Small S bend forming tool for lead pin of armature coil

A technology of armature coils and lead pins, which is applied in the field of small S-bend forming tools for armature coil lead pins, which can solve problems such as difficulties and troubles in the manufacture of lead pins, and achieve the effects of convenient operation, reduced risks, and improved molding quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

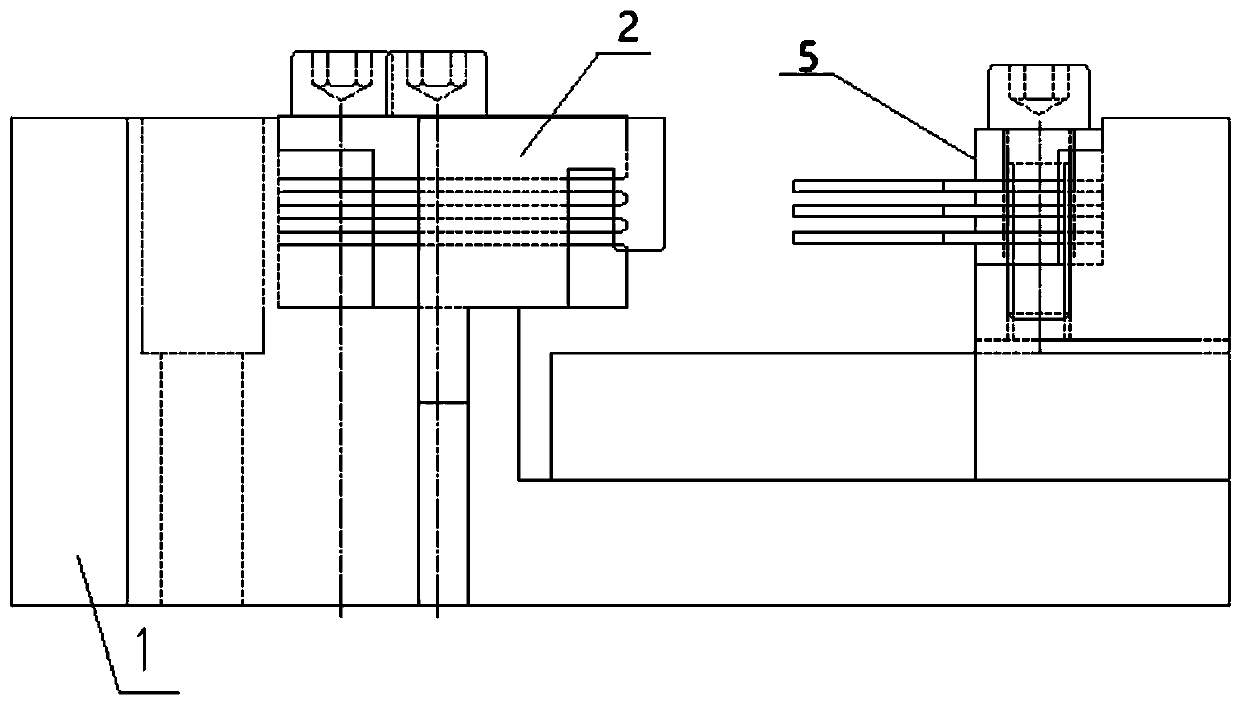

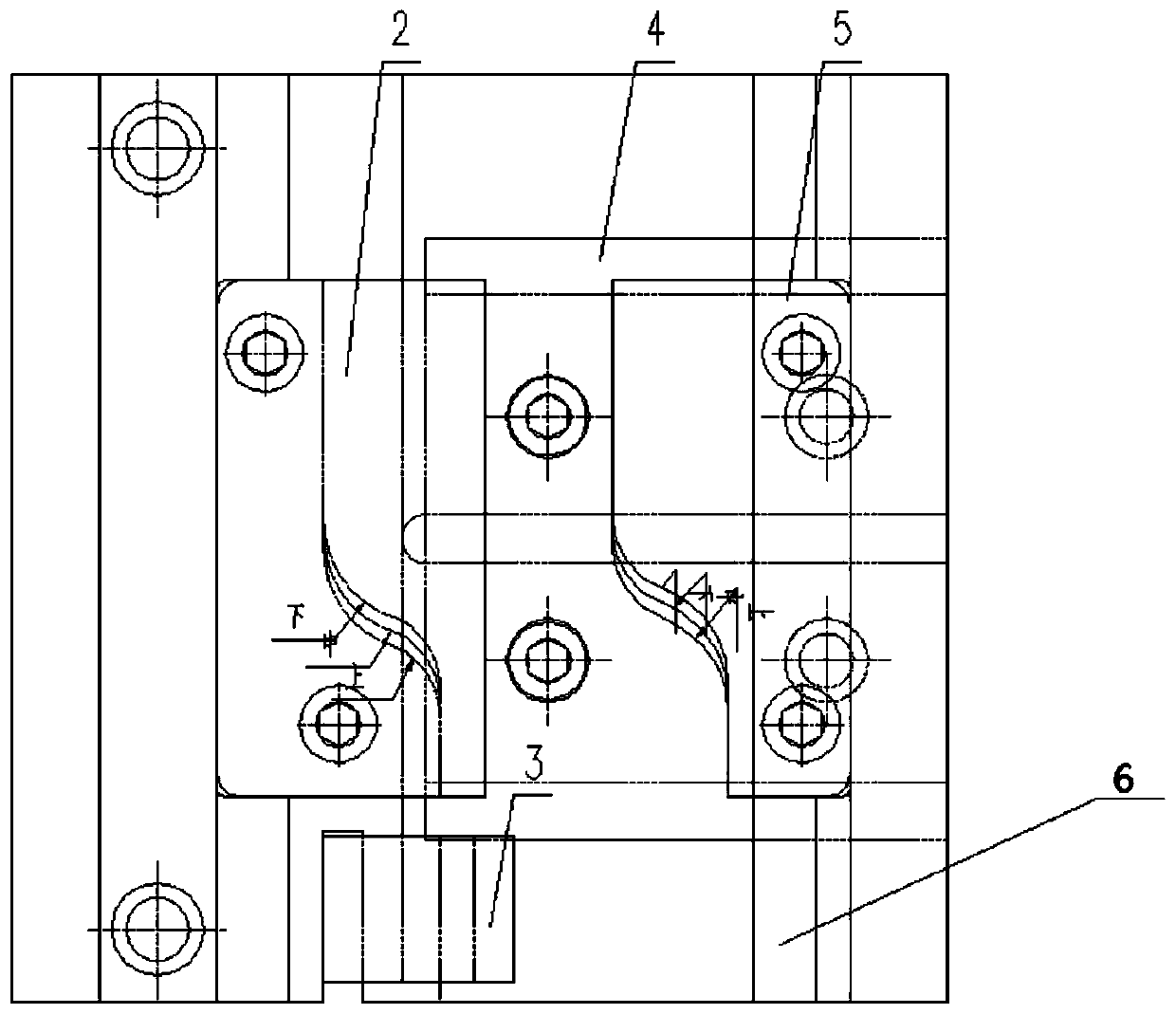

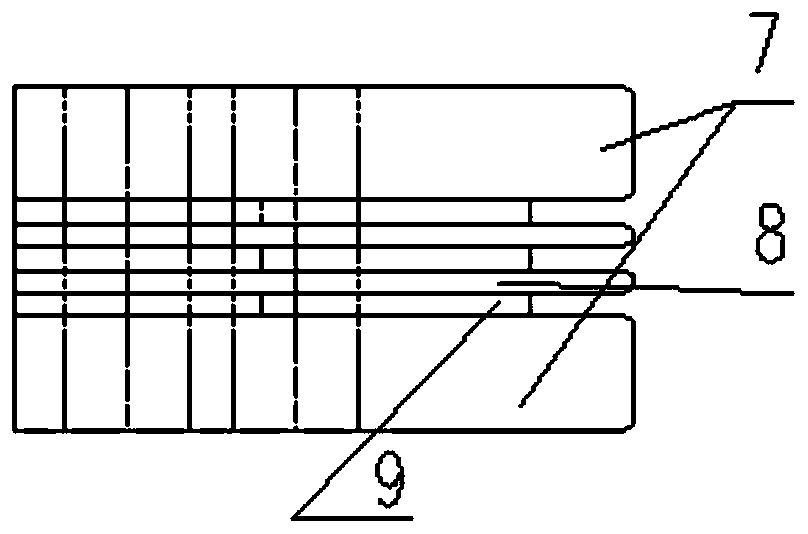

[0018] A small S-bend forming tool for the lead pin of an armature coil, comprising a fixed mold base 1, a female mold combination 2 and a male mold combination 5 are arranged on the fixed mold base 1, and the female mold combination 2 consists of a splint 7, several partitions 8 and The female mold core 9 is composed of; the male mold combination 5 is composed of splint 7, several partitions 8 and male mold core 10; the fixed mold base 1 below the male mold combination 5 is fixed with a track 4, and the male mold combination 5 Slide along the track 4 through the sliding mold base 6; the position of the female mold combination 2 on the fixed mold base 1 corresponds to the running track of the male mold combination 5;

[0019] The lead pins of the lower layer of the armature coil pass through the limit and anti-deformation block 3 and extend into the partition plate 8 of the mother mold combination, and cling to the mold core 9 of the mother mold, start the press to push the sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com