Patents

Literature

254results about How to "Easy ironing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Textile cleaning agent which is gentle on textiles

InactiveUS20050119151A1Enhanced brightness of luster and colorPositive propertyOrganic detergent compounding agentsDetergent materialsEmulsionBiopolymer

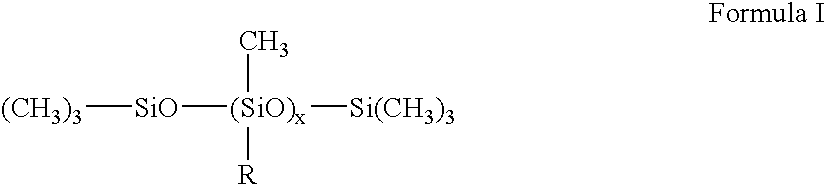

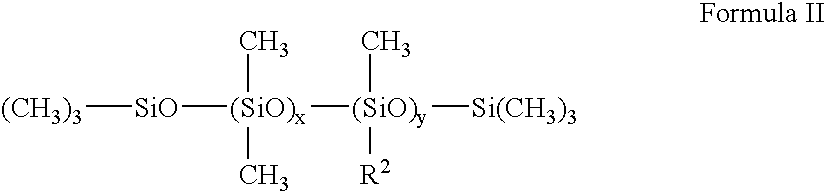

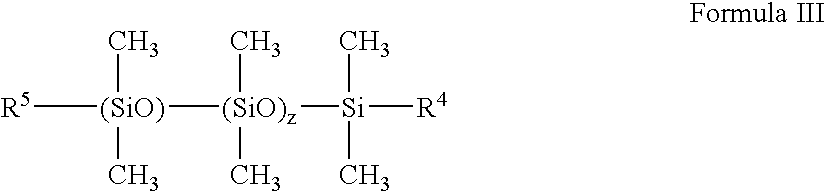

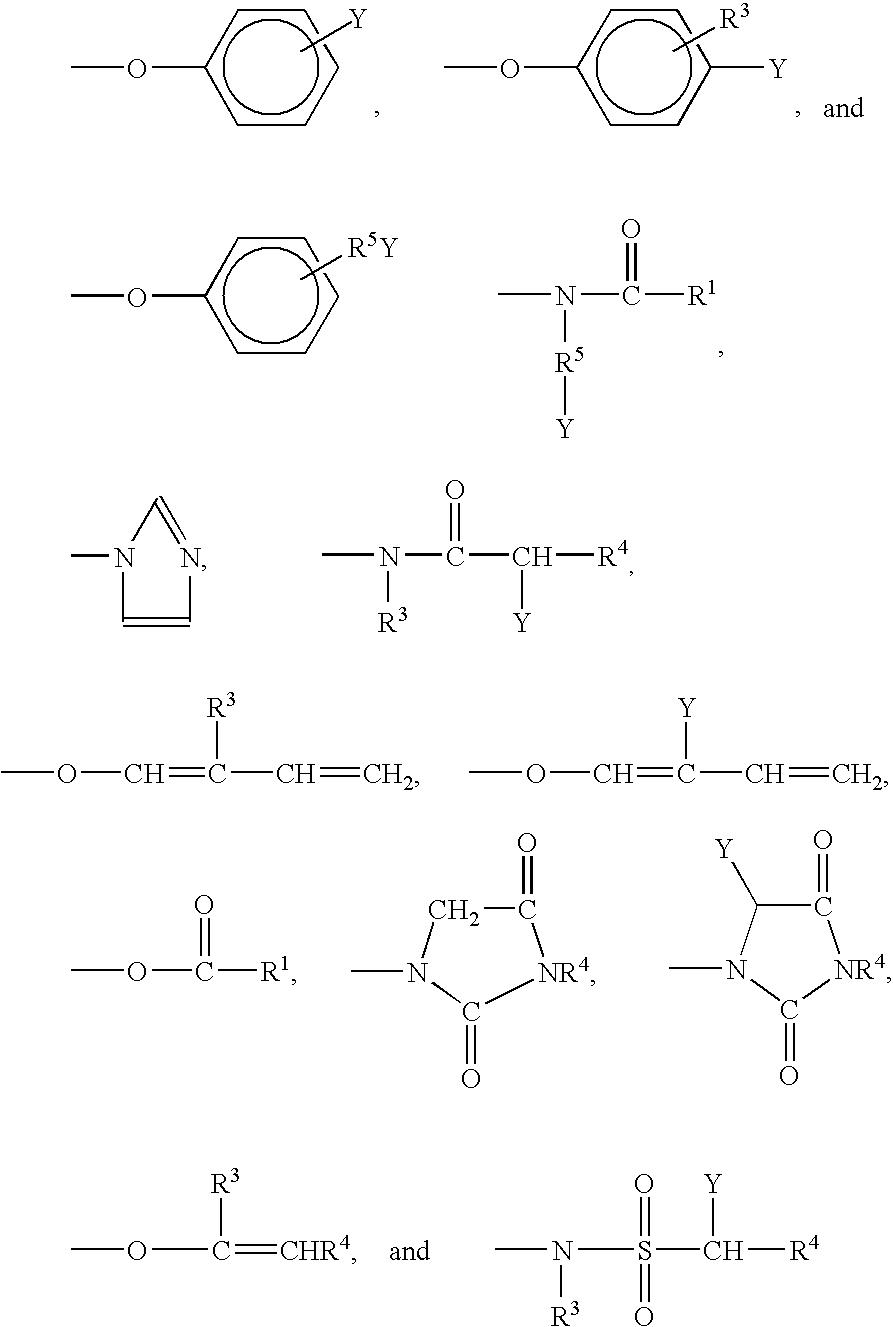

Liquid aqueous and nonaqueous textile-cleaning compositions containing particles of a fuzz-reducing component selected from the group consisting of: a) biological polymers, b) hydrogels, c) synthetic polymers and d) silicone emulsions, wherein not less than 90% of the particles of a fuzz-reducing components a), b) or c) have a particle size of less than 100 μm, and wherein a fuzz-reducing component selected from d) has an average droplet size below 50 μm.

Owner:HENKEL KGAA

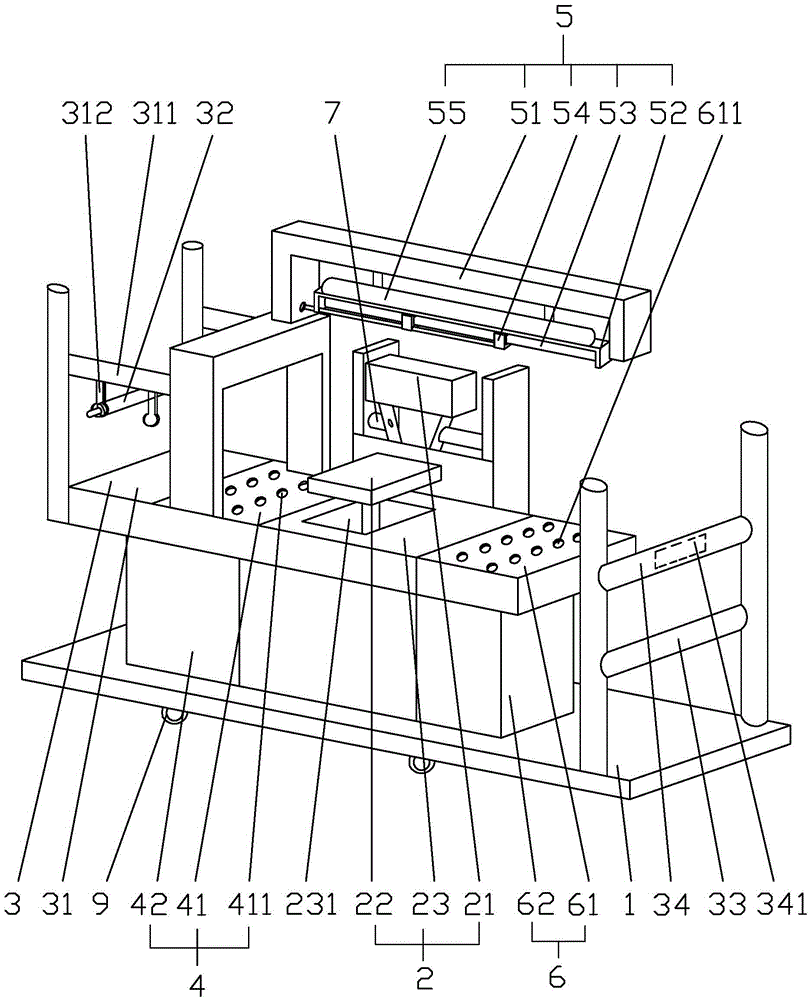

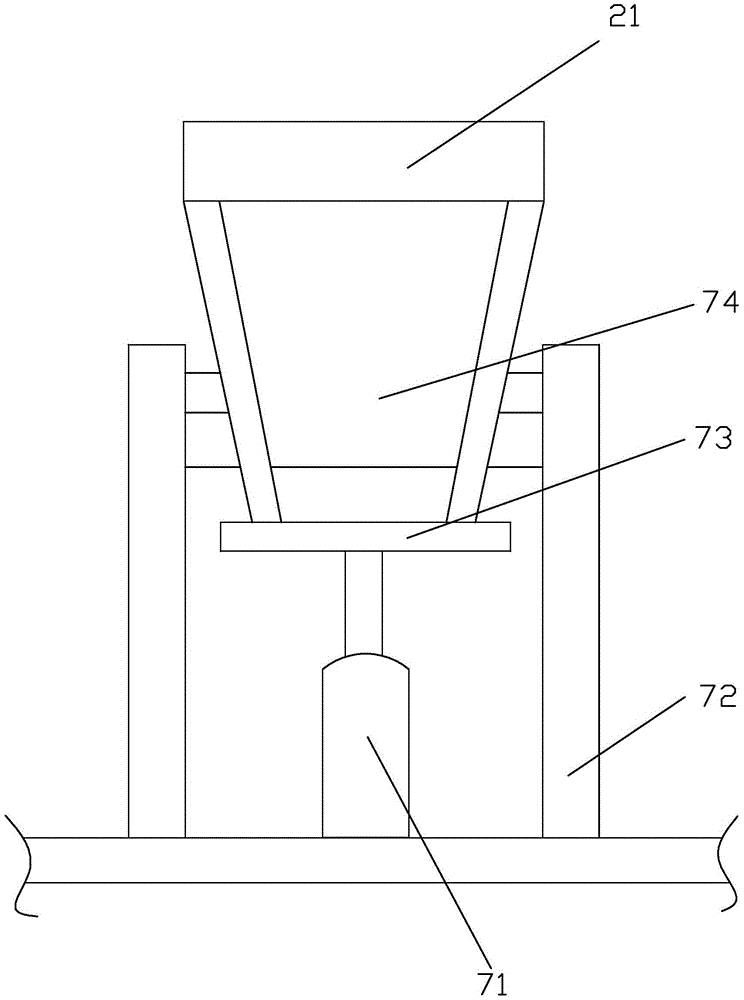

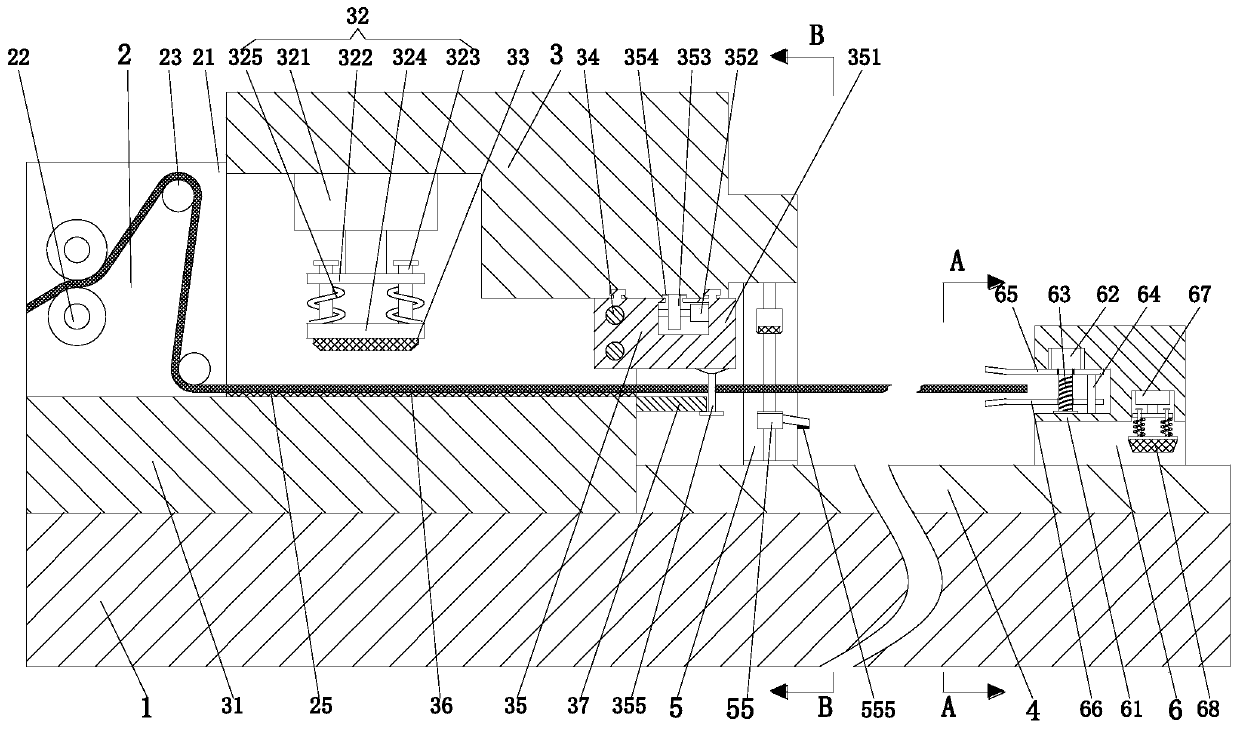

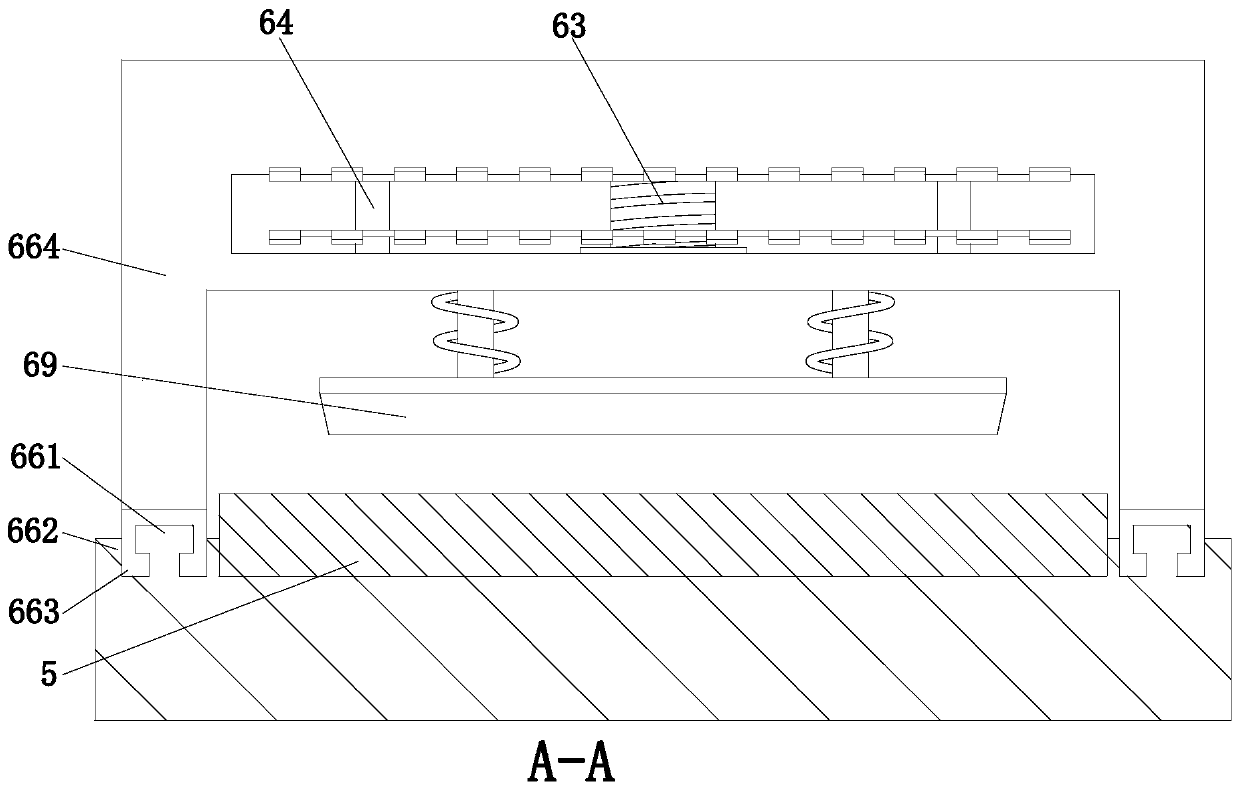

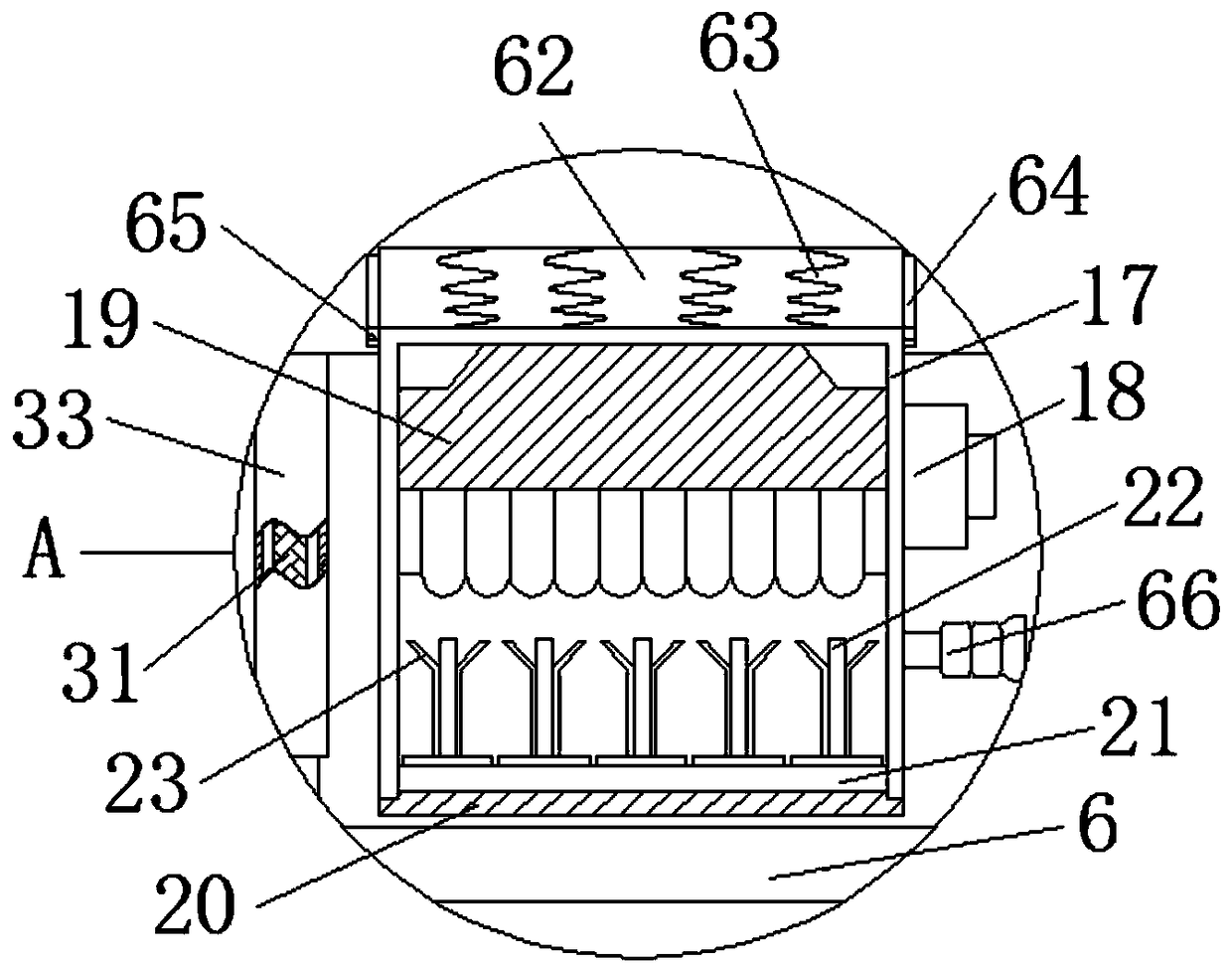

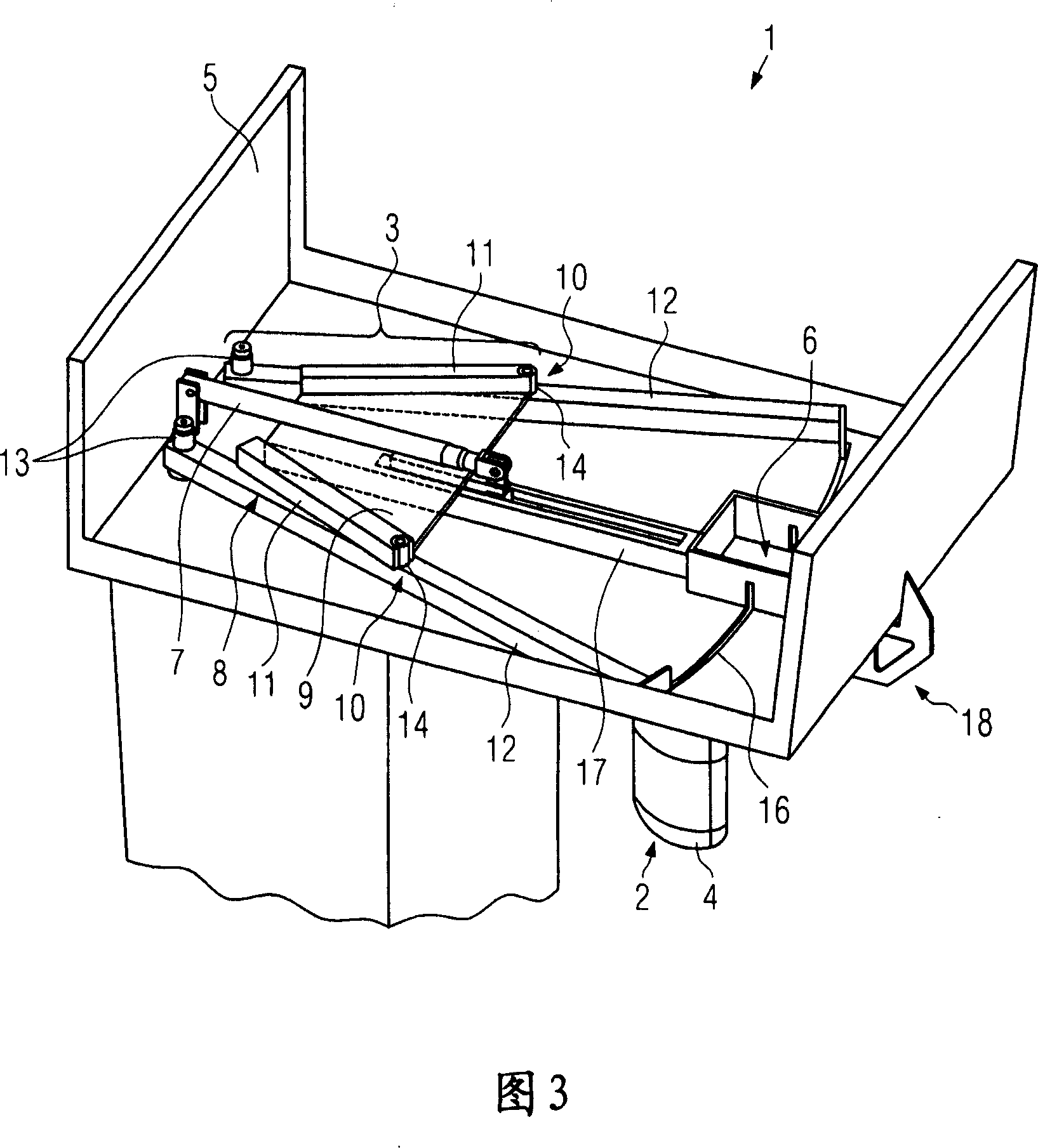

Cloth ironing machine

InactiveCN105463745AAvoid damageQuality improvementHeating/cooling textile fabricsTextile treatment by spraying/projectingEngineeringEnergy consumption

The invention mainly discloses a cloth ironing machine. The technical scheme is that the cloth ironing machine comprises a rack, an ironing mechanism, a conveying mechanism, a preheating mechanism, a sterilization mechanism and a drying mechanism, wherein the conveying mechanism comprises a putting table, cloth putting rollers and a cloth reeling roller, the putting table is provided with hanging rings, two ends of the cloth putting rollers are respectively hung on the hanging rings, one side of the cloth reeling roller is provided with a cooling roller, the ironing mechanism comprises an upper press mould, a lower press mould and an ironing table, the lower sides of the upper press mould and the lower press mould are respectively provided with a first transmission mechanism and a second transmission mechanism for driving the upper press mould and the lower press mould to be in force fit, the preheating mechanism comprises a preheating plate provided with steam holes and a water tank with an electric heater, the sterilization mechanism comprises a lamp base, a lamp holder and an ultraviolet tube with a cleaning device, the drying mechanism comprises a drying plate provided with air outlets and a warm air chamber provided with a warm air machine, and sliding wheels are arranged below the rack. The cloth ironing machine has the advantages of good ironing effect, shaping in one step, high work efficiency and less energy consumption.

