Patents

Literature

51results about How to "Mass production is fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

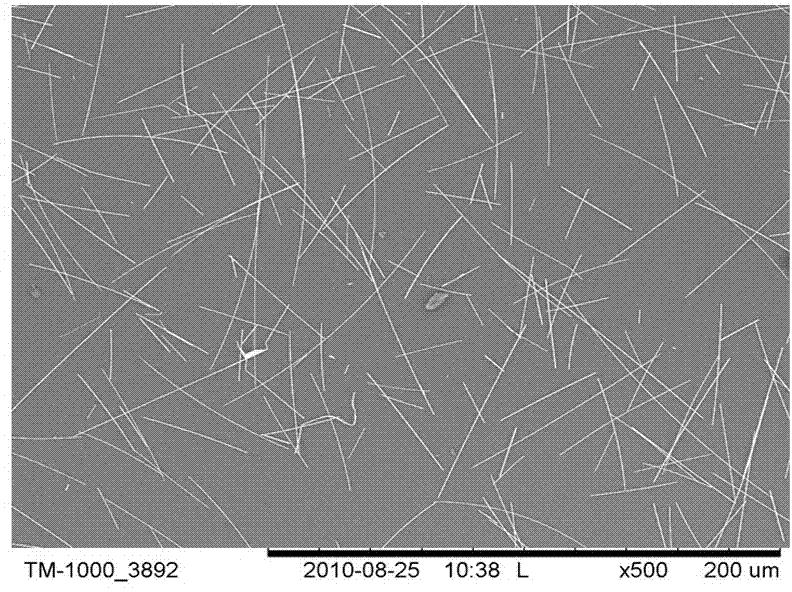

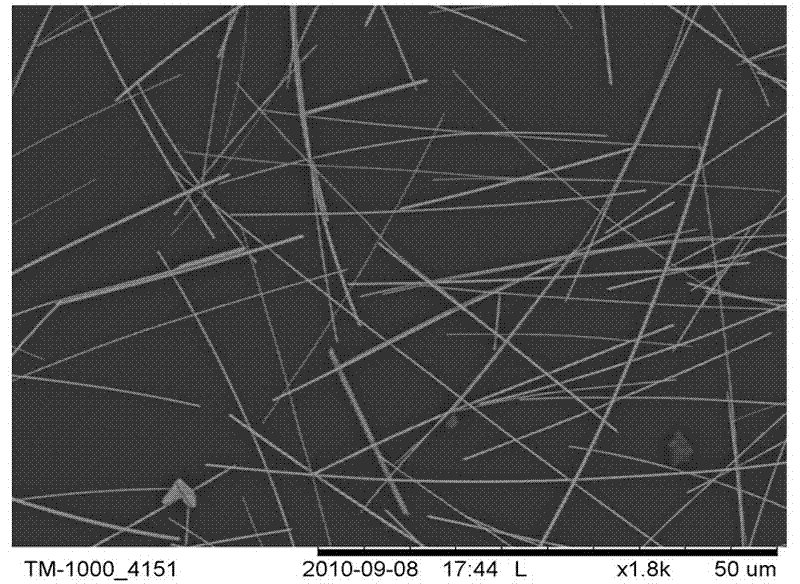

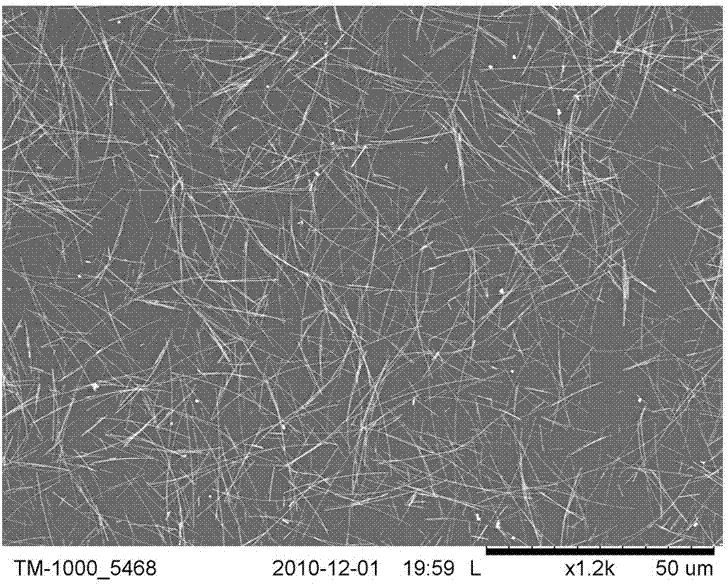

A method for rapid and large-scale preparation of silver nanowires with high aspect ratio

InactiveCN102259190AQuality improvementEasy to prepareMaterial nanotechnologyPolycrystalline material growthWater solubleMaterials science

Disclosed is a method suitable for efficiently producing silver nanowires with high aspect ratio. In this method, silver nanowires with aspect ratio of more than 300 and purity of more than 80% are produced through an acid compound mediated microwave-assisted wet chemistry method. Such silver nanowires are especially suitable for the application in the flexible transparent electrodes, as they can simultaneously improve the electrical conductivity and transparency.

Owner:JIANGSU NANOWELL ADVANCED MATERIALS SCI&TECH

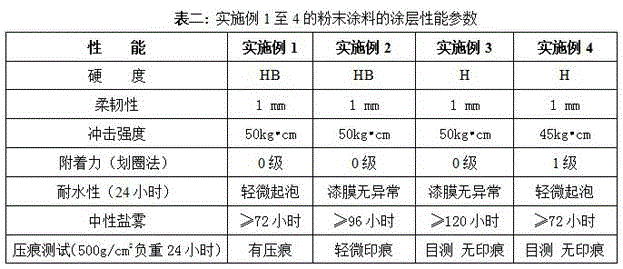

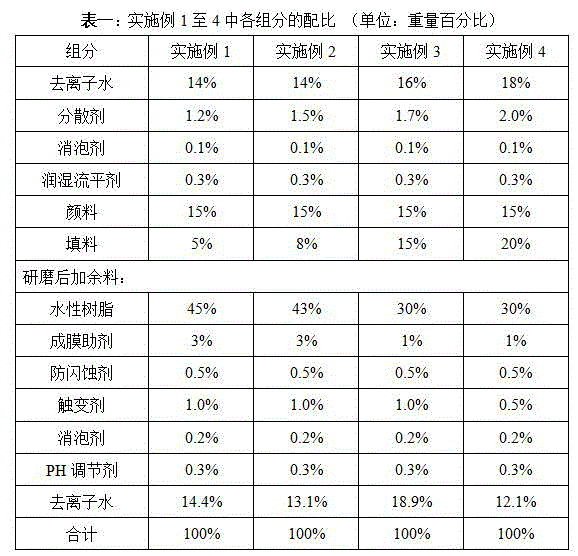

Fast-curing indentation-proof water-based paint for galvanized sheet and preparation method thereof

InactiveCN103602183AReduce usageStrong construction adaptabilityPolyurea/polyurethane coatingsEpoxy resin coatingsWater basedAssembly line

The invention discloses a fast-curing indentation-proof water-based paint for galvanized sheets. A formula of the paint comprises the following components by weight: 30-45% of water-based resin, 1-3% of a dispersant, 20-35% of a pigment filler, 0.3-1% of a wetting leveling agent, 0.5-1% of a thixotropic agent, 0.3-1% of a defoaming agent, 0.1-0.8% of a flash rust inhibitor, 1-3% of a coalescing agent, 0.1-0.5% of a pH regulator and 10-40% of deionized water. The invention also discloses a preparation method of the water-based paint. The paint film provided by the invention can cure fast, and is safe, energy-saving, environment-friendly and simple for construction, so as to meet the fast production requirements of an assembly line. The obtained galvanized sheet has excellent properties and performance indicators reaching the industrial standard for galvanized sheet coating.

Owner:GUANGZHOU KINTE IND +1

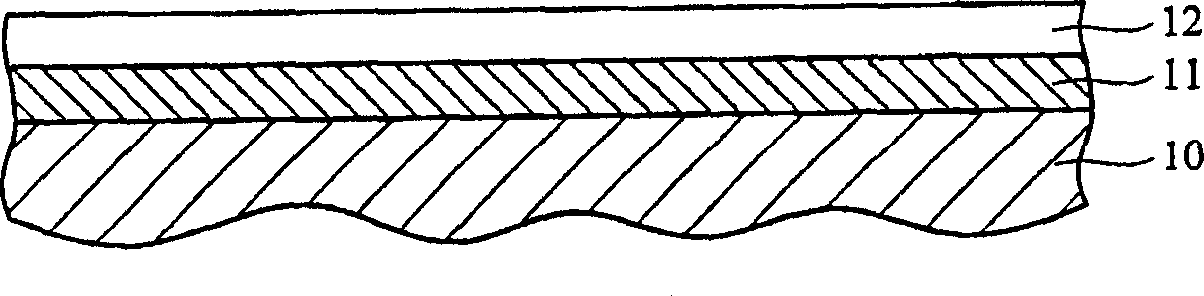

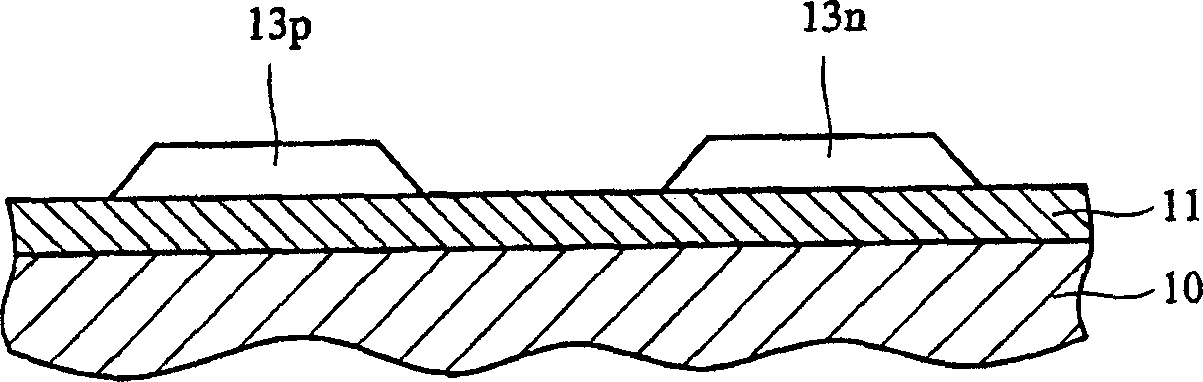

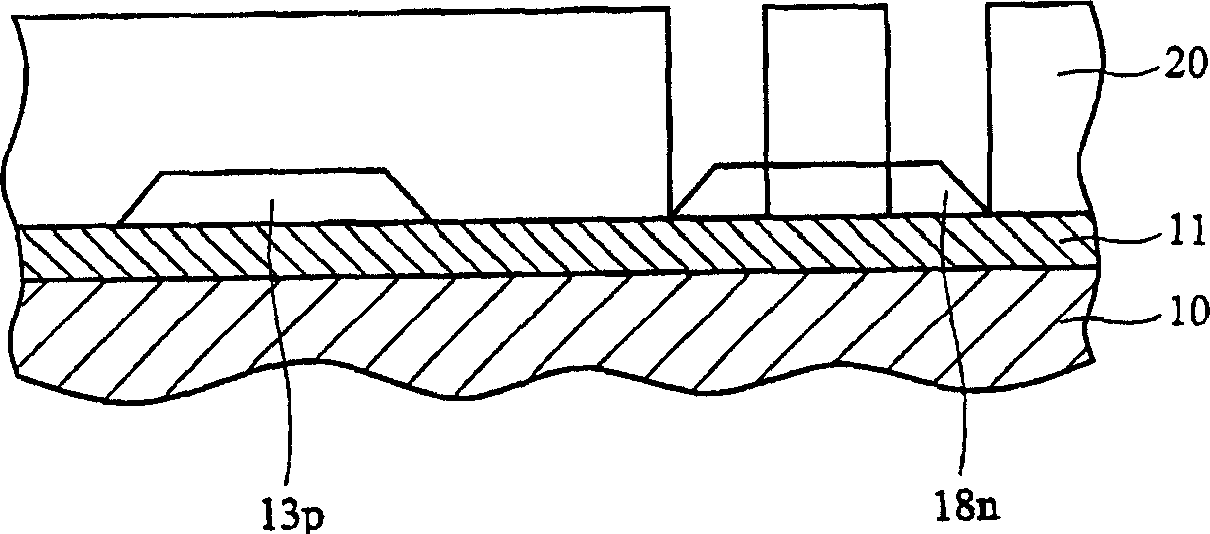

Method for making MOS having light doped drain electrode

ActiveCN1670930AUse lessMass production is fastSemiconductor/solid-state device manufacturingSemiconductorPhotomask

This invention provides a method for making MOS with light doped drain electrode, which contains defining grid, P-type ion heavy doped area and N-type ion light doped area using one photo mask, and can also defining contact window and N-type ion heavy doped area using another photo mask, only six photo masks are needed for completing the process of light doped drain electrode film transistor, so the production speed and yield are increased.

