Copper-free ceramic type friction material and preparation method thereof

A copper-free ceramic type, friction material technology, applied in the field of friction materials, can solve the problems of poor friction stability and thermal recession resistance of friction materials, and achieve good mechanical skeleton performance, good friction and wear performance, and reduce wear effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

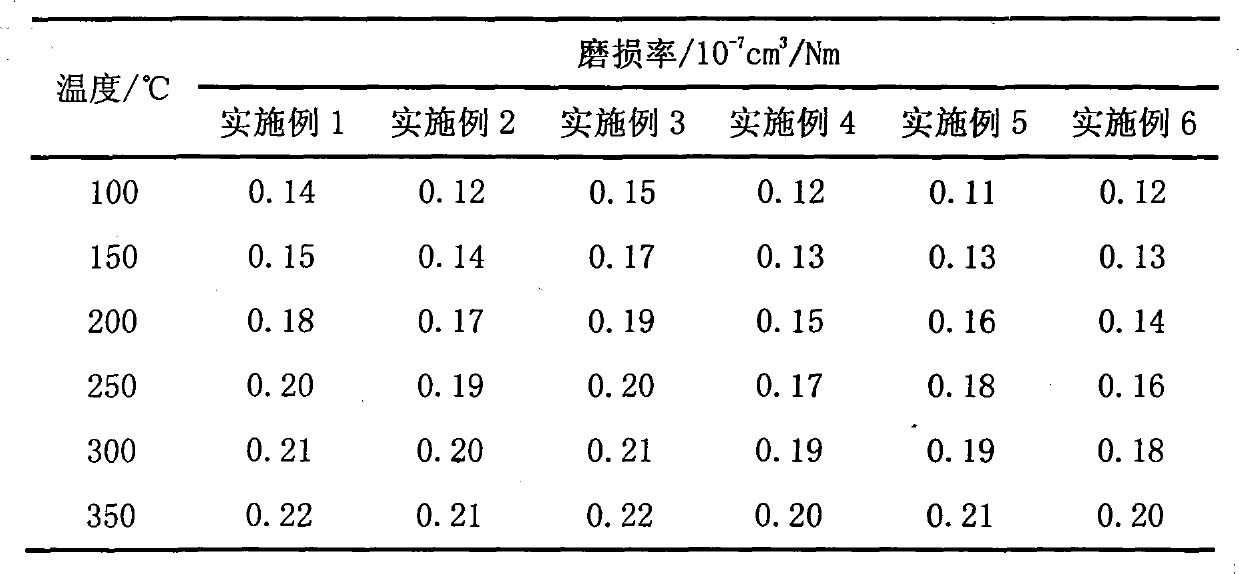

Embodiment 1

[0035] According to weight percentage, alkaline earth metal compound 2%, carbon fiber 2%, phenolic resin 13%, nitrile rubber 4%, aramid fiber 3%, glass fiber 8%, ceramic fiber 4%, zircon 3%, magnesium oxide 4% %, 24% barium sulfate, 7% calcium carbonate, 15% mica powder, 5% vermiculite, and 6% friction powder, put them into a high-speed disperser, stir them evenly, take them out and put them into a mold for pressing and forming, and place them in a flat vulcanizer at 160 ℃, under the condition of pressure 15MPa, hold for 10 minutes, then take out the brake pads, and then sinter at 185 ℃ for 4 hours. Alkaline earth metal compound chooses Mg 0.3 Fe 1.5 TiO 4 , the ratio of equivalent length to equivalent width is 2.5-3, and the thickness is 0.5-5 microns; the carbon fiber is polyacrylonitrile-based carbon fiber.

Embodiment 2

[0037] According to weight percentage, alkaline earth metal compound 30%, carbon fiber 2%, phenolic resin 9%, nitrile rubber 3%, aramid fiber 3%, glass fiber 7%, ceramic fiber 3%, zircon 3%, magnesium oxide 3% %, 19% barium sulfate, 3% calcium carbonate, 5% mica powder, 5% vermiculite, 5% friction powder, put them into the high-speed disperser, stir them evenly, take them out and put them into the abrasive tool for pressing and forming. Under the condition of 160°C and a pressure of 15MPa, hold for 10 minutes, then take out the brake pads, and then sinter at 185°C for 4 hours. Alkaline earth metal compound chooses Mg 0.3 Fe 1.5 TiO 4 , the ratio of equivalent length to equivalent width is 2.5-3, and the thickness is 0.5-5 microns; the carbon fiber is polyacrylonitrile-based carbon fiber.

Embodiment 3

[0039] According to weight percentage, alkaline earth metal compound 2%, carbon fiber 30%, phenolic resin 9%, nitrile rubber 3%, aramid fiber 1%, glass fiber 4%, ceramic fiber 4%, zircon 5%, magnesium oxide 4% %, 24% barium sulfate, 6% calcium carbonate, 3% vermiculite, and 5% fluorite powder are placed in a high-speed disperser, stirred evenly, taken out and put into a mold for pressing and forming, in a flat vulcanizing machine at 160°C, pressure 15MPa Under the conditions, keep it for 10 minutes, then take out the brake pads, and then sinter at 185°C for 4 hours. Alkaline earth metal compound chooses Mg 0.3 Fe 1.5 TiO 4 , the ratio of equivalent length to equivalent width is 2.5-3, and the thickness is 0.5-5 microns; the carbon fiber is polyacrylonitrile-based carbon fiber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com