Patents

Literature

59results about How to "Improved resistance to heat fading" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

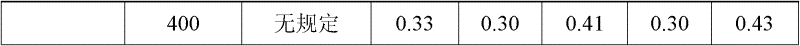

Inventor

Environmental ceramic base friction material free of copper or metal and preparation method of material

InactiveCN103881657AGood mechanical skeleton performanceStable coefficient of frictionOther chemical processesFriction liningSulfurMetallic sulfide

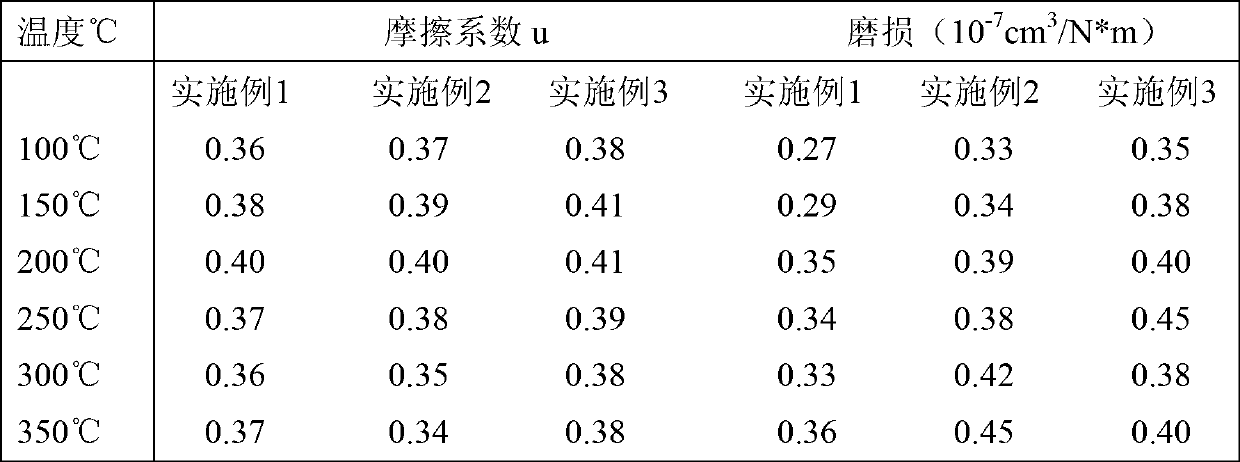

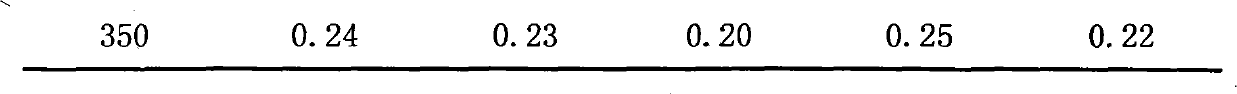

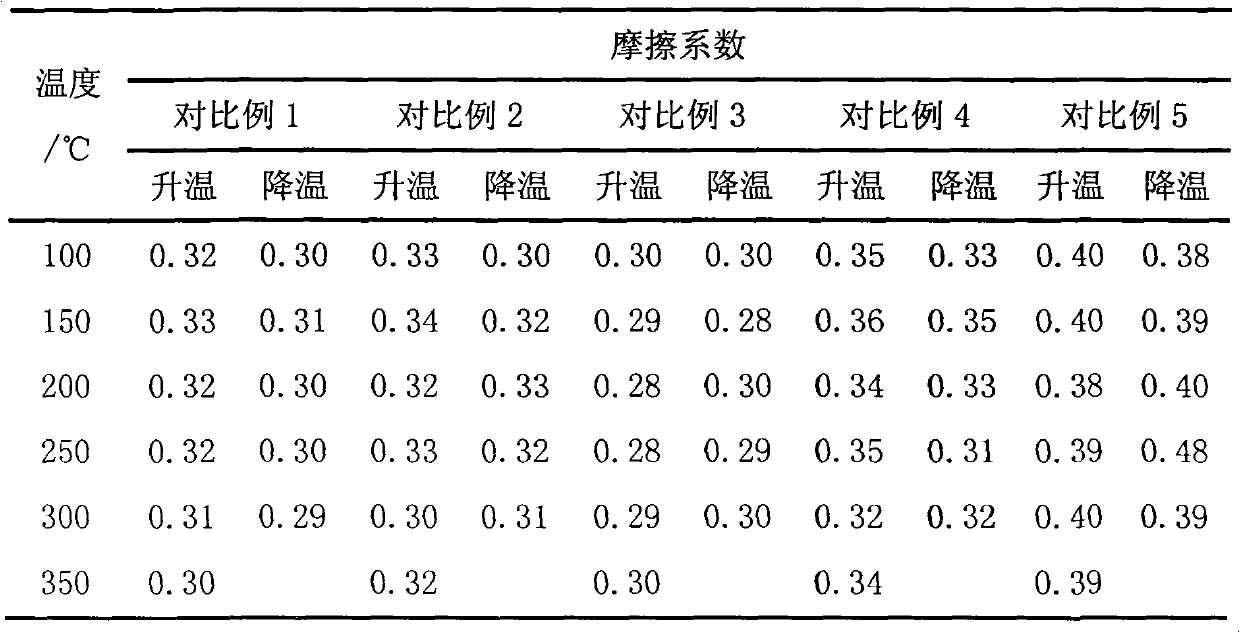

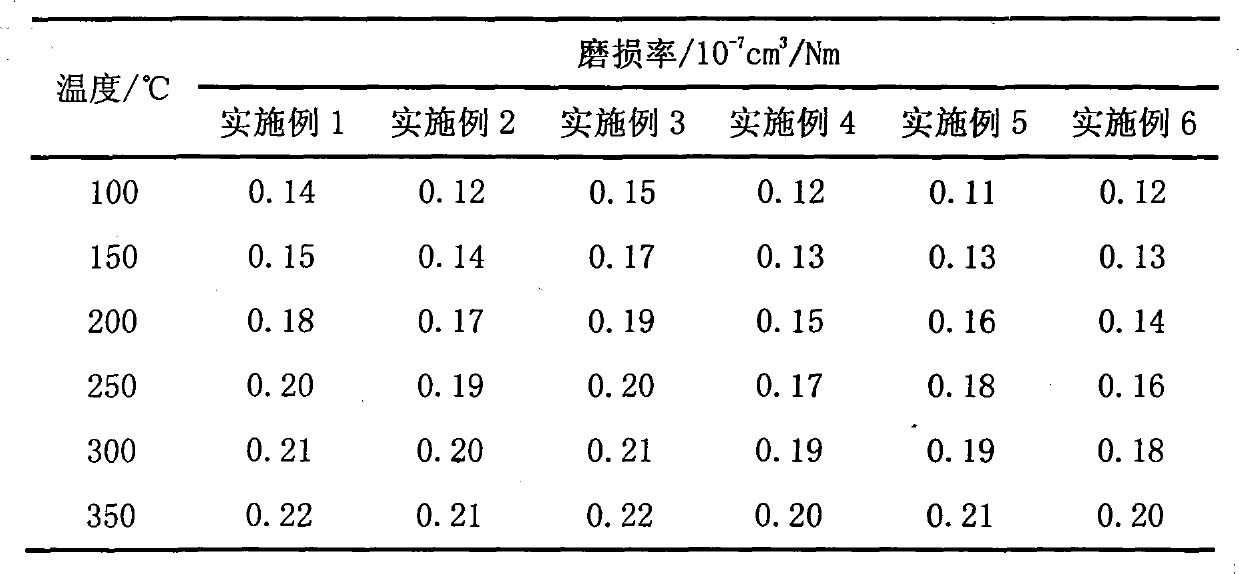

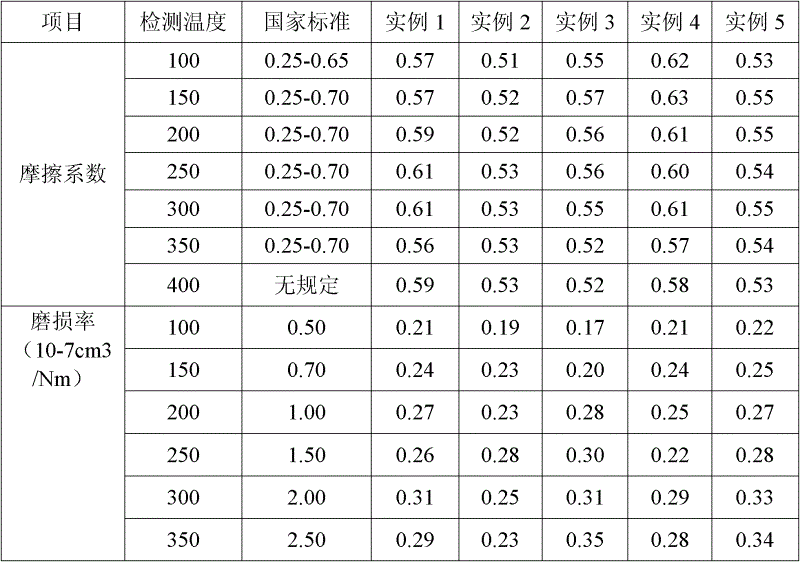

The invention discloses an environmental ceramic base friction material free of copper or metal and a preparation method of the material. The environmental ceramic base friction material is characterized by comprising the following components by weight percent: 6-12% of phenolic resin, 2-10% of ceramic fiber, 2-8% of inorganic fiber, 2-10% of rubber, 4-12% of graphite, 10-25% of potassium titanate lamella, 3-15% of mineral fiber, 4-20% of metal sulfur compound, 6-20% of grinding aid and 5-20% of filler. The prepared friction material has excellent friction and wear properties, high heat-conducting property, excellent high-temperature decline property, stable friction coefficient, and excellent noise performance.

Owner:YANTAI SHENGRUI BRAKE SYST

Reinforced wear-resistant automobile brake composite material and preparation method thereof

ActiveCN103059504AImprove wear resistanceLow costOther chemical processesFriction liningWear resistantCoupling

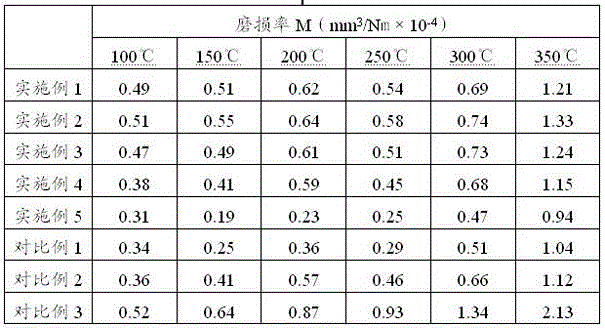

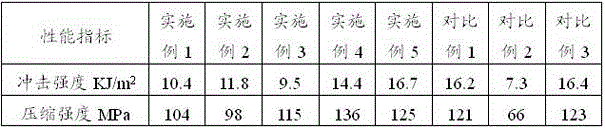

The invention discloses a reinforce wear-resistant automobile brake composite material which is prepared from the following components in parts by weight: 85-100 parts of resin matrix, 100-150 parts of composite reinforcing fiber, 80-120 parts of filler, 25-40 parts of toughening material, 6-10 parts of curing agent, 4-6 parts of curing accelerator, 30-85 parts of frictional property regulator, 30-40 parts of noise reducer and 4.5-6 parts of releasing agent. The resin matrix is reinforced by the composite reinforcing fiber and matched with proper frictional property regulator, filler, toughening material and noise reducer to display the synergic coupling actions among the resin matrix, reinforcing fiber, filler and frictional property regulator, thereby obtaining the novel automobile brake composite material which has the advantages of stable friction factor, small wear rate, high heat fade resistance, favorable braking effect, shock absorption, noise reduction, high mechanical strength, low cost, long service life and favorable braking property at different temperatures.