Owner:AU OPTRONICS CORP

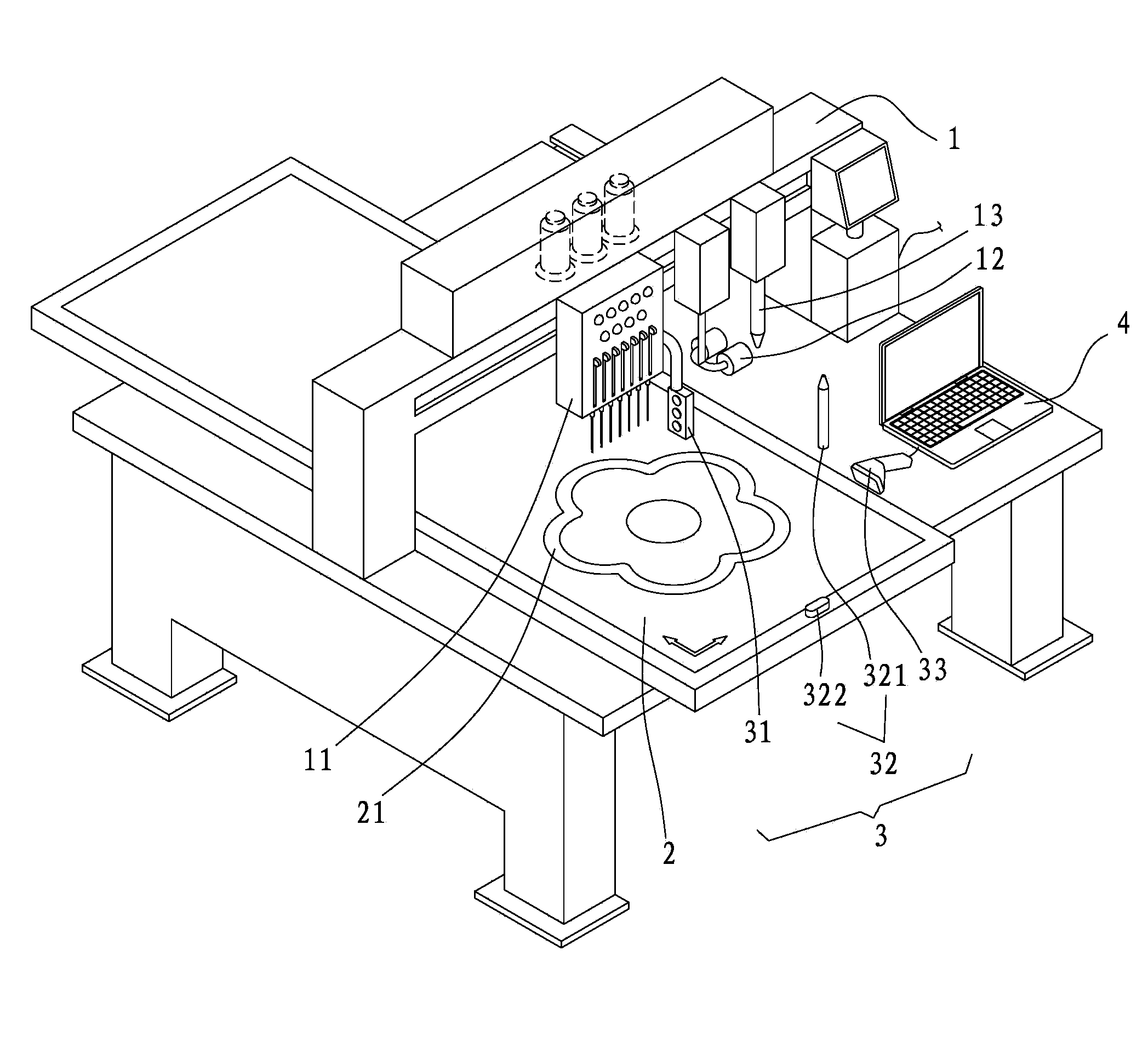

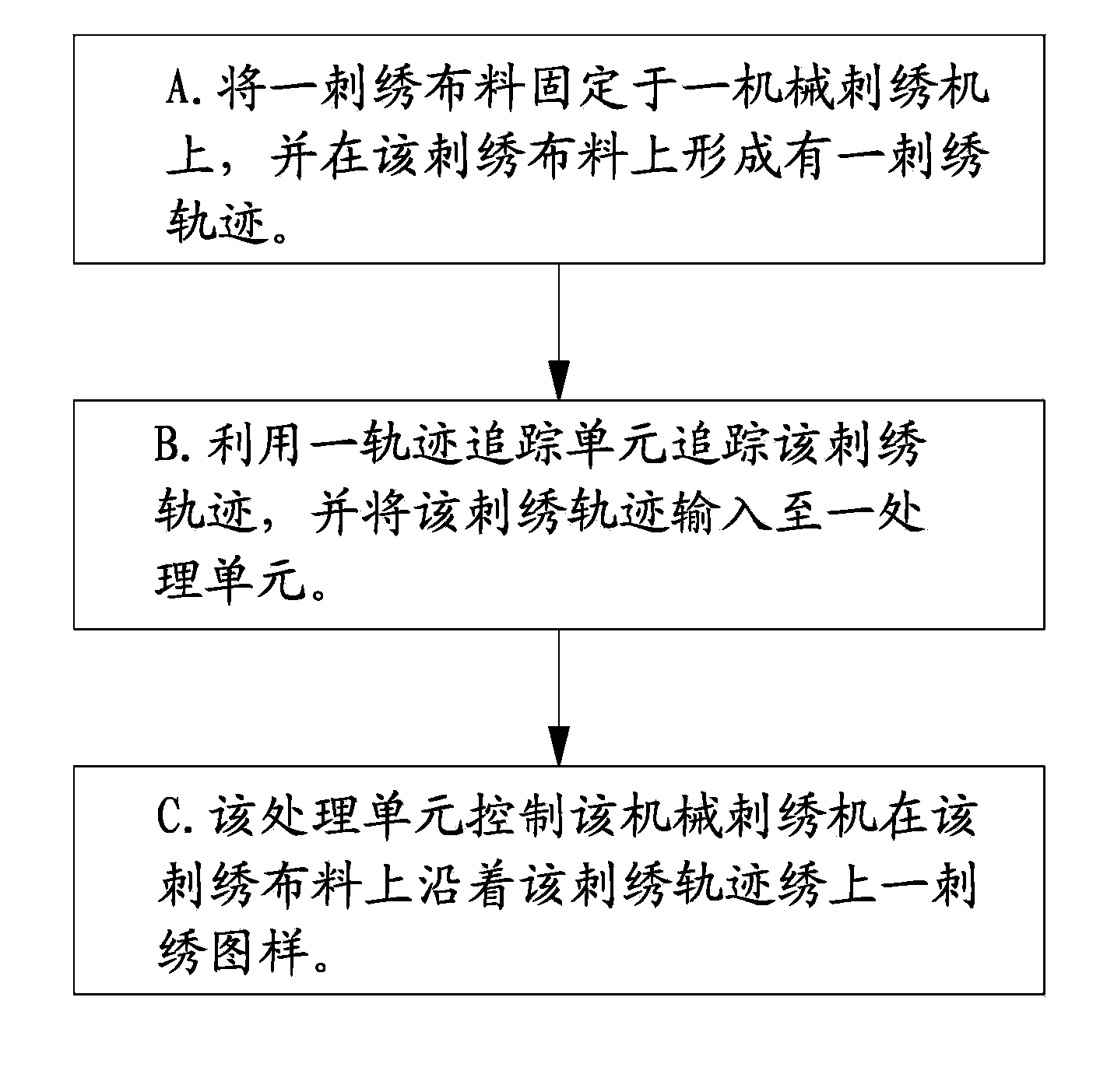

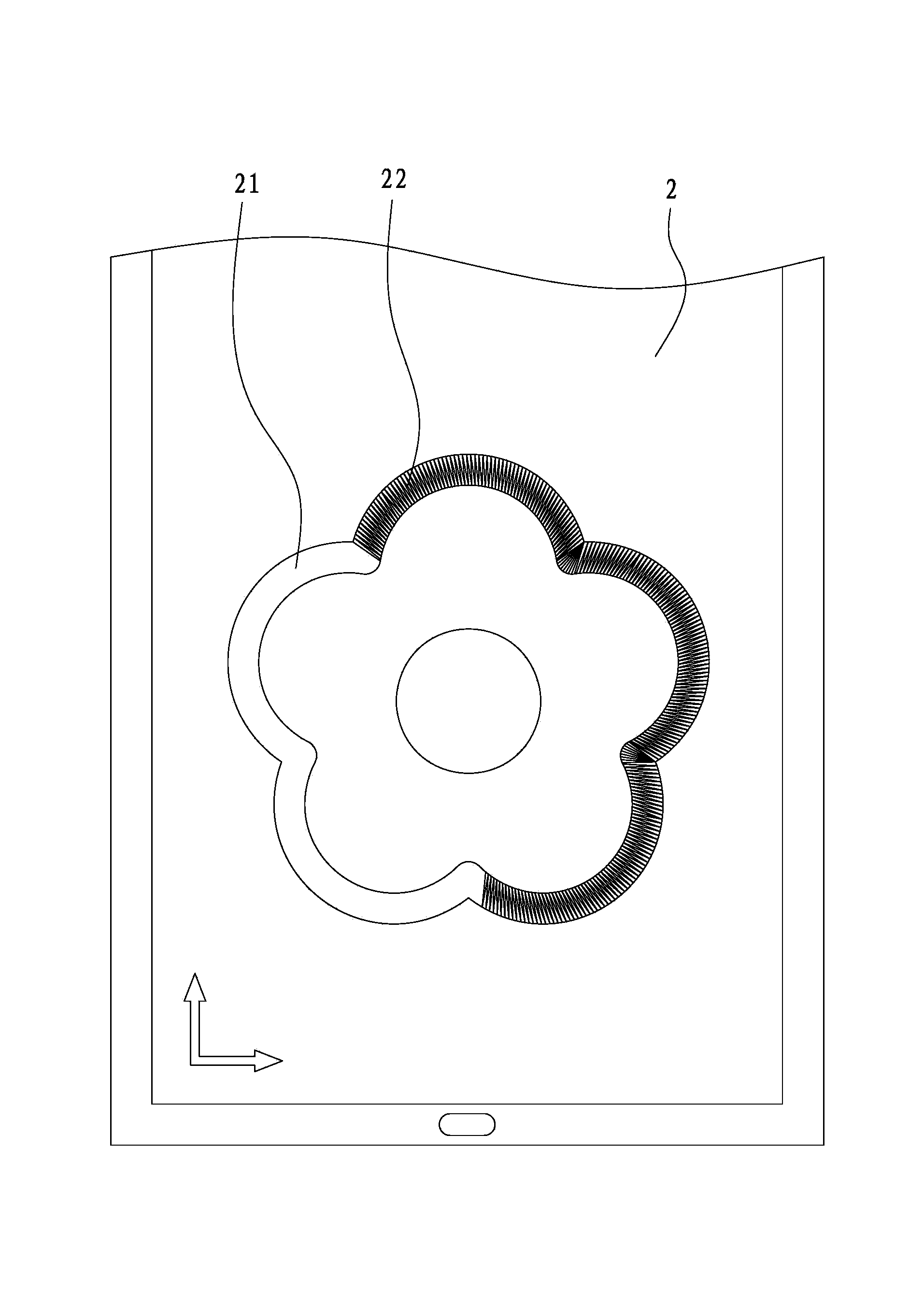

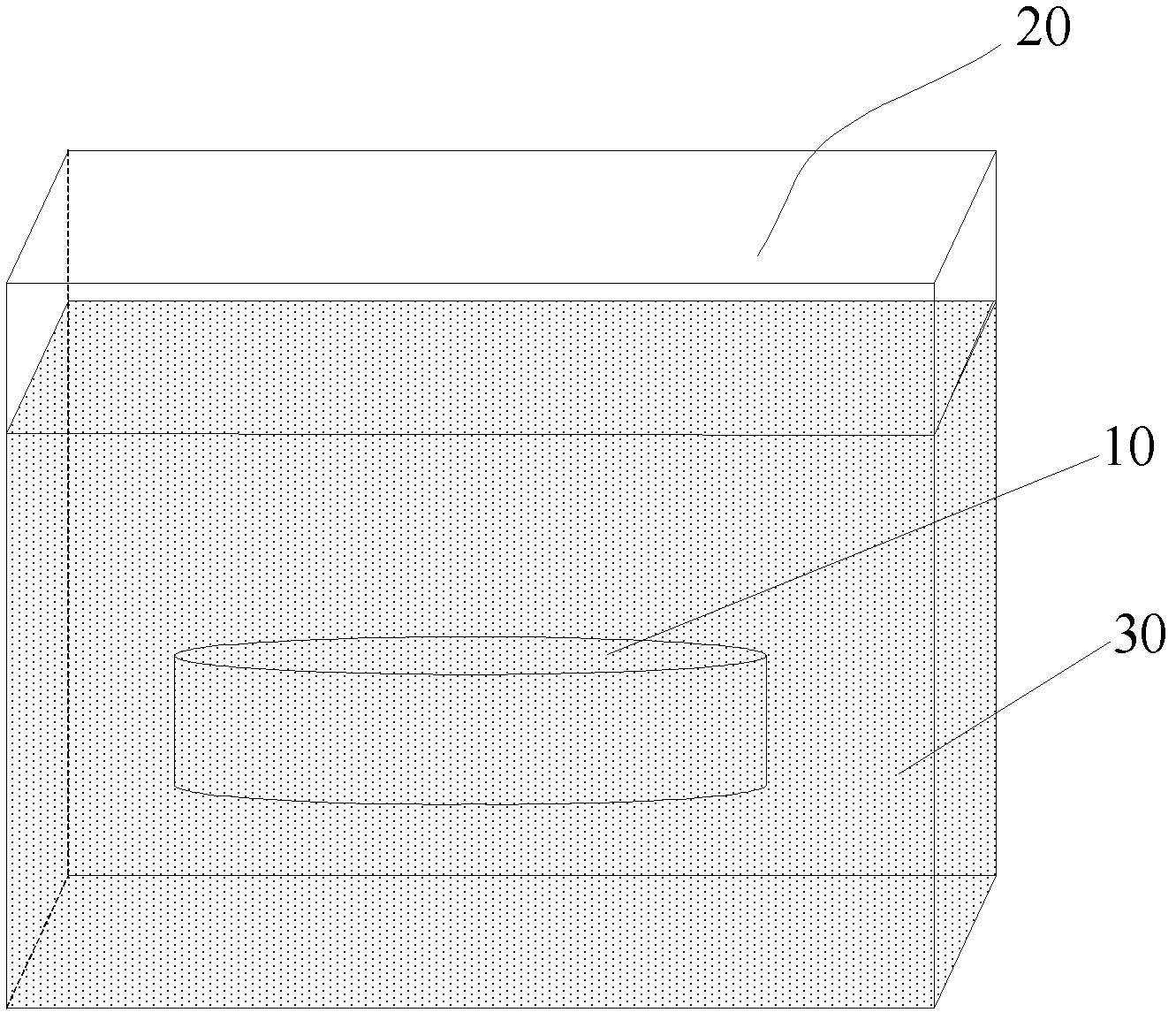

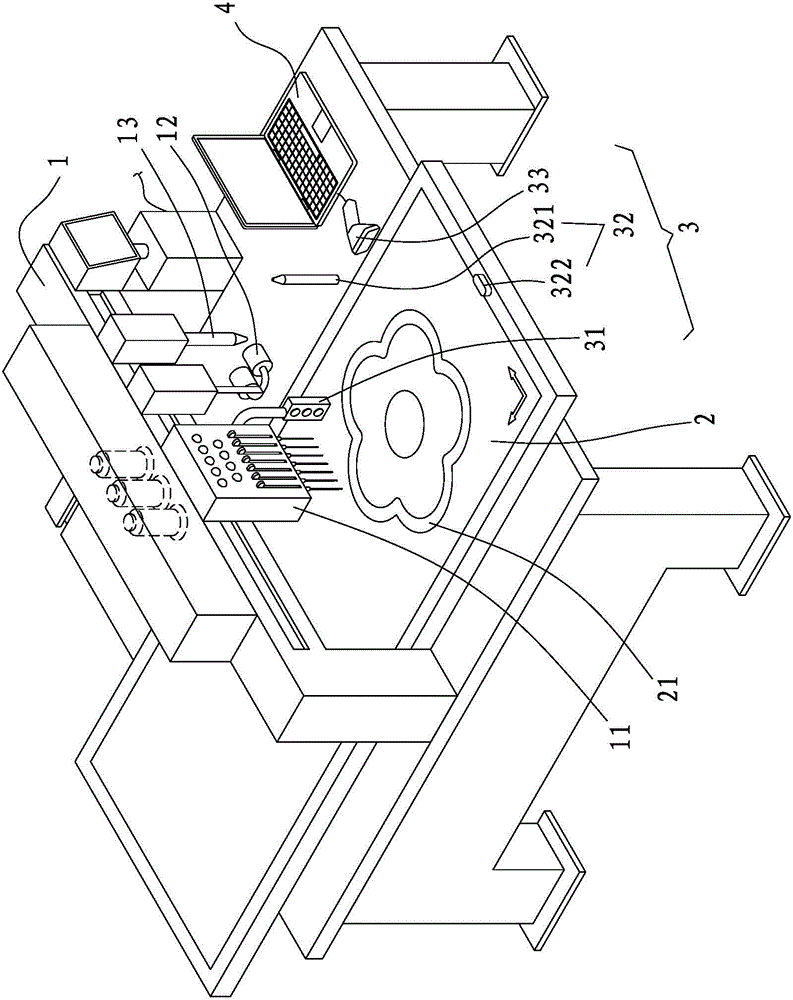

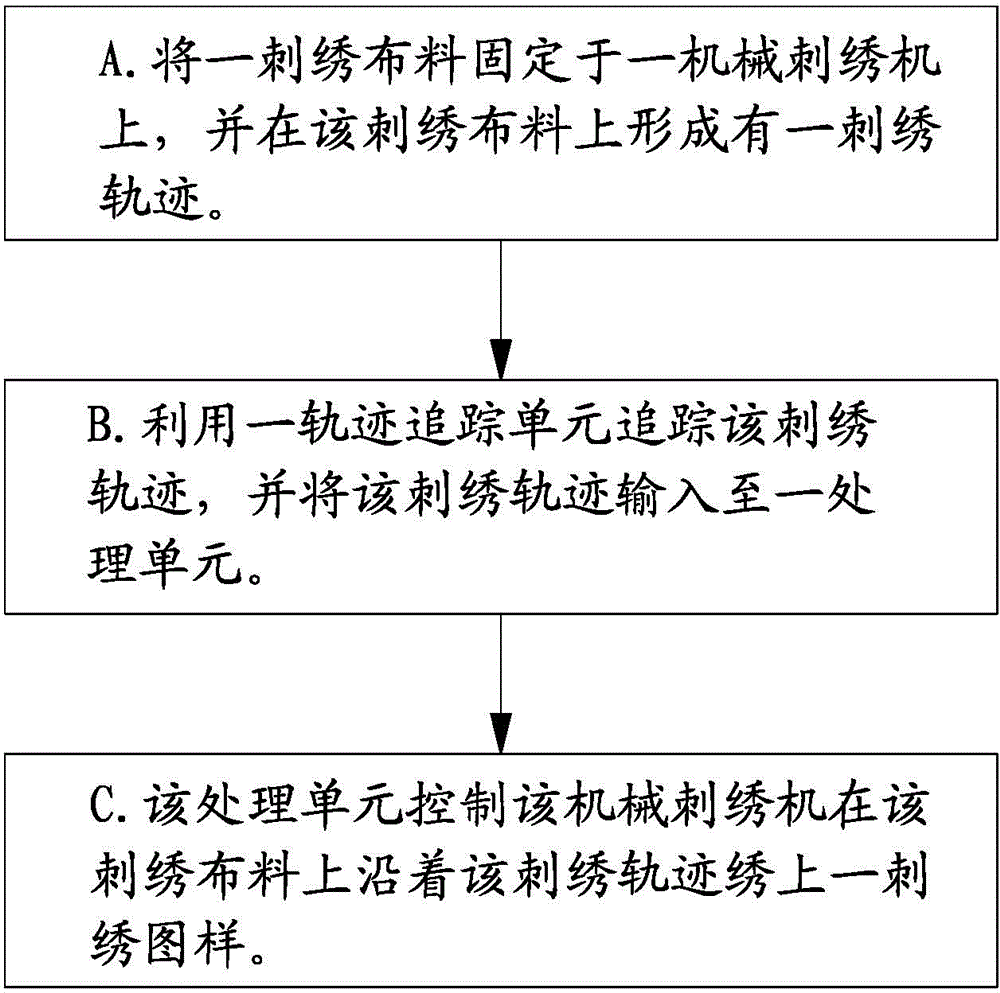

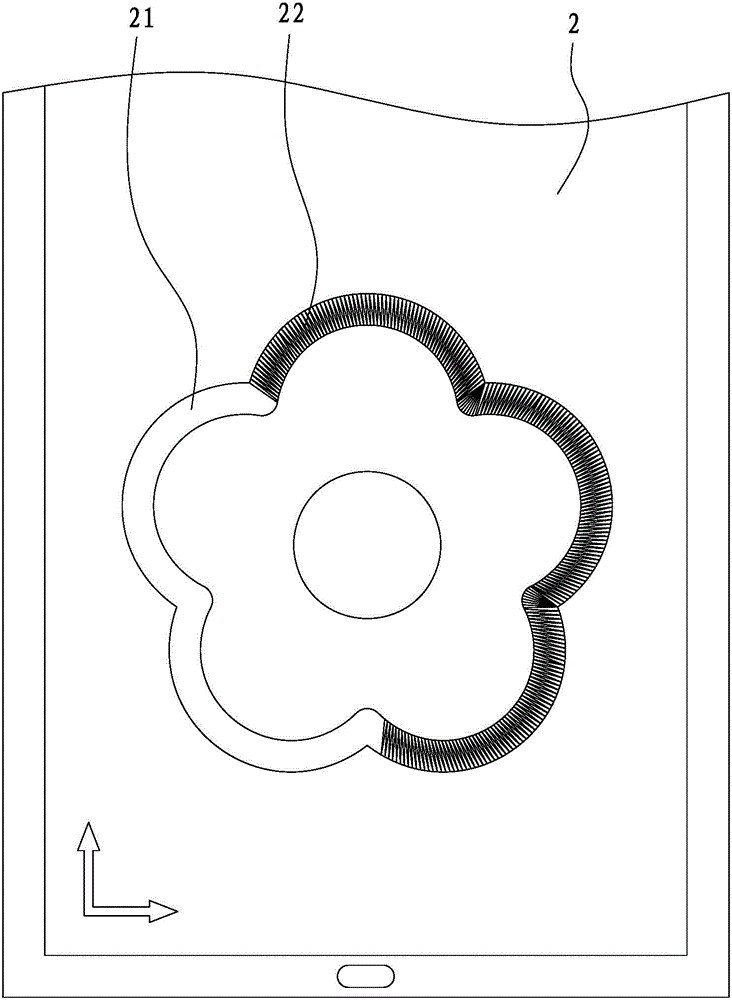

Embroidery making method and embroideries made by using method

The invention relates to an embroidery making method and embroideries made by using the method. The method comprises steps of firstly fixing a cloth material for embroidery on a mechanical embroidery machine, and forming an embroidering track on the cloth material for embroidery; tracking the embroidering track through a track tracing unit, such as photoinduction track tracing equipment, color induction equipment, a scanner, a light pen or CCD (charge coupled device) image capture equipment and the like, and inputting the embroidering track into a processing unit; and embroidering the pattern of the embroidery on the cloth material for embroidery by the processing unit according to the embroidering track. According to the method, the cloth material for embroidery is fixed on the mechanical embroidery machine in advance, steps of scanning and patterning are processed at real time in embroidering process, the coordinates of the embroidering track are directly defined on the cloth material for embroidery, for elastic cloth materials, flexible and deforming characteristics do not cause embroidering position errors and failure in production.

Owner:郑伟源

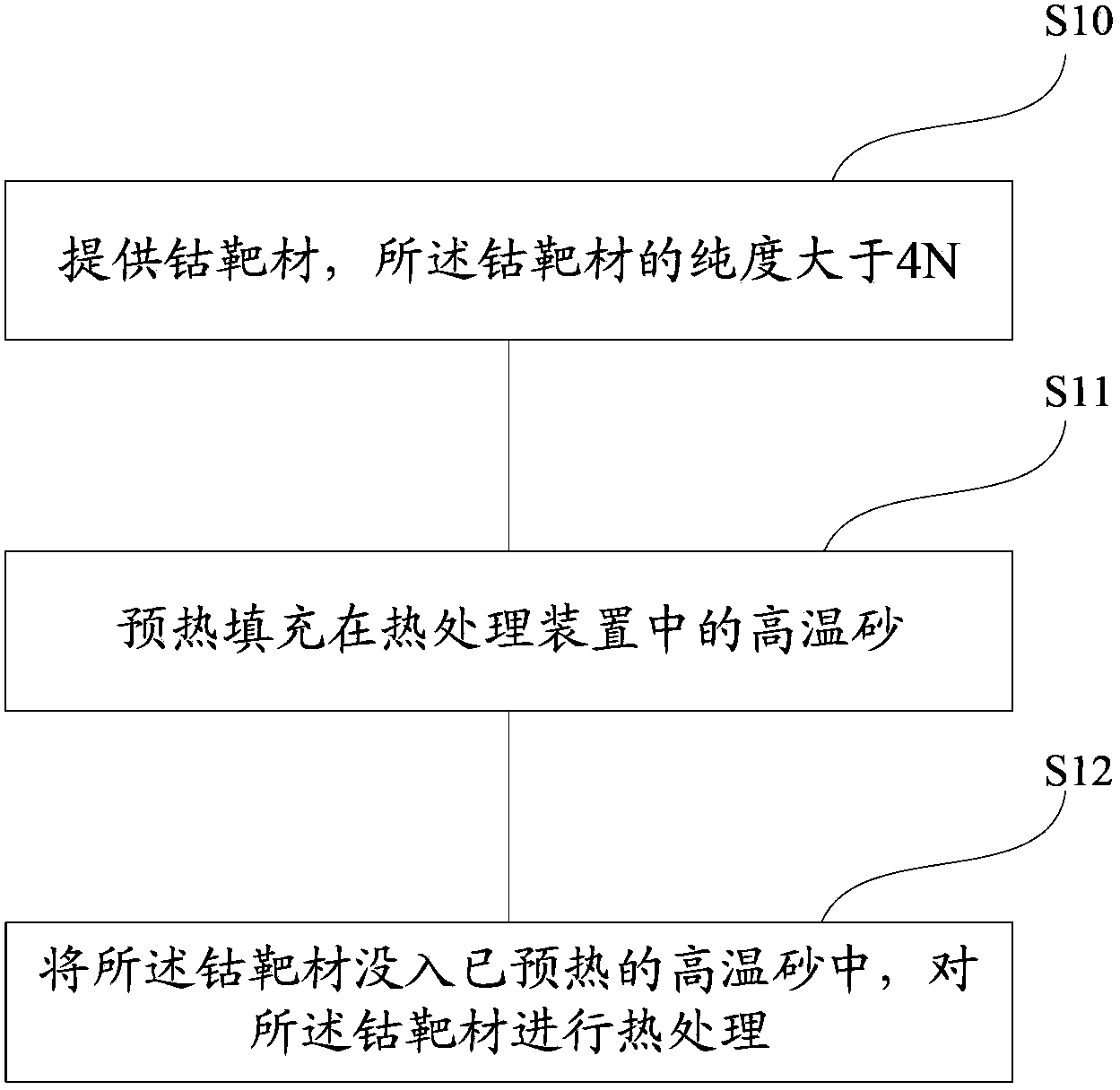

Heat treatment method of cobalt target

The invention provides a heat treatment method of a cobalt target. The heat treatment method comprises the following steps of providing the cobalt target having the purity greater than 4 N; preheating sand; covering the cobalt target with the preheated sand; and performing heat treatment on the cobalt target. Compared with the prior art, the heat treatment method provided by the invention avoids the problems that the cobalt target obtained after the heat treatment process in the prior art does not have the desired magnetic conductivity and the crystalline grains of the cobalt target do not meet the requirements of sputtering in the prior art in the heating way of preheating sand bath.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

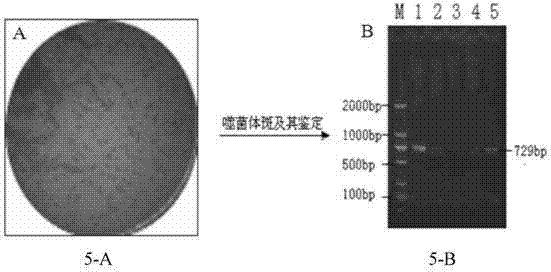

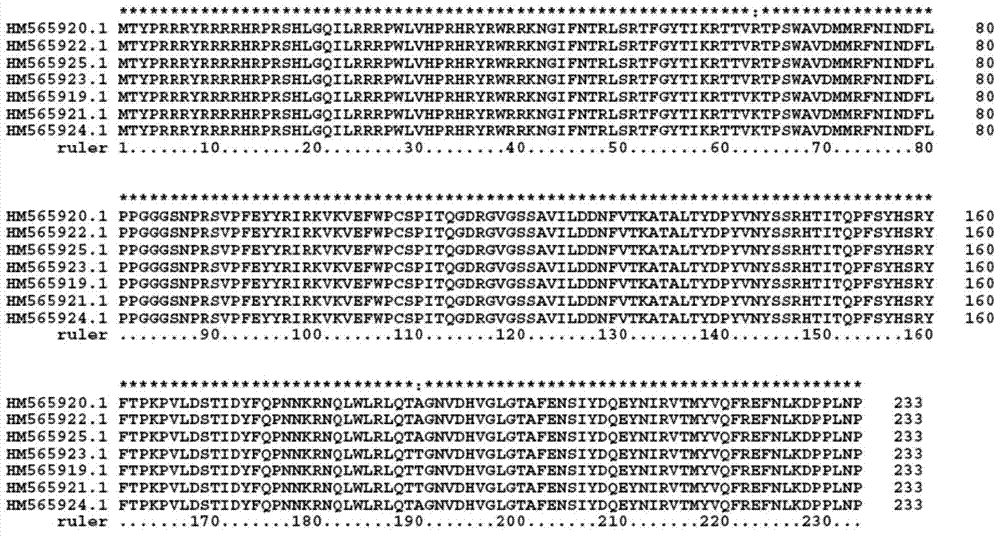

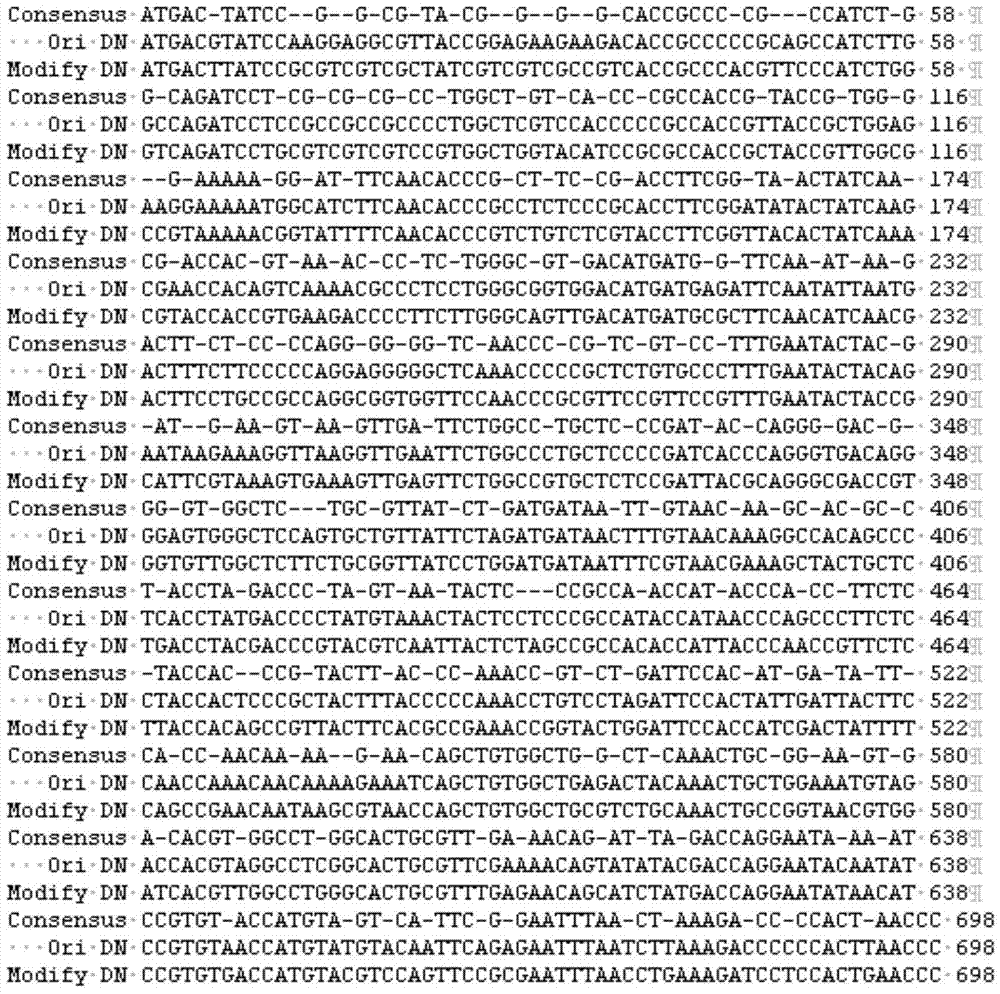

Capsid protein phage display particle of recombinant II porcine circovirus as well as preparation method and application thereof

InactiveCN103540605AReduce manufacturing costOvercome the deficiency of weak immunogenicityViral antigen ingredientsMicroorganism based processesNucleotideCell immune response

The invention belongs to the biological field and particularly relates to preparation and application of recombinant porcine circovirus PCV2-Cap / Phage display particle. A preparation method of the capsid protein phage display particle of recombinant II porcine circovirus specifically comprises the following four steps: (1), optimizing and coding nucleotide of the capsid protein of the recombinant II porcine circovirus; (2), constructing a recombinant plasmid; (3), constructing a recombinant phage genome; and (4), preparing the capsid protein phage display particle of recombinant II porcine circovirus. An animal experiment proves that the recombinan display plasmid has good antigenicity, can stimulate a pig body to generate good humoral immunity and cellular immunity reaction, and can prevent and control II porcine circovirus infection; time needed for copying the process is short, production cost of the recombinant display particle is low, and product is convenient to use, simple and convenient to store and high in cloning yield.