Owner:SHENGZHOU YIHAI MOTOR PARTS FACTORY

Laundry additive sachet

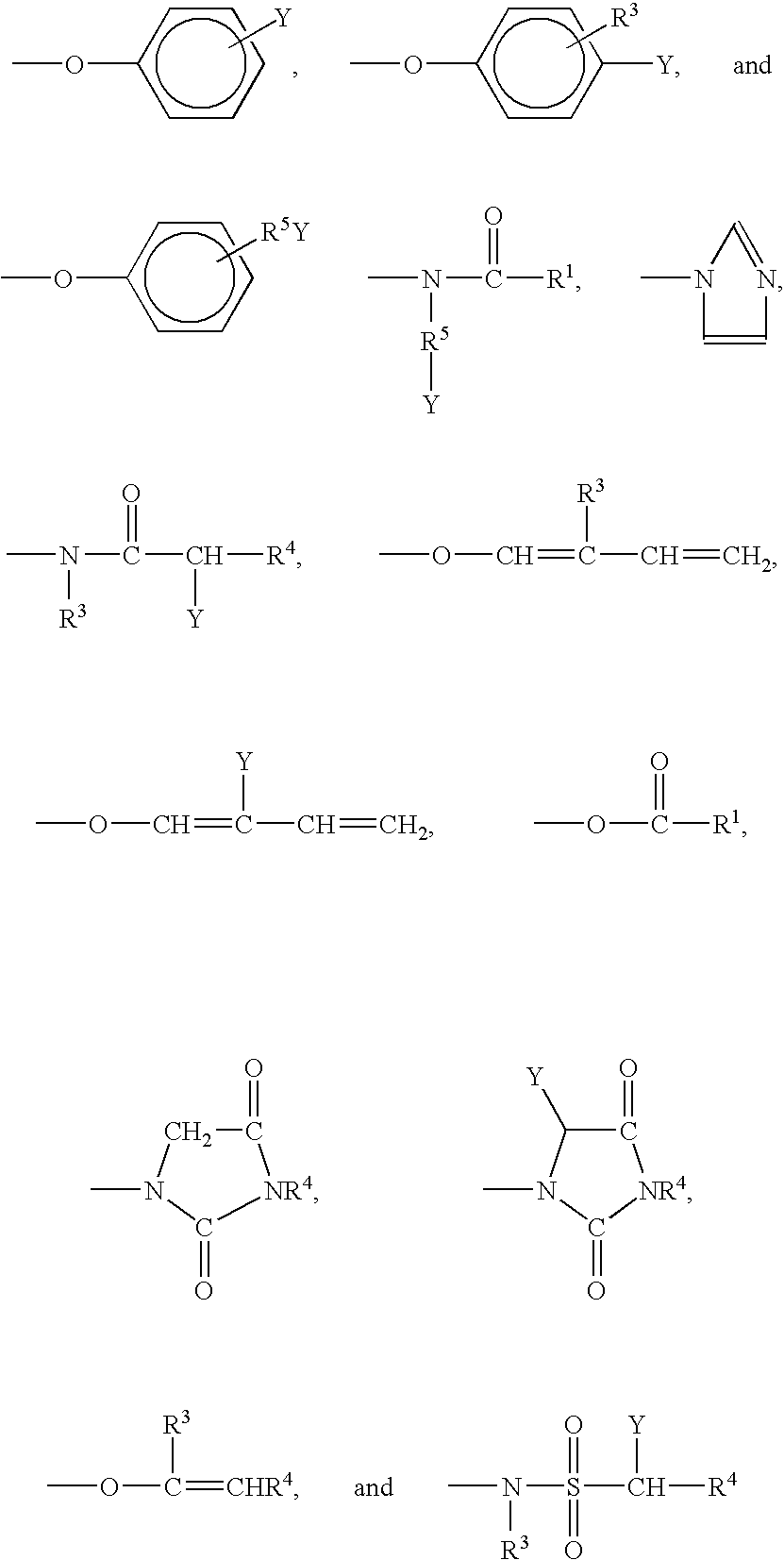

InactiveUS20030216274A1Easy ironingClean and soften fabricOther washing machinesOrganic/inorganic per-compounds compounding agentsLaundryOrganic chemistry

Owner:THE PROCTER & GAMBNE CO

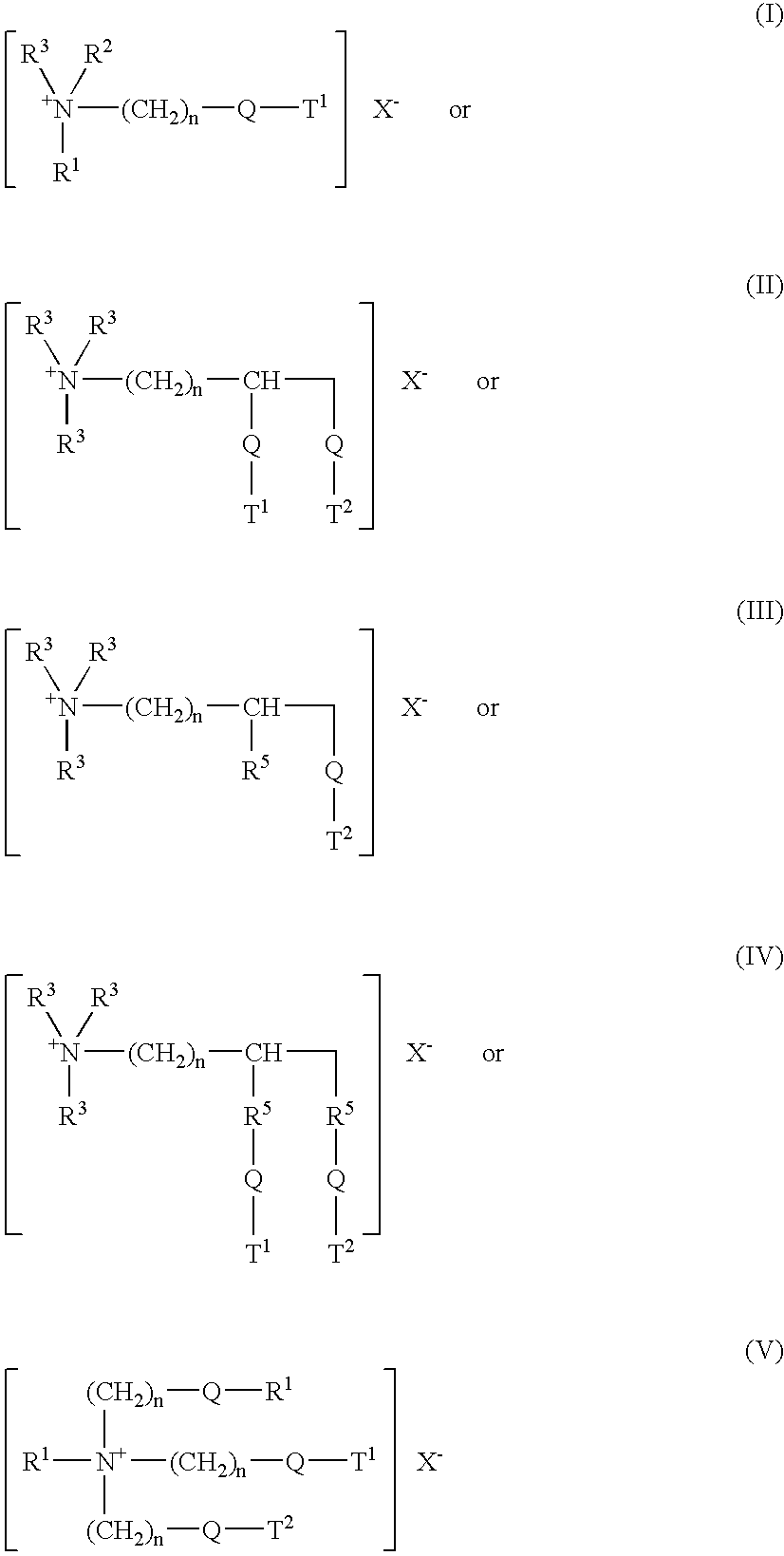

Transparent softening agents

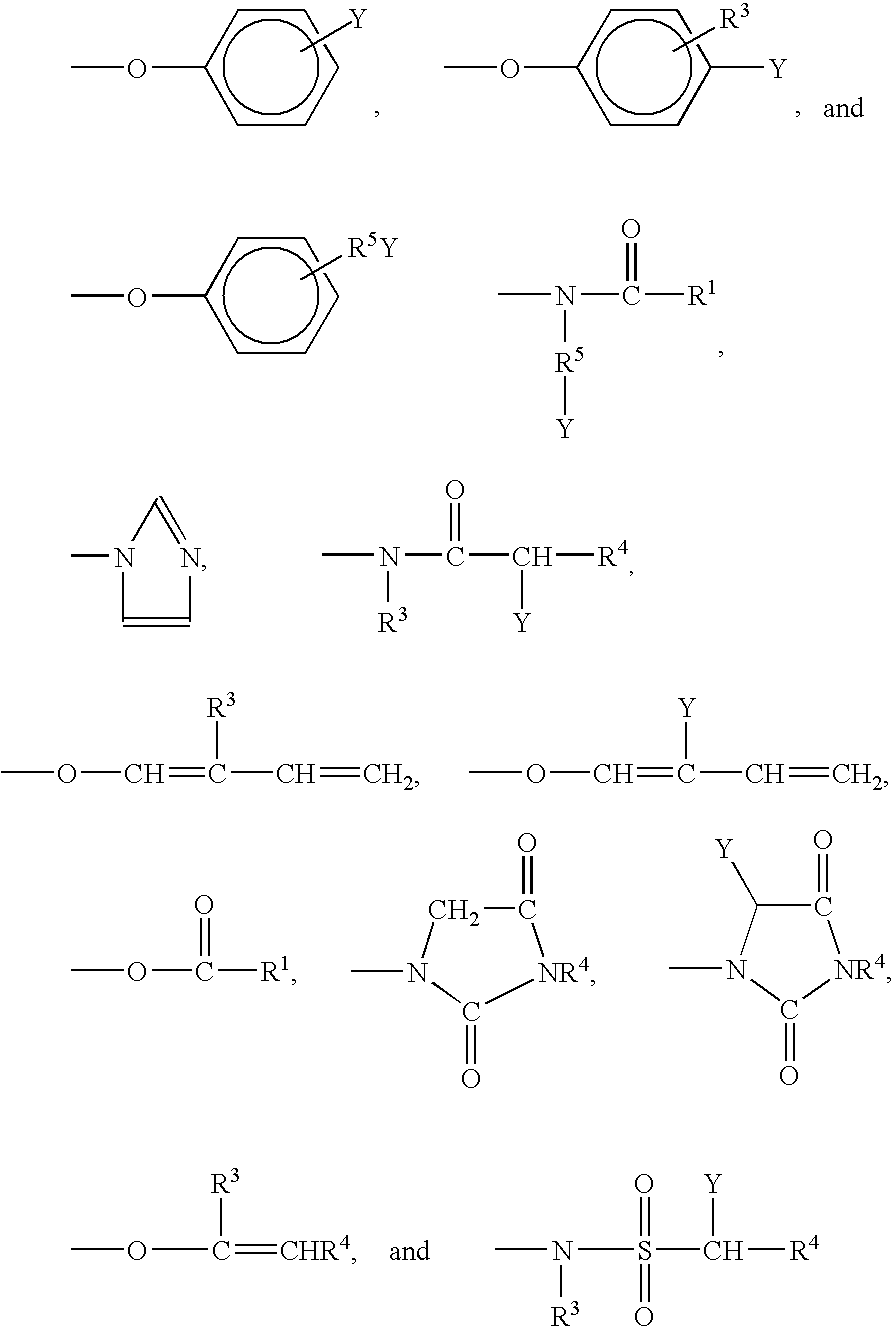

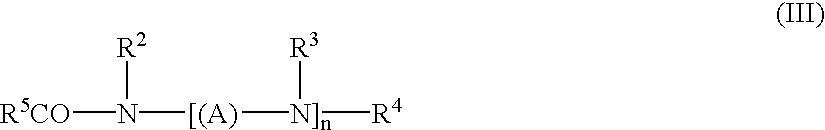

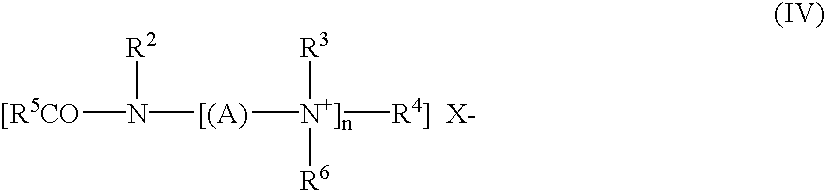

InactiveUS20030130162A1Maintain good propertiesEasy ironingCosmetic preparationsCationic surface-active compoundsBetaineHydrotrope

The invention relates to transparent softening agents containing: (a) ester quaternaries, which are obtained by reacting alkanolamines with a mixture consisting of fatty acids and of dicarboxylic acids, whereby the resulting esters are optionally alkoxylated and subsequently quaternized in a known manner, and containing; (b) auxiliary agents selected from the group formed by: (b1) fatty acid amidoamines and / or quaternization products thereof; (b2) betaines; (b3) nonionic surfactants; (b4) polyols and / or derivatives thereof; (b5) alcohols and / or; (b6) hydrotropes.

Owner:COGNIS IP MANAGEMENT GMBH

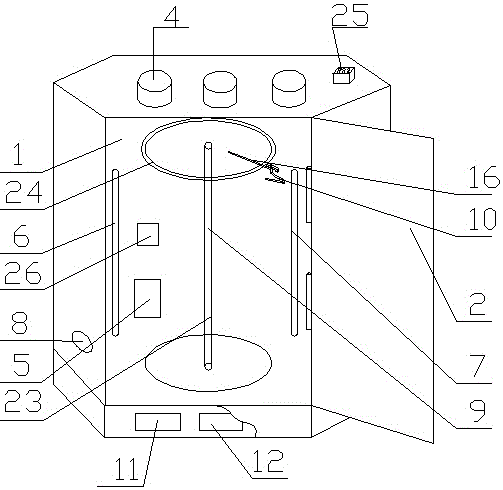

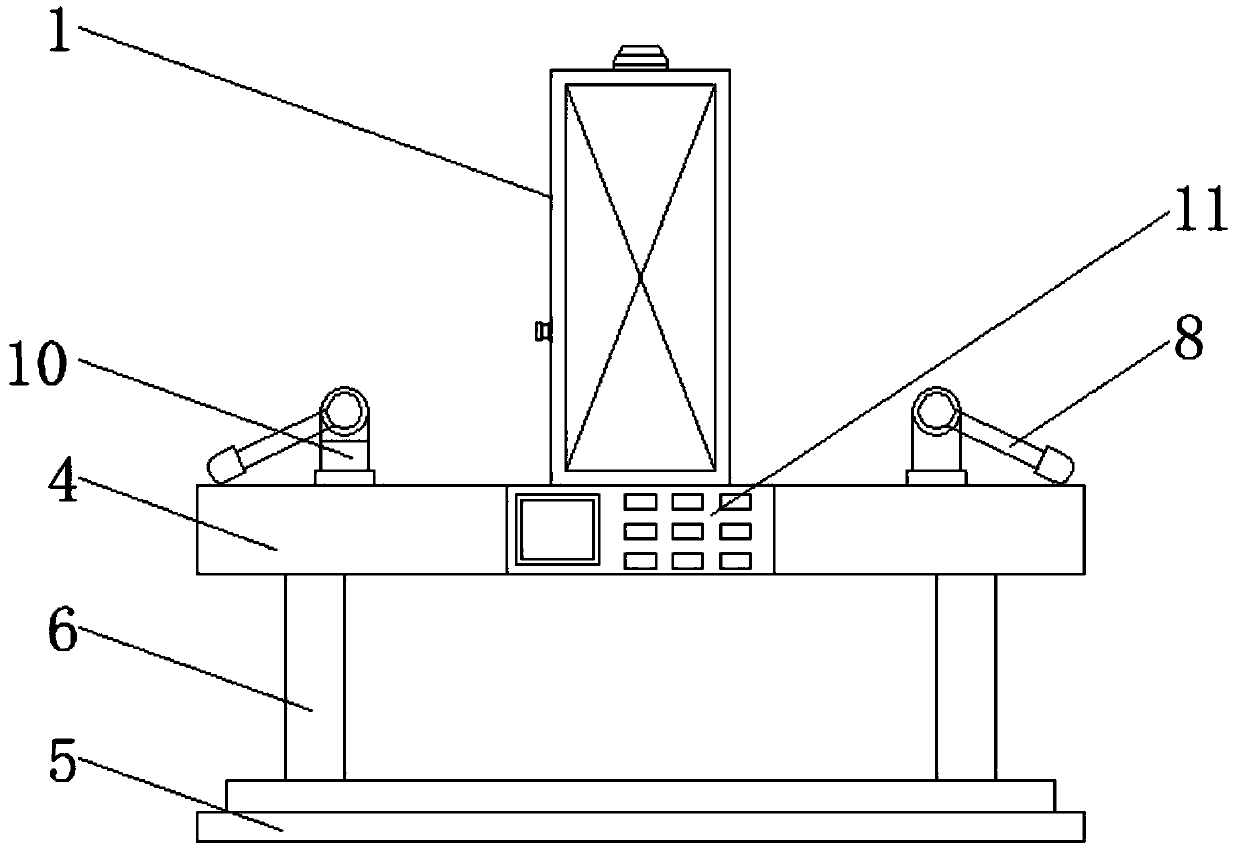

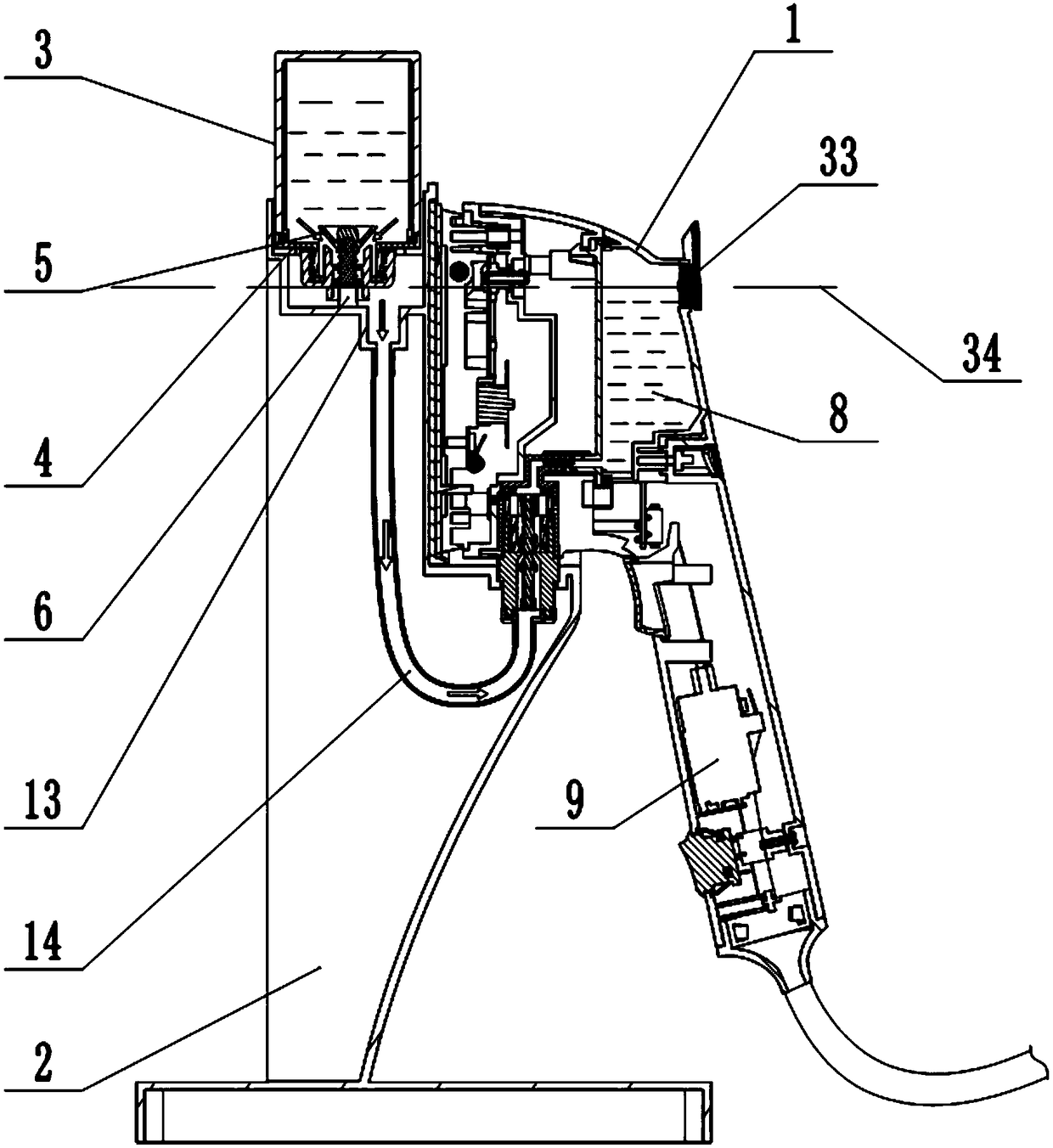

Intelligent wardrobe with hanging ironing function and working method thereof

PendingCN106820633AAvoid moistureAvoid enteringWardrobesIroning apparatusClothes hangerLiquid crystal

The invention provides an intelligent wardrobe with a hanging ironing function and a working method thereof. In the intelligent wardrobe market, the intelligent wardrobe brings multiple advantages, so that manufacturers of the intelligent wardrobe are also growing, but the intelligent wardrobe with the hanging ironing function is not invented. The intelligent wardrobe with the hanging ironing function comprises a cabinet body (1) and a cabinet door (2), wherein the inside of the cabinet body is partitioned into a hanger room and a hanging ironing room (14) by the cabinet body through an automatic expansion door (3); a function control chamber (5) is arranged at the bottom of the cabinet body; a group of suction fans (4) are arranged at the top of the cabinet body; a power supply (11) and a main control module (12) are arranged in the function control chamber; a liquid crystal touch screen (13) is arranged on the cabinet door; an alarm apparatus (25) is also arranged at the top of the cabinet body and connected with a master control module; and the power supply is connected with the suction fans, the liquid crystal touch screen, a sterilization device, a lighting lamp, a rotary coat hanger, a steam heater and the main control module separately. The intelligent wardrobe is used as the intelligent wardrobe with the hanging ironing function.

