Water-soluble phenolic resin solution for woven friction materials and preparation method thereof

A water-soluble phenolic resin and friction material technology, which is applied in chemical instruments and methods, and other chemical processes, can solve the problems of friction material friction coefficient reduction, high brittleness of phenolic resin, and threat to safe operation, etc., to improve wear resistance, Strong adsorption performance, effect of improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

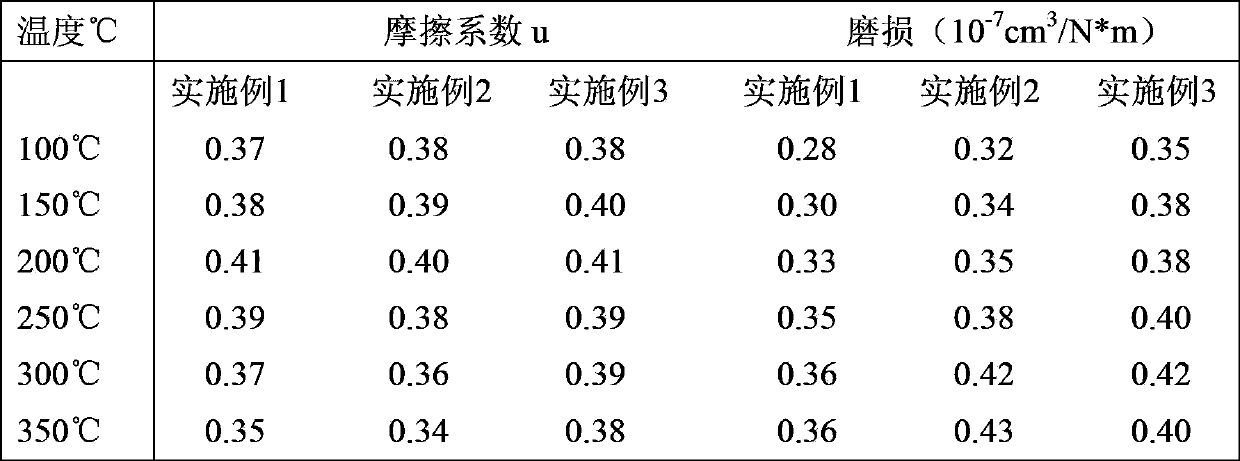

Embodiment 1

[0028] In this embodiment, the modified water-soluble phenolic resin solution is composed of polyvinyl alcohol-modified phenolic resin aqueous solution, nano-scale attapulgite and micron-scale copper powder; The aqueous resin solution is formed by mixing 100 parts by mass of phenol, 115 parts by mass of formaldehyde solution with a concentration of 37% by mass, 5 parts by mass of polyvinyl alcohol with a degree of polymerization of 1700, and 5 parts by mass of basic catalyst NaOH; The polyvinyl alcohol-modified phenolic resin aqueous solution contains 100 parts by mass of phenol, 2 parts by mass of nano-scale attapulgite with a length of 0.5um~5um, a width of 15nm~30nm, and a particle size of 0.5um~2um. 1 mass part of micron copper powder.

[0029] The preparation method of the water-soluble phenolic resin solution of above-mentioned modification comprises the steps:

[0030] (1) Put 5 parts by mass of polyvinyl alcohol with a degree of polymerization of 1700, add 8 parts by ...

Embodiment 2

[0040] In this embodiment, the modified water-soluble phenolic resin solution is composed of polyvinyl alcohol-modified phenolic resin aqueous solution, nano-scale attapulgite and micron-scale copper powder; The aqueous resin solution is made of 100 parts by mass of phenol, 118 parts by mass of formaldehyde solution with a concentration of 37% by mass, 6 parts by mass of polyvinyl alcohol with a degree of polymerization of 1750, and 8 parts by mass of a basic catalyst Ba(OH) 2 mixed reaction According to the content of 100 parts by mass in the phenolic resin aqueous solution modified by polyvinyl alcohol, it contains 1.5 parts by mass of nano-scale attapulgite with a length of 0.5um ~ 5um and a width of 15nm ~ 30nm, and a particle size of 0.5 2 parts by mass of micron copper powder of um~2um.

[0041] The preparation method of the water-soluble phenolic resin solution of above-mentioned modification comprises the steps:

[0042] (1) Add 6 parts by mass of polyvinyl alcohol wi...

Embodiment 3

[0052] In this embodiment, the modified water-soluble phenolic resin solution is composed of polyvinyl alcohol-modified phenolic resin aqueous solution, nano-scale attapulgite and micron-scale copper powder; The aqueous resin solution is formed by mixing 100 parts by mass of phenol, 112 parts by mass of formaldehyde solution with a concentration of 37% by mass, 4 parts by mass of polyvinyl alcohol with a degree of polymerization of 1500, and 8 parts by mass of basic catalyst NaOH; The phenol content in the polyvinyl alcohol-modified phenolic resin aqueous solution is 100 parts by mass, containing 1 part by mass of nano-scale attapulgite with a length of 0.5um~5um, a width of 15nm~30nm, and a particle size of 0.5um~2um. 1.5 parts by mass of micron copper powder.

[0053] The preparation method of the water-soluble phenolic resin solution of above-mentioned modification comprises the steps:

[0054] (1) Put 4 parts by mass of polyvinyl alcohol with a degree of polymerization of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com