Owner:CHONGQING ACAD OF ANIMAL SCI

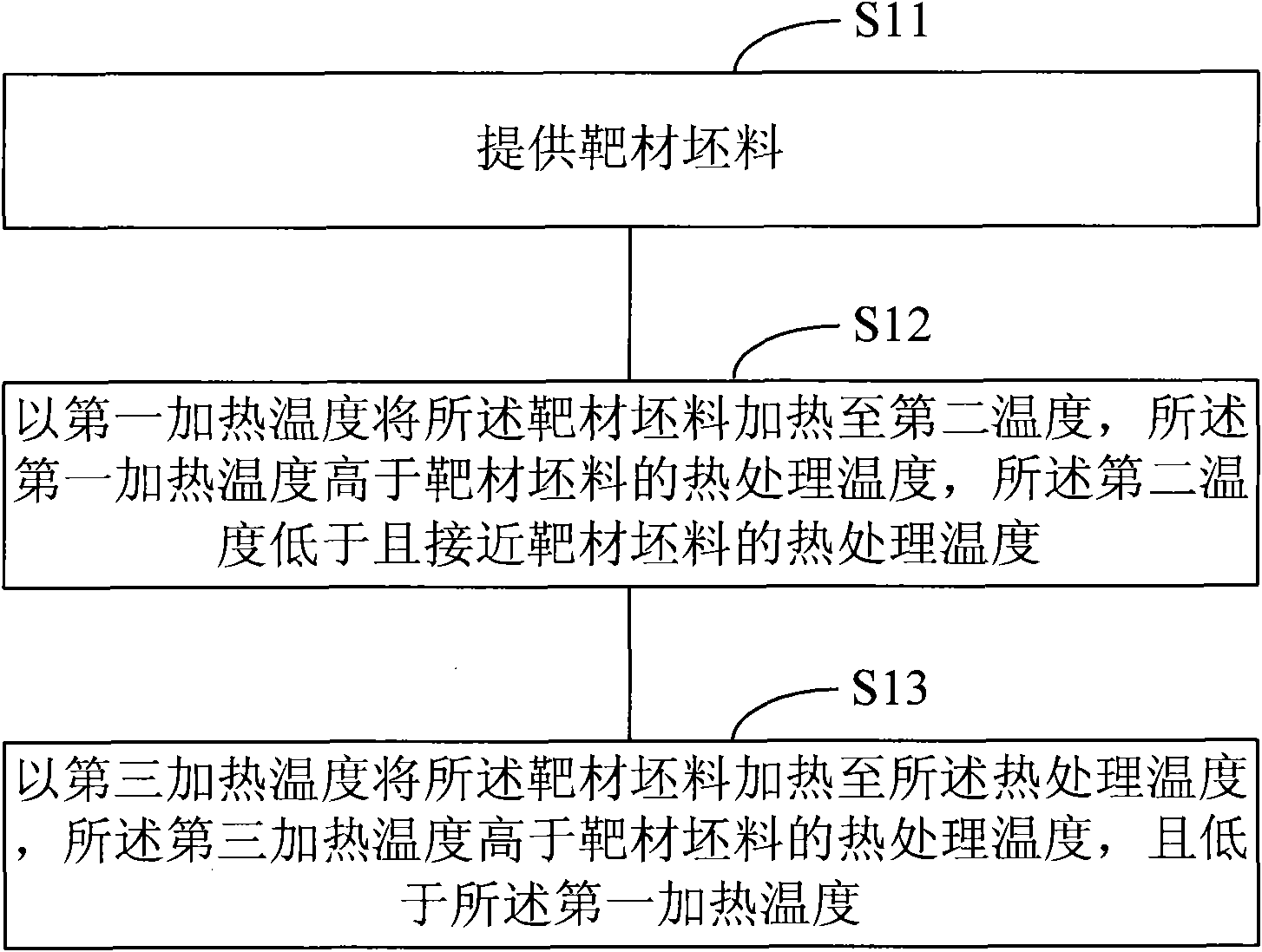

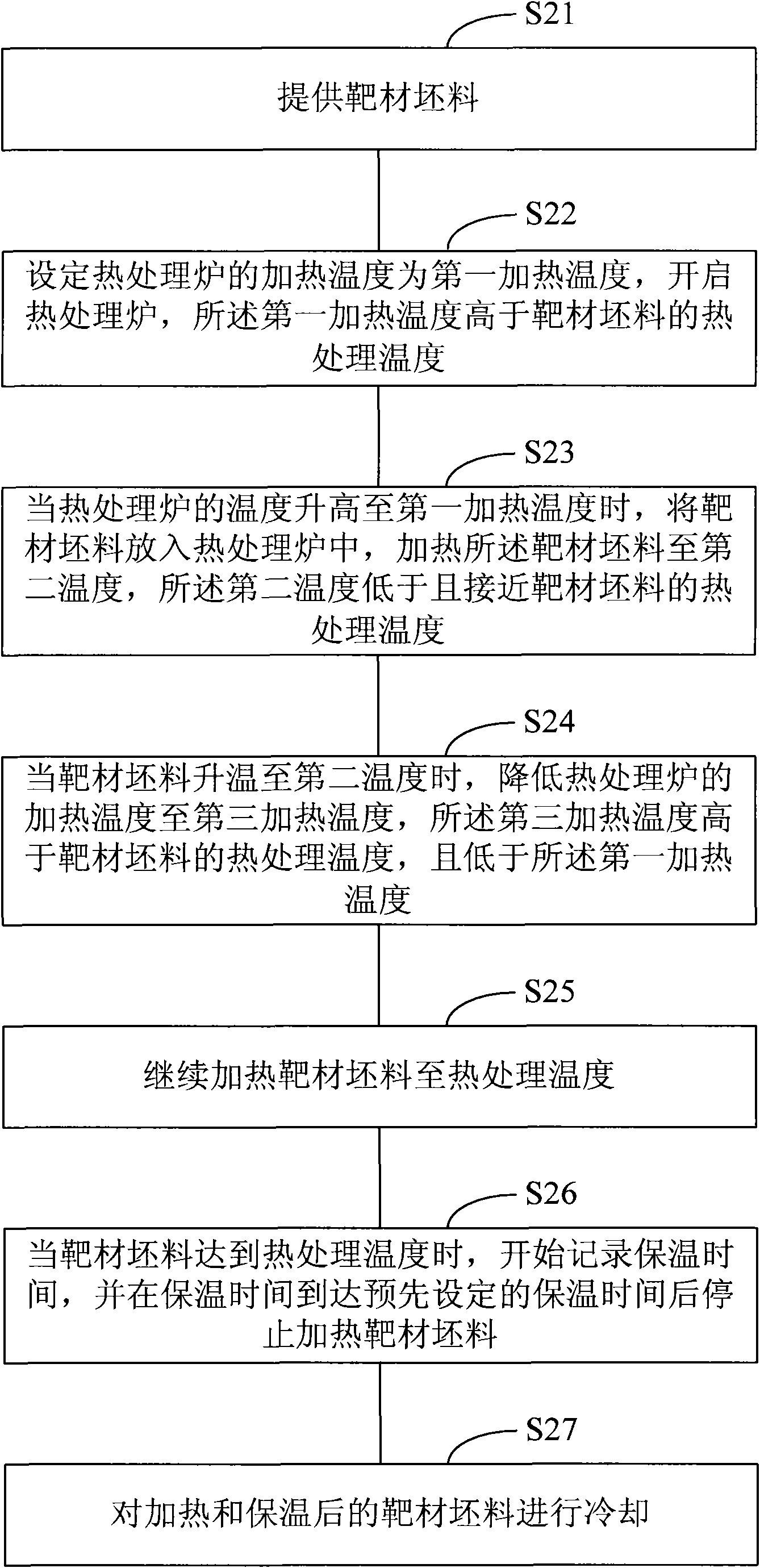

Heat treatment method of target blank

ActiveCN101624695AMass production is fastShort manufacturing cycleVacuum evaporation coatingSputtering coatingHeating temperatureMaterials science

The invention relates to a heat treatment method of a target blank. The method comprises the following steps: providing the target blank; heating the target blank at a first heating temperature to a second temperature, wherein the first heating temperature is higher than the heat treatment temperature of the target blank, and the second temperature is lower than or approximate to the heat treatment temperature of the target blank; and heating the target blank at a third heating temperature to the heat treatment temperature, wherein the third heating temperature is higher than the heat treatment temperature of the target blank and is lower than the first heating temperature. The heat treatment method of the target blank can increase the heating speed of the product and improves the precision and the stability of the heat treatment process.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

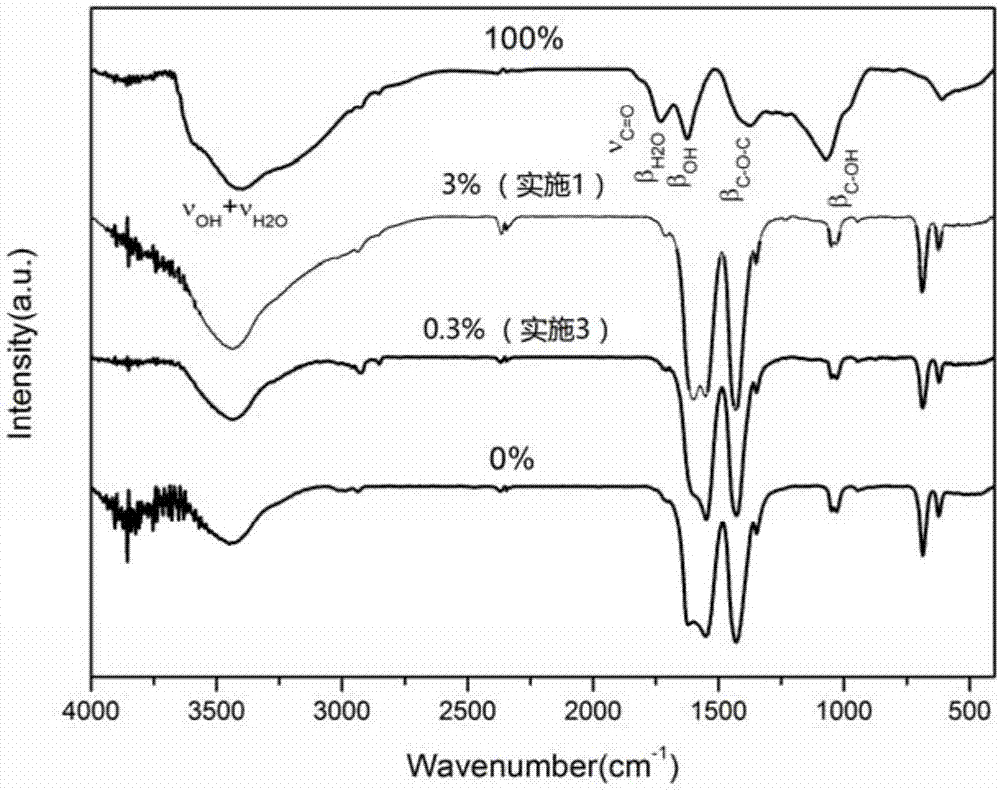

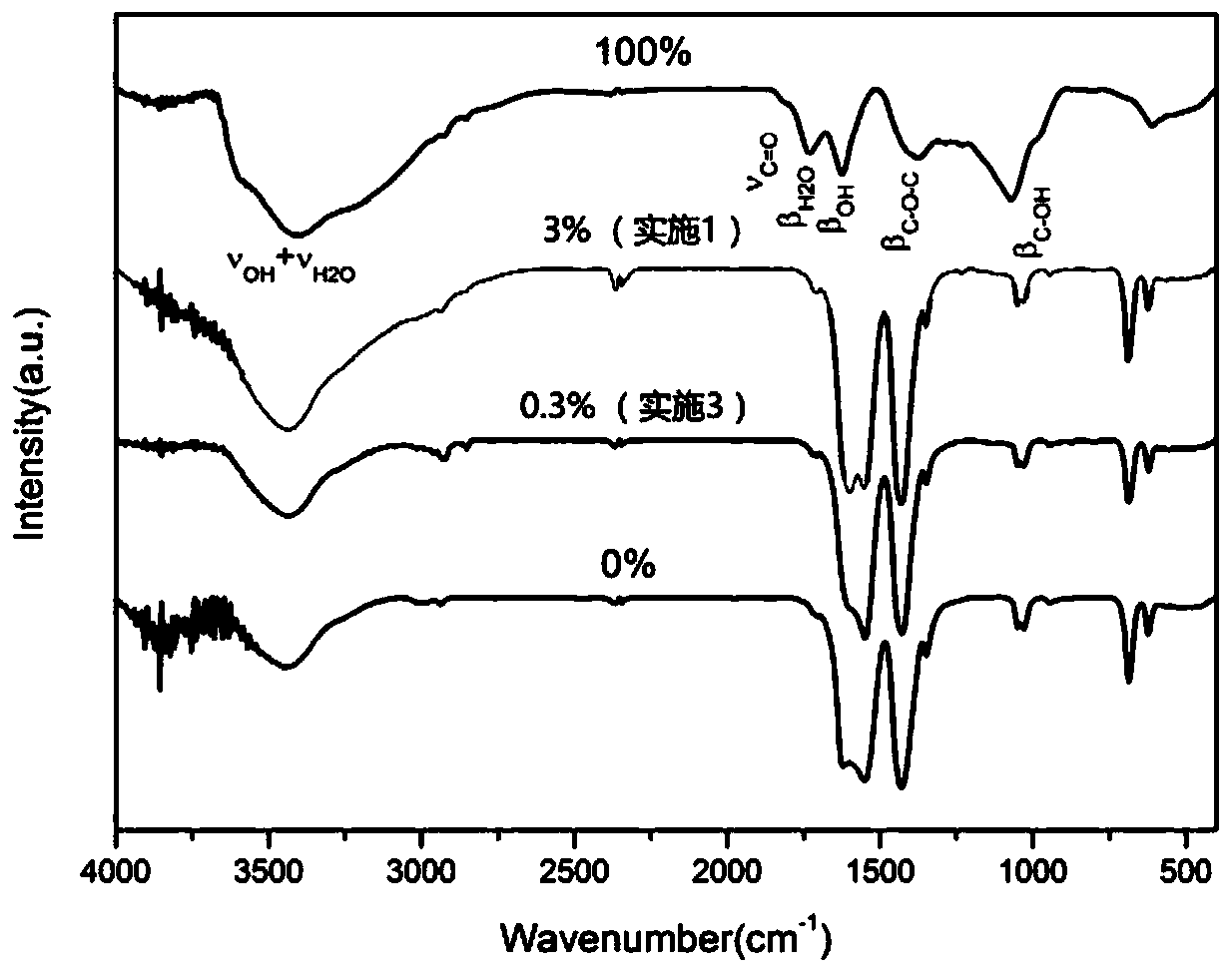

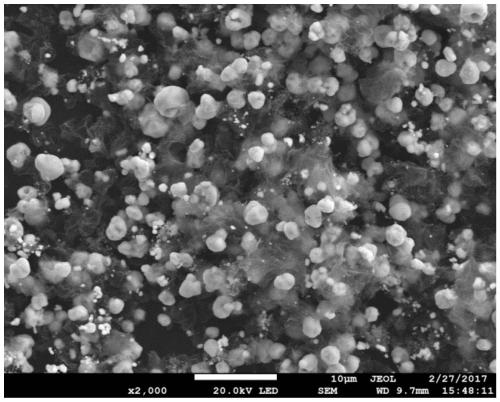

Preparation method for graphene/copper composite powder material

The invention relates to a preparation method for a graphene / copper composite powder material. The method comprises the following steps: adding cupric acetate into a graphene oxide aqueous solution while quickly shearing and stirring the mixed solution; keeping quick shearing and stirring for the mixed solution after completely adding, and meanwhile, adopting a spray dryer for continuously extracting the mixed solution and performing spray drying, thereby acquiring precursor graphene oxide / cupric acetate powder; and raising the temperature of the acquired precursor powder to 350-700 DEG C under reducing atmosphere and keeping the temperature for 15-30min, thereby acquiring the graphene / copper composite powder material. The present graphene oxide reduction preparation equipment is used, the method is simple and efficient, the cost is lower and the preparation method is suitable for wide industrial application and popularization.

Owner:HEBEI UNIV OF TECH

Ultra-silence neck guard pillow

InactiveCN104665406ADesign innovationReduce manufacturing costPillowsVibration massageEngineeringControl switch

The invention relates to an ultra-silence neck guard pillow. The ultra-silence neck guard pillow is characterized by being formed by five main parts including a pillow sleeve, a pillow body, a vibrating motor, a noise shielding layer and a control switch. The pillow sleeve has the fixing effect. The pillow body is a main body for forming the neck guard pillow. The noise shielding layer is adopted for shielding noise generated by the vibrating motor during work to be maximum degree. The control switch is additionally arranged to control the vibrating motor to work in the mode suitable for the comfort degree of the human body. The product health care effect is obvious, a user feels comfortable, and the production cost is low.