Owner:HARBIN UNIV OF SCI & TECH

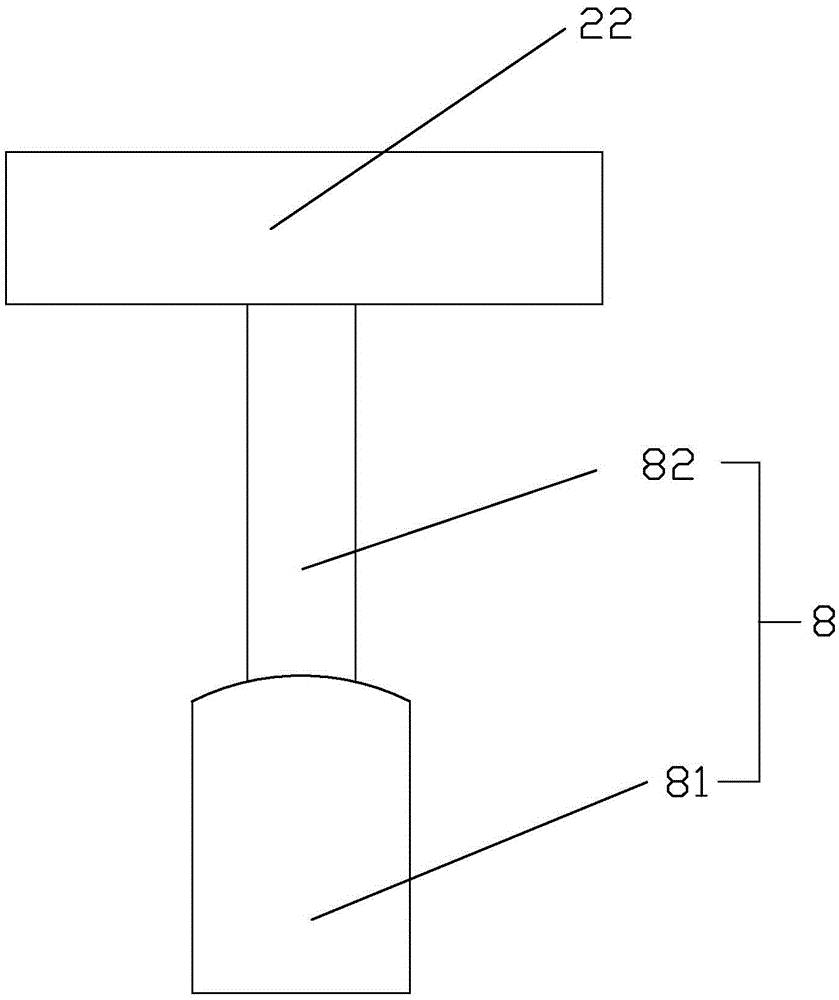

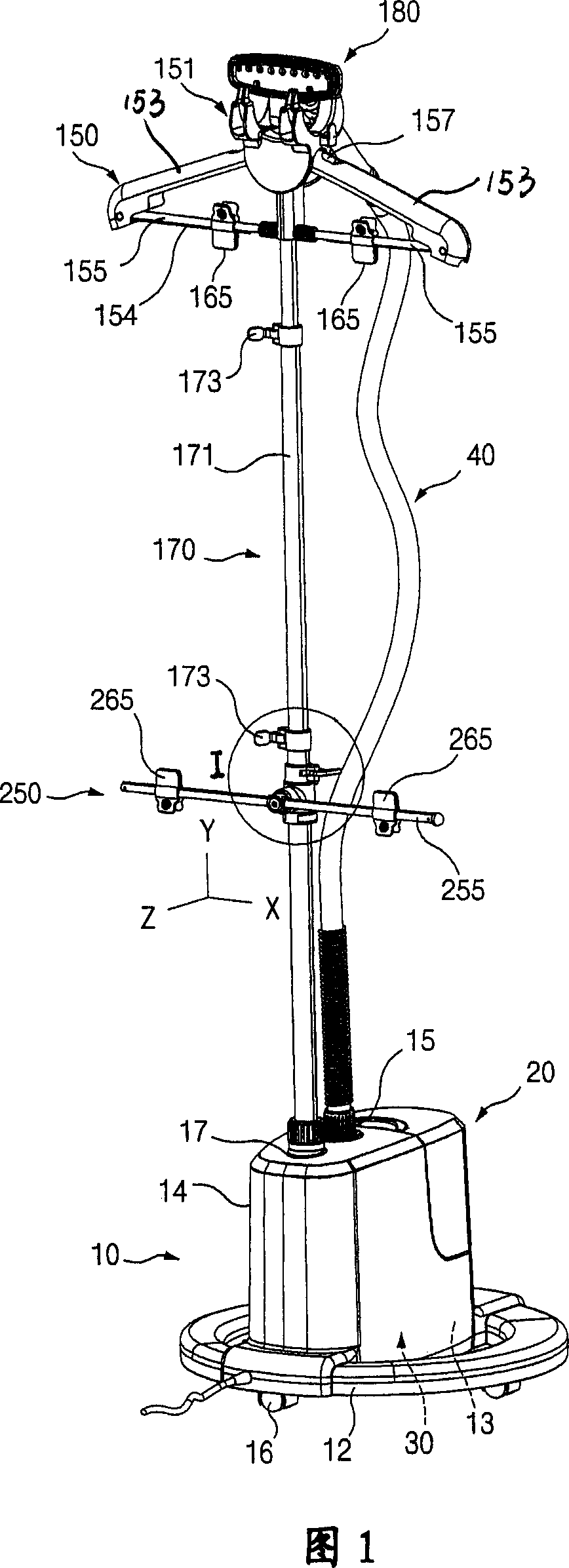

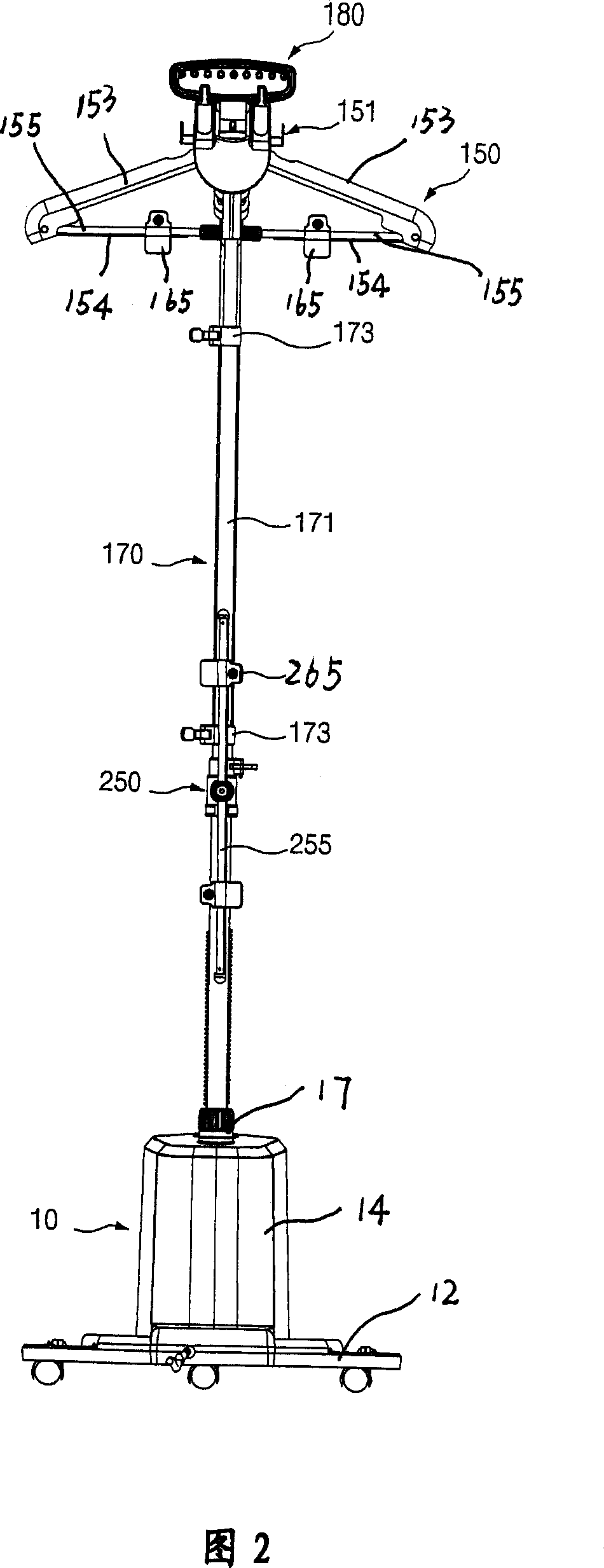

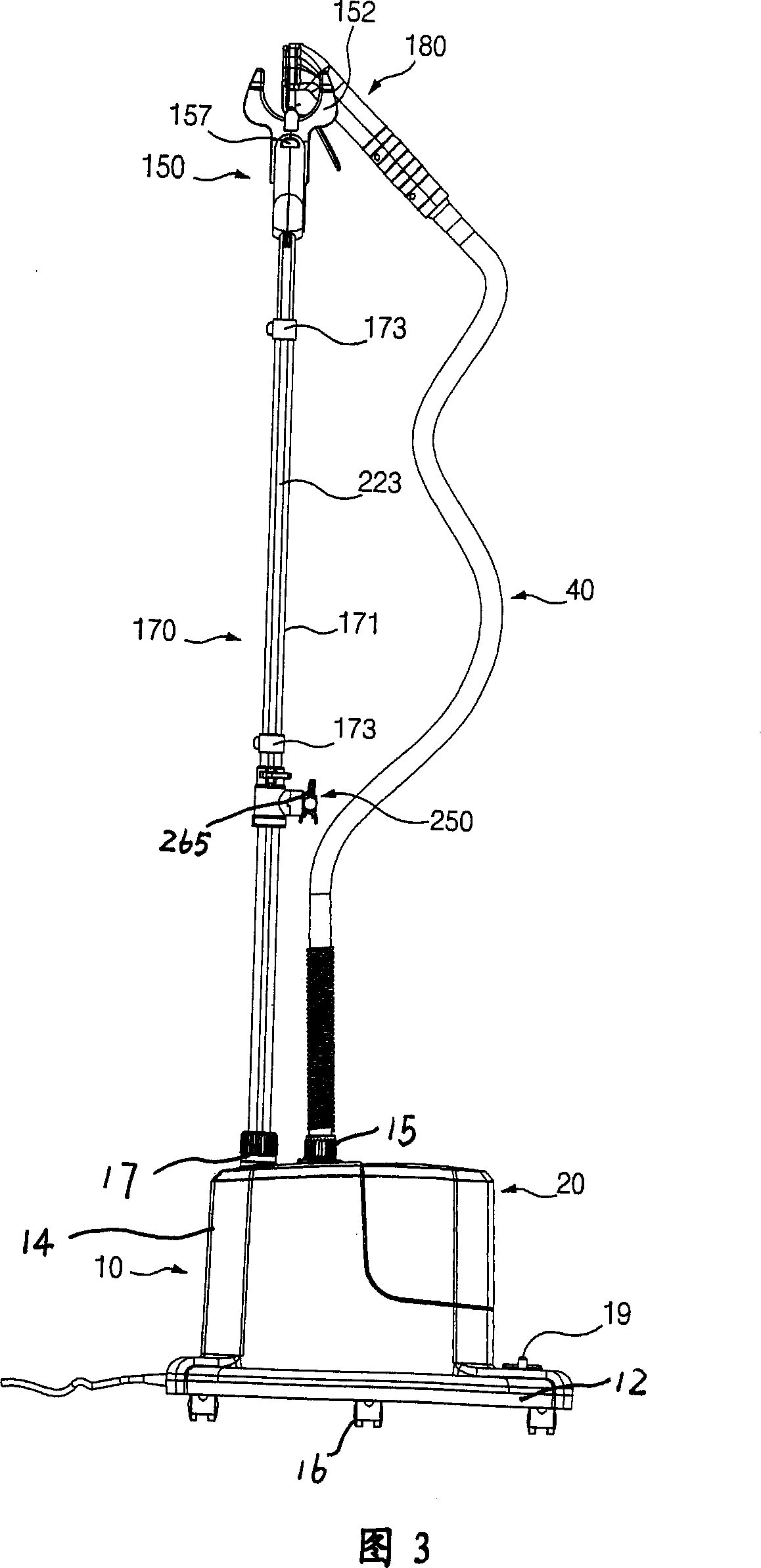

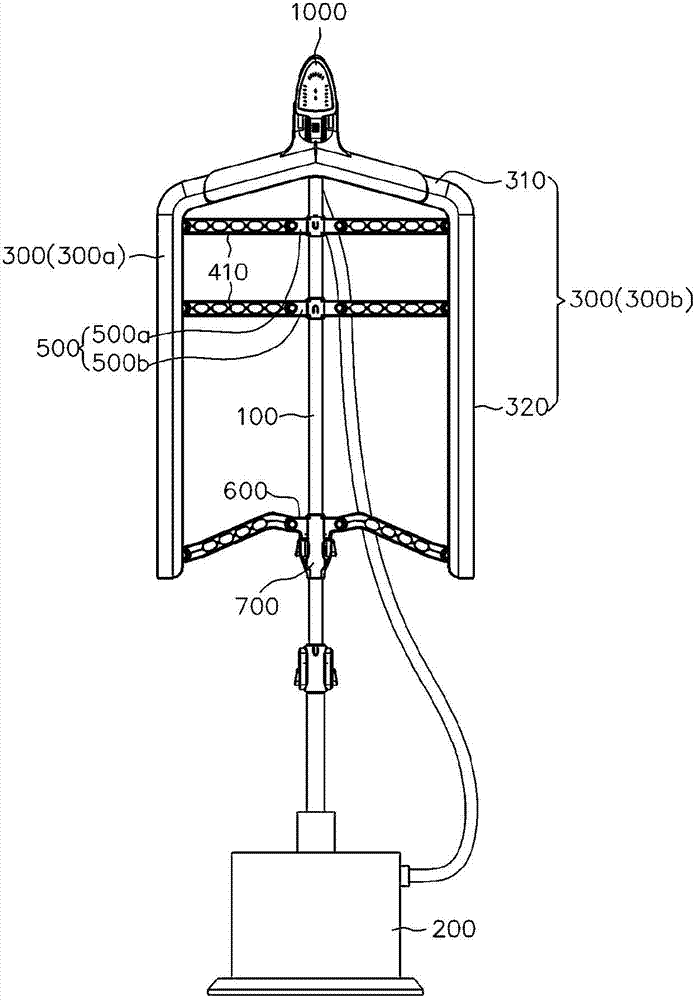

Steam ironing machine

A steam ironing machine comprises a base equipped with a liquid heating device, a barrel to supply liquid to a liquid heating device, a tube connecting to said liquid heating device, a rod which lower parts is connected to said base, hanging parts fixed on upper part of said rod and tension parts mounted on the rod on underside of said hanging parts. Because of combination structure of hanging parts fixed on upper part of said rod and tension parts mounted on lower part of said rod in accordance with the present invention, lower ends of clothes hanging on hanging parts is capable of being stretched by said tension parts to ensure users ironing conveniently with excellent performance. At the same time, a height adjusting device for adjusting the height of said tension parts is adopted to stretch garments or trousers with different lengths, and then greatly facilitates the operations according to the invention.

Owner:韩京姬

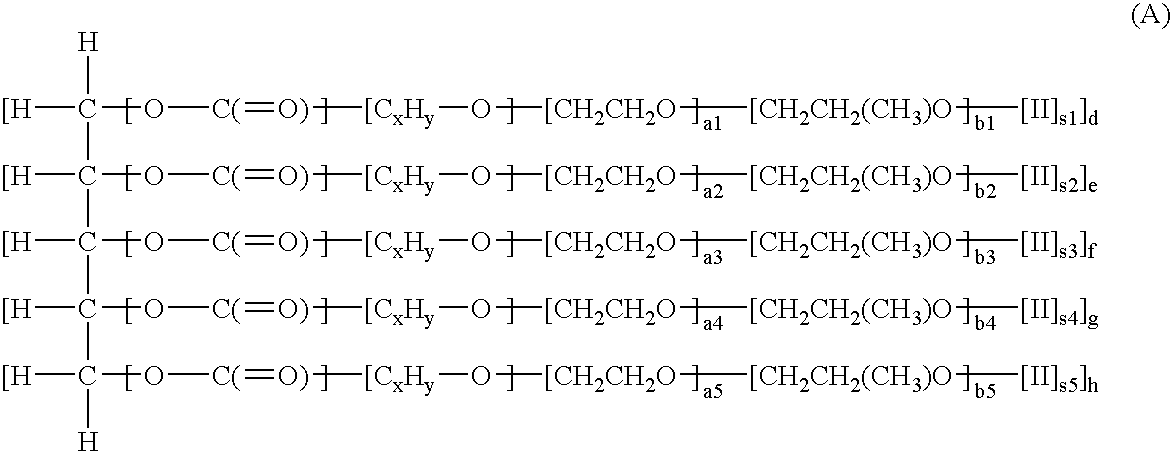

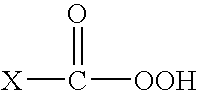

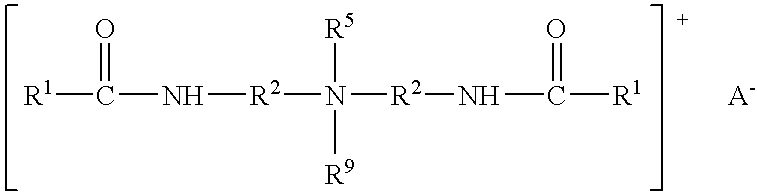

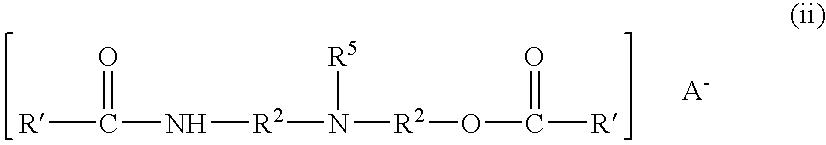

Fabric softeners and treatment agents and methods of use thereof

InactiveUS20030236181A1Low costGood fluidityCationic surface-active compoundsOrganic detergent compounding agentsFabric softenerTarget fibers

Specific types of compounds that impart highly effective softening, antistatic, and ironability characterostics to and for various types of launderable fabrics (such as garments, tablecloths, draperies, and the like) through a rinse-cycle application within a standard machine laundering process are provided. Such compounds provide effective lubricity to target fibers as well as simultaneous static dissipative characteristics either alone or, as one preferred embodiment, in combination with other typical fabric softening agents. Such a composition comprising or method utilizing such compounds thus provides a relatively simple, yet highly effective manner of imparting these highly desired properties to fabrics. A fabric treated with such compounds or in accordance with this method is also provided.

Owner:MILLIKEN & CO

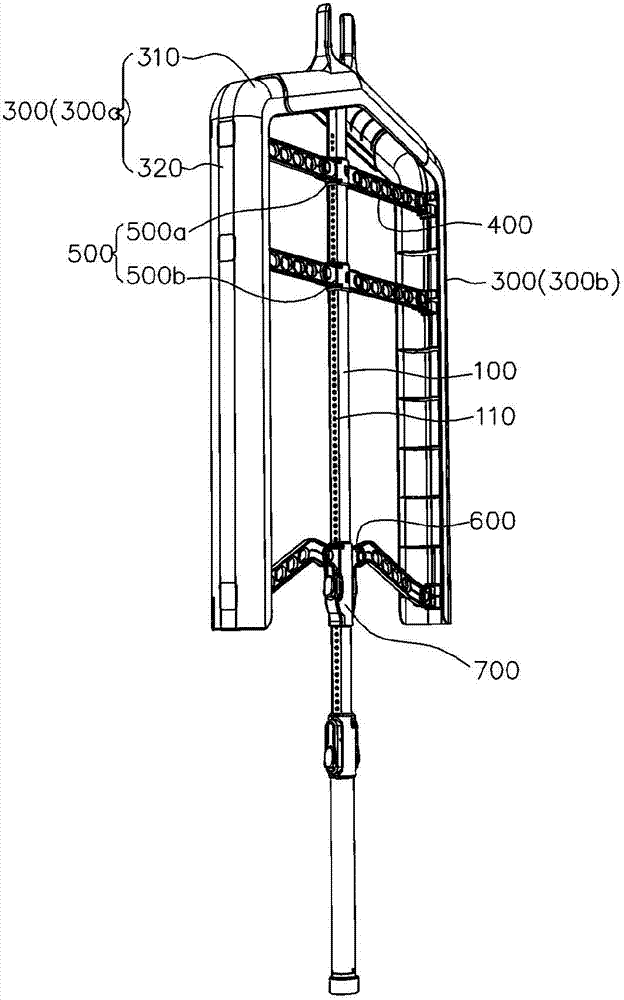

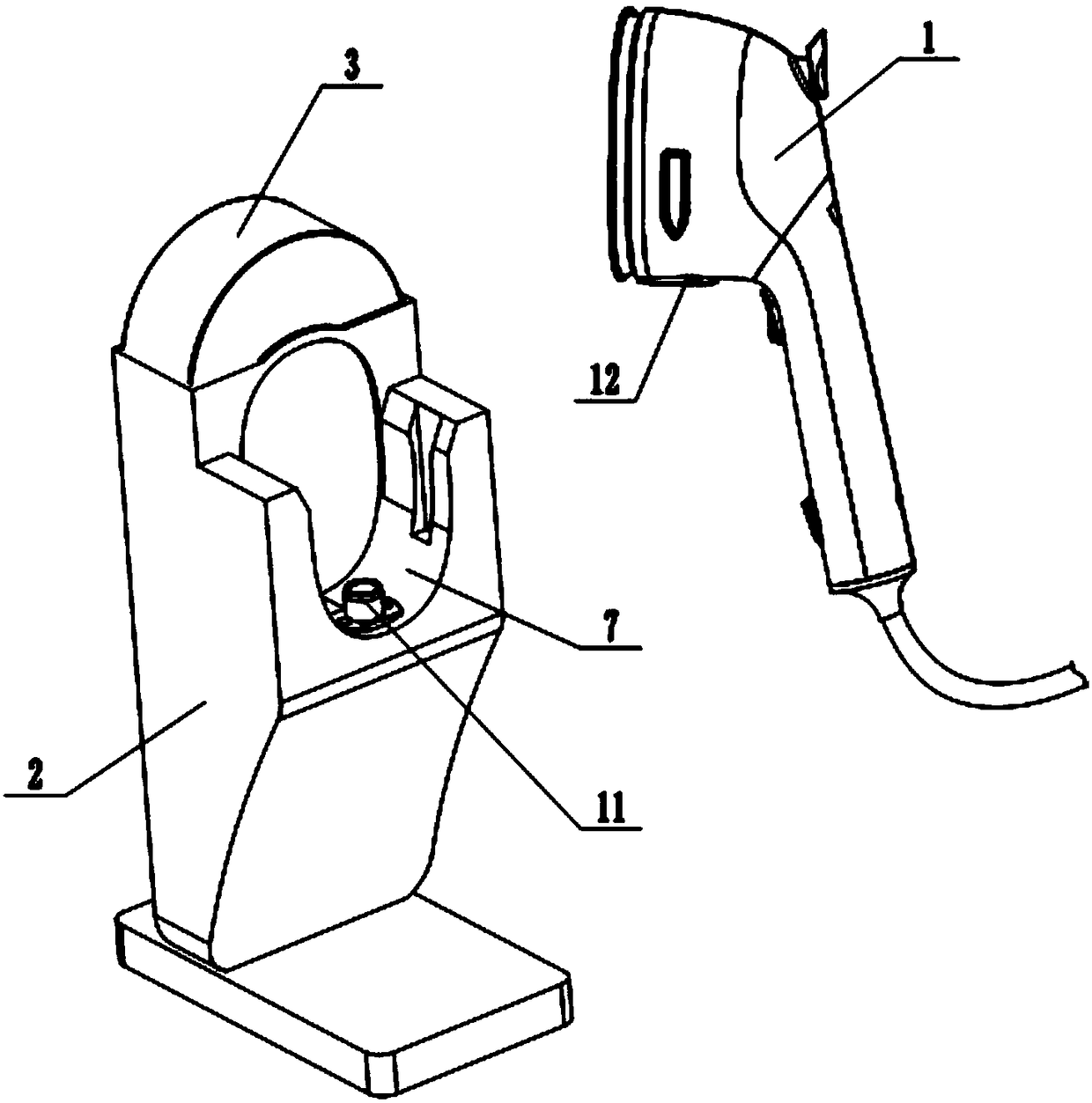

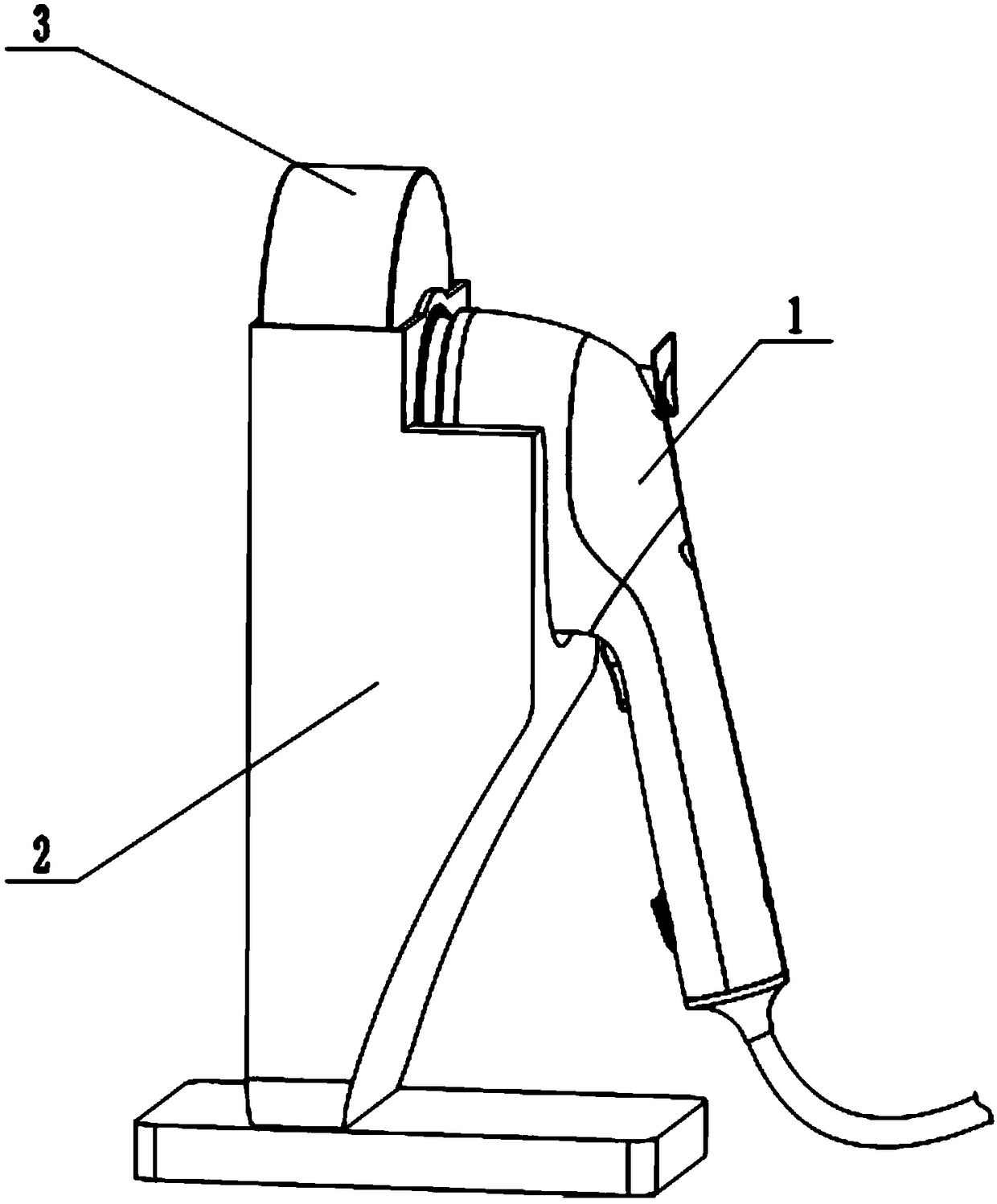

Standing steam iron

InactiveCN102713048AEasy to operateImprove convenienceHand ironIroning apparatusEngineeringSloping shoulders

The present invention relates to a standing steam iron. The standing steam iron according to the present invention comprises a post where rails are formed at left and right lateral sides,a pair of support frames which are arranged at the right and left of the post so as to face each other, are connected to one end of a plurality of link plates, and comprise a sloped shoulder support portion and a straight torso support portion,an upper moving body which is connected to the other end of a first link plate among the plurality of link plates and is fixed to the post or is mounted to the post for up and down movement,a lower moving body which is connected to the other end of a second link plate among the plurality of link plates, is mounted to move up and down the post if the upper moving body is fixed, and is fixed to the post if mounted for up and down movement,and a stopper which is formed below the up and down movable moving body between the upper moving body or the lower moving body, and is engaged with the rails to be coupled or de-coupled. The distance between a pair of the support frames is controlled through the interlocking of the up and down movement of an up and down movably mounted moving body the upper moving body or the lower moving body.

Owner:ALON MAXEY CORP

Terylene leisure sport fabric with elastic weft and warp

The invention discloses terylene sports fabric with elastic warp yarns and weft yarns. The fabric is characterized in that: at least one of the warp yarn and weft yarn is high-elasticity yarn prepared by the combination of polyethylene terephthalate(PET) and polypropylene terephthalate(PTT), the denier of the warp yarn and weft yarn is between 50 and 300D, and the denier per filament is between 0.5 and 3.2D. The fabric has the characteristics of loose texture, soft touch, good elasticity and drapability, good size stability, easy washing, no need of ironing, water resistance, stain resistant and the like.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

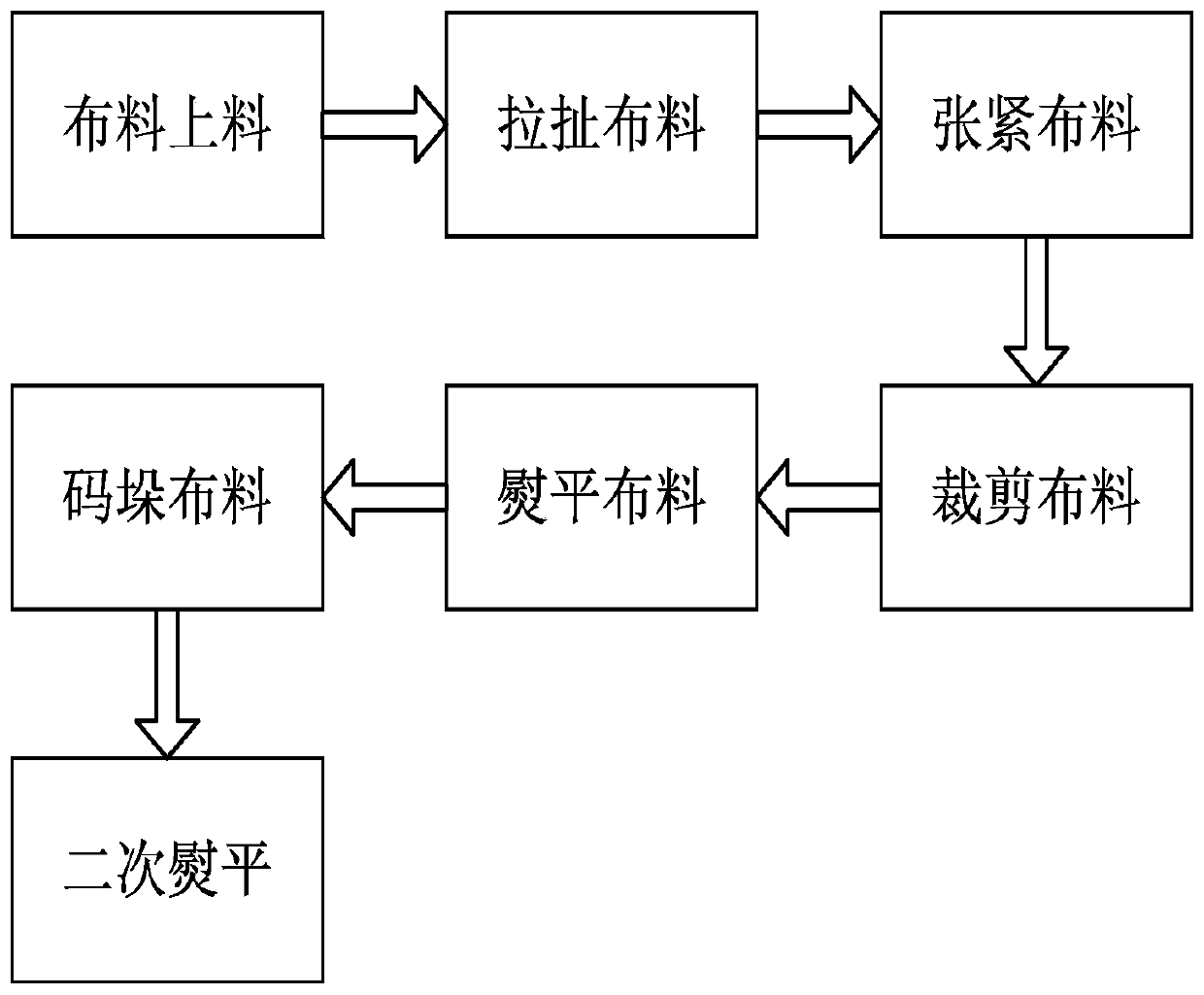

Cutting method of textile garment fabric

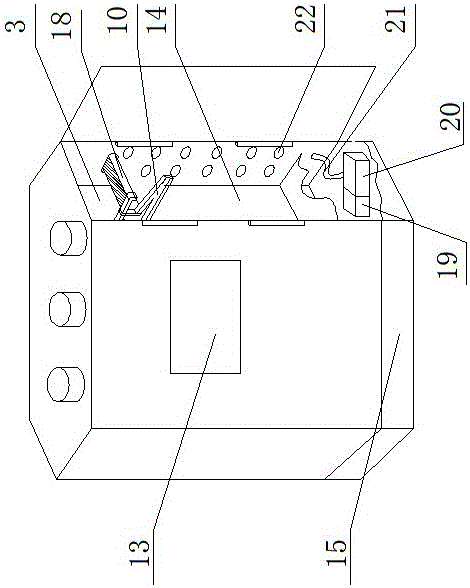

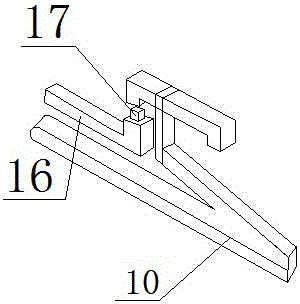

ActiveCN110541297AEasy to follow upReduce labor intensityIroning machinesSevering textilesEngineering

The invention relates to a cutting method of a textile garment fabric. A base, a fabric guiding mechanism, a fixed cutting device, a fabric placement table, an ironing device and a fabric stretching device are involved, the upper end of the base is provided with the fixed cutting device, the fabric placement table and the fabric stretching device in sequence from left to right, the fabric guidingmechanism is installed on the left side of the upper end of the fixed cutting device, and the ironing device is installed on the left side of the upper end of the fabric placement platform; accordingto the provided cutting method of the textile garment fabric, the full-automatic concept is utilized, so that feeding and cutting are integrated, manual assistance is not needed, and the labor intensity of operators is reduced; the design concept is adopted that cutting and ironing are conducted at the same time, the cutting end of a fabric is ironed, so that barbs, protrusions and thread residuesof the cutting end are ironed, and the fabric becomes flatter, and the fabric is conveniently processed in the later period.

