Patents

Literature

72results about How to "Improve light guide effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

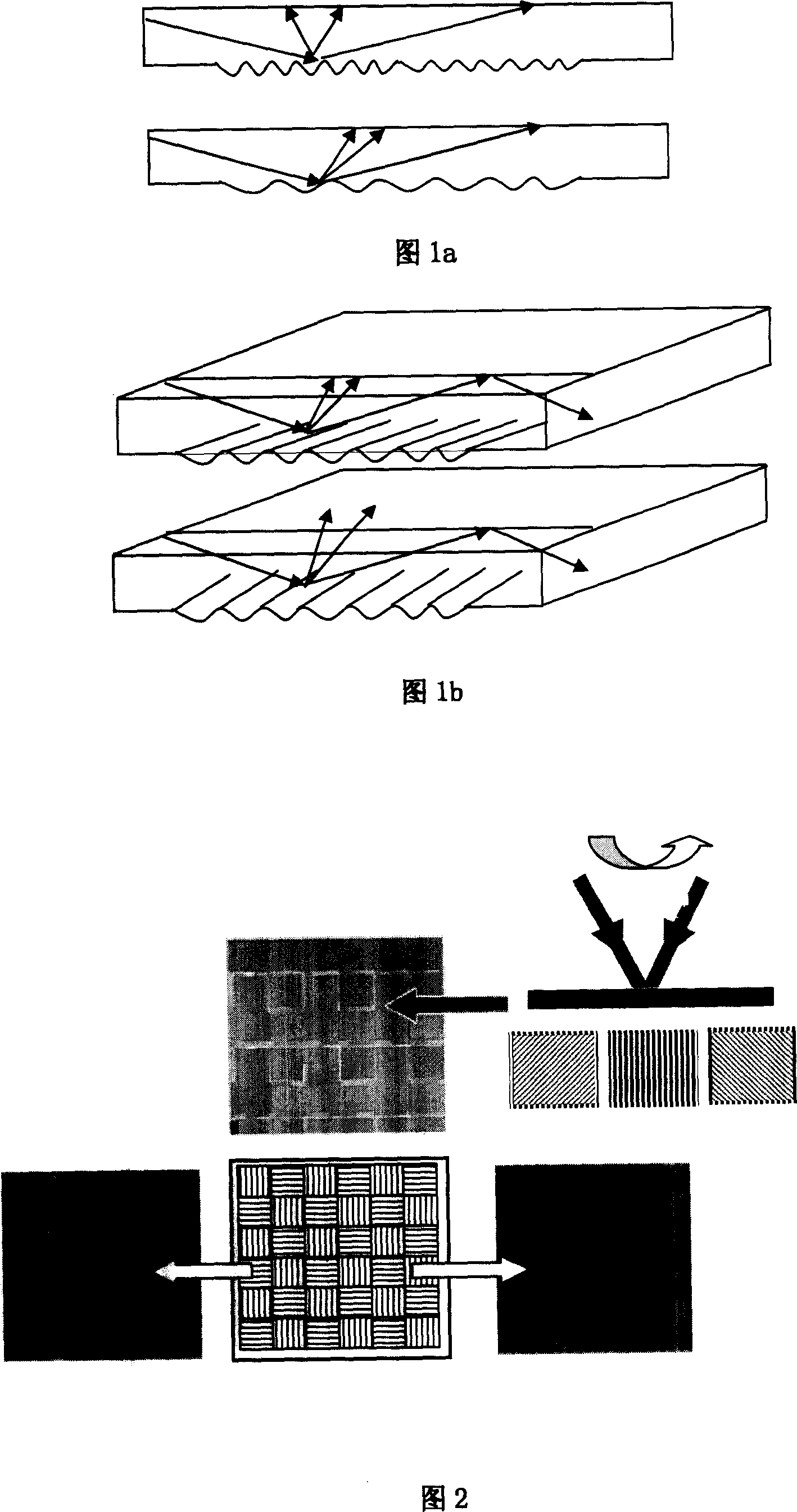

Photoconductive coating film of diffraction grating and manufacture method thereof

InactiveCN101017218AImprove uniformityBest field of viewCoupling light guidesNon-linear opticsCompanion animalDesign guide

This invention discloses one infraction grating guide conductive film, wherein, one side of surface is set with grating pixel units and the invention is characterized by the following: the grating pixel unit is composed of sub pixel structure with each one determined by infraction grating, space frequency, tank depth guide light direction and intensity. The process method comprises the following steps: a, designing guide pattern infraction structure distribution; b, distributing the pixel structure on guide pattern with each unit formed with sub pixel element and each one infraction grating taking, space frequency alternated; c, etching; d, through casting to process metal nickel board for printing on coat layer of PET or PC film.

Owner:SUZHOU UNIV +1

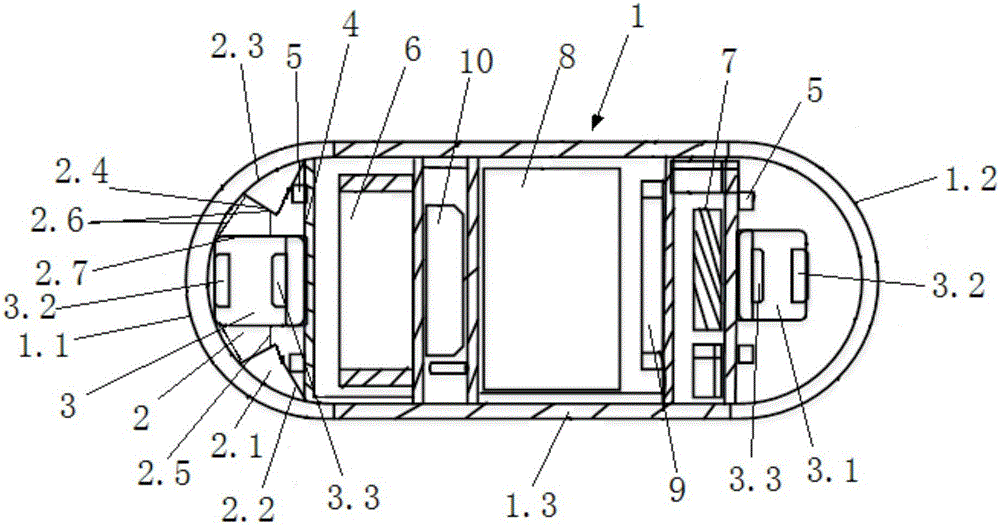

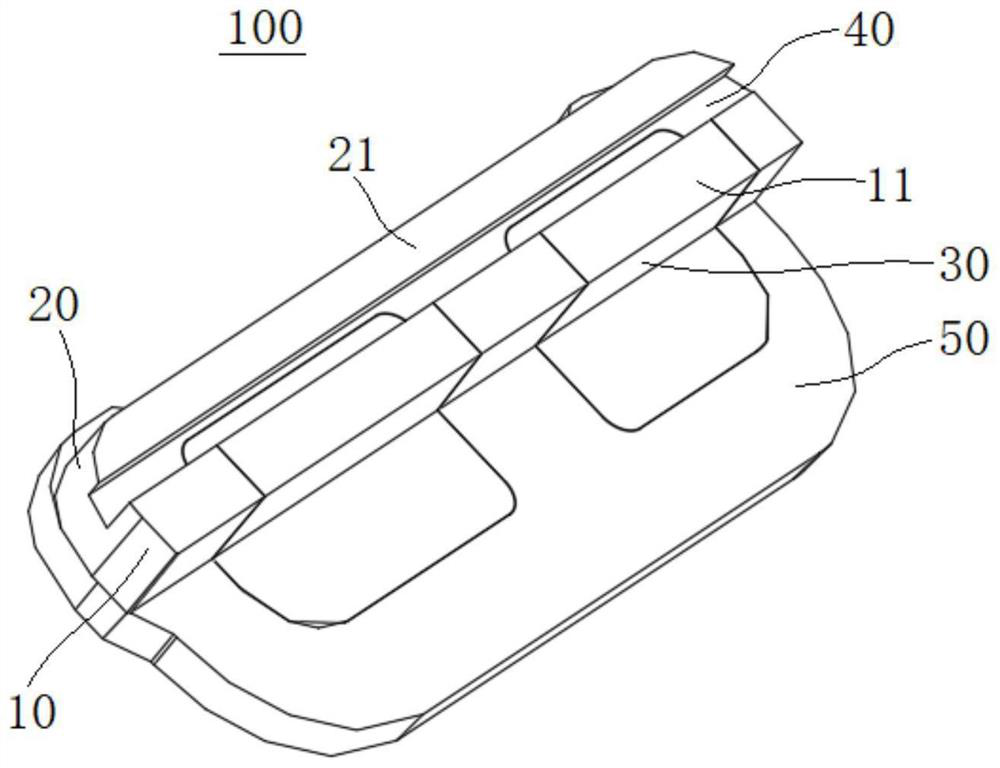

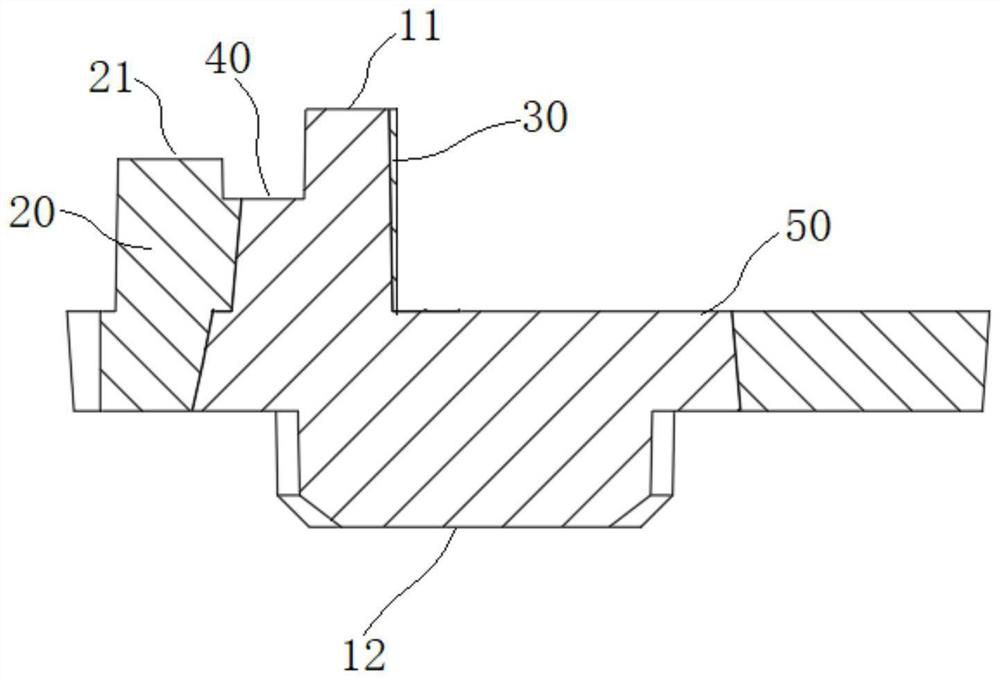

Double-lens capsule endoscope with light guide device

ActiveCN107174188AExpand the field of viewAvoid stray light interferenceSurgeryEndoscopesLight guideFlexible circuits

The invention relates to a double-lens capsule endoscope with a light guide device. The double-lens capsule endoscope is characterized by comprising a capsule shell, a non-transparent shading body, a transparent light guide body, a front camera, a rear camera, a flexible circuit board, a lighting device, a permanent magnet, a radio-frequency signal transmission device, a signal processing device and a motion sensor, wherein the non-transparent shading body, the transparent light guide body, the front camera, the rear camera, the flexible circuit board, the lighting device, the permanent magnet, the radio-frequency signal transmission device, the signal processing device and the motion sensor are arranged in the capsule shell. A combined structure of two parts (the non-transparent shading body and the transparent light guide body) is adopted by the light guide device, so that the light guide effect can be strengthened, light only enters from the transparent light guide body, the non-transparent shading body is capable of shading one part of stray light entering lenses to increase the light guide effect, and meanwhile, the non-transparent shading body and the lenses are clung to the inner wall of a transparent optical dome to reduce the stray light to the maximal extent. In addition, by adopting a double-lens design matched with the light guide device, a shot image is clearer, and meanwhile, the limited space in a capsule is saved through the design of being clung to the inner wall.

Owner:安翰科技(武汉)股份有限公司

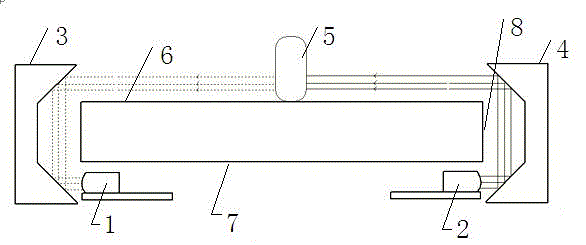

Infrared touch screen for changing infrared light transmission paths and touch point recognizing method for infrared touch screen

InactiveCN102622133ALower suspension heightImprove anti-light interference performanceInput/output processes for data processingInterference resistanceLight guide

The invention discloses an infrared touch screen for changing infrared light transmission paths and a touch point recognizing method for the infrared touch screen. In the touch screen, infrared light emitted by an infrared emission unit positioned on a non-touch face of the touch screen is changed in ray transmission direction by an emitting light guide unit prior to being transmitted to a touch face to form an infrared ray optical network, and then is changed in ray transmission direction by a receiving light guide unit prior to being transmitted to an infrared receiving unit of a non-touch face of the touch screen. By the aid of the infrared touch screen and the method, touch suspension height of the infrared touch screen is decreased, light interference resistance of the infrared touch screen is enhanced, and the protruded height and width of the edge of the touch face of the infrared touch screen are decreased.

