Friction material, organic carbon ceramic brake pad prepared from friction material and used for abrasion-resistant coating braking disc, and preparation method and application of organic carbon ceramic brake pad

A friction material and wear-resistant coating technology, applied in the field of brake materials, can solve the problem of poor matching between brake pads and wear-resistant coated brake discs, and achieve improved thermal recession resistance, good stability, and excellent friction. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

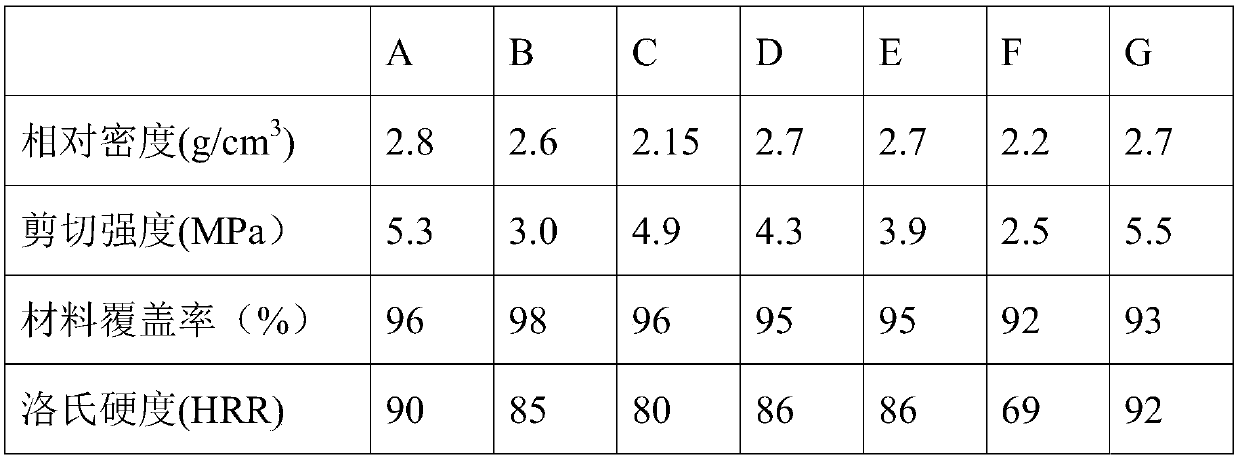

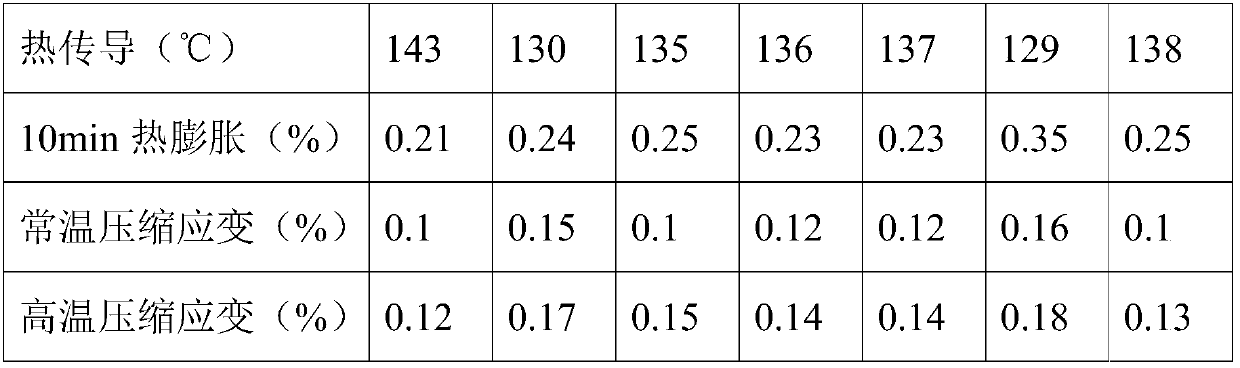

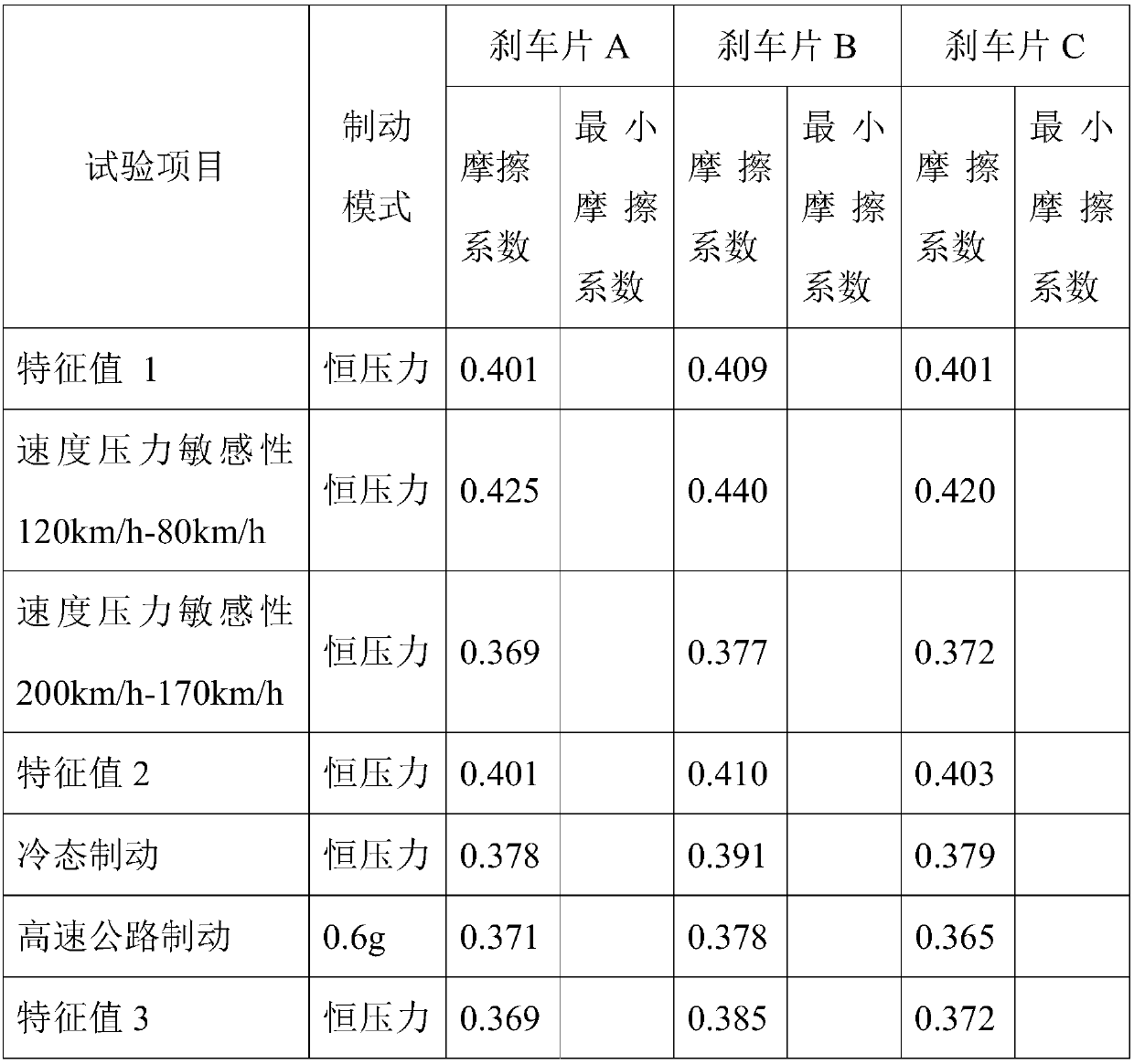

Embodiment 1

[0029] This embodiment provides an organic carbon ceramic brake pad for a wear-resistant coating brake disc. The friction material includes the following raw materials in parts by weight: 3 parts of carbon fiber, 15 parts of steel fiber, 5 parts of mineral fiber, epoxy modified 8 parts of permanent phenolic resin, 5 parts of powdered nitrile rubber, 6 parts of cashew oil friction powder, 10 parts of precipitated barium sulfate, 1 part of acrylic fiber, 2 parts of silicon carbide, 5 parts of soft kaolin, and 12 parts of zirconium silicate.

[0030] Prepare according to the steps of the following preparation method according to the above proportioning ratio:

[0031] (1) Mixing step, accurately weigh each component, and mix for 40 minutes;

[0032] (2) pressing step, the steel back and the mixed material are placed in the mould, and 15Mpa is pressed for 320s to become a blank;

[0033] (3) In the curing step, the pressed blank is heated to 190° C. for 8 hours to make the brake ...

Embodiment 2