Owner:江苏裕铭铜业有限公司

Modified phenolic resin adhesive for friction material and preparation method for modified phenolic resin adhesive

ActiveCN102516911AIncrease reaction rateImprove heat resistanceAldehyde/ketone condensation polymer adhesivesConjugated diene hydrocarbon adhesivesTemperature resistanceCardanol

The invention discloses a modified phenolic resin adhesive for a friction material and a preparation method for the modified phenolic resin adhesive. The method comprises the following steps of: mixing 100 mass parts of phenol, 60 to 120 mass parts of 37 mass percent formaldehyde solution, 2 to 20 mass parts of amine substance and 8 to 40 mass parts of cardanol uniformly, dripping 1 to 20 parts of composite catalyst, heating to the temperature of between 80 and 105 DEG C, and performing constant-temperature reaction for 0.5 to 2 hours; and adding 0 to 10 parts of acid catalyst, continuously performing constant-temperature reaction for 1 to 2 hours to obtain orange milky dope, washing the orange milky dope for 2 to 5 times in water of 60 to 70 DEG C, drying, dehydrating, and thus obtaining the cardanol and amine substance modified phenolic resin adhesive. The amine substance can be well dissolved, so that the reaction rate is quickened; the toughness of the modified phenolic resin adhesive is further enhanced by adding powdery nitrile rubber; and the friction material prepared by using the modified phenolic resin adhesive has the advantages of low abrasion rate, long service life, high toughness, high-temperature resistance, high-strength impact resistance and low noise.

Owner:HUANGSHI JINZHAOYANG POWDER MATERIALS

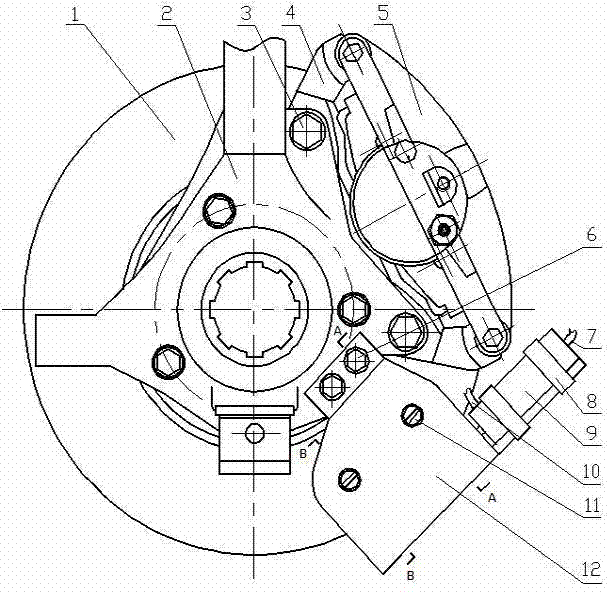

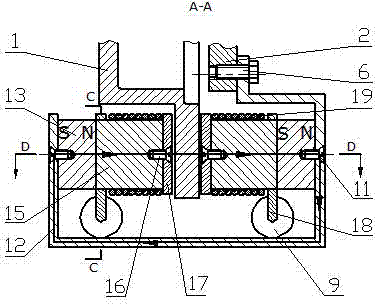

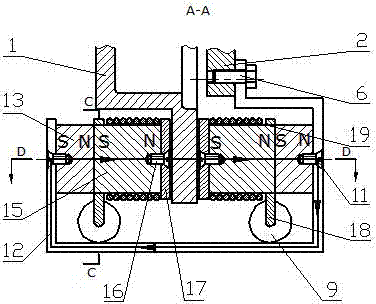

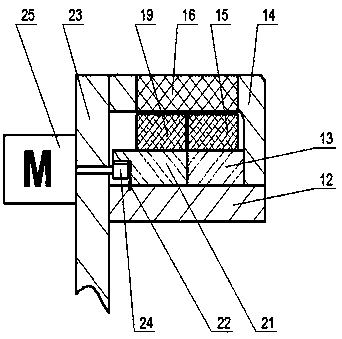

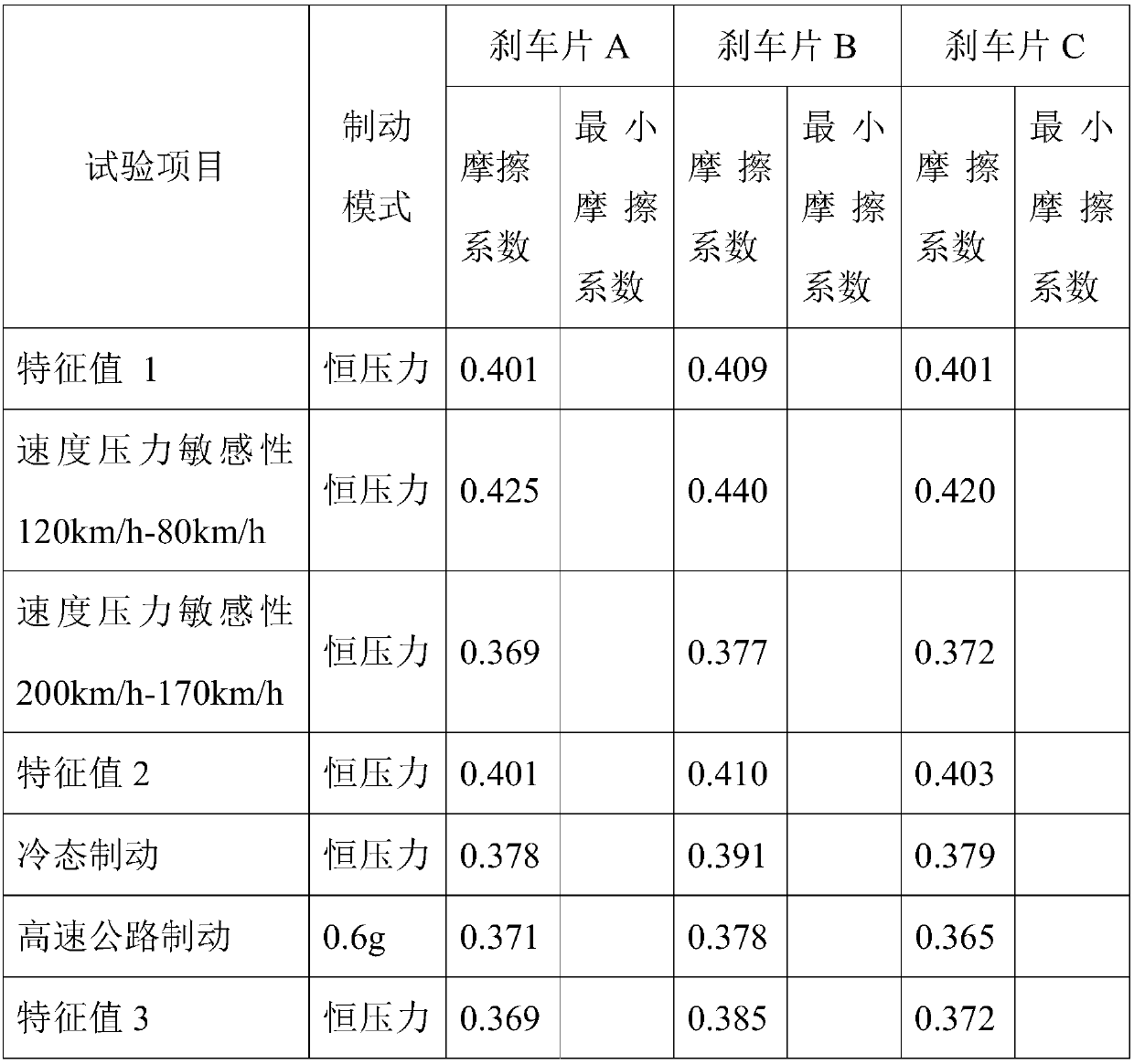

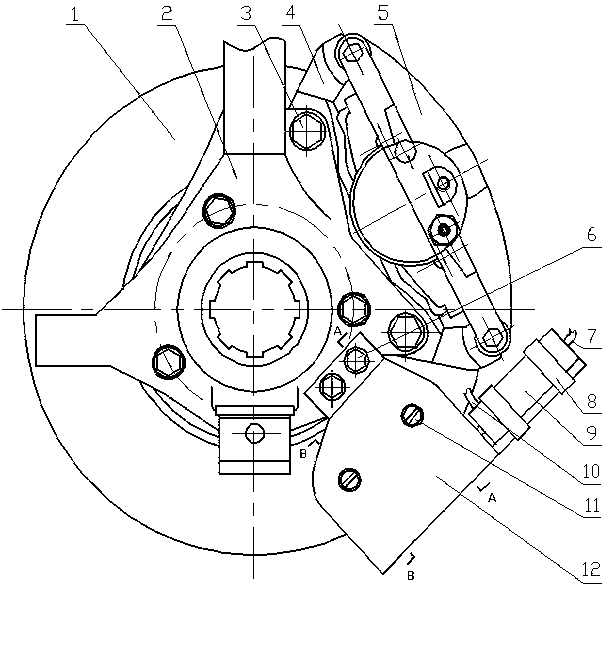

Hybrid brake combined with magnetic brake and friction brake and working mode switching method

ActiveCN102287460AUse lessReduce generationElectrodynamic brake systemsBrake typesBrake torqueCalipers

The invention discloses a magnetic brake and friction brake combined mixed brake and an operating mode switching method thereof. A brake caliper body side is provided with a magnetic brake fixing frame which is fixedly connected with a steering knuckle; the magnetic brake fixing frame is axially fixedly connected with the outer ends of each permanent magnet and each magnetic conducting block; an inner end side of each permanent magnet is provided with an iron core; an inner end of the iron core is fixedly connected with a magnetic conducting plate, and a side face of the iron core is connected with an upper end of a push rod; a lower end of the push rod extends into an oil cylinder; a coil winding is wound outside the iron core; a pair of permanent magnets, iron cores, magnetic conductingplates, coil windings, push rods and oil cylinders are arranged and symmetrically distributed on two sides of a brake disc; and both ends of each oil cylinder are provided with an oil way interface. Retarding brake can be switched back and forth among electromagnetic brake, permanent magnet brake and electromagnetic and permanent magnet brake, the brake requirement of an automobile under different working conditions is met, braking force of electromagnetic and permanent magnet superposed brake is higher than that of only permanent magnet brake, and more needed brake torque in the process of braking the automobile can be borne; and heat-resistant recession of the brake and riding comfort are improved.