Owner:SUQIAN JIANLU GARMENT MFG CO LTD

Laundry additive sachet

InactiveUS7351683B2Clean and soften fabricEasy ironingOther washing machinesDry-cleaning apparatus for textilesLaundryOrganic chemistry

Owner:PROCTER & GAMBLE CO

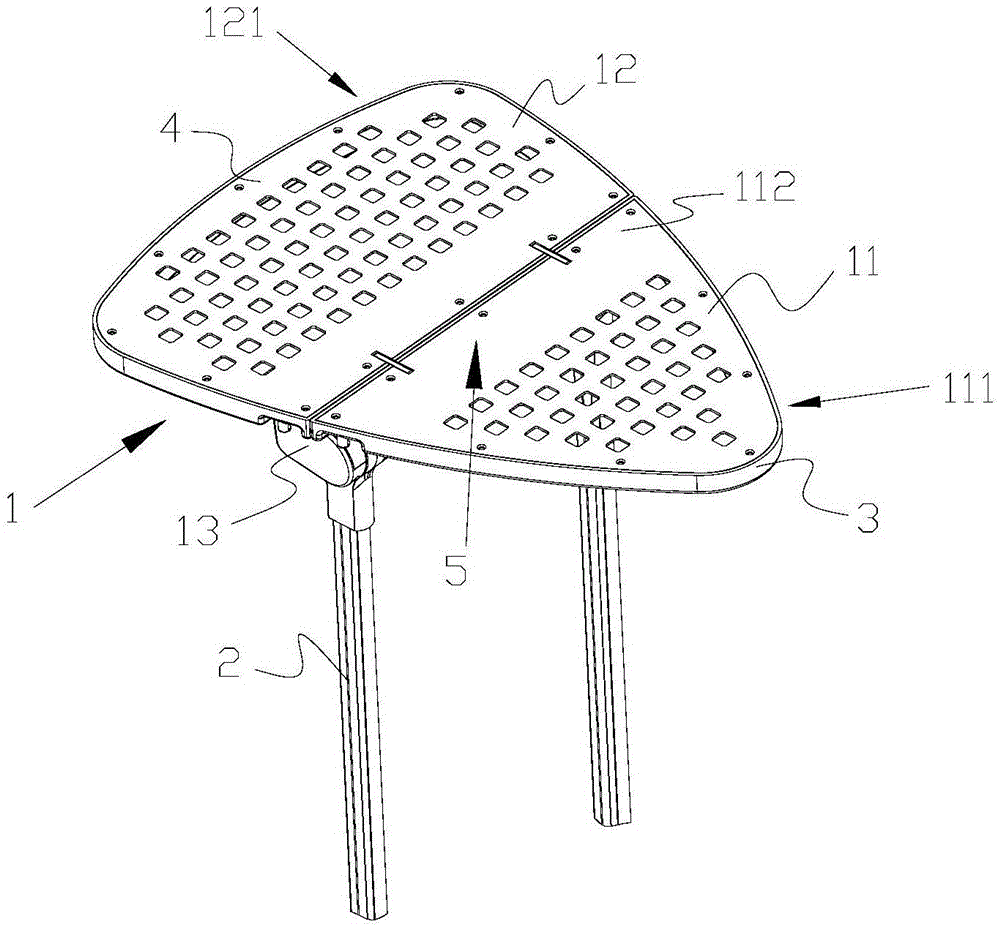

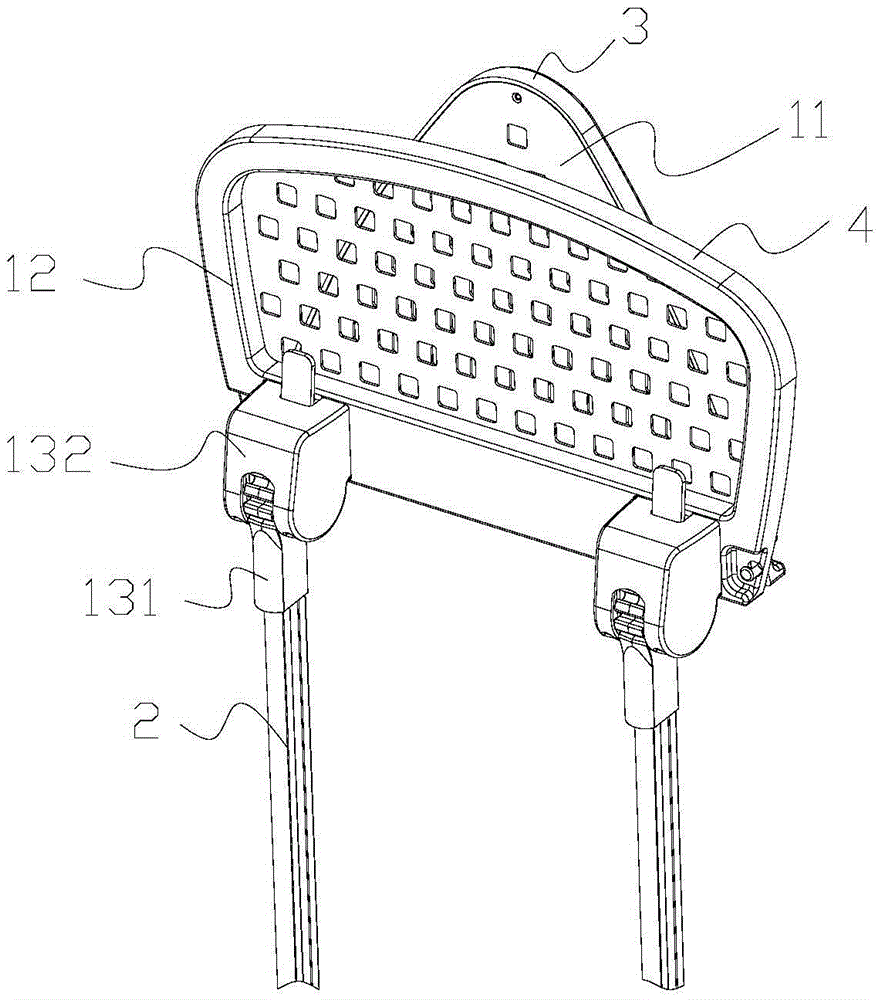

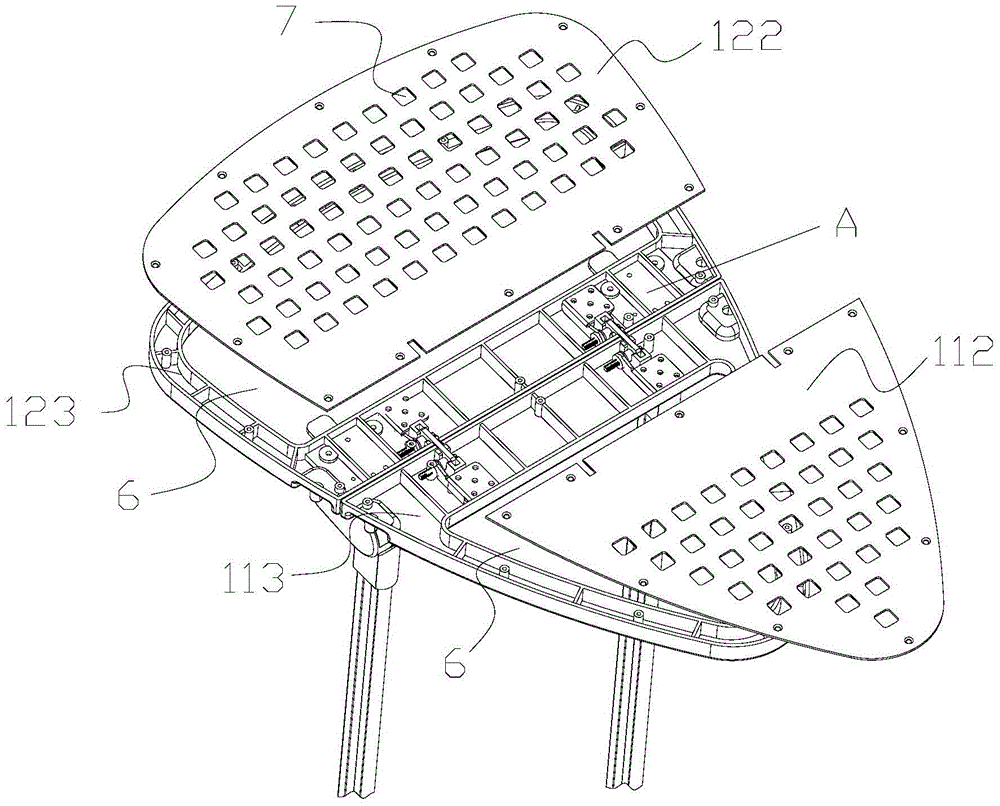

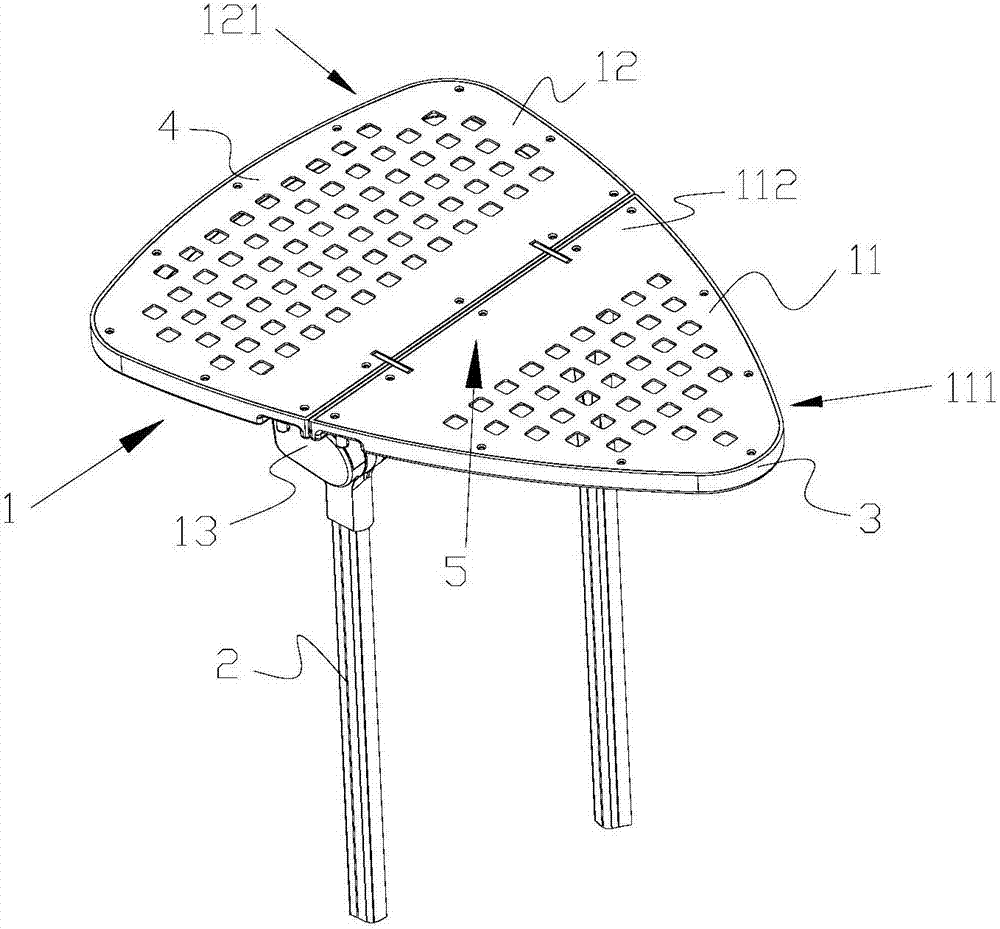

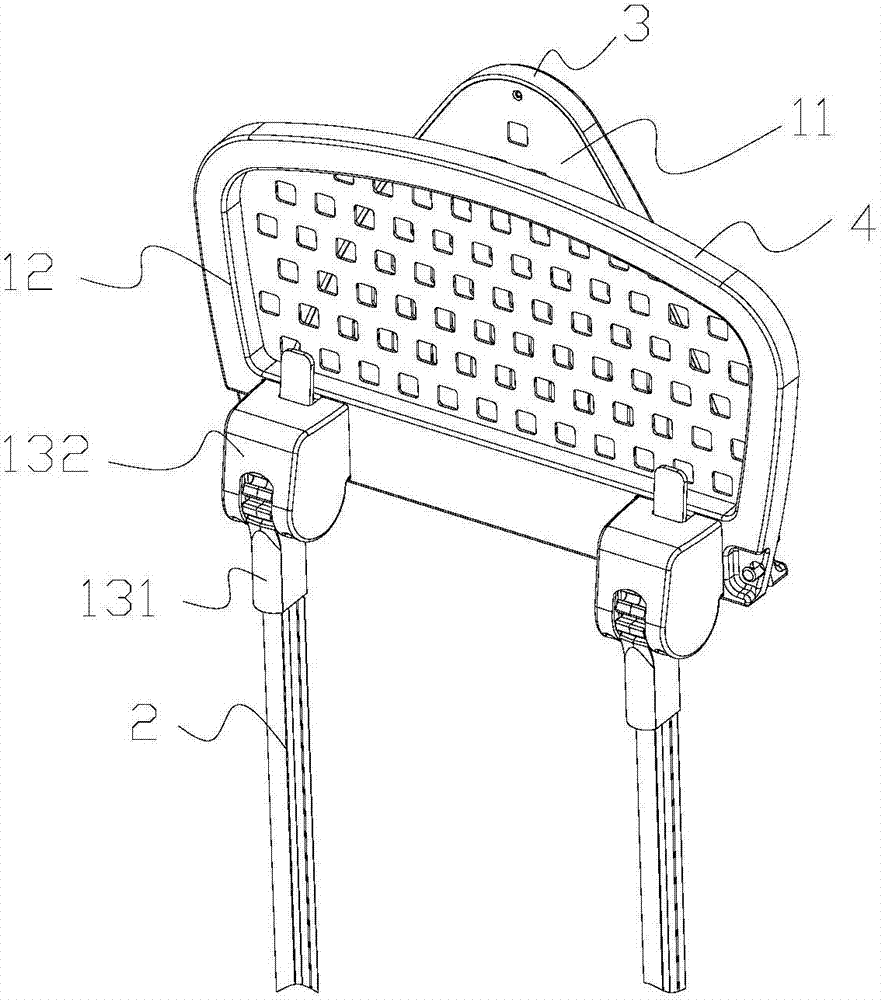

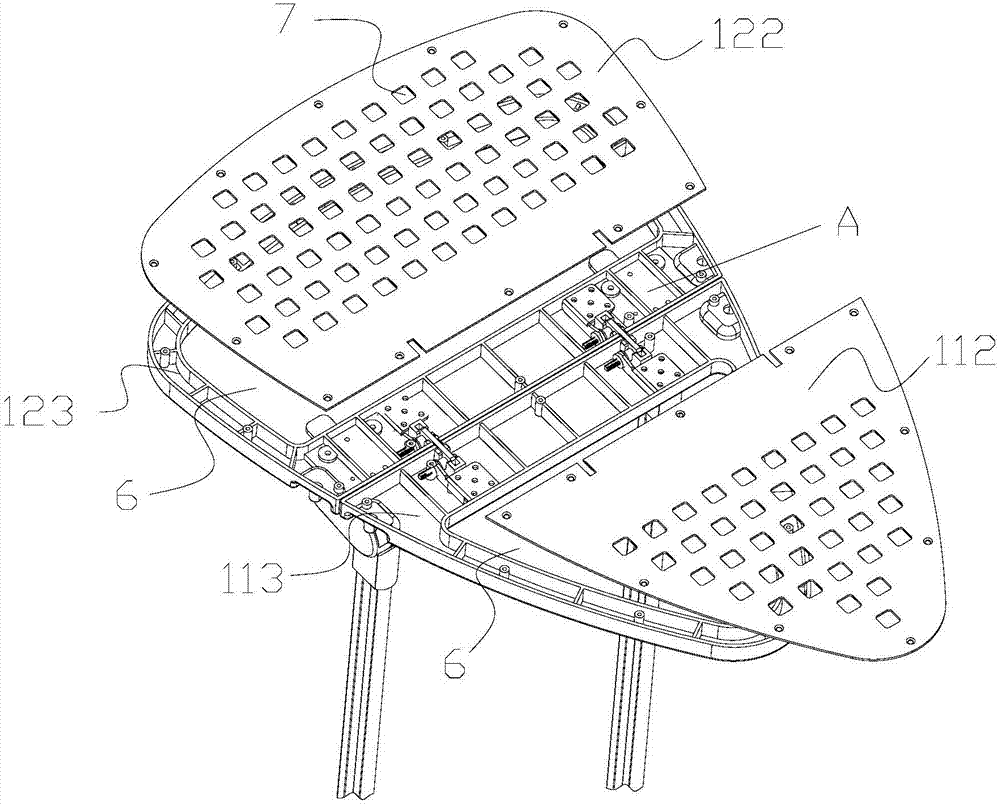

Folding type ironing plate assembly and ironing device

ActiveCN105671927ASimple structureEasy to produceIroning boardsIroning apparatusAgricultural engineeringClothes hanger

The invention provides a folding type ironing plate assembly which comprises an ironing plate and a bracket, wherein the ironing plate comprises a first folding part and a second folding part; the tail end of the first folding part is hinged to the front end of the second folding part, so that the first folding part and the second folding part can be relatively folded; a supporting protrusion is arranged at the front end of the first folding part; a hanging part for hanging clothes is arranged at the outer end of the second folding part; the first folding part or the second folding part is connected to the upper end of the bracket through a connection piece and is connected with the connection piece in a turning manner; a positioning mechanism for positioning the angle of the ironing plate is arranged on the connection piece; the first folding part and the second folding part can be unfolded to form an ironing plane; the positioning mechanism realizes flat ironing in different angles; the first folding part and the second folding part can be vertically folded to form a clothes hanger for hanging ironing; and the supporting protrusion is higher than the hanging part. The ironing plate of the folding type ironing plate assembly positions the collar through the supporting protrusion and can better iron the collar during clothes ironing.

Owner:FOSHAN SHUNDE SINCERE HOME HOME APPLIANCE MFG

Foldable ironing board assembly and ironing device

ActiveCN105671927BEasy ironingIdeal ironing effectIroning boardsIroning apparatusEngineeringClothes hanger

Owner:FOSHAN SHUNDE SINCERE HOME HOME APPLIANCE MFG CO LTD

A non-ironing finishing liquid for a ready-to-wear shirt and a non-ironing finishing method for a ready-to-wear shirt

InactiveCN105839414AEasy ironingImprove wrinkle resistanceWrinkle resistant fibresVegetal fibresNational standardPre washing

The invention relates to a non-ironing finishing liquid for a ready-to-wear shirt. The non-ironing finishing liquid is characterized by comprising 10-50% by mass of a crosslinking agent, 0.5-5% by mass of an improver, 5-10% by mass of a softening agent and 1-5% by mass of a penetrant, with the balance being deionized water the impurity content of which is less than 20 ppm. A non-ironing finishing method for a ready-to-wear shirt by adopting the non-ironing finishing liquid is also disclosed. The method includes steps of (1) pre-washing, (2) drying, (3) processing with the non-ironing finishing liquid, (4) drying to certain humidity, (5) finishing and ironing, (6) baking, (7) allowing the ready-to-wear shirt to stand, (8) washing again, and (9) drying. Through the non-ironing finishing liquid and the method, non-ironing shirts are free of formaldehyde really, the content of free formaldehyde meets the undetected grade of the textile product formaldehyde testing national standard GB / T2912.1-2009, crease resistance of shirts is improved, and the appearance of a finished shirt is made durable.

Owner:SANCANAL GARMENT CO LTD

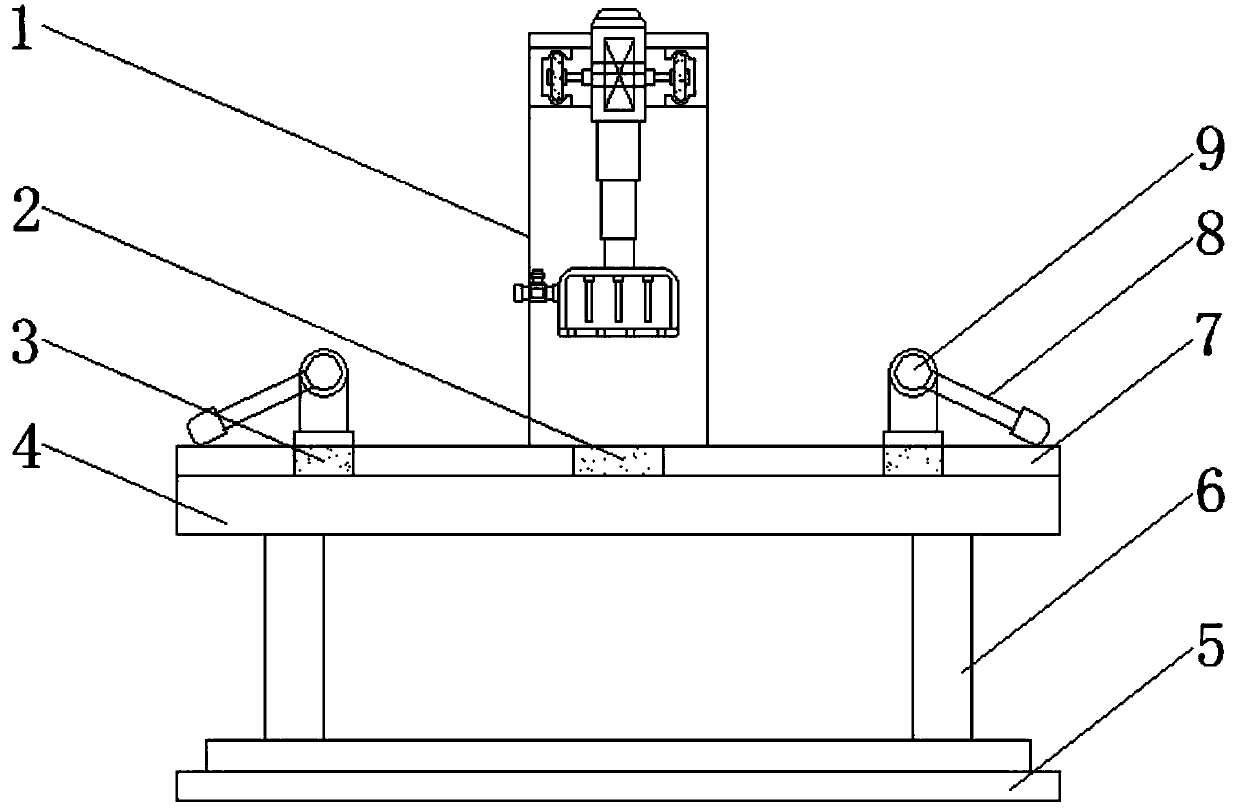

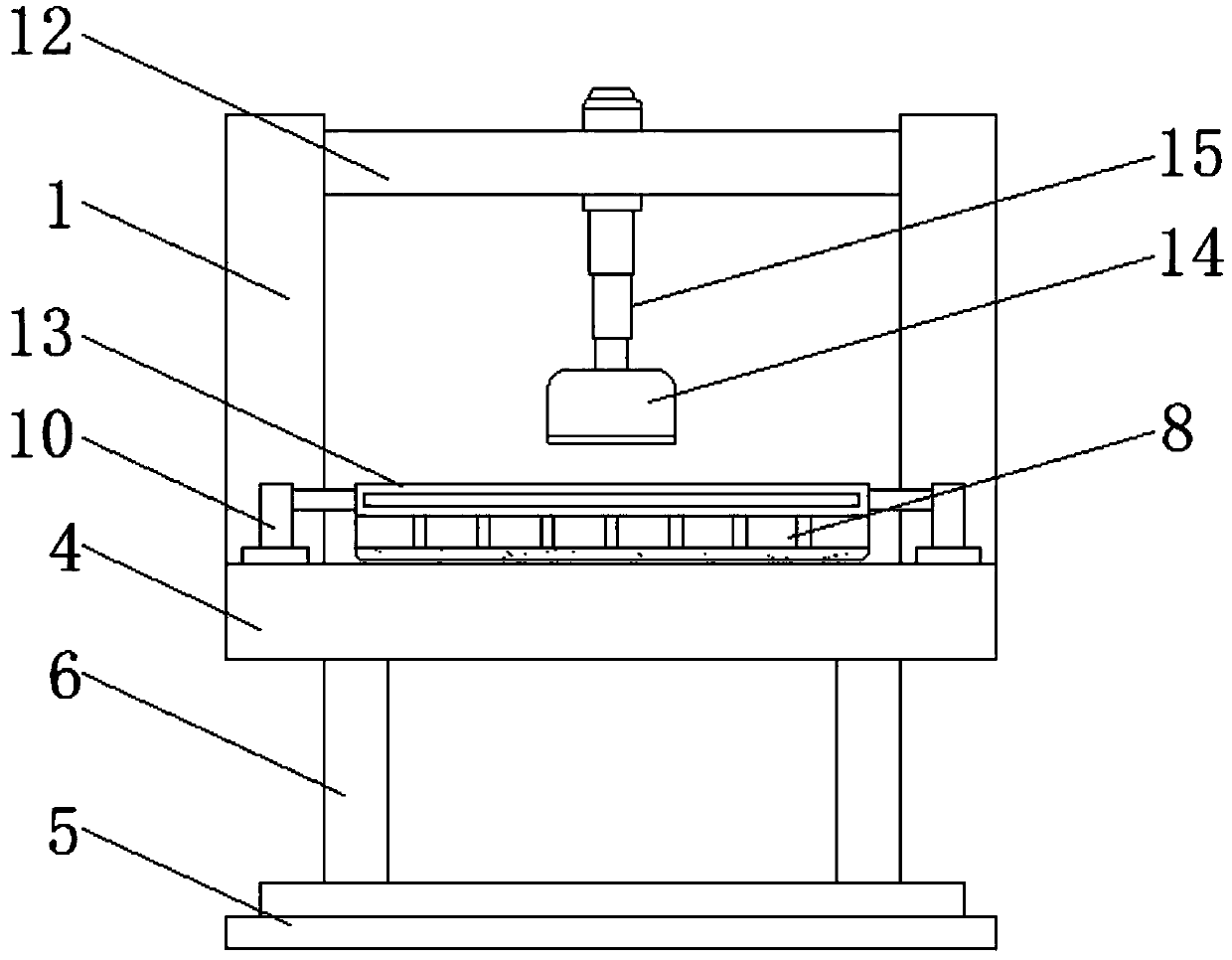

Ironing and pressing equipment for textile fabrics

InactiveCN107904904AEasy ironingReduce security risksIroning apparatusTextiles and paperHydraulic cylinderEngineering

The invention discloses an ironing and pressing equipment for textile fabrics. The ironing and pressing equipment for textile fabrics comprises two fixing seats, a working platform, a supporting pedestal, a controlling box, a heating box, an ironing plate and a hydraulic cylinder. A supporting frame is arranged on the top end of the supporting pedestal, the working platform is arranged in transversal direction, on the top end of the supporting frame, the controlling box is arranged in the middle of one side of the working platform; two first slide grooves are respectively arranged on the two sides of the top end of the working platform, two fixing seats are respectively arranged in the middle of the two sides of the top end of the working platform, two first-slide-blocks are respectively arranged in the middle of bottom end of the two fixing seats. The ironing and pressing equipment for textile fabrics is also provided with the hydraulic cylinder, hydraulic telescopic rods, the heatingbox, heating bars and the ironing plate. When in use, the hydraulic cylinder is controlled by the controlling box, the hydraulic telescopic rods are driven by the hydraulic cylinder to stretch frontand draw back; in the heating box, the heating bars are heated, the water is heated by the heating bars, the heat is transferred onto the ironing plate, then conducting the ironing and pressing to theclothes, the mechanized operation is quick and convenient, and the safety hazards at work are reduced.