[0035] This embodiment provides an organic carbon ceramic brake pad for a wear-resistant coating brake disc. The friction material includes the following raw materials in parts by weight: 5 parts of carbon fiber, 10 parts of steel fiber, 10 parts of mineral fiber, epoxy 12 parts of modified phenolic resin, 10 parts of powdered nitrile rubber, 10 parts of cashew oil friction powder, 20 parts of precipitated barium sulfate, 3 parts of acrylic fiber, 4 parts of silicon carbide, 10 parts of soft kaolin, 9 parts of zirconium silicate.

[0036] Prepare according to above-mentioned proportioning with following preparation method:

[0037] (1) Mixing step, accurately weigh each component, and mix for 30 minutes;

[0038] (2) Pressing step, steel back and mixed material are placed in mold, 10Mpa presses 250s to become blank;

[0039] (3) In the curing step, the pressed blank is heated to 220° C. for 5 hours to be cured to obtain a brake pad B.

Embodiment 3

[0041] This embodiment provides an organic carbon ceramic brake pad for a wear-resistant coating brake disc. The friction material includes the following raw materials in parts by weight: 3 parts of carbon fiber, 12 parts of steel fiber, 8 parts of mineral fiber, epoxy 10 parts of modified phenolic resin, 6 parts of powdered nitrile rubber, 8 parts of cashew oil friction powder, 15 parts of precipitated barium sulfate, 2 parts of acrylic fiber, 3 parts of silicon carbide, 9 parts of soft kaolin, and 11 parts of zirconium silicate.

[0042] Prepare according to above-mentioned proportioning with following preparation method:

[0043] (1) Mixing step, accurately weigh each component, and mix for 30 minutes;

[0044] (2) pressing step, the steel back and the mixed material are placed in the mould, and 15Mpa is pressed for 300s to become a blank;

[0045] (3) In the curing step, the pressed blank is heated to 220° C. for 6 hours to be cured to obtain a brake pad C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com