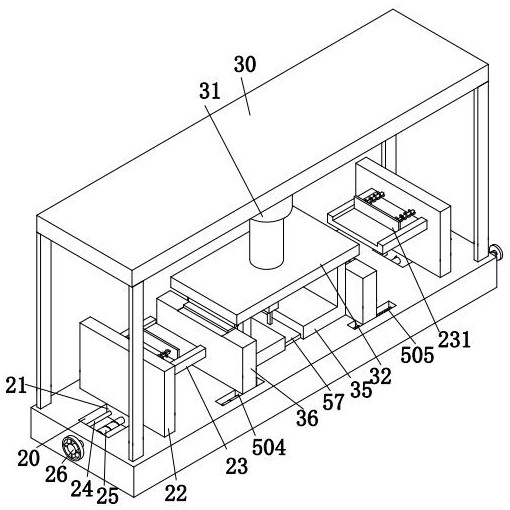

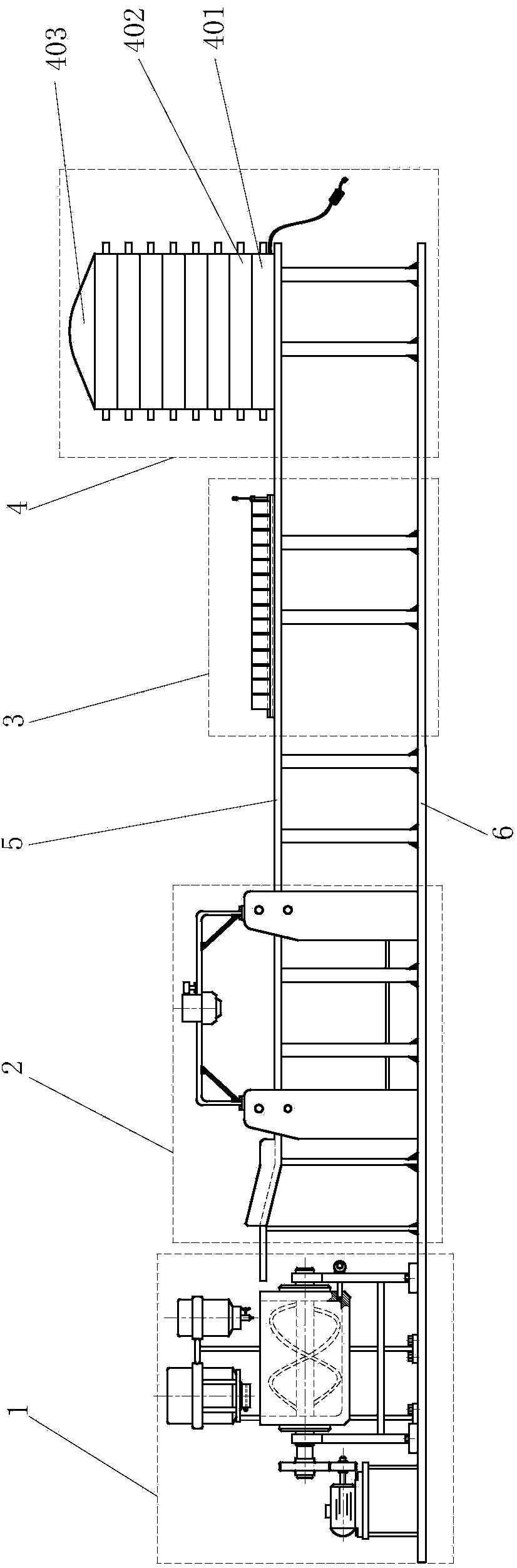

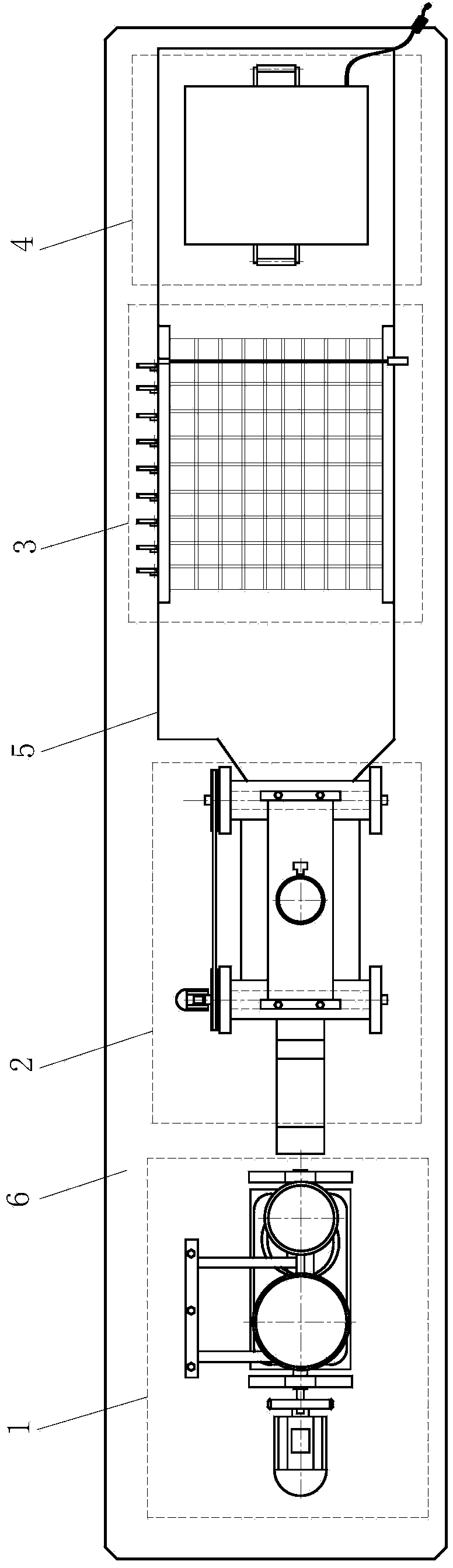

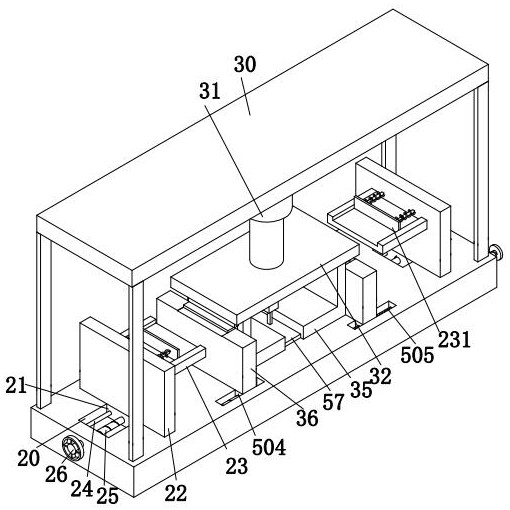

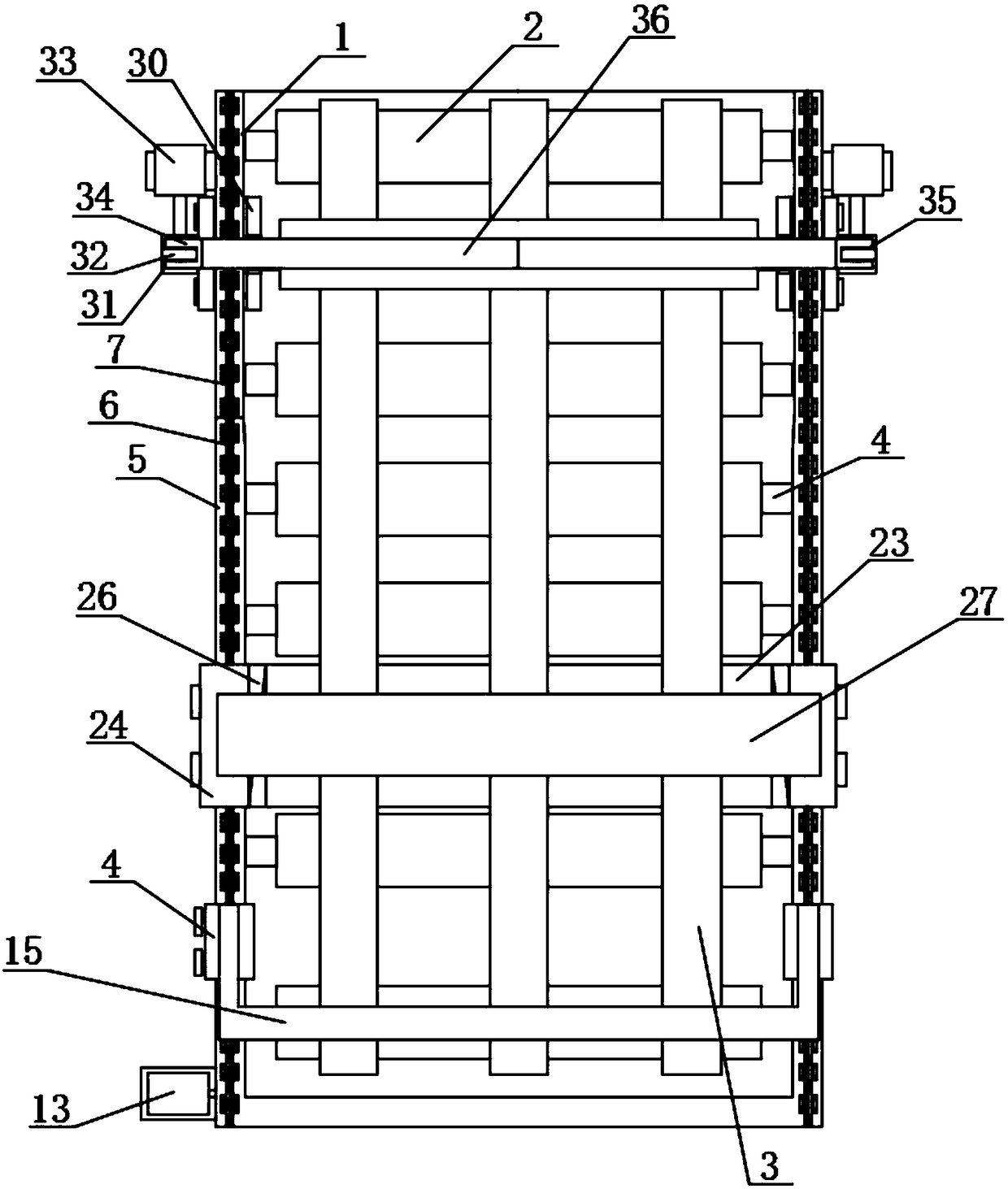

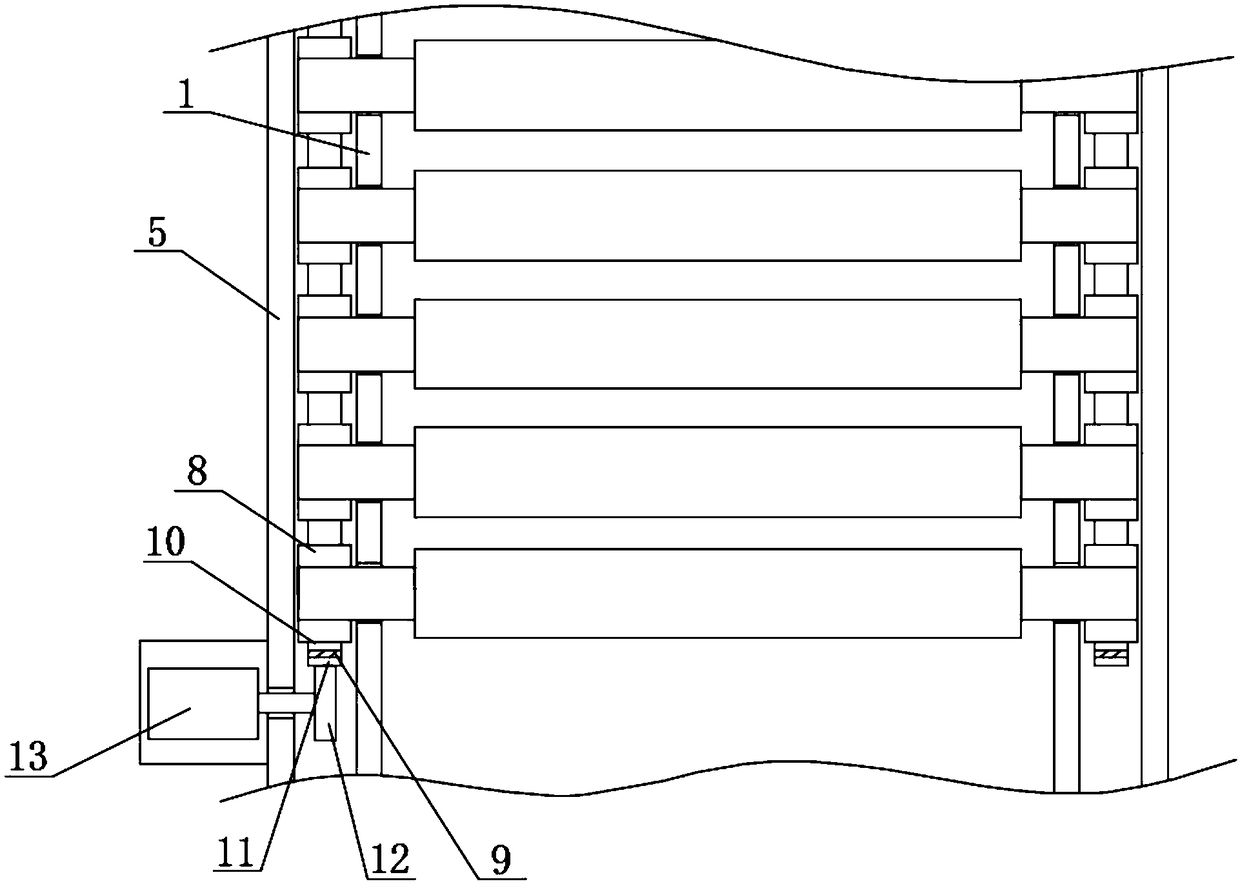

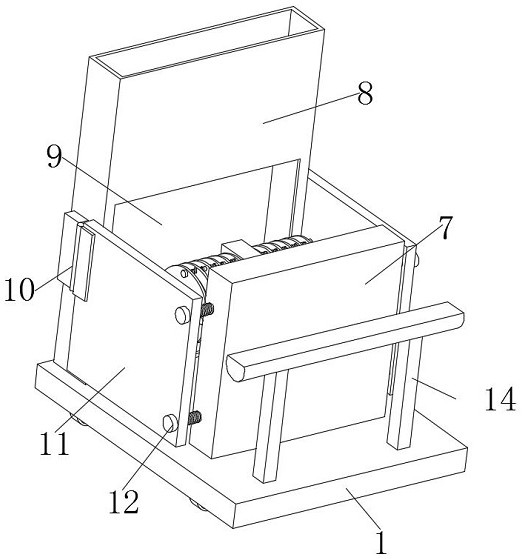

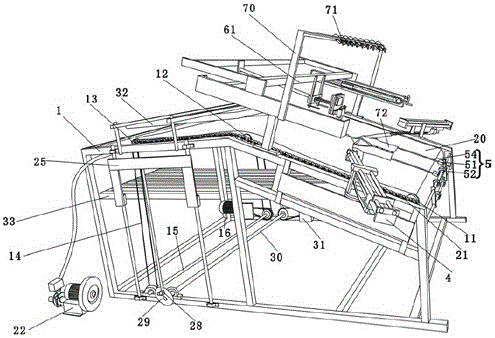

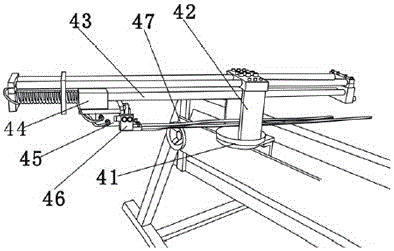

Woolen knitwear steaming setting machine

InactiveCN104805666AAchieve ironing and settingAvoid out of shapeHeating/cooling textile fabricsIroning apparatusSupport groupPulp and paper industry

The invention provides a woolen knitwear steaming setting machine. The woolen knitwear steaming setting machine comprises a machine frame, a steam evaporating group, a transmission group, an ironing positioning group, a ventilating dehumidifying group, a counting clothes supporting group and an electric control group, wherein the machine frame comprises a main frame part, an inclined frame part and a top frame part; the main frame part is provided with a main rod, an upper frame and a lower frame; the inclined frame part is combined with the front side of the upper frame body and is provided with a surface beam; the top frame part is arranged on the upper frame body; the steam evaporating group comprises a steam temporary storage device; the steam temporary storage device is communicated with the ventilating dehumidifying group through a pipeline; the transmission group drives a first roller, a second roller, a third roller and a conveying cloth belt of the transmission group by adopting chain transmission; a transmission chain used for the chain transmission is provided with ear holes; the first roller is overlapped to the second roller and the third roller through the conveying cloth belt; metal rings are arranged on the two side peripheries of the conveying cloth belt corresponding to the ear holes; the ear holes are connected with the metal rings through springs. Through the structure, the technical problems about woolen knitwear steaming and setting are solved; good effects that the operation is facilitated, and the steaming efficiency is improved are achieved.

Owner:郑野

Curtain wall aluminum veneer bending equipment

ActiveCN113290085AReduce workloadImprove molding efficiencyConstruction materialWallsSingle plateWorkbench

The invention relates to the technical field of processing of curtain wall aluminum veneers, in particular to curtain wall aluminum veneer bending equipment. The curtain wall aluminum veneer bending equipment comprises a workbench, a placement frame, a bending mechanism, an adjusting mechanism and an edge folding mechanism. The placement frame and the bending mechanism are installed on the upper end face of the workbench. The adjusting mechanism and the edge folding mechanism are installed on the bending mechanism. According to the curtain wall aluminum veneer bending equipment, the distance between a left L-shaped pressing plate and a right L-shaped pressing plate is adjusted through the adjusting mechanism, and therefore aluminum veneers with different sizes can be processed into n-shaped structures with the corresponding sizes, corresponding equipment or bending extrusion heads do not need to be replaced, and therefore the equipment input cost of a manufacturer is reduced. According to the edge folding mechanism, the aluminum veneers can be directly subjected to edge folding treatment after being bent through the bending mechanism, the tedious process that the formed aluminum veneers are taken down and then subjected to edge folding is omitted, the workload of operators is reduced, and meanwhile the forming efficiency of the hollowed-out aluminum veneers is improved.