Owner:杨泽

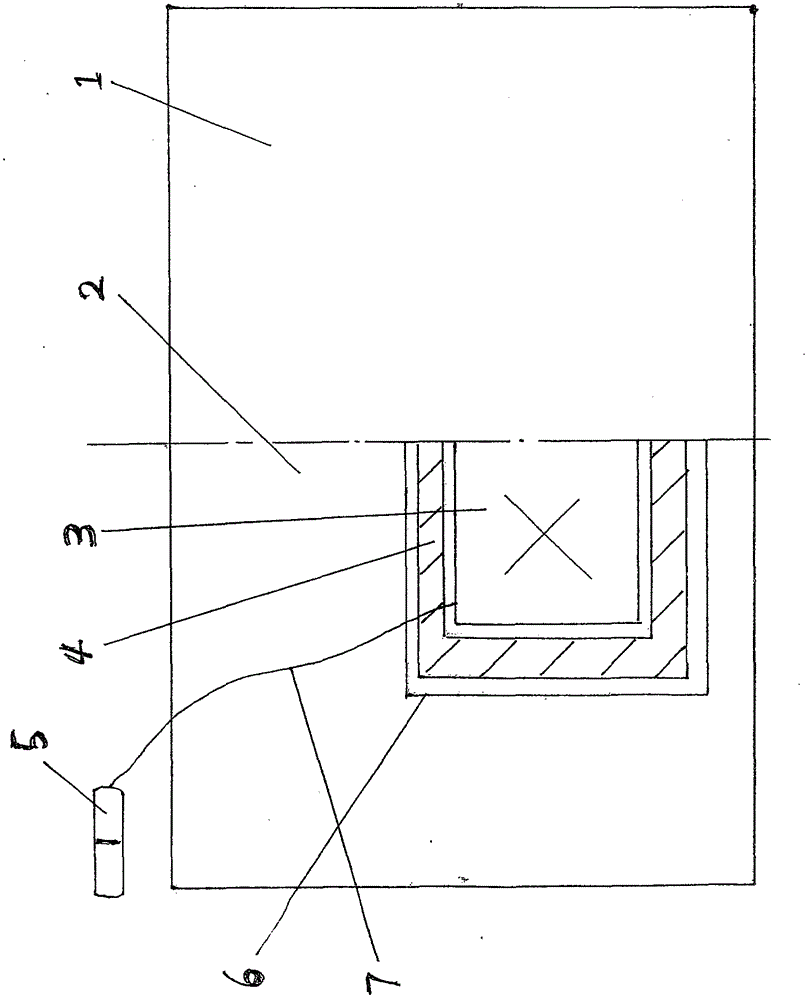

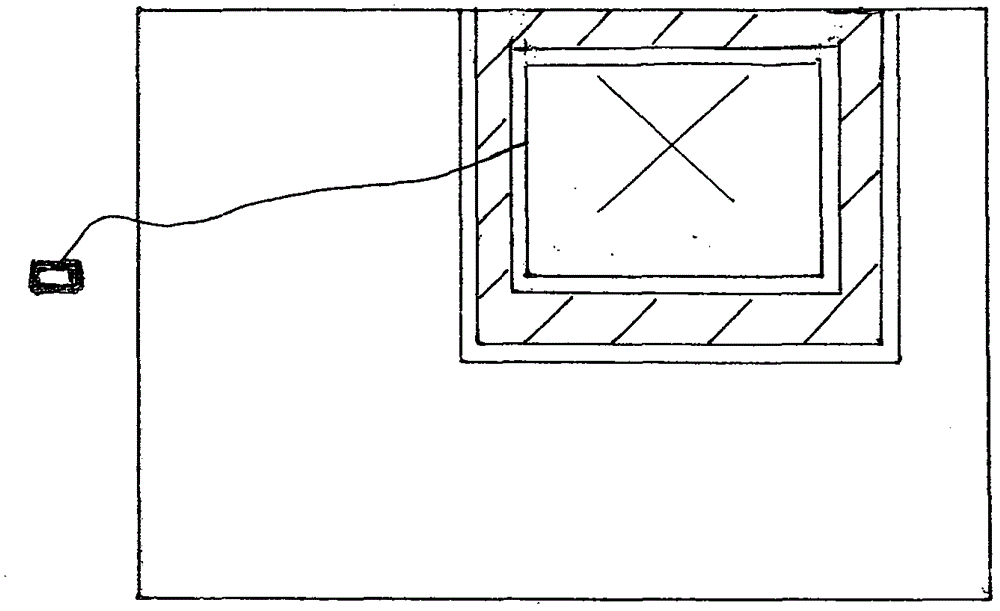

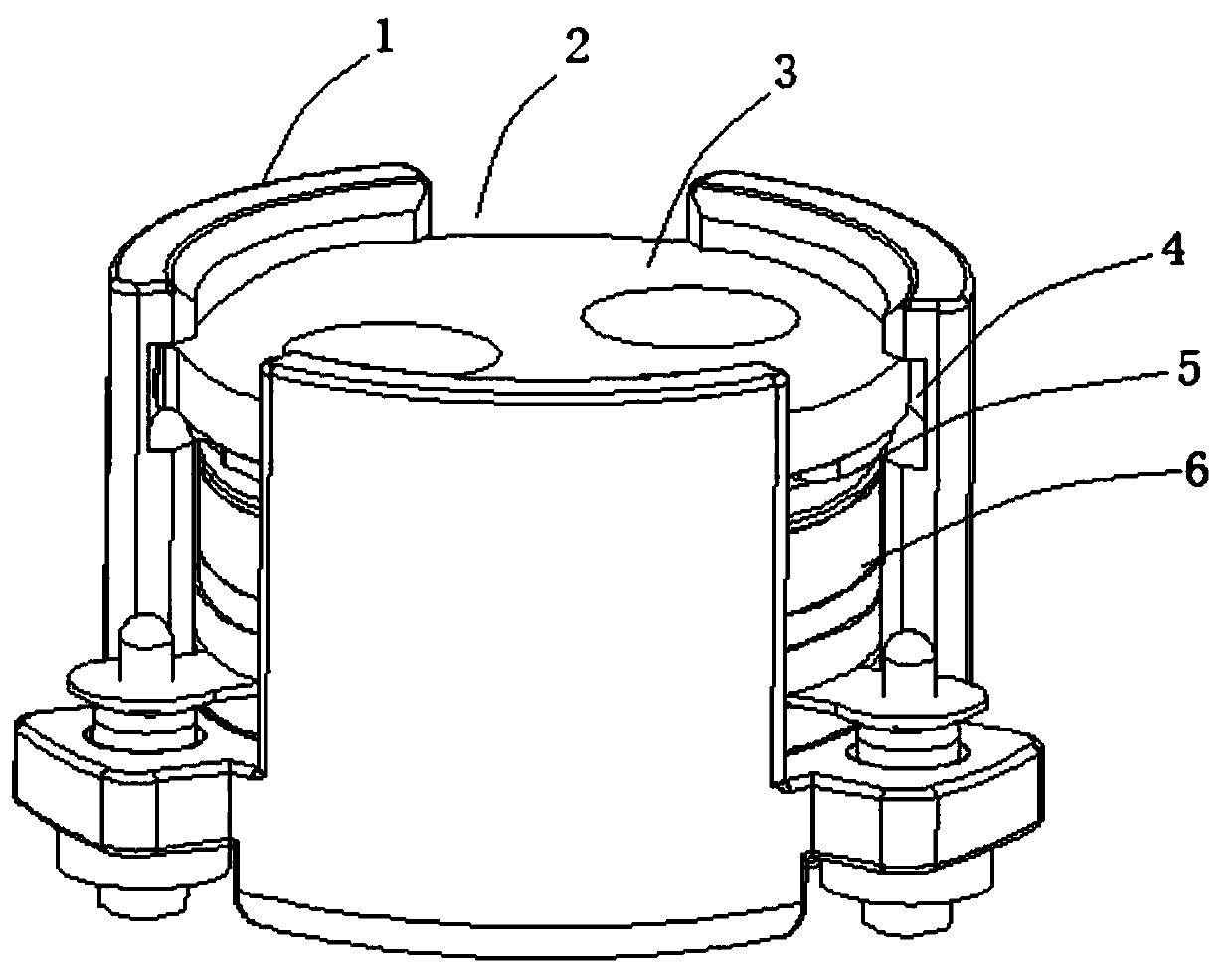

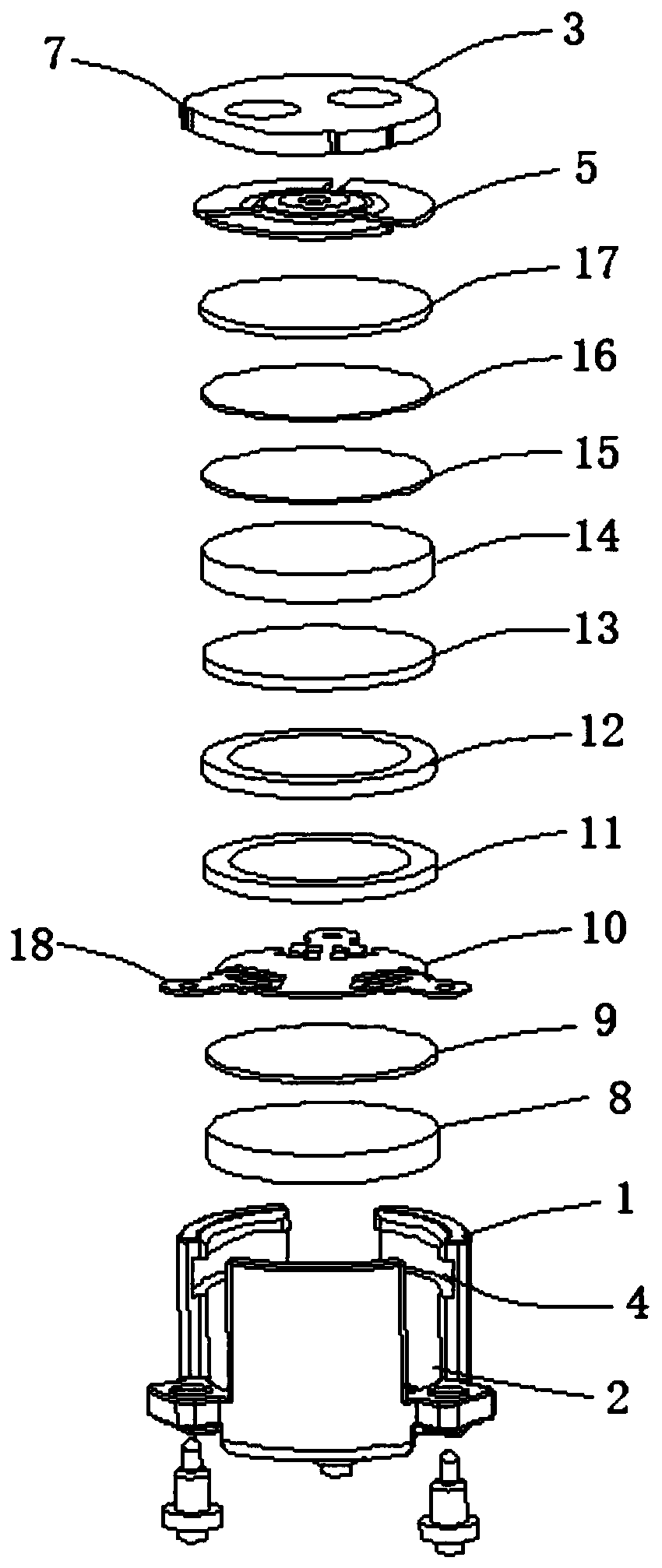

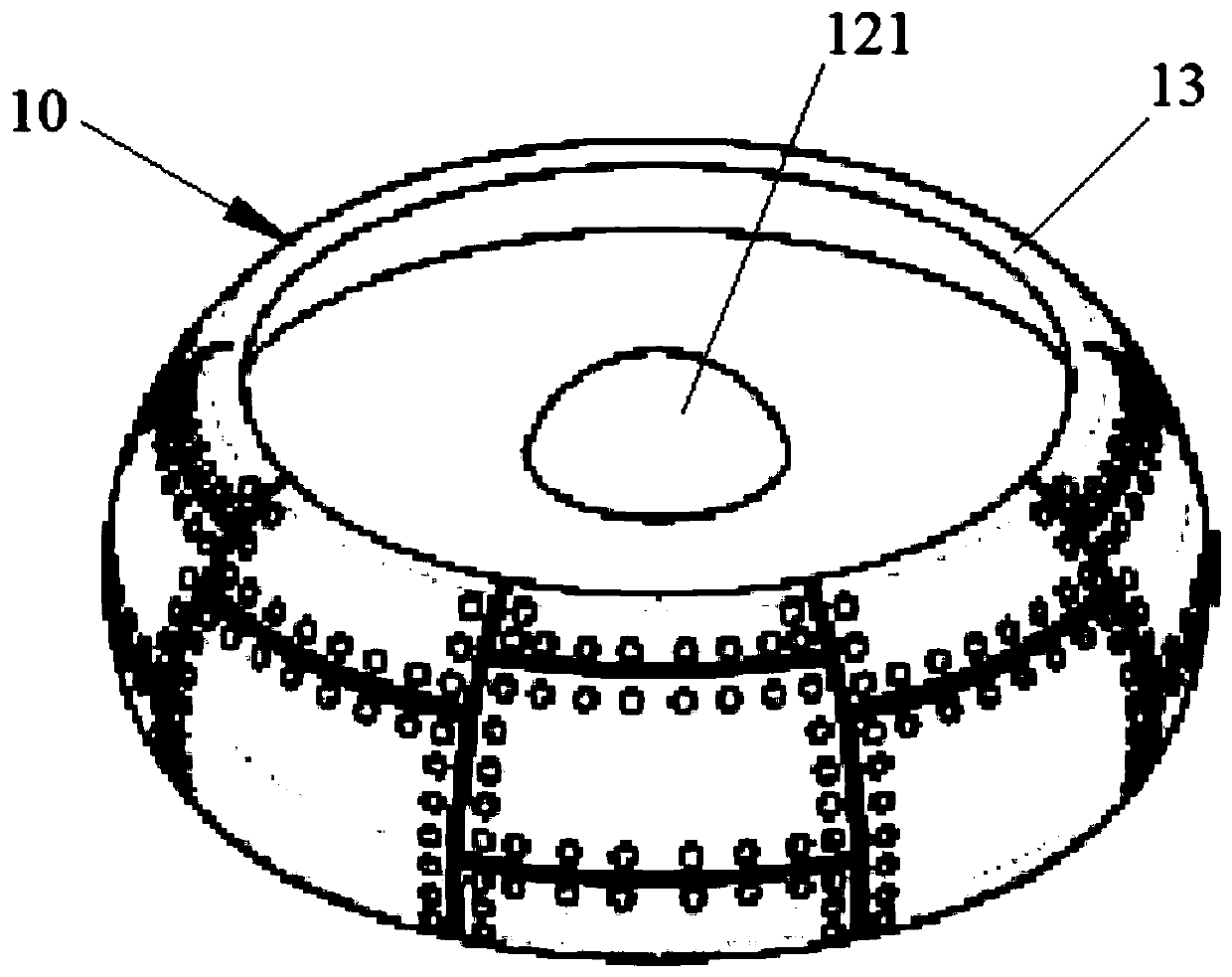

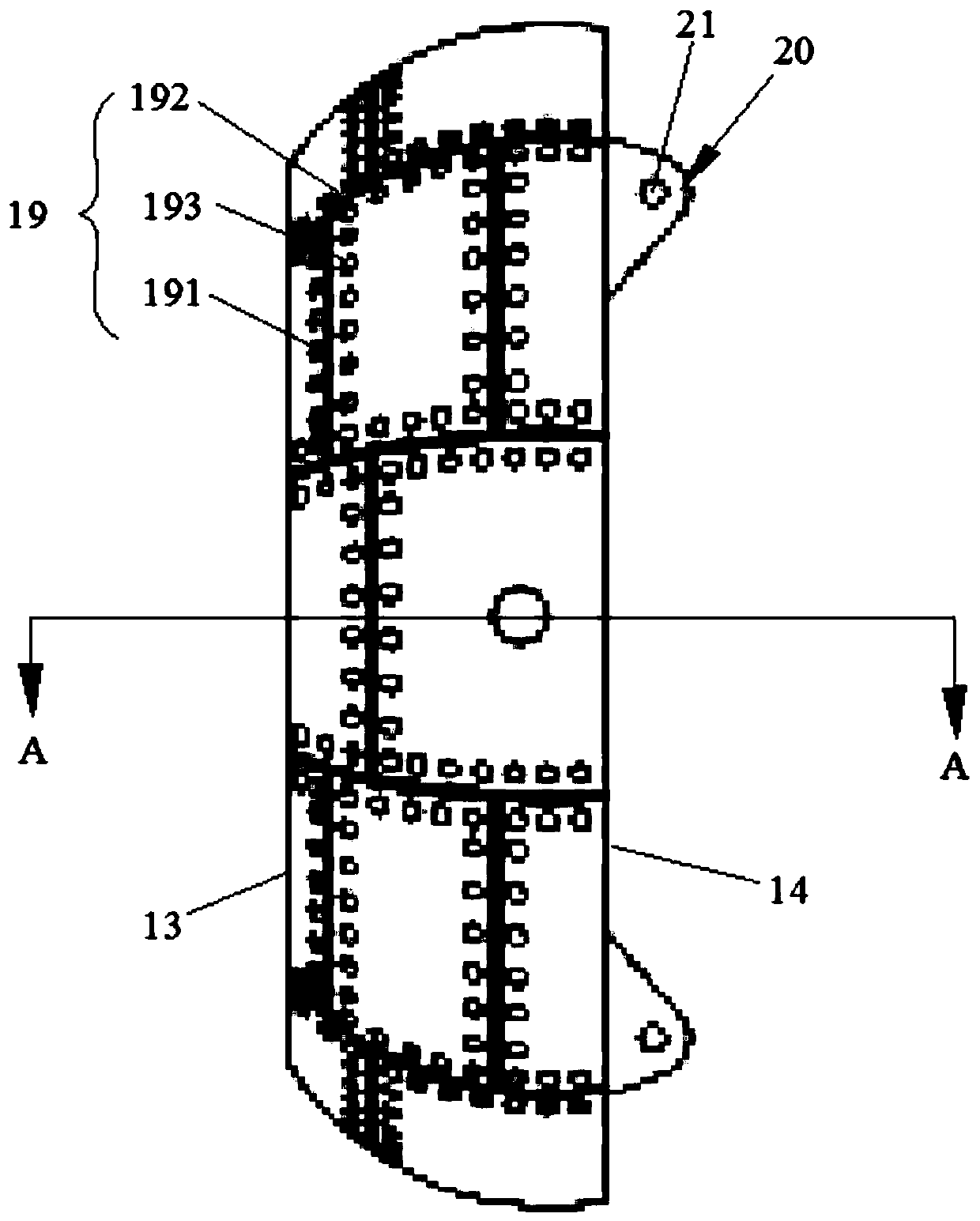

Buckling and pressing inner screw cap type circulator

PendingCN111416186AEasy to assembleImprove assembly efficiencyWaveguide type devicesStructural engineeringScrew cap

The invention provides a buckling and pressing inner screw cap type circulator. The circulator comprises a shell and a cover plate, wherein the shell is a semi-open cavity; a plurality of notches areformed in the side wall of the shell at intervals, a groove is formed in the inner side wall of the shell, the two ends of the groove are communicated with the two adjacent notches in the shell, a clamping block which extends outwards and is matched with the groove is arranged on the outer edge of the cover plate, a working assembly is contained in the shell, and the cover plate is pressed above the working assembly in a covering mode. According to the invention, the cover plate and the shell are connected through the pressing fit of the clamping block and the groove; accurate positioning of the cover plate and the shell does not need to be considered, the assembling operation of assembling personnel is simplified, the assembling efficiency is improved, batch production can be achieved more quickly, and the percent of pass is high; meanwhile, internal threads are prevented from being machined in an inner cavity of the shell, the shell can be formed through punching, and the machining difficulty and the machining cost of the shell are reduced.

Owner:WUHAN FINGU ELECTRONICS TECH

Lightweight high-elasticity liquid metal watch shell and production method thereof

The invention discloses a lightweight high-elasticity liquid metal watch shell and a production method thereof. The watch shell is produced by utilizing a liquid metal material, the characteristics ofhigh intensity and wear resistance of liquid metal are sufficiently utilized, and intensity of the watch shell is improved, so that falling resistance of a watch is improved, a wall thickness of thewatch shell can be further reduced, a weight of the watch can be reduced, and wearing comfort is improved; and moreover, the liquid metal has excellent shaping capacity and can be formed like plastic,and thus, a complex watch shell structure can be produced, production accuracy is high, the surface is smooth and wear-resistant, and the lightweight high-elasticity liquid metal watch shell has veryhigh durability and corrosion resistance. By the production method disclosed by the invention, the liquid metal and a curing agent are reasonably mixed, lightweight and elastic effects are achieved,and the lightweight high-elasticity liquid metal watch shell is directly formed by injection and is easy to process and high in accuracy.

Owner:DONGGUAN DELI CLOCK CO LTD

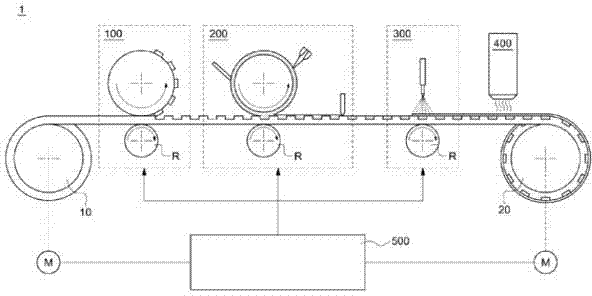

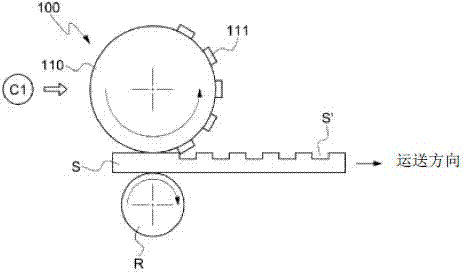

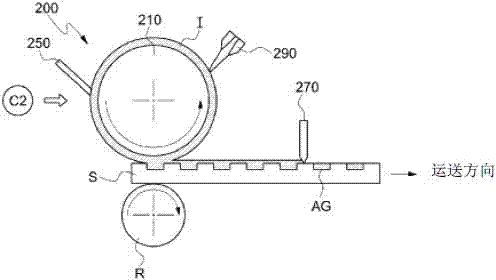

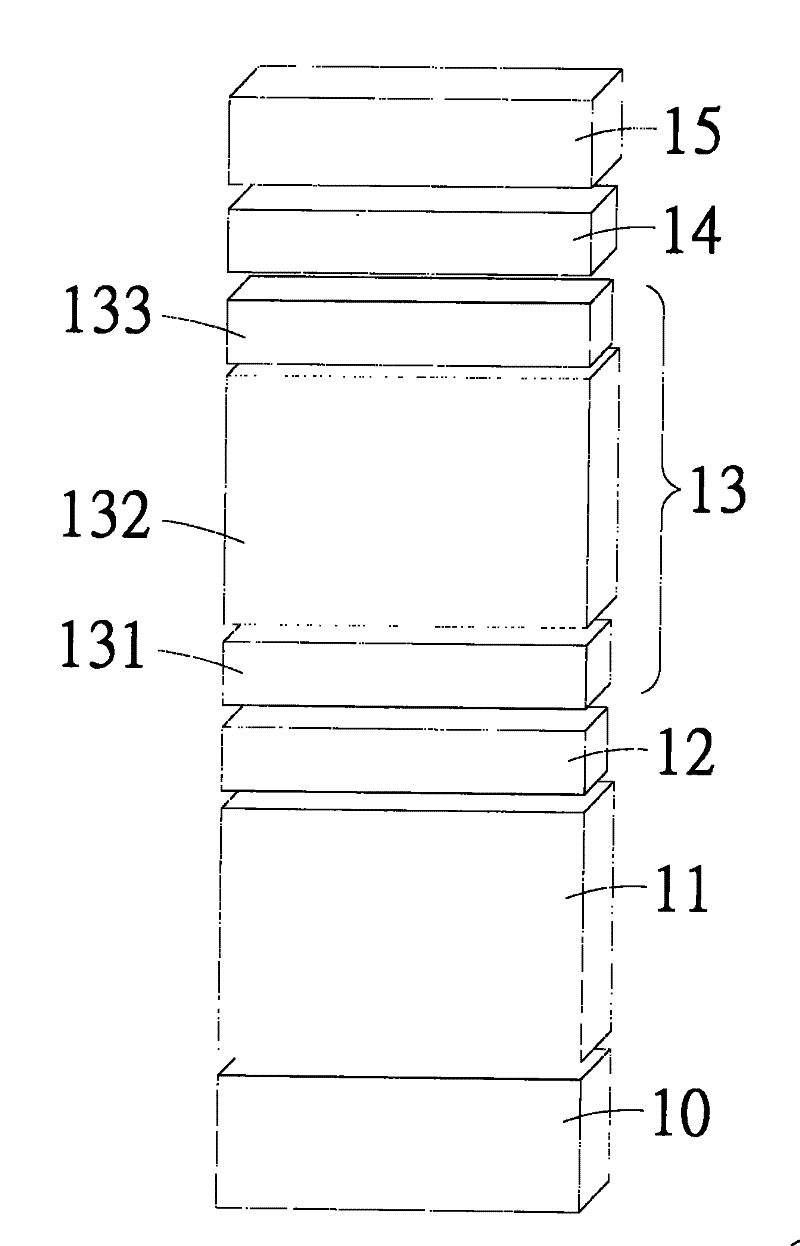

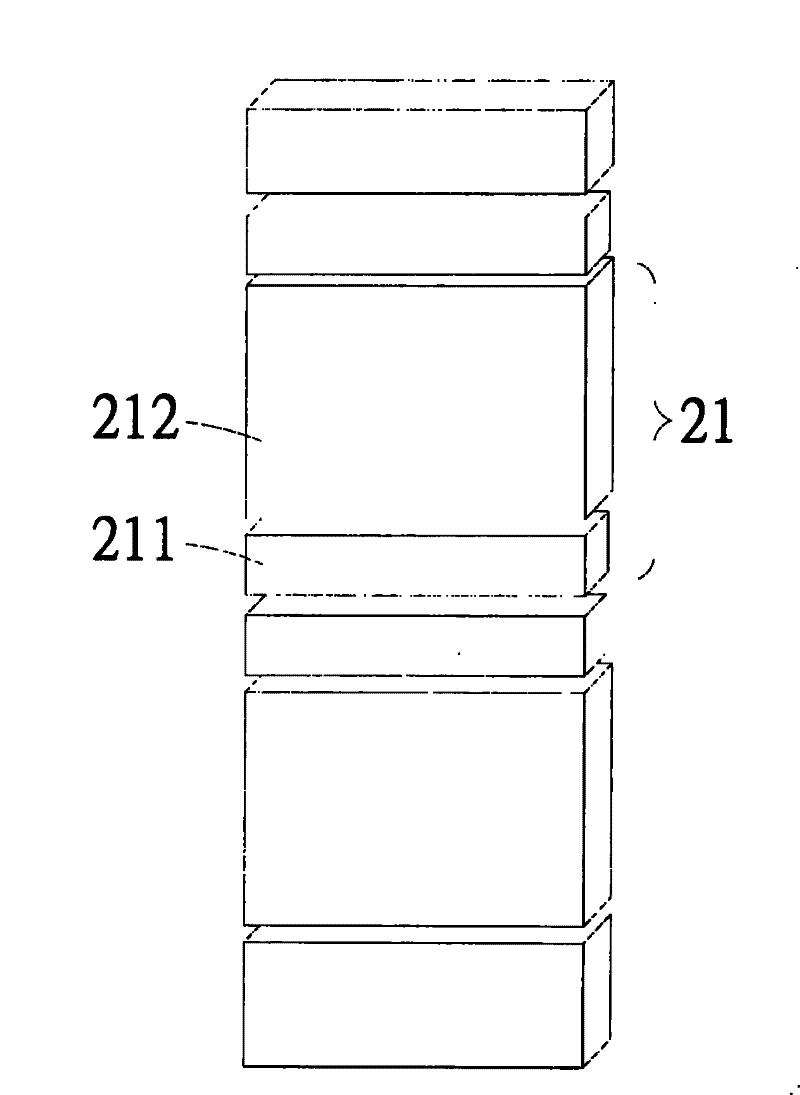

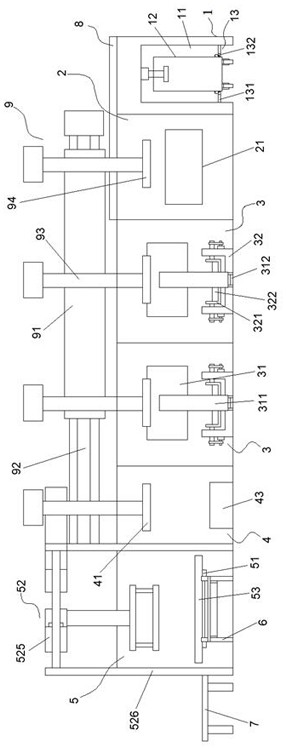

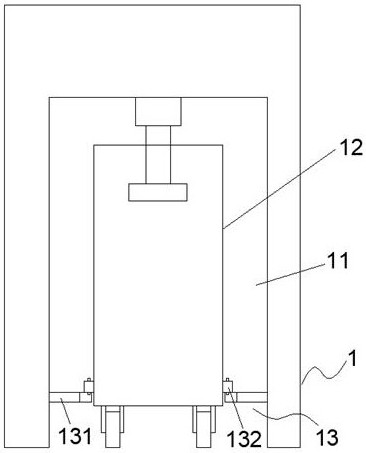

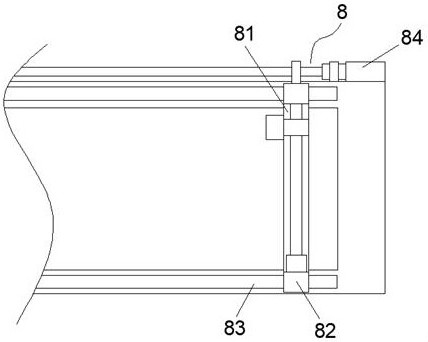

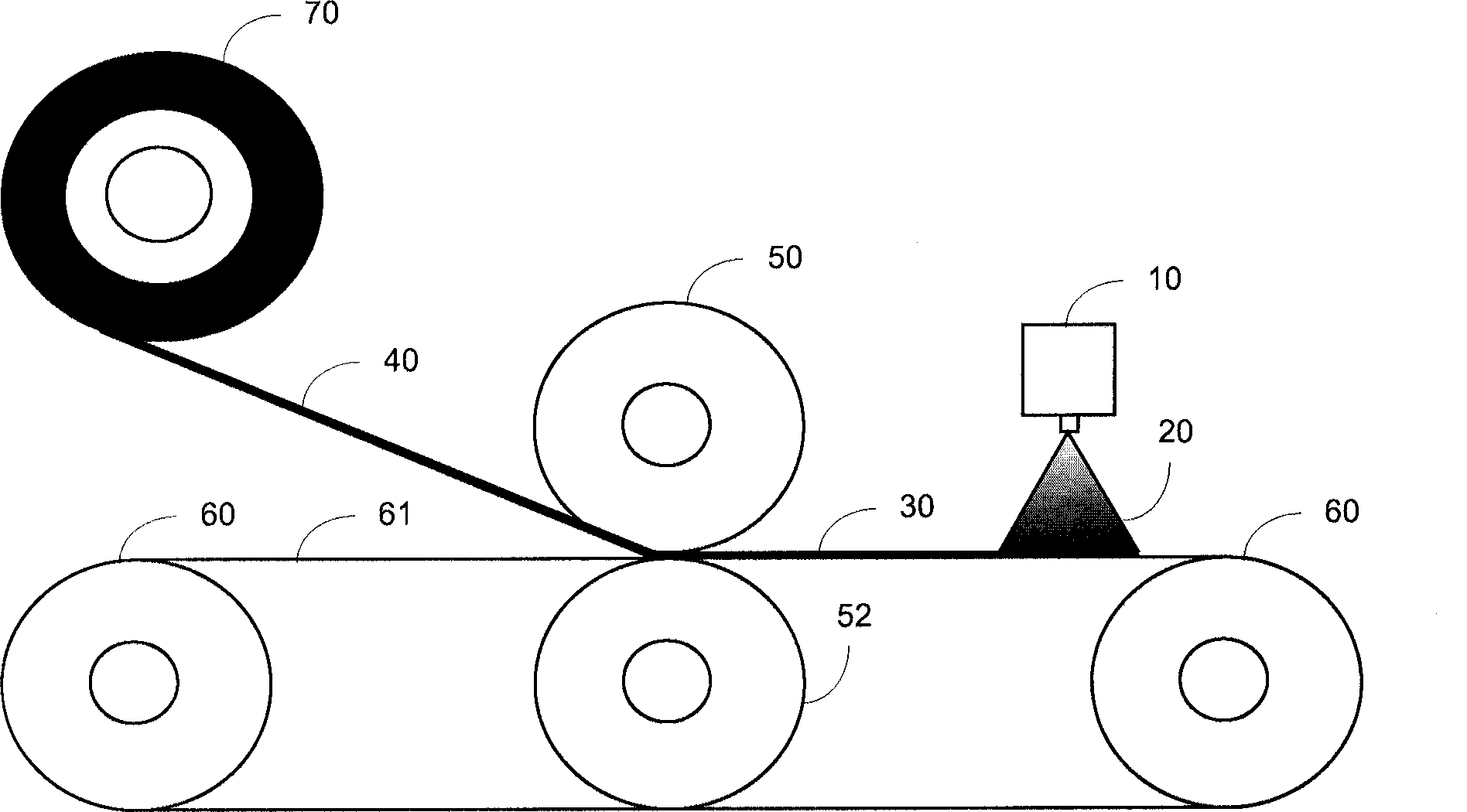

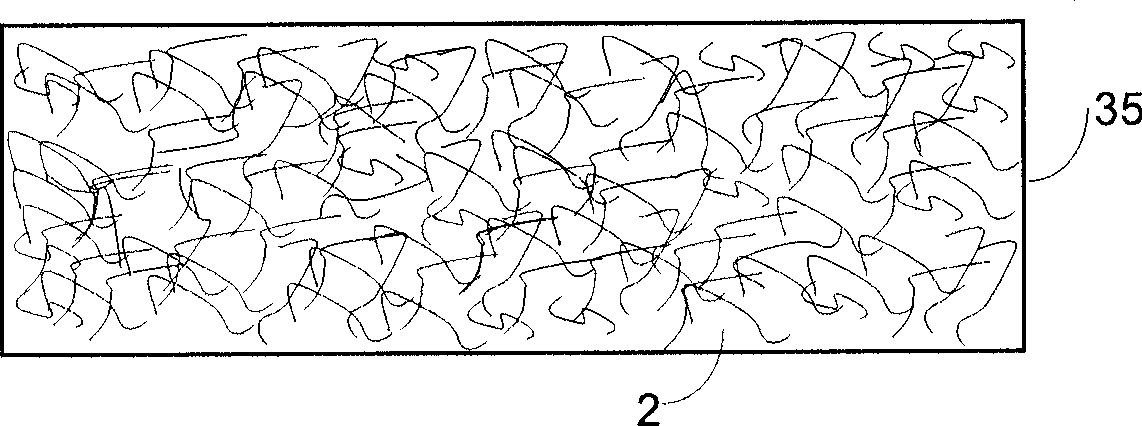

Transparent electrode film manufacturing device and transparent electrode film manufacturing method

InactiveCN104508762AMass production is fastImprove surface roughnessConductive layers on insulating-supportsPhotovoltaic energy generationSurface roughnessOptoelectronics

The present invention relates to a transparent electrode film manufacturing device and a transparent electrode film manufacturing method and, more specifically, to a transparent electrode film manufacturing device which can quickly mass produce transparent electrode films and can improve surface roughness characteristics of a transparent electrode down to several nanometer levels.