Owner:丽水遂智科技咨询有限公司

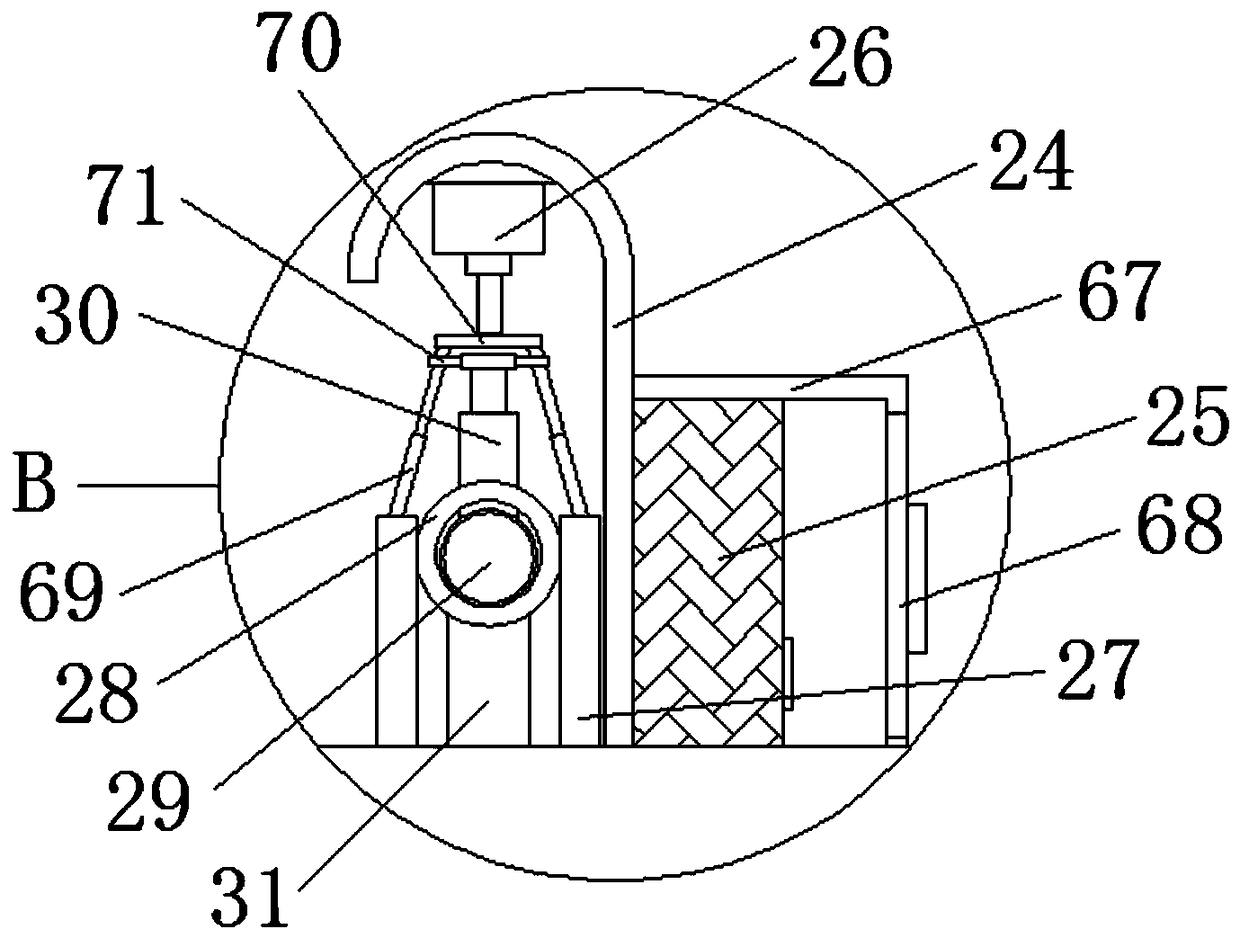

Ironing machine supplementing water rapidly and conveniently

InactiveCN108914521AQuick and easy hydrationSmooth hydrationHand ironTextiles and paperEngineeringWater pipe

The invention relates to the technical field of clothes nursing, and discloses an ironing machine supplementing water rapidly and conveniently. The ironing machine comprises an ironing machine body, abase, and a large water tank. The base is provided with a groove. The ironing machine body is internally provided with a small water tank, a steam generation assembly, and a pump body. A water absorption pipe is communicated between the pump body and the small water tank. The pump body is communicated with a water outlet pipe. The large water tank is provided with a water supplementing cover. Thewater supplementing cover is provided with a water outlet. The water outlet is provided with a valve body. The base is internally provided with a first water supplementing joint. The base is providedwith a trench. A water guiding pipe is communicated between the trench and the first water supplementing joint. The ironing machine body is provided with a second water supplementing joint. One end of the water supplementing joint is communicated with the small water tank. When the ironing machine body is placed in the groove, the first water supplementing joint and the second water supplementingjoint are abutted and communicated, and water in the large water tank flows into the small water tank through the water guiding pipe. When the ironing machine body is separated from the groove, the first water supplementing joint and the second water supplementing joint are separated and communication is stopped. The ironing machine is advantaged by convenient and rapid water supplement.

Owner:ZHEJIANG YUELI ELECTRICAL

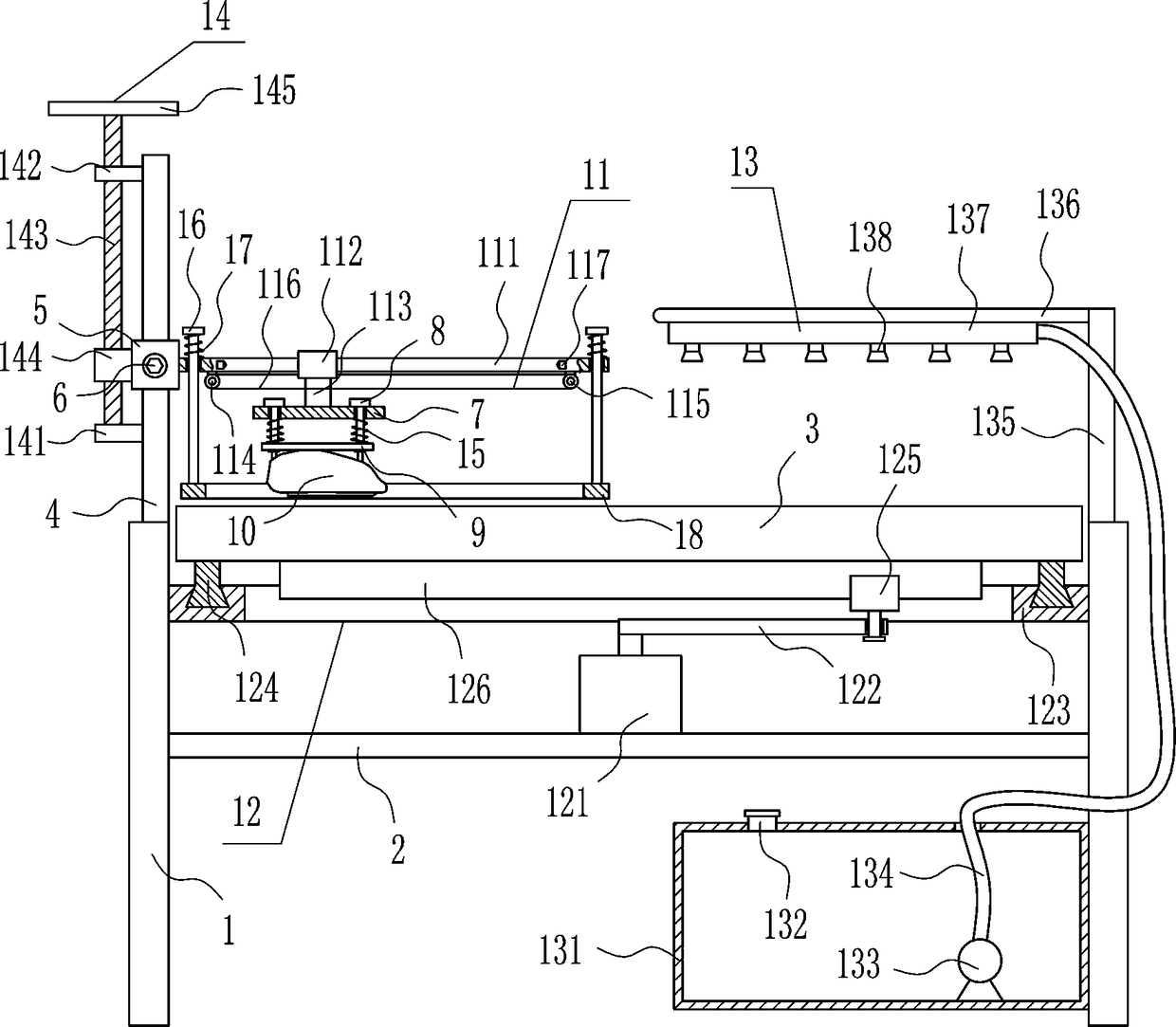

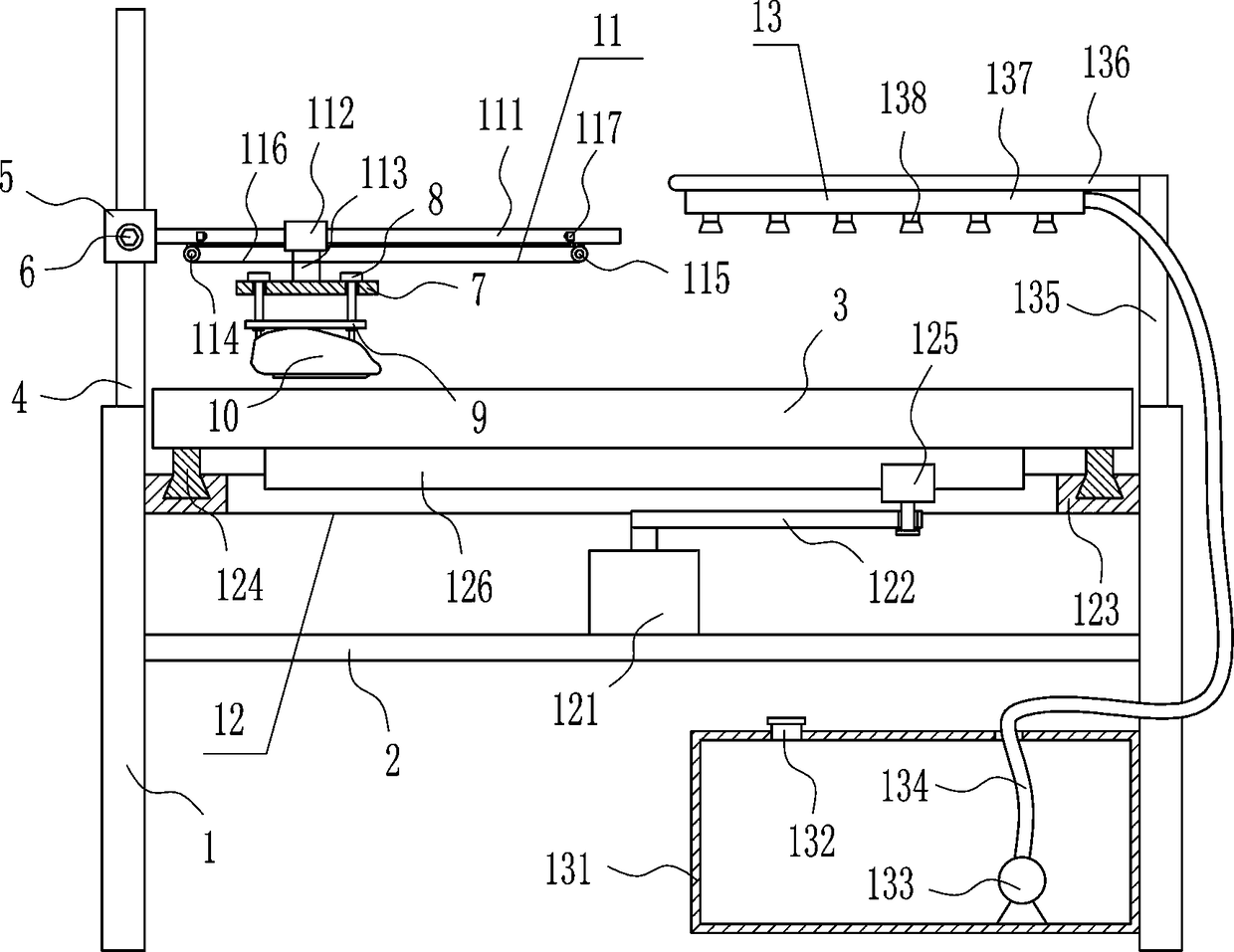

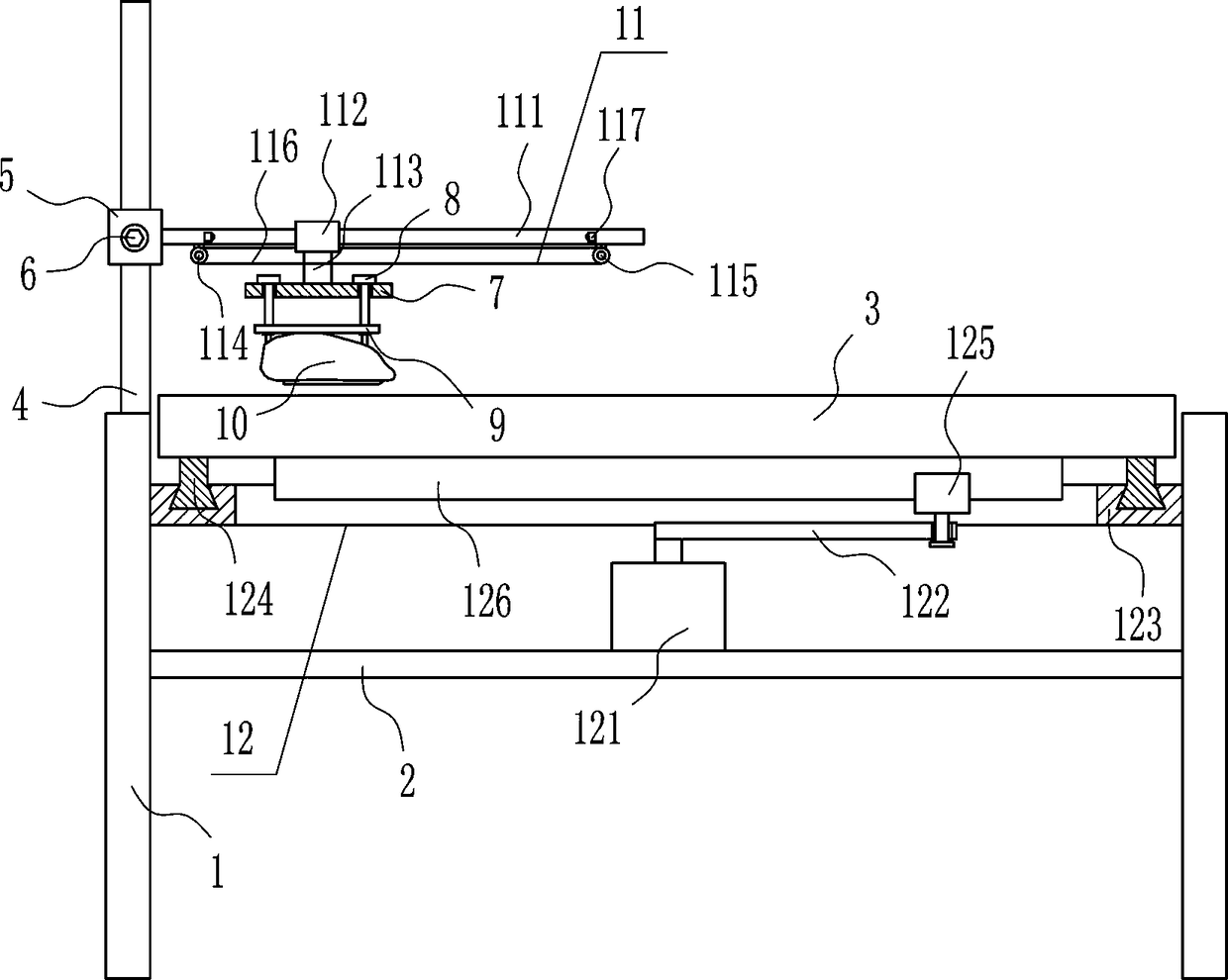

Rapidly cooling ironing table for garment processing

The invention discloses a rapidly cooling ironing table for garment processing. The rapidly cooling ironing table for garment processing comprises a working table, supporting legs are fixedly connected around the lower end of the working table, a fixing block is fixedly connected to one side of the end of the working table, and a supporting rod is fixedly connected to the upper end of the fixing block. An L-shaped support rod sleeves the outer wall of the supporting rod, a pressing plate is fixedly connected to the end, away from the supporting rod, of the L-shaped supporting rod, a pluralityof exhausting vent holes are evenly communicated with the inner wall of the working table, a water recovery tank is communicated with the lower end of an exhausting funnel through a radiating barrel,and a conduit is communicated with one side of the outer wall of the radiating barrel. A water pumping pipe is communicated with one side of the outer wall of the lower end of the water recovery tank,a booster pump is arranged on a pipeline of the water pumping pipe, and an iron placing rack is fixedly connected to the other side of the end of the working table. The rapidly cooling ironing tablefor garment processing has the advantages of being simple in structure and easy to operate, and capable of rapidly radiating and cooling high-temperature steam generated during ironing, recycling of recycled water and saving water resources.

Owner:湖州翔顺工贸有限公司

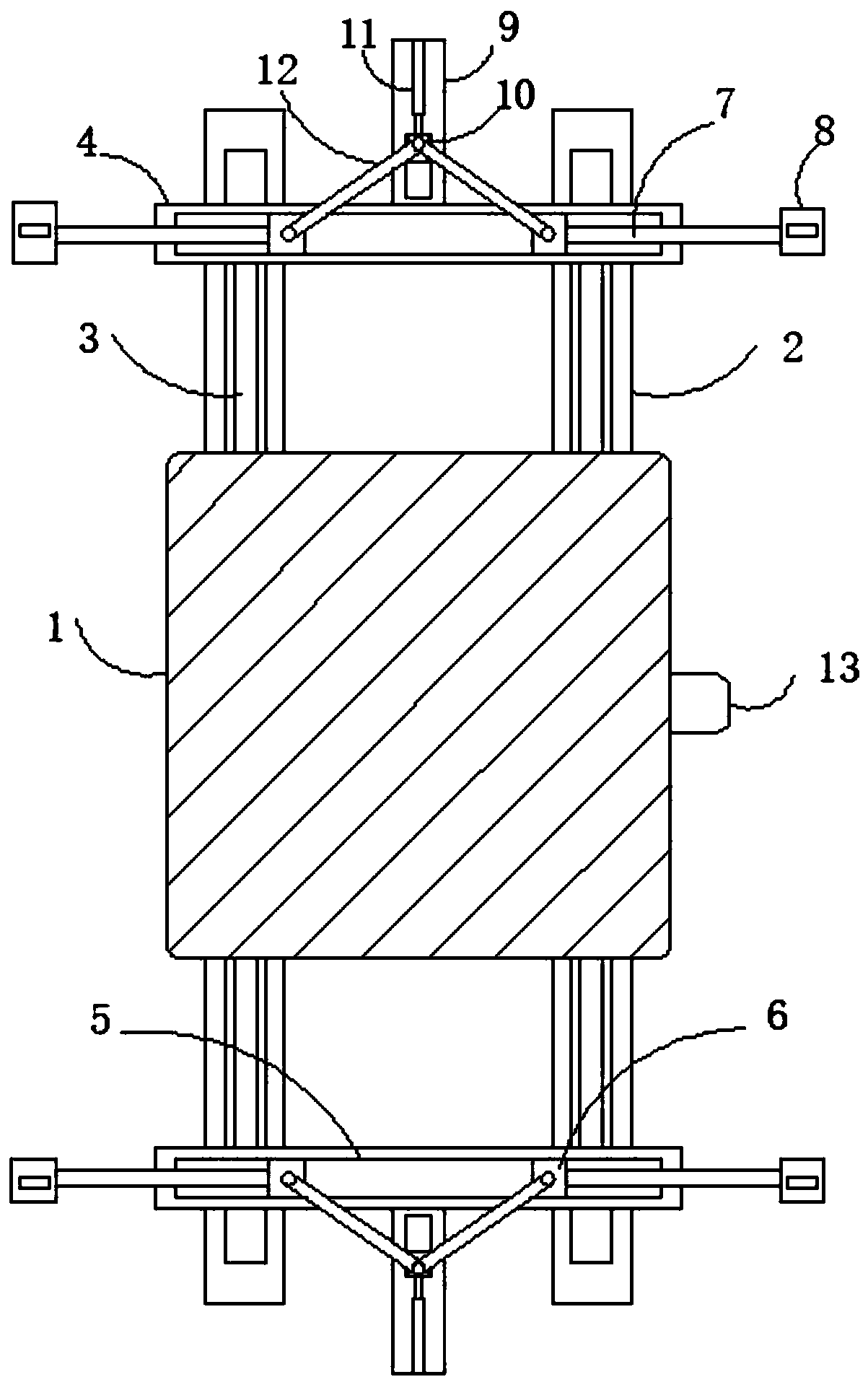

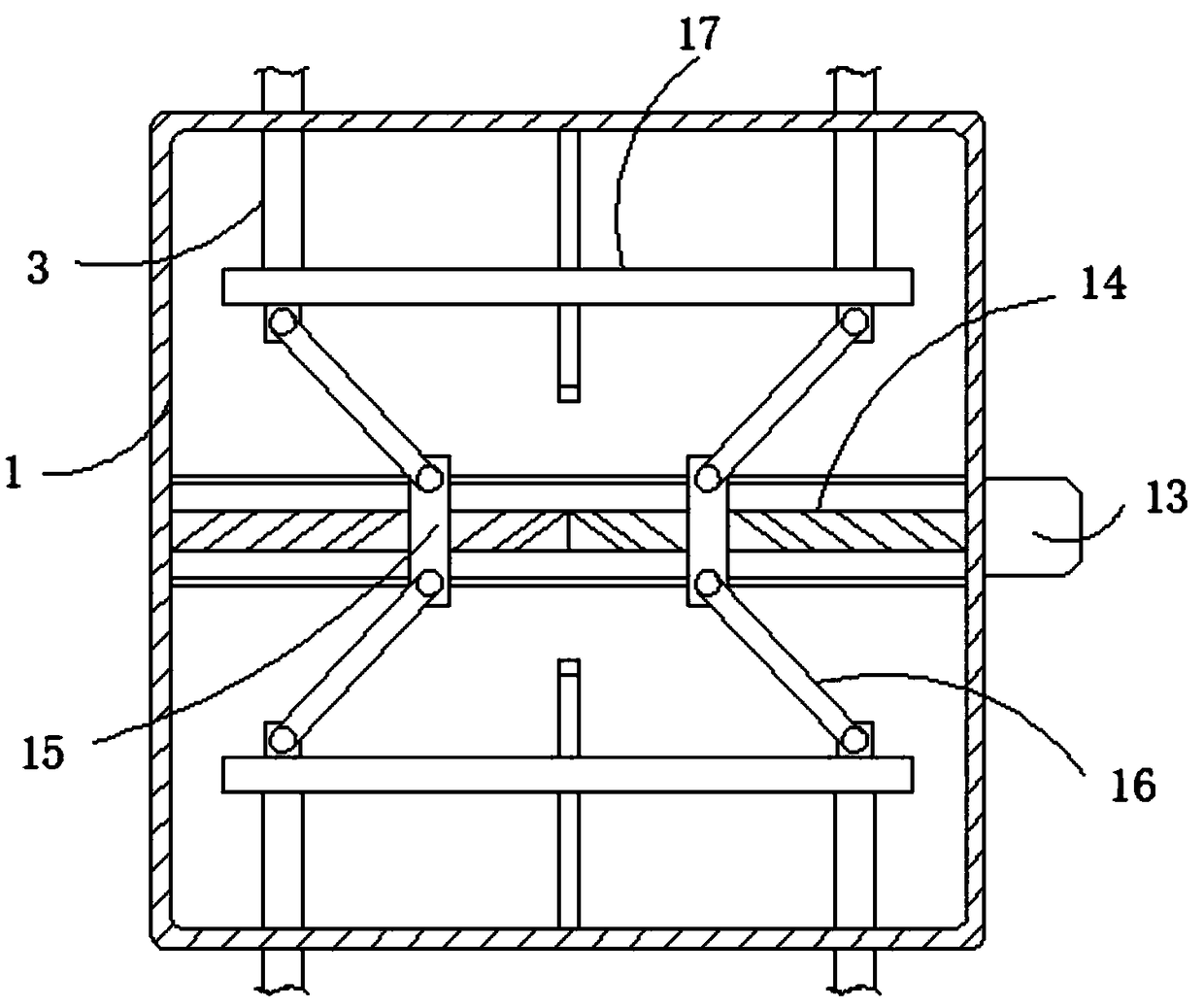

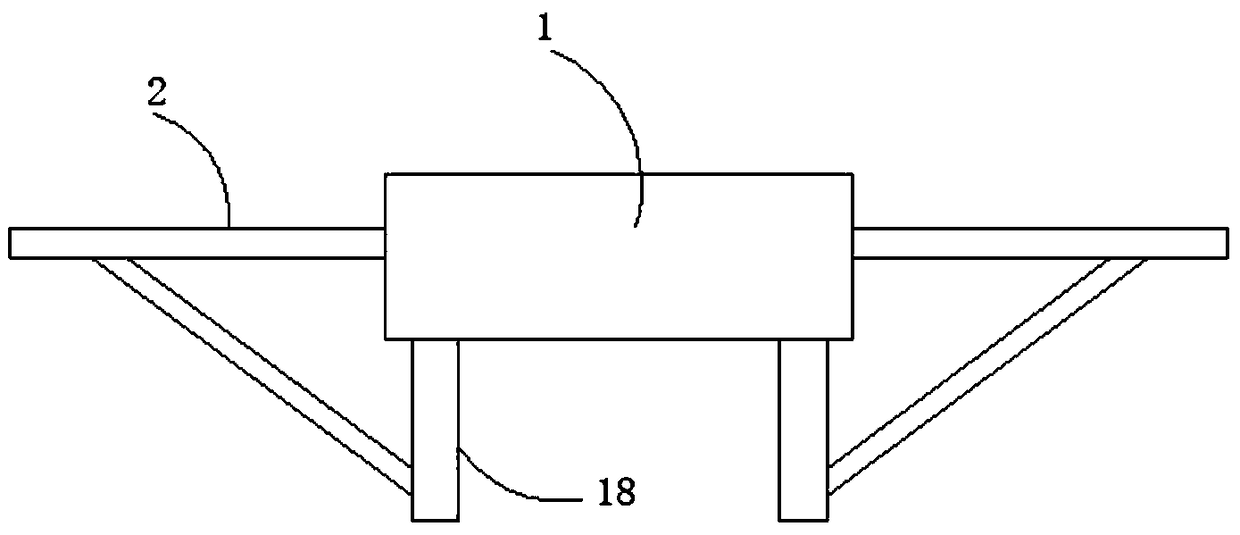

Ironing device for processing bedding textile products

InactiveCN109162061AEasy ironingImprove ironing efficiencyStretchingMechanical engineeringBed sheets

The invention relates to the technical field of processing of textile products and discloses an ironing device for processing bedding textile products. The ironing device for processing the bedding textile products comprises a control box; two rail plates are fixedly arranged at the top and the bottom of the control box; vertical rods are movably arranged at the top and the bottom of the control box; the vertical rods are in sliding connection with the rail plates; transverse plates are movably arranged on the rail plates; one end of each vertical rod is fixedly connected with each transverseplate; sliding grooves are formed in the transverse plates; two adjusting blocks are arranged on the sliding grooves in a sliding way; the adjusting blocks are fixedly connected with transverse rods;the transverse rods are in sliding connection with the transverse plates; one end of each transverse rod is fixedly connected with a clamping block; vertical plates are welded on the transverse plates; a push rod motor is arranged on each vertical plate; and a moving block is arranged on each vertical plate in a sliding way. The ironing device for processing the bedding textile products can realize stretching and unfolding of bed sheet fabric, is suitable for bed sheets with different length and width, is labor-saving, facilitates ironing of the bed sheet fabric, improves the ironing efficiency of the bed sheet fabric and is easy to popularize.