Owner:JIANGSU HAIDEMAN BUILDING MATERIALS IND

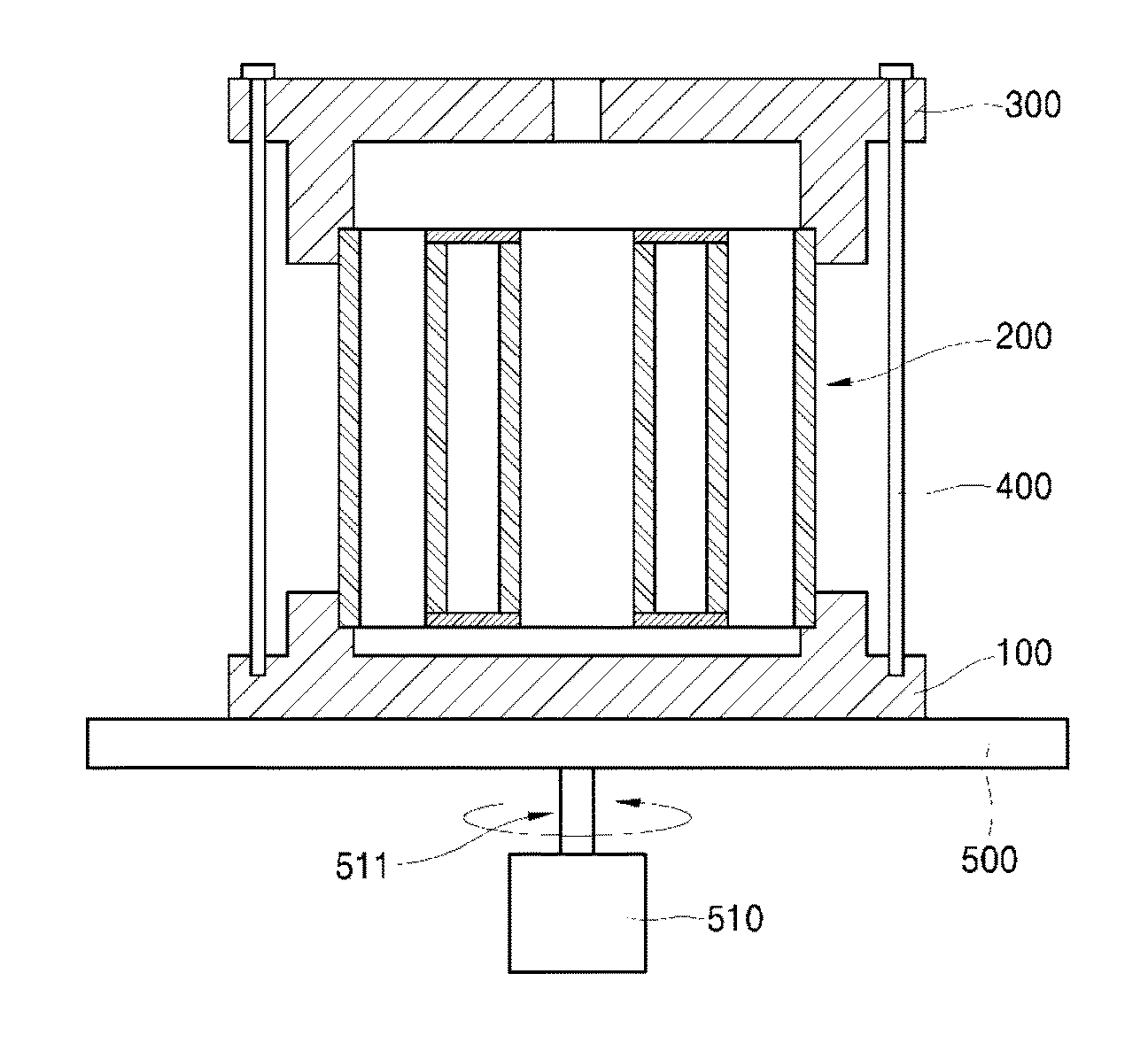

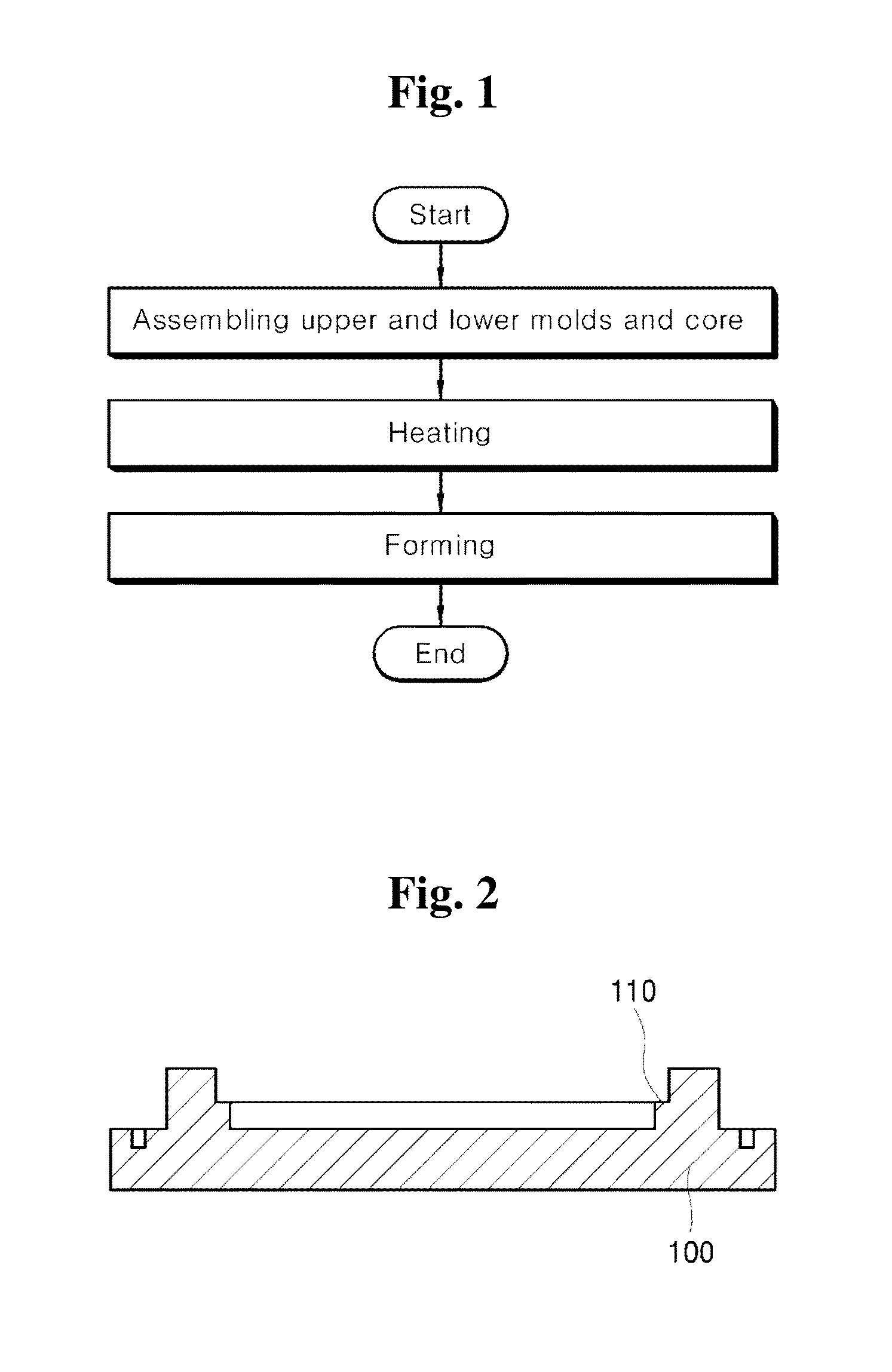

Method for centrifugal casting of motor rotor

InactiveUS20150343525A1Avoid out of shapeGood fluidityManufacturing cage rotorsManufacturing stator/rotor bodiesMolten metalElectric machine

Disclosed herein is a method for centrifugal casting of a motor rotor. The method includes: assembling molds and a core; heating the assembled mold and core to a preset temperature; and forming a motor core by injecting molten metal into a forming space inside the mold and the core while rotating the assembled mold.

Owner:HYUNDAI HEAVY IND CO LTD

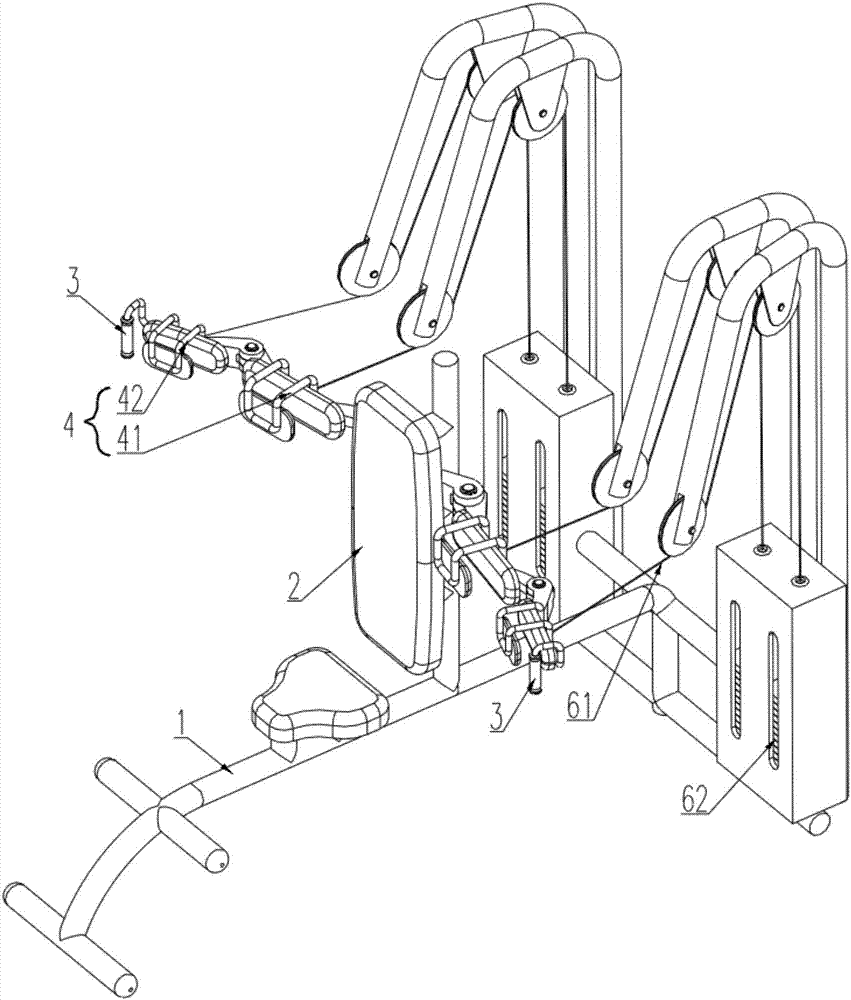

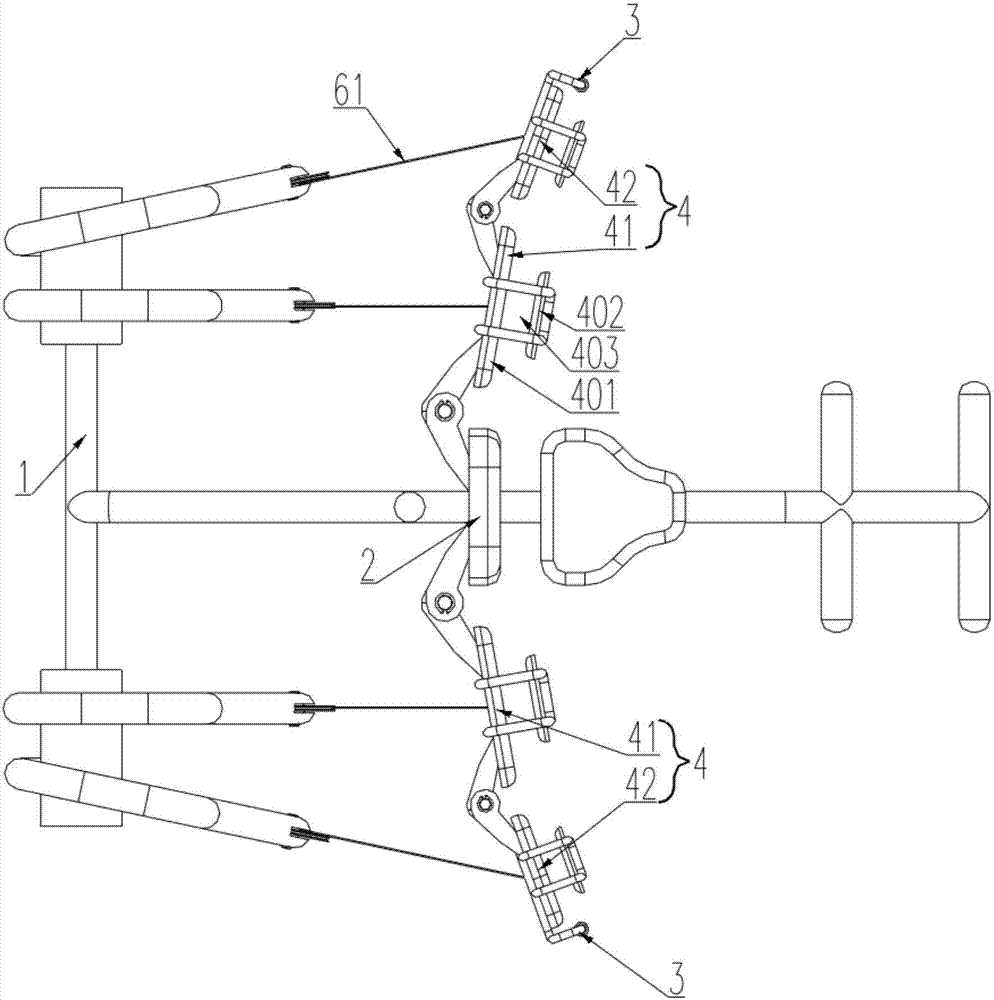

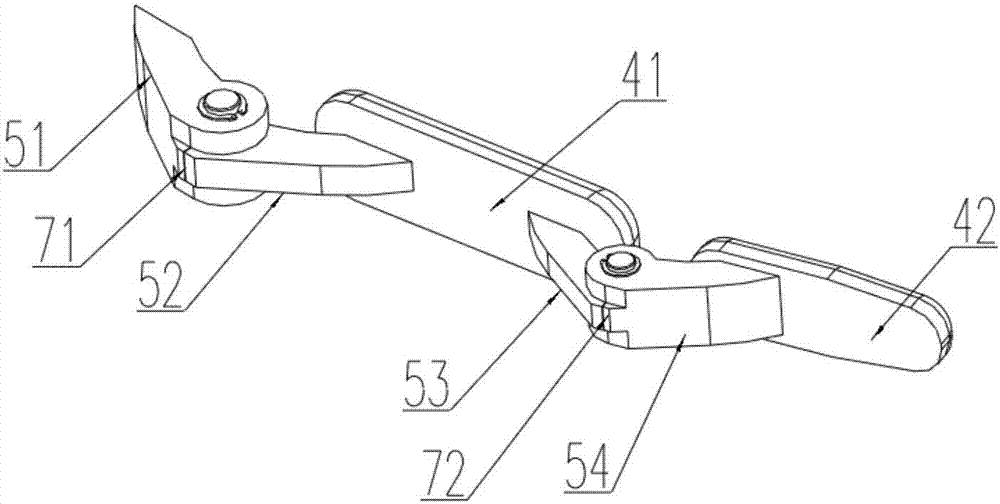

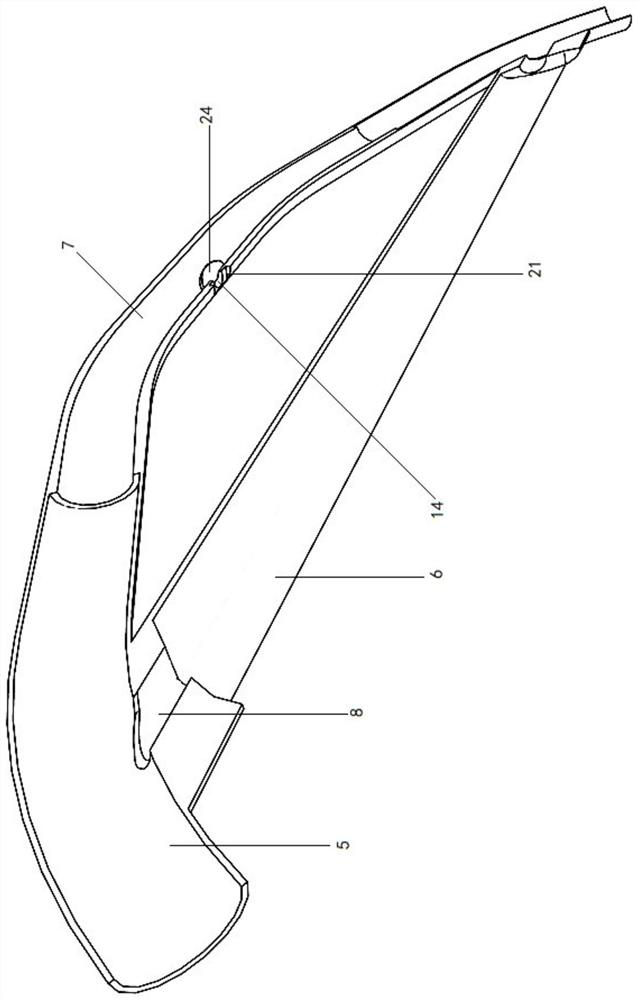

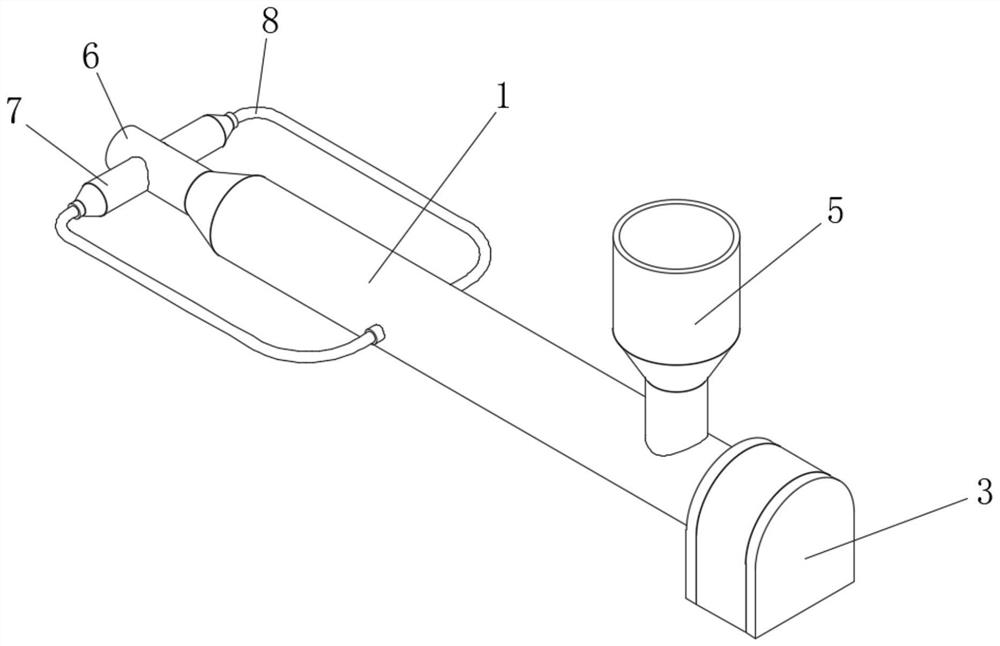

Chest expanding instrument

InactiveCN107376210AAvoid damageAvoid movement out of shapeMuscle exercising devicesJoint damageEngineering

The invention discloses a chest expanding instrument and belongs to the field of exercising instruments. The chest expanding instrument comprises a support, a back support part, arm stretching load-bearing parts and holding devices, wherein the back support part is mounted on the support; the two arm stretching load-bearing parts are mounted on two sides of the back support part, and the arm stretching load-bearing parts can perform resistance-resisting clamping under a horizontal state; the two holding devices are respectively fixedly arranged at the tail ends of the two arm stretching load-bearing parts; each arm stretching load-bearing part comprises an upper arm support part and a lower arm support part, the upper arm support part and the lower arm support part can perform resistance-resisting clamping, and each holding device is fixedly arranged at the tail end of the corresponding lower arm support part. The chest expanding instrument has the advantages that the chest expanding instrument is balanced in shaping effect, movement deformation cannot occur easily, joint damage can be prevented, and the like.

