Double-motor brake actuation mechanism of vehicle decoupling distribution brake system

A braking system and actuator technology, applied in the direction of brake actuator, brake type, gear shifting mechanism, etc., can solve the problem of inability to shunt, and achieve the effect of preventing excessive temperature, compact structure, and good resistance to failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

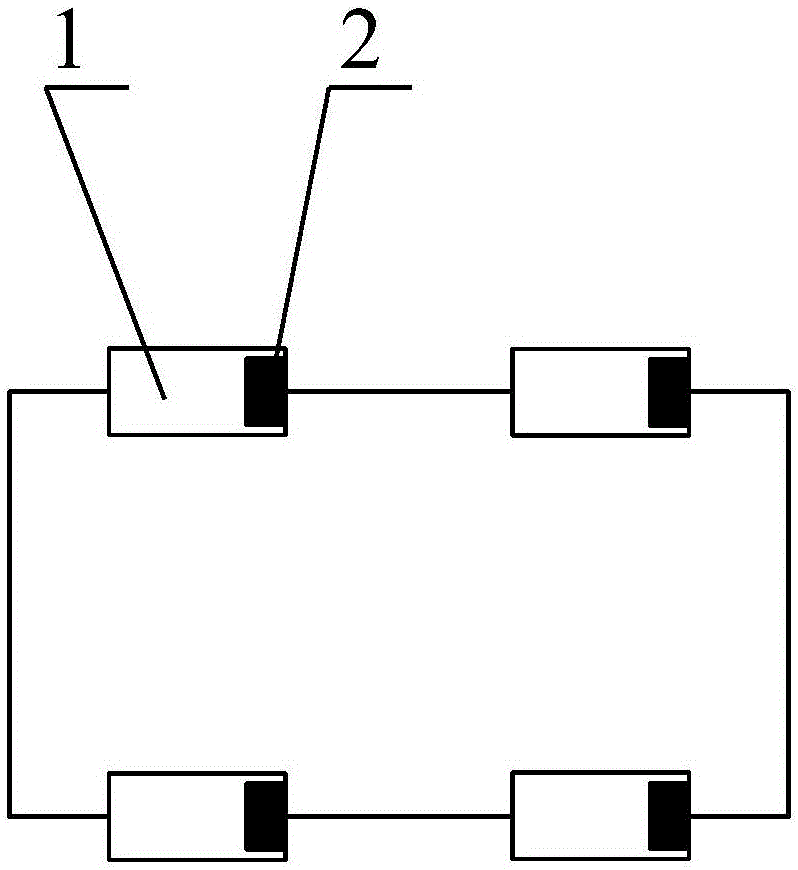

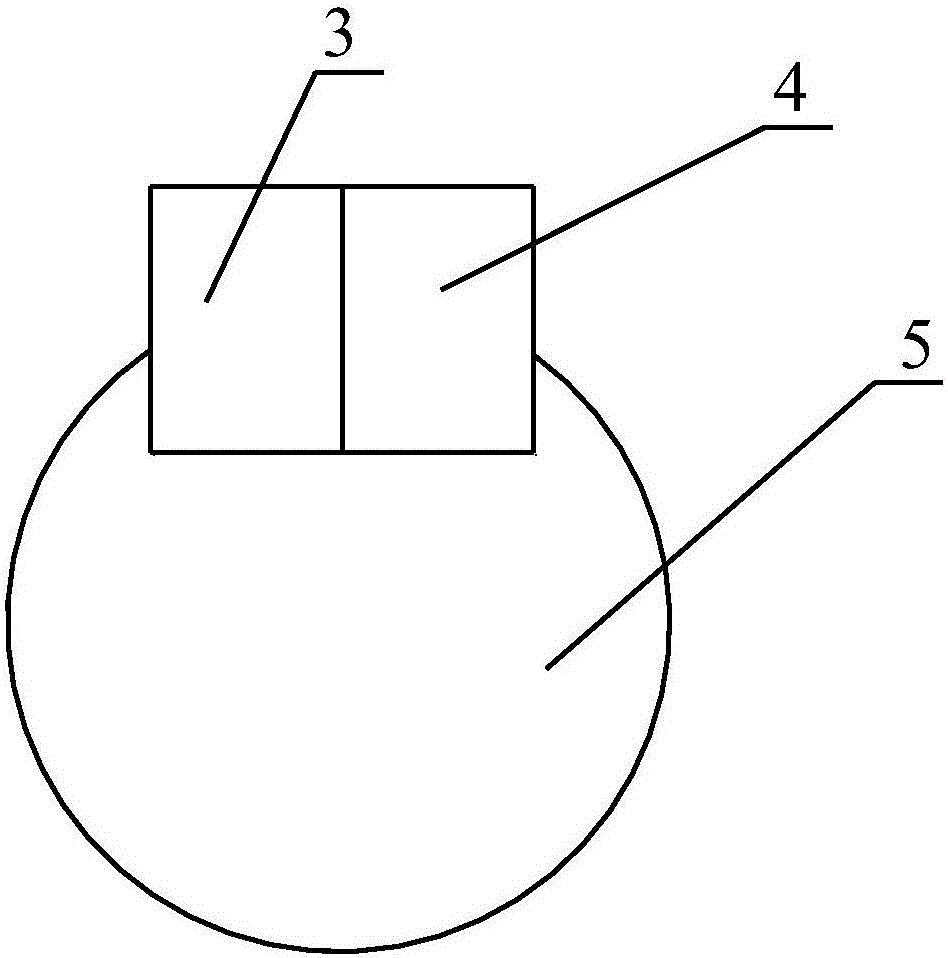

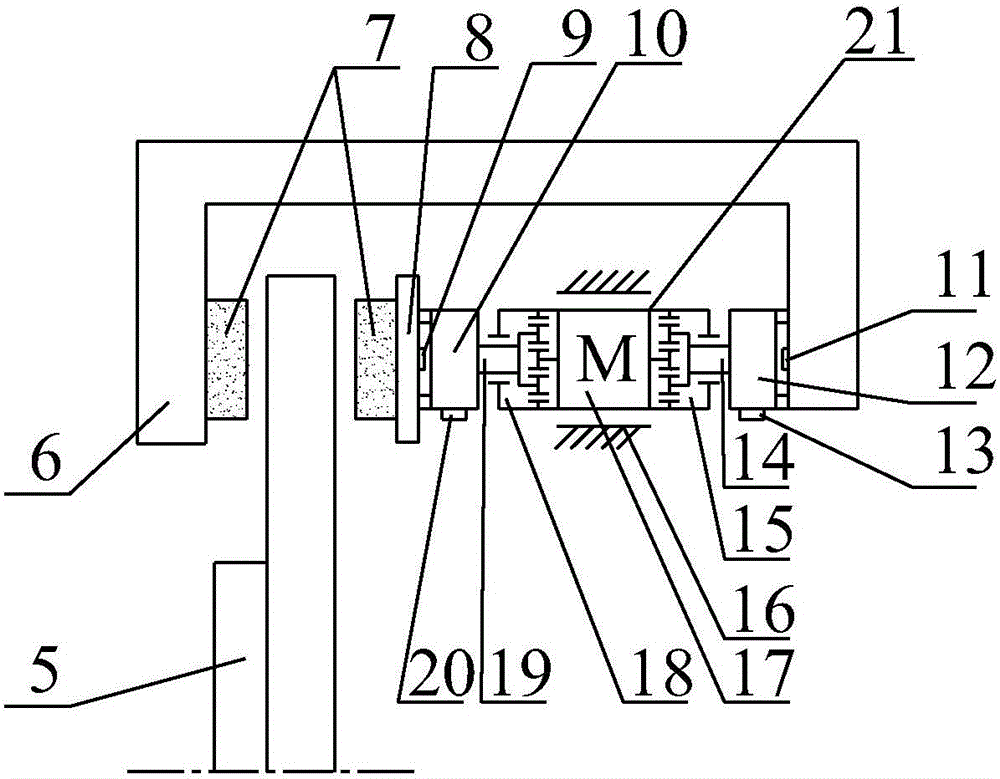

[0026] Such as figure 1 As shown, each wheel 1 is independently provided with a brake actuator 2, wherein the brake actuator 2 is a dual-motor brake actuator of the automobile decoupling distributed braking system, such as figure 2 As shown, it includes a brake disc 5, a brake execution part 3 and a regenerative motor part 4, such as image 3As shown, the brake executive part 3 includes a stepper motor 17 and a brake caliper body 6, the two ends of the brake caliper body 6 are respectively located on both sides of the brake disc 5, and the stepper motor 17 is arranged between the brake caliper body 6 and the brake disc 5, and the brake caliper body 6 and the stepper motor 17 are both slidably connected with the housing 16 of the brake execution part, and the brake caliper One end of the body 6 is provided with a friction block 7, and the other end is connected with the stepping motor 17;

[0027] Such as image 3 As shown, the stepper motor 17 has two output shafts, wherei...

Embodiment 2

[0037] The difference from Example 1 is that, as Figure 5 As shown, the stepper motor 17 has only one output shaft, and saves the second planetary wheel, the second leading screw 14, the second nut 12, the second limit switch 11 and the second displacement sensor 13 connected with it, and the stepping One end of the motor 17 is directly fixedly connected with one end of the brake caliper body 6 . Compared with Embodiment 1, the volume of the brake actuator 2 is reduced, and the basic function and basic working principle of each component are similar to Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com