Friction material containing bismuth oxychloride/sulphur/potassium titanate compound ingredient

A technology of bismuth oxychloride and friction materials, which is applied in the field of friction materials, can solve problems such as increasing production costs, increasing product quality control difficulties, and difficulties, and achieves the effects of reducing pollution, reducing thermal decay resistance, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below through examples and comparative examples, but the present invention is not limited to these examples.

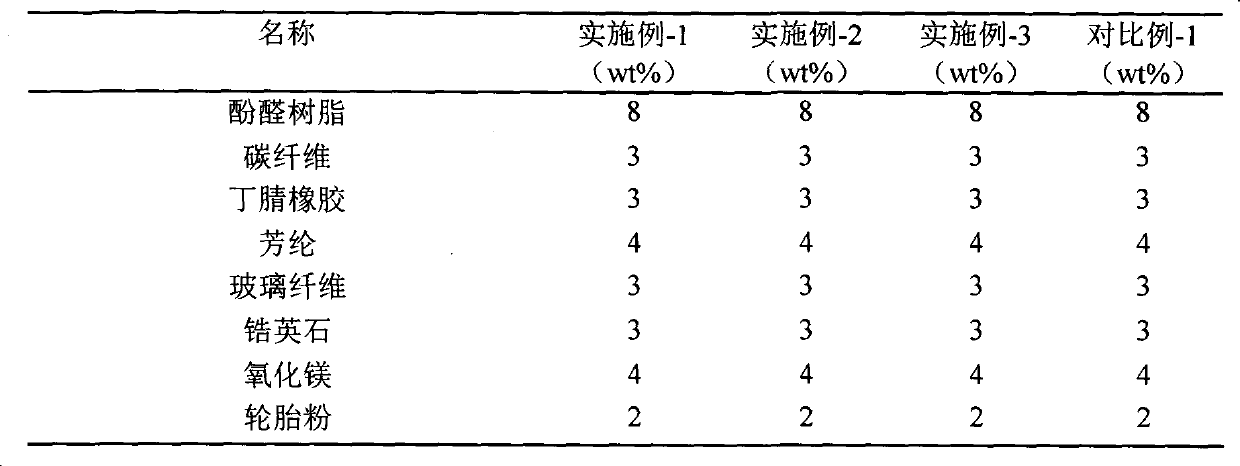

[0018] Table 1 investigates the influence of the molar ratio in the compound on its performance

[0019]

[0020]

[0021] Pressing process: put the raw materials into the mixer and mix for 4 minutes, and keep warm for 8 minutes at 175°C and 20Mpa. Heat treatment process: the pressed sample was heat treated at 200°C for 5 hours, and then cooled naturally.