Owner:JINGDEZHEN CERAMIC INSTITUTE

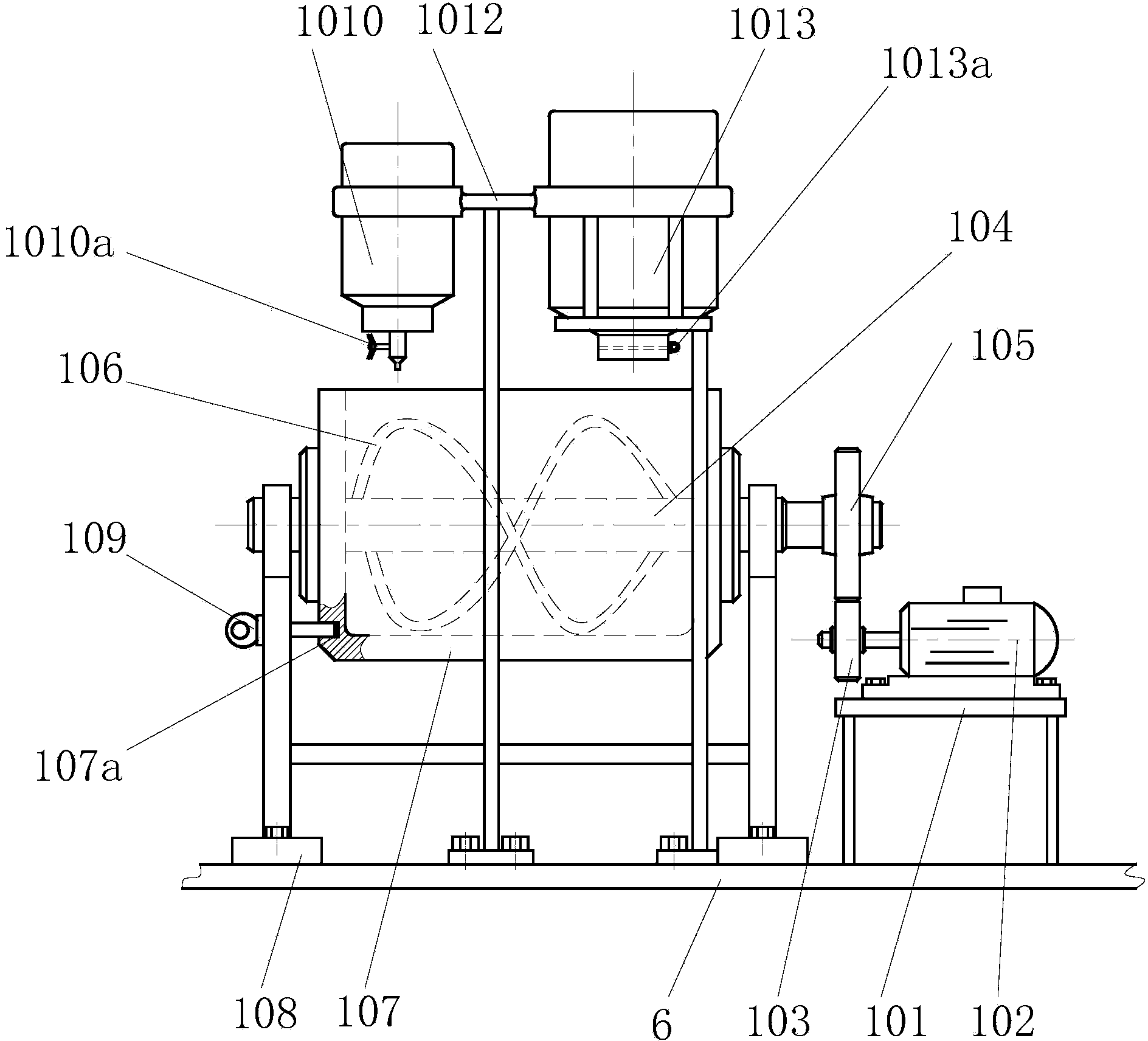

Extrusion, cutting and insulation integrated machine

InactiveCN104247724AFast preparationDeliciousMixing/kneading with horizontally-mounted toolsDough shaping and cutting apparatusFlavorEngineering

The invention relates to an extrusion, cutting and insulation integrated machine. The machine comprises a dough kneading device, a dough pressing device, a cutting device, a rising device, a chopping board and a base, wherein the dough kneading device is mounted at the left part of the base; the dough pressing device is positioned on the right side of the dough kneading device; the dough pressing device is mounted on the base; the chopping board is positioned on the right side of the dough pressing device and fixed above the base; the cutting device is positioned on the right side of the dough pressing device; the cutting device is fixedly connected with the chopping board; the rising device is positioned on the right side of the cutting device; in addition, the rising device is fixedly connected with the chopping board. The machine disclosed by the invention is reasonable in structural design, high in working efficiency, low in cost, and capable of realizing quick manufacture of the knife cut steamed buns, and meanwhile can ensure that the knife cut steamed buns cannot lose the flavor; the steamed bun blanks are raised by a heating manner of a heating sheet, so that the appearance of the steamed buns is good looking, and that the steamed buns are deformed in the rising process can be effectively prevented.

Owner:WUHU HENGHAO MACHINERY MFG

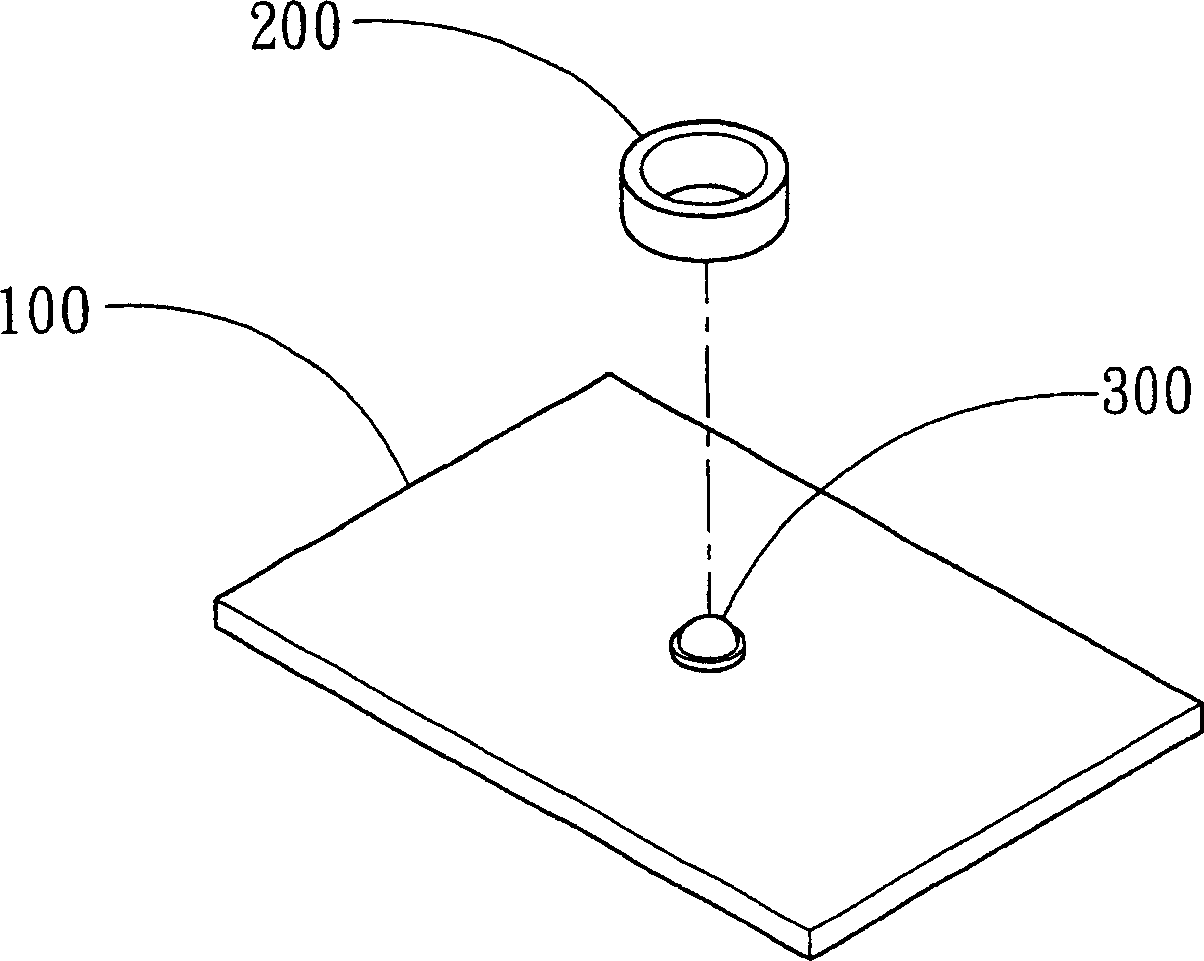

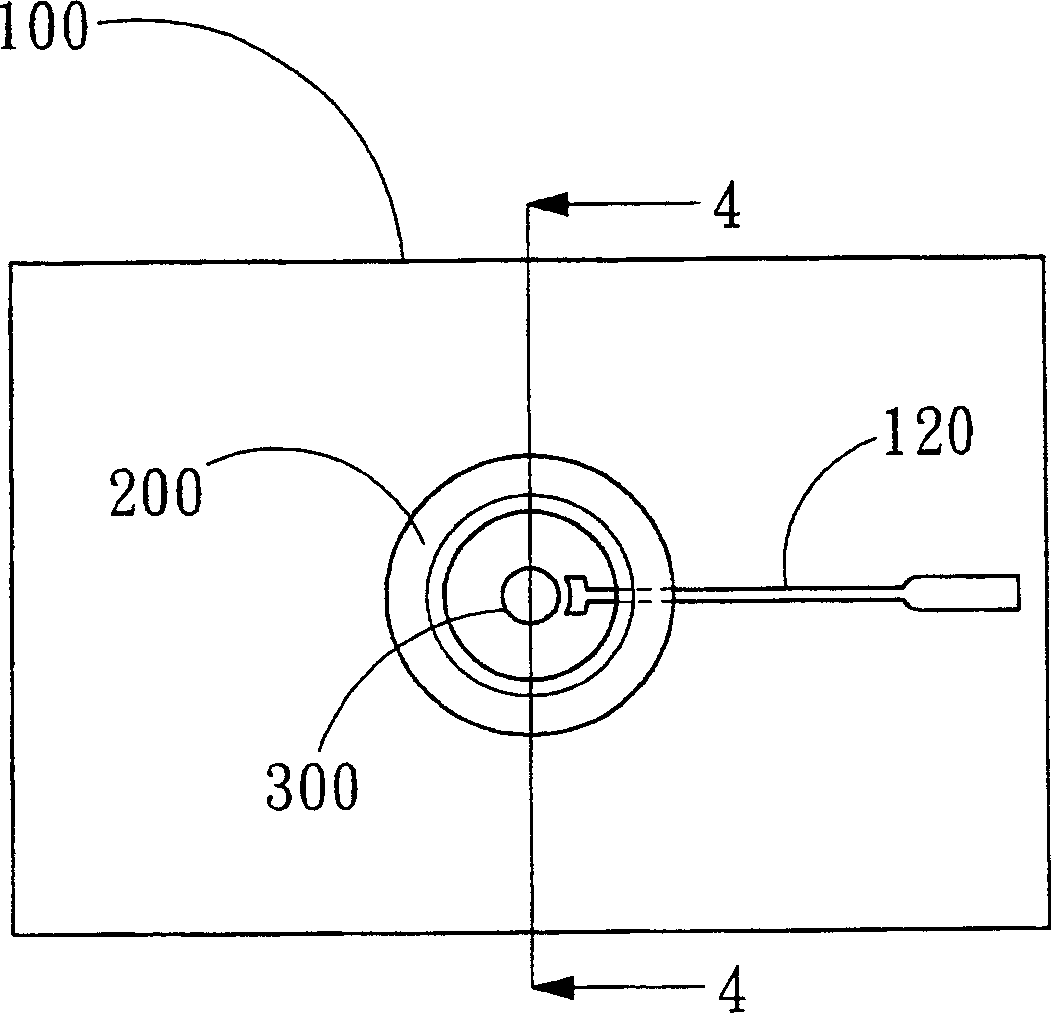

Base with ring-body and producing method

InactiveCN1893126APrevent outflowAvoid out-of-shapeSemiconductor/solid-state device detailsSolid-state devicesColloidEngineering

The base seat with ring body is composed of following arts: a base plate possesses at least an insulating layer and a circuit layer; a ring body setup on surface of the base plate; being setup on surface of the base plate circled by the ring body, a chip of light emitting diode (LED) is connected to the circuit layer on the base plate electrically, height of the ring body on the base plate is larger than height of the LED on the base plate; being prepared from euphotic material, an euphotic colloid layer is in use for covering the chip of LED so as to prevent the chip of LED from contacting outside directly.

Owner:周志邦

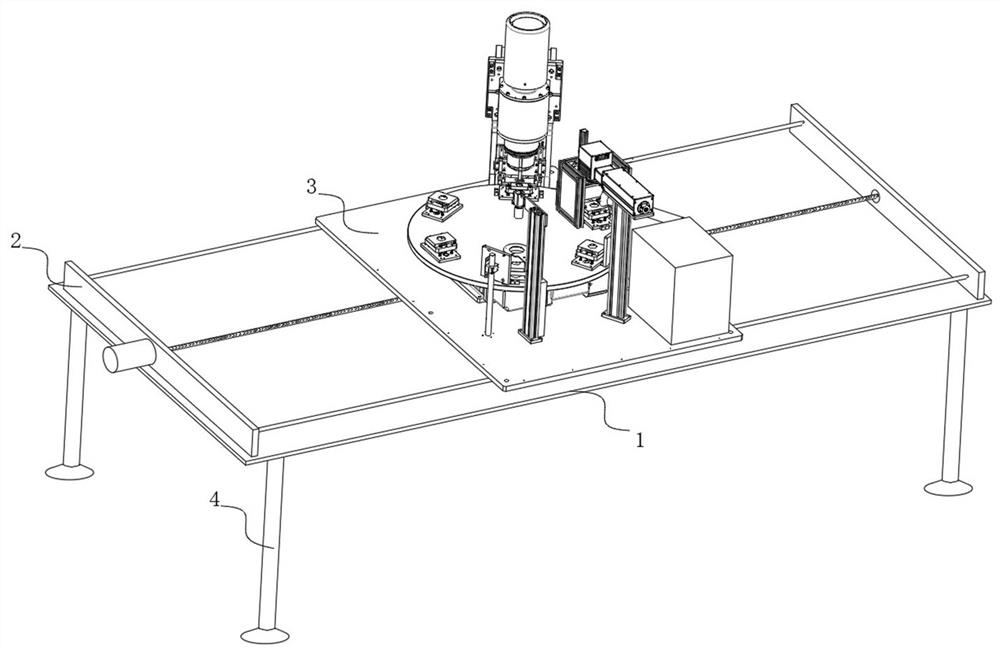

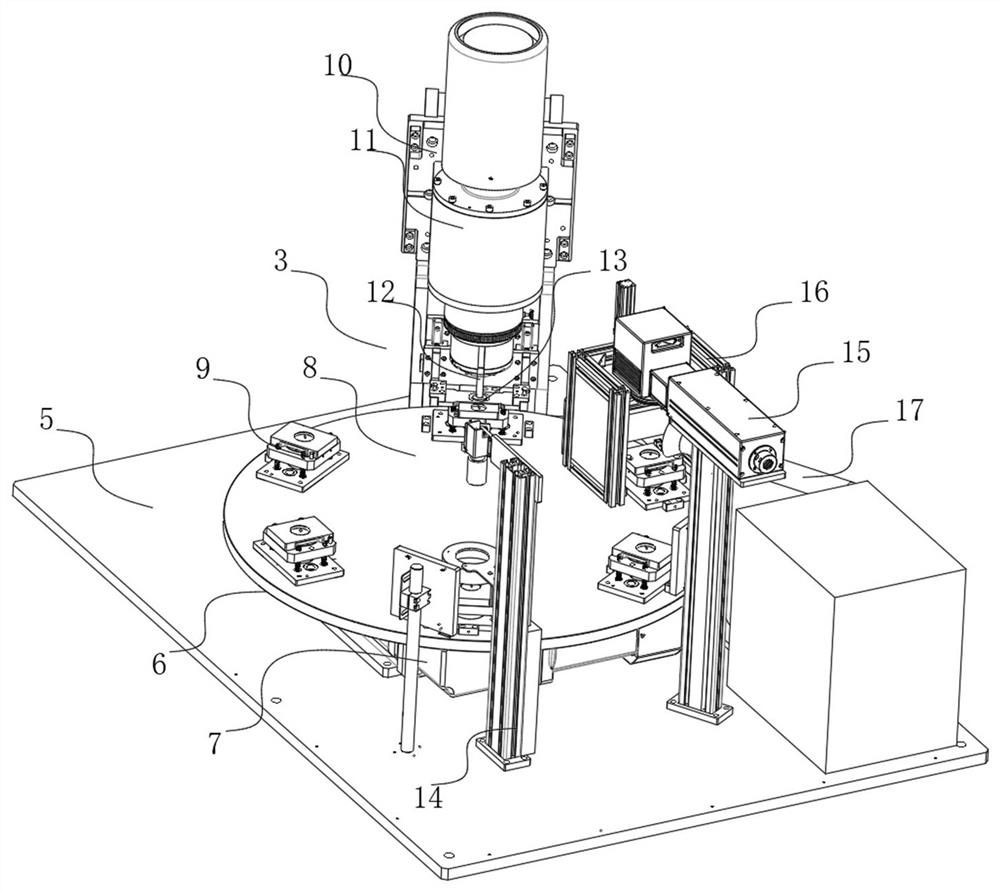

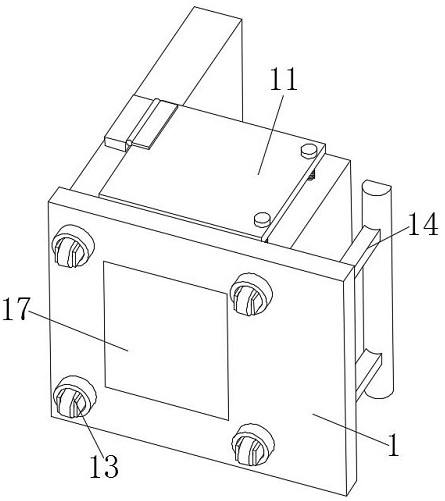

Tablet pressing equipment for lightning arrester processing and its working method

ActiveCN113103009BEasy loadingEasy to removeEdge grinding machinesShaping toolsHydraulic cylinderElectric machine

The invention discloses a tablet pressing device for processing a surge arrester and a working method thereof, comprising a horizontally arranged swing table, a transmission support and a pressing sliding plate, a transmission support is horizontally arranged above the swing table, and the A pressure sliding plate is installed on the transmission support, and the pressure sliding plate includes a mounting plate, a turntable, a side pressure seat and an abrasive seat. The beneficial effects of the invention are as follows: as soon as the motor drives the support plate to rotate, the pendulum seat is moved to the lower part of the side pressure seat, and as soon as the hydraulic cylinder drives the pressure hammer downward to form the resistance sheet in the mounting groove, the pressure slide is driven by the screw rod. The adjustment of the disc movement is very convenient to load or remove the resistance sheet into the pressure slide plate, and as soon as the motor drives the support plate to rotate, it can quickly drive different resistance sheets to move to the underside of the pressure hammer to be pressed, which greatly improves the The efficiency of the equipment for pressing the resistance sheet; the grinding ring on the upper end of the resistance sheet removes the convex material generated when the pressure hammer is separated from the resistance sheet, which greatly improves the smoothness and smoothness of the surface of the resistance sheet.