Owner:GENERALTOUCH TECH

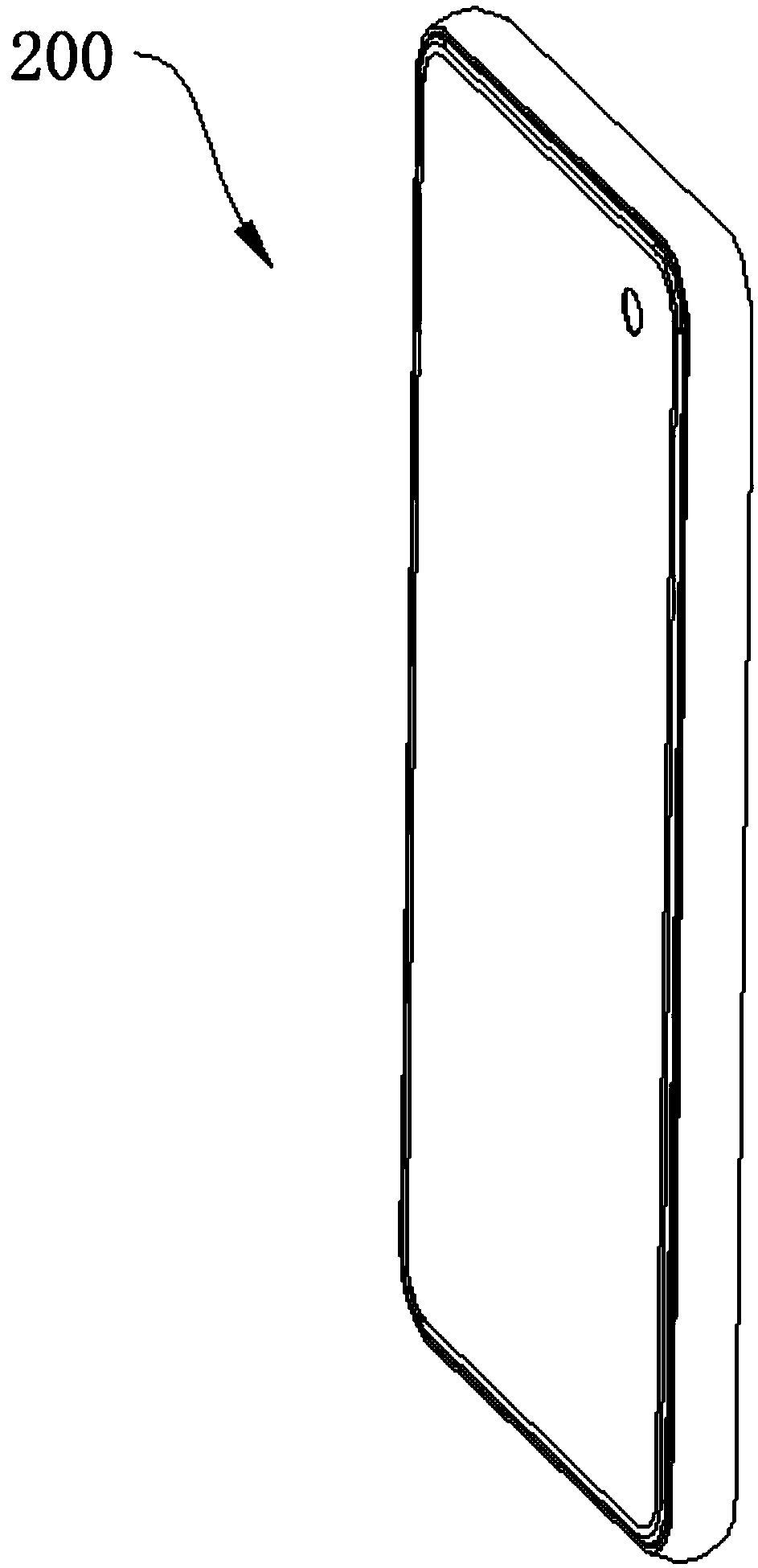

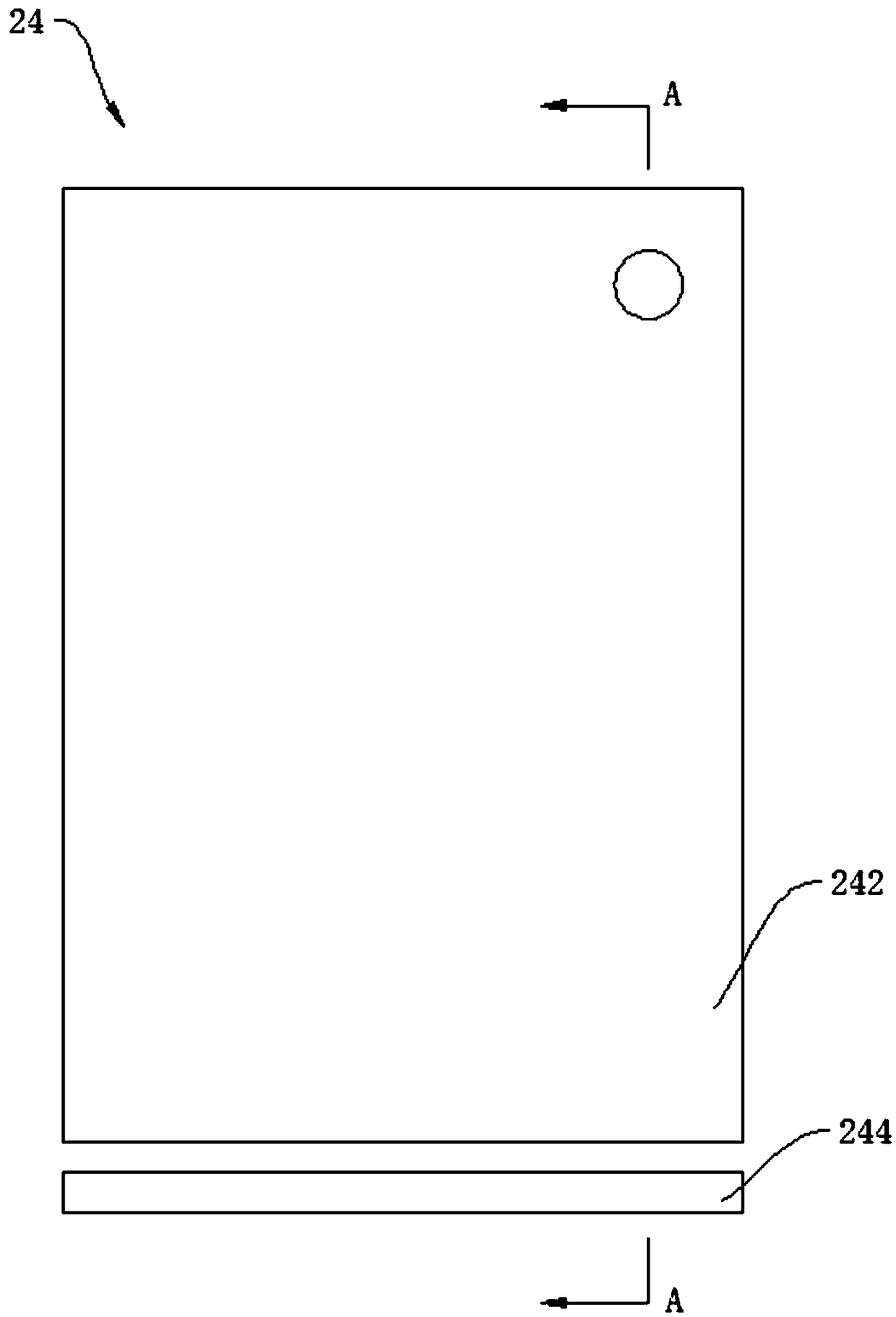

Backlight module, display screen assembly and electronic equipment

InactiveCN108873471AIncrease distribution densityImprove light guide effectOptical light guidesNon-linear opticsLight guideComputer science

The invention discloses a backlight module. The backlight module comprises a light source and a light guide plate, the light guide plate comprises a first side face, a second side face, a first end face and a second end face, the first side face and the second side face are opposite to each other, and the first end face and the second end face are connected between the first side face and the second side face; the light guide plate is provided with a first through hole communicated with the first end face and the second end face, the first through hole comprises an inner wall face, the secondend face comprises a first light guide area and a second light guide area which are connected with each other, and the first light guide area is located between the inner wall face and the second sideface; the second end face is provided light guide points, the distribution density of the light guide points located in the first light guide area is larger than that of the light guide points located in the second light guide area, and the light source exactly faces the first side face. The invention further discloses a display screen assembly and electronic equipment. The backlight module can provide the backlight source with uniform brightness, and the display effect of the display screen assembly and the electronic equipment is good.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