Owner:CHANGXING JUFENG SILK WEAVING FACTORY

Laundry additive sachet

InactiveUS7615524B2Clean and soften fabricEasy ironingOther washing machinesOrganic/inorganic per-compounds compounding agentsLaundryOrganic chemistry

Owner:THE PROCTER & GAMBLE COMPANY

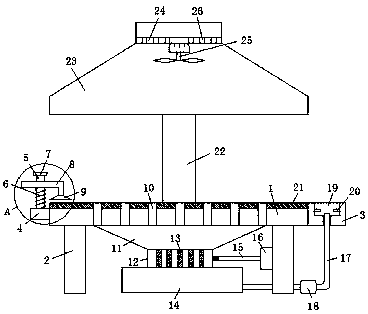

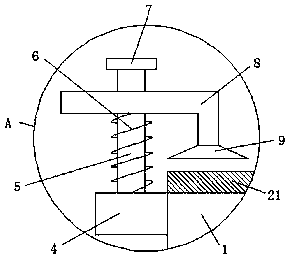

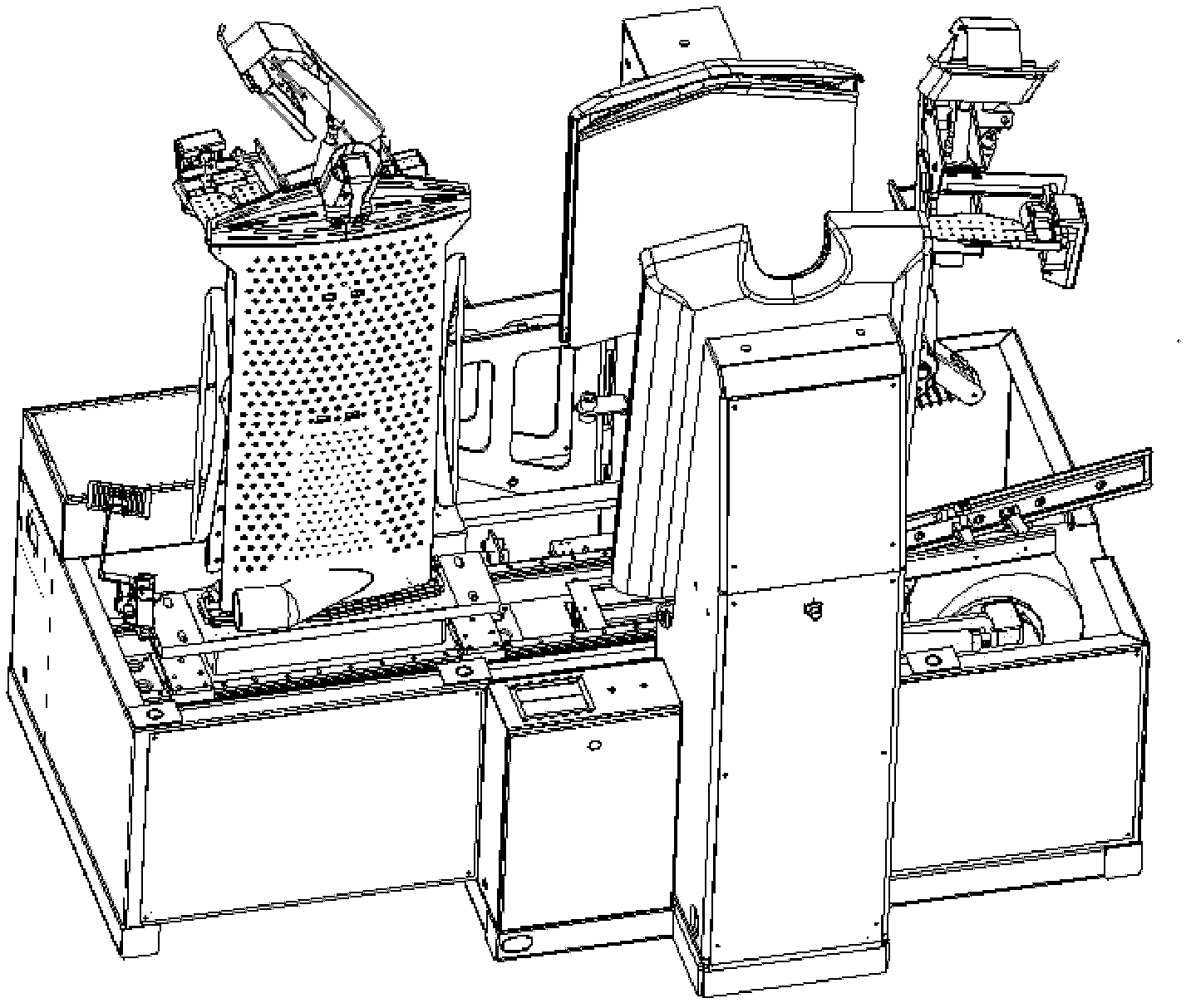

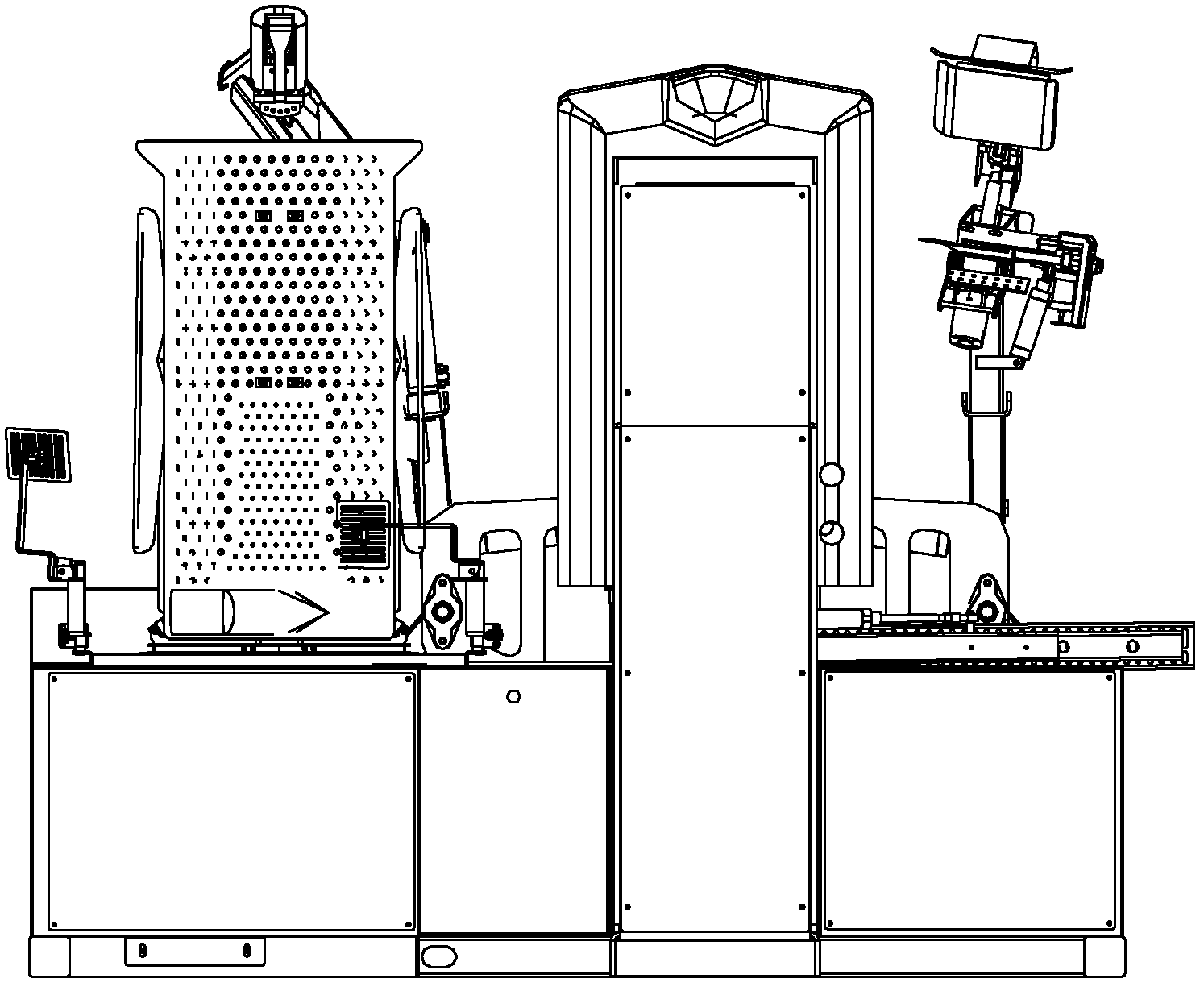

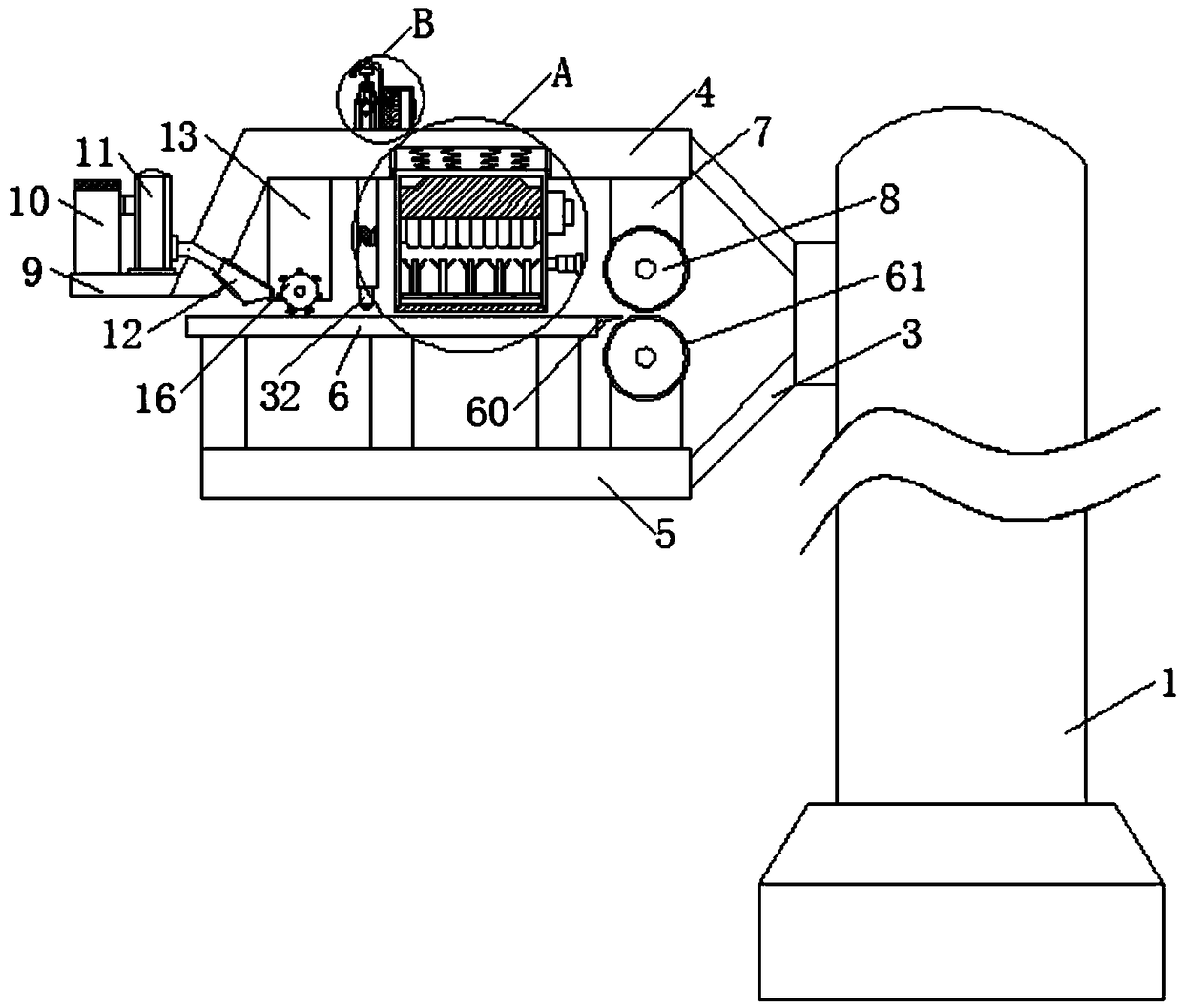

Multifunctional shirt ironing machine

ActiveCN102383297AImprove work efficiencyReduce investmentIroning apparatusTextiles and paperEngineeringVacuum pump

The invention relates to a multifunctional shirt ironing machine. The multifunctional shirt ironing machine comprises a base, wherein a vacuum pump is arranged on the left side of the base; a fan is arranged on the right side of the base; a heat exchanger is arranged on a base workbench; a heat exchanger workbench is provided with a middle die moving guide rail arranged horizontally; a rectangular middle die device is arranged on the middle die moving guide rail; a left side pressing plate mechanism is fixedly arranged on the left side of the rectangular middle die device; a right side pressing plate mechanism is fixedly arranged on the right side of the rectangular middle die device; a front die device is arranged in front of the heat exchanger; a closure pressing plate mechanism is arranged on the corresponding front end face of the base and below the heat exchanger; a rear die device is arranged behind the heat exchanger; a left pull sleeve mechanism is arranged on the left side ofthe rear die device; a right pull sleeve mechanism is arranged on the right side of the rear die device; a left sleeve clamp is arranged on the left pull sleeve mechanism; and a right sleeve clamp isarranged on the right pull sleeve mechanism. In the multifunctional shirt ironing machine, each electromagnetic air cylinder is controlled through a control device and by compiling a control program,so that a hot pressing process and an air pressing process are finished on one piece of ironing equipment, capital investment is reduced and production efficiency is improved.

Owner:SHANGHAI WEISHI MACHINERY

Low melting point spandex slice and preparation method thereof

The invention discloses a low melting point spandex slice and a preparation method thereof, and belongs to the field of chemical materials. The low melting point spandex slice comprises following raw materials, by weight, 65 to 70% of a mixture of polyether polyols and polyester polyols, 25 to 30% of isocyanate, and 4 to 7% of a chain extender, wherein the mixture comprises 85 to 95wt% of the polyether polyols, and 5 to 15wt% of the polyester polyols. Advantages of the preparation method are that: vicat softening temperature of the low melting point spandex slice prepared by the preparation method is relatively low, and vicat softening temperature of spandex fiber made of the low melting point spandex slice is relatively low, so that ironing and pressing are convenient.

Owner:南通华盛高聚物科技股份有限公司

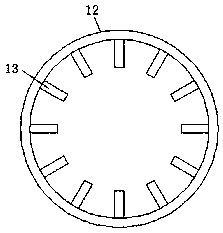

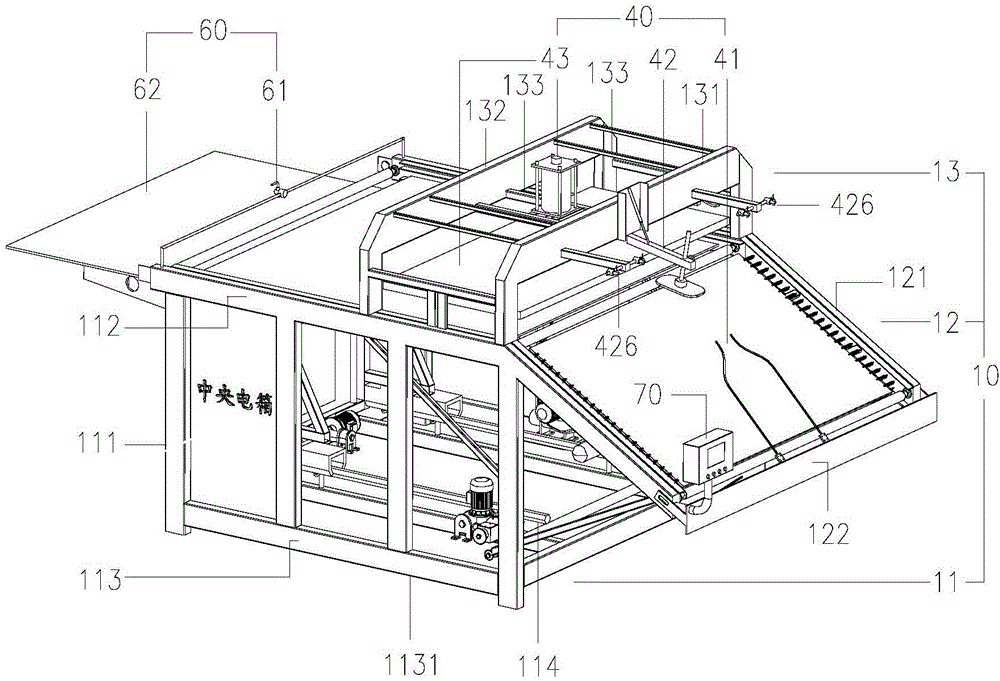

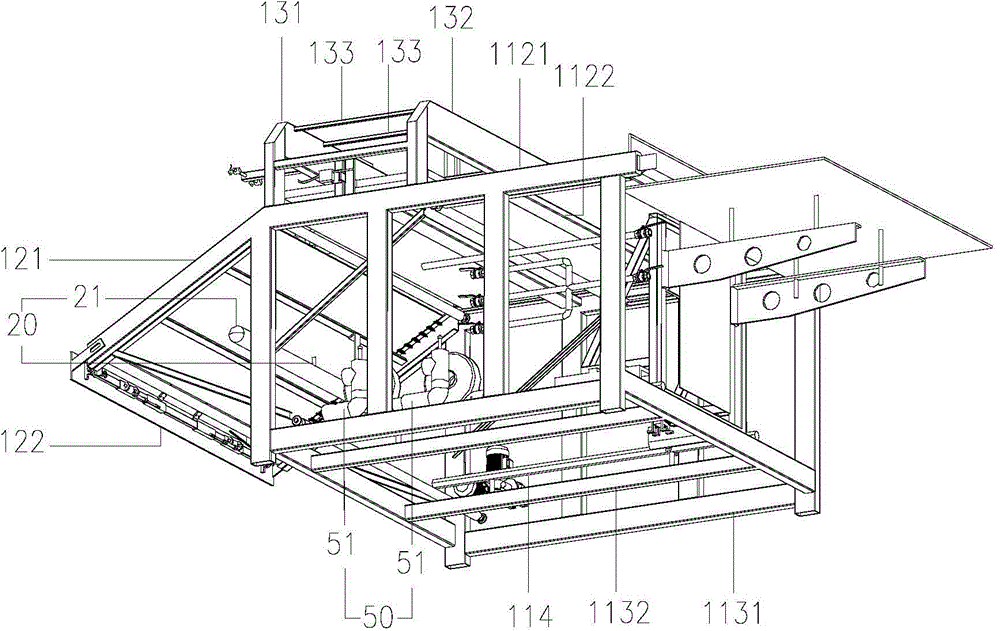

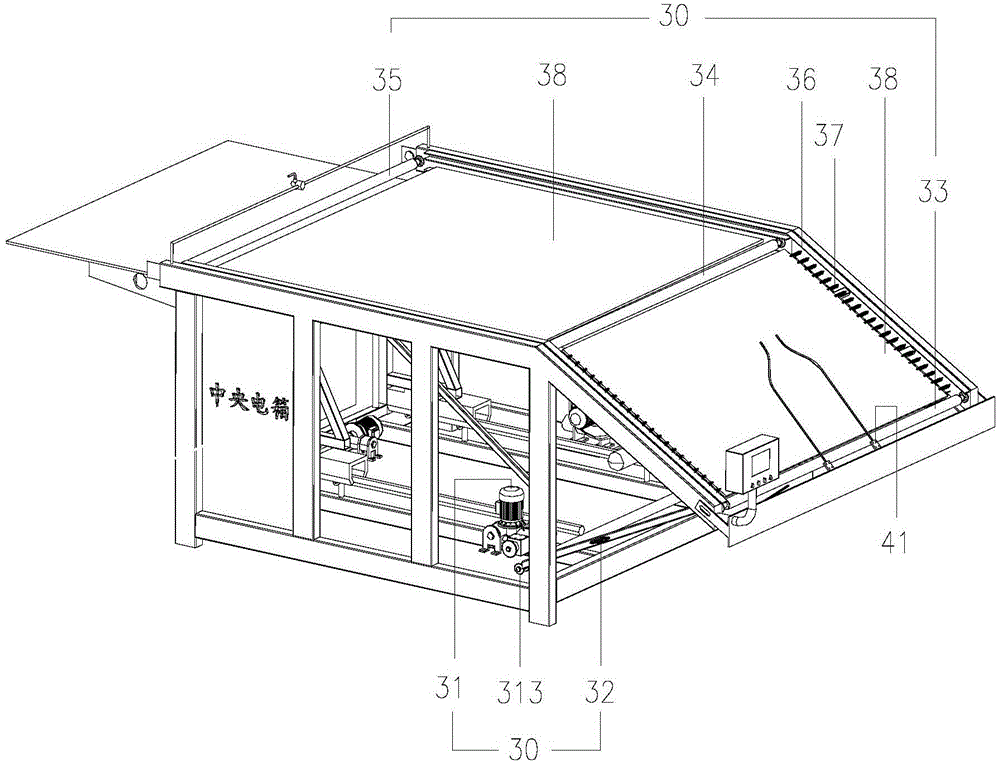

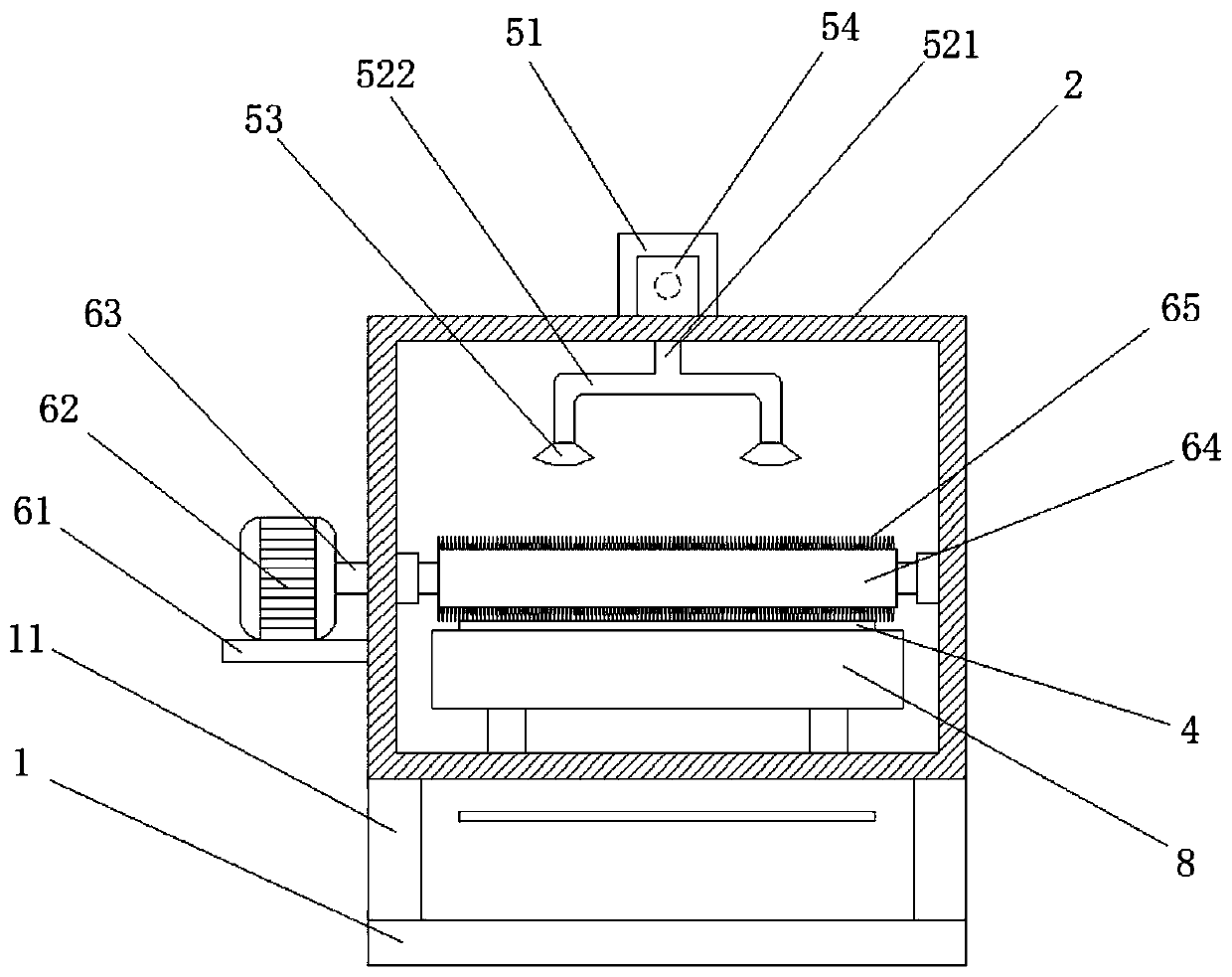

Woolen knitwear steaming setting machine

InactiveCN104805666AAchieve ironing and settingAvoid out of shapeHeating/cooling textile fabricsIroning apparatusSupport groupPulp and paper industry

The invention provides a woolen knitwear steaming setting machine. The woolen knitwear steaming setting machine comprises a machine frame, a steam evaporating group, a transmission group, an ironing positioning group, a ventilating dehumidifying group, a counting clothes supporting group and an electric control group, wherein the machine frame comprises a main frame part, an inclined frame part and a top frame part; the main frame part is provided with a main rod, an upper frame and a lower frame; the inclined frame part is combined with the front side of the upper frame body and is provided with a surface beam; the top frame part is arranged on the upper frame body; the steam evaporating group comprises a steam temporary storage device; the steam temporary storage device is communicated with the ventilating dehumidifying group through a pipeline; the transmission group drives a first roller, a second roller, a third roller and a conveying cloth belt of the transmission group by adopting chain transmission; a transmission chain used for the chain transmission is provided with ear holes; the first roller is overlapped to the second roller and the third roller through the conveying cloth belt; metal rings are arranged on the two side peripheries of the conveying cloth belt corresponding to the ear holes; the ear holes are connected with the metal rings through springs. Through the structure, the technical problems about woolen knitwear steaming and setting are solved; good effects that the operation is facilitated, and the steaming efficiency is improved are achieved.