Owner:安徽淮光智能科技有限公司

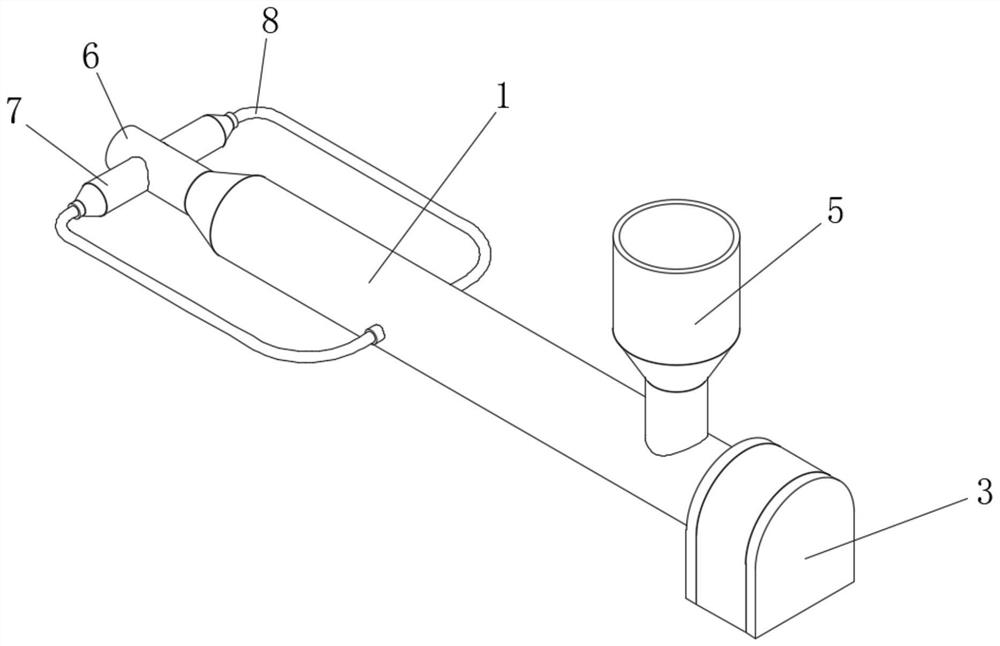

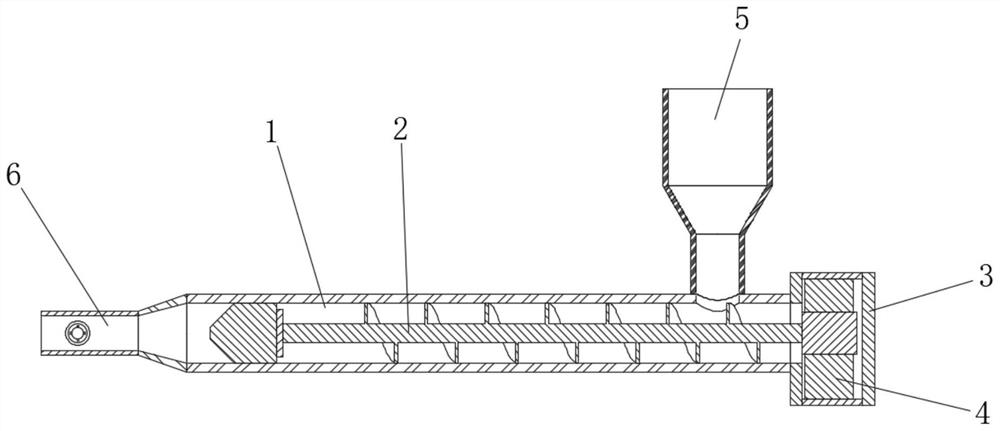

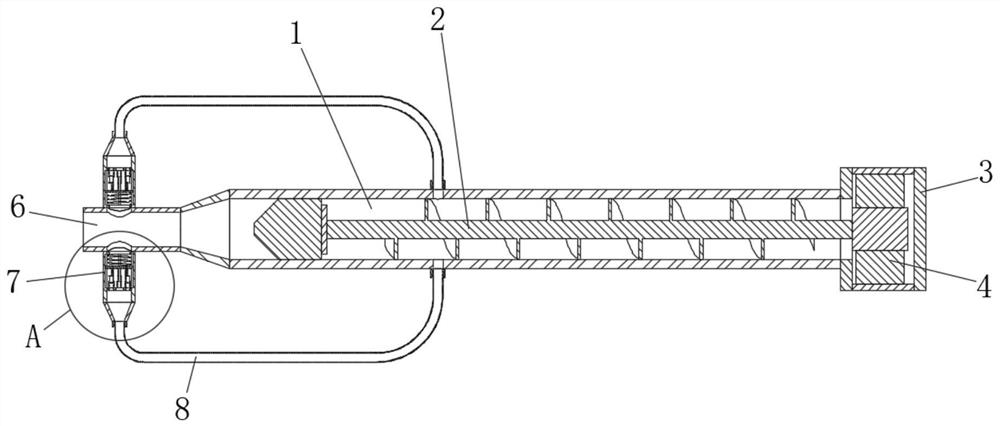

Injection molding device for molding plastic grinding tool

The invention relates to the technical field of casting molds, and discloses an injection molding device for molding a plastic grinding tool. Circular through holes are formed in the two sides of the outer surface of a discharging pipe, and a flow limiting device is fixedly mounted at one end of each circular through hole. In the material pushing process of a material pushing device, molten plastic in a discharging pipe flows into the mold, at the moment, the pressure intensity in the flow limiting device is small, and when the flow limiting device completely corresponds to a high-pressure discharging hole through an outflow hole, the thrust borne by a stroke plate and the elastic force of a flow limiting spring are mutually balanced, so that an outflow pipe moves until the outflow pipe is completely located in the high-pressure discharge hole, the molten plastic cannot flow out of the outflow hole, the molten plastic can only flow into a mold through the discharge pipe, therefore it is guaranteed that sufficient plastic enters the mold, and the problem that bubbles appear in finished products or the finished products are not formed due to insufficient feeding is avoided, and the feeding stability of the device is improved.

Owner:昆山佳禾兴电子科技有限公司

Cutoff device

The invention relates to a cutoff device which comprises cutter grooves, a dough cutter, a base, a cutter seat, a slide groove, a limiting rotary block and anti-dough-deformation grooves, wherein the cutter grooves are longitudinally distributed; the cutter seat is mounted in the slide groove; the dough cutter is hinged to the cutter seat; the limiting rotary block is hinged to one side of the base; the anti-dough-deformation grooves are transversely distributed. According to the cutoff device, strip-shaped dough is put into the anti-dough-deformation grooves, the position of the cutter seat is limited by the limiting rotary block, the dough cutter is operated to move towards the cutter grooves to cut the strip-shaped dough into long steamed buns, after the dough in one groove is cut, the cutter seat is moved left once and is positioned through the limiting rotary block, and the process is repeated in the way, so that the dough can be completely cut into the steamed buns. The cutoff device is reasonable in structural design, relatively high in working efficiency and relatively low in cost; steamed bun billets can be quickly obtained by cutting; the steamed buns can be effectively prevented from deforming in a cutting process and are kept very good in shape.

Owner:WUHU HENGHAO MACHINERY MFG

A curtain wall aluminum veneer bending processing equipment

ActiveCN113290085BReduce workloadImprove molding efficiencyConstruction materialWallsSingle plateWorkbench

The invention relates to the technical field of curtain wall aluminum veneer processing, in particular to a curtain wall aluminum veneer bending processing equipment, including a workbench, a placing frame, a bending mechanism, an adjustment mechanism and a hemming mechanism. The upper end surface of the workbench is A placing frame and a bending mechanism are installed, and an adjusting mechanism and an edge folding mechanism are installed on the bending mechanism. The present invention adjusts the distance between the left and right L-shaped pressure plates through the adjustment mechanism, so that the aluminum veneers of different sizes can be processed into corresponding sized U-shaped structures, and there is no need to replace corresponding equipment or bending and extrusion heads, thereby The equipment investment cost of the manufacturer is reduced; the hemming mechanism provided by the invention can directly perform hemming processing on the aluminum veneer after the bending mechanism bends the aluminum veneer, eliminating the need to remove the formed aluminum veneer and then The tedious process of hemming reduces the workload of the operator and improves the forming efficiency of the hollow aluminum veneer.

Owner:JIANGSU HAIDEMAN BUILDING MATERIALS IND

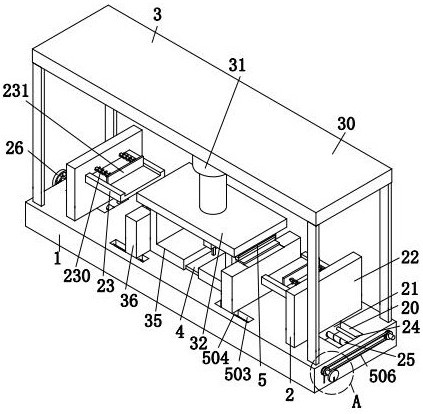

A fully automatic folder gluer

ActiveCN106799863BEasy to installEasy to disassembleBox making operationsPaper-makingMechanical engineering

The invention relates to the technical field of box pasting machines, in particular to a full-automatic box pasting machine. The full-automatic box pasting machine comprises a box pasting machine body support which comprises a positioning mechanism, a bottom hooking mechanism and a flat clapping mechanism, a plurality of conveying rollers are arranged inside the box pasting machine body support, a conveying belt is fixed to the outer sides of the conveying rollers in a sleeving manner, and rotating shafts are fixedly installed at the two ends of each conveying roller. According to the full-automatic box pasting machine, the manner that a shell is arranged on the outer side of the box pasting machine body support is adopted, the shell and the box pasting machine body support are connected through a first connecting piece and a second connecting piece, and mounting and dismounting by people are facilitated; and the manner that an auxiliary gear and a main gear are driven by an inner rack and an outer rack correspondingly for transmission is adopted, and therefore a driving mechanism composed of a first driving motor and the main gear is separated from the conveying roller, a traditional integrated structure is avoided, mounting and maintenance by people are facilitated, and convenience is brought to use by people.

Owner:东莞市亚都机械有限公司

A kind of preparation technology of imitation whole body brick

ActiveCN107520950BAvoid cross mixingAvoid out of shapeFeeding arrangmentsAuxillary shaping apparatusBrickMechanical engineering

A preparation process for imitating whole-body bricks. The preparation process includes the following steps: Step 1: Place a grid with a square grid on a cloth table; Step 2: Spread the cloth to form a preset texture pattern; Step 3: Spray the auxiliary color The material is distributed in the grid without the main color spray material in the grid; step 4: apply another layer of fabric and then punch it; step 5: mark the brick adobe according to the code of the texture of the bottom material clothed by the press, and obtain Decorate the imitation whole body brick with the same texture in the fabric layer and the bottom material layer. Even if the imitation whole-body brick prepared by the present invention is grooved, the texture in the groove can be perfectly connected to the seepage texture of the surface layer, and there is no segmental offset or fracture phenomenon. In addition, a kind of above-mentioned imitation whole-body brick is proposed The grid used in the preparation process is a square grid, which can avoid the cross-mixing of the powder after the cloth and the deformation of the texture during the pushing process.

