Fast-curing indentation-proof water-based paint for galvanized sheet and preparation method thereof

A fast-curing, water-based coating technology, used in epoxy resin coatings, polyurea/polyurethane coatings, coatings, etc. Large-scale production, saving energy use, satisfying the effect of safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038]Some specific examples are listed below to illustrate the present invention. It should be pointed out that the following specific examples are only used to further illustrate the present invention, and do not represent limitations to the protection scope of the present invention. Some non-essential modifications and adjustments made by others according to the present invention still belong to the protection scope of the present invention.

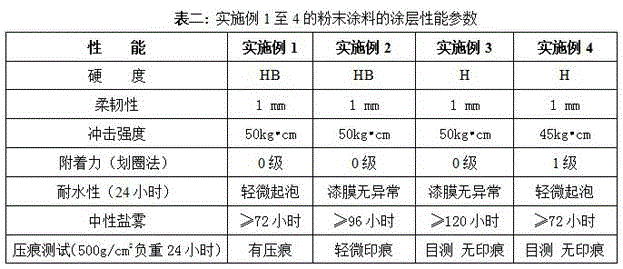

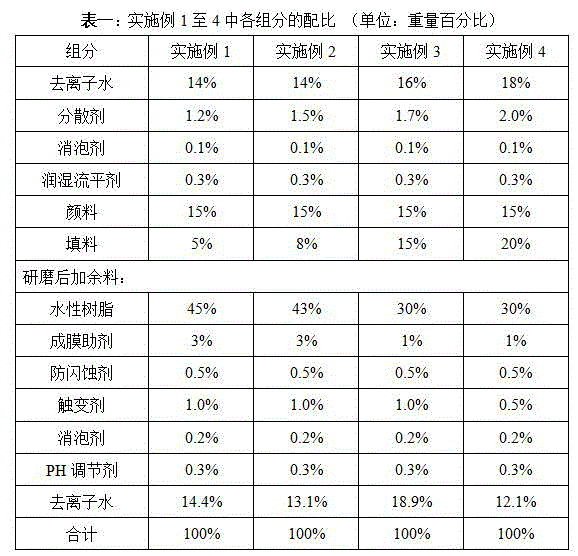

[0039] The composition of the water-based coatings of Examples 1 to 4 is shown in Table 1. The preparation method is as follows: add 1 / 3 of the deionized water to the stirring tank, add the dispersant while stirring, then add 1 / 3 of the defoamer, add all the Pigment fillers are finally dispersed at high speed for 20 minutes, transferred to a sand mill and ground to a fineness of less than 15 microns.

[0040] (2) Add water-based resin, wetting and leveling agent, thixotropic agent, anti-flash corrosion agent, film-forming aid, remaini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com