LED reflection cover manufacturing method

A technology of light-emitting diodes and manufacturing methods, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve problems such as easy generation of air bubbles, failure to meet customer needs, and inability to accurately control the amount of glue to achieve the effect of reducing air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

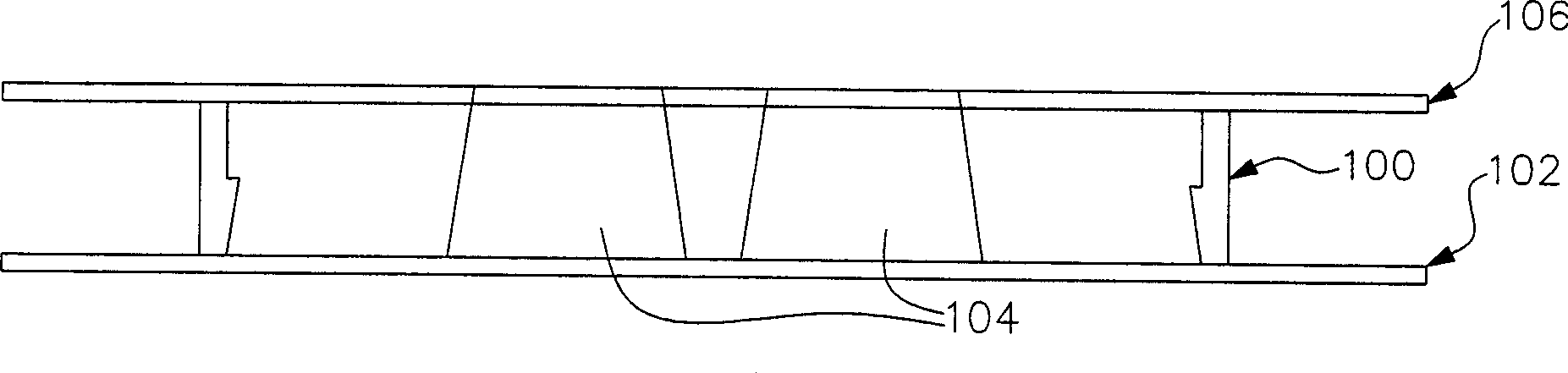

[0022] In order to solve the shortcomings of the known manufacturing method of the reflective cover that the amount of glue cannot be accurately controlled, the speed is slow, and bubbles are easily generated, the present invention proposes an improved manufacturing method of the reflective cover to overcome the above-mentioned problems. In this method, the reflective cover is designed as the upper half of the reflective cover and the lower half of the reflective cover, and the transparent glue is brushed into the hollow hole of the upper half of the reflective cover by brushing glue in the vacuum chamber. Finally, the upper half of the reflective cover and the lower half of the reflective cover are combined into a complete reflective cover.

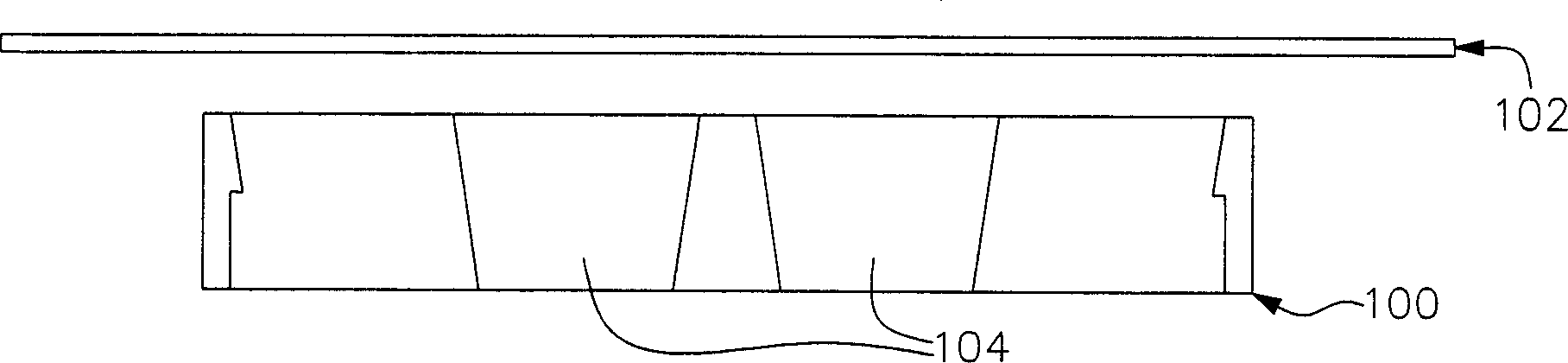

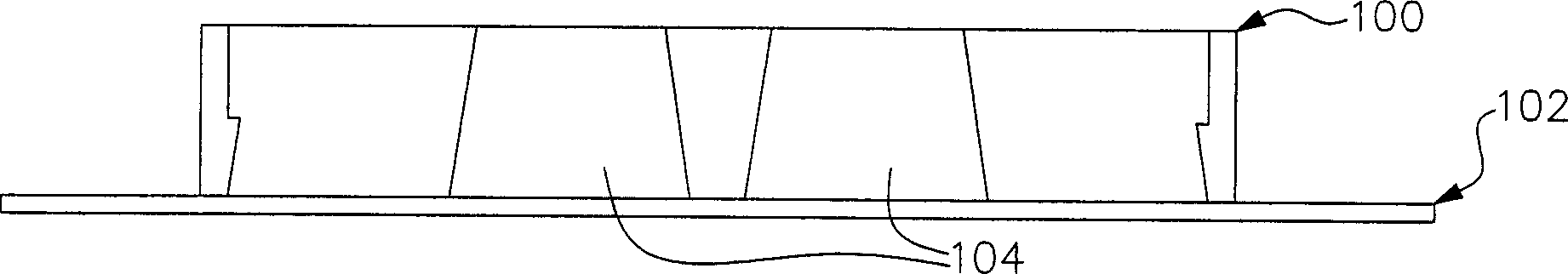

[0023] Please refer to Figures 1A-1H , which represent the manufacturing steps of a light emitting diode reflective cover according to a preferred embodiment of the present invention. Figure 1A It shows the upper half 100 of a reflecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com