Owner:汉田大学校产学协力团

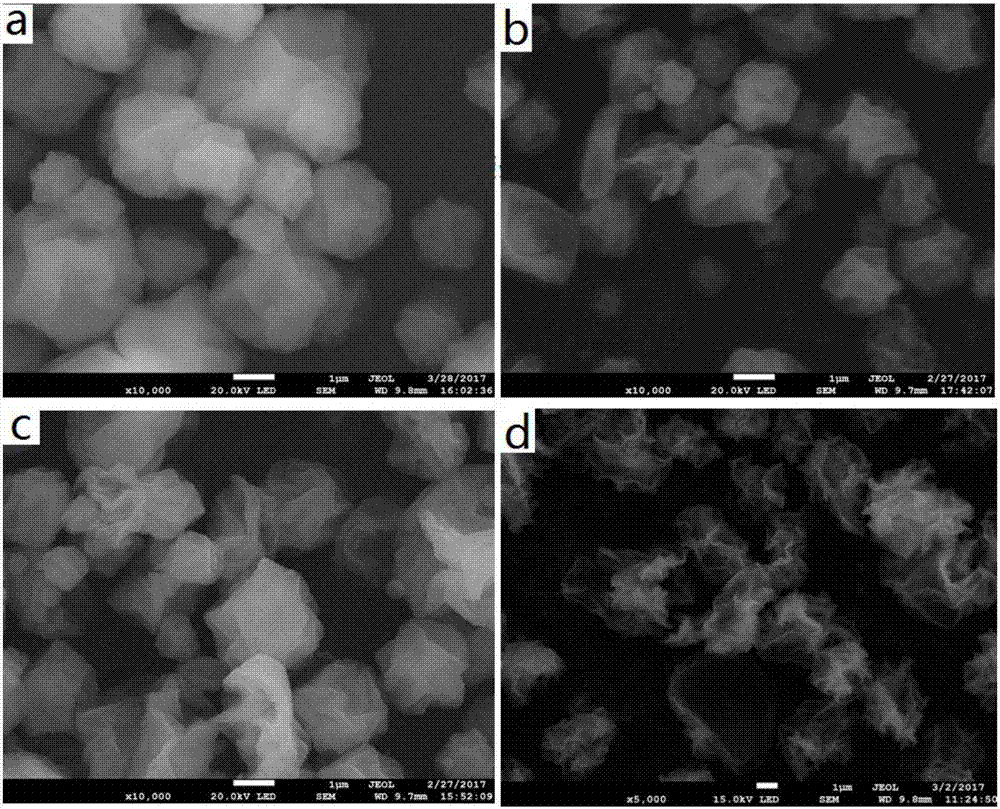

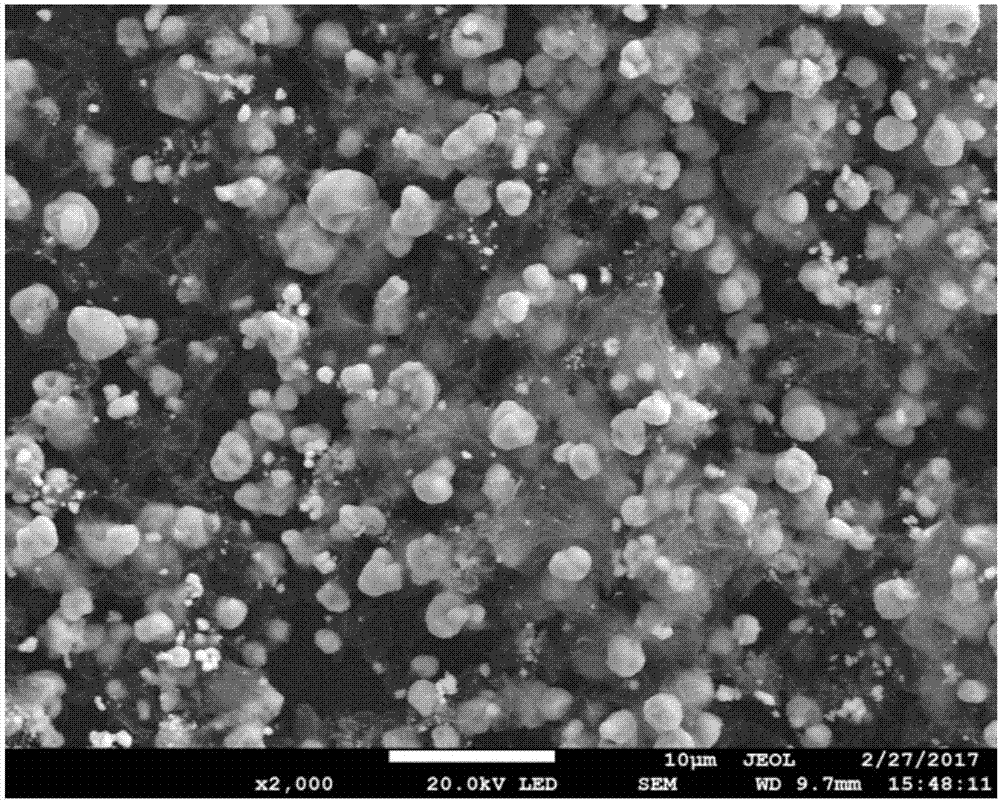

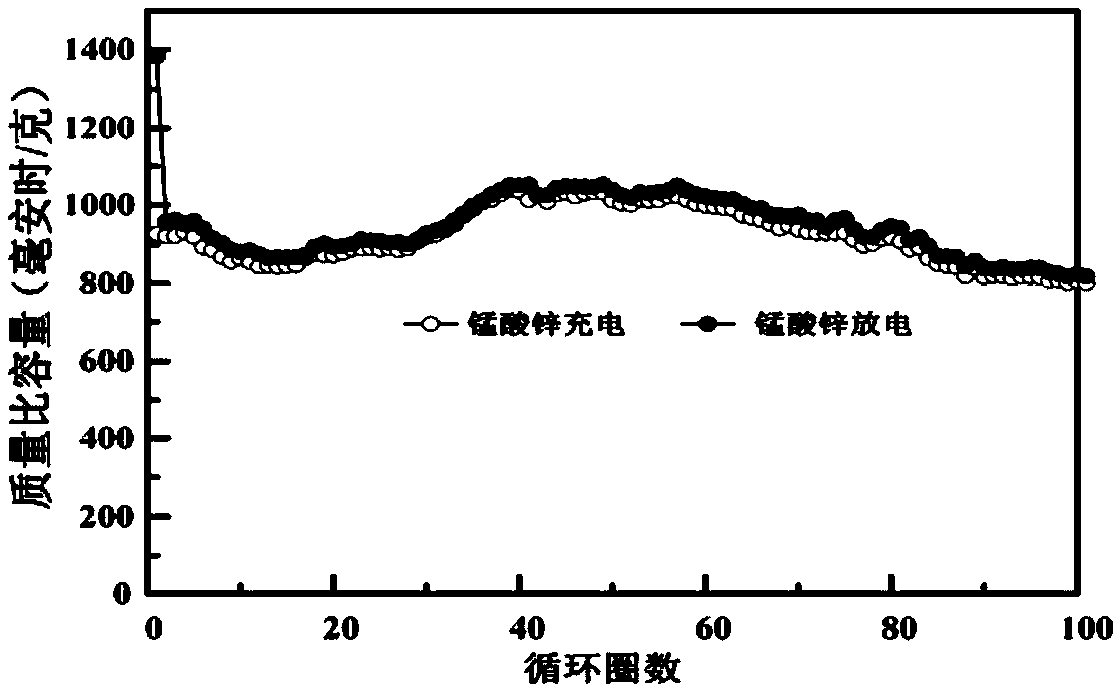

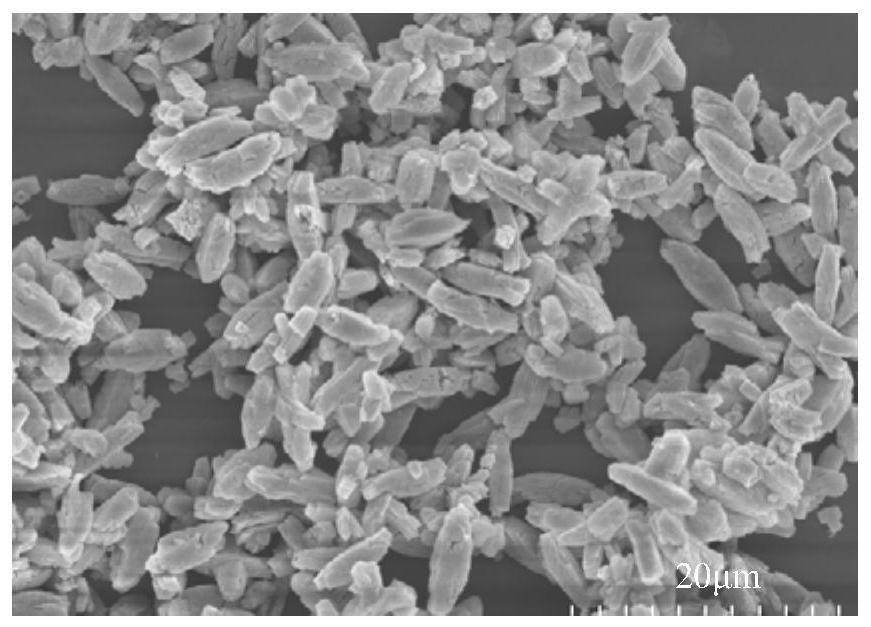

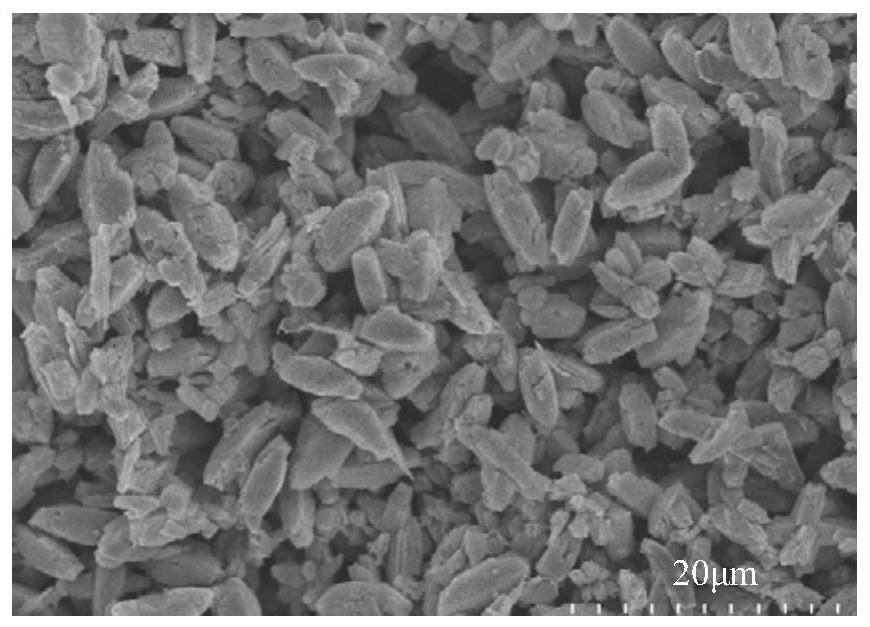

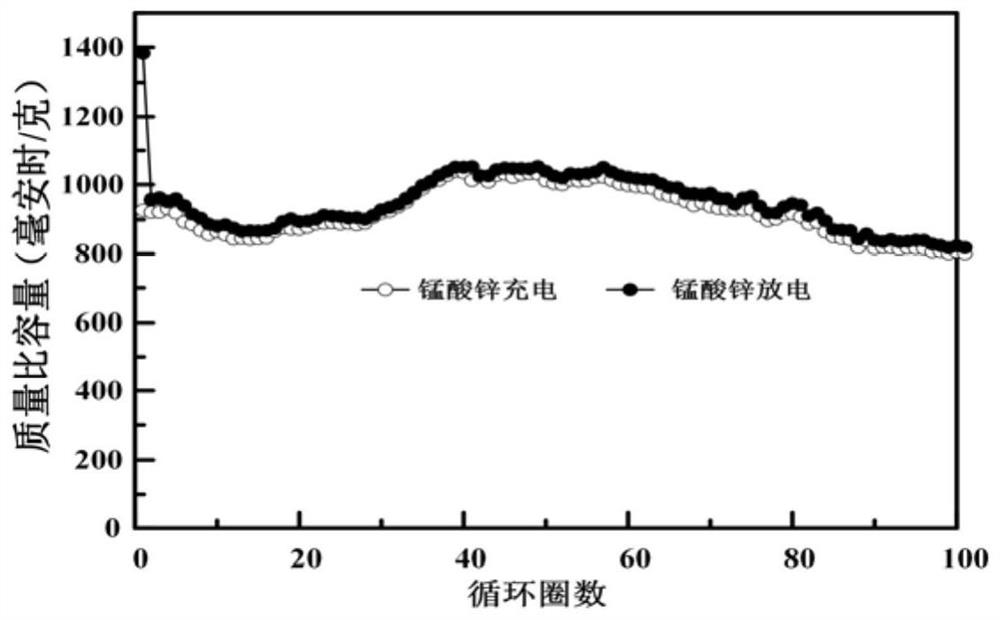

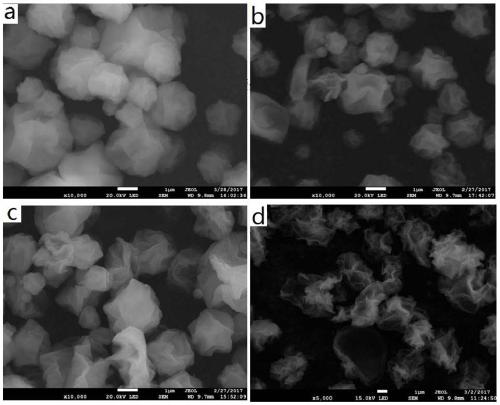

Preparation method of zinc manganate/silver composite material

A preparation method of zinc manganate / silver composite material relates to a preparation method of the composite material. The preparation method includes the steps of dissolving zinc nitrate, manganese nitrate and silver nitrate in water and stirring to obtain a solution A; dissolving oxalic acid in absolute ethanol and stirring to obtain a solution B; adding the solution A into the solution B,stirring to obtain a solution C; centrifugally separating precipitate from solution C, washing with ethanol and water, drying, and then calcinating in a tubular furnace to obtain the zinc manganate / silver composite material. The zinc manganate / silver composite is composited by the precursor of zinc manganate and silver in situ. After calcination, the composite material with uniformly distributed zinc manganate and silver is formed directly, which is obviously different from the composite matieral formed by the direct physical mixing of zinc manganate and silver. The homogeneous composition ofzinc manganate and silver can effectively improve the conductivity of the zinc manganate material. The coprecipitation method is simple and can be prepared in large quantities without special processequipment.

Owner:XIAMEN UNIV

Method for preparing texture on surface of silicon wafer

InactiveCN102002682AReduce reflectivityRealize controllableAfter-treatment detailsFinal product manufactureChemical reactionNitrogen gas

The invention discloses a method for preparing texture on the surfaces of silicon wafers. The method comprises the following steps: the surfaces of the silicon wafers are cleaned and purified, each two cleaned and purified silicon wafers are overlapped and placed in a vapor deposition reacting furnace; when the temperature of the vapor deposition reacting furnace is controlled to 1050 to 1200 DEG C and the vacuum degree is controlled in the range of 1*10<-2>Pa to 1*10<-4>Pa, trichlorosilane and hydrogen are mixed according to the required reaction molar ratio of the chemical equation, the mixture is introduced in the vapor deposition reacting furnace to ensure that crystalline silicon deposits on the exposed surfaces of each two overlapped silicon wafers and silicon grain texture surfaces are formed; and nitrogen is introduced after the deposition, the temperature of the vapor deposition reacting furnace is reduced to the room temperature, the pressure of the furnace is increased to the atmospheric pressure, and the silicon wafers with the deposited silicon grain texture surfaces are taken out. The thickness of the texture layers of the silicon grain texture surfaces which are prepared on the surfaces of the silicon wafers by the texture-preparing method of the invention is 5mu m-8mu m, and the average reflectivity of the surfaces of the silicon wafers to the light with the wavelength of 300nm-1100nm is 7.5%-8.5%. The silicon grain texture surface layers can be controlled, the reflectivity of the silicon grain texture surface is reduced, the production process is simple, and the speed of the batch production is fast.