Owner:FOSHAN DONGPENG CERAMIC +2

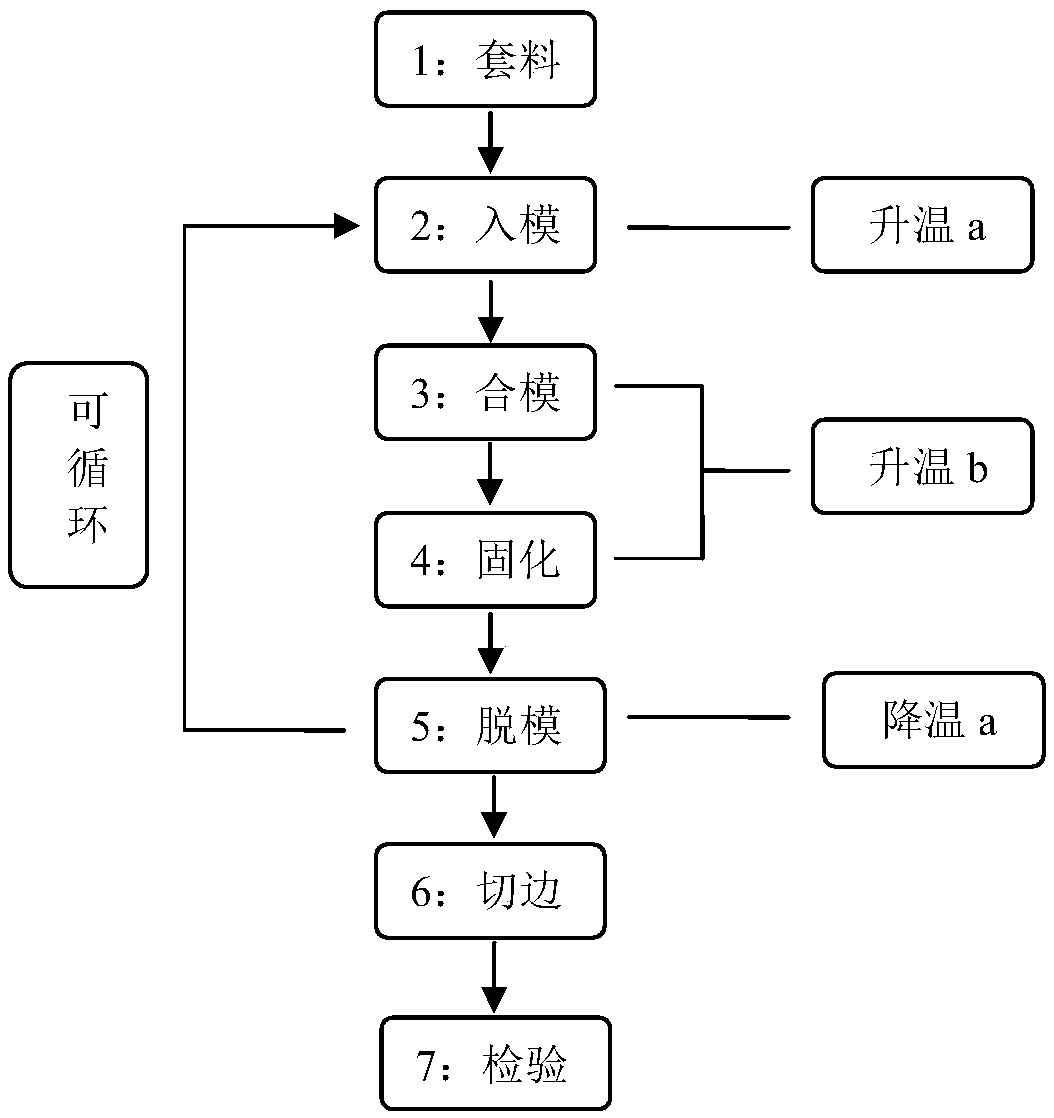

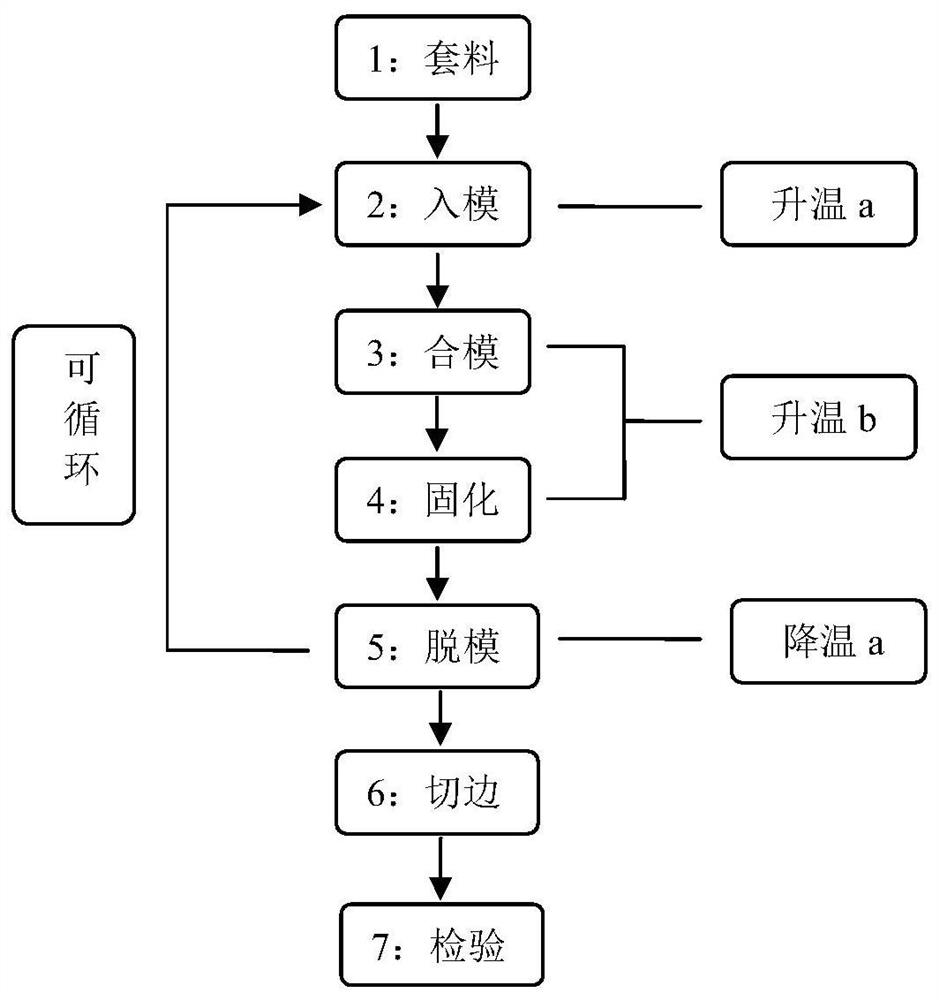

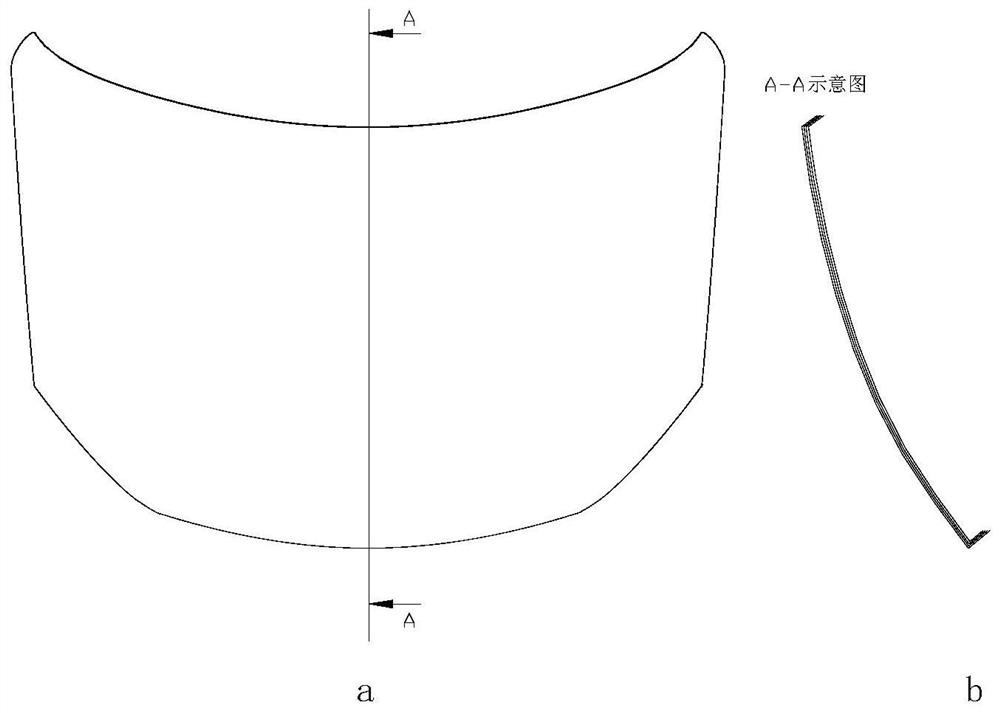

Compression molding method for carbon fiber automotive front cover

The invention relates to a compression molding technological process for a carbon fiber automotive front cover, and belongs to the technical field of traffic facilities. Compared with the general compression molding method for the carbon fiber automotive front cover, the provided compression molding method for the carbon fiber automotive front cover has the advantages that three procedures including prepreg preheating, premolding and semi-finished product cooling are omitted, the technological process is simplified, equipment and tooling released by a production line are reduced, occupation space of the equipment and the tooling is saved, investment cost is reduced, and quality risks in position deviation and fiber texture disorder probably caused by preform transfer are avoided; medium-temperature cured carbon fiber prepreg with curing time of 5-10 min is selected, so that the compression molding period of the automotive front cover is shortened remarkably, and one giant leap is madefor adapting to fast production rhythm in the automotive industry; a semi-finished product is demolded after mold temperature is reduced to 80-100 DEG C, mold occupation time of the semi-finished product is reduced, molding period is further shortened, and the quality problems of deformation, mold sticking and fiber texture disorder of the semi-finished product are solved.

