Method for preparing clutch facing through taking water soluble phenol-formaldehyde resin as adhesion agent

A technology of water-soluble phenolic resin and clutch face, which is applied in the field of preparing high-performance motor vehicle clutch face, which can solve the problems of cumbersome preparation process of modified phenolic resin, high price of powdered nitrile rubber, and increased cost, so as to enhance toughness , Improve heat resistance, increase the effect of bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

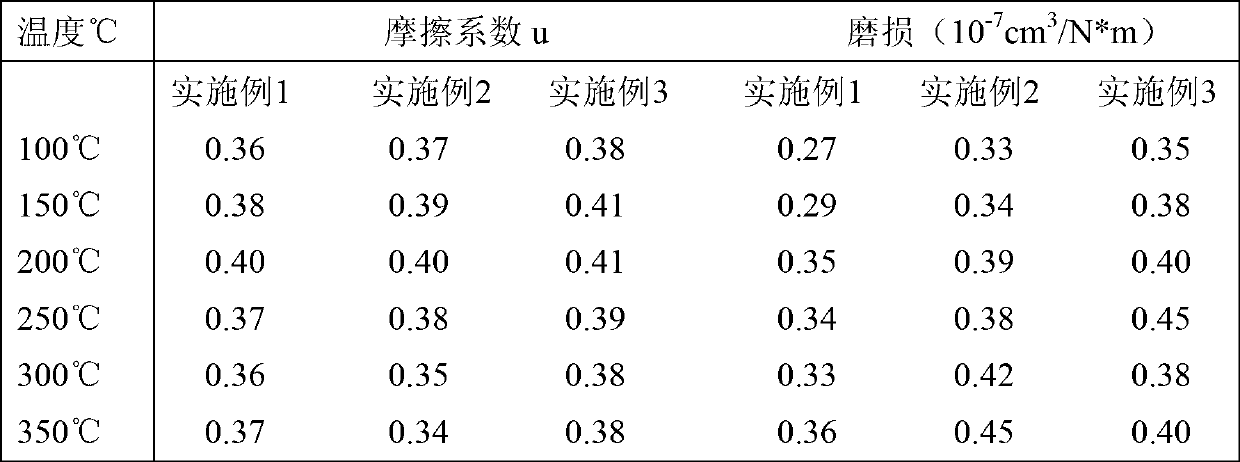

Examples

Embodiment 1

[0032] In this embodiment, the clutch face uses water-soluble phenolic resin solution as a binder, and its preparation method includes the following steps:

[0033](1) Preparation of water-soluble phenolic resin solution:

[0034] Add 100 parts by mass of phenol, 5 parts by mass of polyvinyl alcohol and 5 parts by mass of NaOH into the reaction vessel, then add 115 parts by mass of formaldehyde solution into the reaction vessel, heat up to 93°C, and stir for 40 minutes to obtain Aqueous solution of polyvinyl alcohol-modified phenolic resin; stop heating, and after the temperature drops below 50°C, add 4 parts by mass of nano-sized attapulgite and 1 part by mass of micron-sized copper powder particles into the reaction vessel, and stir for 25 minutes Stop stirring, collect the reaction solution, place it in an ultrasonic dispersion device, control the temperature at about 40°C, and disperse it by ultrasonic wave at a frequency of 45 Hz for 90 minutes to obtain a water-soluble p...

Embodiment 2

[0043] In this embodiment, the clutch face uses water-soluble phenolic resin solution as a binder, and its preparation method includes the following steps:

[0044] (1) Prepare the first water-soluble phenolic resin solution:

[0045] 100 parts by mass of phenol, 4 parts by mass of polyvinyl alcohol and 8 parts by mass of Ba(OH) 2 Add it into the reaction container, then add 116 parts by mass of formaldehyde solution into the reaction container, raise the temperature to 90°C, stir and react for 45 minutes to obtain an aqueous solution of polyvinyl alcohol-modified phenolic resin; stop heating, and wait until the temperature drops to 50°C After the following, 2 mass parts of nano-scale attapulgite and 1.5 mass parts of micron-sized copper powder particles were added to the reaction vessel, and stirred for 30 minutes; the stirring was stopped, and the reaction solution was collected, placed in an ultrasonic dispersion device, and the temperature was controlled at 45 At about ℃,...

Embodiment 3

[0054] In this embodiment, the clutch face uses water-soluble phenolic resin solution as a binder, and its preparation method includes the following steps:

[0055] (1) Preparation of water-soluble phenolic resin solution:

[0056] Add 100 parts by mass of phenol, 6 parts by mass of polyvinyl alcohol and 6 parts by mass of NaOH into the reaction vessel, then add 112 parts by mass of formaldehyde solution into the reaction vessel, raise the temperature to 95°C, and stir the reaction for 48 minutes to obtain Aqueous solution of polyvinyl alcohol-modified phenolic resin; stop heating, and after the temperature drops below 50°C, add 3 parts by mass of nano-sized attapulgite and 1.5 parts by mass of micron-sized copper powder particles into the reaction vessel, and stir for 25 minutes Stop stirring, collect the reaction solution, place it in an ultrasonic dispersion device, control the temperature at about 40°C, and disperse it ultrasonically at a frequency of 45 Hz for 120 minutes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com