Sweater steaming and setting machine

A technology for setting machines and sweaters, which is applied to washing devices, wrinkle-removing and flattening equipment, textiles and papermaking, etc. It can solve the problems of not solving the industrial requirements for setting the whole garment, so as to reduce the process time and cost , reduce workload, good stereotyped effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The preferred embodiments of the present invention will be described below with reference to the drawings.

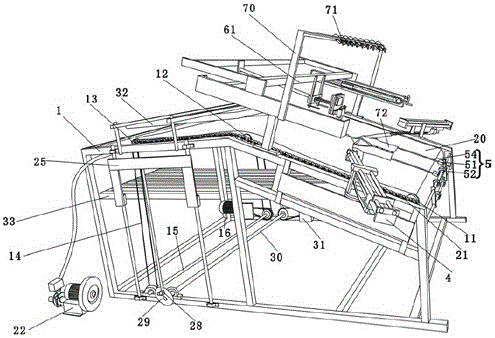

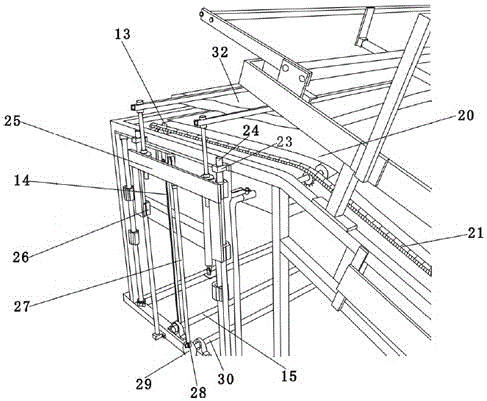

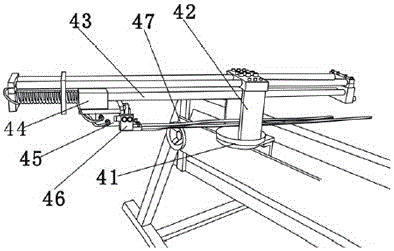

[0032] A sweater steaming and ironing setting machine, such as figure 1 , 2 As shown, the frame 1 is formed by welding and laying steel pipes, which is divided into a front part and a rear part. The front part is an inclined table with a low front and a high rear, and the rear is a horizontal platform. A front roller set 11 is installed at the front end of the rack, a middle roller set 12 is installed at the junction of the front and rear racks, and a rear roller set 13 is installed at the rear of the rack. Left and right transmission gear plates are installed at both ends of the roller. The rear roller group is connected to the conveying motor 16 through the chain 14 and the conveying shaft 15.

[0033] The front end, the rear end roller group and the middle roller group of the frame support a cloth belt 20, and a chain 21 is meshed and installed between the left a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com