Owner:郑野

Ironing machine facilitating adjustment of ironing angle

ActiveCN108755065AFull ironingAvoid burnsTextile treatment machine arrangementsHand ironEngineeringWater spray

The invention relates to an ironing machine, in particular to an ironing machine facilitating adjustment of an ironing angle. The ironing machine facilitating the adjustment of the ironing angle aimsat achieving the technical purposes that the time and labor are saved, and water mist can be sprayed onto clothes to prevent the clothes from being burnt by an iron. The ironing machine facilitating the adjustment of the ironing angle comprises support legs, a transverse plate, a placement plate, a vertical rod, a first sliding sleeve, fastening bolts, a fixing plate and the like; the support legsare symmetrically installed on the left and right side faces of the transverse plate, a rotating device is arranged between the top of the transverse plate and the upper portions of the inner side faces of the left and right support legs and connected with the placement plate, and the vertical rod is installed at the top of the left support leg and provided with the first sliding sleeve. According to the ironing machine, the water mist is sprayed onto the clothes through a water spraying device, so that the situation that the clothes are damaged due to excessive temperature during ironing isprevented, and the ironing machine has the advantages that the time and labor are saved, and the water mist can be sprayed onto the clothes to prevent the clothes from being burnt by the iron.

Owner:NANJING HANERSI BIOLOGY TECHNOLOGY CO LTD

Working method for textile electric cloth canister with ironing and dedusting functions

The invention relates to the technical field of textile cloth, in particular to a textile electric cloth canister with ironing and dedusting functions. The textile electric cloth canister includes a left column and a right column, wherein both the left sides of the left column and the right column are symmetrically connected with slanting rods through mounting plates; the slanting rods are together and correspondingly connected with a top plate and a bottom plate; the upper end of the bottom plate is connected with a placement plate through a support column; the ends, corresponding to each other, of the top plate and the bottom plate are symmetrically connected with first vertical plates; the sides, corresponding to each other, of the first vertical plates are movably connected with leading-in rollers; the left side of the top plate is connected with a first support plate; the upper end of the first support plate is provided with a collecting tank; and the upper end of the first support plate is equidistantly provided with dust suction fans. The textile electric cloth canister has the advantages that the structure design is reasonable; the textile cloth is convenient to stably wind; the textile cloth is dedusted and ironed while being wound; the number of functions of the wind mechanism is increased; the cloth canister is convenient to arrange and disassemble; and the work efficiency can be improved.

Owner:福建省福州市华伟针织有限公司

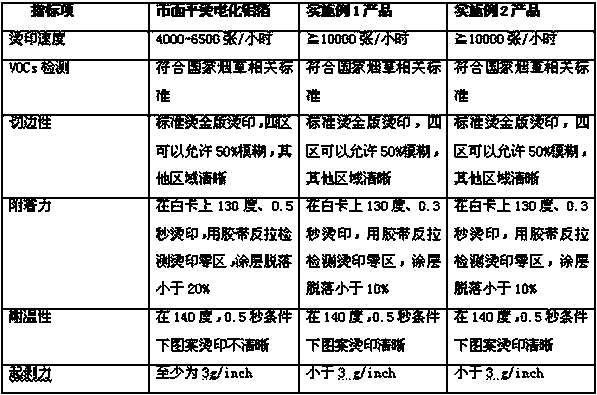

Electrochemical aluminum foil suitable for high-temperature and high-speed hot stamping

ActiveCN107650525AImprove adhesionLow softening temperatureDuplicating/marking methodsHot stampingTemperature resistance

The invention provides electrochemical aluminum foil suitable for high-temperature and high-speed hot stamping. The electrochemical aluminum foil comprises a carrier film, a release layer, an imaginglayer, an aluminized layer and a rubber layer. The imaging layer comprises melamine acrylice resin, butanone, butyl ester, colourment and alkyd resin, the imaging layer is printed through a plate roller with 200 meshes, and the dry coating quantity is (1.00+-0.05) g / m<2>. The rubber layer comprises nitrile butadiene rubber modified phenolic resin, modified polyurethane resin, modified vinyl acid resin, ethyl ester, methylbenzene and silicon dioxide, the rubber layer is printed through a plate roller with the 180 meshes, and the dry coating quantity is (1.15+-0.05) g / m<2>. The hot stamping adhesive force of the electrochemical aluminum foil is strong, stripping force is smaller than 3 g / inch, the hot stamping speed is 100 m / min or above, the stamping suitability, temperature resistance, rubber aluminum firmness and color aluminum firmness are all good, and the electrochemical aluminum foil is specially suitable for the high-temperature and high-speed circular-pressing and circular-stamping technique.

Owner:GUANGDONG XINRUI NEW MATERIAL TECH

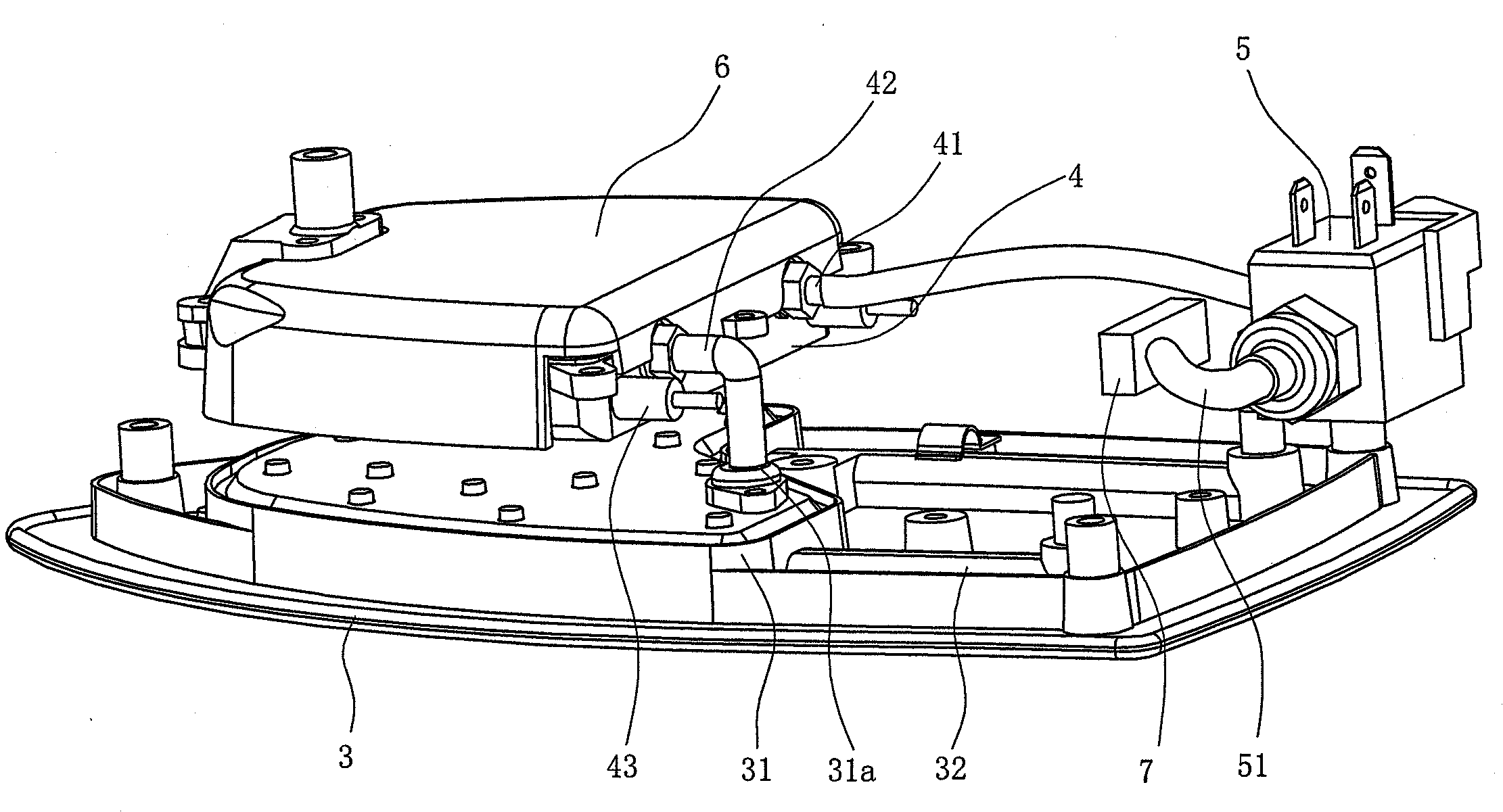

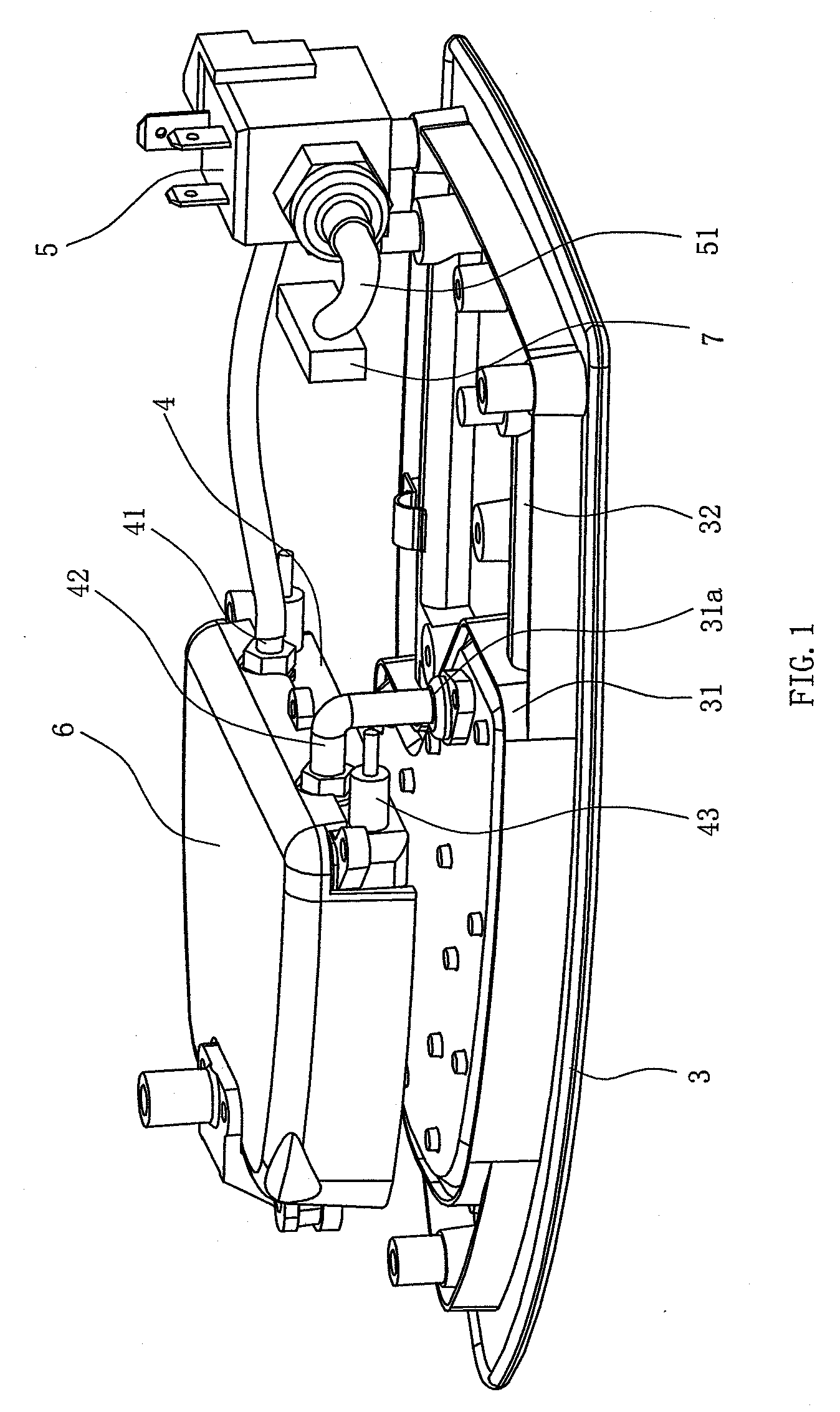

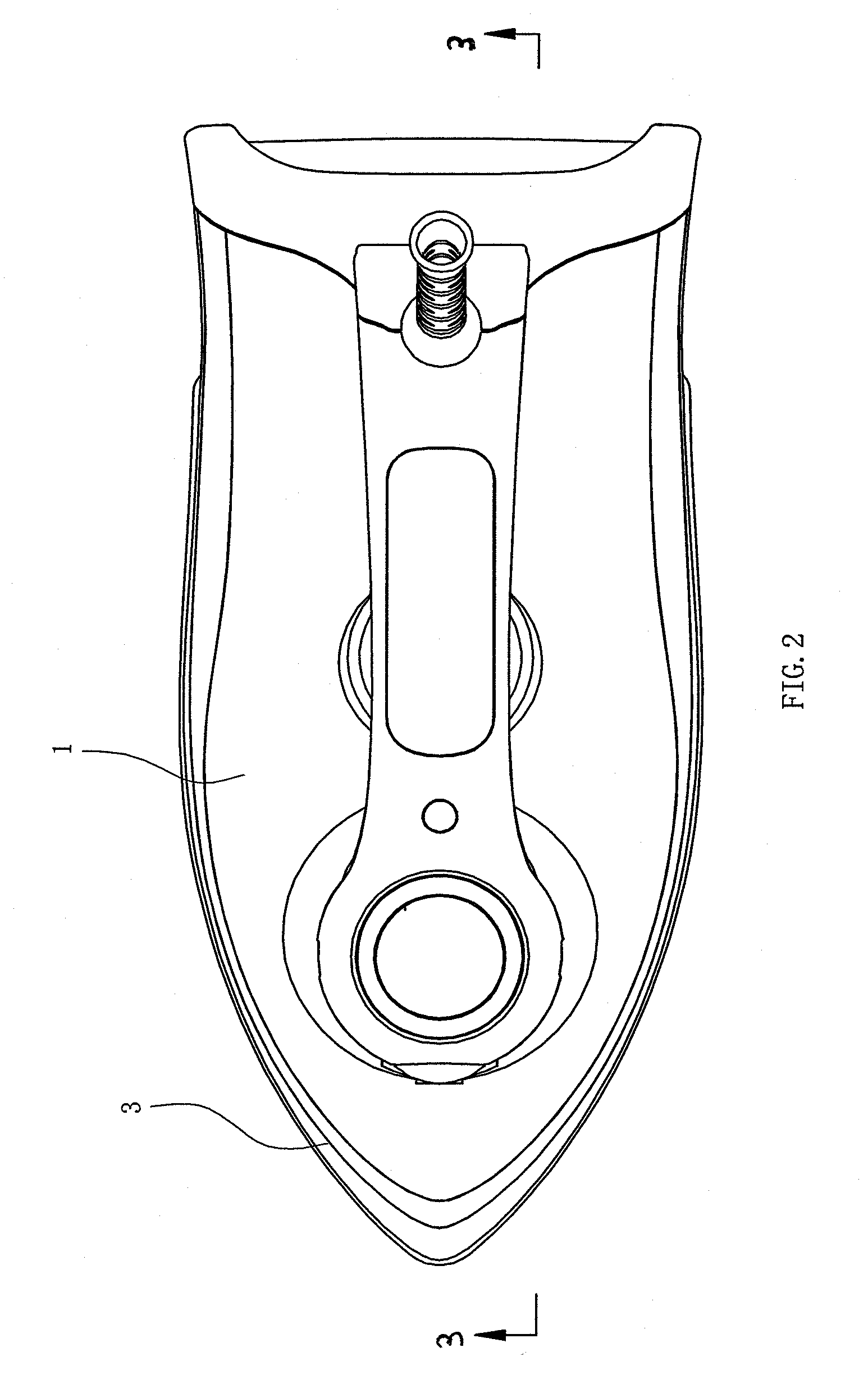

Electric steam iron

InactiveUS20090000162A1Good effectGood boiling effectHand ironTextiles and paperElectricityEngineering

Owner:ZHEJIANG YUELI ELECTRICAL

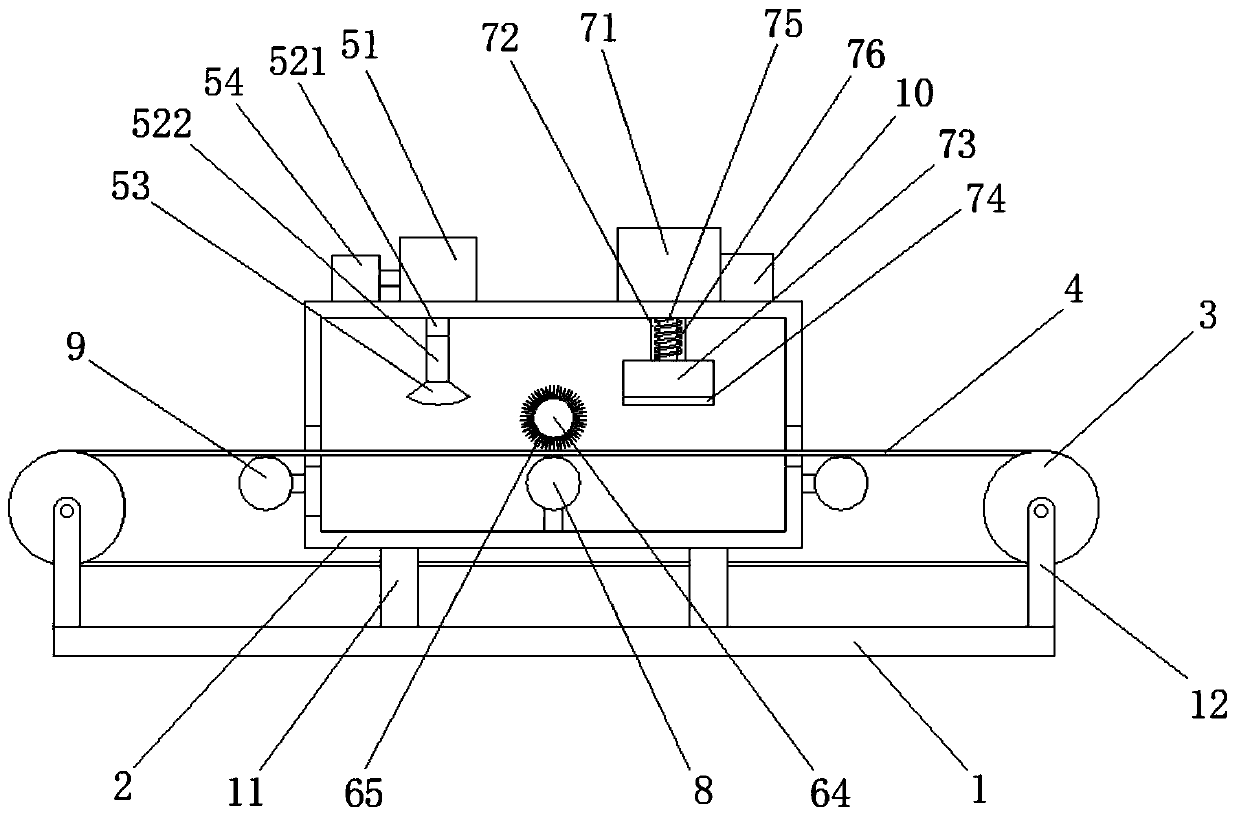

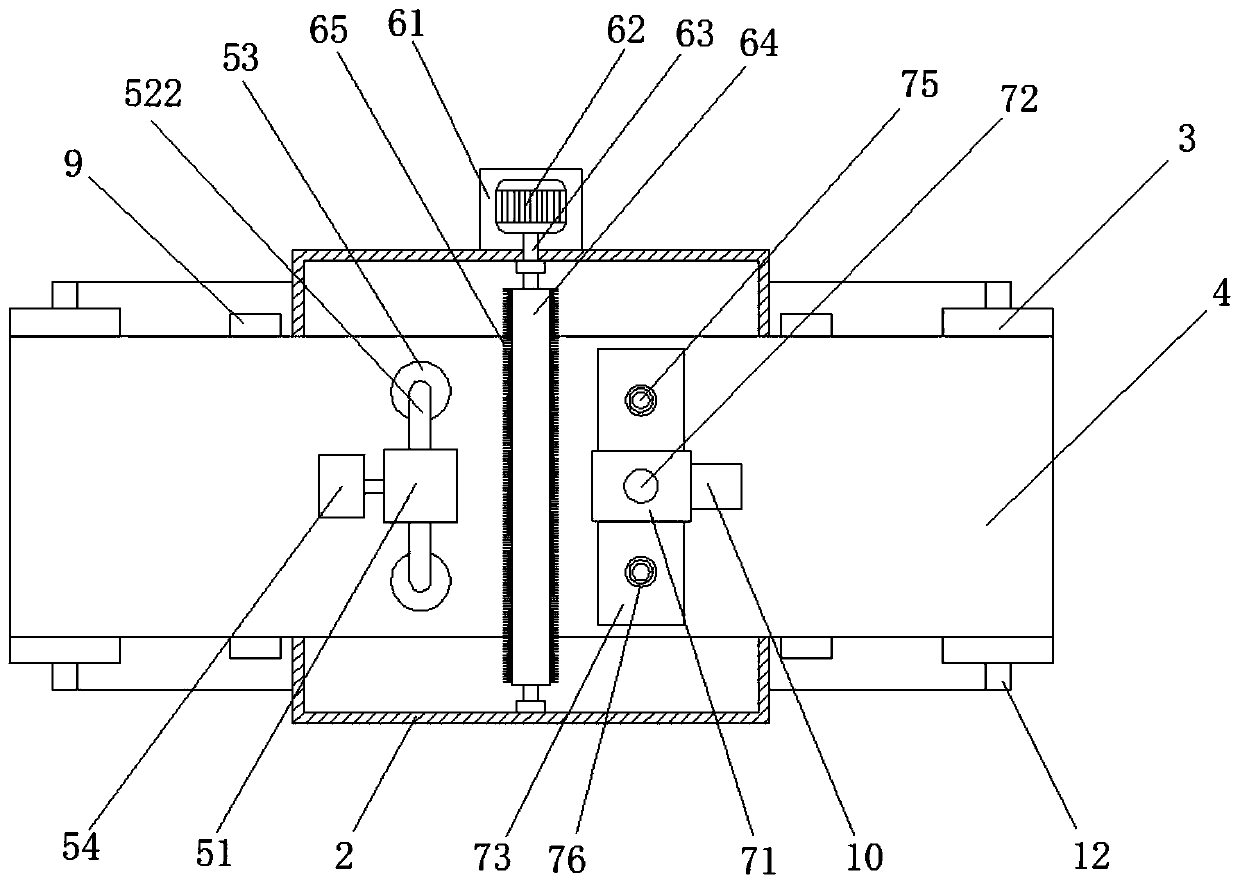

Ironing device with air suction and dust removal functions

InactiveCN110172811AImprove cleanlinessEasy ironingMechanical cleaningPressure cleaningBristlePulp and paper industry

The invention discloses an ironing device with an air suction and dust removal functions. The ironing device comprises a base; a plurality of fixing columns are arranged in the middle of the base; a working box is arranged on the fixing columns; roller brackets are arranged at two ends of the base; rollers are erected on the roller brackets; conveyor belts are arranged on the rollers, and pass through the working box in the transverse direction; an air suction device, a bristle device and an ironing device body are sequentially arranged at parts, above the conveyor belt, in the working box inthe feeding direction; the air suction device comprises an induced draft fan, a dust removal pipeline, an air suction opening and a dust collection chamber; the bristle device comprises a bottom plate, a motor, a rotating shaft, a bristle roller and bristles; and the ironing device comprises an air cylinder, a piston rod, a steam chamber, an ironing board, a telescopic rod and a reset spring. Theironing device can be convenient for clearing and collecting dust on the surface of clothing, keeps clothing clean, is convenient for ironing of clothing, further keeps fabric smooth, improves the recovery effect, improves the operation stability and the safety, is high in ironing efficiency, and is suitable for batch production.