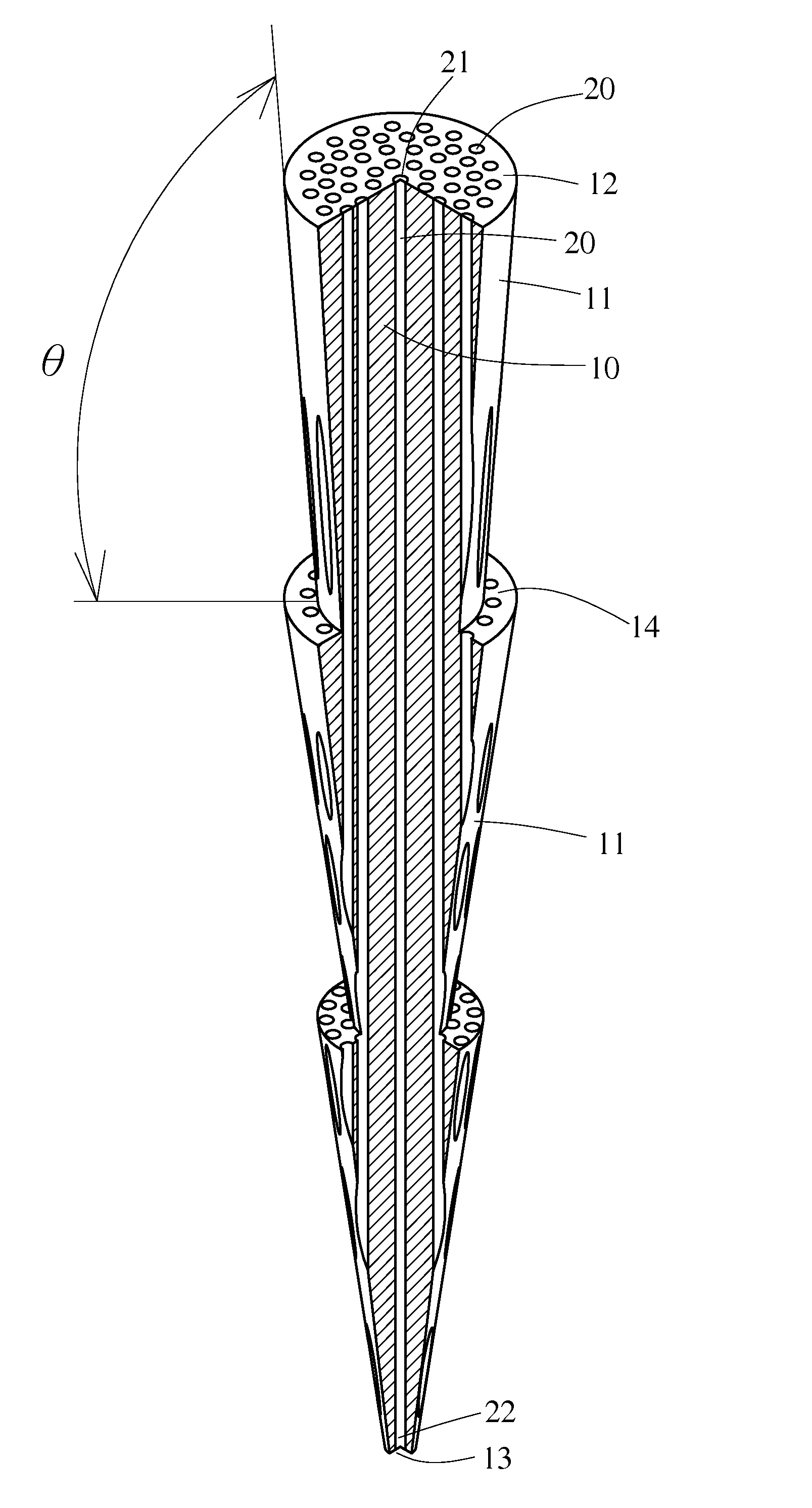

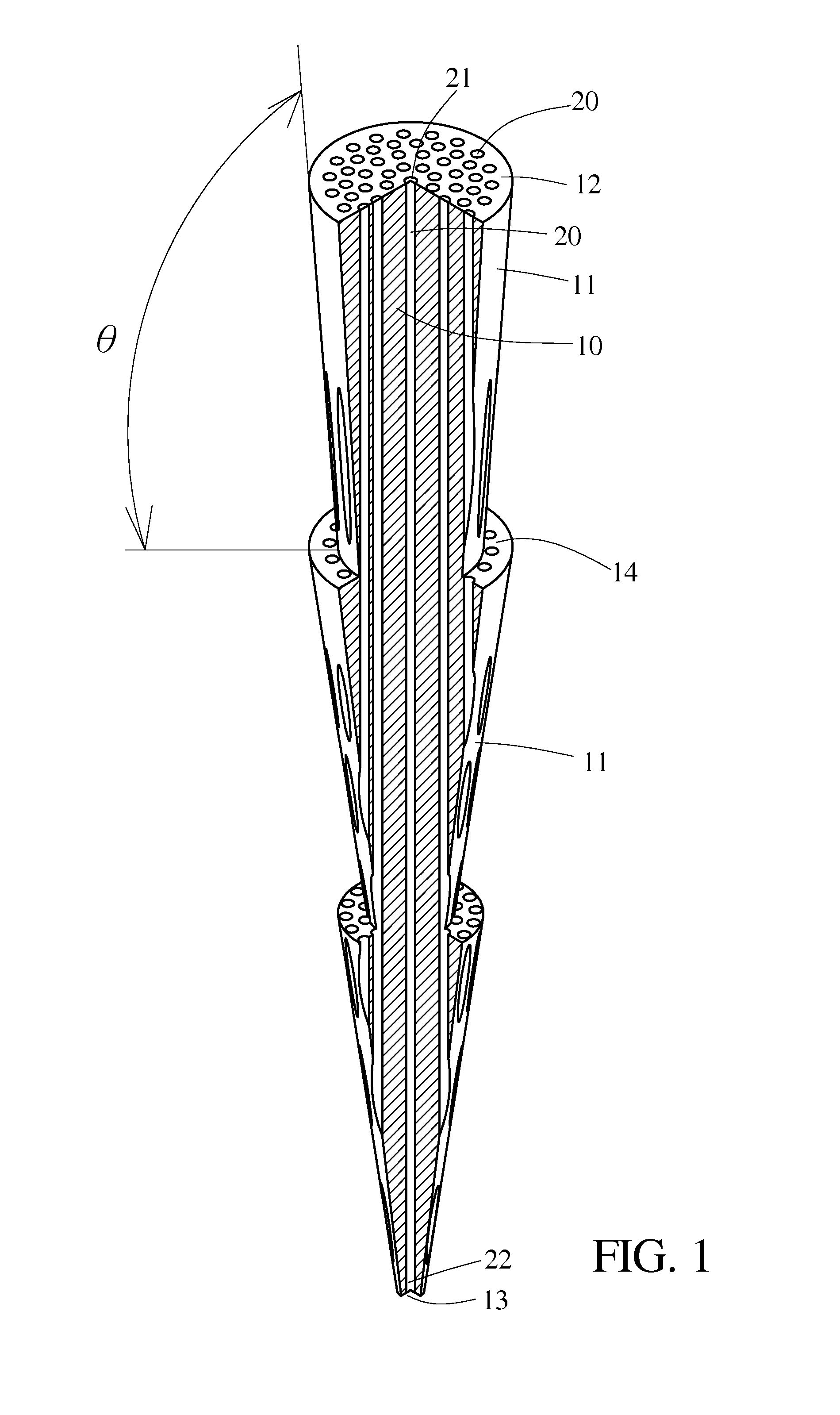

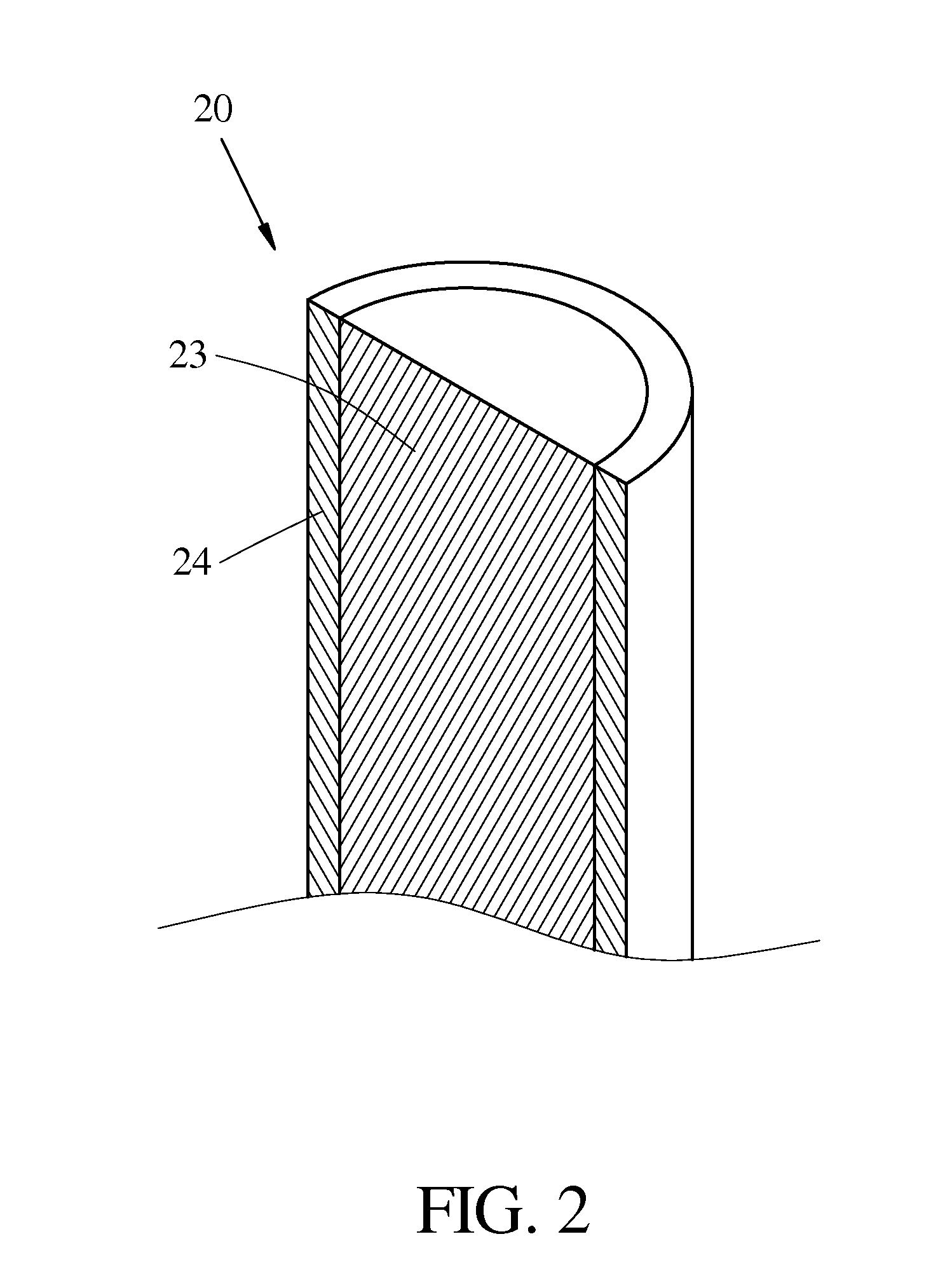

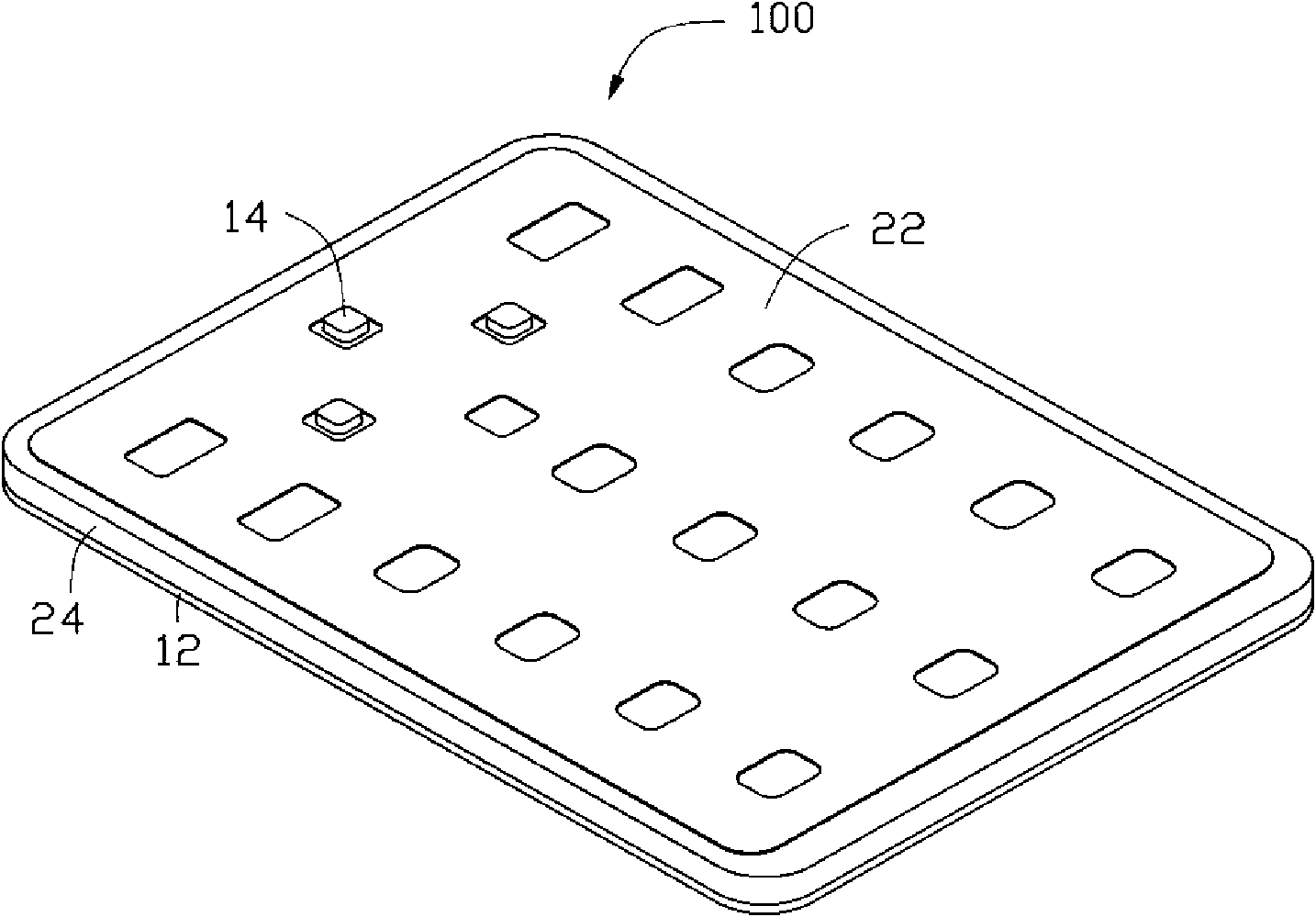

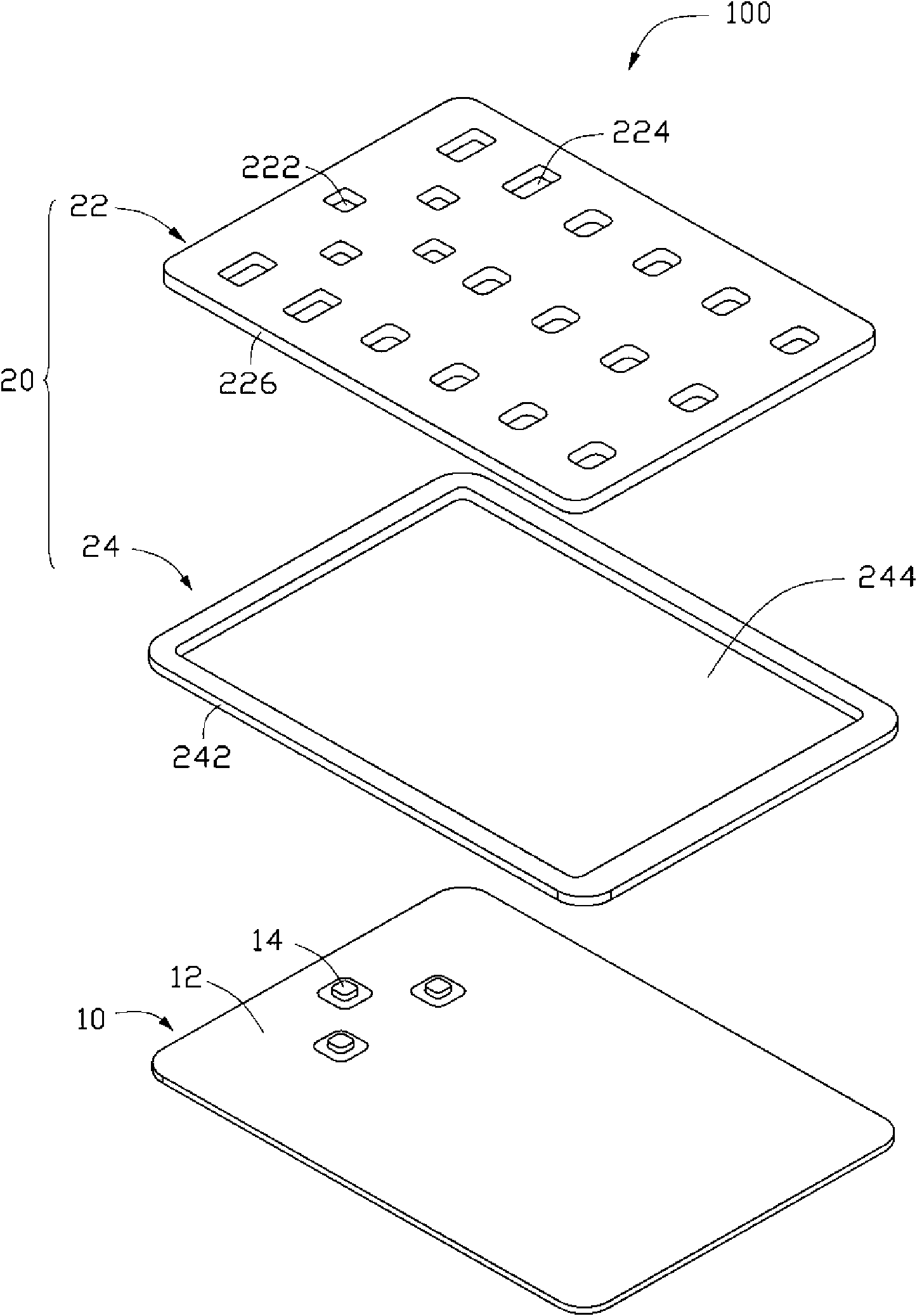

Fiber optics dental post

A fiber optics dental post includes a resin body and plural fiber optics center shafts; wherein the resin body includes an outer peripheral face, a receiving irradiation portion, and a bottom; each of the fiber optics center shafts pierces through and is fixed in the resin body, and has a receiving irradiation end and a light-guide irradiation end; each receiving irradiation end placed on the receiving irradiation portion of the resin body is used to receive the light irradiating on the receiving irradiation portion, and each light-guide irradiation end is respectively placed on the outer peripheral face and at the bottom of the resin body, thus the light received by each receiving irradiation end is propagated to the outer peripheral face and the bottom of the resin body through the light-guide irradiation end for irradiation, so as to effectively enhance the adhesion strength of the dental post.

Owner:TAIWAN FIBER OPTICS

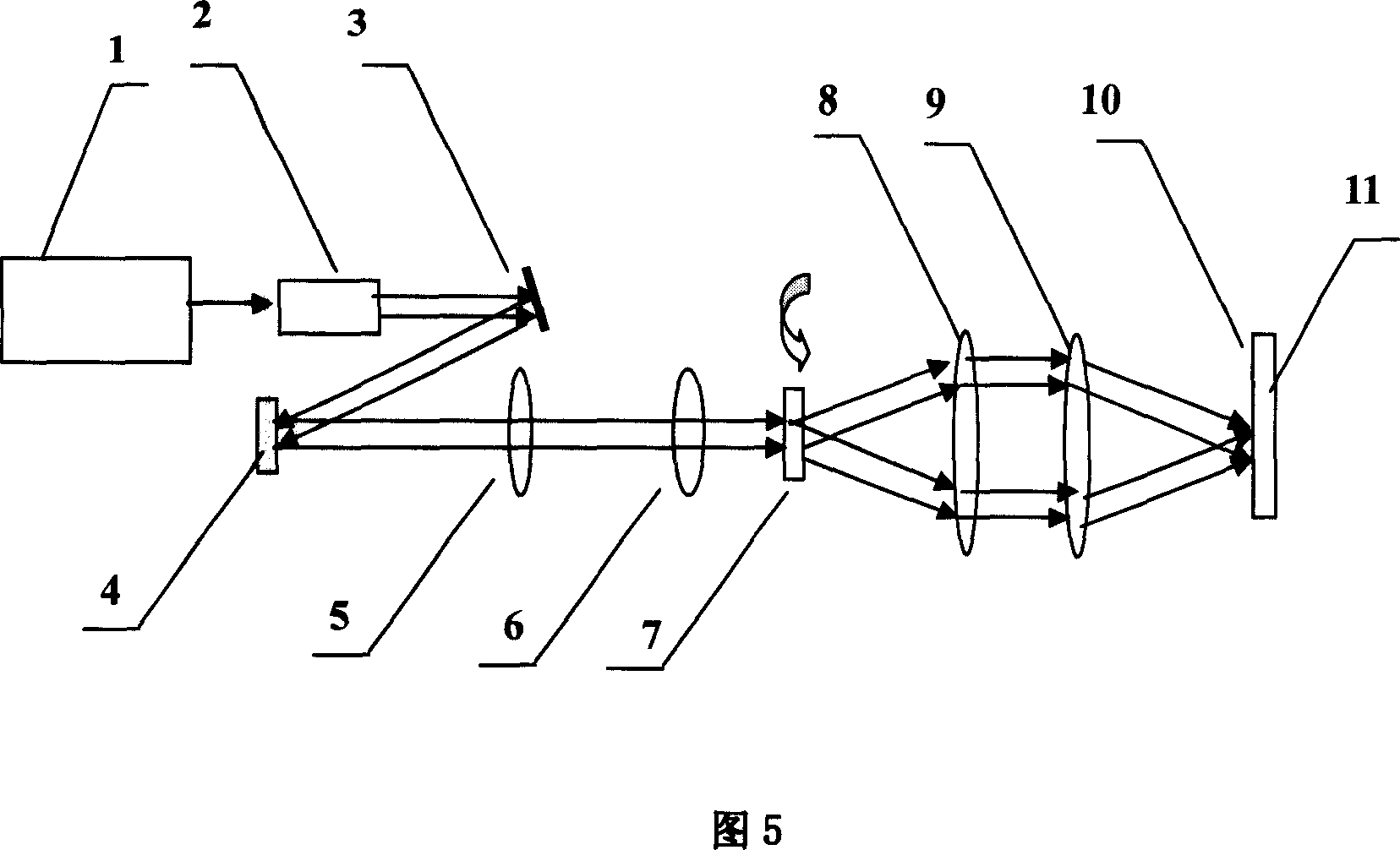

Method for manufacturing glass light guide plate

ActiveCN107167868AIncrease productivityImprove light guide effectOptical light guidesMaximum levelLaser intensity

The invention provides a method for manufacturing a glass light guide plate. The method includes the following steps: preparing a glass substrate with a preset size, preferably an ultra clear glass in order to increase the properties of the light guide plates, cleaning and edging the ultra clear glass, one side of the glass substrate serving as a lattice point side, coating a protection film to the lattice point side; using a laser engraving machine to print dots of a predetermined lattice point pattern on the lattice point side, adjusting the laser intensity to the maximum level upon printing dots so that the glass substrate does not generate fine cracks; performing printing or coating on the lattice point side or spraying a printing ink to the lattice point side and curing the printing ink which can be selected from an UV curing printing ink or a thermal curing printing ink; and unveiling the protection film to obtain the glass light guide plate. The method herein uses a laser dotting method to form light guide points, uses the protection film, and synchronously perforates in the process of the laser dotting, obviates the need for silk screen printing in coating the printing ink and can perform direct printing, unveils the protection film after performing curing and can form recessed light guide lattice points which are coated with light guide printing ink. The method herein increases production efficiency and light guide properties.