Owner:百力达太阳能股份有限公司

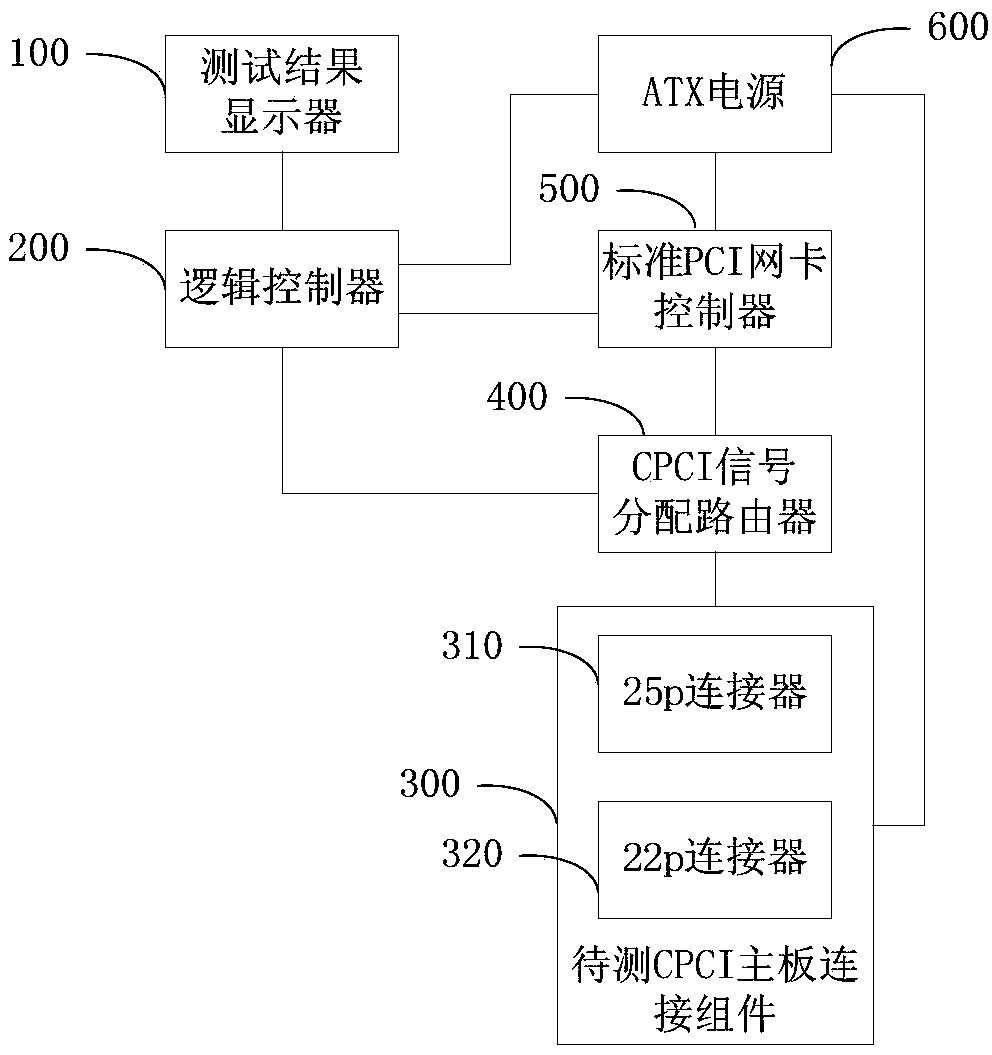

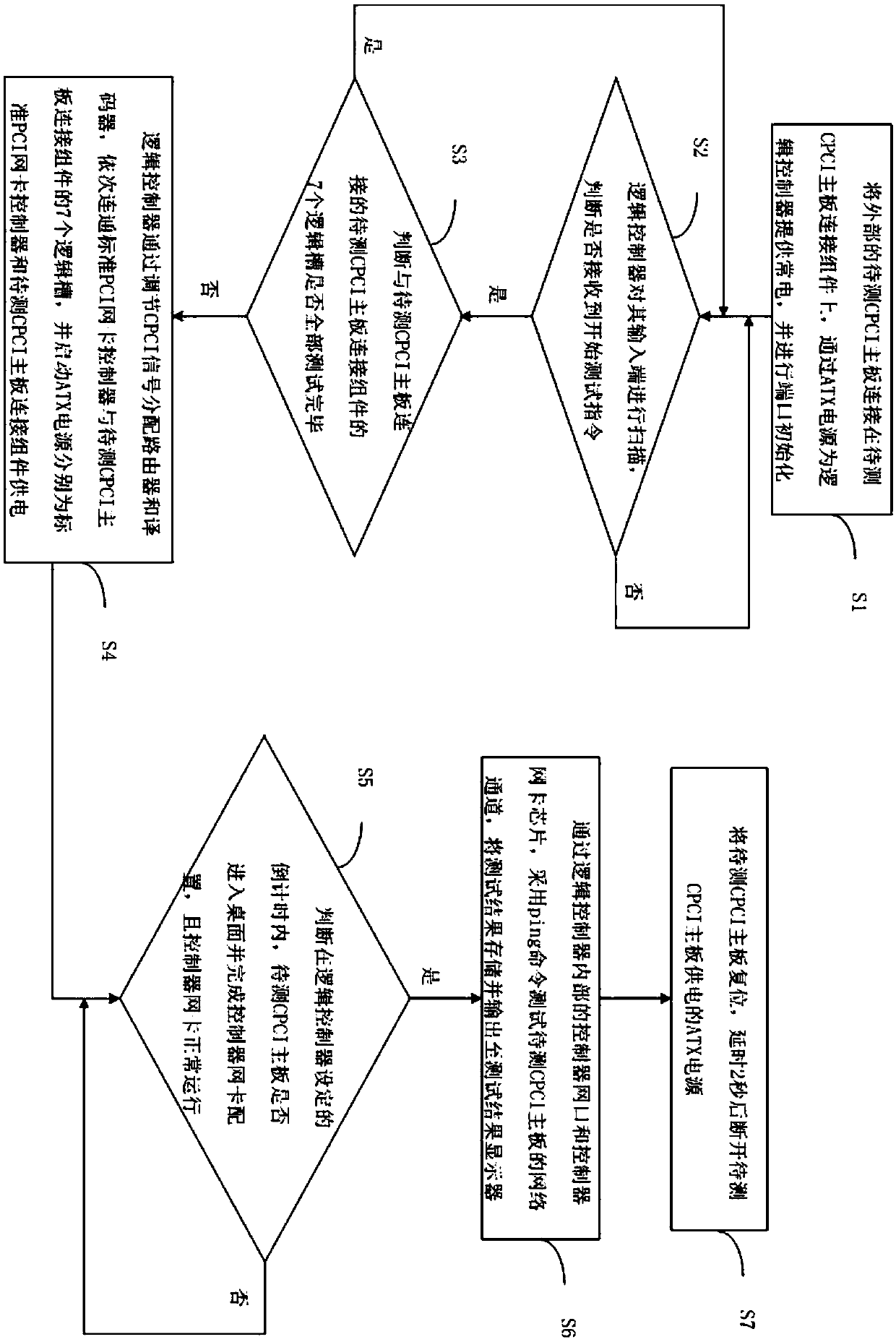

CPCI bus test device and method

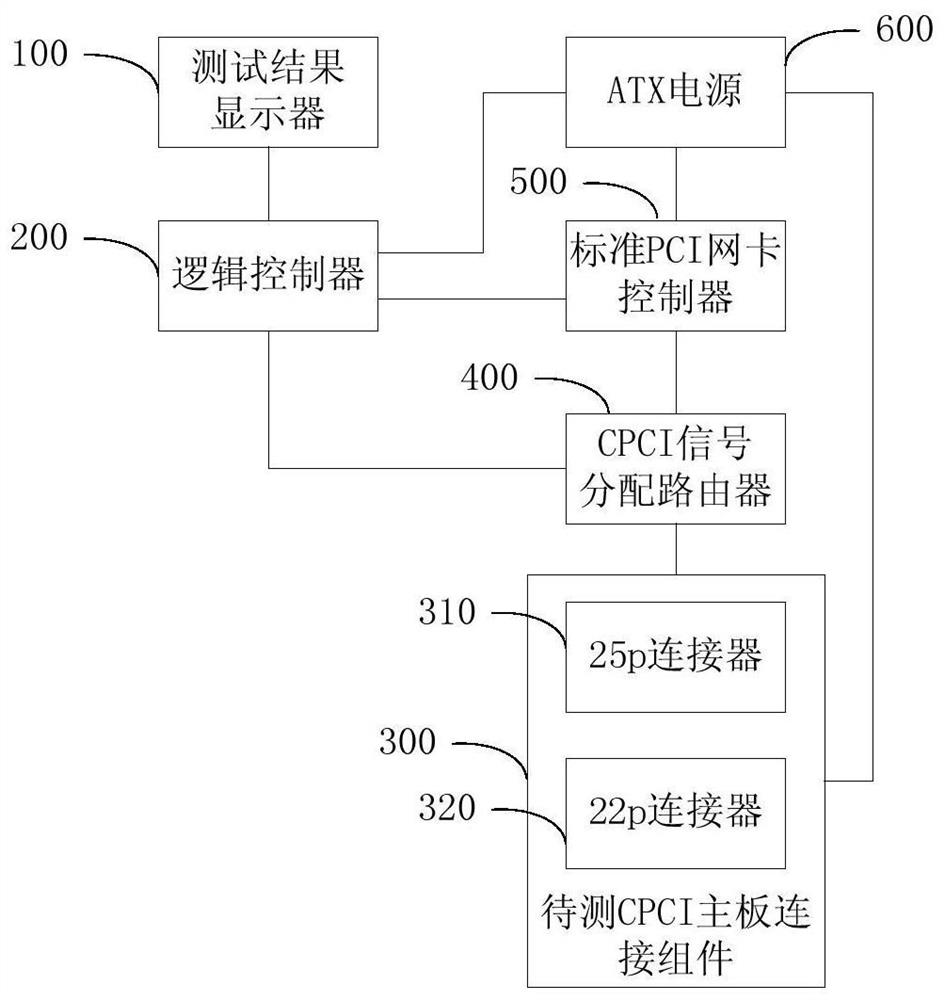

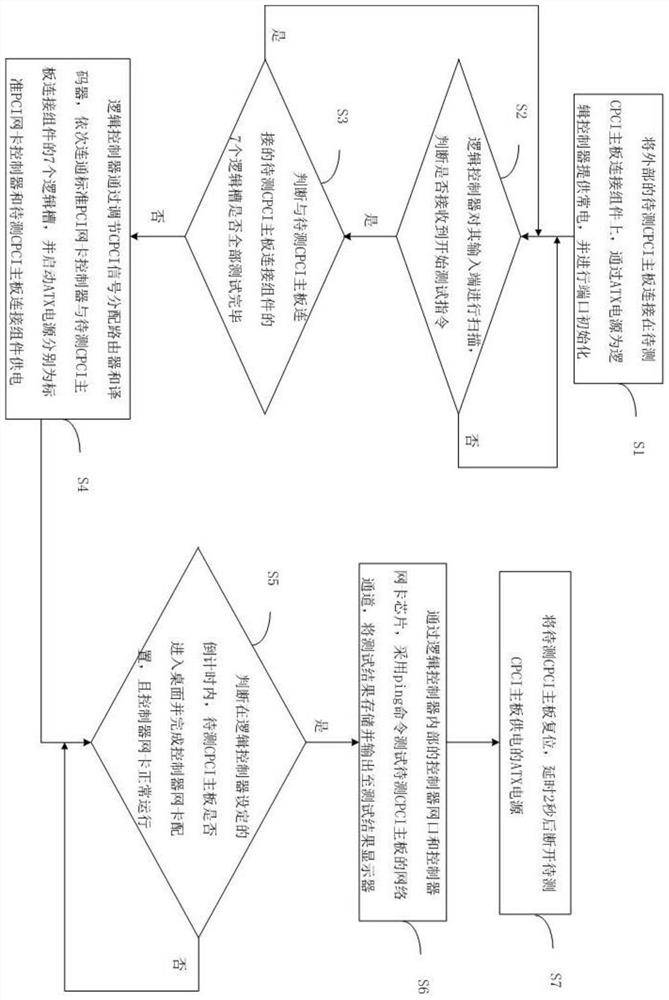

ActiveCN108681497AMass production is fastReduce labor costsFunctional testingTest efficiencyDisplay device

The invention provides a CPCI bus test device and method, which relates to the technical field of data transmission bus automation test. The device includes a test result display, a logic controller,a CPCI motherboard connection component to be tested, a CPCI signal distribution router, a standard PCI network card controller and an ATX power supply. The logic controller is connected to the ATX power supply, the standard PCI network card controller and the CPCI signal distribution router, the standard PCI network card controller, the CPCI signal distribution router, the CPCI motherboard connection assembly to be tested are connected sequentially, the ATX power supply is connected with the CPCI motherboard connection assembly to be tested and the standard PCI network card controller respectively, the CPCI motherboard connection assembly to be tested comprises a 25p connector and a 22p connector, and a test result display is connected with the logic controller. The technical scheme realizes the automatic test of the CPCI motherboard, improves the test efficiency of the CPCI motherboard, reduces the human cost of the test of the CPCI motherboard, and alleviates the technical problemsof low bus detection efficiency and high human cost of the existing CPCI motherboard.

Owner:TIANJIN EMBEDTEC

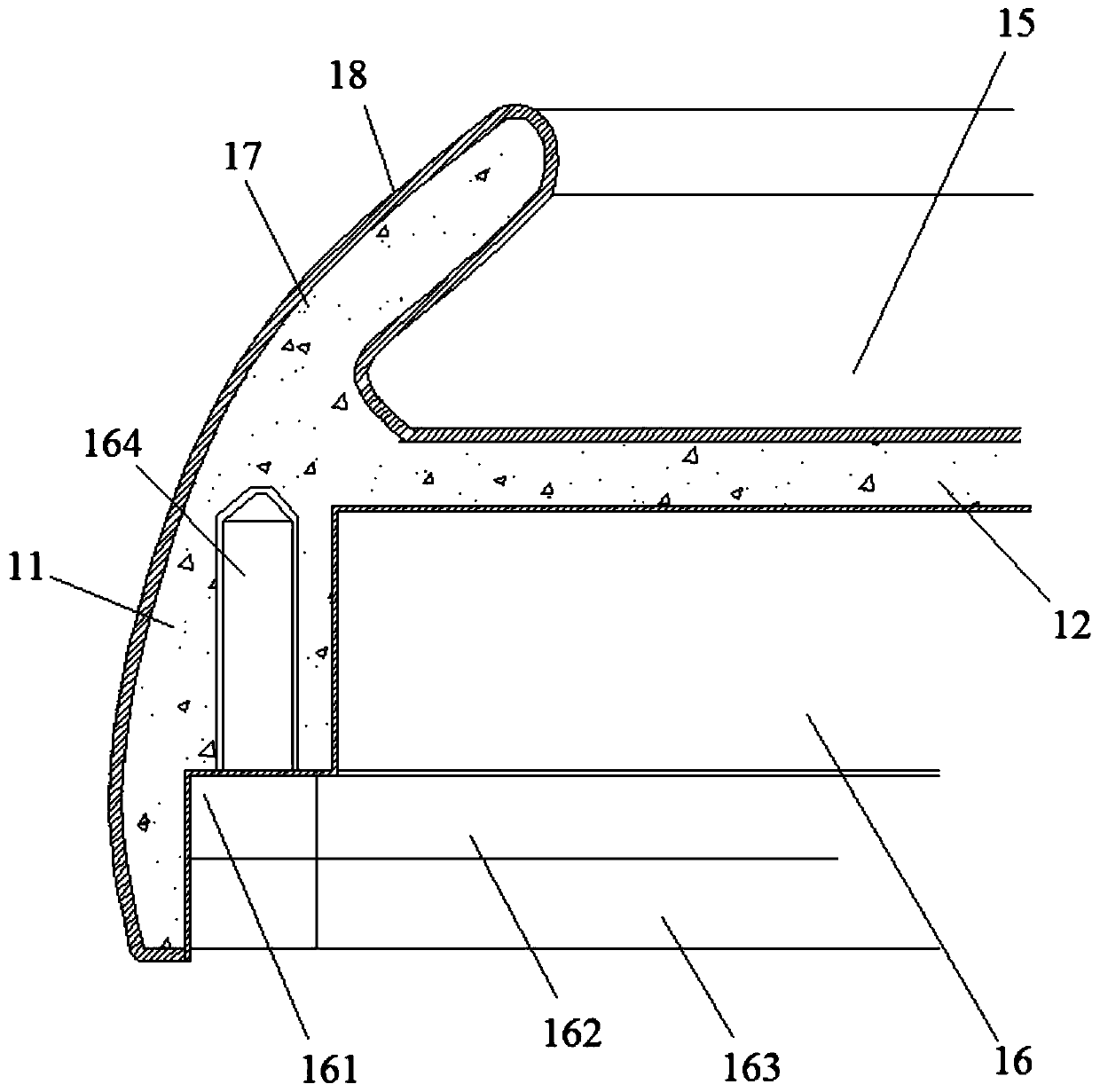

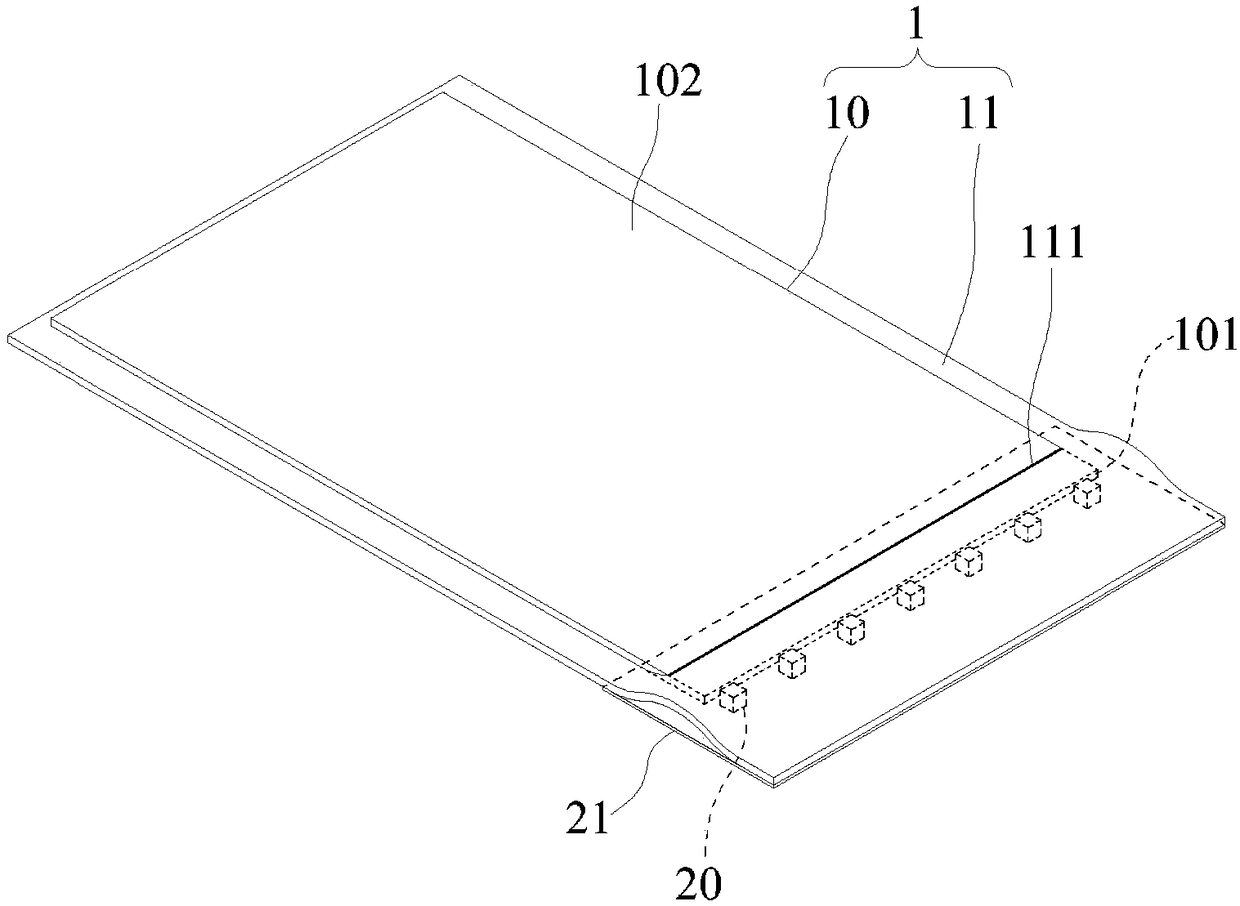

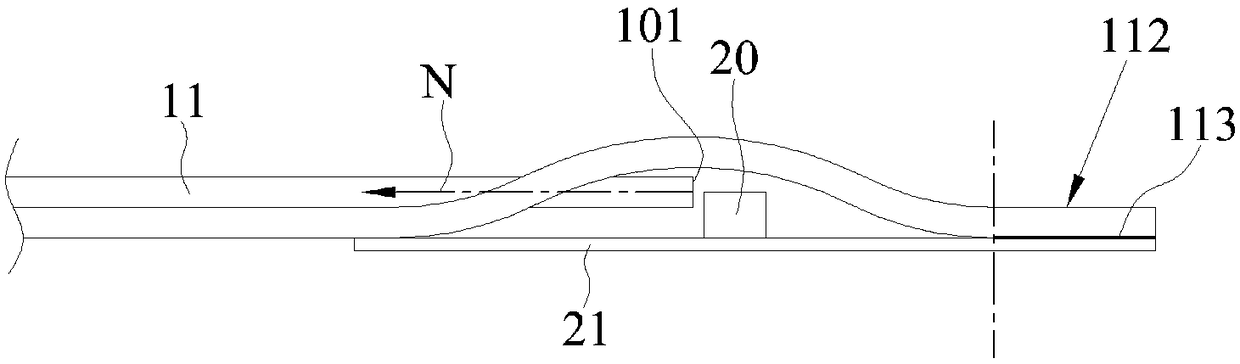

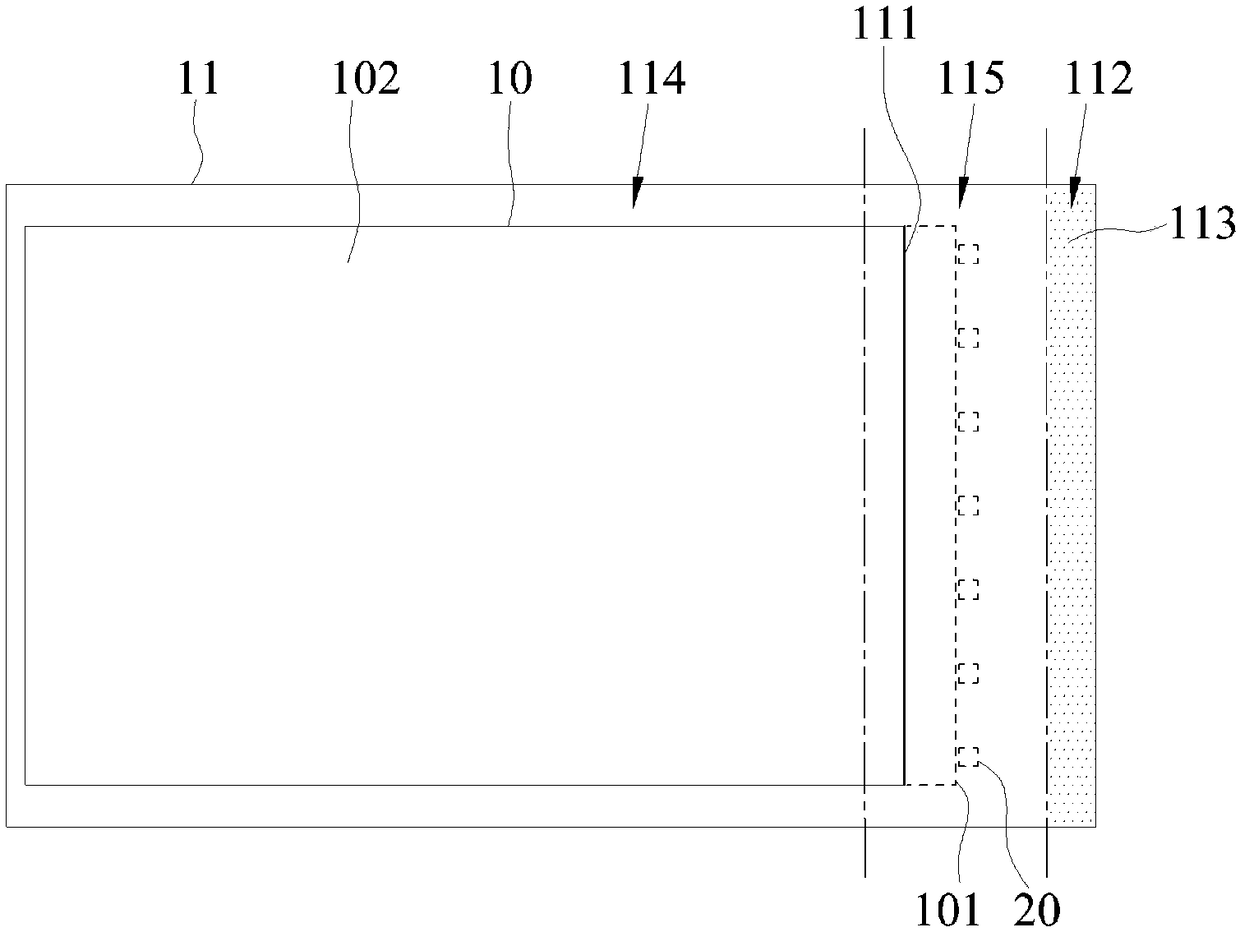

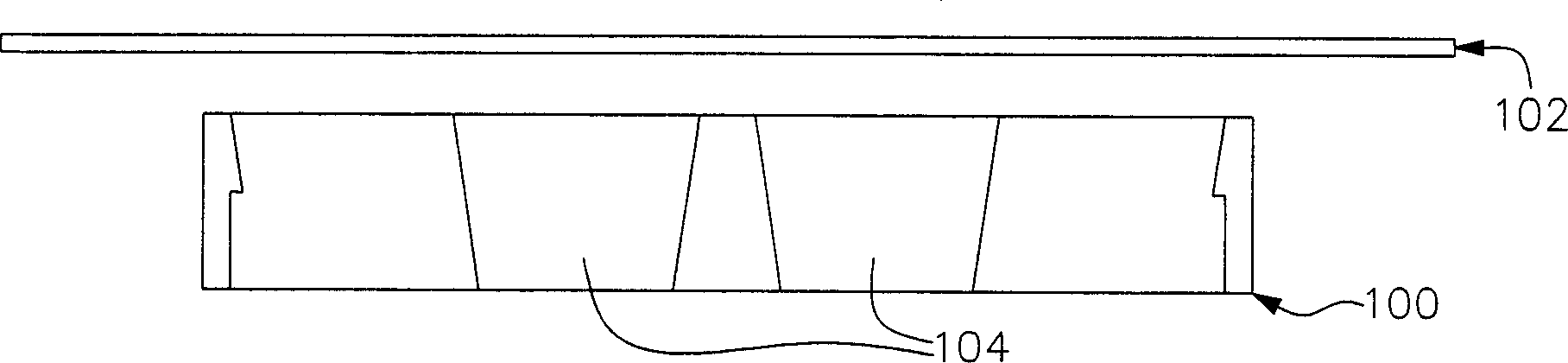

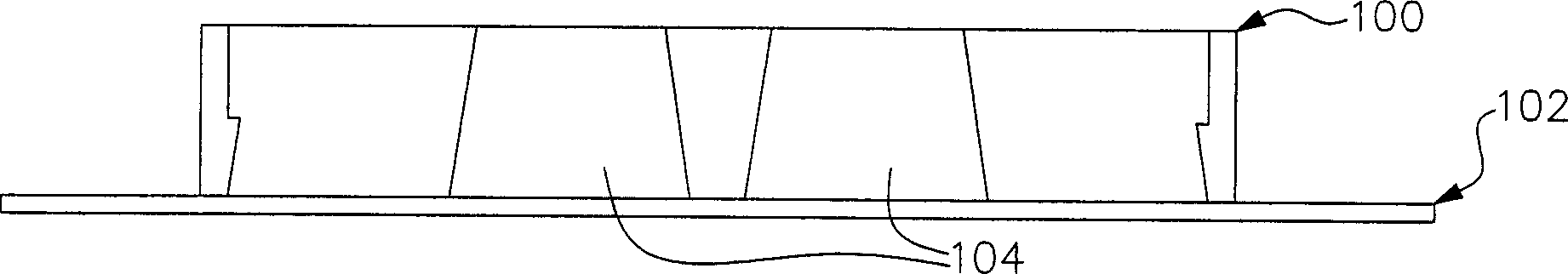

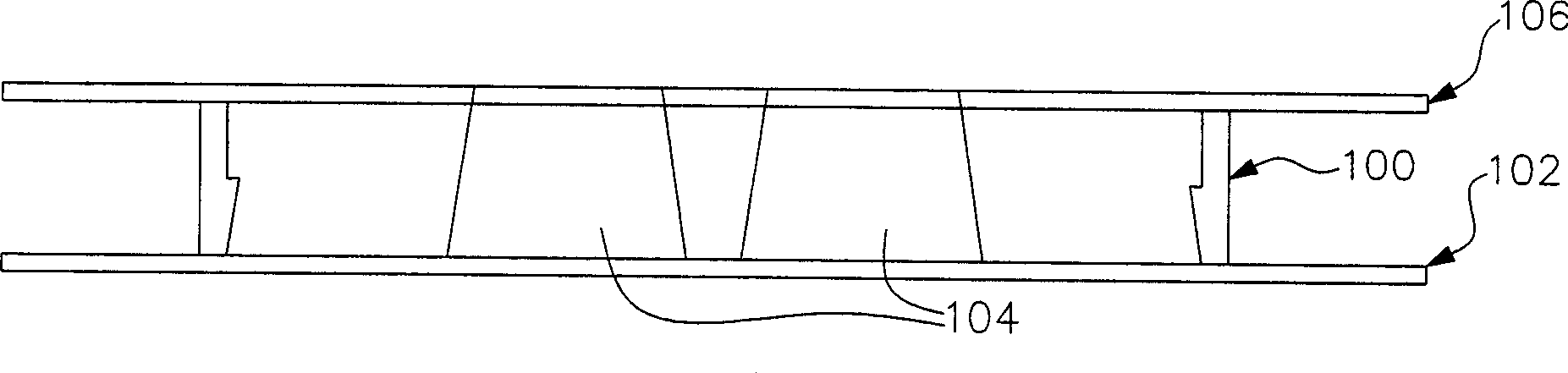

Thin type light guide structure and method for assembling thin type light supply module

InactiveCN108387969AImprove processing speedImprove light guide effectOptical light guidesLight guideOptoelectronics

The invention discloses a thin type light guide structure and a method for assembling a thin type light supply module. The thin type light guide structure includes a light guide plate and a reflectorplate, the light guide plate has a light incidence surface, the reflector plate has a mounting gap and a bonding region, and two opposite surfaces of the reflector plate are reflecting layers. One side of the light guide plate, which has the light incidence surface, penetrates through the mounting gap, and the reflector plate and the light guide plate are arranged in a staggered and laminated manner. The thin type light guide structure is assembled with a light source for use, the bonding region of the reflector plate and a substrate of the light source are combined and fixed, so that an LED on the substrate is arranged corresponding to the light incidence surface, light emitted by the LED can be reflected to the light incidence surface via the reflector plate, lateral incidence light is formed relative to the light guide plate, so that LED light is effectively utilized and an LED of a smaller size can be further carried for use, thereby providing an optical product that better satisfies market demand.