Owner:JIANGSU UNIV

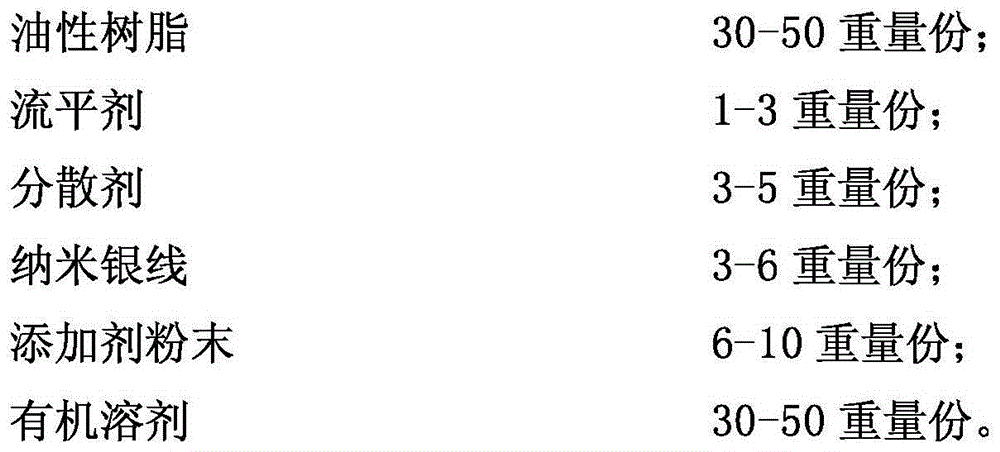

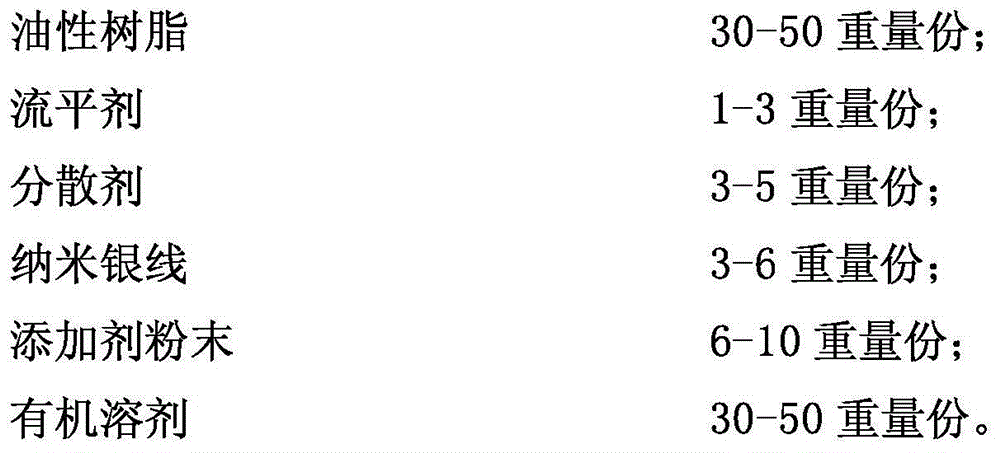

Heat-resistant flexible transparent conductive film and preparation method thereof

InactiveCN104464880AImprove conductivityImprove heat resistanceConductive layers on insulating-supportsNon-conductive material with dispersed conductive materialFiberCarbon fibers

The invention discloses a heat-resistant flexible transparent conductive film and a preparation method of the film. According to the film, the surface of PET is coated with coating, and then the film is prepared after being dried . According to the formula of the coating, the coating is composed of nanometer silver wires, oleoresin, additive powder, flatting agents and a proper quantity of organic solvents. The nanometer silver wires excellent in electrical conductivity and mixed additives composed of carbon fibers, nanometer limestone powder, nanometer palygorskite powder, nanometer aluminum oxide powder and propyl gallate are adopted for improving the electrical conductivity and the heat resistance of the film. The heat-resistant flexible transparent conductive film is low in cost and raw materials are easy to obtain.

Owner:SUZHOU SIDIKE NEW MATERIALS SCI & TECH

Preparation method of friction particles, composition of friction particles and friction material and friction material

ActiveCN102101916AStable coefficient of frictionImproved resistance to heat fadingFriction liningFiberAdhesive

The invention provides a preparation method of friction particles. The method comprises the following steps of: uniformly mixing the friction particles as raw materials with water to obtain slurry, wherein the friction particles as the raw material contain fibers, resin, a water-soluble adhesive and a filler, and the weight ratio of water to the water-soluble adhesive is (1-3):1; pelletizing the slurry to obtain particles; and drying the particles at the temperature of between 100 DEG C and 120 DEG C for 30-60 minutes. The invention also provides friction particles obtained by the method provided by the invention. The invention provides a friction material composition, wherein the friction material composition contains the friction particles, tubular fibers, powder resin and a powder filler; and the friction particles are the friction particles provided by the invention. The invention also provides a friction material for preparing a brake pad. The friction material is obtained by performing hot press molding and thermal treatment on the friction material composition, wherein the friction material composition is the friction material composition provided by the invention.

Owner:BYD CO LTD

Vibration-damping, denoising and yaw low-speed braking pad and fabrication method thereof

ActiveCN103256325AStable coefficient of frictionGood high temperature friction performanceFriction liningLow speedCarbon fibers

The invention relates to a braking pad, in particular to a vibration-damping, denoising and yaw low-speed braking pad for a yaw braking device of a wind generating set and a fabrication method of the braking pad. The vibration-damping, denoising and yaw low-speed braking pad comprises a steel backing and an abrasive layer attached to the steel backing, wherein the abrasive layer is fabricated by taking PTS (Phenolic Thermospheres) suspension method phenolic resin as a gluing agent, taking graphite, tin sulfide and copper sulfide as a lubricant, taking antimony trisulfide, zirconium silicate, silicon carbide and silicon dioxide as an abradant, taking potassium titanate whiskers, ceramic fibers, aramid fibers, carbon fibers, steel fibers and copper fibers as reinforced fibers, taking calcium carbonate, mica, vermiculite and foam ferrous powder as an inorganic filler, and taking cashew nut shell oil friction powder and rubber powder as an organic filler according to a wet method pressing technology. The braking pad has the advantages that component percentages of a friction material and a processing technology are reasonable; the braking sensitivity is high; the braking vibration is small; the friction noise is low; and the braking pad is provided with a pad abrasion alarm line.

Owner:JIAOZUO LICHUANG BRAKE

Method for preparing clutch facing through taking water soluble phenol-formaldehyde resin as adhesion agent

The invention discloses a method for preparing a clutch facing through taking water soluble phenol-formaldehyde resin as an adhesion agent. The method adopts the water soluble phenol-formaldehyde resin which is multiply modified by polyvinyl alcohol, nanoscale attapulgite and micron-order copper powder as the adhesion agent, the water soluble phenol-formaldehyde resin, a friction performance conditioning agent and water are mixed to produce slurry, fibers are soaked in the slurry, are dried and are wound to form a parison, the parison is then subjected to hot-press forming to form the facing, grinding and drilling are carried out after the thermal treatment, the clutch facing is obtained. The modified adhesion agent has high solubility, cohesiveness, toughness, heat resistance, thermal fading resistance and abrasion resistance; and the clutch facing which is produced through the adhesion agent is low in cost, green and environment-friendly, can bear impact force during the processing and using processes, cannot crack and has high thermal stability, high and stable friction coefficient and low abrasion resistance.

Owner:浙江科马摩擦材料股份有限公司

Copper-free ceramic type friction material and preparation method thereof

InactiveCN101948673AImprove thermal conductivityImprove friction performanceOther chemical processesCeramic shaping apparatusFiberAlkaline earth metal

The invention discloses a copper-free ceramic type friction material and a preparation method thereof. The friction material at least comprises 2 to 30 mass percent of alkaline earth-based metallic compound and 2 to 30 mass percent of carbon fiber, wherein the alkaline earth-based metallic compound is MxFeyTiOz, M is alkaline earth metallic element, namely Be, Mg, Ca, Sr or Ba, x is 0.2 to 2, y is 1 to 2, and z is 4 to 16. The friction material prepared by the method has the advantages of: high friction and wear property, higher heat conductivity, high performance of resisting high-temperature recession, and capacity of efficiently reducing the temperature of a friction surface in the braking process.

Owner:南京钛威科技有限公司 +1

Environment-friendly type ceramic-based friction material

InactiveCN104164211AImproved resistance to heat fadingImprove thermal conductivityOther chemical processesFriction liningBorideFiber

The invention discloses an environment-friendly type ceramic-based friction material, and is characterized in that the ceramic-based friction material includes the following materials in parts by weight: 16-31 parts of cashew nut shell oil modified phenolic resin, 3-18 parts of carbon fiber, 12-30 parts of organosilicon modified phenolic resin, 25-60 parts of graphite, 3-9 parts of molybdenum disulfide, 11-14 parts of a talc powder, 3-9 parts of mica, 5-18 parts of zircon, 35-60 parts of ceramic fiber, 20-60 parts of butadiene-acrylonitrile rubber, 10-20 parts of a scallop shell powder, 3.5-7 parts of a zeolite powder, 1.5-3.9 parts of zinc sulfide, 1-5 parts of hornblende, 5-11 parts of borax, 3-6 parts of titanium oxide, 0-2 parts of quartz sand, 4-8 parts of a boride, 6-18 parts of silicon nitride, and 1-5 parts of titanium carbide. The ceramic-based friction material has the beneficial effects that the ceramic-based friction material has excellent heat-conducting property, ensures the stability of the friction material, improves heat fading resistance of the friction material, provides good and stable braking force output, and has longer service life and comfort.

