Resin-based friction material

A friction material and resin-based technology, applied in the field of friction materials, can solve problems such as friction and wear performance degradation, affecting driving brake safety, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

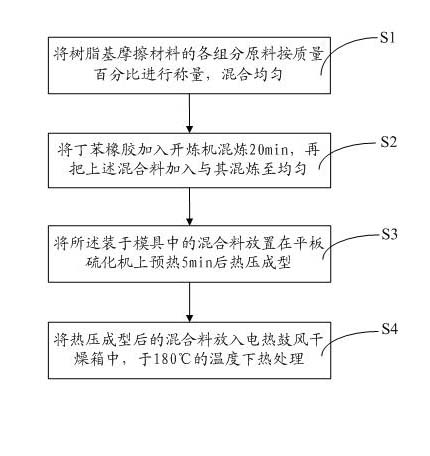

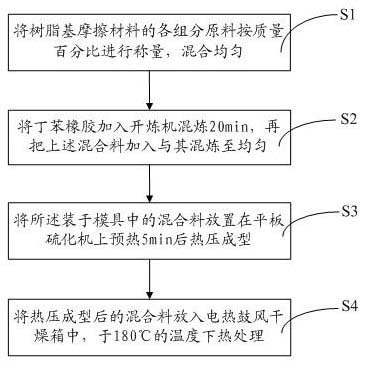

[0028] see figure 1 , figure 1 It is a schematic flow chart of a preferred embodiment of the preparation method of the resin-based friction material of the present invention. The preparation method of the resin-based friction material of the preferred embodiment of the present invention comprises the following steps:

[0029] Step S1: Weigh the raw materials of each component of the resin-based friction material by mass percentage, mix them uniformly, and obtain a mixture, wherein the mass percentage of each component raw material is 10-40% mullite, 10-40% 30% phenolic resin, 10-30% barium sulfate, 5-20% feldspar powder, 1-10% carbon black and 0.1-5% zinc stearate.

[0030] The uniform mixing in this step is specifically to manually premix the weighed raw materials respectively, and then mix them in a high-speed mixer for 40 minutes.

[0031] Step S2: Add styrene-butadiene rubber with a mass percentage of 10 to 30% into the open mill, knead for 20 minutes at the temperature...

Embodiment 1

[0037] One of the raw materials is mullite with a median diameter of 12.80 μm and a mass content of 10%, and then mixed with 18% phenolic resin, 18% styrene-butadiene rubber, 0.9% zinc stearate, and 10.8% carbon Black, 27.9% barium sulfate, and 14.4% feldspar powder were used as raw materials, and the resin-based friction material mixed with mullite was made by blending and dry hot pressing. When the resin-based friction material is tested for friction and wear at 350°C, its friction coefficient (μ) and wear rate (V) are 0.38 and 0.67×10-7cm respectively 3 / (N·m).

Embodiment 2

[0039] One of the raw materials is mullite with a median diameter of 5.26 μm and a mass content of 10%, and then mixed with 18% phenolic resin, 18% styrene-butadiene rubber, 0.9% zinc stearate, and 10.8% carbon Black, 27.9% barium sulfate, and 14.4% feldspar powder were used as raw materials, and the resin-based friction material mixed with mullite was made by blending and dry hot pressing. When the resin-based friction material is tested for friction and wear at 350°C, the friction coefficient (μ) and wear rate (V) are 0.40 and 0.62×10-7cm respectively 3 / (N·m).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median diameter | aaaaa | aaaaa |

| Median diameter | aaaaa | aaaaa |

| Median diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com