Transparent electrode film manufacturing device and transparent electrode film manufacturing method

A technology for transparent electrodes and preparation devices, which can be used in cable/conductor manufacturing, circuits, photovoltaic power generation, etc., and can solve the problem of long time required for conductive polymer coating, several hours of time, and reduced product production efficiency, etc. problem, to achieve the effect of speeding up the overall mass production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Next, the preparation device and method of the transparent electrode film according to the preferred embodiment of the present invention will be described in detail with reference to the accompanying drawings.

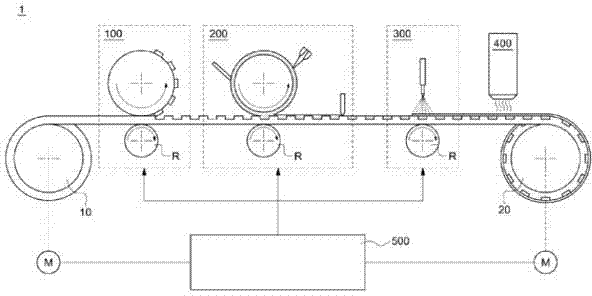

[0041] figure 1 It is a brief conceptual diagram showing the overall structure of a preparation device for a transparent electrode film according to an embodiment of the present invention.

[0042] Such as figure 1 As shown, the shown transparent electrode film preparation device (1) includes: at least one unwinding roller (10), which can unwind the film substrate material for supply; and at least one take-up roller (20), the The take-up roll winds and stores the transparent electrode film prepared through the whole process. The unwinding roller (10) and the winding roller (20) can be operated at the same speed by their respective drive motors (M), and the unwinding roller (10) can be controlled simultaneously by the control unit (500) described later preferably...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com