Owner:QINGDAO QIANXIANG ENVIRONMENTAL PROTECTION TECH

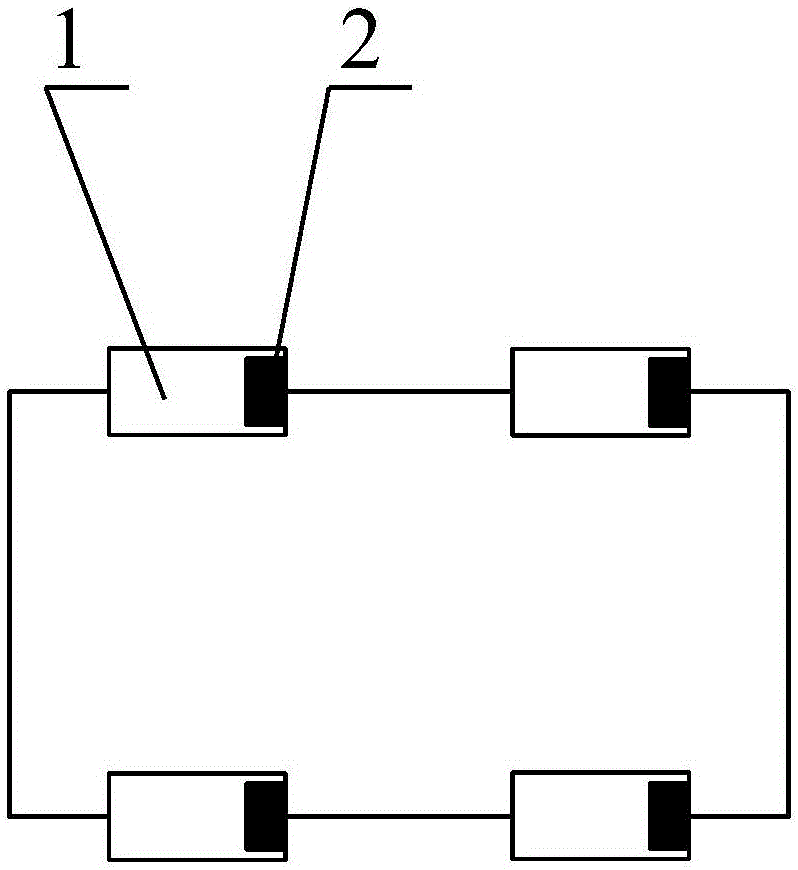

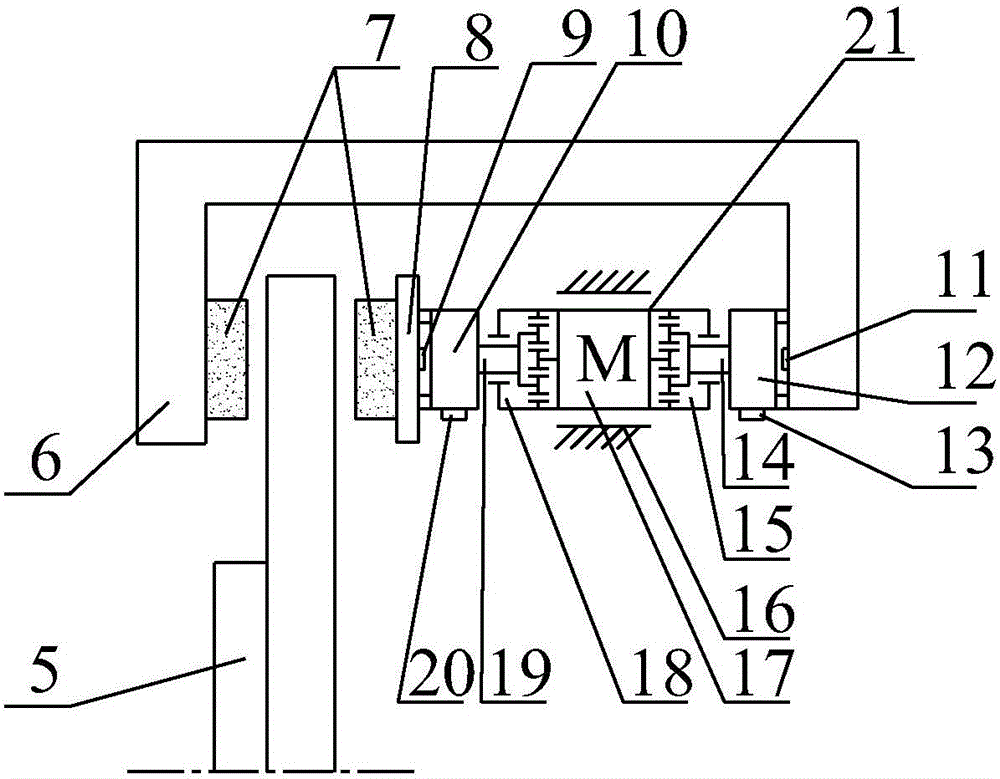

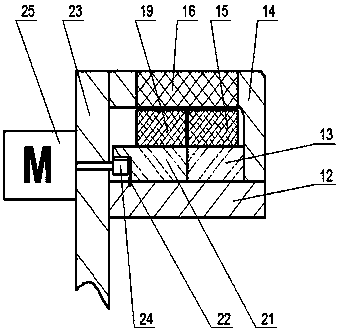

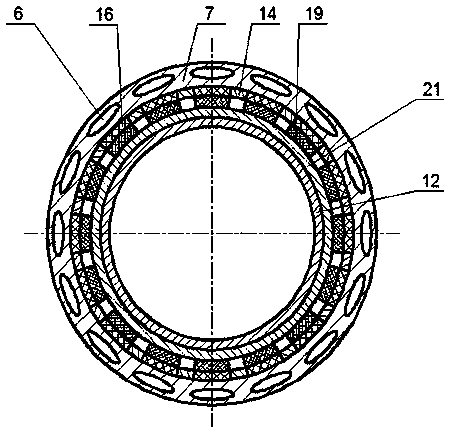

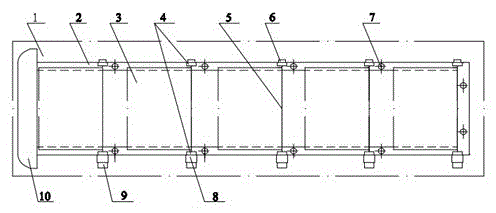

Double-motor brake actuation mechanism of vehicle decoupling distribution brake system

ActiveCN106523551AImprove utilization efficiencyExtended service lifeAxially engaging brakesBrake actuating mechanismsElectricityPower flow

The invention relates to the technical field of vehicle brake, in particular to a double-motor brake actuation mechanism of a vehicle decoupling distribution brake system. The mechanism comprises a brake disc, a brake actuation part and a regeneration motor part; the brake actuation part includes a stepper motor and a brake clamp body; two ends of the brake clamp body are respectively positioned on two sides of the brake disc; the brake clamp body and the stepper motor are both slidingly connected with a shell of the brake actuation part; a friction block is arranged at one end of the brake clamp body; the other end of the brake clamp body is connected with the stepper motor; the stepper motor is in transmission connection with a first lead screw; a first nut is arranged on the first lead screw, and is connected with the friction block; the friction block on the brake clamp body and a friction block on a first nut are positioned on two sides of the brake disc; the regeneration motor part includes an electromagnetic clutch, a regeneration motor, a battery set and an electronic control unit; the battery set is electrically connected with the stepper motor; and the electronic control unit controls connection and disconnection of current between the battery set and the stepper motor. The mechanism converts brake energy to electric energy as brake power, and can share brake loads.

Owner:JIANGSU UNIV OF TECH

High temperature-resistant heavy-duty vehicle brake disc

InactiveCN106084631AIncrease coefficient of frictionImprove wear resistanceFriction liningActuatorsCarbon fibersSic fiber

The invention discloses a high temperature-resistant heavy-duty vehicle brake disc. The high temperature-resistant heavy-duty vehicle brake disc comprises a steel sheet and a friction base material pasted on the steel sheet, raw materials of the friction base material comprise phenolic resin, hydroxyl-terminated liquid polybutadiene rubber, acrylate rubber, silicone rubber, composite modified graphite, meerschaum fibers, potassium titanate whiskers, carbon fibers, aluminum fibers, silicon carbide fibers, molybdenum fibers, talcum powder, zirconium silicide, aluminum carbide, barium sulfate, zinc stannate, octaphenyl silsesquioxane and zirconium boride; and the composite modified graphite is prepared through the following steps: adding phenolic resin, a silane coupling agent KH-550, natural graphite oxide, nano-silica, nanometer titanium dioxide, nano-alumina, ethyl orthosilicate and phenyltriethoxysilane to ethanol, uniformly mixing above added materials and ethanol, stirring the added materials and ethanol at normal temperature for 2-4 h, heating the obtained mixture to 65-75 DEG C, stirring the heated mixture for 20-50 min, evaporating the stirred mixture, drying the evaporated mixture, carrying out dry crushing, and filtering the crushed mixture through a 300-350 mesh sieve.