Owner:HAIYAN WEIBOYA KNITTING CLOTHING

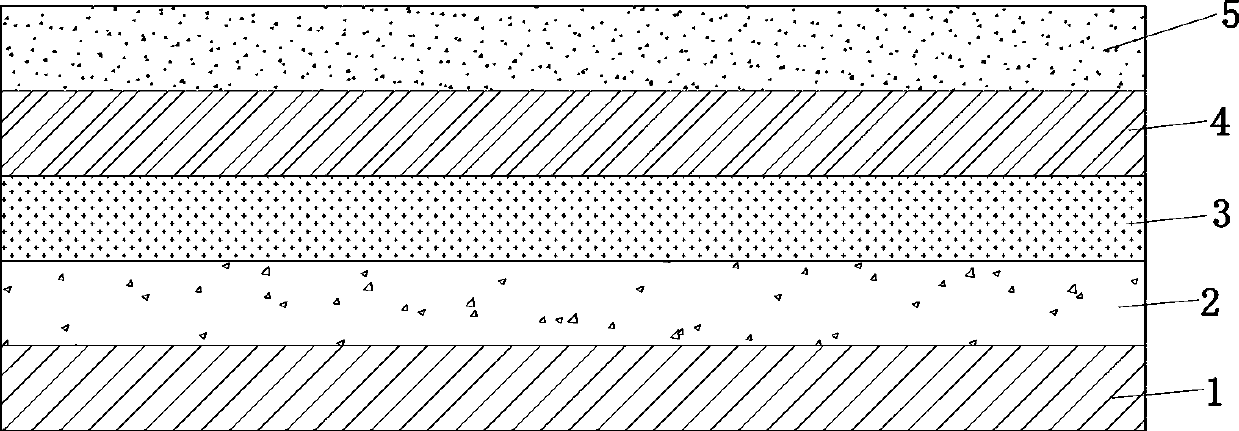

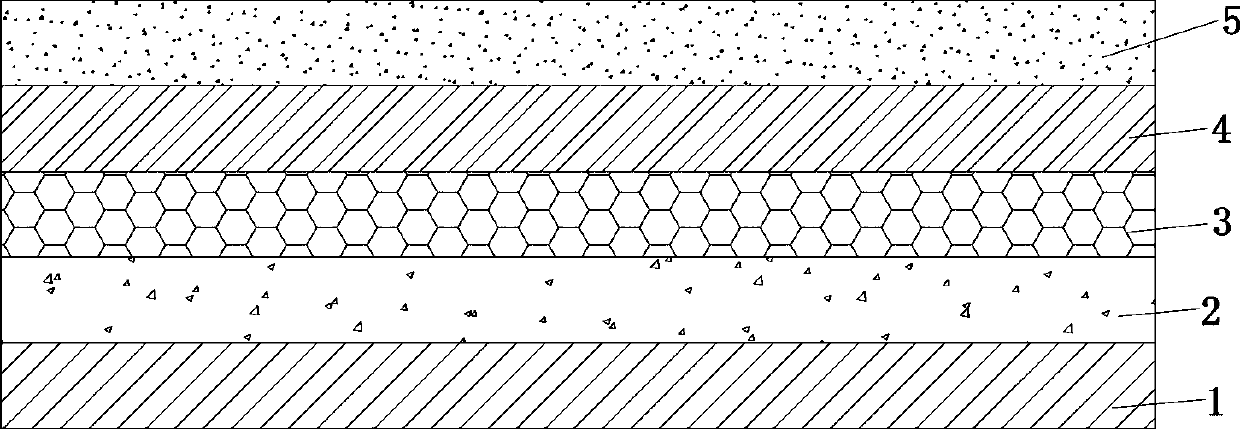

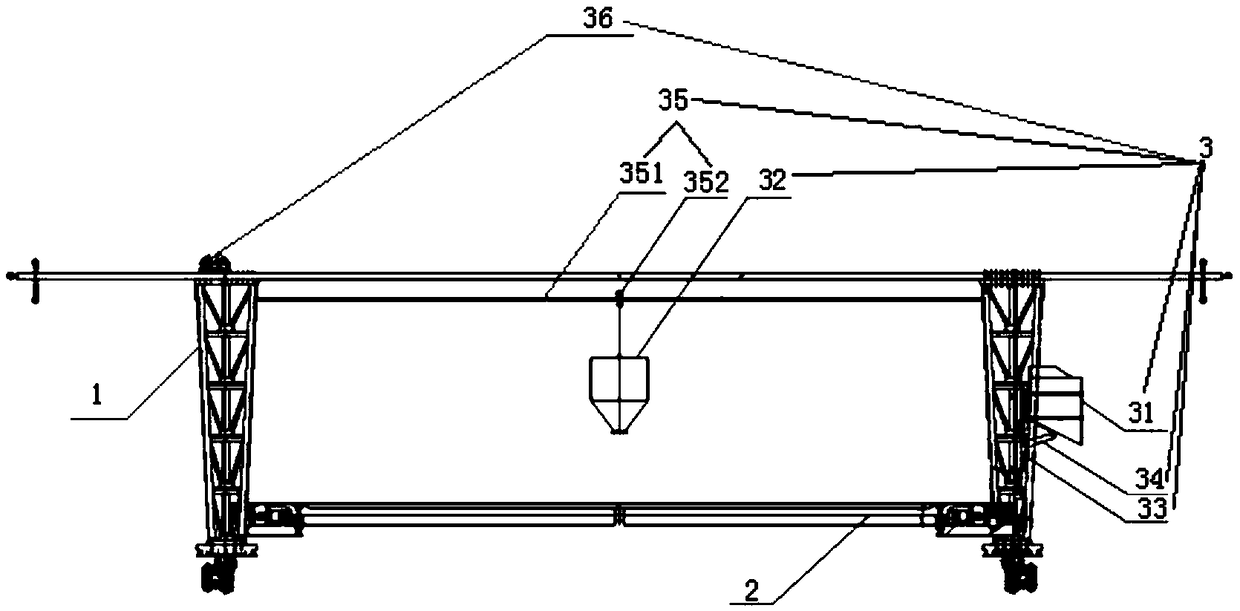

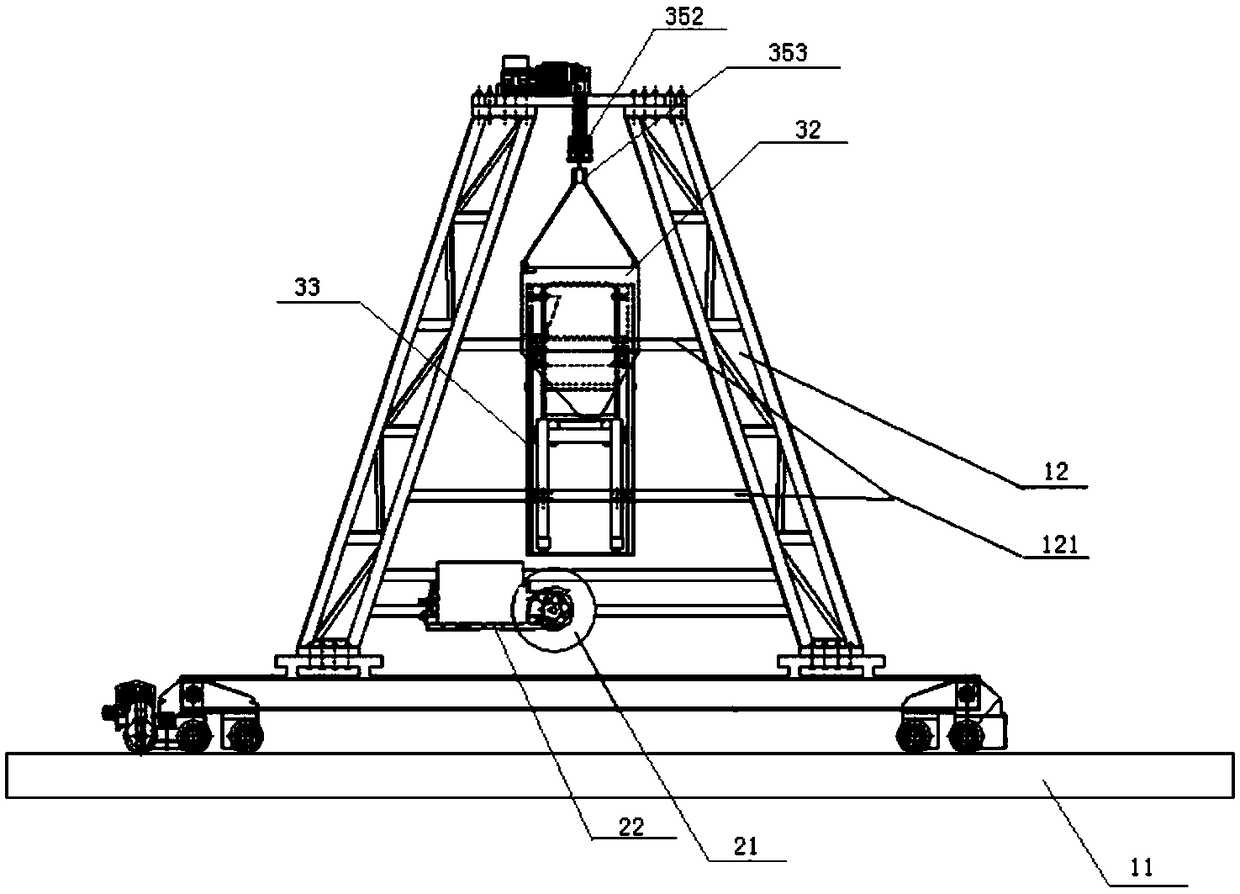

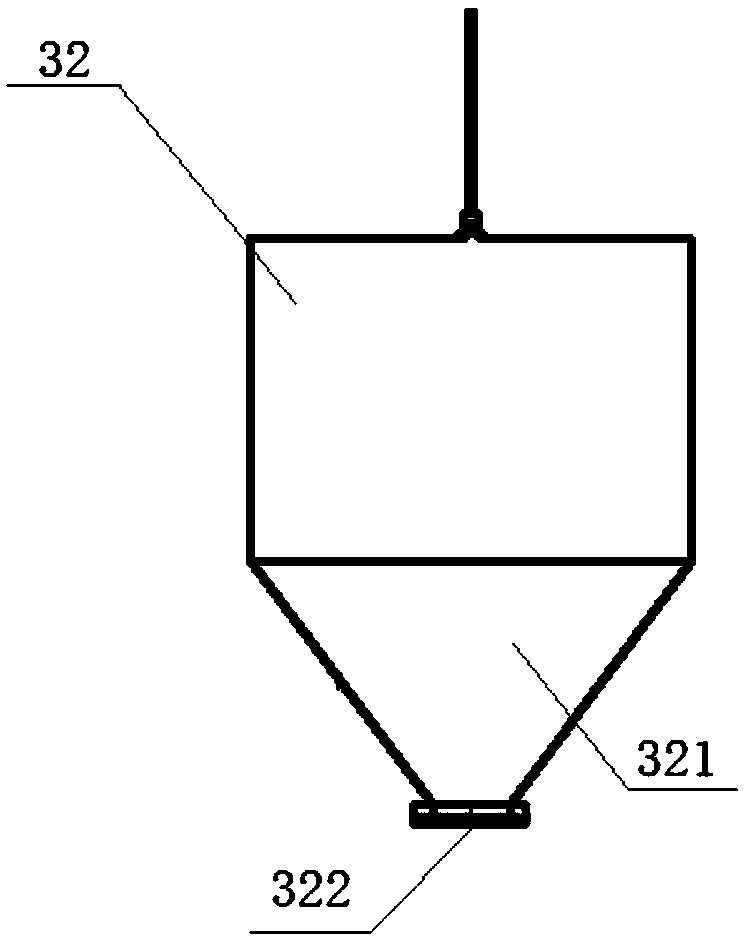

Steel bridge deck prefabricated paving equipment

ActiveCN109306649AReduce construction proceduresReduce the impactBridge structural detailsBridge erection/assemblyBridge deckPortal frame

The invention discloses steel bridge deck prefabricated paving equipment. The steel bridge deck prefabricated paving equipment can change the traditional steel bridge deck pavement construction procedure and technology. The steel bridge deck subjected to sand blasting and anti-rust coat and tack coat spraying can be paved with asphalt concrete in a factory, and is conveyed to a construction site for bridge deck assembling after forming. After assembling, the SMA asphalt mixture and other surface materials can be directly paved on the steel bridge deck. On-site construction procedures are reduced, construction difficulty is lowered, influence on construction by weather is avoided, and steel bridge paving quality and efficiency are effectively improved. The steel bridge deck prefabricated paving equipment comprises a walking machine frame and a paving mechanism, and is provided with a moving material cabin. The walking machine frame comprises a moving portal frame, a guide rail and the like. The paving mechanism comprises a spiral material arranging machine, an ironing plate and an ironing plate lifting device. The moving material cabin comprises a vertical lifting material cabin anda horizontal paving material cabin.

Owner:CHANGAN UNIV

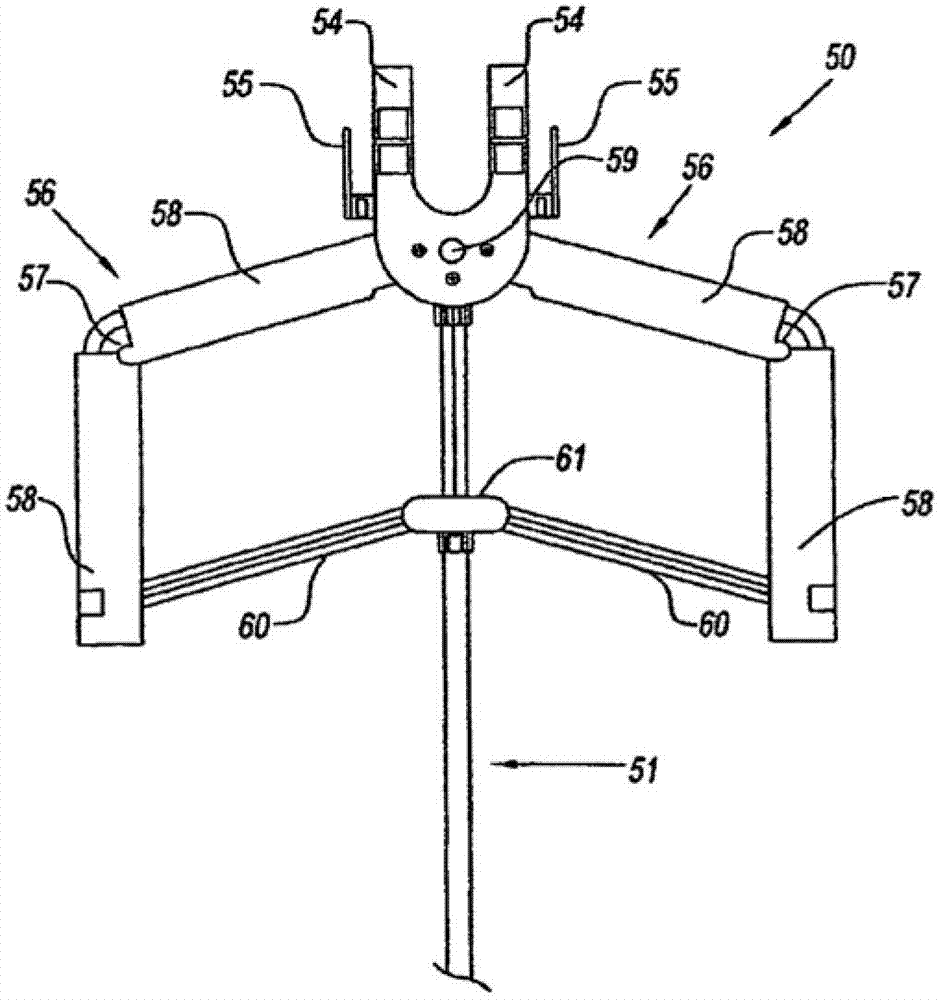

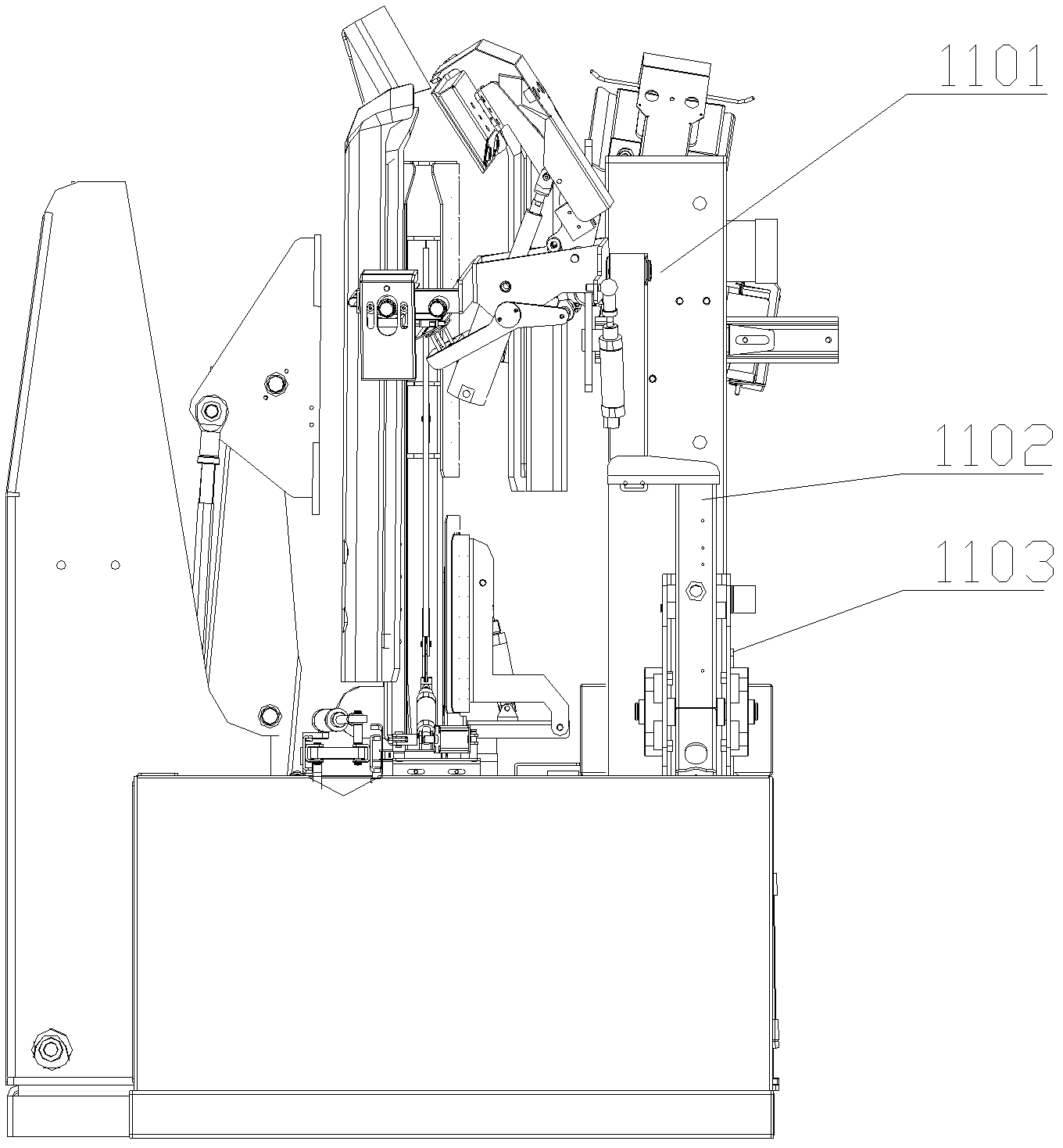

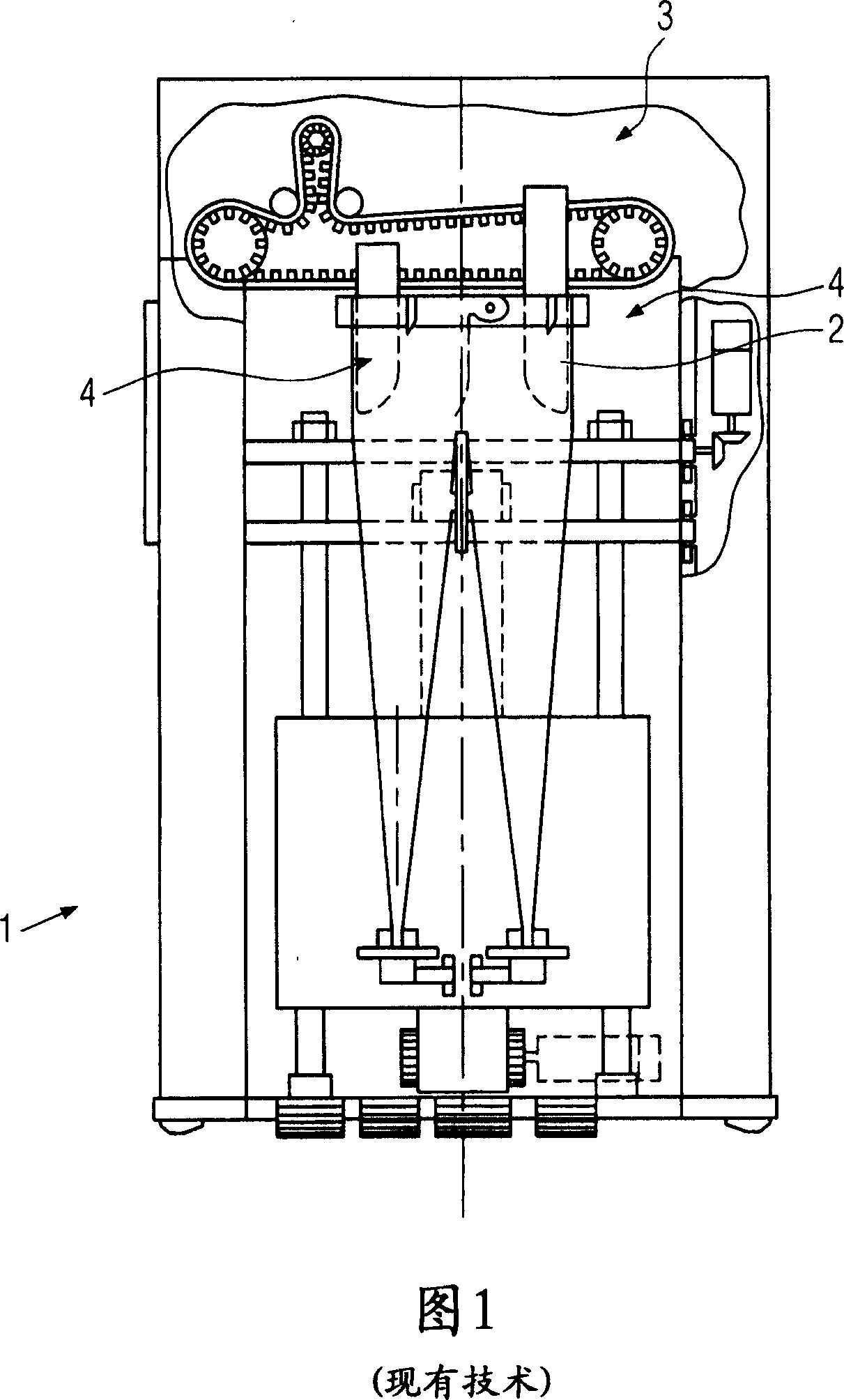

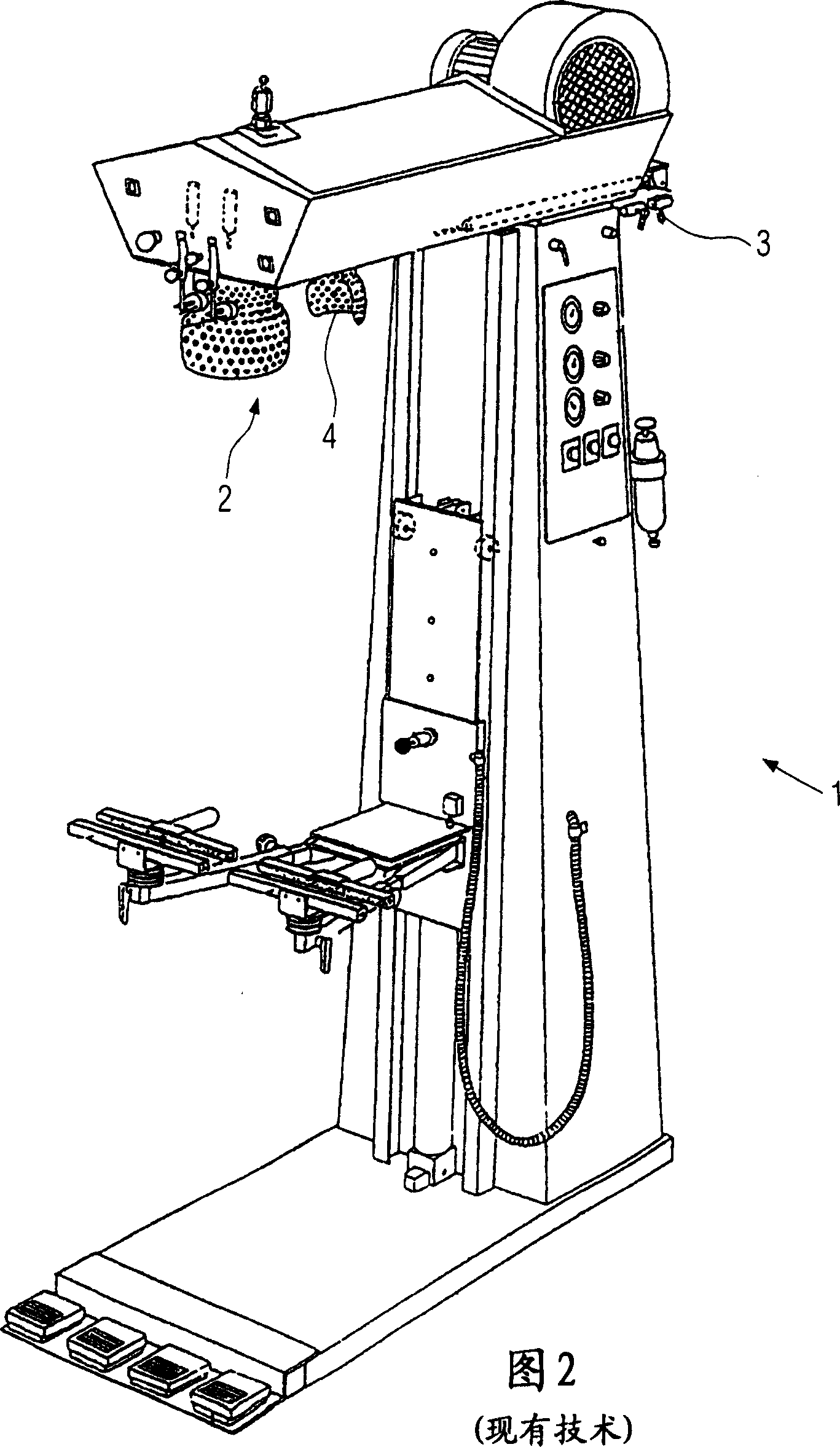

Trousers flattening machine containing stretching device containing claw connected to rotable rack

InactiveCN101003941AComprehensive processingSeparate installation spaceIroning apparatusTextiles and paperEngineeringJaw movement

The invention relates to a trousers flattening machine comprising a stretching device for stretching a trouser waist, wherein said stretching device comprises a drive device and at least two lateral jaws capable of passing through The drive means moves, characterized in that said side jaws are each attached to a frame which is pivotally rotatable about the jaw's distal point of rotation to move said side jaws.

Owner:VEITH GMBH & CO KG

Fabric care composition for directly applying to fabrics

InactiveUS20050183204A1Softer clothesReduce staticPhysical treatmentDetergent compounding agentsMedicineSolvent

The present invention relates to a fabric care composition containing from about 0.01% to about 1% fabric softening active by weight, a solvent, and the balance adjunct materials. The fabric care composition is substantially free of starch, and substantially free of silicone. The present invention also relates to a fabric care method having the steps of providing the fabric care composition described above, applying the fabric care composition directly onto a fabric, and ironing the fabric. The present invention also relates to a fabric care kit containing a container having a hollow body member having at least one reservoir. At least one application mechanism is in connected relation to the reservoir, and the reservoir contains the fabric care composition described above. The present invention also relates to a fabric care method having the steps of providing a concentrated fabric care composition, providing a dilution solvent, diluting the concentrated fabric care composition with the dilution solvent to form a fabric care composition, applying the fabric care composition directly onto a fabric, and ironing the fabric. The concentrated fabric care composition contains from about 1% to about 75% fabric softening active by weight, a solvent, and the balance adjunct materials. The concentrated fabric care composition is diluted with the dilution solvent at a dilution ratio of from about 1:1 to about 1:100. The fabric care composition is substantially free of starch. The present invention also relates to a concentrated fabric care kit comprising a hollow body member, dilution instructions, application instructions, and ironing instructions. The hollow body member has at least one reservoir containing a concentrated fabric care composition containing from about 1% to about 75% of a fabric softening active by weight, a solvent, and the balance adjunct materials. When the concentrated fabric care composition is diluted according to the dilution instructions, it forms a fabric care composition which is substantially free of starch.

Owner:GUARIN LEDA MARIE PERLADO +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com