Owner:AVIC COMPOSITES

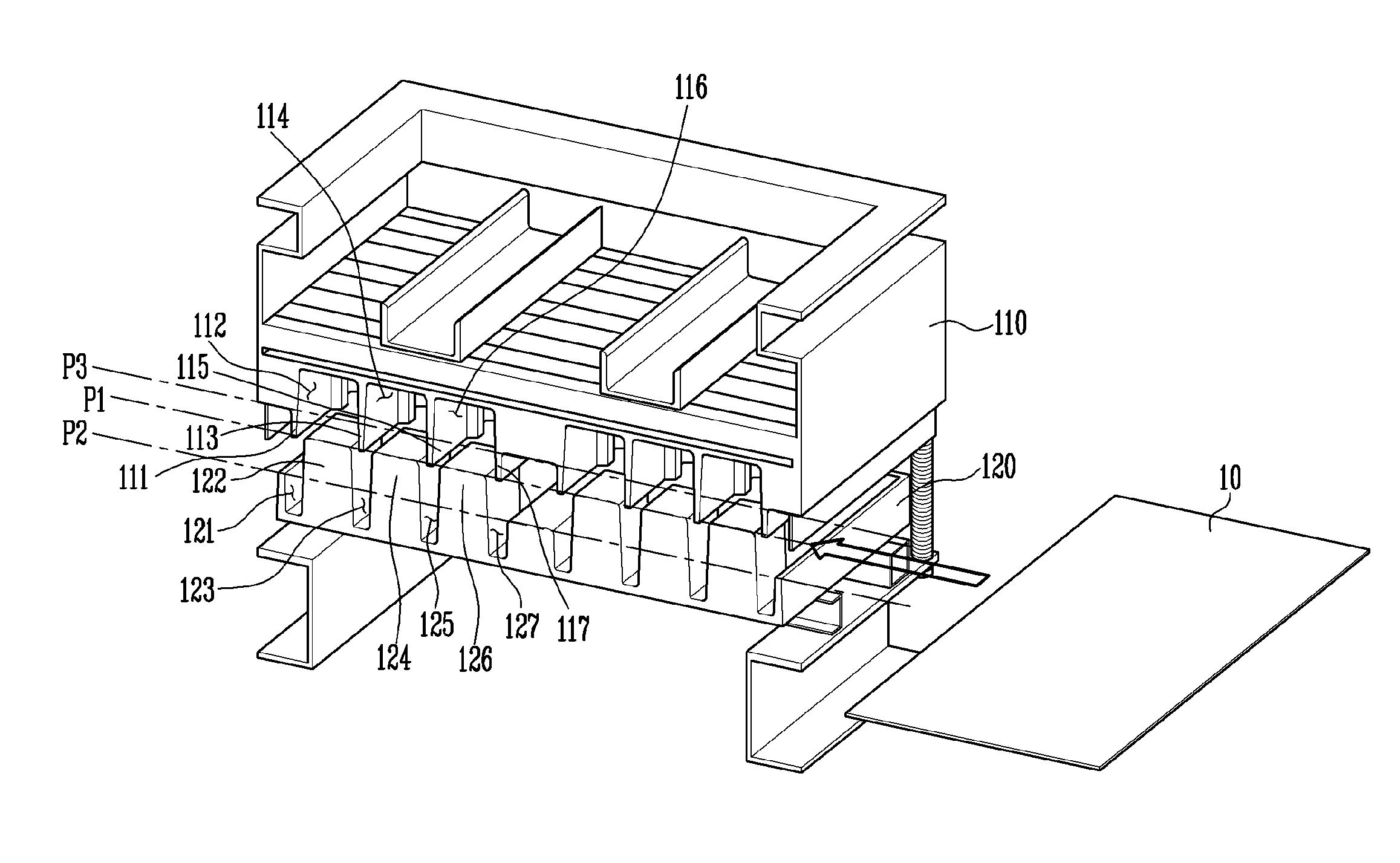

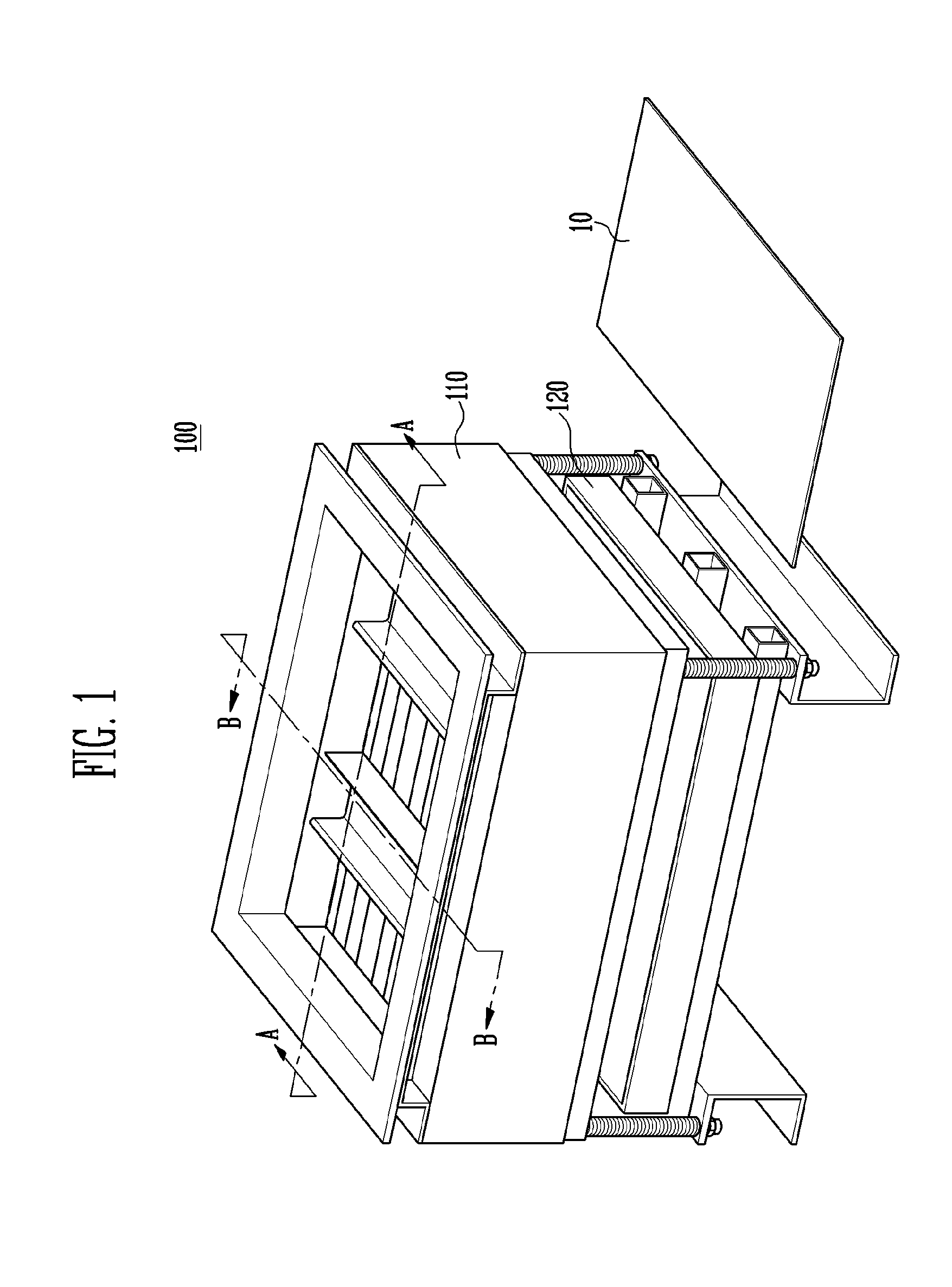

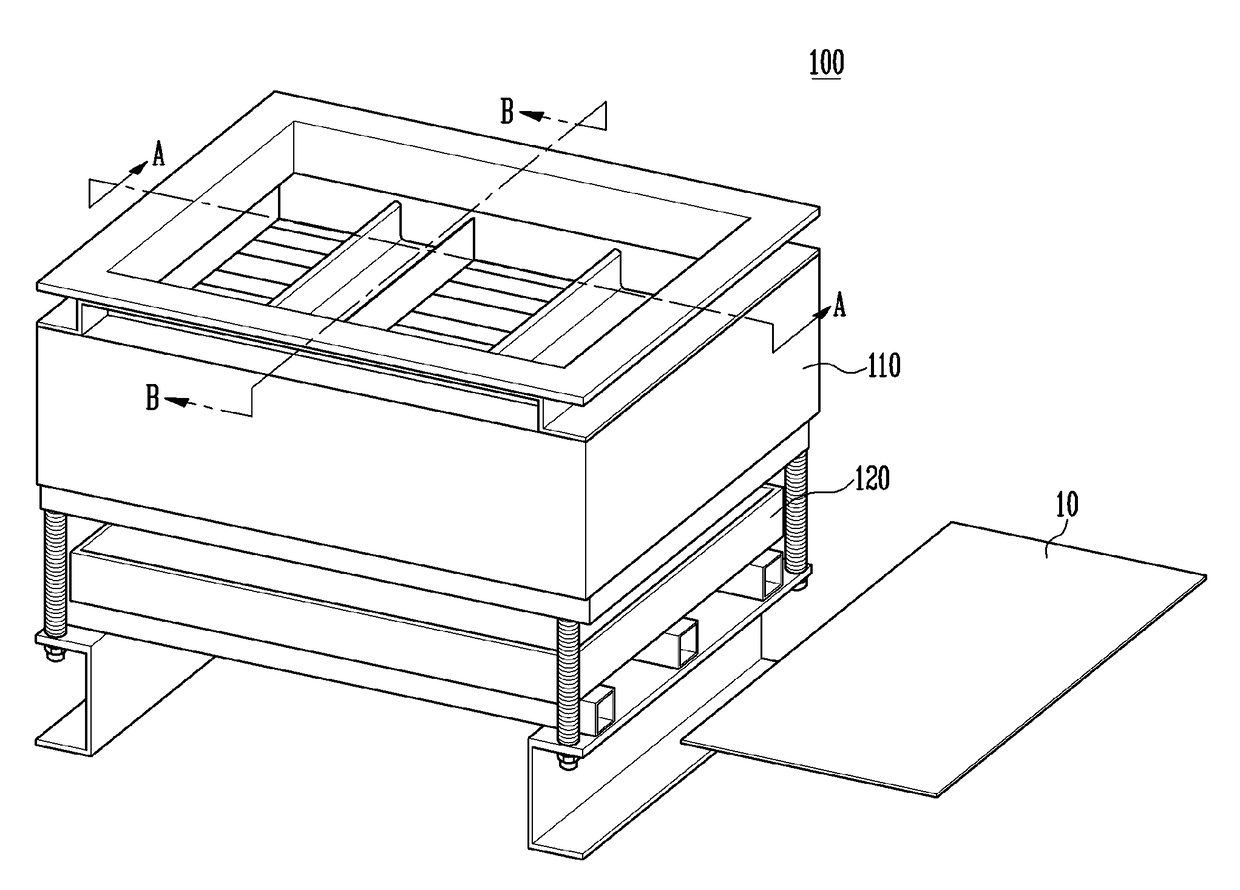

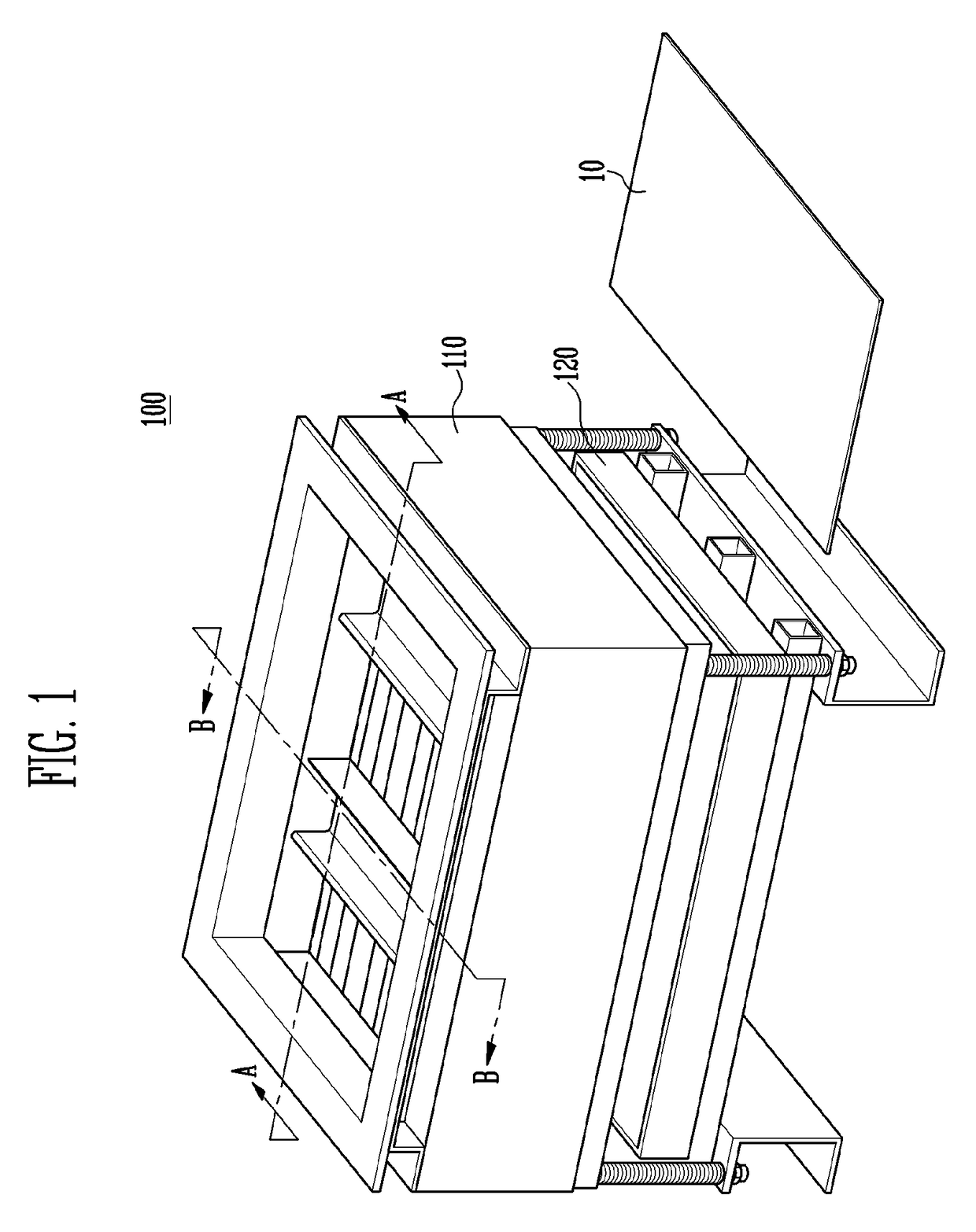

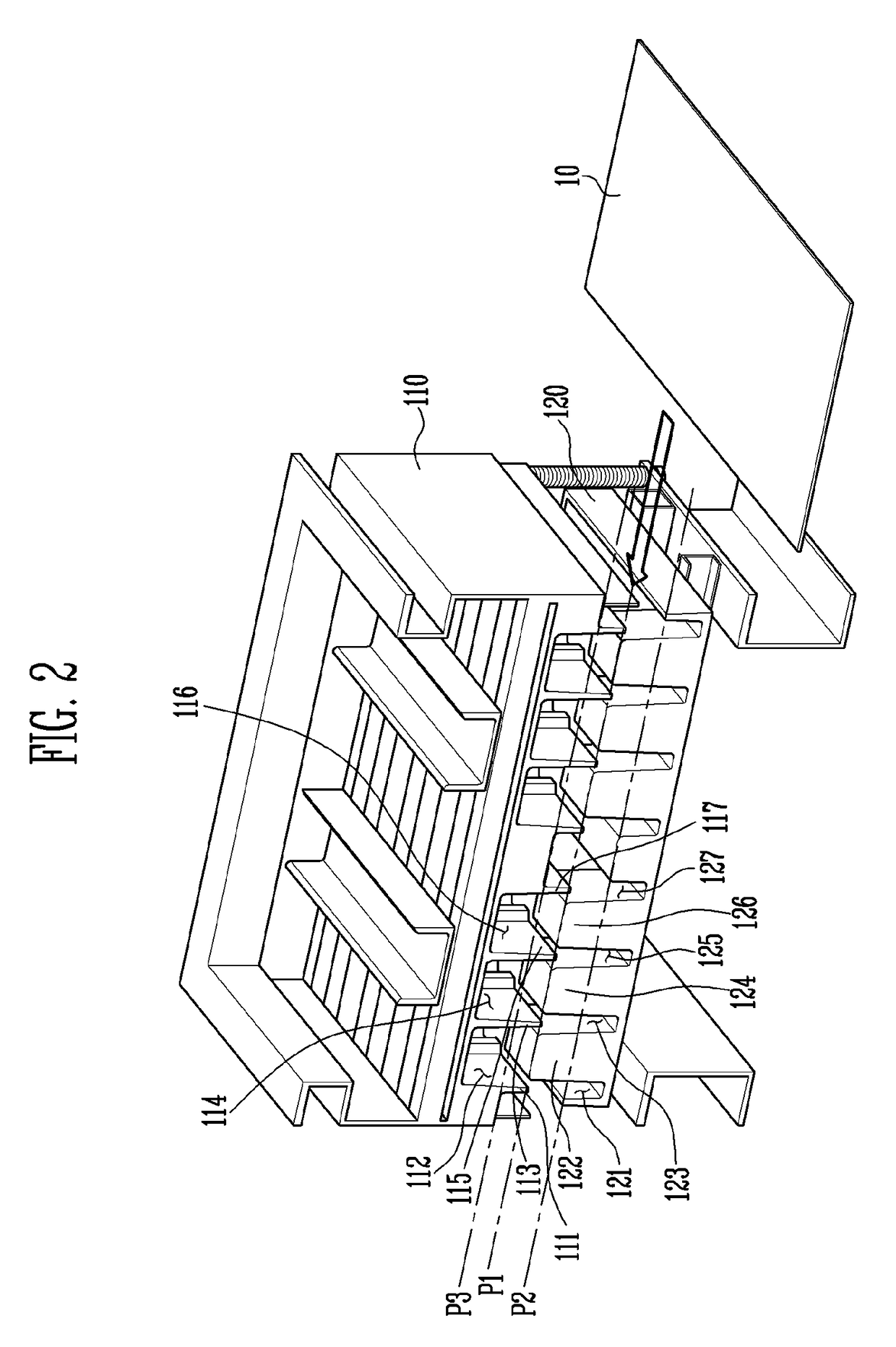

Molding apparatus and battery tray manufactured thereby

ActiveUS20160059470A1Minimize thicknessThickness minimizationConfectioneryCeramic shaping apparatusElectrical batteryEngineering

Owner:SAMSUNG SDI CO LTD

Molding apparatus and battery tray manufactured thereby

ActiveUS9643354B2Thickness minimizationAvoid out of shapeCell component detailsDomestic articlesElectrical batteryShell molding

Owner:SAMSUNG SDI CO LTD

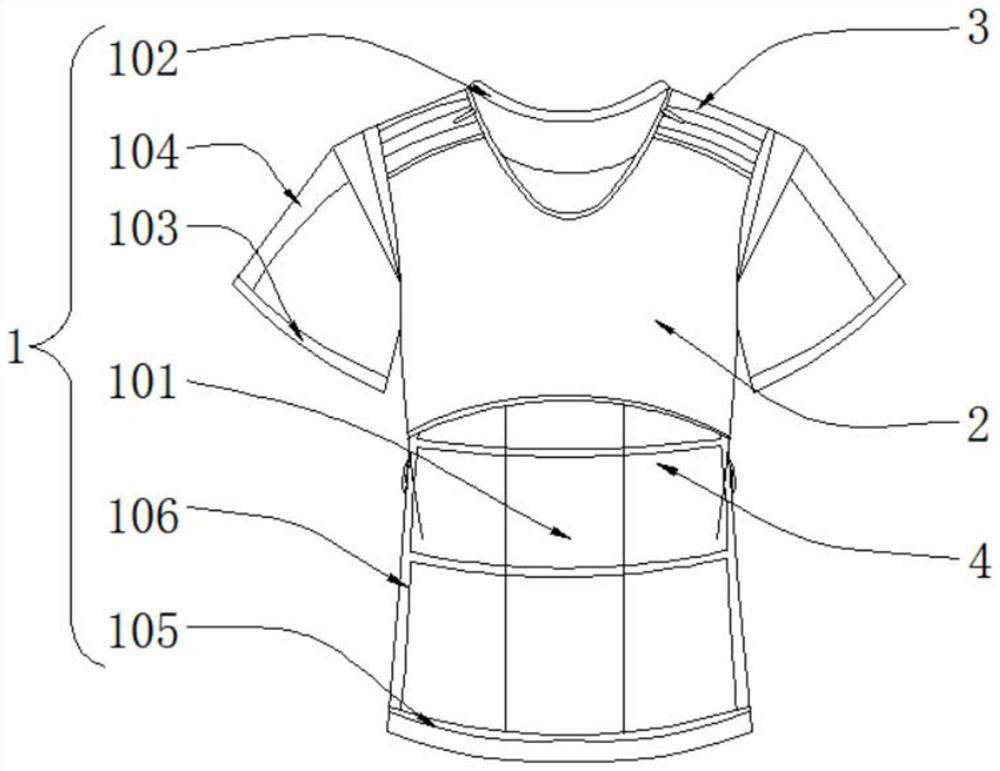

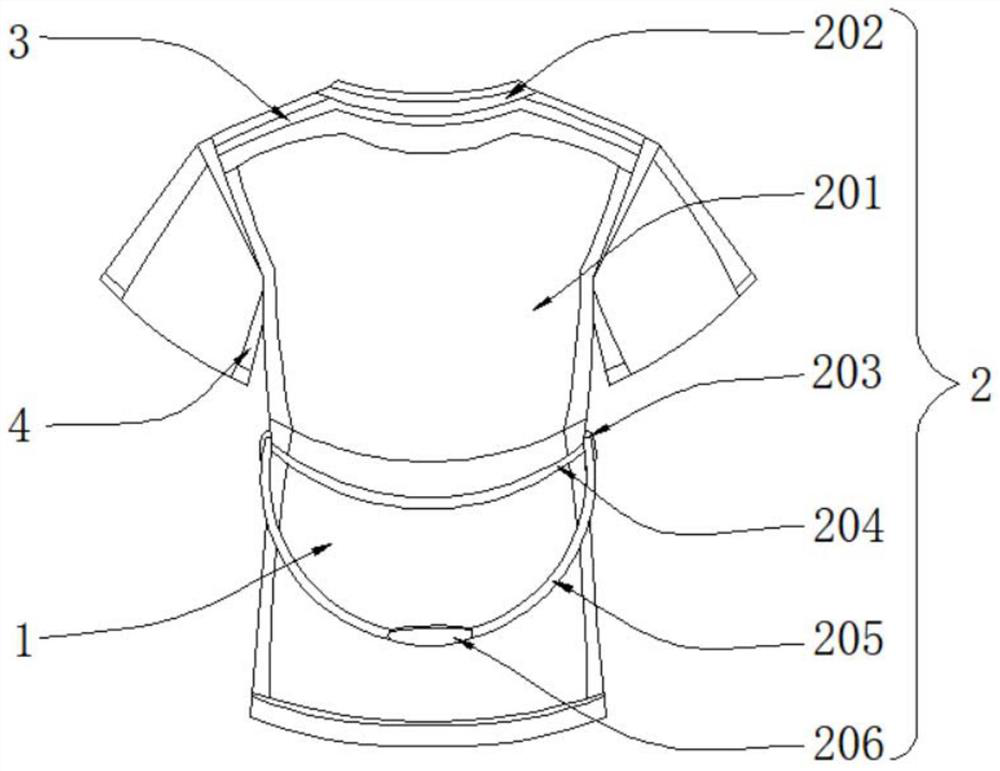

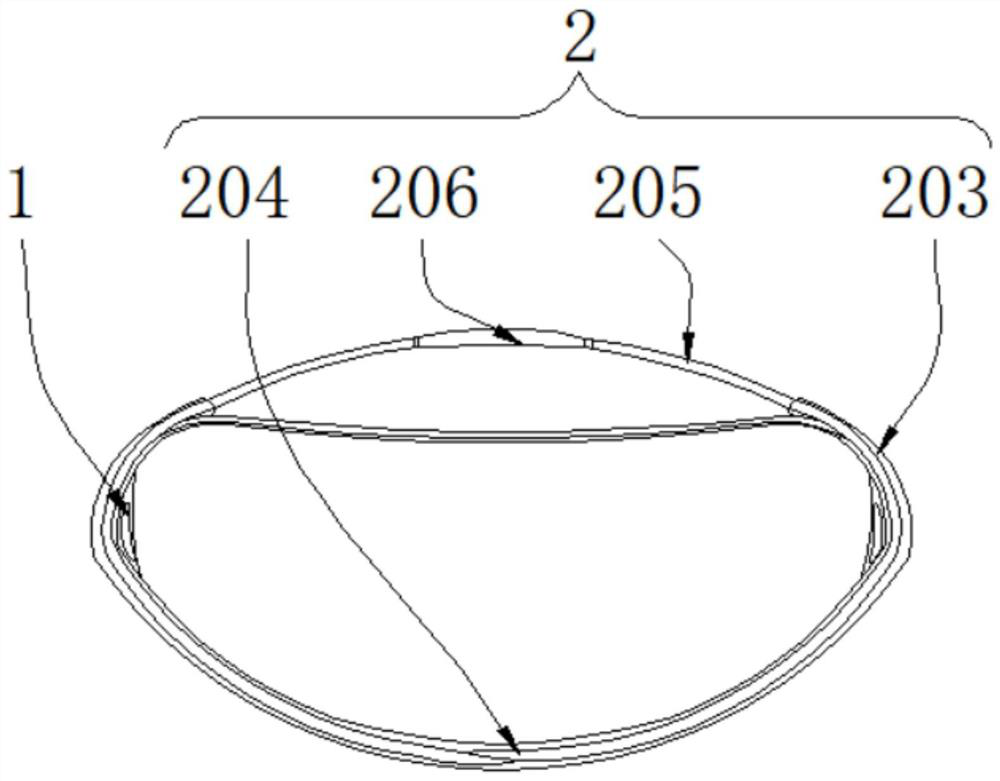

Anti-fouling T-shirt for lovers

InactiveCN113974239AImproved shape stabilityAvoid out of shapeProtective garmentSpecial outerwear garmentsProcess engineeringDirty environment

The invention discloses an anti-fouling T-shirt for lovers. The anti-fouling T-shirt comprises a stable inner container mechanism, external protection mechanisms, shoulder shaping mechanisms and interlayer anti-fouling mechanisms, the external protection mechanisms are attached to the outer walls of the periphery of the stable inner container mechanism, the shoulder shaping mechanisms are arranged at the top ends of the external protection mechanisms, and the interlayer anti-fouling mechanisms are distributed in the external protection mechanisms. According to the anti-fouling T-shirt for the lovers, the shape of the whole inner container is kept fixed in the mode that the anti-fouling T-shirt is distributed in the inner wall of the periphery of the inner container, the T-shirt is prevented from deforming in the cleaning or airing process, when a user faces a dry and dirty environment, the external protection mechanisms solve the problem that the body of the user is dry and dirty in the outdoor environment, and embarrassment caused by the user in the outdoor environment is avoided; the shoulder shaping mechanisms and the interlayer anti-fouling mechanisms have the function of keeping the shoulder positions shaped in the wearing process, and through mixed weaving of spandex and bamboo charcoal fibers, the T-shirt has the characteristics of dirt prevention, oil prevention and permeation prevention, and the whole T-shirt has the anti-fouling capacity.

Owner:义乌市完型科技有限公司

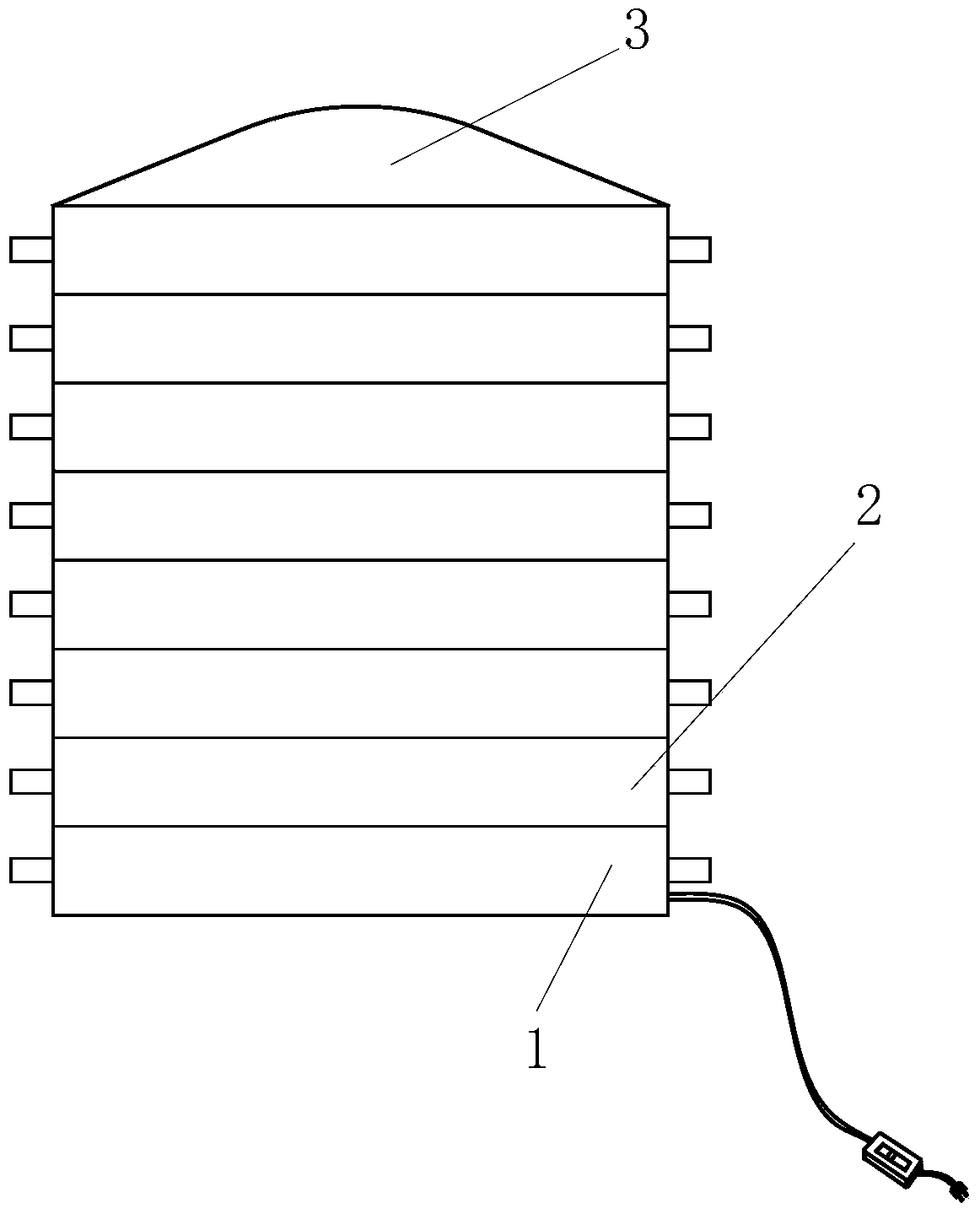

Heat-preserving device

The invention relates to a heat-preserving device. The heat-preserving device comprises a bottom heat-preserving box, a middle heat-preserving box and a box cover, wherein the box cover covers the middle heat-preserving box; the bottom heat-preserving box comprises a bottom heat-preserving box body, a temperature controller and a heating sheet I; a plug hole I is formed in one side of the upper surface of the bottom heat-preserving box body; a step I is arranged on the inner surface of the bottom heat-preserving box body; the middle heat-preserving box comprises a middle heat-preserving box body; a plug hole II is formed in one side of the upper surface of the middle heat-preserving box body; a plug is arranged on one side of the lower surface of the middle heat-preserving box body; a step II is arranged below the middle heat-preserving box body; a heating sheet II is arranged inside the middle heat-preserving box body. The heat-preserving device can preserve heat of a cut steamed bun blank for fermenting so as to ensure delicious taste of the cut steamed bun, and can ensure the outer shape of the steamed bun so as to effectively prevent the steamed bun from deforming in a fermenting process.