Owner:DONGGUAN YINTAIFENG OPTICAL TECH CO LTD

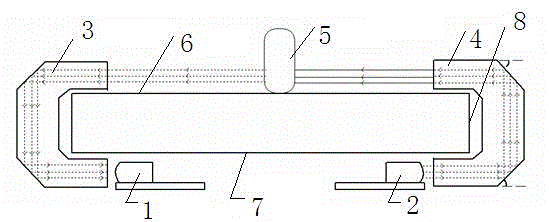

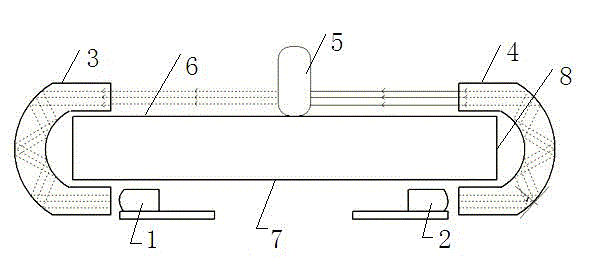

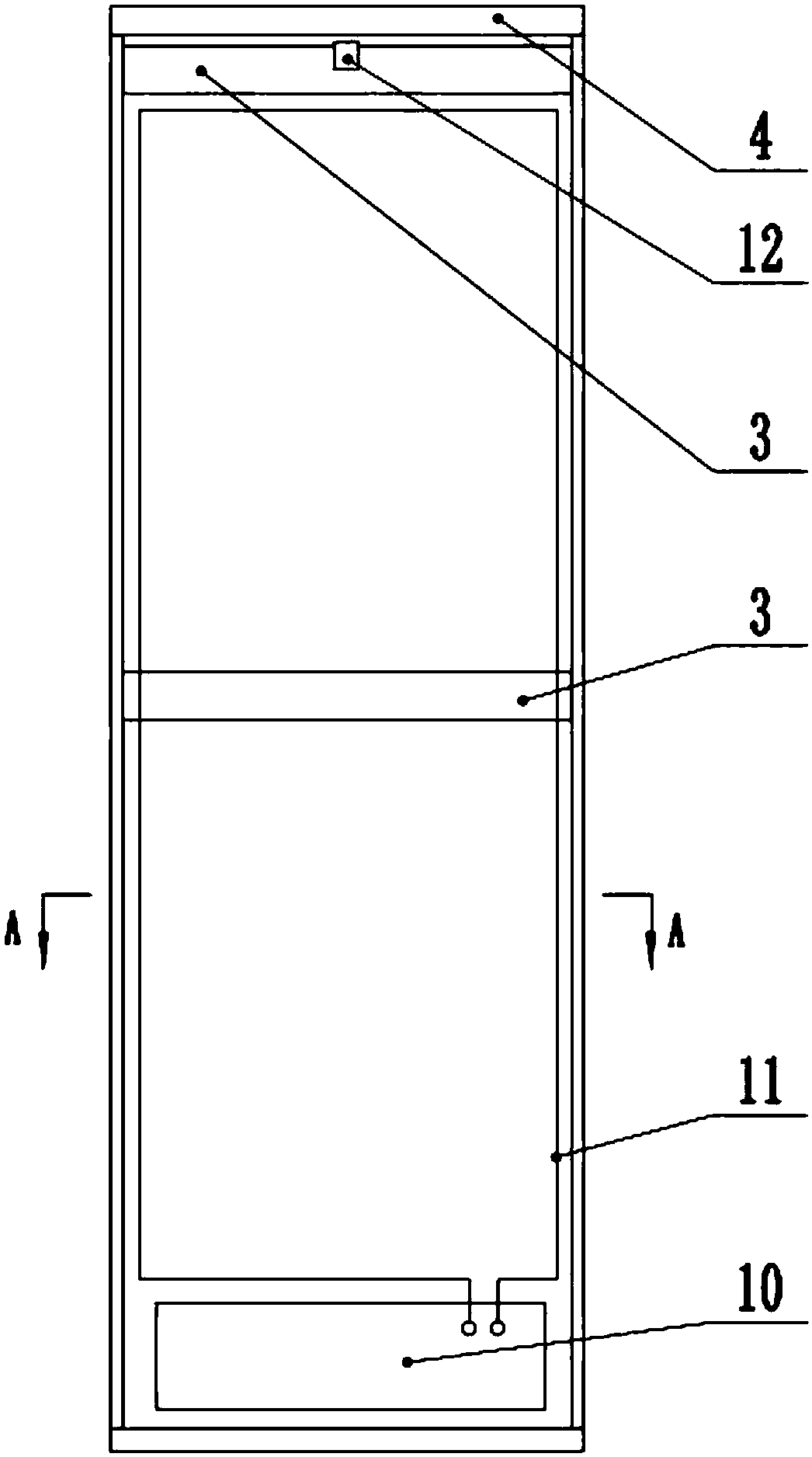

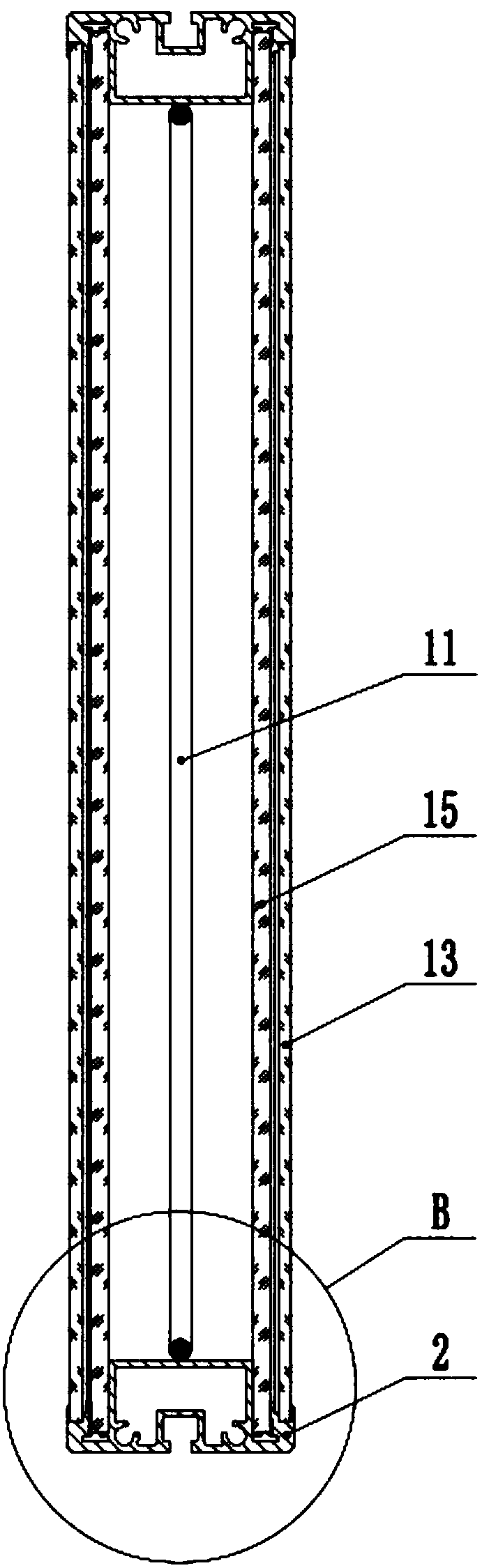

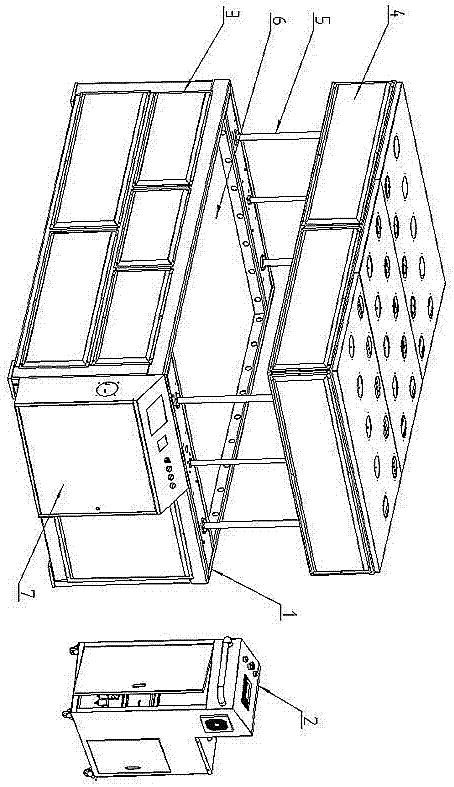

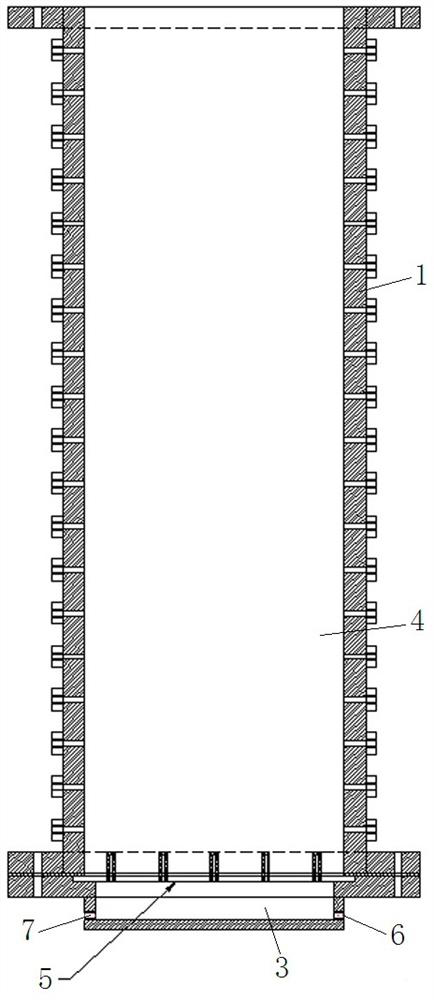

Shopping mall anti-theft device with advertisement displaying function

PendingCN108492739AWith ad display functionImprove light guide effectArticle advertisingElectric transmission signalling systemsLight guidePulp and paper industry

The invention discloses a shopping mall anti-theft device with an advertisement displaying function. The device comprises a supporting frame, an alarming system and two advertisement displaying parts,the supporting frame is a rectangular framework, the alarming system is fixed in the frame, two advertisement displaying parts are arranged on two sides of the supporting frame respectively, an anti-theft function is provided for the shopping mall anti-theft device by the alarming system, the advertisement displaying function is directly provided for the shopping mall anti-theft device by the advertisement displaying parts, wherein the supporting frame comprises a base and two aluminum section bars, the two aluminum section bars are fixed on the base at an interval, the advertisement displaying parts comprise acrylic displaying panels, light guiding panels and aluminum-based LED lamp strips, two ends of the acrylic displaying panels are fixed in a displaying panel groove of the supportingframe, two ends of the light guiding panels are fixed in a light guiding panel groove of the supporting frame, the aluminum-based LED lamp strips are fixed in an LED lamp strip groove of the supporting frame, and advertisement lamp sheets are arranged between the acrylic displaying panels and the light guiding plates at intervals, so that the shopping mall anti-theft device is attractive in appearance, and the advertisement displaying effect is obvious.

