Fabric care composition for directly applying to fabrics

a technology of fabric care and composition, applied in the field of fabric care composition, can solve the problems of wrinkles, wrinkling, and certain drawbacks, and achieve the effects of reducing static, reducing wrinkles, and facilitating ironing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

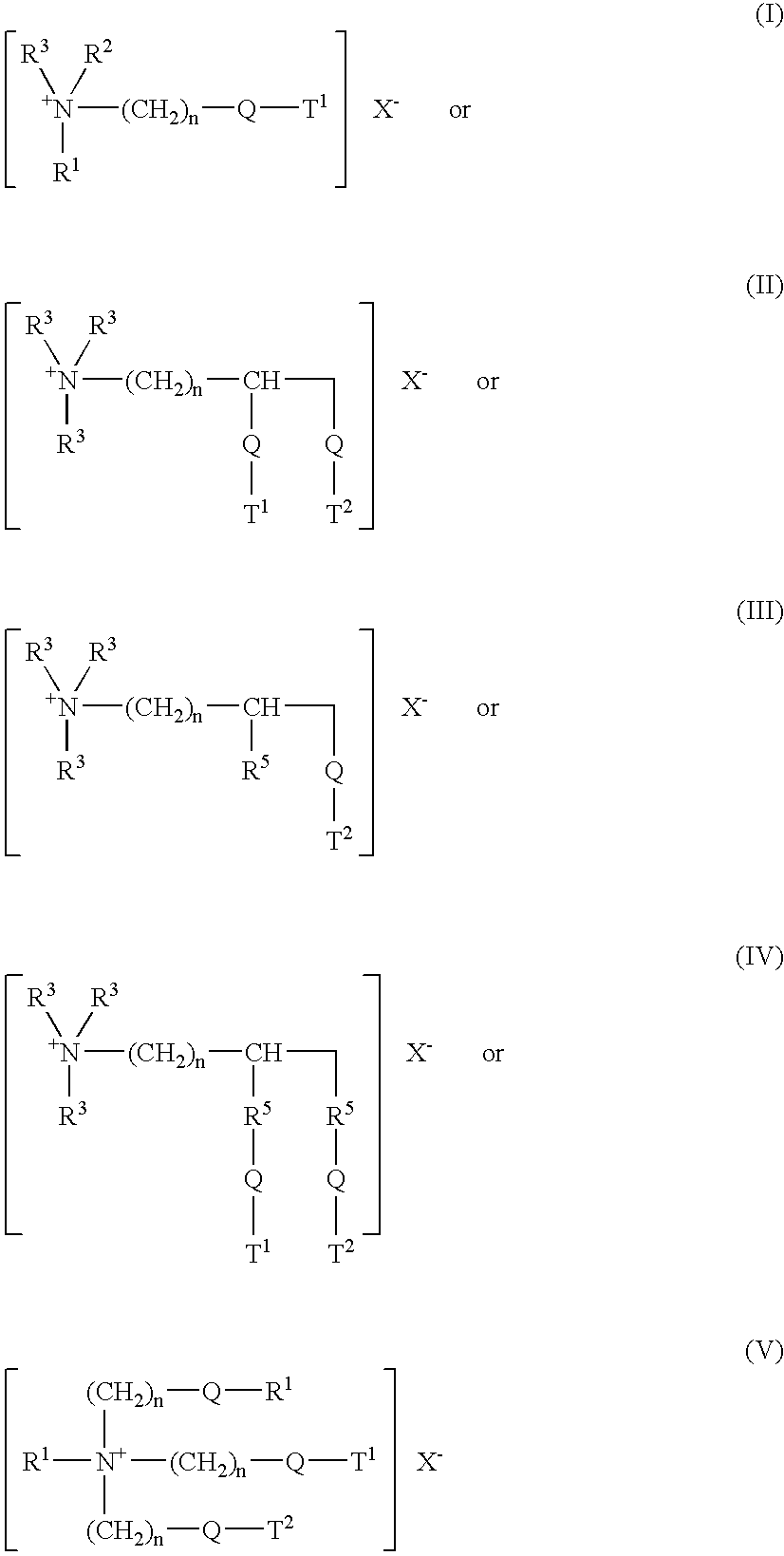

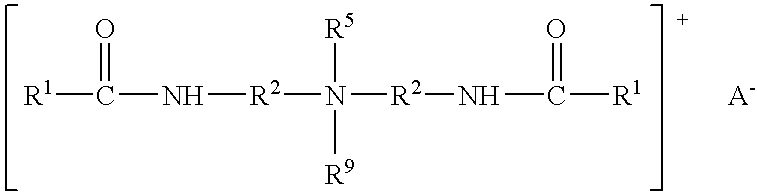

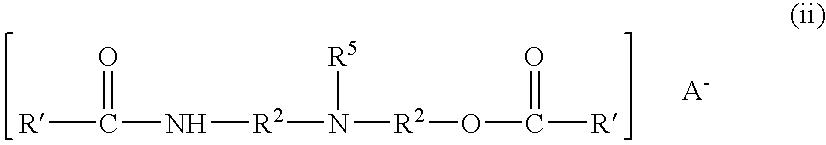

Method used

Image

Examples

example a

[0152] A concentrated fabric care kit is provided, containing an empty plastic spray container, and a plastic bottle (i.e., the hollow body member) containing a concentrated fabric care composition. The concentrated fabric care composition is provided according to the following formulations:

TABLE IExample 1Example 2Example 3DTDMAC* as 85% active in water6.500and isopropanolDitallow oxy ethyl dimethyl0100chloride, 80% active in water andethanolDipalmityl ethoxy oxy ethyl mono0014ethoxyoxyethyl monomethylammonium methyl sulfate as 85%active in propylene glycol andwaterNeodol ® 91-90231-tallow(amidoethyl)-2-300tallowimidazolineHCl0.50.20.21,2-hexanediol01525solvent, minors, and other adjunctbalance **balance †balance ‡materials balance to 100%

All percentages are by weight of the concentrated fabric care composition.

*DTDMAC = Ditallow dimethyl ammonium chloride.

** solvent = deionized water

† solvent = propylene glycol and deionized water.

‡ solvent = glycerol and water

[0153] Exampl...

example b

[0154] Concentrated fabric care compositions of the present invention have the following formulations:

