A vehicle wheel-side composite braking device integrating permanent magnet braking and friction braking

A friction braking and compound braking technology, applied in the components of brakes, brake discs, brake types, etc., can solve the problems of large air gap between magnetic lines of force, small braking torque, low magnetic efficiency, etc. Increase braking torque and reduce wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

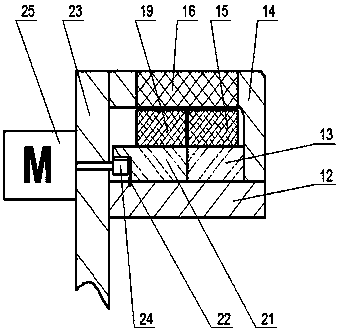

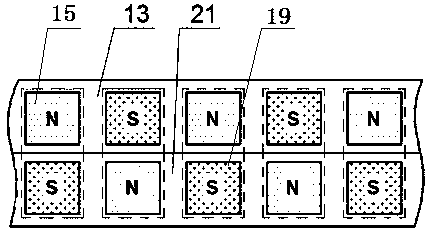

[0020] Such as figure 1 As shown, the vehicle wheel compound braking device integrating permanent magnet braking and friction braking according to the present invention includes: friction braking assembly, permanent magnetic braking assembly, integrated brake disc 7 and planetary gear mechanism, each part All can be independently installed on the wheel edge of each wheel.

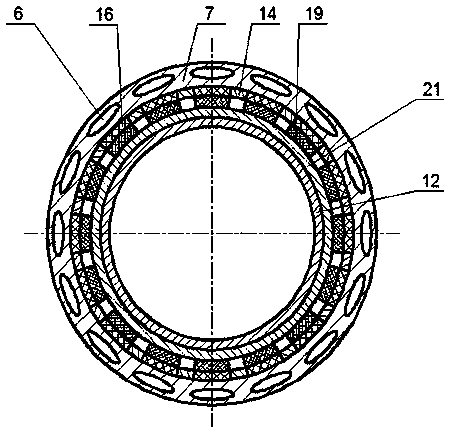

[0021] Such as figure 1 , 2 As shown, the integrated brake disc 7 is an intermediate connecting body between the friction brake assembly and the permanent magnet brake assembly. The integrated brake disc 7 is cylindrical in shape, the left end of the cylindrical shape in the axial direction is open, the right end face is closed, and a central through hole 20 is opened in the middle of the right end face, and the coaxial fixed sleeve in the central through hole 20 has a rotating Axis 11. There are several closed sodium-filled cavities 6 evenly distributed along the circumference in the side wall of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com