Owner:益世传媒科技有限公司

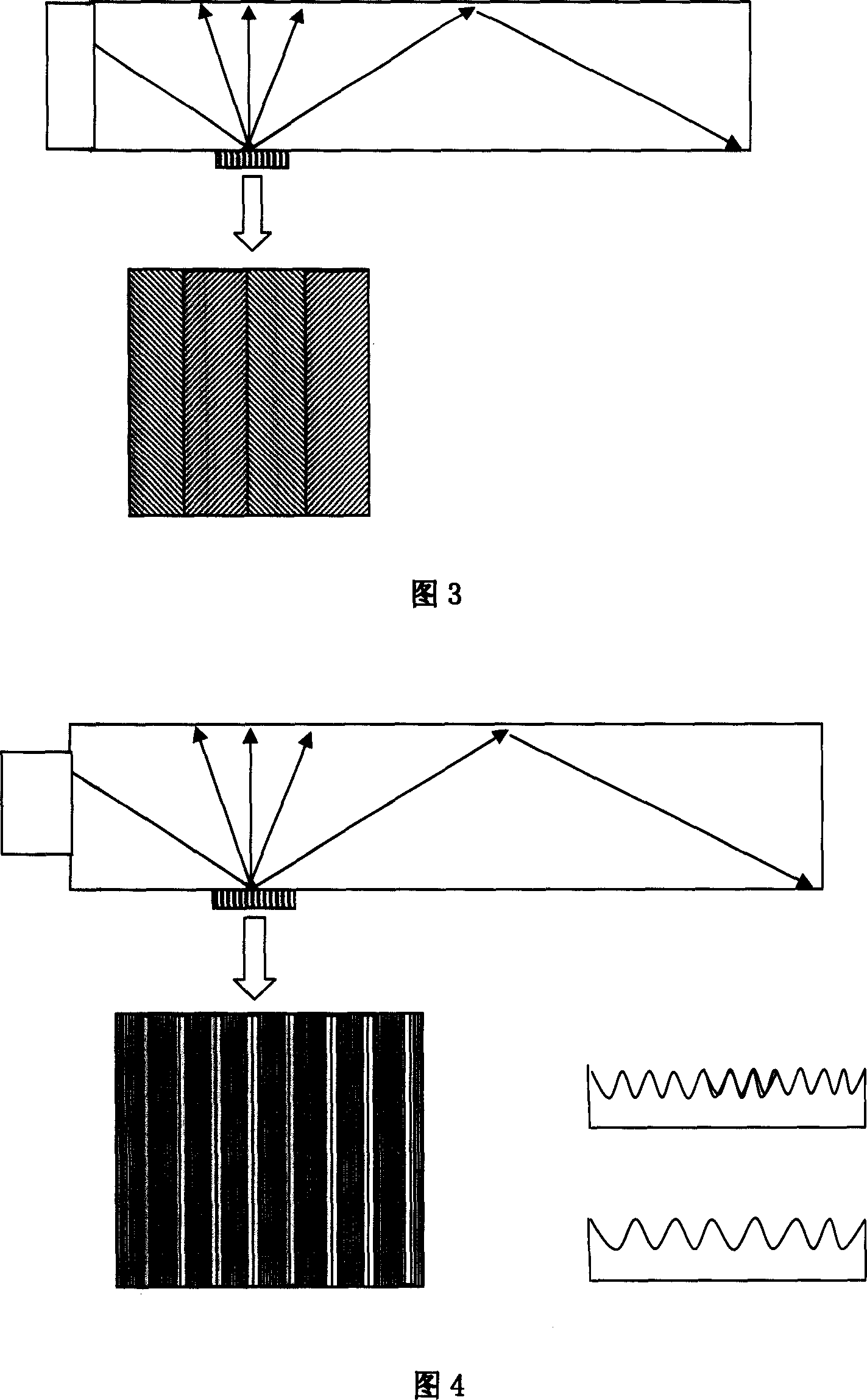

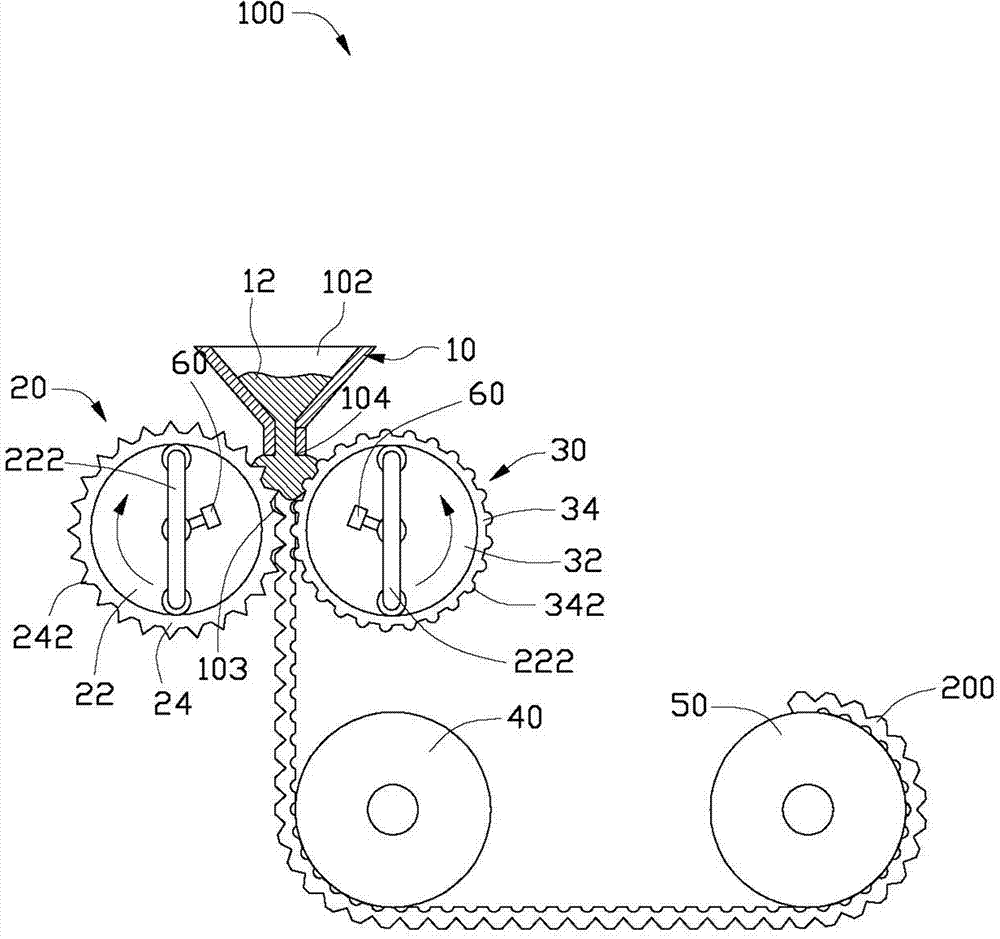

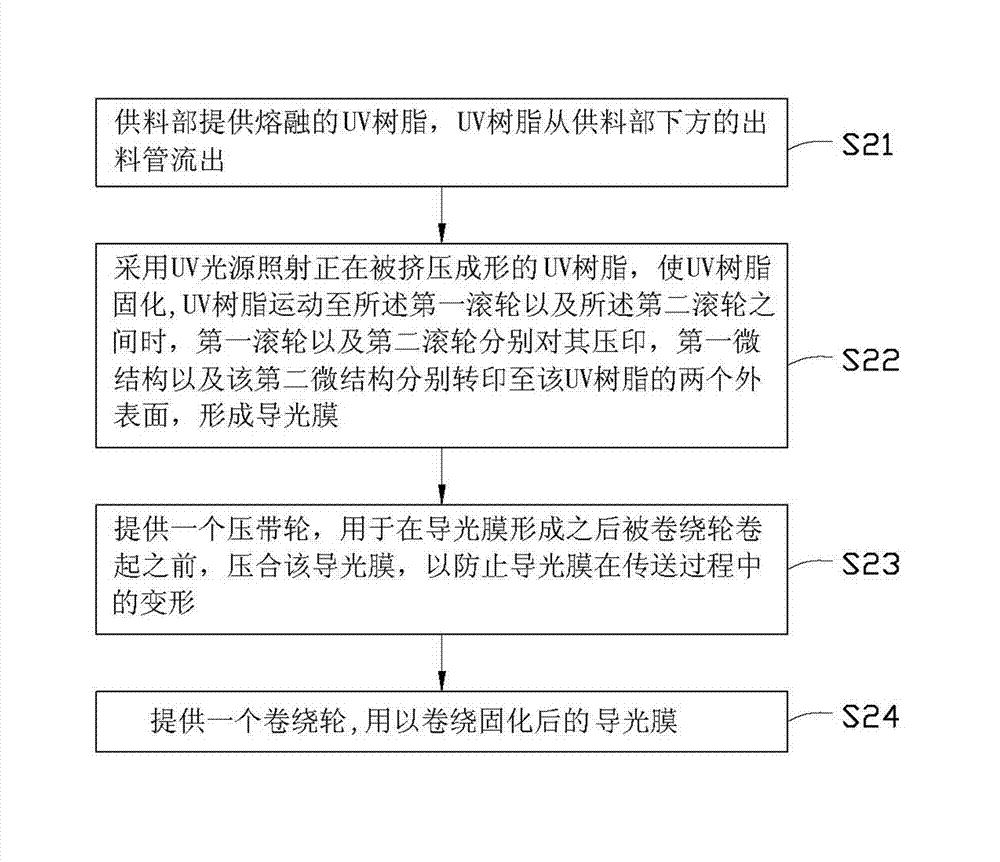

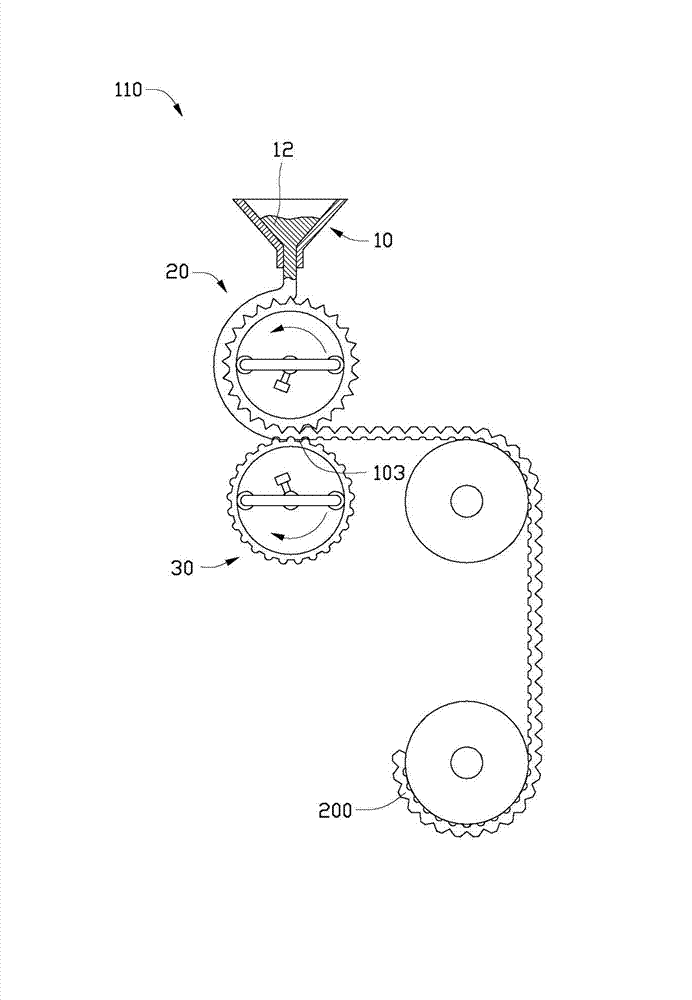

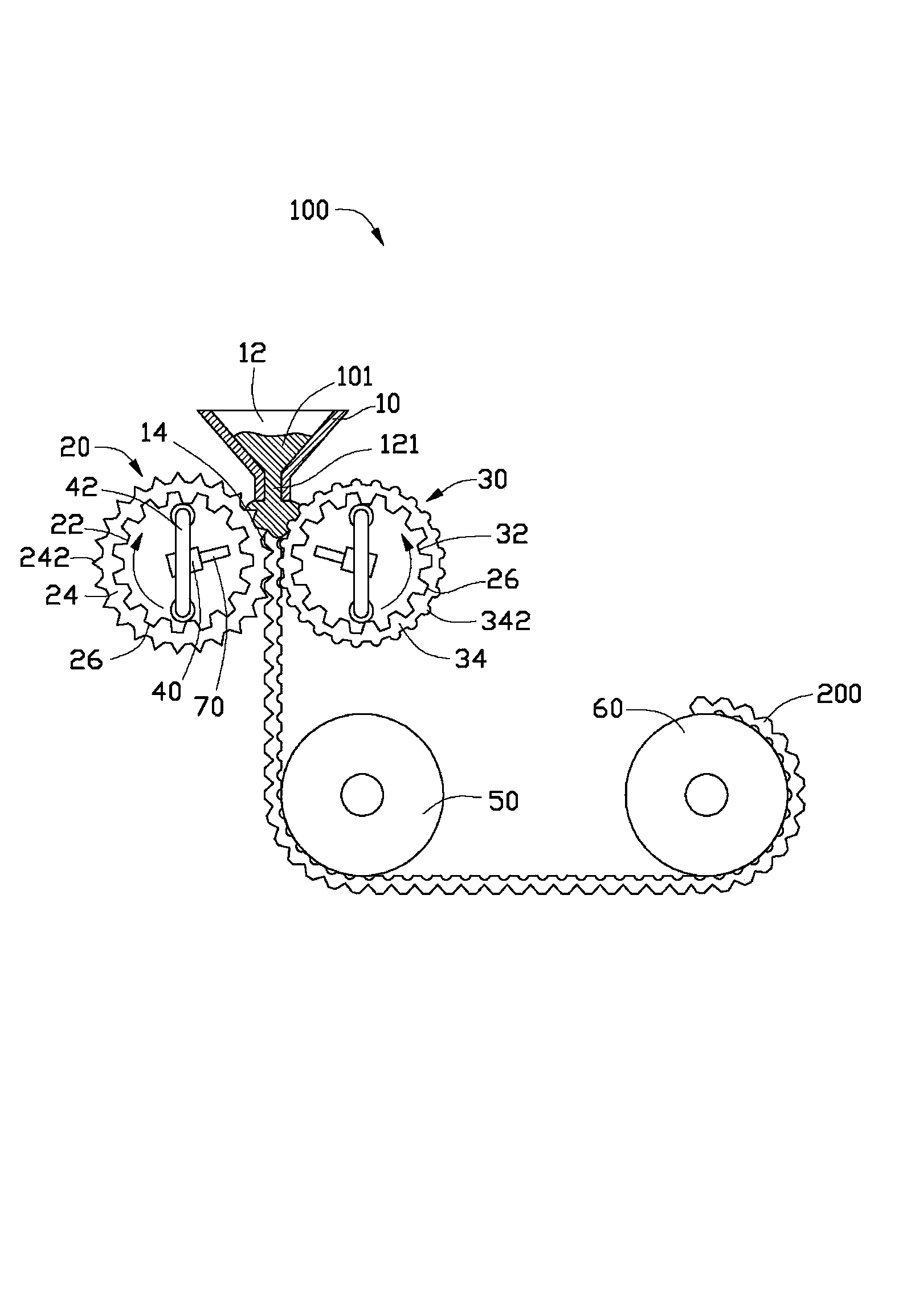

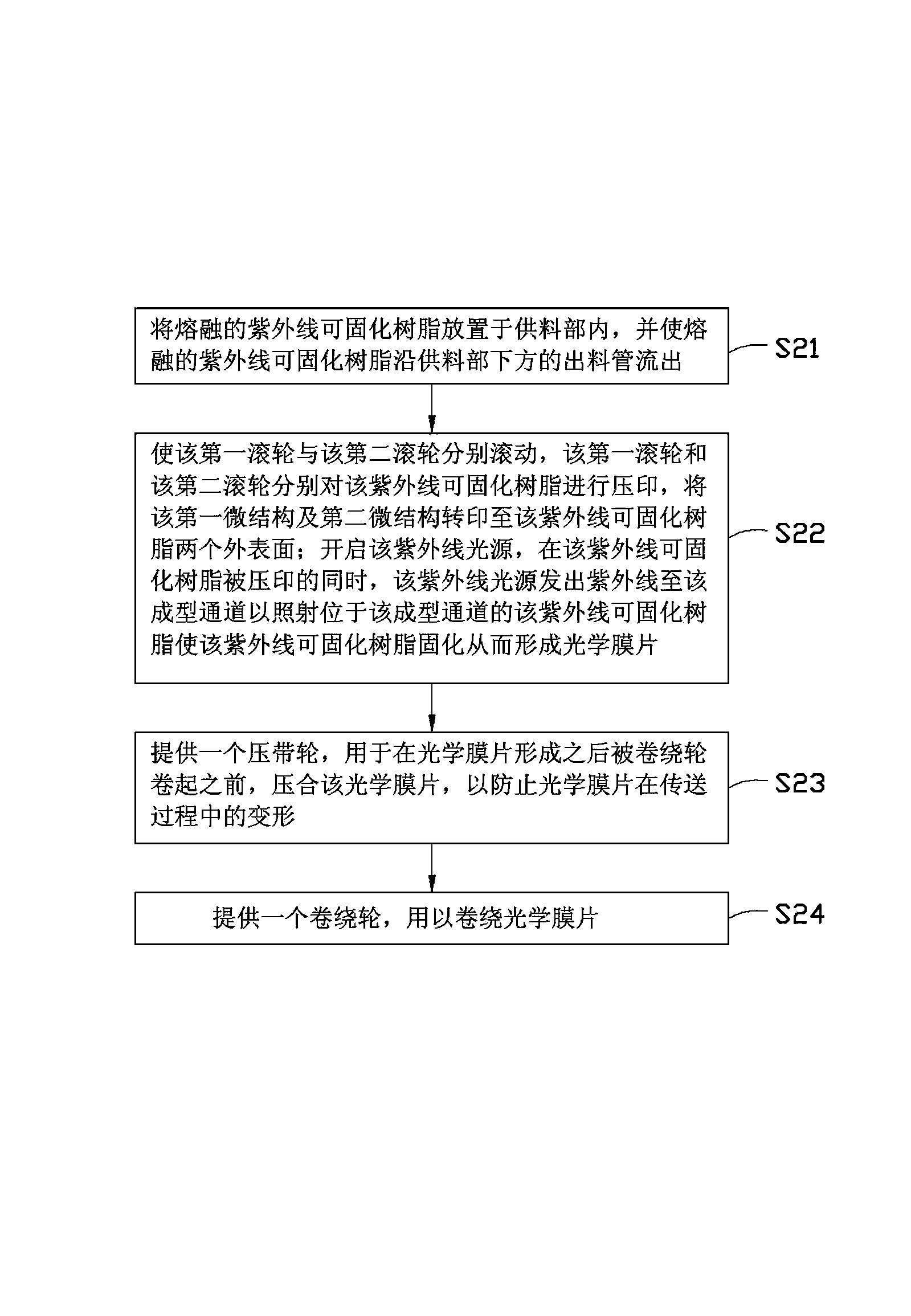

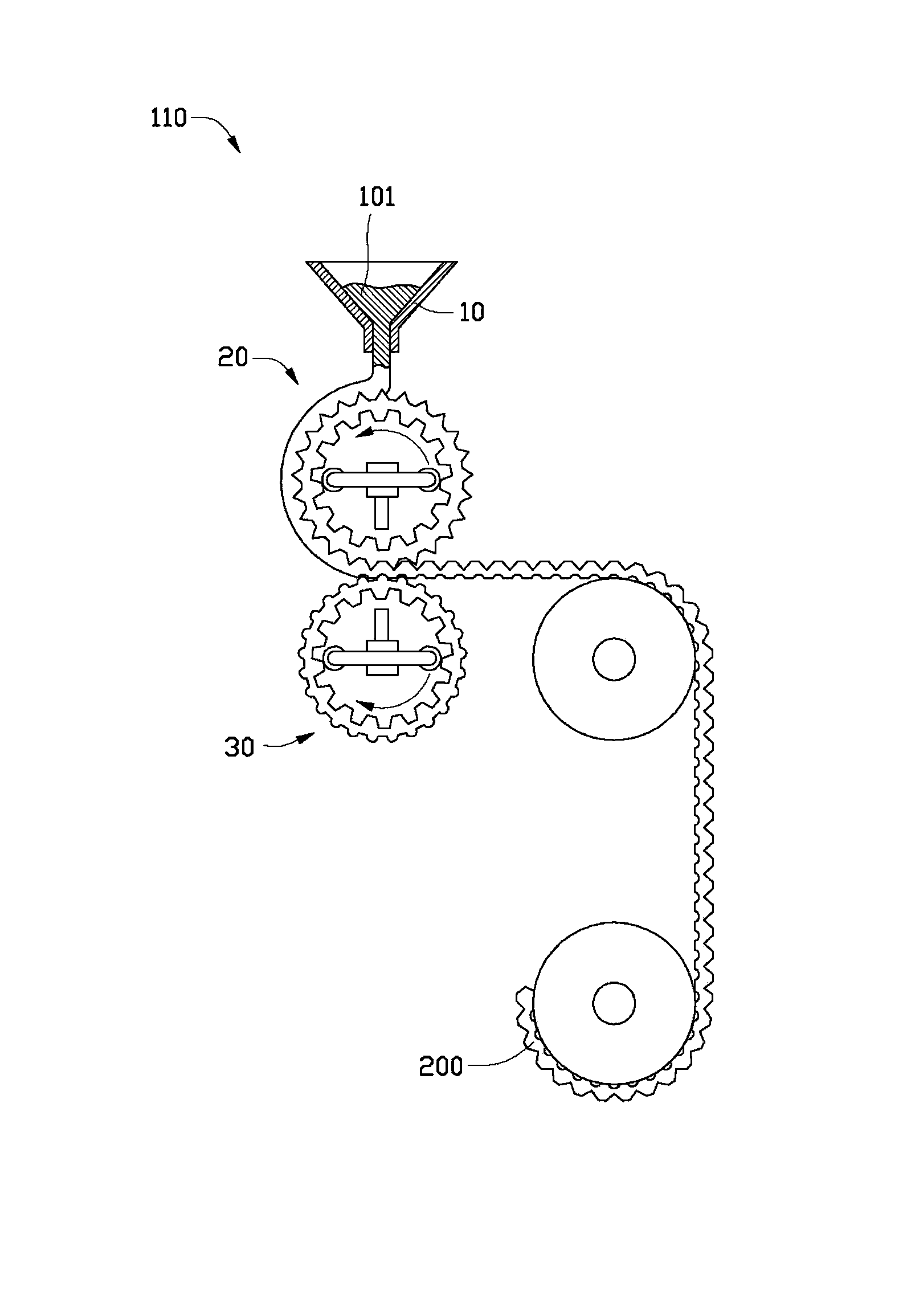

Manufacturing device and manufacturing method for light guide film

InactiveCN103246006AReduce thicknessReduce usageLamination ancillary operationsLaminationLight guideEngineering

The invention relates to a manufacturing device for a light guide film. The manufacturing device comprises a material feeding part, a first rolling wheel, a second rolling wheel as well as at least one UV (Ultraviolet) light source arranged inside the first rolling wheel or the second rolling wheel, wherein the material feeding part is used for providing molten UV resin; the first rolling wheel and the second rolling wheel are oppositely arranged at a predetermined interval; a plurality of grooves are formed in the surface of the first rolling wheel; the second rolling wheel is provided with a screen-dot microstructure; the first rolling wheel and the second rolling wheel are used for extrusion moulding of the UV resin; and the UV light sources are used for solidifying the UV resin in extrusion moulding. The invention further relates to a manufacturing method for the light guide film.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

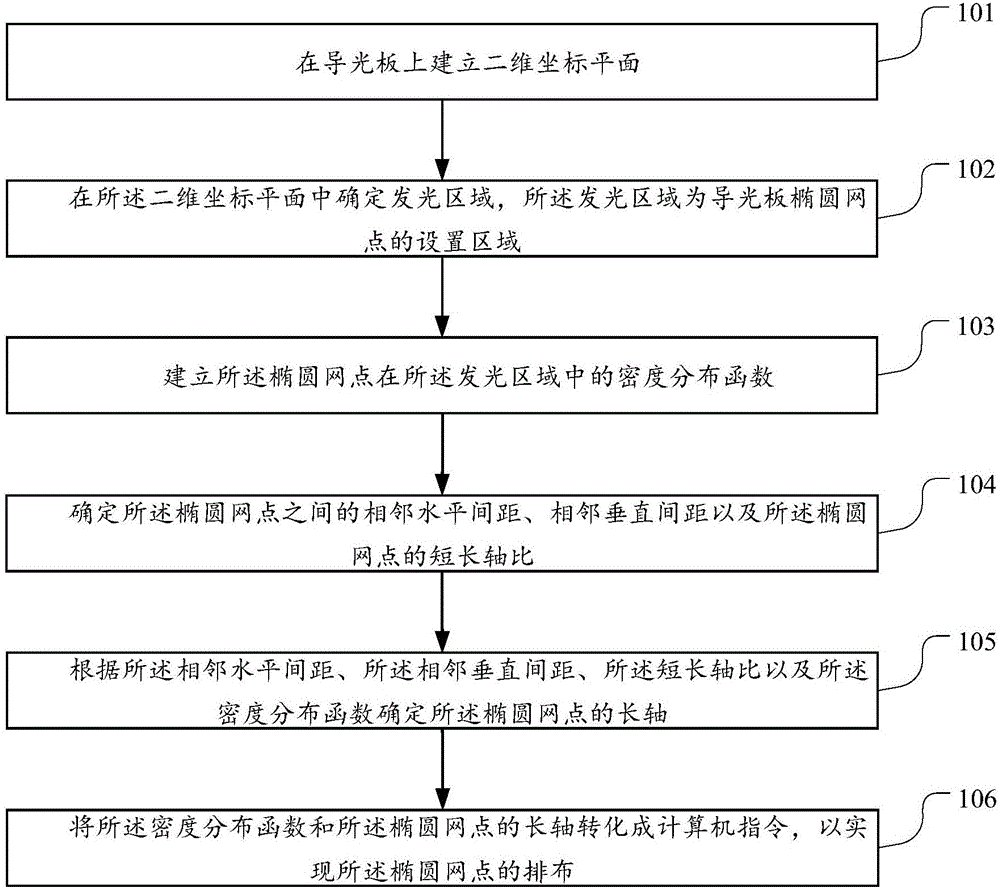