Owner:NINGGUO FEIYING AUTO SPARE PARTS

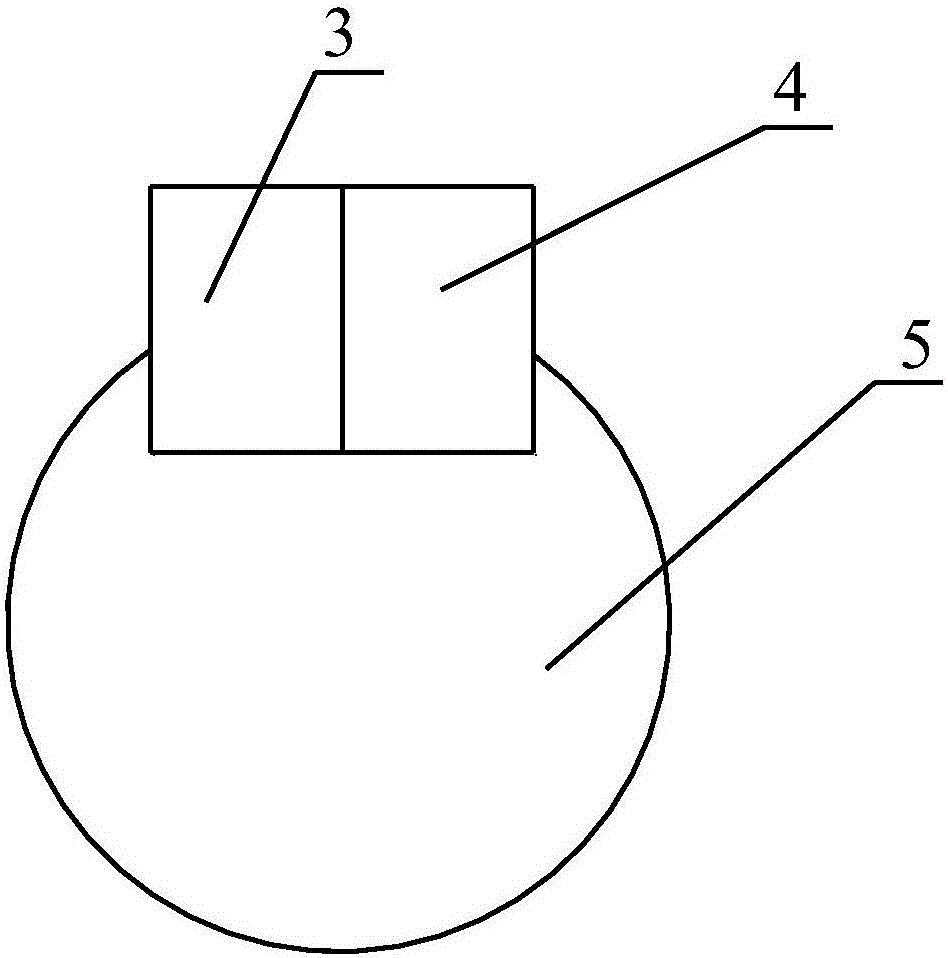

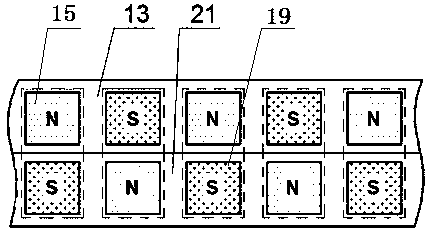

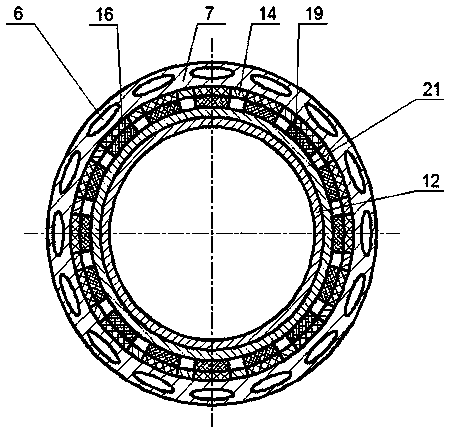

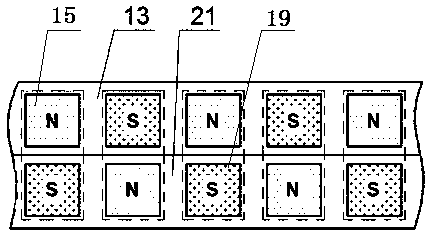

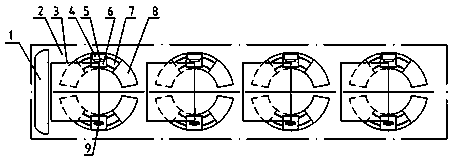

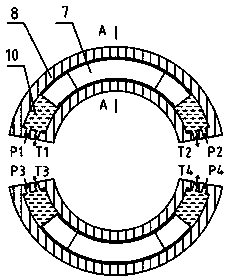

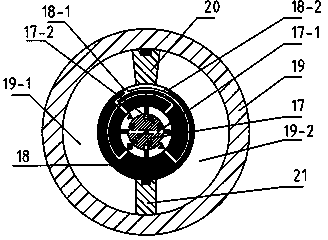

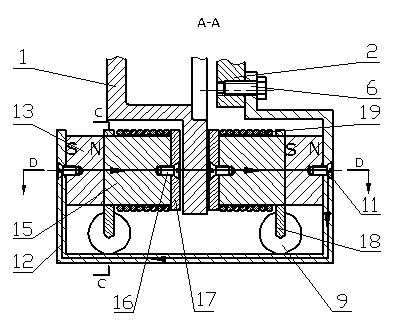

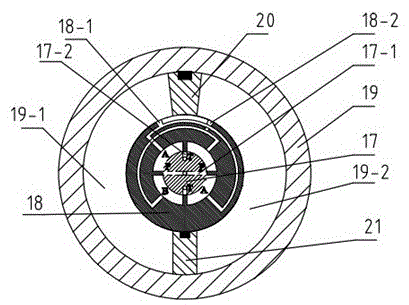

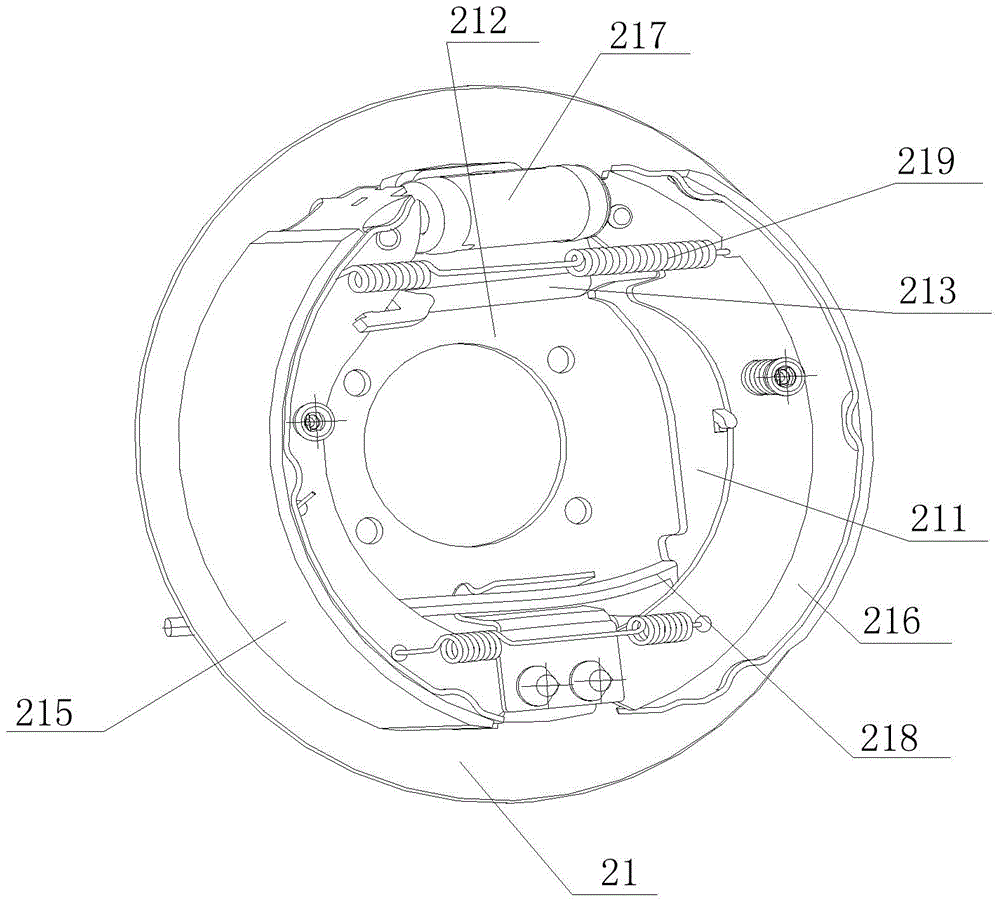

A vehicle wheel-side composite braking device integrating permanent magnet braking and friction braking

ActiveCN109058328BImproved resistance to heat fadingReduce wearBraking discsBrake actuating mechanismsClassical mechanicsMagnetic poles

Owner:合肥九州龙腾科技成果转化有限公司

Whisker composite material for reinforcing automobile brake friction and a method for producing the same

The invention provides a whisker composite material for reinforcing automobile brake friction and a method for producing the same, wherein the composite friction material consists of basic magneislum whisker, pyrophyllite power, phenol resin, copper powder, graphite powder, aluminium oxide and zine stearate, as raw materials; the producing method comprises raw material pretreatment, raw material mixing, hot press molding and cooling. The invention achieves the phenol resin reinforcement by the basic magneislum whisker [MgSO4.5MgO.8H2O] with excellent low cost, selects the pyrophyllite [Al4Si8O20OH4] as the filler for the assorted fiber brake friction material, the concerted coupling function of a substrate, the whister and the filler can be exerted according to the addition of a friction reinforcing agent, and an antiwear agent, thereby the novel automobile brake composite material has advantages of good heat resistance, moderate coefficient of friction, small wear rate, well heat fade resistance, good brake effect and low cost.

Owner:FUZHOU UNIV

Vehicle wheel rim composite brake device integrating permanent magnet braking and friction braking

ActiveCN109058328AReduce wearImproved resistance to heat fadingBraking discsBrake actuating mechanismsPole pieceMagnetic circuit

The invention discloses a vehicle wheel rim composite brake device integrating permanent magnet braking and friction braking, and belongs to the field of vehicle braking. A support base ring is coaxially sleeved with an integrated brake disc, the support base ring is coaxially and fixedly sleeved with a magnetic circuit guide frame, a plurality of magnetic conductive pole pieces are evenly embedded in the side wall of the magnetic circuit guide frame in the circumferential direction, the support base ring is sleeved with a movable magnet support through a bearing, the support base ring is fixedly sleeved with a fixed magnet support, a plurality of movable magnets are evenly and fixedly connected to the outer wall of the movable magnet support in the circumferential direction, a plurality of fixed magnets are evenly and fixedly connected to the outer wall of the fixed magnet support in the circumferential direction, the movable magnets and one fixed magnet are arranged left and right inthe axial direction, the fixed magnets and the movable magnets which are opposite in the axial direction at the initial position are opposite in magnetizing direction, the movable magnets are rotatedto enable each movable magnet and the corresponding fixed magnet opposite to the movable magnet in the axial direction to be the same in magnetizing direction during permanent magnet braking, brakingenergy is shared through non-contact permanent magnet braking, and friction braking abrasion is reduced.

Owner:JIANGSU UNIV

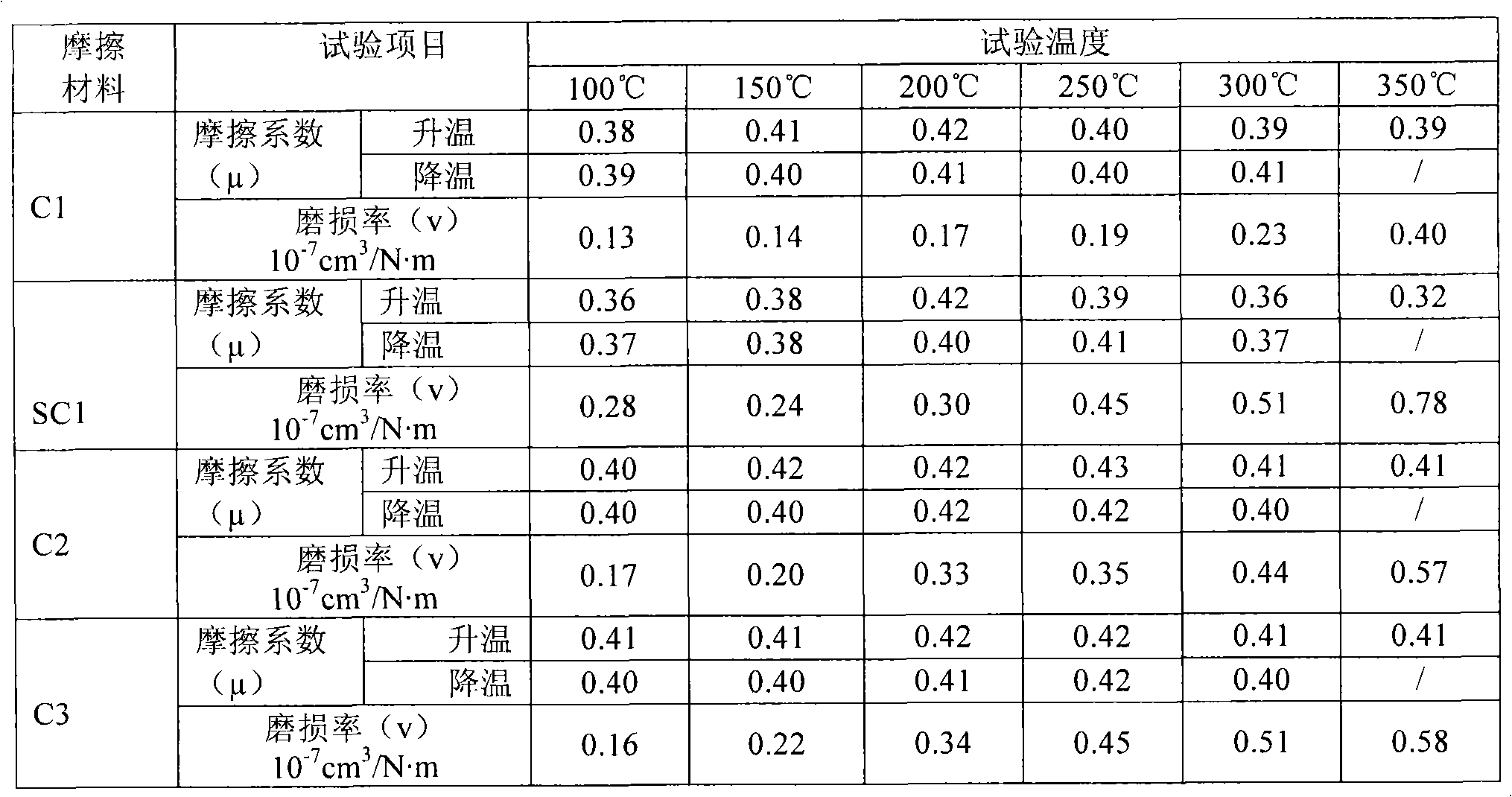

Ceramic-like friction material and preparation method thereof

InactiveCN102618216AImproved resistance to heat fadingCoefficient of friction without attenuationOther chemical processesHeat resistanceOrganic synthesis

The invention discloses a ceramic-like friction material and a preparation method thereof, and is used for solving the technical problem that the friction material prepared by the traditional method is poor in heat resistance. The technical scheme is as follows: in the components of the friction material, powdery silicate inorganic binder replaces the organic binder in the prior art to prepare the ceramic-like high-temperature-resistant friction material, so that the heat fading resistance of the friction material is improved. The preparation method of the ceramic-like friction material adopts a preparing process of organically synthesizing the friction material, the friction material with ceramic characteristics is prepared by dry-process mixing and low-temperature treatment, and by test with a constant speed testing machine, the result shows that the friction factor does not attenuate at 400 DEG C.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Automobile brake lining

InactiveCN105202075AGood strengthExcellent wear resistanceOther chemical processesBraking membersBrake liningOxide

An automobile brake lining is prepared from, by weight, 14%-18% of ceramic fibers, 3%-6% of carbon fibers, 3%-7% of cellulose fibers, 8%-13% of aramid fibers, 8%-13% of modified phenolic resin, 2%-4% of aluminium oxide, 3%-5% of barium sulphide, 6%-9% of graphite, 4%-6% of zirconite, 8%-12% of quartz sand, 1%-2% of bauxite, 1%-2% of zinc oxide, 2%-4% of chemigum, 1%-4% of antimony sulfide, 7%-10% of friction powder and 6%-9% of nanometer silicon carbide. According to the automobile brake lining, a ceramic brake pad is kept to be stable in braking, low in noise and the like, the mechanical strength of the brake lining is further improved, and the service life of the brake lining is prolonged; meanwhile, recession and expansion of the high temperature can be avoided, and the automobile brake lining has the advantages of being good in braking performance and abrasion resistance, stable in braking, less in dust, moderate in hardness and good in high temperature recovery performance.