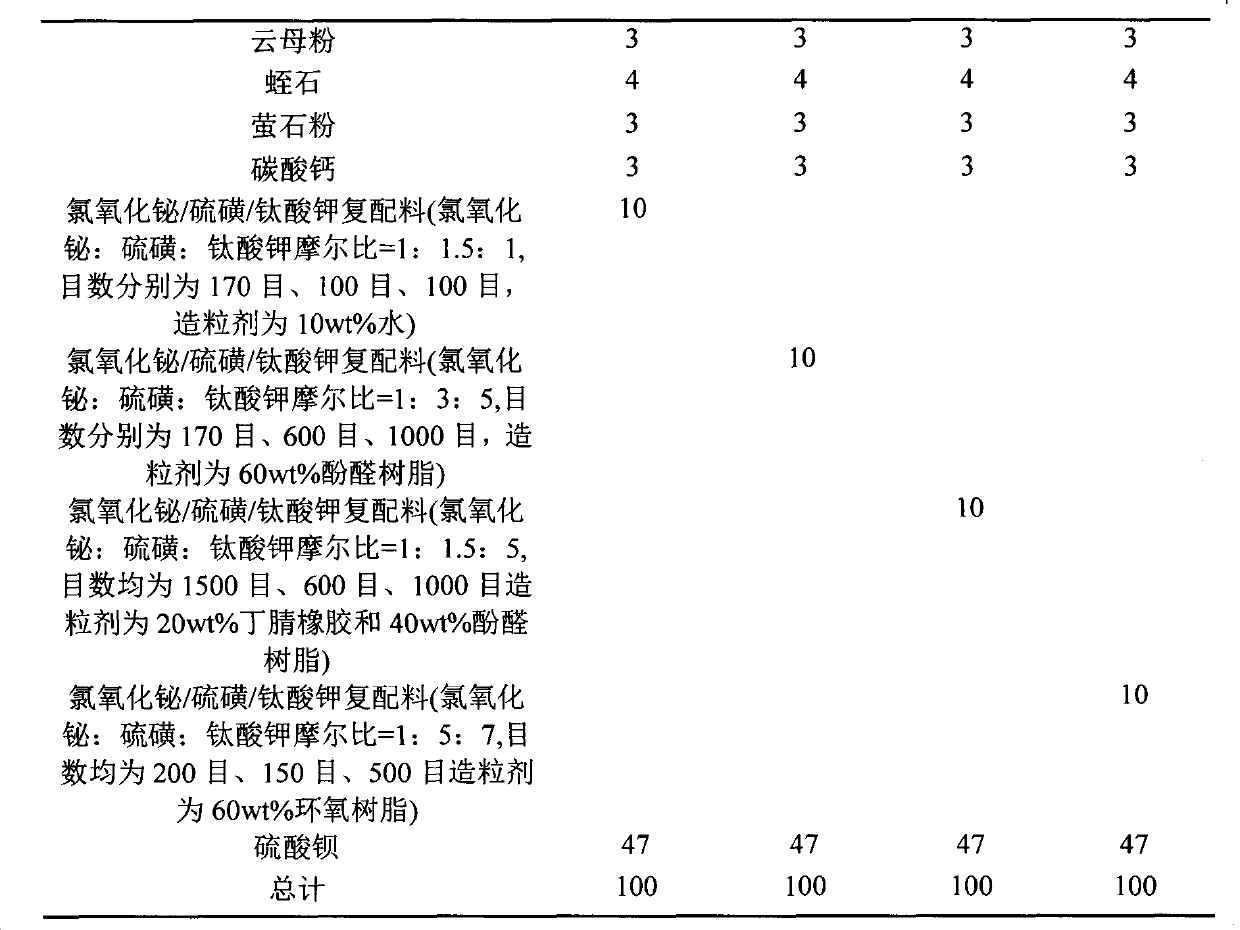

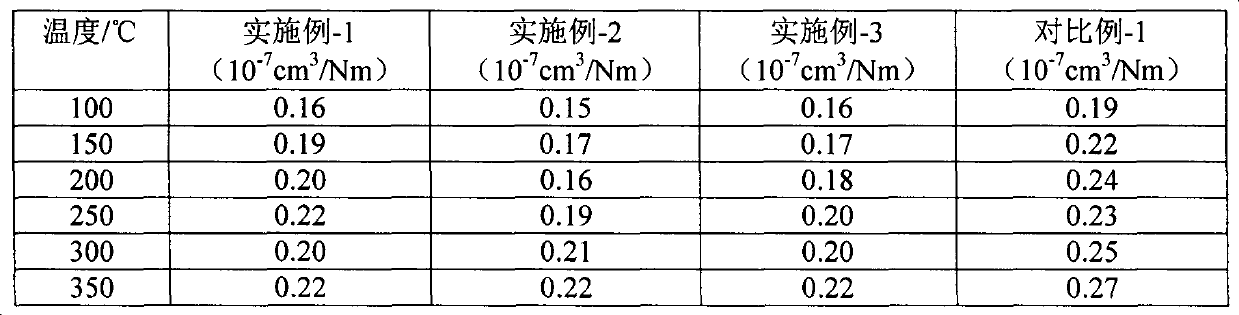

[0022] Table 2 Comparison of coefficient of friction

[0023] temperature / ℃

Example-1

Example-2

Example-3

Comparative example-1

100

0.29

0.30

0.31

0.29

150

0.31

0.31

0.31

0.32

200

0.30

0.33

0.33

0.35

250

0.35

0.36

0.34

0.31

300

0.31

0.35

0.33

0.34

350

0.30

0.34

0.33

0.29

[0024] Table ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com