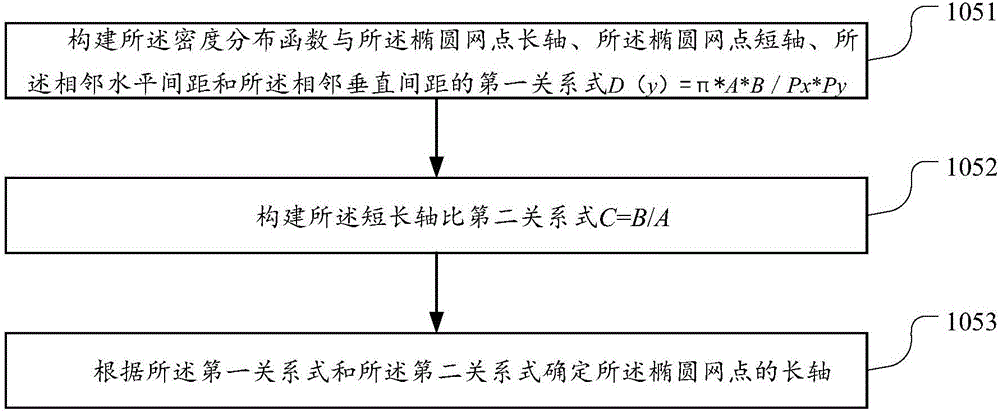

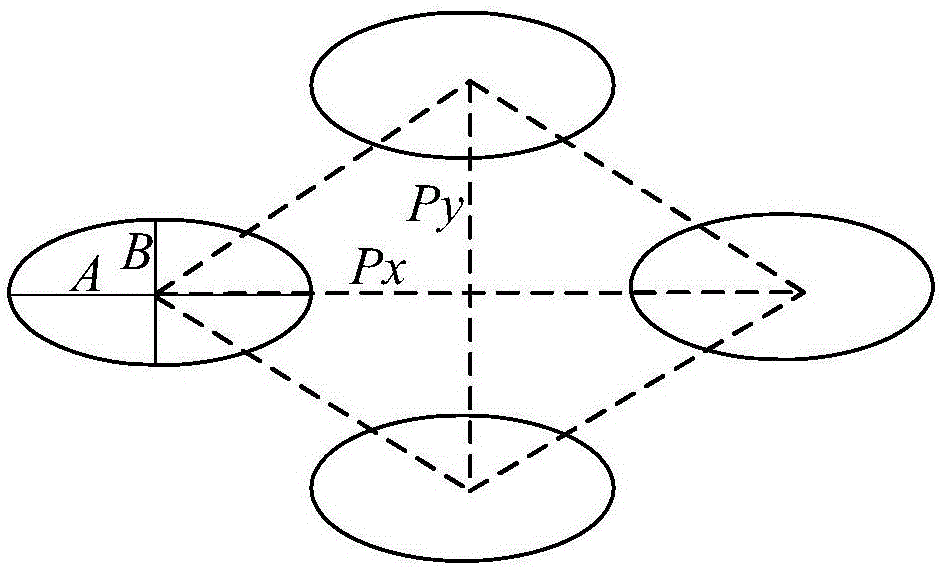

Light guide plate and elliptical dot designing method and device thereof

ActiveCN106646728AImprove light guide effectRealize arrangementOptical light guidesLaser processingAxial ratio

The invention relates to the technical field of light guide plate design and discloses a light guide plate and an elliptical dot designing method and device of the laser-processing light guide plate. The elliptical dot designing method includes: building a two-dimension coordinate plane on the light guide plate; determining a light emitting area in the two-dimension coordinate plane; building a density distribution function of elliptical dots in the light emitting area; determining adjacent horizontal interval and adjacent vertical interval among the elliptical dots and short-long axial ratio of the elliptical dots; determining long axis of the elliptical dots according the the adjacent horizontal interval, the adjacent vertical interval, the short-long axial ratio and the density distribution function; converting the density distribution function and the long axis of the elliptical dots into a computer instruction to realize distribution of the elliptical dots. Length of the long axis of the elliptical dots acquired by calculation is closer to actual distribution of dots compared with conventional linear dots, so that light guide effect of the light guide plate is improved effectively.