Owner:刘桂华

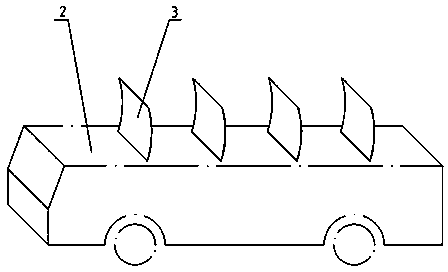

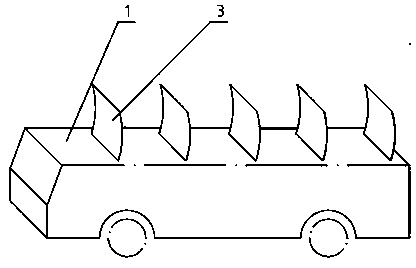

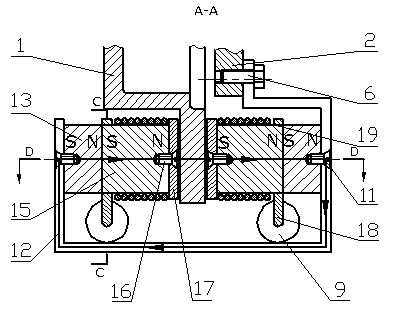

Roof steering follow-up air resistance retarder

ActiveCN103522995AImproved resistance to heat fadingLow costBraking element arrangementsAerospace engineeringThermal load

The invention discloses a roof steering follow-up air resistance retarder comprising a control system, a fixed support and at least one sub-retarder. Each sub-retarder comprises a wind resisting blade, a steering follow-up mechanism, a transmission mechanism and a locking mechanism, wherein the steering follow-up mechanism is used for driving the wind resisting blade to perpendicularly rotate in relation to a car roof and mounted on the fixed support, the transmission mechanism is used for driving the wind resisting blade to horizontally swing in relation to the car roof and mounted on the steering follow-up mechanism, the transmission mechanism comprises rotating shafts and a motor, the rotating shafts are rotatably supported on the steering follow-up mechanism, the motor is movably connected with the rotating shafts, one wind resisting blade is fixedly connected to each rotating shaft, the locking mechanism disposed on the rotating shafts is used for limiting the swing angles of the rotating shafts which horizontally swing in relation to the car roof. The roof steering follow-up air resistance retarder has the advantages that the roof steering follow-up air resistance retarder has the steering follow-up function, a car is retarded by means of air resistance, thermal load of a frictional brake during vehicle continuous braking and continuous downhill running is distributed effectively, heat fading is prevented, vehicle driving safety is improved, and wear of the frictional brake is reduced.

Owner:JIANGSU UNIV OF TECH

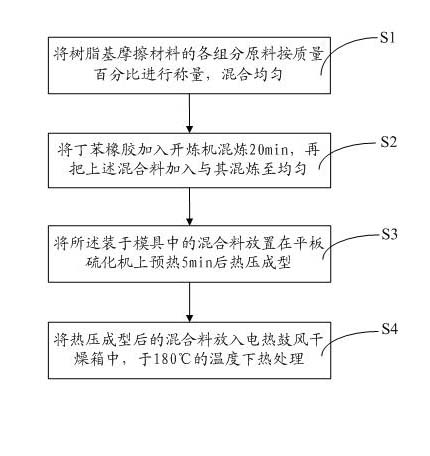

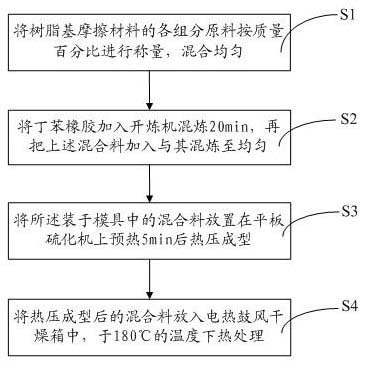

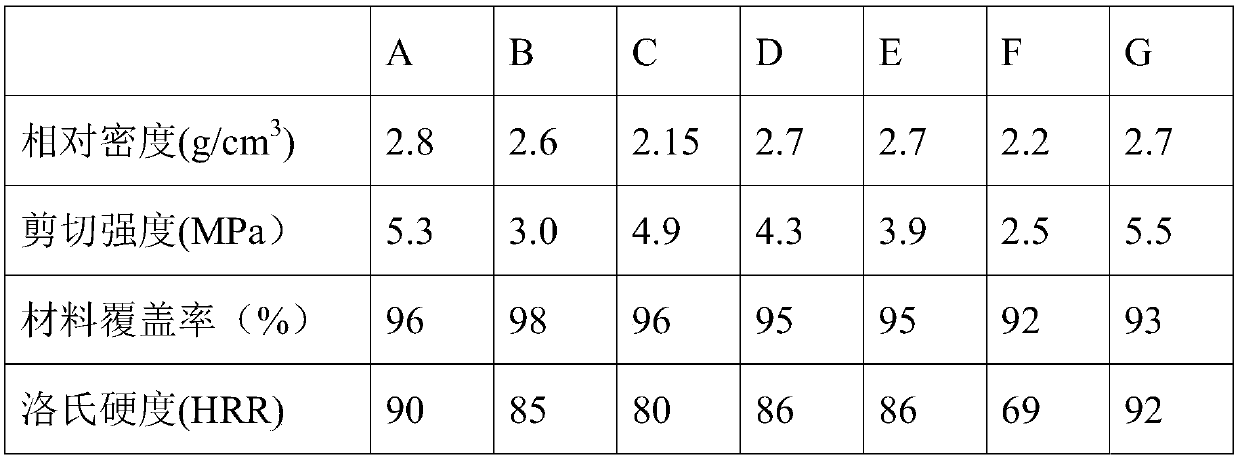

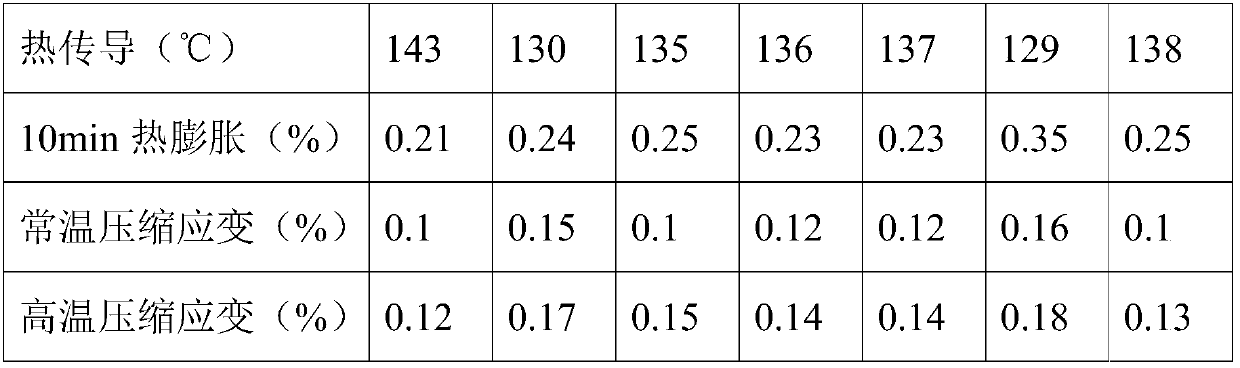

Resin-based friction material

InactiveCN101967366AImprove thermal stabilityImproved resistance to heat fadingOther chemical processesCarbon blackPolymer chemistry

The invention provides a resin-based friction material, which comprises the following components in percent by mass: 10 to 40 percent of mullite, 10 to 30 percent of phenolic resin, 10 to 30 percent of butadiene rubber, 10 to 30 percent of barium sulfate, 5 to 20 percent of feldspar powder, 1 to 10 percent of carbon black and 0.1 to 5 percent of zinc stearate, wherein the sum of the percent content of each component of the resin-based friction material is 100 percent. In the resin-based friction material, the mullite is taken as a component material of the friction material, and the high specific heat of the mullite is utilized to improve the thermal stability of the resin-based friction material, so that the heat fading resistance of an organic group friction material is greatly improved.

Owner:YANCHENG INST OF TECH

Metallurgical friction material for high and cold area high-speed train brake pad

InactiveCN106838079AImprove heat resistanceImprove the ability to resist heat declineOther chemical processesFriction liningDriving safetyCold area

A metallurgical friction material for high-speed train brake pads in alpine regions of the present invention relates to the field of powder metallurgy materials and is composed of the following components in parts by weight: 30-70 parts of copper, 10-30 parts of iron, 5-30 parts of graphite 20 parts, 1-20 parts of zirconia, 1-10 parts of molybdenum disulfide, 3-5 parts of silicon carbide, 1-5 parts of tin, 1-5 parts of manganese, 1-5 parts of nickel, 0.5-5 parts of ferrochromium, 1.5-3.5 parts of aluminosilicate ore powder. A metallurgical friction material for brake pads of high-speed trains in alpine regions according to the present invention is suitable for making brake pads for high-speed trains in high-cold regions. Compared with the existing metallurgical friction materials, silicon carbide and mullite are added. These two ingredients improve the product's ability to resist heat fading, avoiding the possible heat fading phenomenon of brake pads in alpine regions, and greatly ensuring the safety of high-speed trains in alpine regions. At the same time, they can obtain good physical and mechanical properties and stability. friction and wear performance.