Owner:WUHU HENGHAO MACHINERY MFG

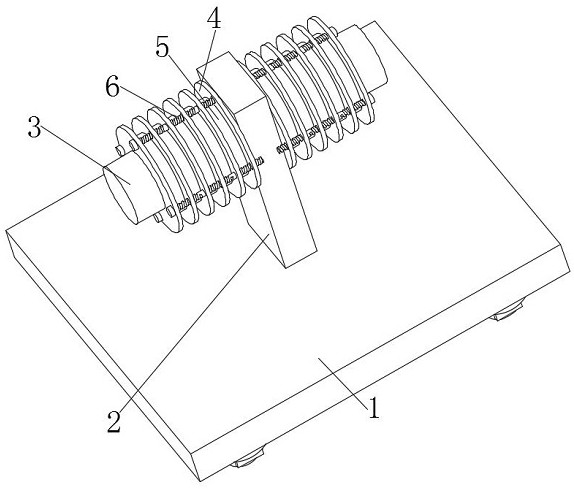

Steel wire inner ring machining machine for high-bearing-capacity mine tire and machining technology of steel wire inner ring machining machine

InactiveCN114102055AAvoid affecting take outAvoid out of shapeFurnace typesTyre beadsMachining processScrew thread

The high-bearing-capacity mine tire steel wire inner ring machining machine comprises a bottom plate, the top of the bottom plate is fixedly connected with a supporting block, one side of the supporting block is fixedly connected with a fixing column, the outer surface of the fixing column is movably sleeved with an isolation plate, and the outer surface of the fixing column is fixedly sleeved with a steel wire ring. A threaded hole is formed in one side of the isolation plate, the isolation plate is provided with a first bolt in threaded connection with the threaded hole, a fan is arranged at the top of the bottom plate, and an air outlet pipe is fixedly connected to the top of the bottom plate. According to the high-bearing-capacity mine tire steel wire inner ring machining machine and the machining technology thereof, the steel wire ring is arranged on the fixing column in a sleeving mode and located between the two isolation plates, then the two isolation plates and the steel wire ring are fixed through the first bolts, and therefore the situation that the steel wire ring deforms in the cooling and shaping process is avoided as much as possible; the method is suitable for general popularization and use.

Owner:JIANGSU SHENGDA TECH

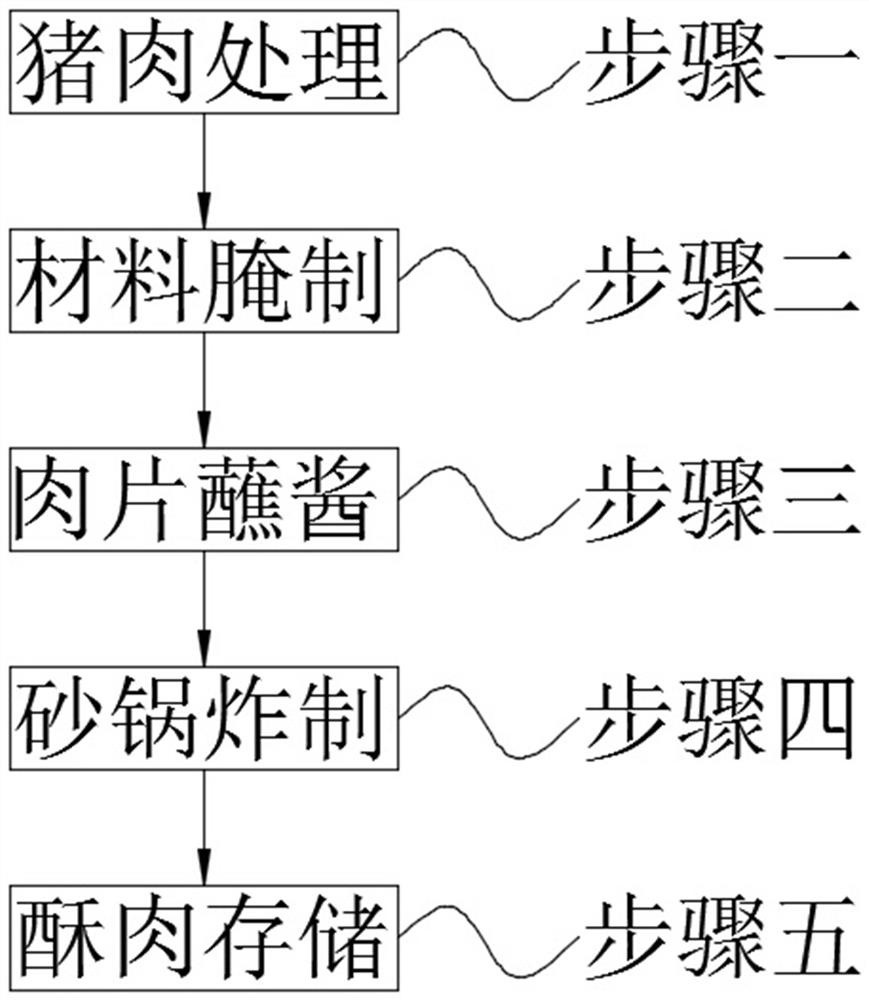

Preparation method of small crispy pork slices suitable for children's mouth feel

PendingCN114052205AAvoid out of shapeGreat tasteFood ingredient as mouthfeel improving agentBiotechnologyNutritive values

The invention discloses a preparation method of small crispy pork slices suitable for children's mouth feel, and the preparation method comprises the following steps of: 1, pork treatment; 2, material pickling; 3, dipping of sliced meat in sauce; 4, frying in a marmite; and 5, storage of the crispy pork slices; wherein in the step 1, pig tenderloin which is bright in color, ruddy in color, transparent in meat quality, compact in texture, rich in elasticity, capable of being quickly restored after being pressed by hands and special in pork flavor is manually selected; the small crispy pork slices are safe and reliable, the pork tenderloin is adopted as the raw material, sweet potato starch and eggs are added, the mouthfeel is good and the nutritional value is high, the phenomenon that the small crispy pork slices is not shaped during frying is avoided, and the pork slices are fried with rapeseed oil over big fire and then over soft fire, so that the small crispy pork slices are not loose, better in taste and suitable for children to eat; the technology can replace other expensive small crispy pork slice processing technologies, raw materials are cheap and low in cost, the production cost is greatly saved, and small crispy pork slice processing production is facilitated.

Owner:ZHANGZHOU SHENGLONG FOOD

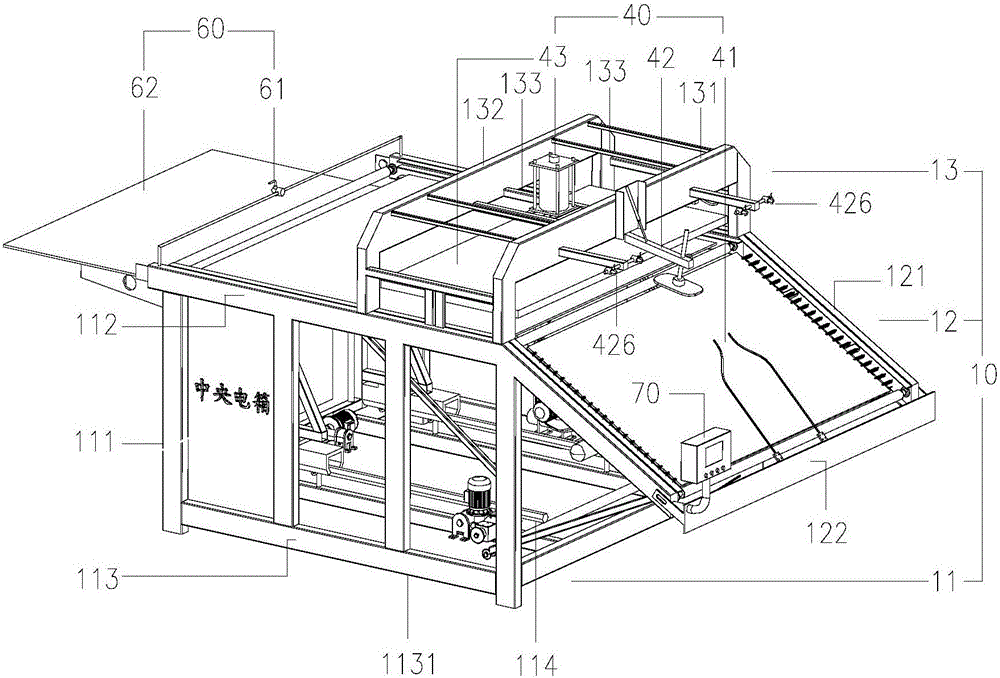

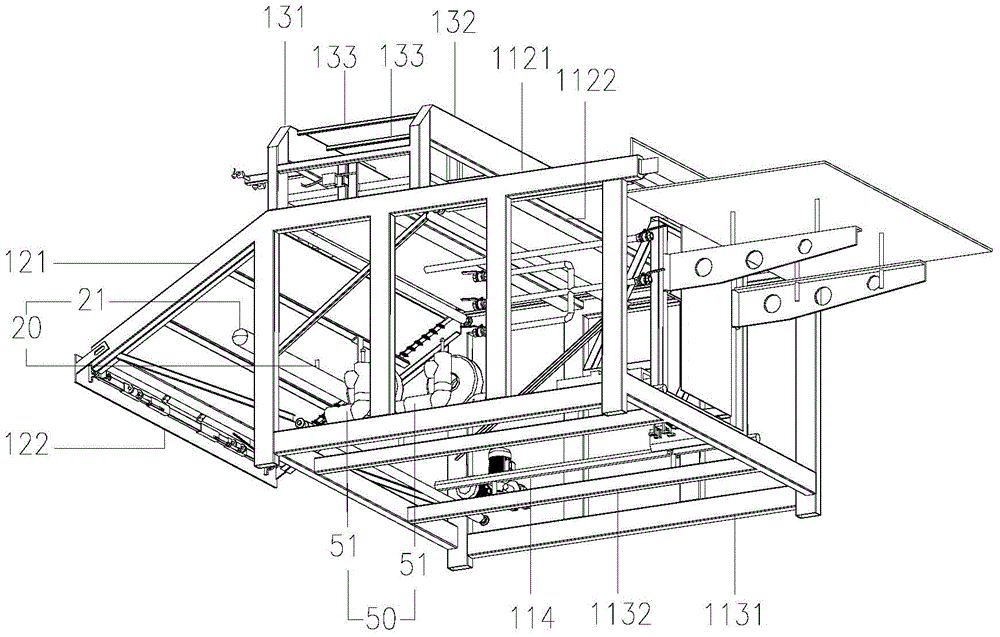

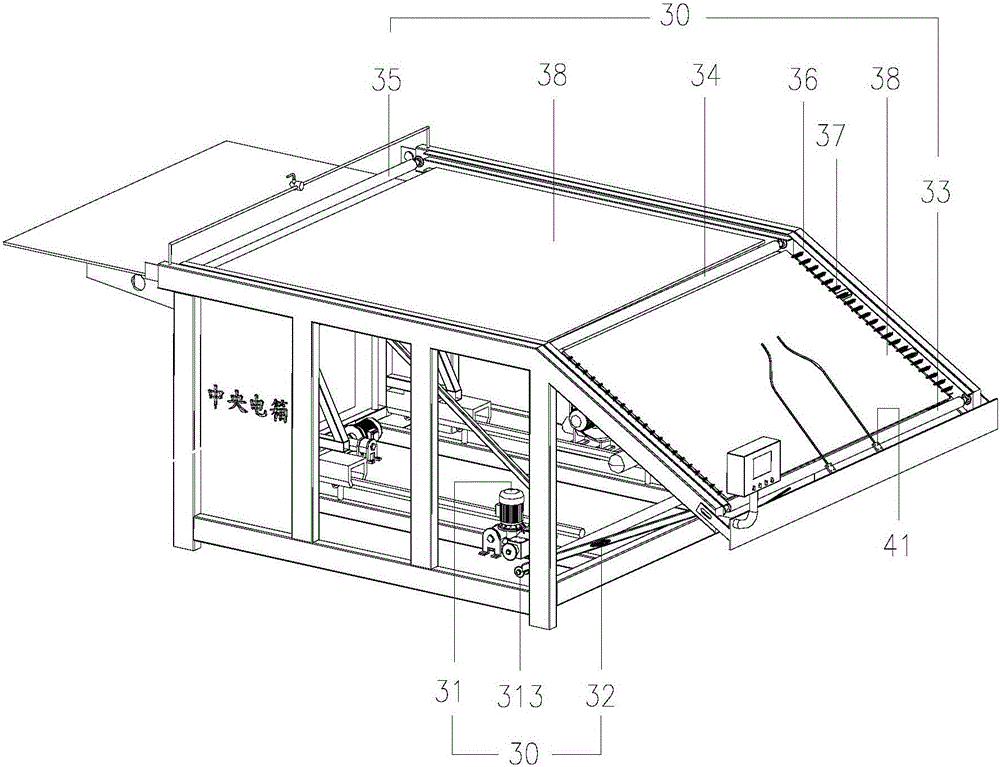

A wool fabric steaming and ironing setting machine

InactiveCN104805666BAchieve ironing and settingAvoid out of shapeHeating/cooling textile fabricsIroning apparatusSupport groupPulp and paper industry

The invention provides a woolen knitwear steaming setting machine. The woolen knitwear steaming setting machine comprises a machine frame, a steam evaporating group, a transmission group, an ironing positioning group, a ventilating dehumidifying group, a counting clothes supporting group and an electric control group, wherein the machine frame comprises a main frame part, an inclined frame part and a top frame part; the main frame part is provided with a main rod, an upper frame and a lower frame; the inclined frame part is combined with the front side of the upper frame body and is provided with a surface beam; the top frame part is arranged on the upper frame body; the steam evaporating group comprises a steam temporary storage device; the steam temporary storage device is communicated with the ventilating dehumidifying group through a pipeline; the transmission group drives a first roller, a second roller, a third roller and a conveying cloth belt of the transmission group by adopting chain transmission; a transmission chain used for the chain transmission is provided with ear holes; the first roller is overlapped to the second roller and the third roller through the conveying cloth belt; metal rings are arranged on the two side peripheries of the conveying cloth belt corresponding to the ear holes; the ear holes are connected with the metal rings through springs. Through the structure, the technical problems about woolen knitwear steaming and setting are solved; good effects that the operation is facilitated, and the steaming efficiency is improved are achieved.

Owner:郑野

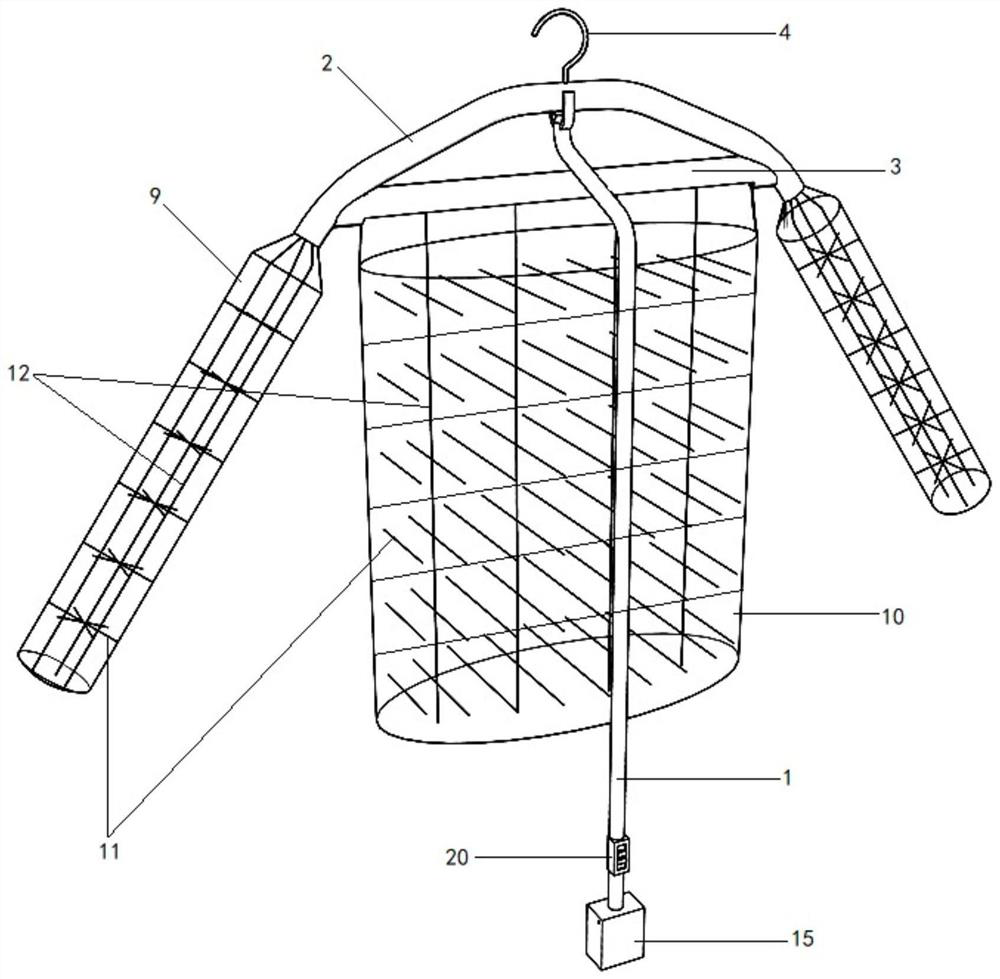

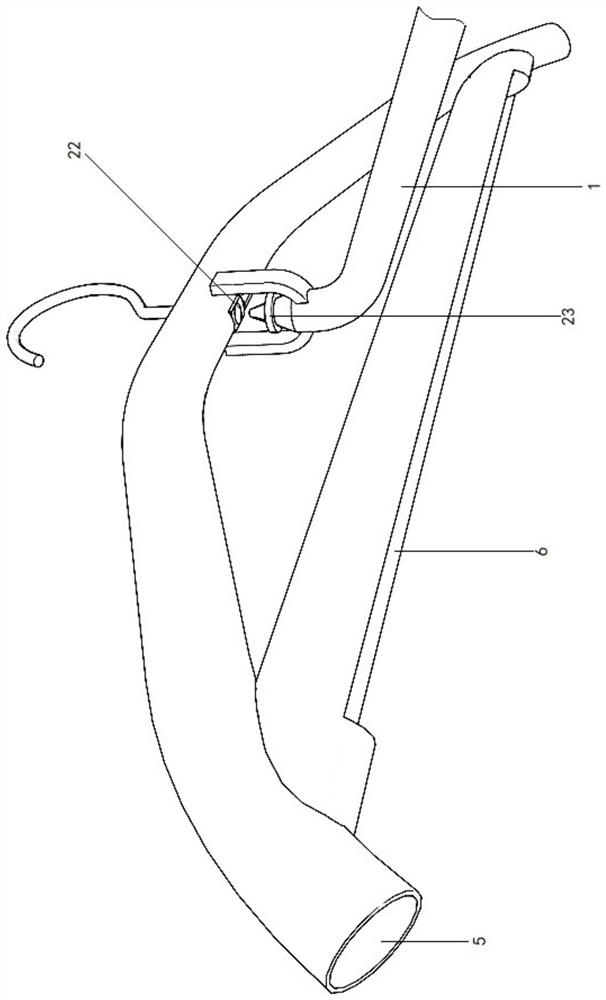

Multifunctional clothing showing stand

PendingCN114343397AImprove the effect of three-dimensional displayEasy to carryShow cabinetsShow shelvesClothes hangerStructural engineering

The invention discloses a multifunctional clothes showing stand, and relates to the technical field of clothes showing. The clothes hanger comprises a clothes hanger body and a clothes fork rod used for hanging the clothes hanger body. The clothes hanger body comprises a clothes supporting rod on the upper side and a transverse connecting rod on the lower side. Hooks are fixed at the upper ends of the clothes supporting rods; the left and right ends of the transverse connecting rod are correspondingly fixed with the left and right sides of the lower part of the clothes supporting rod; an expansion device is arranged on the clothes hanger body; an inflating device is arranged on the clothes fork rod; the expanding and supporting device comprises first storage grooves formed in the left end and the right end of the clothes supporting rod respectively, and a second storage groove formed in the lower side of the transverse connecting rod in the left-right direction. An air guide channel is formed in the clothes supporting rod along the trend; the left and right ends of the air guide channel correspondingly communicate with the first storage grooves. The three-dimensional display rack has the advantages that the upper garment can be supported, the three-dimensional effect during display is improved, the problem that the occupied space is large during carrying is solved, and three-dimensional display of the upper garments of all styles can be conveniently achieved.