TABLE IIEx. 4Ex. 5Ex. 6Ex. 7Ex. 8Ex. 9Ex. 10Ex. 11DTDMAC / MTTMAC*10.4810.480000010.48blend, 83% inIsopropanoltallow imidazoline ester00022.000014.0100%1-tallow(amidoethyl)-2-00900000tallow imidazoline ester100%1-tallow(amidoethyl)-2-14.314.3000000tallow imidazoline 100%Methyl-1-tallow000065000amidoethyl-2-tallowimidazolinium methylsulfate 90% inisopropanol(VARISOFT ® 475)Methyl bis(tallow000004000amidoethyl)2-hydroxyethylammonium methylsulfate (VARISOFT ®LM-90) 90% active inisopropanolMTTMAC as 75% in000004000isopropanolMethyl000000350bis(oleylcarboxyethyl)2-hydroxy ammoniummethyl sulfate 90% inisopropanolHCl0.850.850.971.250.50.50.70.85PVP3.1501.08.00000Perfume1.31.53.00.510.50.81.0PDMS emulsion from0.30000010Dow CorningCalcium Chloridetracetracetracetrace000traceKATHON ®tracetracetracetrace000traceLiquitint ® Blue 65tracetrace00000trace2-2-Ethyl 1,3-1500010000hexanediol1,2-hexane...

example c

[0155] A fabric care composition of the present invention was provided having the following formulations:

TABLE IIIEx. 12Ex. 13Ex. 14Ex. 15VARISOFT ® 4750.2000MTTMAC 90% in isopropanol0.20.300DTDMAC 70% in water0.30-0.10.250Monopalmityl dihydroxyethyl0001methyl ammonium chloride40% in waterDobanol C10E100.5102Alkaquat DMB-451-500.100.10.11,2-hexanediol5.09.00152,2,4-Trimethyl008.001,3-propanediolButylated hydroxytoluene0.10.100.2Citric acid0.10.20.20.25Perfume0.050.10.050.05solvent, minors, and otherbal. *bal. **bal. †bal. †adjunct materials balanceto 100%

All percentages are by weight of the concentrated fabric care composition.

* solvent = deionized water

** solvent = propylene glycol and water

† solvent = propylene glycol, glycerol and water

[0156] The fabric care compositions in Examples 12-15, are substantially free of both starch and silicone. When they are applied directly onto an already washed and dried 100% cotton fabric via spraying from a plastic spray container, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight ratio | aaaaa | aaaaa |

| weight ratio | aaaaa | aaaaa |

| weight ratios | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com