Owner:黑龙江省瑞相制动装备有限责任公司

Friction material, organic carbon ceramic brake pad prepared from friction material and used for abrasion-resistant coating braking disc, and preparation method and application of organic carbon ceramic brake pad

ActiveCN109555802AHigh strengthImproved resistance to heat fadingOther chemical processesFriction liningCarbon fibersNew energy

The invention relates to the technical field of brake materials, in particular to a friction material, an organic carbon ceramic brake pad prepared from the friction material and used for an abrasion-resistant coating braking disc, and a preparation method and application of the organic carbon ceramic brake pad. The friction material is prepared from the following raw materials in parts by weight:3-5 parts of carbon fibers, 10-15 parts of steel fibers, 5-10 parts of mineral fibers, 8-12 parts of modified phenolic resin, 5-10 parts of powdered nitrile rubber, 6-10 parts of cashew nut oil frictional powder, 10-20 parts of precipitated barium sulfate, 1-3 parts of acrylic fibers, 2-4 parts of silicon carbide, 5-10 parts of soft kaolin and 9-12 parts of zirconium silicate. The preparation method of the organic carbon ceramic brake pad comprises the steps of pressing, solidifying and forming. The organic carbon ceramic brake pad for the abrasion-resistant coating braking disc is stable instructure, good in heat resistance and friction performance, simple in preparation process and short in preparation period, the matching property between the organic carbon ceramic brake pad and the abrasion-resistant coating braking disc is good, an abrasion-resistant friction pair is made of the organic carbon ceramic brake pad and the abrasion-resistant coating braking disc, and the service life of the braking disc of an automobile, or a new energy vehicle or a bullet train can be effectively prolonged.

Owner:BEIJING TIANRENDAOHE NEW MATERIAL CO LTD

Ceramic based friction materials with high stability

InactiveCN105131905AImproved resistance to heat fadingImprove thermal conductivityOther chemical processesFriction liningFiberBoride

The invention discloses ceramic based friction materials with the high stability. The ceramic based friction materials with the high stability are characterized by being prepared from, by weight, 25-41 parts of cashew nut shell oil modified phenolic resin, 3-15 parts of medical stone, 2-11 parts of boride, 6-17 parts of rock wool, 1.5-3.6 parts of magnesium oxide, 3-21 parts of fiber brucite, 5-21 parts of vermiculite, 25-62 parts of calcite, 8-41 parts of potassium feldspar, 8-15 parts of carbon fiber, 5-11 parts of calcium oxide, 25-46 parts of Datong soil, 3-12 parts of water glass binders, 2-8 parts of silicon nitride and 1-5 parts of titanium carbide. According to the ceramic based friction materials with the high stability, an excellent thermal conductivity property is achieved, the stability of the friction materials is guaranteed, the heat fading resistance of the friction materials is improved, good and stable braking force output is provided, and the long service life and the comfort are achieved.

Owner:宁贻伟

Preparation method of friction particles, composition of friction particles and friction material and friction material

ActiveCN102101916BStable coefficient of frictionImproved resistance to heat fadingFriction liningFiberAdhesive

The invention provides a preparation method of friction particles. The method comprises the following steps of: uniformly mixing the friction particles as raw materials with water to obtain slurry, wherein the friction particles as the raw material contain fibers, resin, a water-soluble adhesive and a filler, and the weight ratio of water to the water-soluble adhesive is (1-3):1; pelletizing the slurry to obtain particles; and drying the particles at the temperature of between 100 DEG C and 120 DEG C for 30-60 minutes. The invention also provides friction particles obtained by the method provided by the invention. The invention provides a friction material composition, wherein the friction material composition contains the friction particles, tubular fibers, powder resin and a powder filler; and the friction particles are the friction particles provided by the invention. The invention also provides a friction material for preparing a brake pad. The friction material is obtained by performing hot press molding and thermal treatment on the friction material composition, wherein the friction material composition is the friction material composition provided by the invention.

Owner:BYD CO LTD

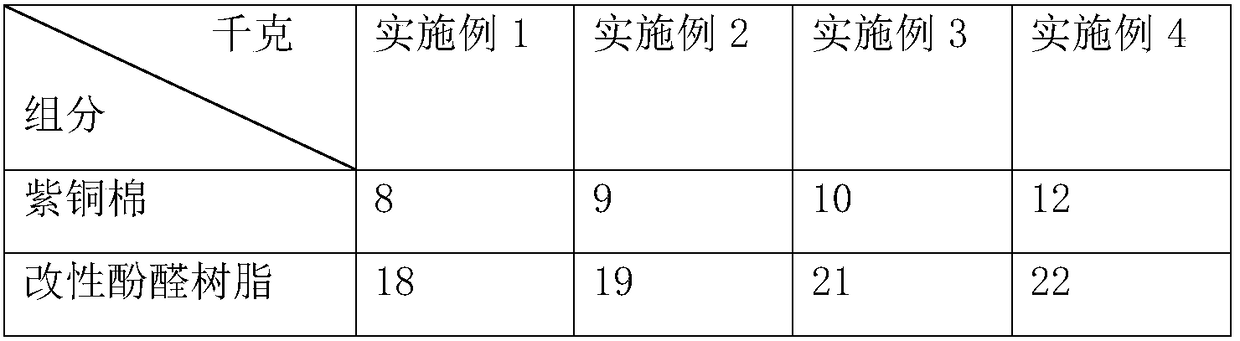

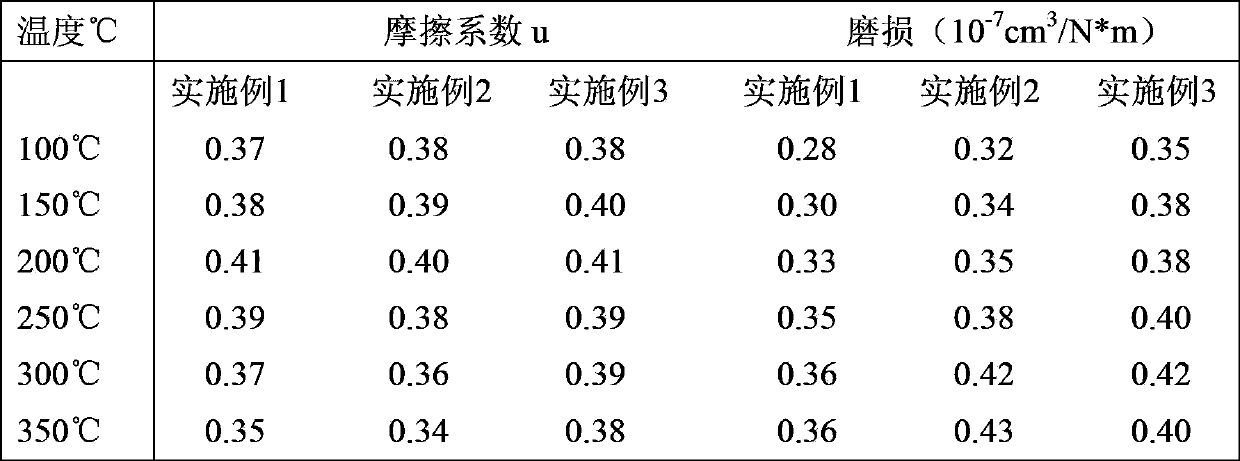

Motorbike hydraulic disc brake non-asbestos lining and preparation method thereof

ActiveCN109185371AImprove surface roughnessIncrease the number ofOther chemical processesFriction liningTitanium carbideAramid

The invention discloses a motorbike hydraulic disc brake non-asbestos lining and a preparation method thereof. The motorbike hydraulic disc brake non-asbestos lining comprises the following componentsof, by weight, 8-12 parts of copper fiber, 18-22 parts of modified phenolic resin, 4-8 parts of butyronitrile powder, 5.5-10.5 parts of modified aramid fiber, 6-10 parts of potassium titanate whisker, 5-9 parts of aluminum fiber, 10-16 parts of natural graphite powder, 4-8 parts of friction powder, 4-10 parts of filler, 6-10 parts of titanium carbide, 20-24 parts of rock wool, 5-10 parts of a lubricating agent and 4-9 parts of an abrasive material. The preparation method of the motorbike hydraulic disc brake non-asbestos lining comprises the steps of S1, raw material mixing, S2, pre-pressingforming, S3, steel backing preparation, S4, hog pressing forming, S5, heat treatment, and S6 grinding and drilling. The motorbike hydraulic disc brake non-asbestos lining has the advantages of being good in heat resistance, stable in high-temperature friction coefficient, and good in heat fading performance. The preparation method has the advantages of being simple and convenient and high in preparing accuracy.

Owner:海宁易达自动化设备有限公司

Water-soluble phenolic resin solution for woven friction materials and preparation method thereof

The invention provides a water-soluble phenolic resin solution for woven friction materials and a preparation method thereof. According to the water-soluble phenolic resin solution, polyvinyl alcohol, nano attapulgite and micro copper powder are utilized to modify the water-soluble phenolic resin. In the synthesis technique of the water-soluble phenolic resin solution, a small amount of polyvinyl alcohol is added to enhance the water solubility, bonding property and toughness of the resin; and meanwhile, the nano attapulgite and micro copper powder granules are added to enhance the heat resistance and wear resistance of the resin and also further improve the toughness. When being used as a bonding agent for preparing the woven friction material, the water-soluble phenolic resin solution has the advantages of low cost and low environmental pollution, can enhance the bonding property of fibers and other materials with slurry so as to prevent the slurry from falling off the material surface, can enhance the high temperature resistance and frictional resistance of the friction material, and effectively avoids reduction of the friction factor due to the thermal decomposition of the resin.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

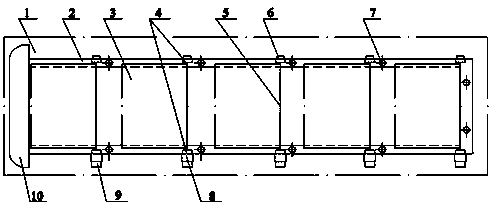

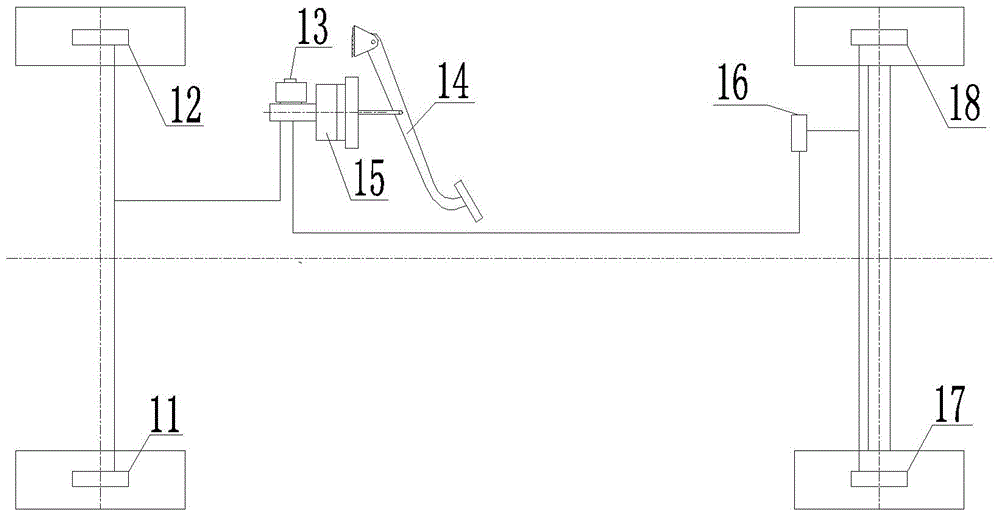

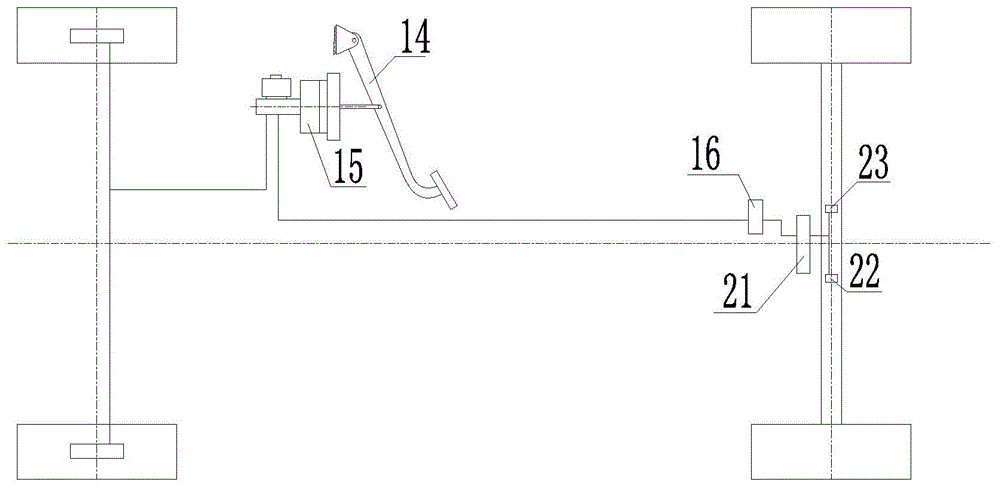

Active adjustment type air resistance retarding device on car roof

ActiveCN103625443AIncrease the windward areaImproved resistance to heat fadingBraking element arrangementsAerodynamic dragControl system