Owner:HANGZHOU VOCATIONAL & TECHN COLLEGE

Sweater steaming and setting machine

ActiveCN104372595BEasy ironingEasy to shapeIroning apparatusTextiles and paperEconomic benefitsEvaporation

Owner:NINGBO YUREN INTELLIGENT CONTROL TECH CO LTD

Endoscope anastomat anti-skidding nail anvil

InactiveCN107802305AAvoid out of shapeReduce tissue clampingSurgical staplesSustainable productionMedicine

The invention discloses an endoscope anastomat anti-skidding nail anvil. The nail anvil is characterized in that the nail anvil comprises a nail anvil plate and an anvil head; the anvil head is located at the head portion of the nail anvil plate and is fixedly connected with the nail anvil plate; a plurality of globular anti-skidding bulges are arranged on the anvil head; an anti-skidding layer isarranged on the surface of the anti-skidding bulges. Compared with the prior art, the nail anvil has the advantages of being easy to operate, low in blood oozing risk, high in sustainable productivity, and low in cost.

Owner:无锡贝恩外科器械有限公司

A kind of injection molding device for plastic abrasive molding

Owner:昆山佳禾兴电子科技有限公司

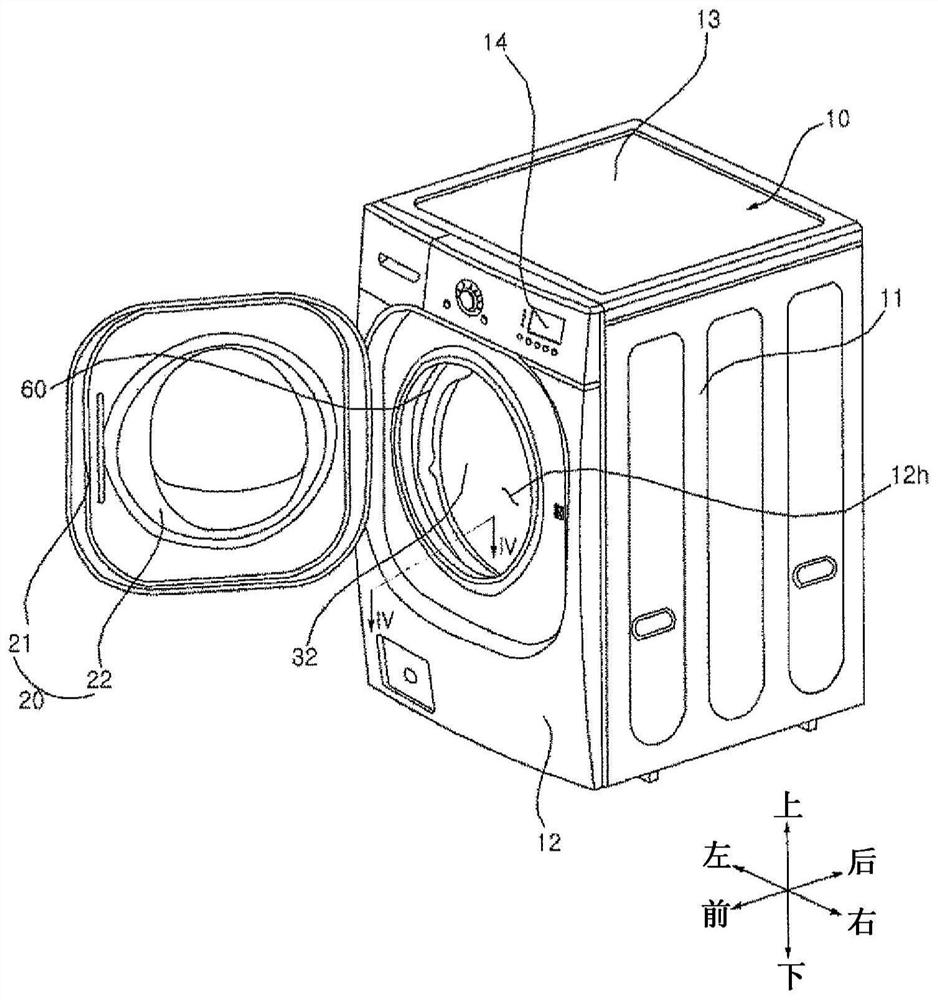

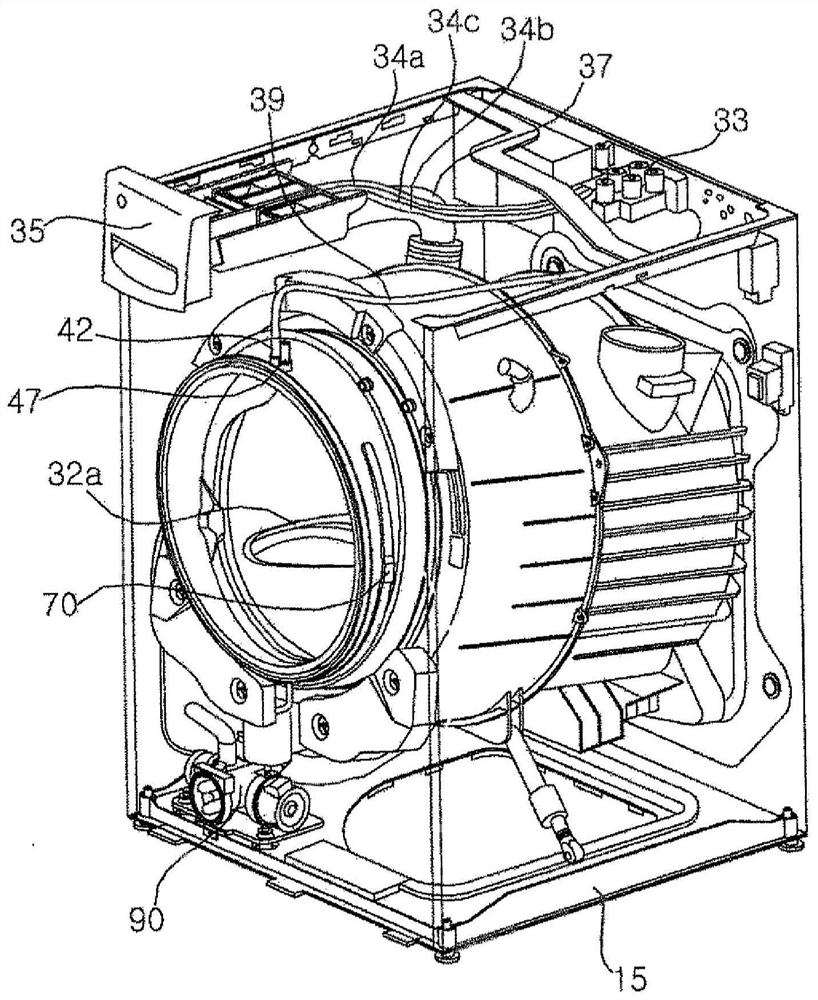

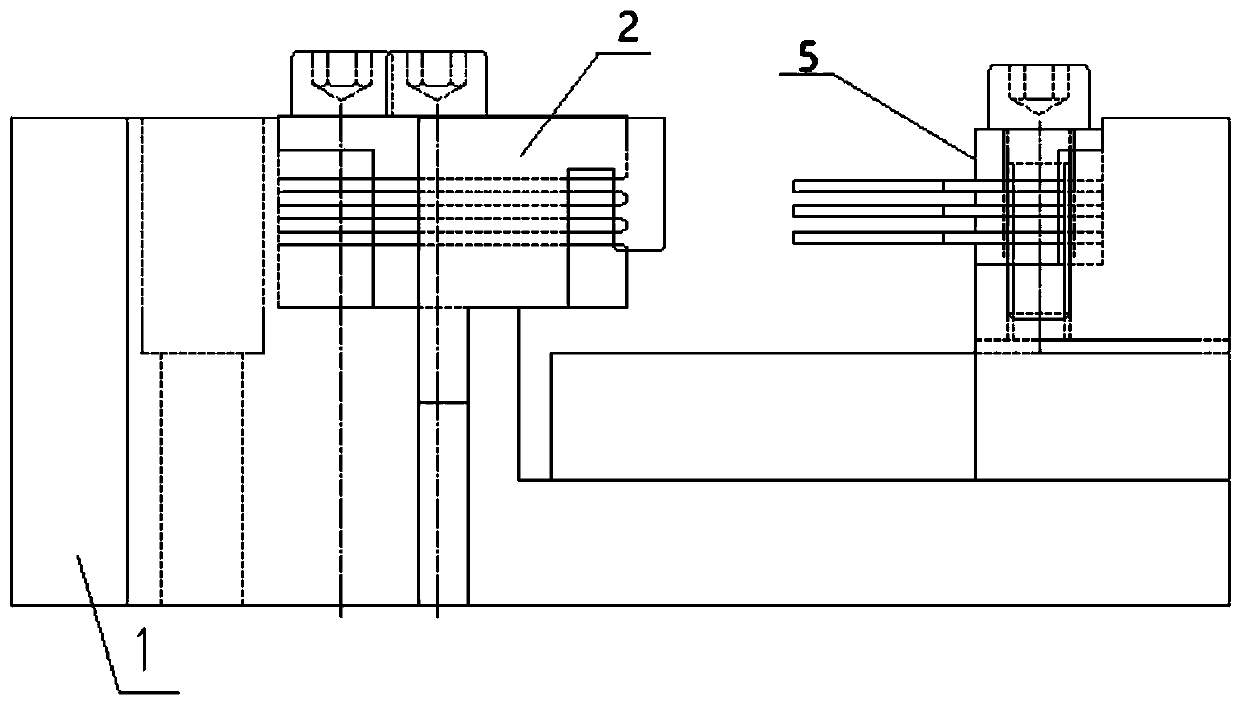

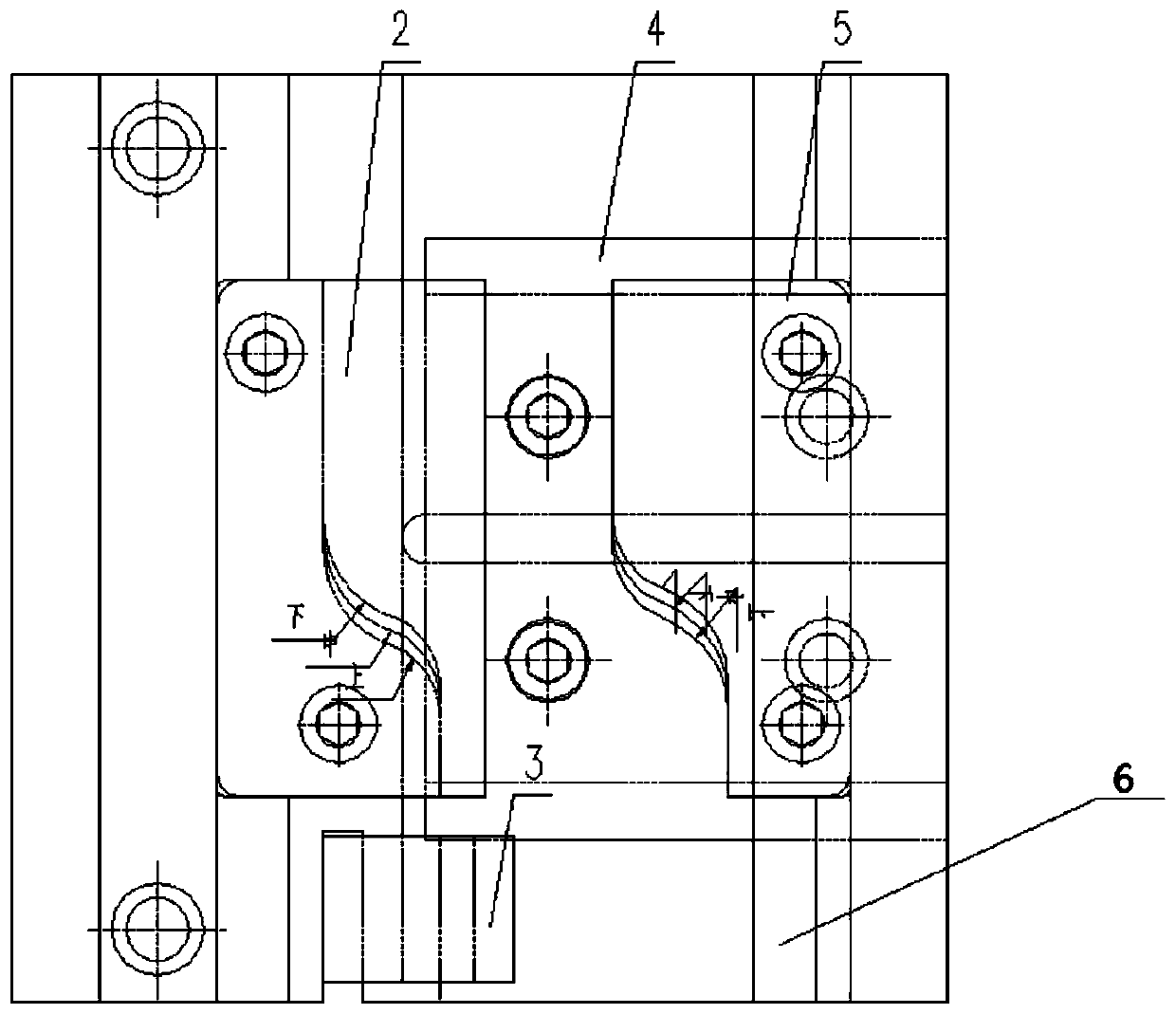

Washing machine with conduit for supplying water to nozzles at gasket and manufacturing method of the conduit

ActiveCN112543825AReduce wasteIncrease productivityOther washing machinesDomestic articlesLaundry washing machineWasher

The present invention relates to a washing machine comprising a conduit supplying circulating water to a plurality of circulation nozzles formed in a gasket, and a method of manufacturing the conduit,the method including: positioning a plurality of nozzle water supply ports in a cavity of a lower mold; forming a molten parison having a hollow opening, by extruding a raw material; positioning theparison in the cavity of the lower mold; assembling an upper mold and the lower mold; and injecting gas into the hollow opening.

Owner:LG ELECTRONICS INC

Small S bend forming tool for lead pin of armature coil

PendingCN110071609AAvoid out of shapeStructure is not limitedManufacturing dynamo-electric machinesEngineeringElectrical and Electronics engineering

The invention discloses a small S bend forming tool for a lead pin of an armature coil. A female die combination and a male die combination are arranged on a fixed die holder; the male die combinationslides along a track through a sliding die holder; the female die combination is arranged in a corresponding position; and when the lower-layer lead pin of the armature coil penetrates through a limiting and anti-deformation block to extend into a partition plate of the female die combination to be tightly attached to a female die core, a pressing machine is started to push the sliding die holderto drive a male die core of the male die combination to be inserted in the partition plate of the female die combination, and the male die combination and the female die combination are combined to extrude the lead pin to be bent. The problems that during manual forming or simple tool forming, the shape is not in place, the position is not accurate to locate, and the position deviation between adjacent electromagnetic wires is relatively large can be avoided. By changing forming mode and method of the lead pin, the forming quality and efficiency of the lead pin of the coil are greatly improved, the risk of armature winding manufacturing and armature operation is reduced, and the quality problem of a motor armature is greatly reduced.

Owner:威伊艾姆电机(无锡)有限公司

A carbon fiber automobile front hatch cover molding method

The invention relates to a rapid molding process flow of a carbon fiber front hatch cover for automobiles. It belongs to the technical field of traffic facilities. A carbon fiber automobile front hatch cover molding method provided by the present invention, compared with the common automobile carbon fiber front hatch cover molding method, cancels the three processes of prepreg preheating, preforming, and semi-finished product cooling, and simplifies the process flow , so that the equipment and tooling put into the production line are reduced, the space occupied by equipment and tooling is saved, the input cost is reduced, and the quality risk of position deviation and fiber texture disorder that may be caused by the transfer of preforms is avoided; the curing time is selected to be 5 The ‑10min medium temperature curing carbon fiber prepreg greatly shortens the molding cycle of the automobile front hatch, which is a big step forward to adapt to the high-efficiency production rhythm of the automobile industry; the semi-finished product is demolded after the mold temperature drops to 80‑100 °C, reducing the semi-finished product Occupying the mold time shortens the molding cycle and solves the quality problems of semi-finished product deformation, mold sticking, and fiber texture disorder.

Owner:AVIC COMPOSITES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com