Hybrid brake combined with magnetic brake and friction brake and working mode switching method

A technology of friction braking and magnetic braking, applied in the direction of brake types, electric braking systems, electric vehicles, etc., can solve the problems of difficult adjustment of braking torque, small slow braking torque, vehicle energy loss, etc. Achieve the effects of improving transportation economy, continuous braking torque, and improving environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

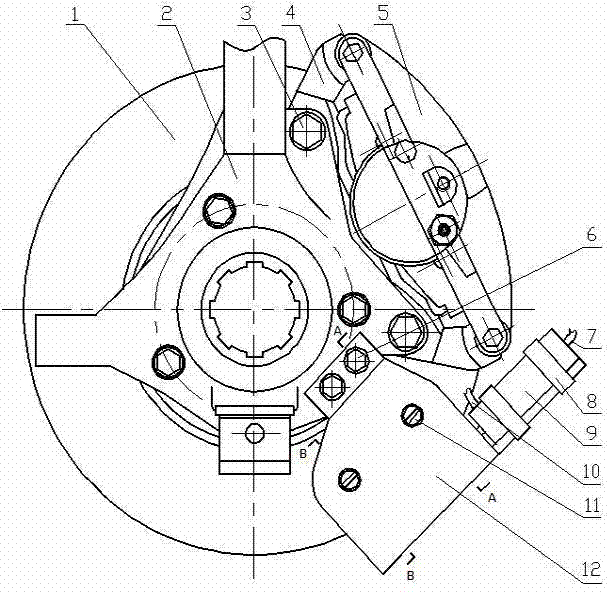

[0022] like figure 1 As shown, the traditional friction brake includes a brake caliper bracket 4, a steering knuckle 2 and a brake caliper body 5. The brake caliper bracket 4 is connected to the steering knuckle 2 through bolts 3, and the brake caliper body 5 is mounted on the brake caliper bracket. 4 on. On the side of the brake caliper body 5 is a magnetic brake fixing frame 12, the magnetic brake fixing frame 12 is fixedly connected to the steering knuckle 2 through another bolt 6, and the oil cylinder 9 is fixedly connected to the magnetic brake fixing frame 12, and the oil cylinder 9 It is fixed on the magnetic brake fixing frame 12 through the fixing sleeve 8 .

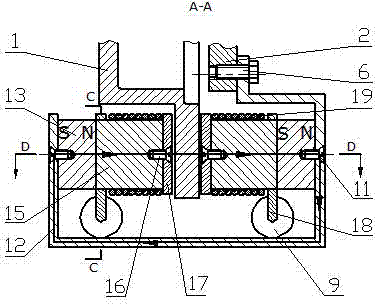

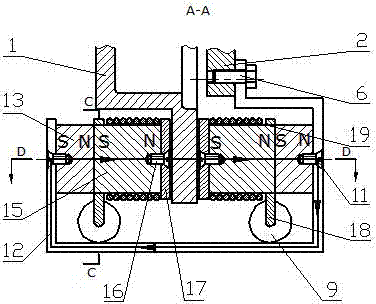

[0023] like Figure 1-4 As shown, the magnetic brake fixing frame 12 is axially fixedly connected to the outer end of the permanent magnet 13 through a screw 11 , and the magnetic braking fixing frame 12 is axially fixedly connected to the outer end of the magnetic conductive block 14 through another screw 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com