The invention discloses an active adjustment type air resistance retarding device on a car roof. The active adjustment type air resistance retarding device comprises a fixed support, a hydraulic oil way, at least one retarding secondary device and a control system. The retarding secondary devices comprise servo motors, hydraulic servo valves, air resistant blades and rotating shafts. The rotating shafts are supported on the fixed support through fixing assemblies in a rotating mode. The air resistant blades are fixedly connected to the rotating shafts. Input shafts of the hydraulic servo valves are connected with the servo motors, and output shafts of the hydraulic servo valves are connected with the rotating shafts. The control system comprises a speed sensor, a switch knob, blade position sensors and a controller used for controlling the servo motors and the hydraulic oil way to work, wherein the blade position sensors are arranged on the rotating shafts. According to the active adjustment type air resistance retarding device, the windward area of a car can be increased through automatic adjusting of angles or direct adjusting of the angles, retardant braking of the car can be achieved by means of air resistance, and the active adjustment type air resistance retarding device can convert weak signals into big hydraulic power to carry out adjustment, and is high in sensitivity and good in speedability.

Owner:JIANGSU UNIV OF TECH

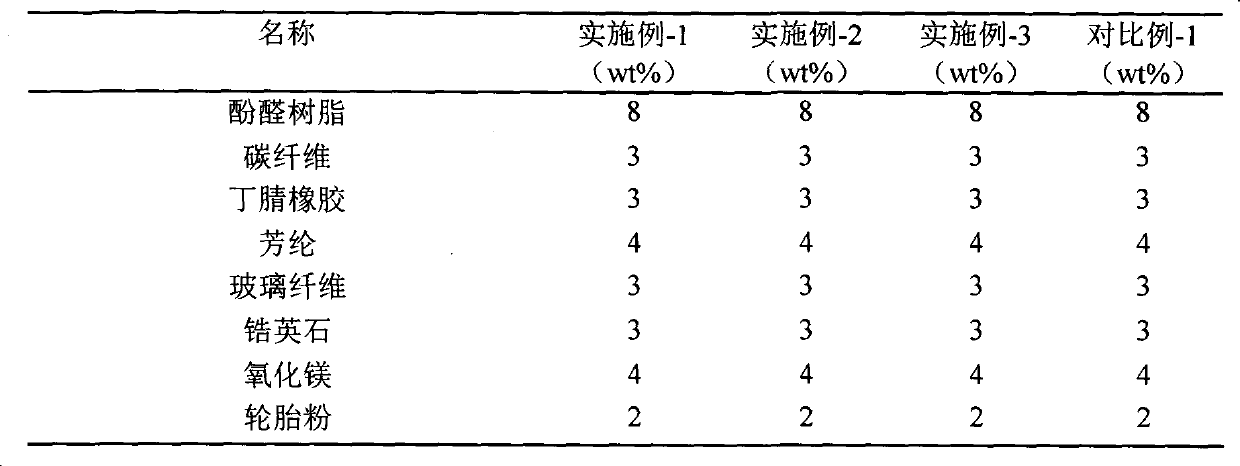

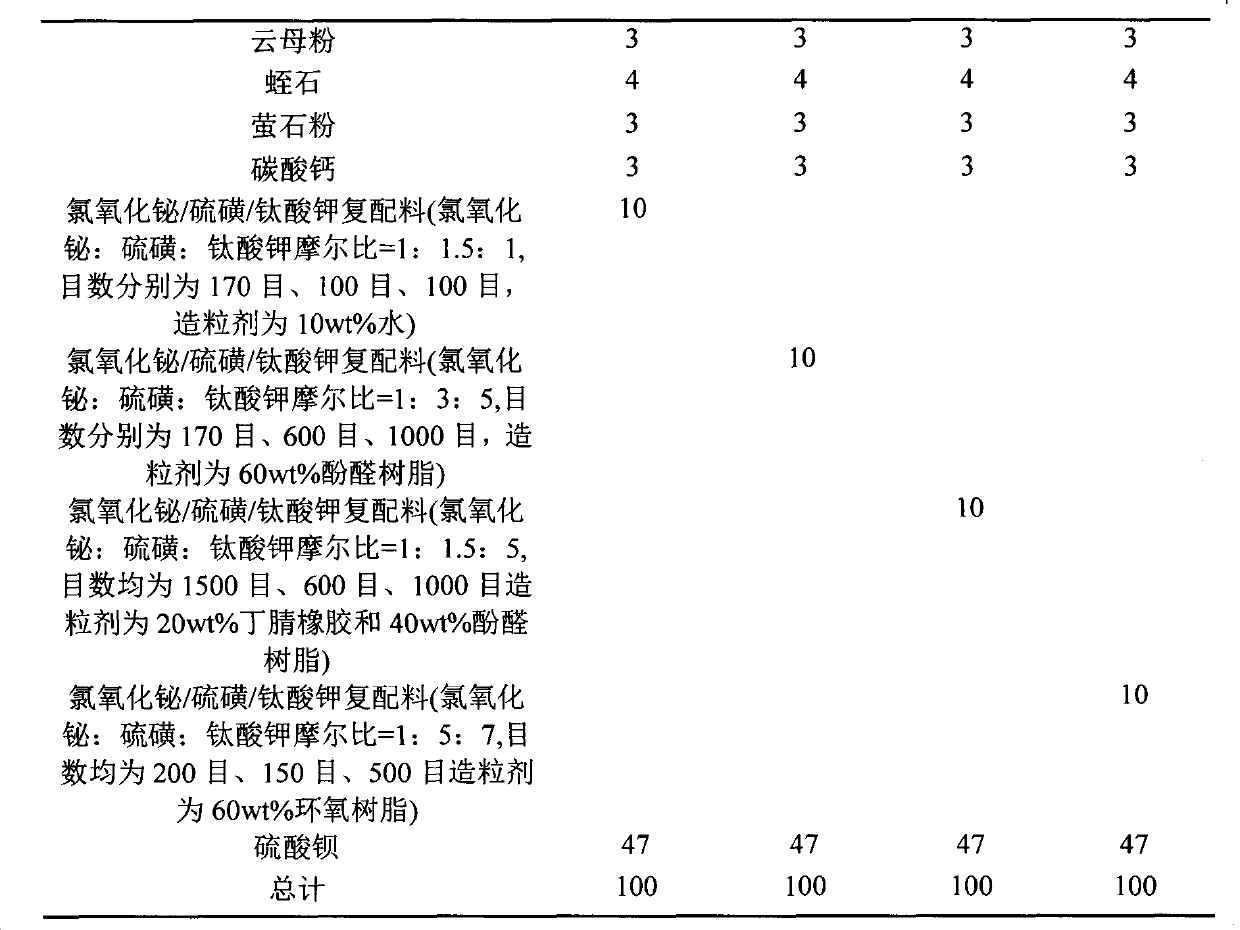

Friction material containing bismuth oxychloride/sulphur/potassium titanate compound ingredient

InactiveCN102994046AReduce pollutionImproved coefficient of friction stabilityOther chemical processesBismuth oxychloridePotassium titanate

The invention relates to application of a bismuth oxychloride / sulphur / potassium titanate compound ingredient to a phenolic-resin-based friction material. The compound ingredient is obtained through pelleting; the content of the compound ingredient in the phenolic-resin-based friction material is 5-40wt%; and the compound ingredient is capable of increasing the stability of the friction coefficient, reducing the wear rate and replacing poisonous and harmful sulfides.

Owner:CHANGSHU YUTYRONE ADVANCED WEAR MATERIALS TECH

Magnetic brake and friction brake combined mixed brake and operating mode switching method thereof

ActiveCN102287460BUse lessReduce generationElectrodynamic brake systemsBrake typesBrake torqueCalipers

The invention discloses a magnetic brake and friction brake combined mixed brake and an operating mode switching method thereof. A brake caliper body side is provided with a magnetic brake fixing frame which is fixedly connected with a steering knuckle; the magnetic brake fixing frame is axially fixedly connected with the outer ends of each permanent magnet and each magnetic conducting block; an inner end side of each permanent magnet is provided with an iron core; an inner end of the iron core is fixedly connected with a magnetic conducting plate, and a side face of the iron core is connected with an upper end of a push rod; a lower end of the push rod extends into an oil cylinder; a coil winding is wound outside the iron core; a pair of permanent magnets, iron cores, magnetic conductingplates, coil windings, push rods and oil cylinders are arranged and symmetrically distributed on two sides of a brake disc; and both ends of each oil cylinder are provided with an oil way interface. Retarding brake can be switched back and forth among electromagnetic brake, permanent magnet brake and electromagnetic and permanent magnet brake, the brake requirement of an automobile under different working conditions is met, braking force of electromagnetic and permanent magnet superposed brake is higher than that of only permanent magnet brake, and more needed brake torque in the process of braking the automobile can be borne; and heat-resistant recession of the brake and riding comfort are improved.

Owner:JIANGSU UNIV

Roof actively adjustable air resistance retarder

ActiveCN103625443BIncrease the windward areaImproved resistance to heat fadingBraking element arrangementsControl signalElectric machine

Owner:JIANGSU UNIV OF TECH

Running brake system and vehicle

ActiveCN104828048AReduce line pressureImproved resistance to heat fadingFluid braking transmissionDifferential gearingsBrake torqueDifferential effects

The invention provides a running brake system and a vehicle. A rear brake loop in the running brake system comprises a second cavity of a mater pump assembly, a central brake assembly, a left differential lock assembly and a right differential lock assembly. When a pedal plate of a brake pedal plate assembly is treaded, the left differential lock assembly and the right differential lock assembly enable a rear axle differential mechanism to lose the differential effect under the hydraulic effect. The running brake system solves the problems that an existing running brake system is poor in heat-fading resistance and reliability, the phenomenon that when the vehicle is braked, due to affected by poor part consistency, large differences exist in brake torque of a left wheel and a right wheel of a rear axle is avoided, and the brake stability is improved.

Owner:BEIQI FOTON MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com