Owner:苏州茂立光电科技有限公司

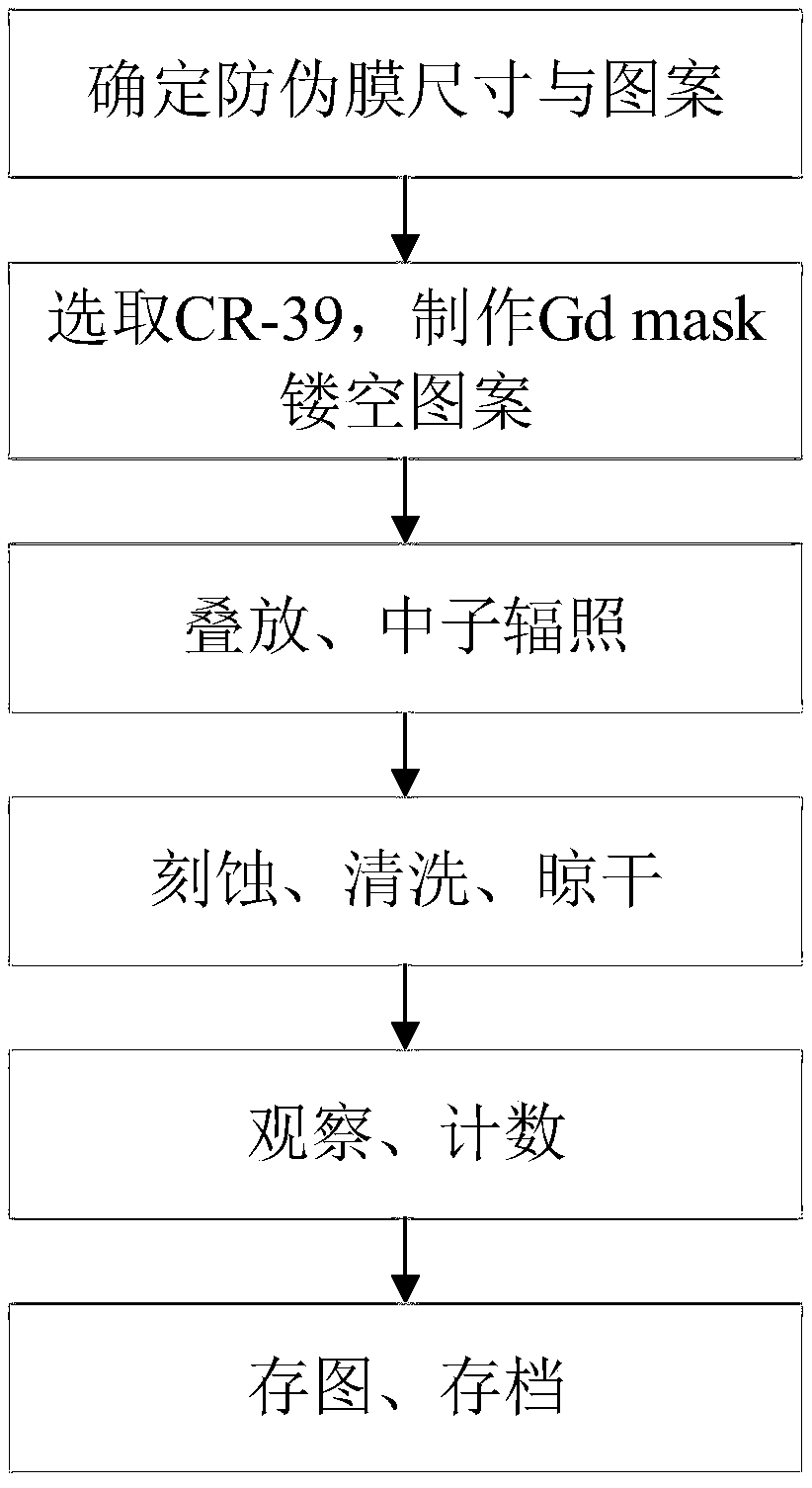

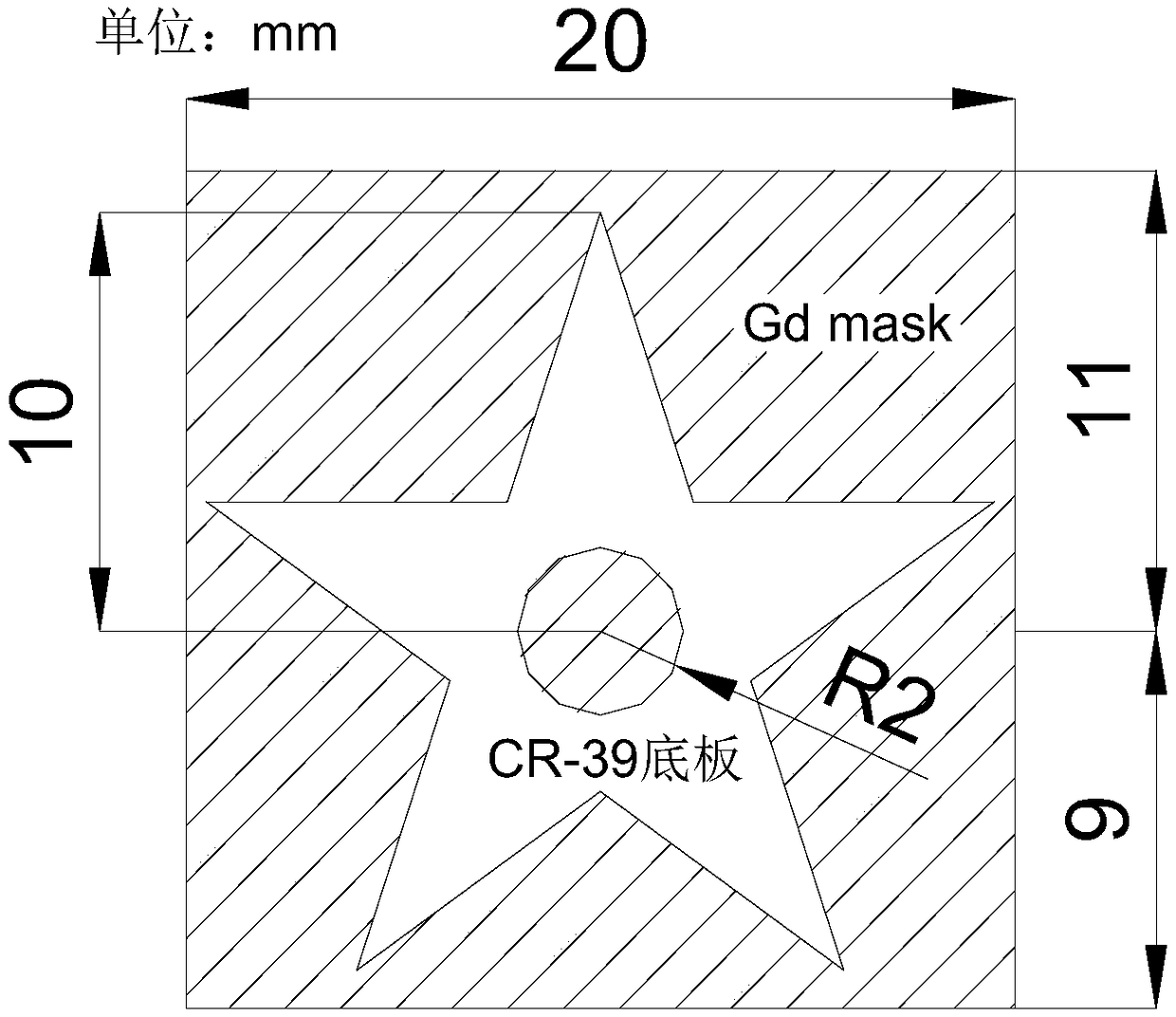

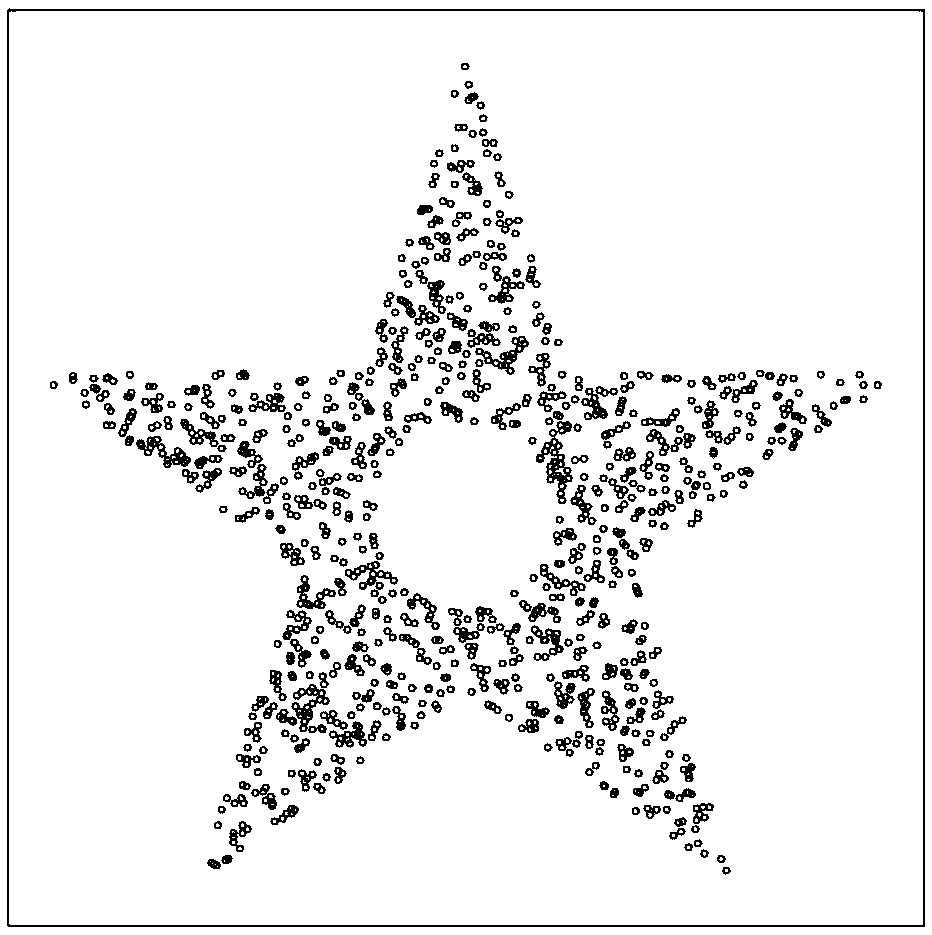

Method for manufacturing nuclear hole anti-counterfeiting film of target anti-counterfeiting pattern by one-step molding

InactiveCN109118947AReduce complexityHigh mechanical strengthStampsIdentification meansEngineeringPlastic film

The invention discloses a method for manufacturing nuclear hole anti-counterfeiting film of target anti-counterfeiting pattern by one-step molding, which solves the problems of complicated process, poor mechanical performance and poor anti-counterfeit strength of the anti-counterfeit film in the prior art. The method of the invention utilizes the thermal neutron absorption characteristic of the metal Gd to place a Gdmask sheet with a hollow anti-counterfeiting pattern in front of a plastic film, and then irradiates the Gdmask sheet on a thermal neutron beam to obtain an anti-counterfeiting pattern formed by combining nuclear pores on the plastic film. As the thermal neutron beam is irradiated, the nuclear hole anti-counterfeiting film pattern is prepared by one-step molding according to the thermal neutron absorption characteristic of the metal Gd. The invention raises the threshold of making the anti-counterfeit film, reduces the complexity of making the pattern of the nuclear hole anti-counterfeit film, improves the mechanical strength of the nuclear hole anti-counterfeit film, and is more convenient for application.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING +2

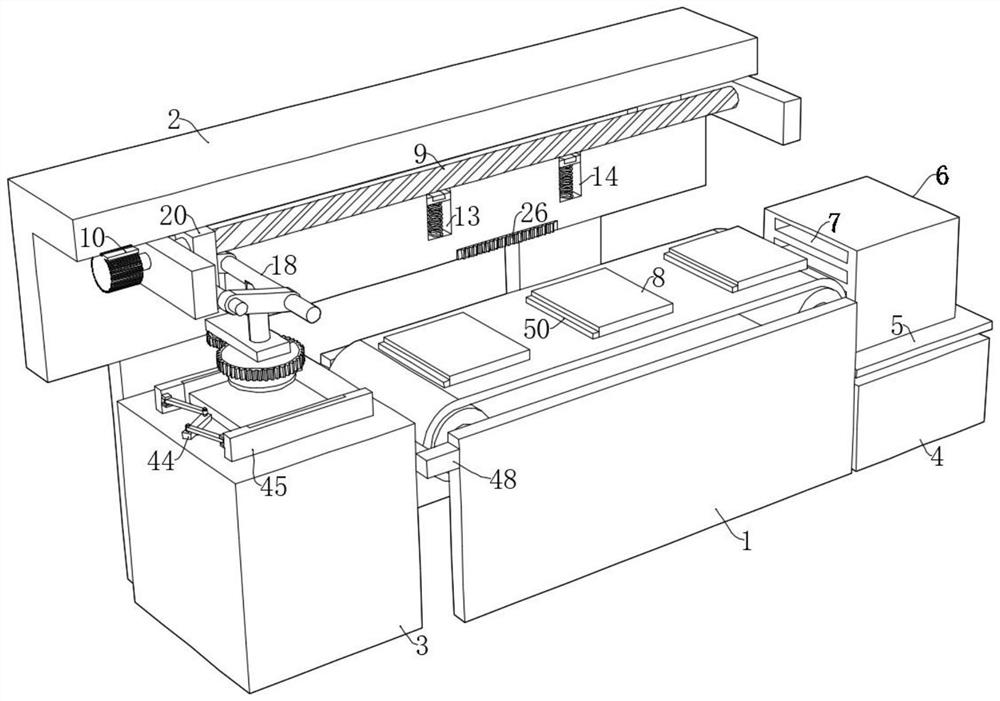

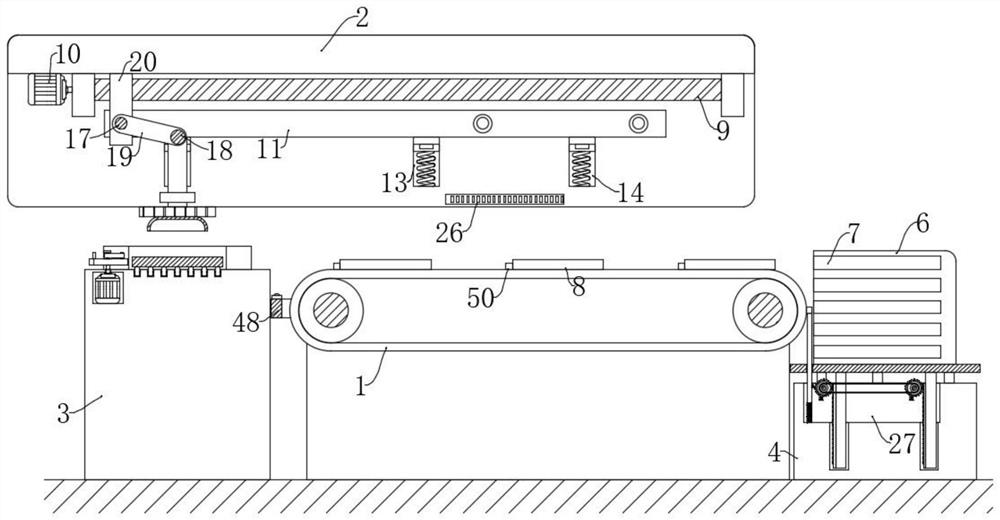

Automatic slot inserting device for glass cleaning and using method of automatic slot inserting device

PendingCN114701837AAdjust directionAccurate directionConveyor partsGlass productionElectric machineEngineering

The invention relates to an automatic slot device for glass cleaning and a using method thereof, and belongs to the technical field of liquid crystal glass processing.The automatic slot device comprises a conveying belt and glass located on the conveying belt, a U-shaped frame is arranged above the conveying belt, a fixing table and a lifting table are arranged at the two ends of the conveying belt respectively, and a lifting plate is arranged at the top of the lifting table; according to the glass conveying device, the rotating motor can be started to drive the rotating plate to rotate, so that the parallelism of glass can be kept, in addition, the driving motor is started to drive the threaded rod to rotate forwards and backwards, and the glass can be conveyed to the conveying belt through the groove frame. The glass conveying device can convey glass and can be matched with the first rack to adjust the direction of the glass, so that the glass is inserted into the insertion groove in the unified direction, manual operation is not needed, automation is improved, the insertion groove efficiency is improved, and the batch production speed is further increased.

Owner:湖南晶讯光电股份有限公司

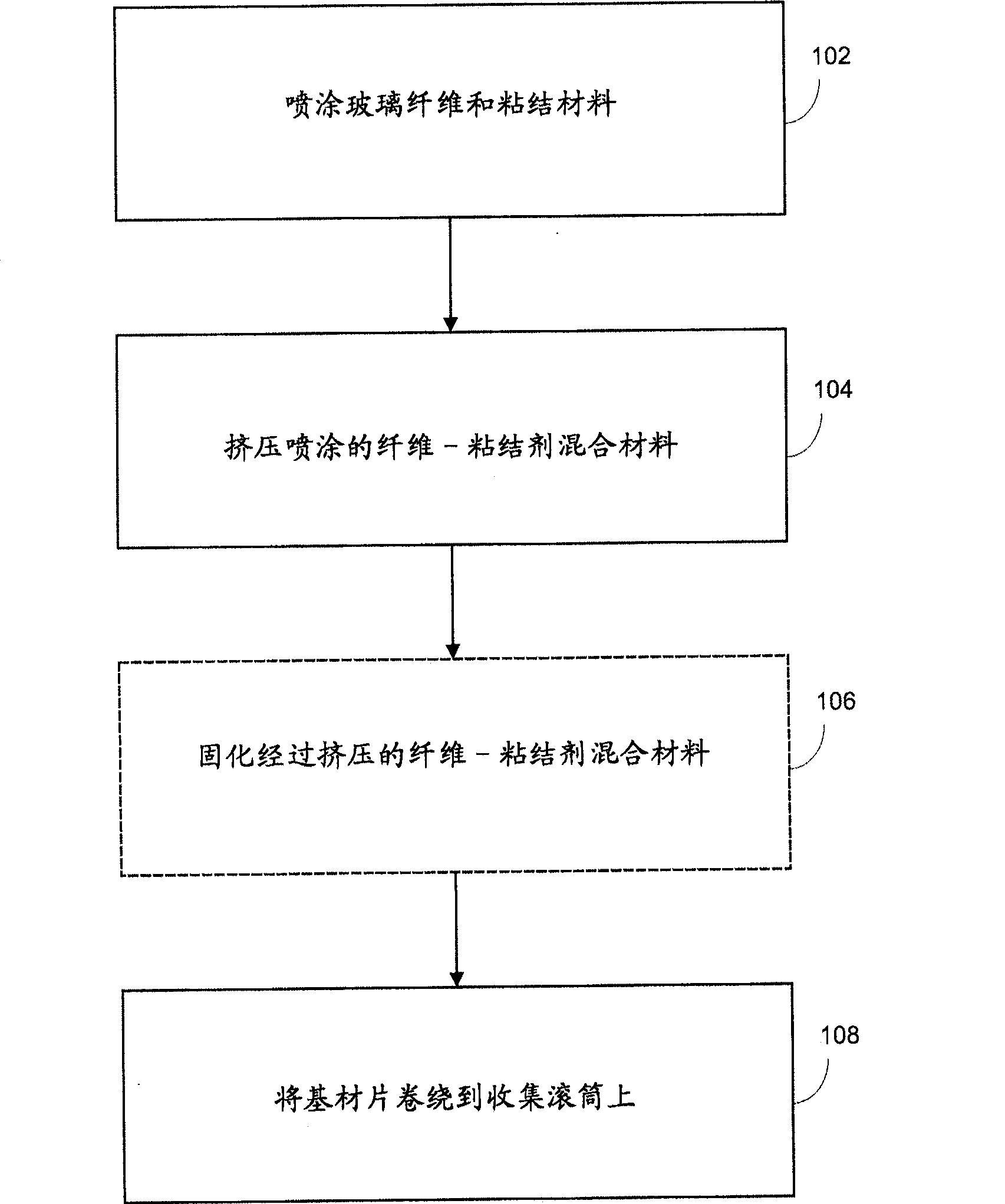

Manufacturing method of thin film solar cells and thin film solar cells thereof

InactiveCN102544134AImprove photoelectric conversion efficiencyMass production is fastFinal product manufacturePhotovoltaic energy generationAmorphous siliconContact layer

Owner:NEXPOWER TECH

Method for preparing ultrathin noble metal film catalyst by heat collection strategy

InactiveCN113289617AEasy to mass produceMass production is fastMetal/metal-oxides/metal-hydroxide catalystsIridiumPtru catalyst

The invention relates to a method for preparing an ultrathin noble metal film catalyst by a heat collection strategy, and belongs to the field of material science and engineering technology and chemistry. The ultrathin noble metal film catalyst prepared by the method comprises gold (Au), platinum (Pt), ruthenium (Ru), rhodium (Rh), iridium (Ir), palladium (Pd) and various oxides of gold (Au), platinum (Pt), ruthenium (Ru), rhodium (Rh), iridium (Ir) and palladium (Pd). The preparation method comprises the steps: firstly, preparing a noble metal chlorate solution with a certain concentration, dropwise coating a silicon wafer as a material A, and rapidly changing the environment temperature to prepare the ultrathin noble metal film catalyst. The method has the advantages of simplicity in operation, controllable yield, high expansibility and the like, and has the advantages of easiness in operation, high yield, safety, reliability and the like compared with a traditional method for preparing a ultrathin noble metal film.

