Glass fibre reinforced plastic substrate

A glass fiber and base material technology, which is applied in the field of flexible base materials and the manufacture of such flexible base materials, can solve the problems of complicated and expensive manufacturing process, and achieve the effect of good mechanical strength and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

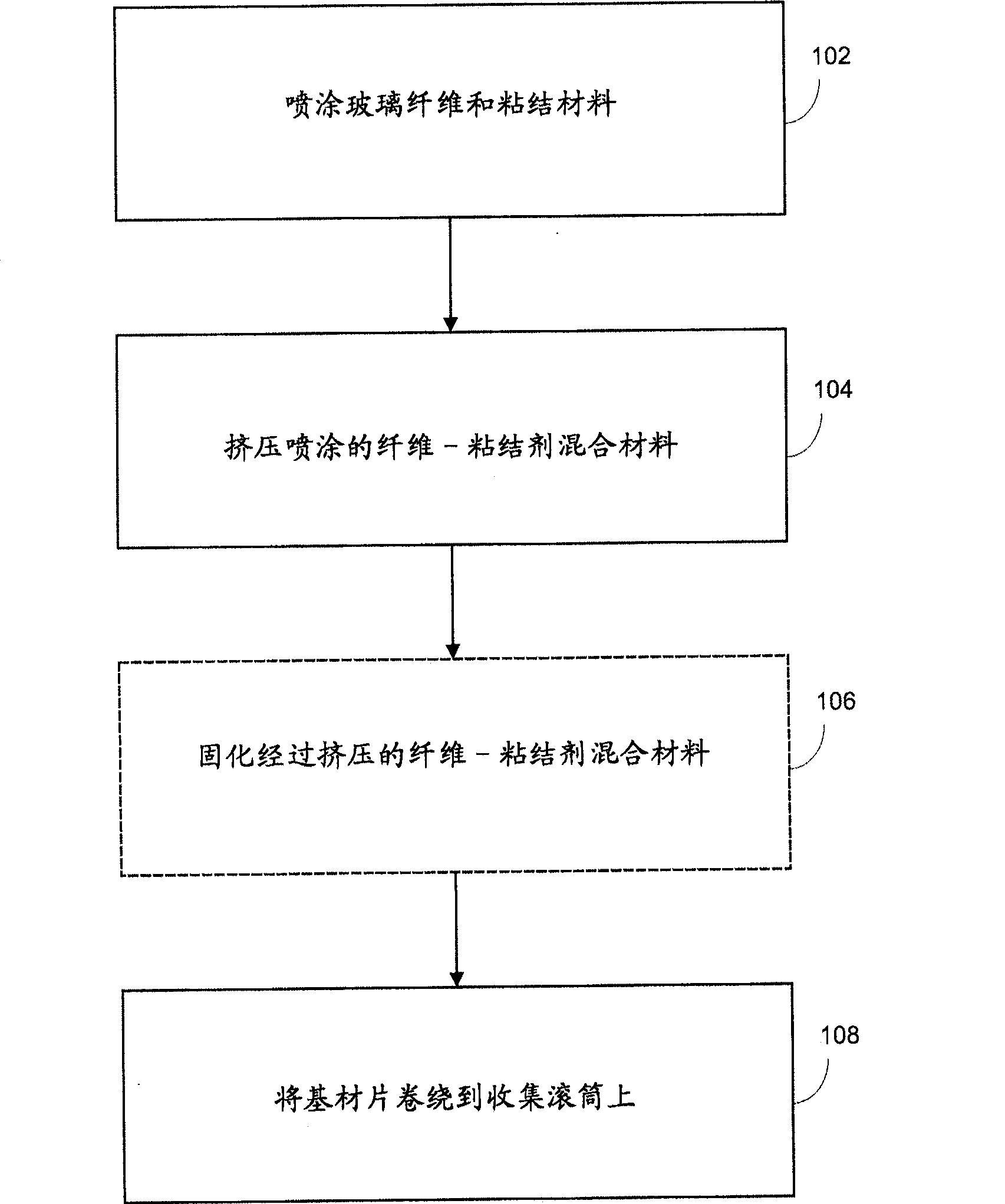

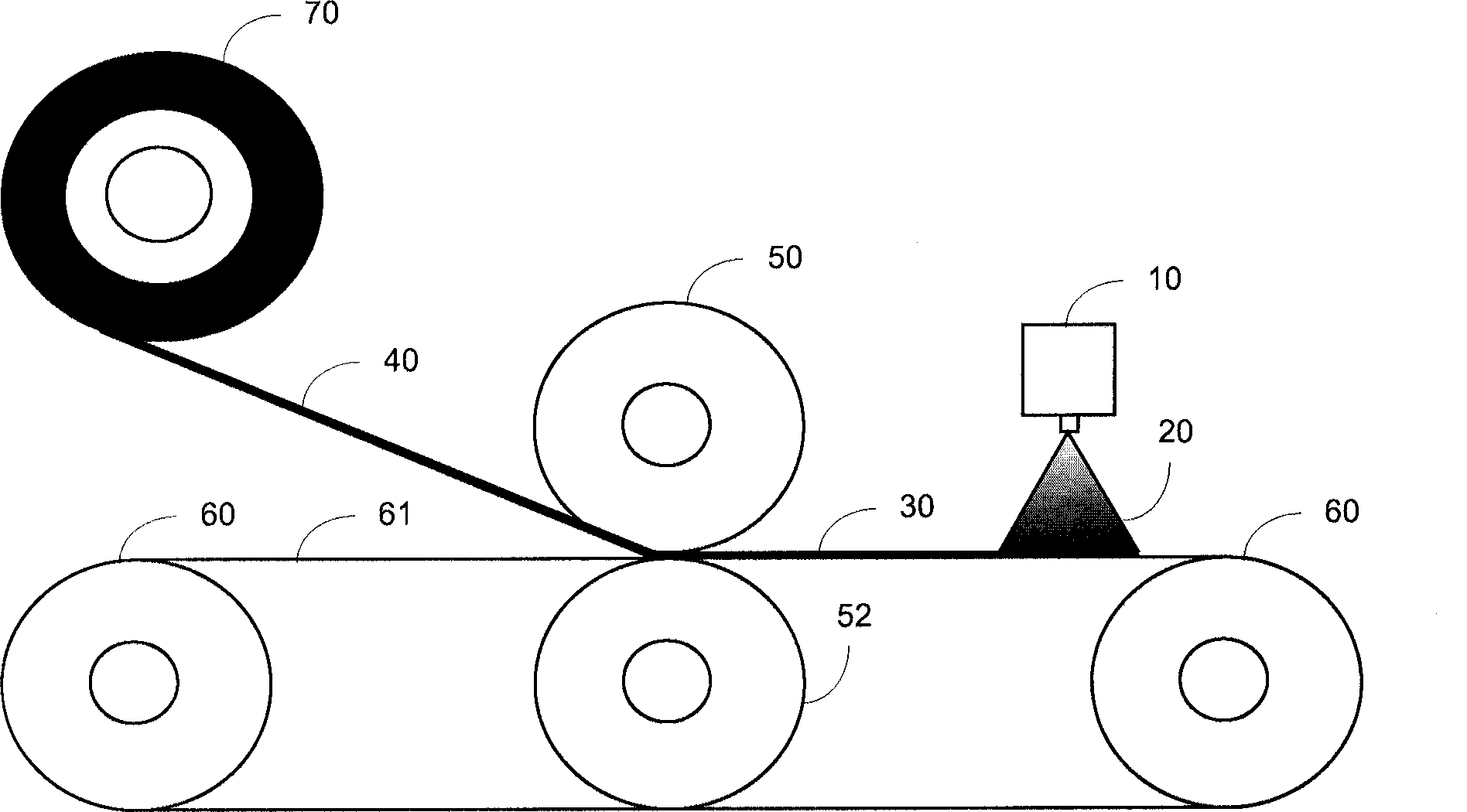

Method used

Image

Examples

Embodiment approach

[0060] Figure 4 An exploded view showing a flexible display device according to an embodiment of the present invention. The flexible display device 8 includes a flexible base material layer 40 and a liquid crystal layer 5 facing each other, and the flexible base material layer 40 is equipped with a plurality of transistors 3 and a plurality of wires 4 . The multiple wires 4 are used to interconnect the multiple transistors 3 . According to one embodiment of the present invention, the flexible substrate 40 forms the basis of an active matrix backplane together with a plurality of transistors 3 and a plurality of wires 4 assembled on the flexible substrate 40 . An active matrix backplane consisting of a substrate 40 with transistors 3 and wires 4 can be used as a backplane for control electronics such as in a liquid crystal display. The formation of Si transistor structures can be optimized on the flexible substrate 40 according to the present invention, eg processing of depo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com