Owner:CHUZHOU HKC OPTOELECTRONICS TECH CO LTD

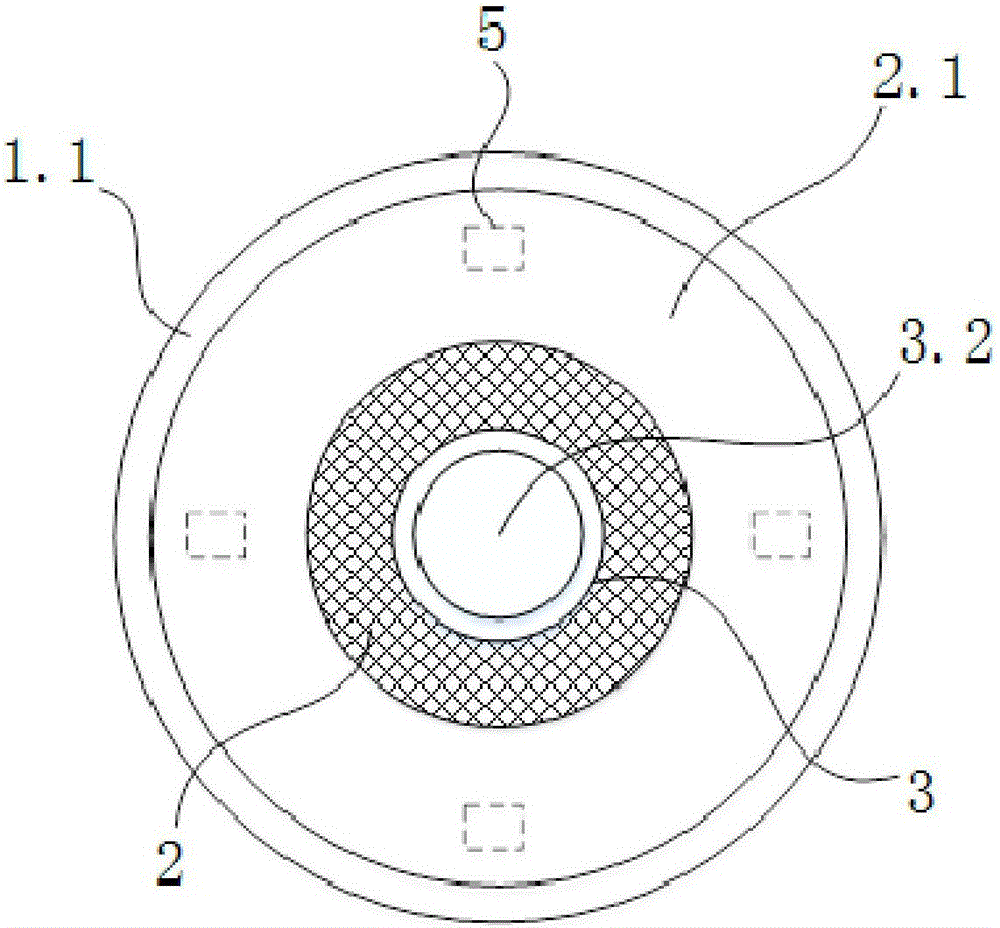

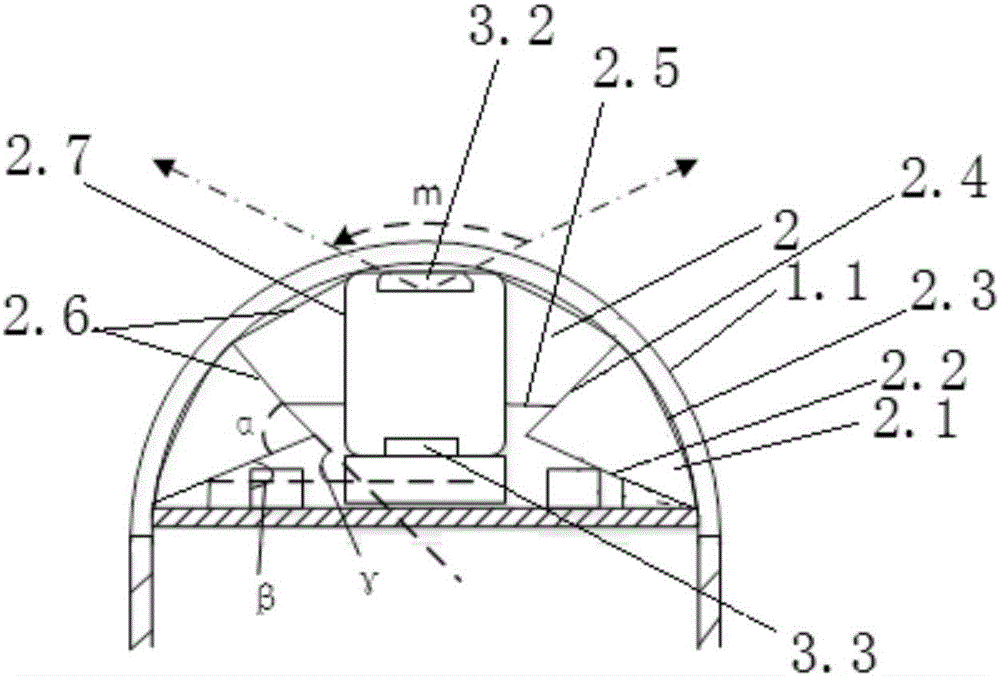

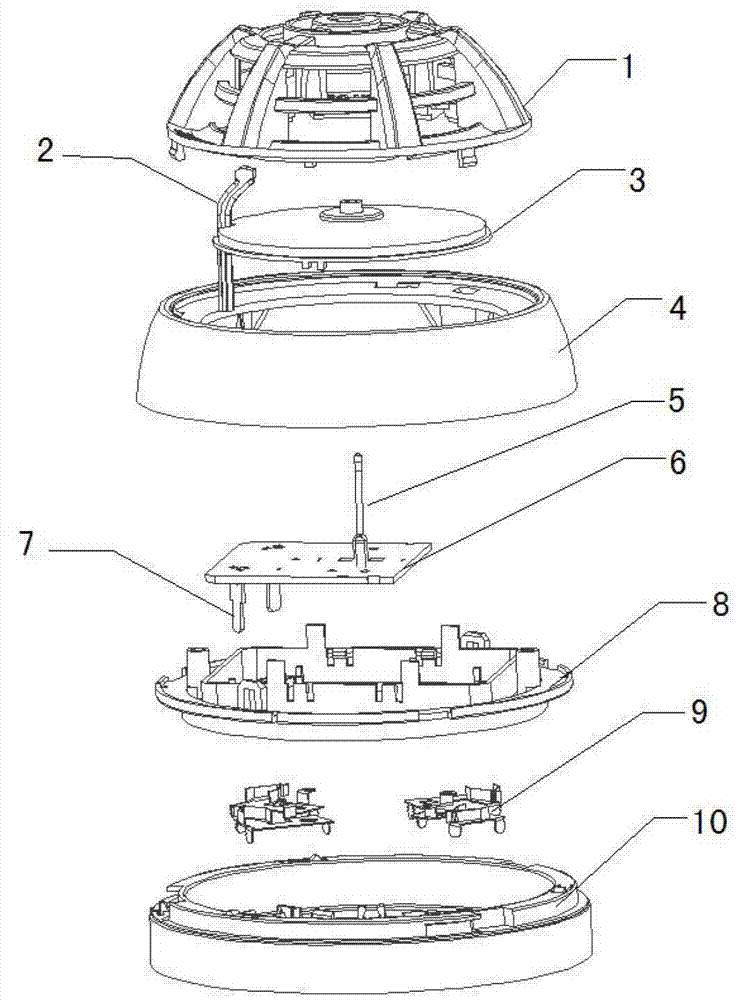

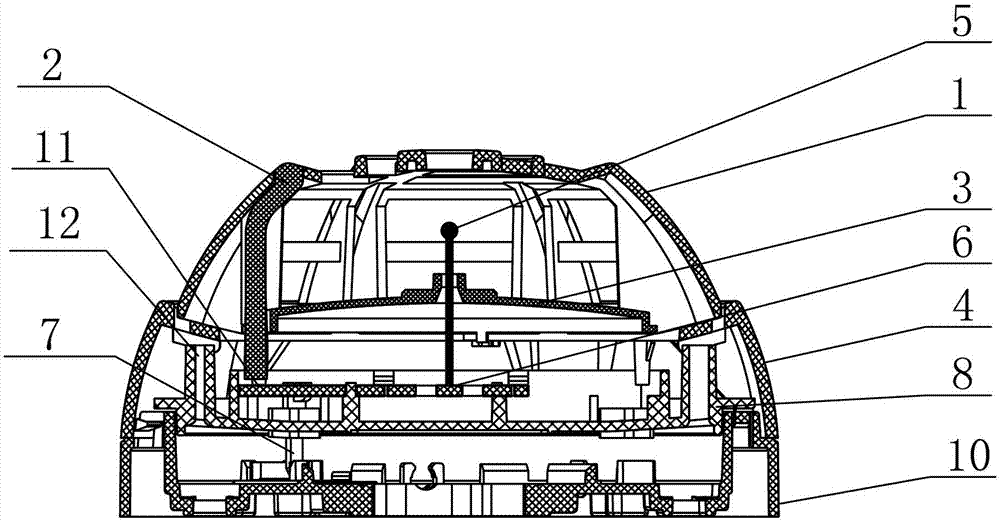

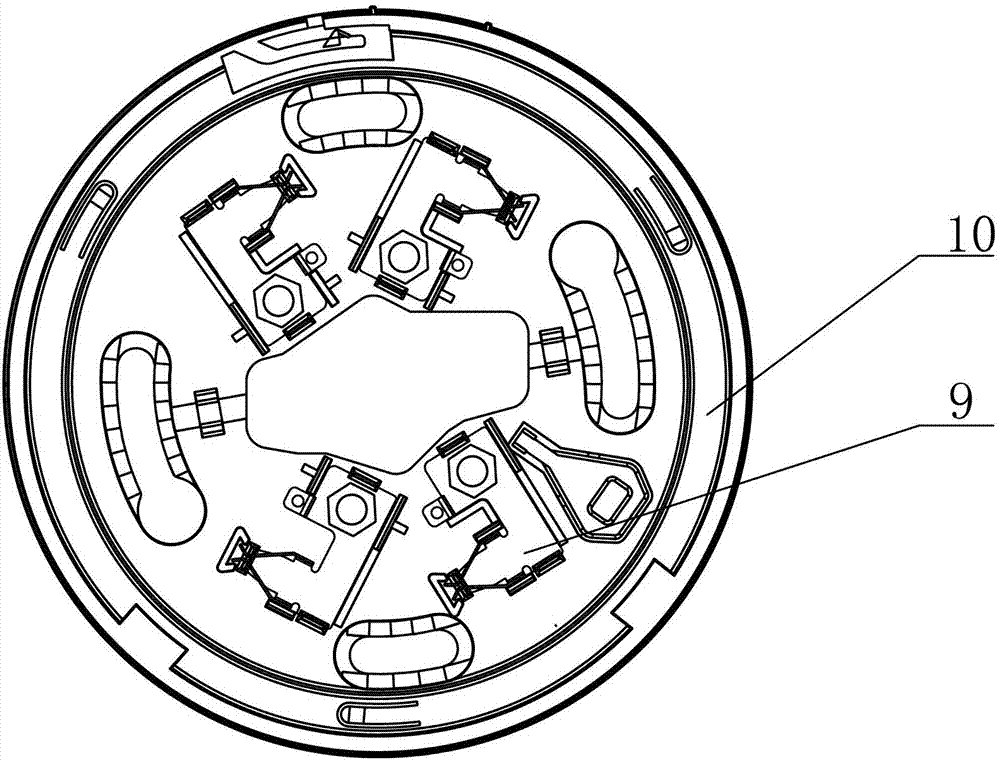

Point-type heat fire detector

InactiveCN102903199ASimple processImprove conduction efficiencyFire alarm electric actuationFire detectorLight guide

The invention relates to a point-type heat fire detector. The point-type heat fire detector comprises a shell and a circuit board in the shell, wherein a thermistor and a light emitting diode are arranged on the circuit board; a light guide column and a plate-like middle fastener are arranged in the shell; the shell comprises a base, an annular middle cover and an upper cover, which are sequentially connected; an outer contour which consists of the base, the annular middle cover and the upper cover is in a shape of a hemispherical table; the upper cover is positioned on the top of the hemispherical table; the middle fastener is clamped in the annular middle cover; the circuit board is clamped on the middle fastener; the surface of a light emitting part of the light emitting diode faces the upper cover; the light guide column has a columnar bending structure; one end of the light guide column faces and approaches the light emitting part of the light emitting diode, and the other end of the light guide column is bent to the top of the upper cover along the radian of the upper cover and corresponds to an annular through structure which is arranged on the upper cover; and one end of the light guide column, which is bent along the radian of the upper cover, is bent back at the end head, so the light conduction directions of the end heads of the two ends of the light guide column are the same. By adoption of the point-type heat fire detector, a light emitting display effect can be improved, an installation process is simplified, and reliability is improved.