Owner:BEIJING UNIV OF POSTS & TELECOMM

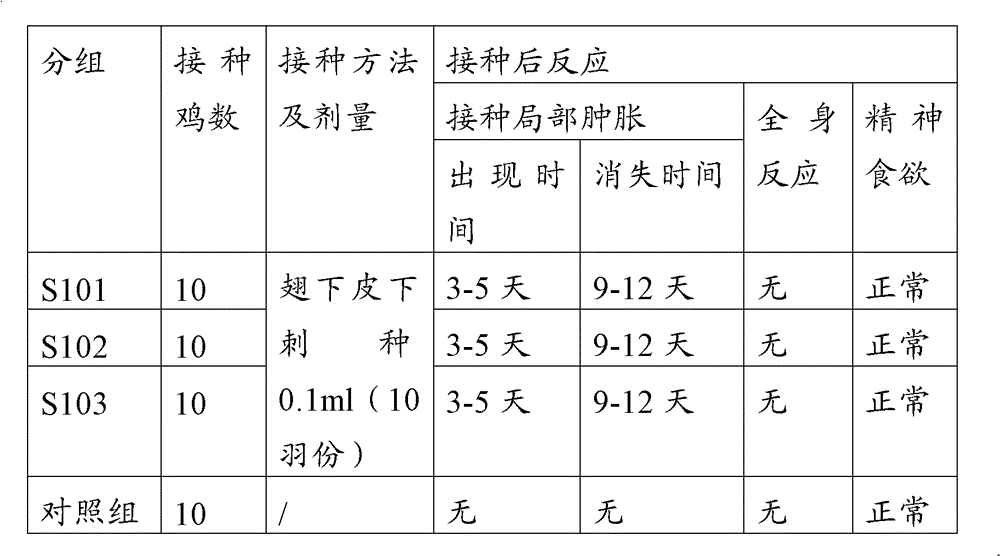

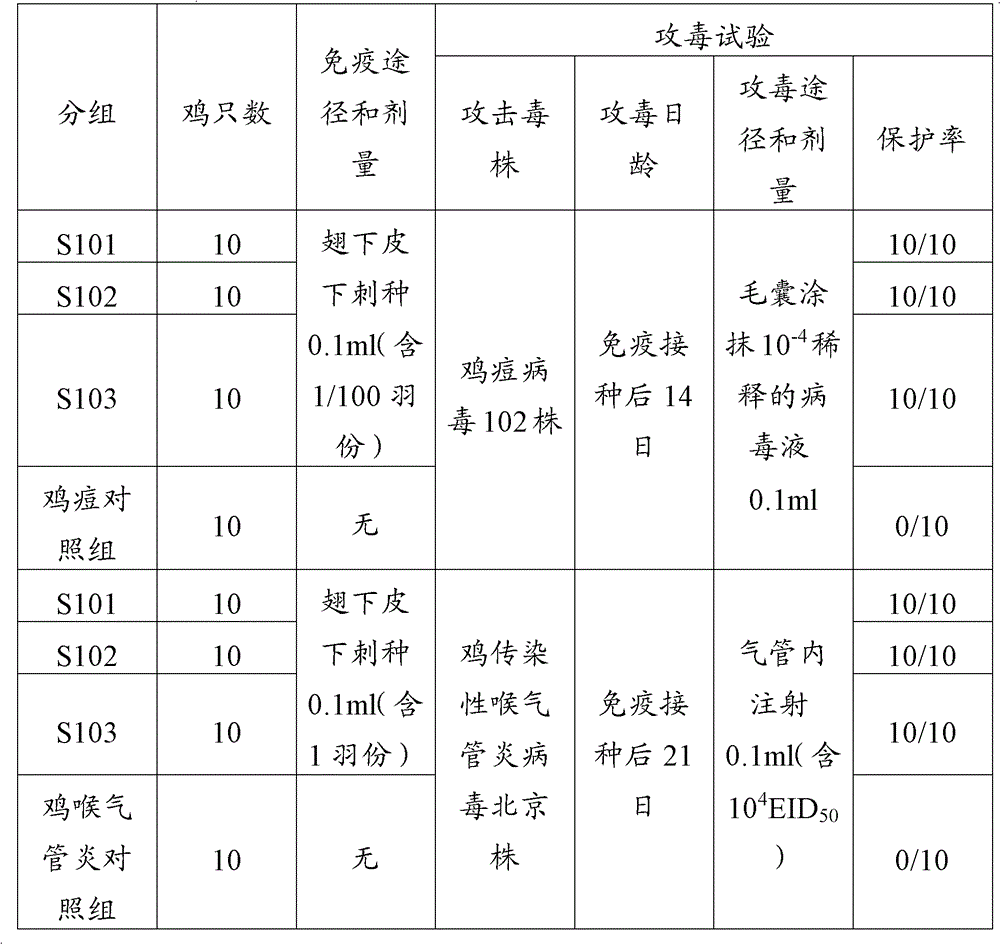

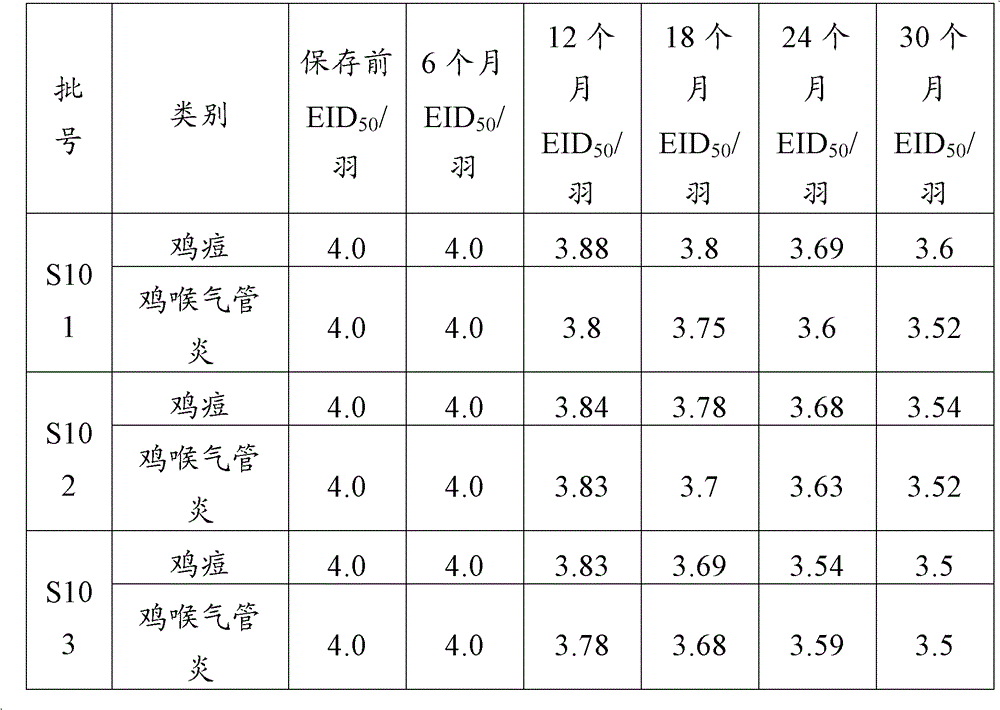

Avian infectious laryngotracheitis-fowl pox combined active vaccine

ActiveCN103182080BHigh titerAchieve mass productionAntiviralsAntibody medical ingredientsFowlSide effect

The avian infectious laryngotracheitis virus and fowl pox virus are cultured by using chicken whole embryo fibroblasts. Particularly, the avian infectious laryngotracheitis virus is successfully cultured by using the chicken whole embryo fibroblasts, the avian infectious laryngotracheitis virus and the fowl pox virus cultured by using the chicken whole embryo fibroblasts are obtained, and a combined freeze-drying active vaccine after a proper freeze-drying protectant is added. The combined freeze-drying active vaccine can be inoculated for immunization in a subalar and subcutaneous inoculation manner, so that side effects of the avian infectious laryngotracheitis virus can be alleviated, immune operations can be simplified, stress response can be reduced and production cost can be lowered. At the same time, the freeze-drying protectant prepared by a novel formula can effectively prolong storage time of the active vaccine and provide convenience for storing and transporting the products.

Owner:PU LIKE BIO ENG

A kind of preparation method of zinc manganate/silver composite material

ActiveCN109119608BImprove conductivityImprove efficiencyCell electrodesOXALIC ACID DIHYDRATEManganate

A preparation method of zinc manganate / silver composite material relates to a preparation method of the composite material. The preparation method includes the steps of dissolving zinc nitrate, manganese nitrate and silver nitrate in water and stirring to obtain a solution A; dissolving oxalic acid in absolute ethanol and stirring to obtain a solution B; adding the solution A into the solution B,stirring to obtain a solution C; centrifugally separating precipitate from solution C, washing with ethanol and water, drying, and then calcinating in a tubular furnace to obtain the zinc manganate / silver composite material. The zinc manganate / silver composite is composited by the precursor of zinc manganate and silver in situ. After calcination, the composite material with uniformly distributed zinc manganate and silver is formed directly, which is obviously different from the composite matieral formed by the direct physical mixing of zinc manganate and silver. The homogeneous composition ofzinc manganate and silver can effectively improve the conductivity of the zinc manganate material. The coprecipitation method is simple and can be prepared in large quantities without special processequipment.

Owner:XIAMEN UNIV

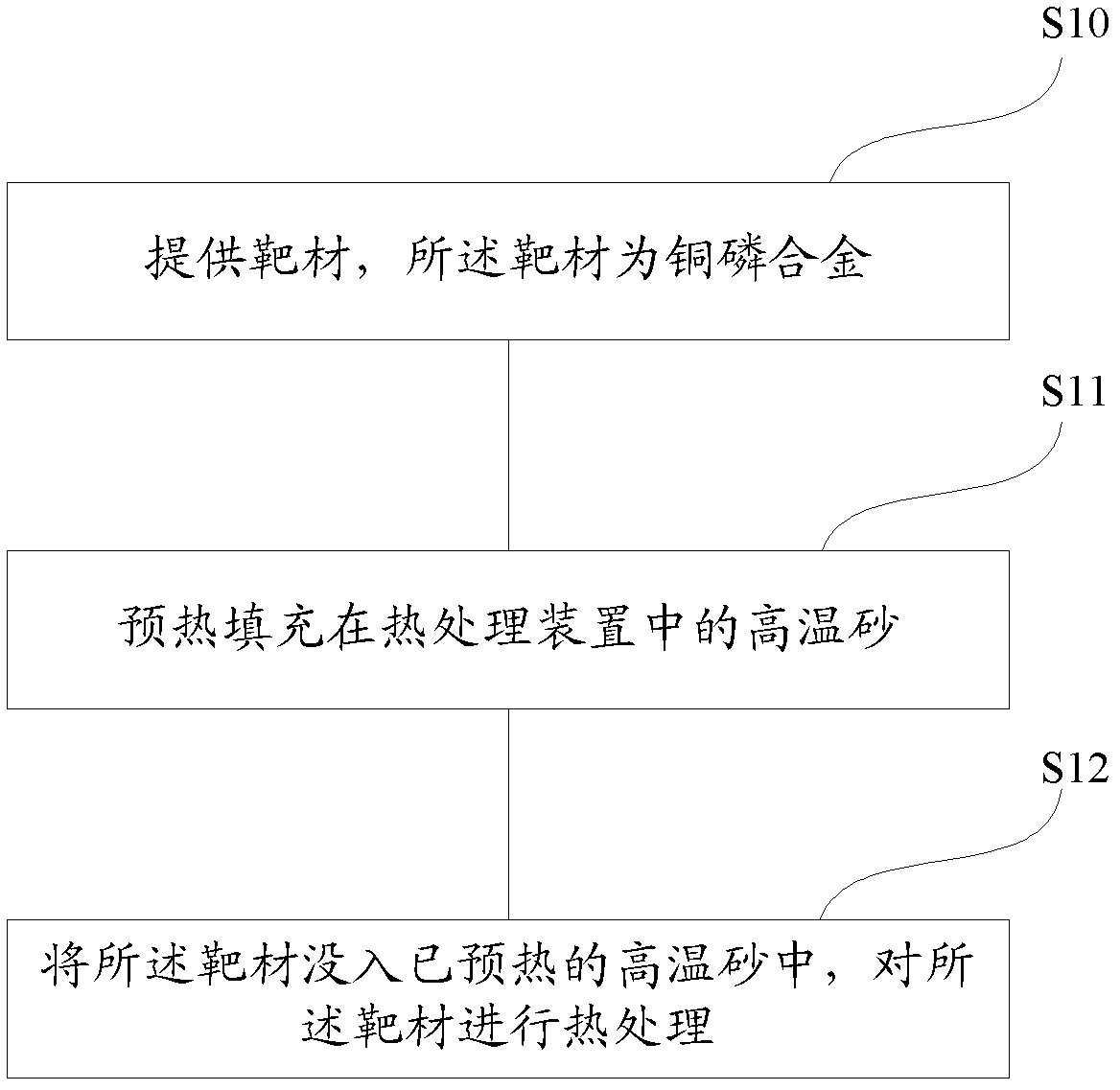

Heat treatment method for target material

The present invention provides a heat treatment method for a target material. The method comprises: providing a target material, wherein the target material is a copper-phosphorus alloy; preheating sand; coating the target material by the sand; carrying out a heat treatment for the target material. Compared to the prior art, with the present invention, the heating method of the sand bath preheating is adopted, such that the uniform heating of the target material is ensured, the uniformity of the target material organization structure is achieved, and the electroplating requirements are met.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Embroidery production method and embroidered objects

InactiveCN103541163BPrecise positioningSave human effortAutomatic machinesEngineeringMechanical engineering

The invention relates to an embroidery making method and embroideries made by using the method. The method comprises steps of firstly fixing a cloth material for embroidery on a mechanical embroidery machine, and forming an embroidering track on the cloth material for embroidery; tracking the embroidering track through a track tracing unit, such as photoinduction track tracing equipment, color induction equipment, a scanner, a light pen or CCD (charge coupled device) image capture equipment and the like, and inputting the embroidering track into a processing unit; and embroidering the pattern of the embroidery on the cloth material for embroidery by the processing unit according to the embroidering track. According to the method, the cloth material for embroidery is fixed on the mechanical embroidery machine in advance, steps of scanning and patterning are processed at real time in embroidering process, the coordinates of the embroidering track are directly defined on the cloth material for embroidery, for elastic cloth materials, flexible and deforming characteristics do not cause embroidering position errors and failure in production.

Owner:郑伟源

A kind of preparation method of graphene/copper composite powder material

The invention relates to a preparation method for a graphene / copper composite powder material. The method comprises the following steps: adding cupric acetate into a graphene oxide aqueous solution while quickly shearing and stirring the mixed solution; keeping quick shearing and stirring for the mixed solution after completely adding, and meanwhile, adopting a spray dryer for continuously extracting the mixed solution and performing spray drying, thereby acquiring precursor graphene oxide / cupric acetate powder; and raising the temperature of the acquired precursor powder to 350-700 DEG C under reducing atmosphere and keeping the temperature for 15-30min, thereby acquiring the graphene / copper composite powder material. The present graphene oxide reduction preparation equipment is used, the method is simple and efficient, the cost is lower and the preparation method is suitable for wide industrial application and popularization.

Owner:HEBEI UNIV OF TECH

A kind of cpci bus testing device and method

ActiveCN108681497BMass production is fastReduce labor costsFunctional testingData transmissionAutomatic testing

The present invention provides a kind of CPCI bus test device and method, relate to the technical field of automatic test of data transmission bus, comprising: test result display, logic controller, CPCI motherboard connection assembly to be tested, CPCI signal distribution router, standard PCI network card controller and ATX power supply. The logic controller is connected to the ATX power supply, the standard PCI network card controller and the CPCI signal distribution router respectively. The connection component is connected with the standard PCI network card controller, the connection component of the CPCI motherboard to be tested includes a 25p connector and a 22p connector, and the test result display is connected with the logic controller. The technical solution realizes the automated testing of the CPCI main board, improves the efficiency of the CPCI main board test, reduces the labor cost of the CPCI main board test, and alleviates the technical problems of low bus detection efficiency and high labor cost of the existing CPCI main board.

Owner:TIANJIN EMBEDTEC

LED reflection cover manufacturing method

InactiveCN1838438AReduce the presence of air bubblesAccurately control the amount of glueSemiconductor devicesEngineeringLight-emitting diode

This invention relates to a light emitting diode reflection cover making method, which includes: designing a reflection cover into an upper part and a down part. Affixing a spoiler at the face of the upper part; putting a deflector up to the surface of the upper part, and making the surface up toward. Pasting the glue into the hollow hole of the upper part through the hole of the deflector; firing the upper part; at last joining the upper part and the down part into a complete reflection cover.

Owner:EVERLIGHT ELECTRONICS

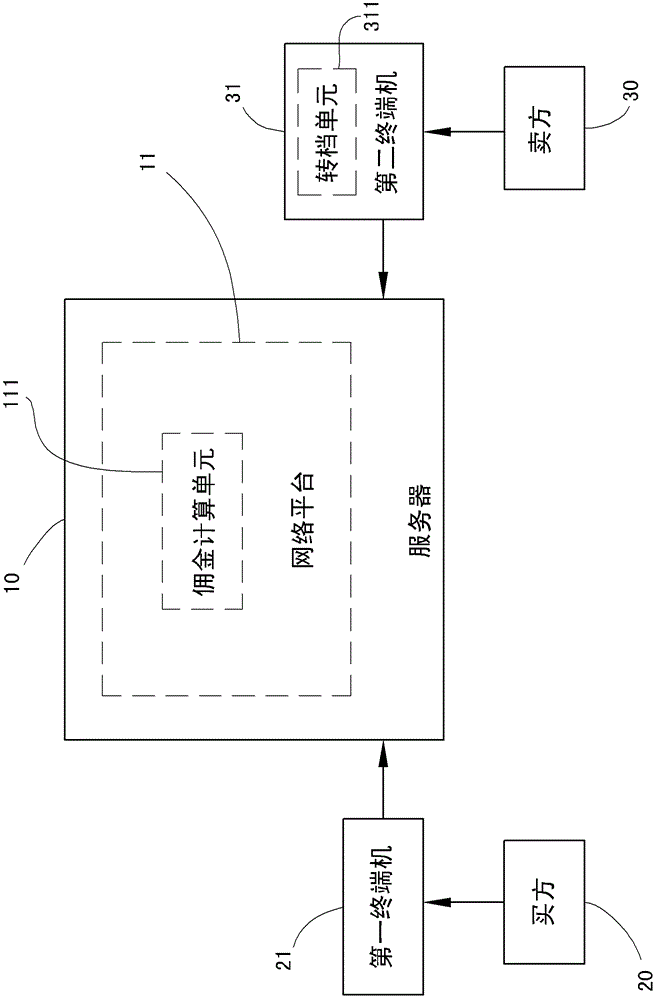

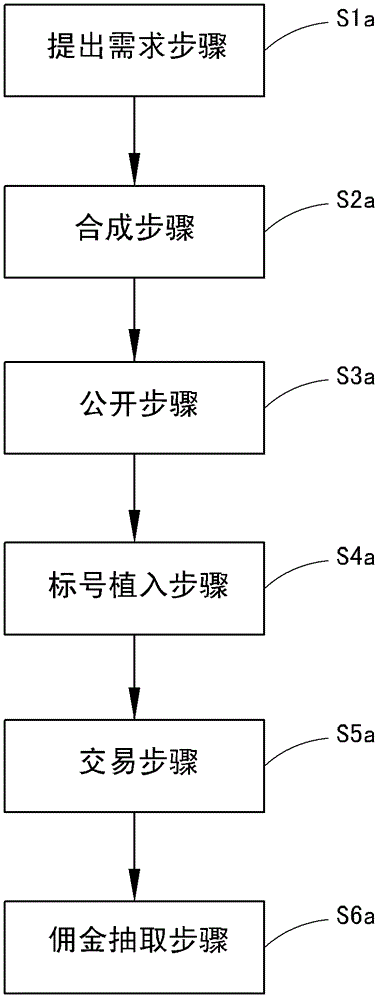

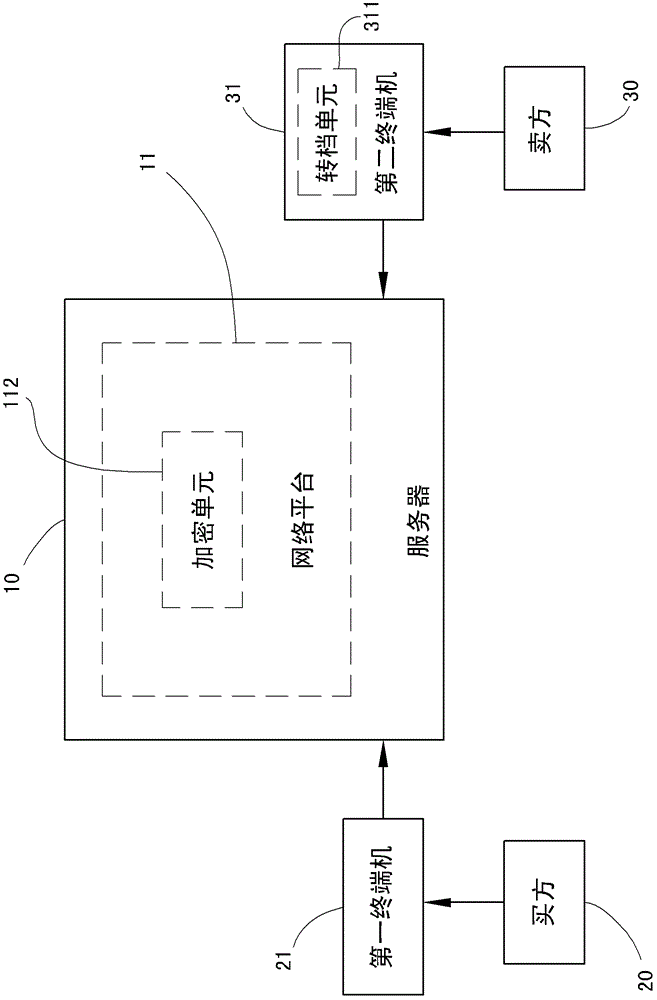

Method for trading and trial running integrated circuit design code

ActiveCN102800010AProtected creationMass production is fastBuying/selling/leasing transactionsFinancial transactionNetlist

A method for trading and trial running an integrated circuit design code is provided. In the method, the integrated circuit design code is converted to a netlist, which is then trial ran and traded between a buyer and a seller on a network platform. The buyer raises a procurement request for an integrated circuit design code on the network platform, and the seller synthesizes the integrated circuit design code to the netlist and completes a trade with the buyer on the network platform. Alternatively, the buyer raises a trial run request for the netlist described by the seller on the network platform, and the seller encrypts the netlist to an encrypted netlist for the trial sampling of the buyer. Accordingly, a trade for the integrated circuit design code is achieved via the network platform for promoting cloud computing, competitiveness and affordability of the industry.

Owner:MICROIP

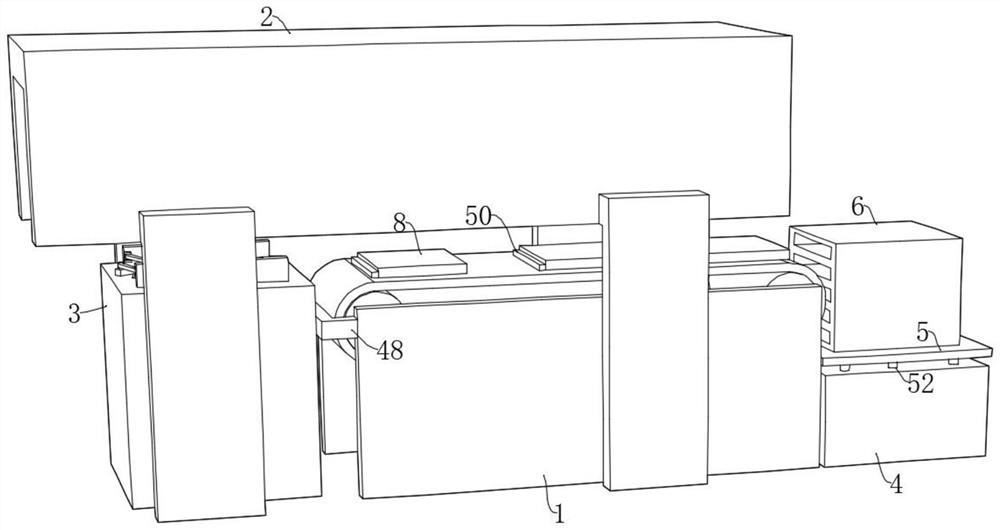

Manufacturing equipment for aviation attitude control motor aluminum alloy member

ActiveCN113541422ARealize splicingMass production is fastLiquid surface applicatorsManufacturing dynamo-electric machinesElectric machineryAutonomation

The invention discloses manufacturing equipment for an aviation attitude control motor aluminum alloy member. The manufacturing equipment comprises a feeding mechanism, a cleaning mechanism, a gluing mechanism, an assembling and feeding mechanism and a splicing mechanism, wherein the material car of the feeding mechanism enters a feeding channel for feeding, the position of the material car is positioned through a positioning device, an adsorption head adsorbs an aluminum alloy body and conveys the aluminum alloy body to the cleaning mechanism for dust cleaning, the gluing mechanism is used for gluing the side surface of the aluminum alloy body through a gluing head, the feeding adsorption seat of the assembling and feeding mechanism adsorbs the aluminum alloy bodies on a material buffer seat and conveys the aluminum alloy bodies to the splicing mechanism, and the gluing surfaces of the adjacent aluminum alloy bodies are bonded through the splicing mechanism to achieve splicing of the aluminum alloy bodies. According to the invention, when the aluminum alloy bodies are spliced into the aluminum alloy member, the aluminum alloy bodies are subjected to feeding, cleaning, gluing, assembly feeding and splicing correspondingly, the high-precision and high-automation manufacturing process of the aluminum alloy member is achieved, and rapid batch production of the aluminum alloy member is facilitated.

Owner:南通成安金属材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com