Owner:北京福赛尔安全消防设备有限公司

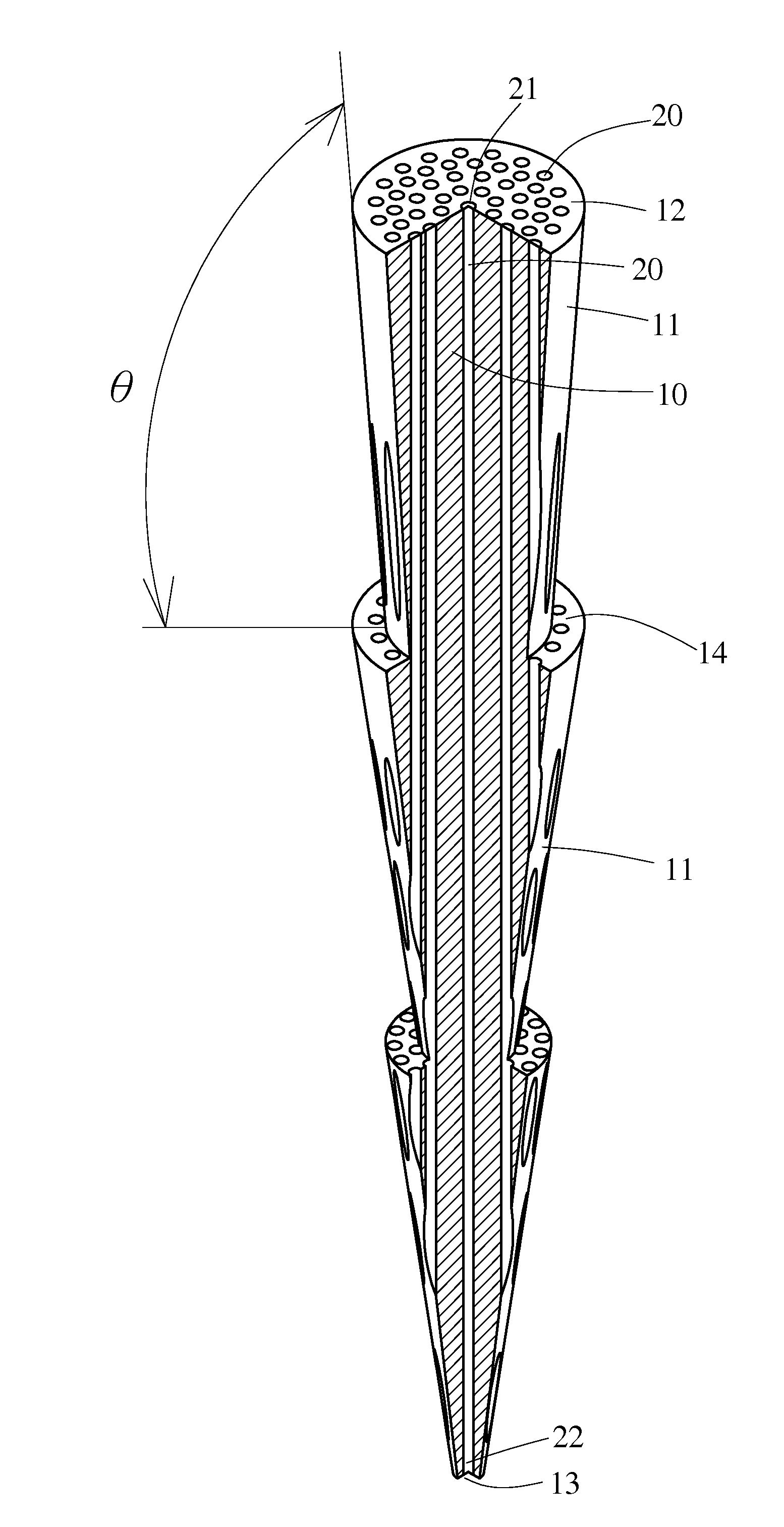

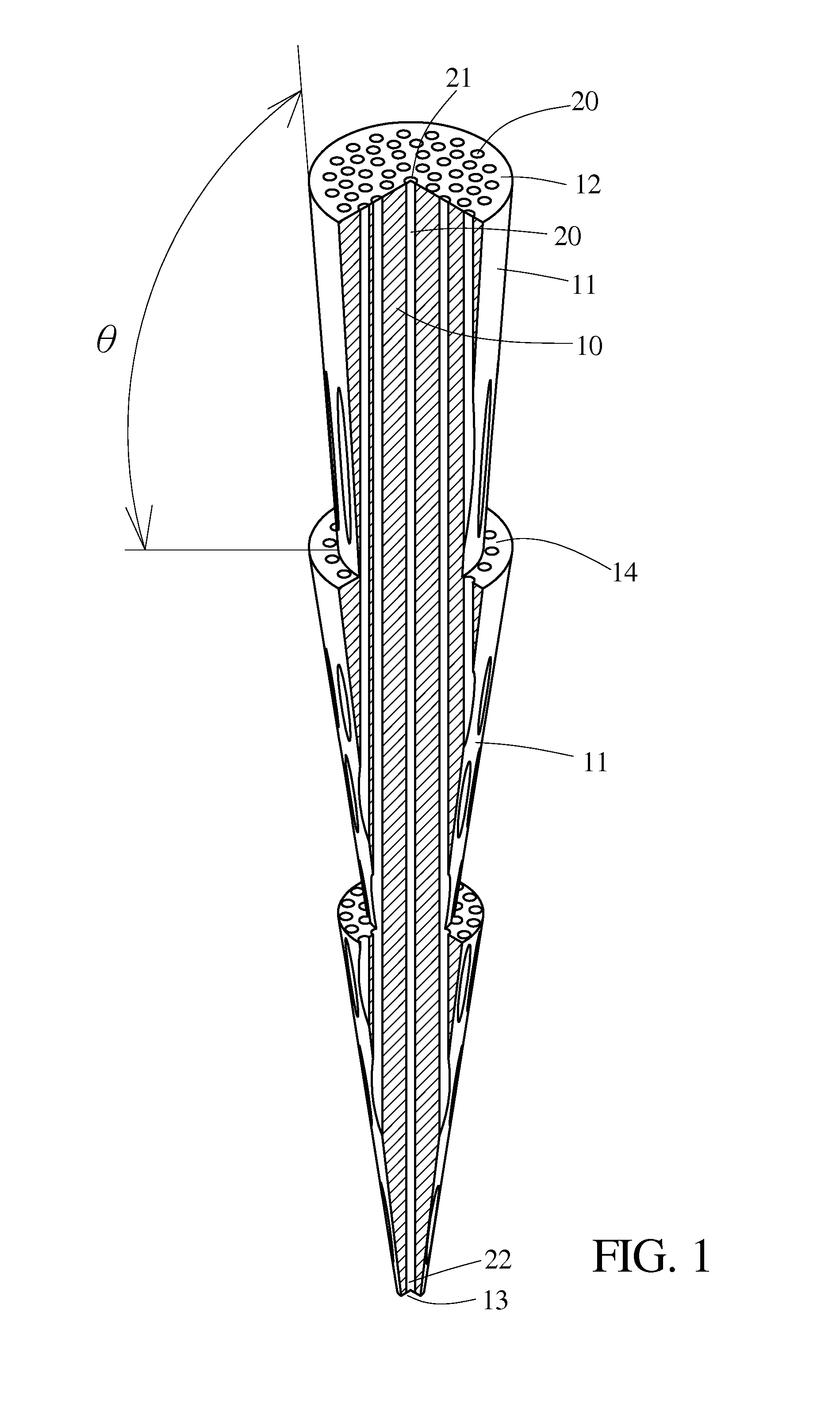

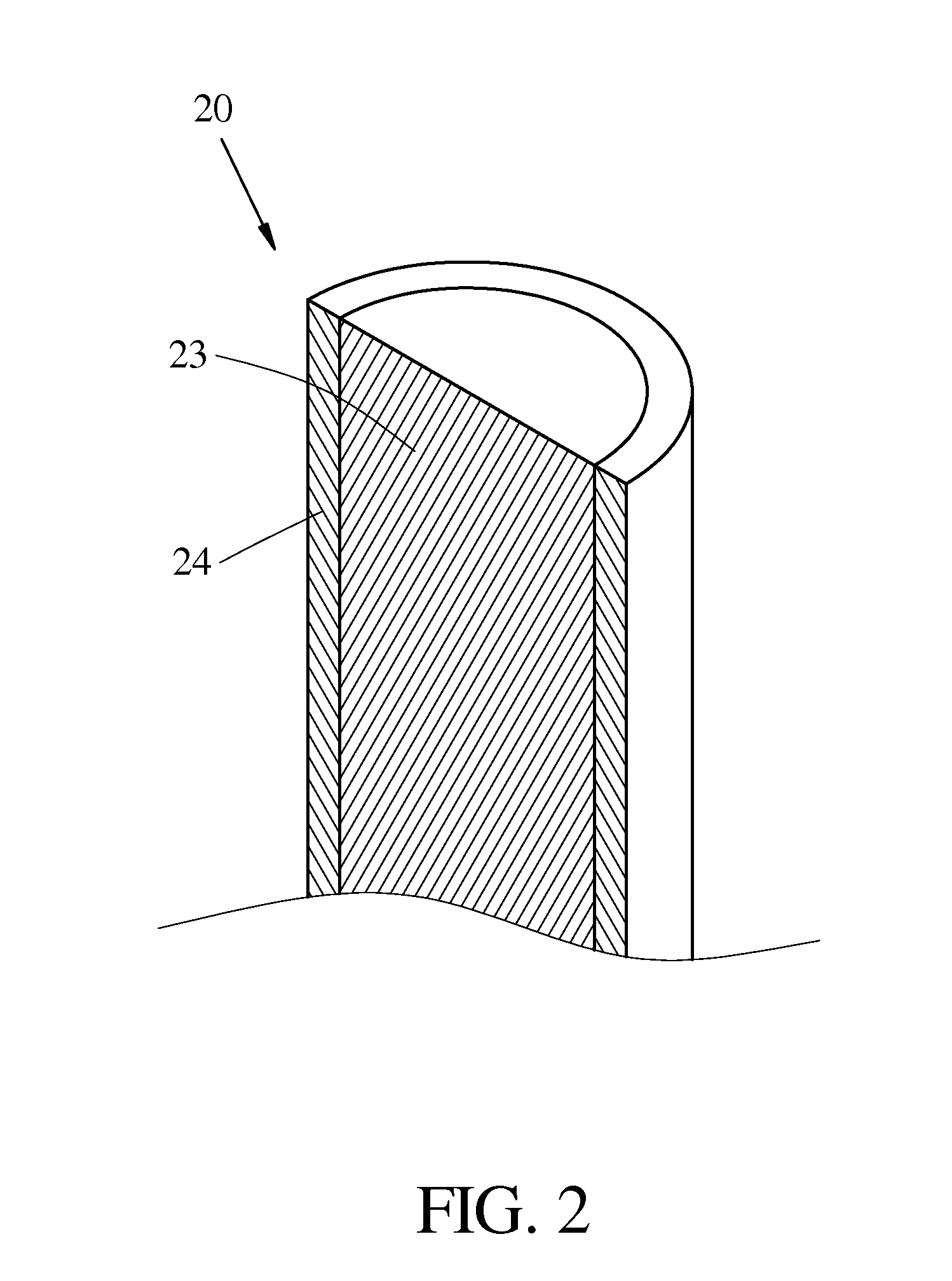

Fiber optics dental post

ActiveUS8197256B2Improve light guide effectEasy to useTeeth fillingFastening prosthesisFiberMedicine

Owner:TAIWAN FIBER OPTICS

Light guide plate combination

InactiveCN101561529AImprove light guide effectAvoid exportingOptical light guidesTelephone set constructionsLight guideEngineering

The invention provides a light guide plate combination, which comprises a light guide plate and a shadowing part comprising a framework; the framework surrounds a containing room; the light guide plate is contained in the containing room of the shadowing part; and the framework is formed on the periphery wall of the light guide plate.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

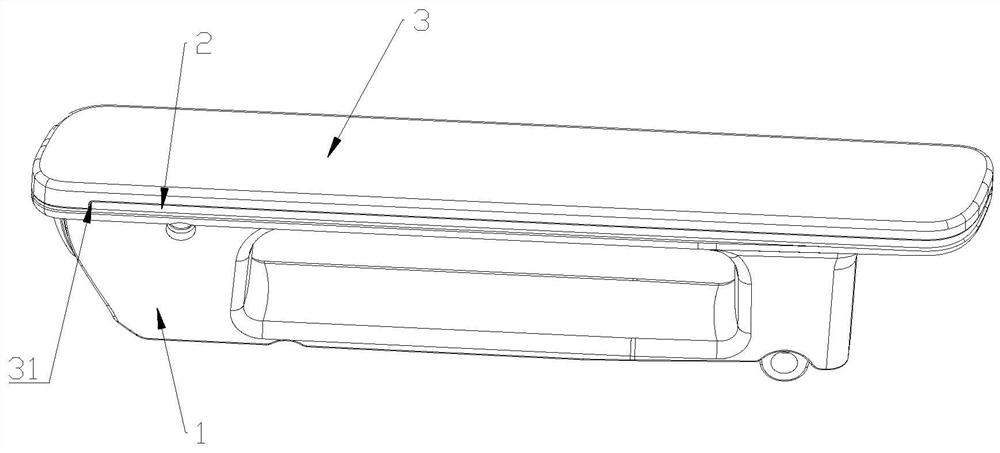

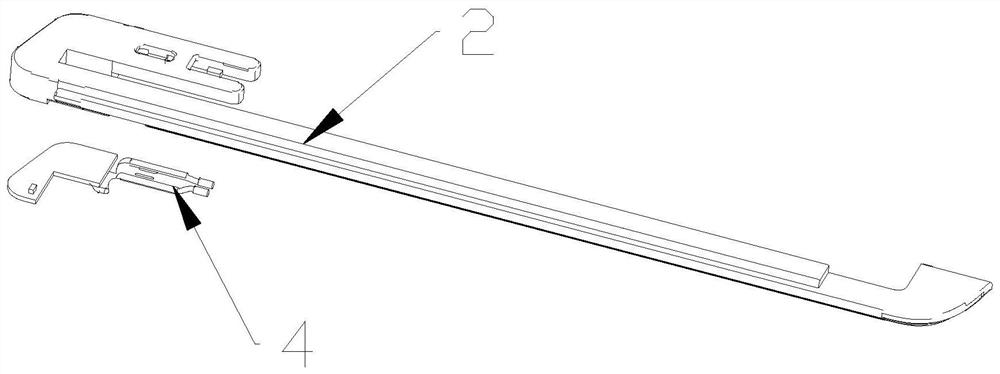

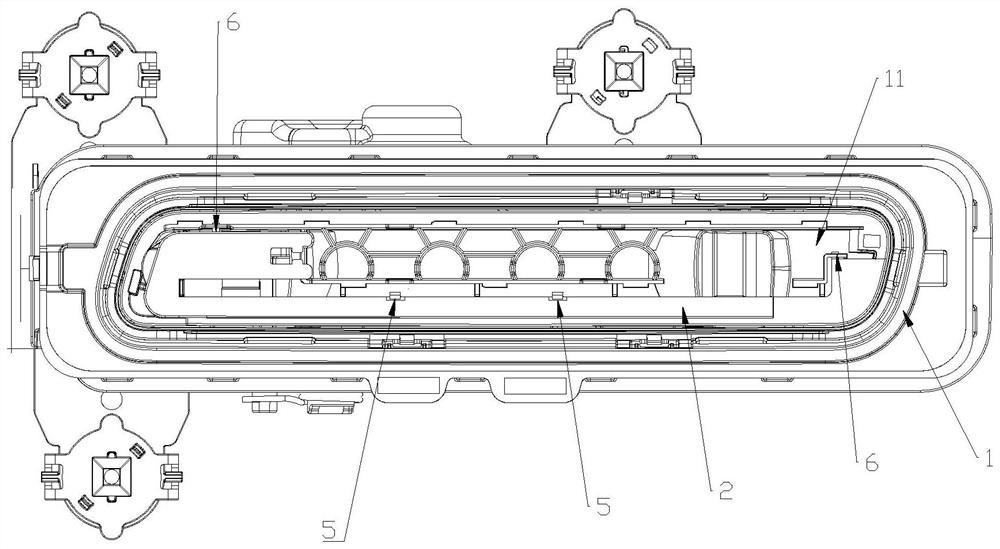

Hidden outward-opening handle

PendingCN113700401AImprove ease of useImprove light guide effectMechanical apparatusVehicle locksCar doorEngineering

The invention relates to a hidden outward-opening handle. The hidden outward-opening handle comprises a handle body, a light guide part and a shell; the handle body is provided with an installation face; the installation face is provided with a light emitting part; the light guide part is arranged on the installation face and makes contact with the light emitting part; the shell is arranged on the installation face and covers the light guide part; and the side wall of the shell is provided with a first opening used for light transmission. According to the hidden outward-opening handle, the light emitting part capable of emitting a line light source is arranged in the handle body, the light guide part for converting the line light source into an area light source is arranged in the handle body, the light guide part is arranged between the handle body and the shell, the light guide part synchronously moves along with the handle body, a user can accurately find the holding position of the pop-up handle through light transmitted from the first opening in the shell, and then a vehicle door can be rapidly opened; and the light guide part synchronously moving along with the handle body enables a door opener to observe light emitted by the light guide part at multiple angles.

Owner:VOYAH AUTOMOBILE TECH CO LTD

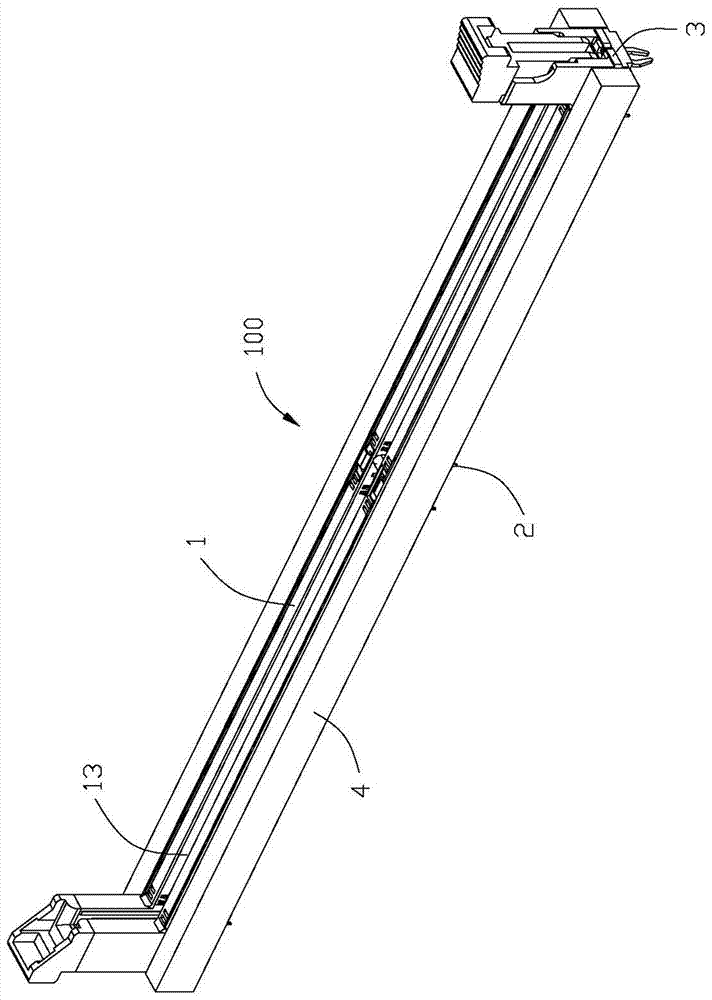

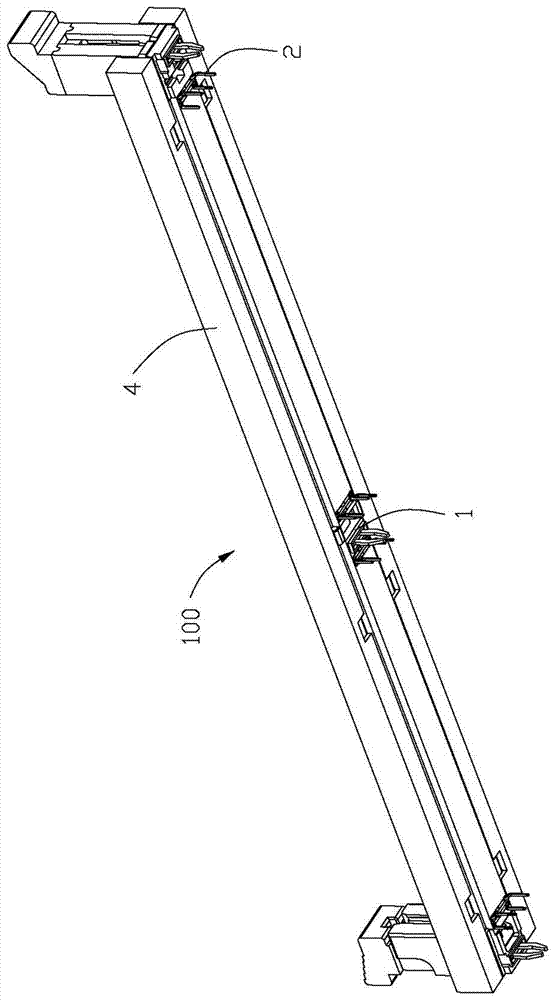

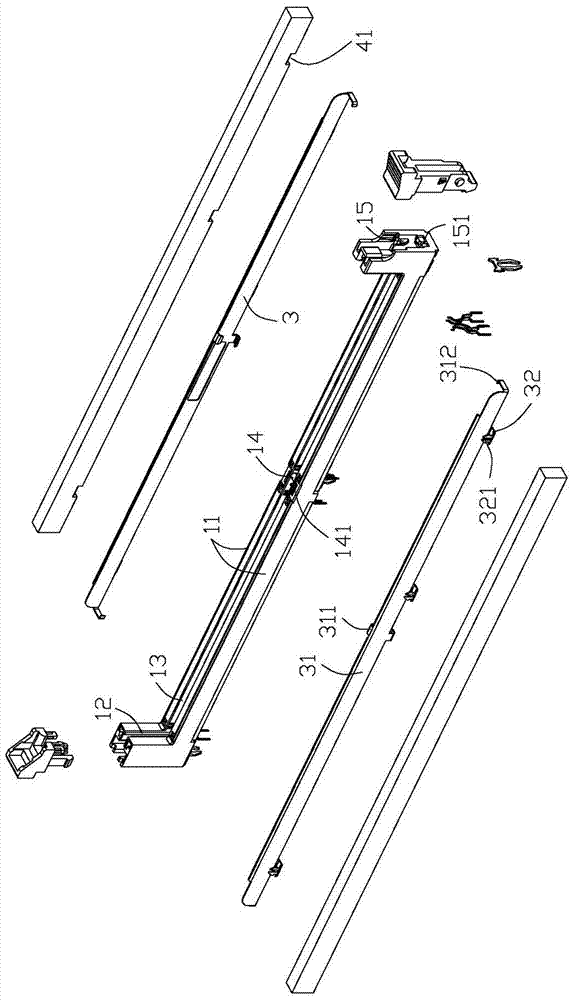

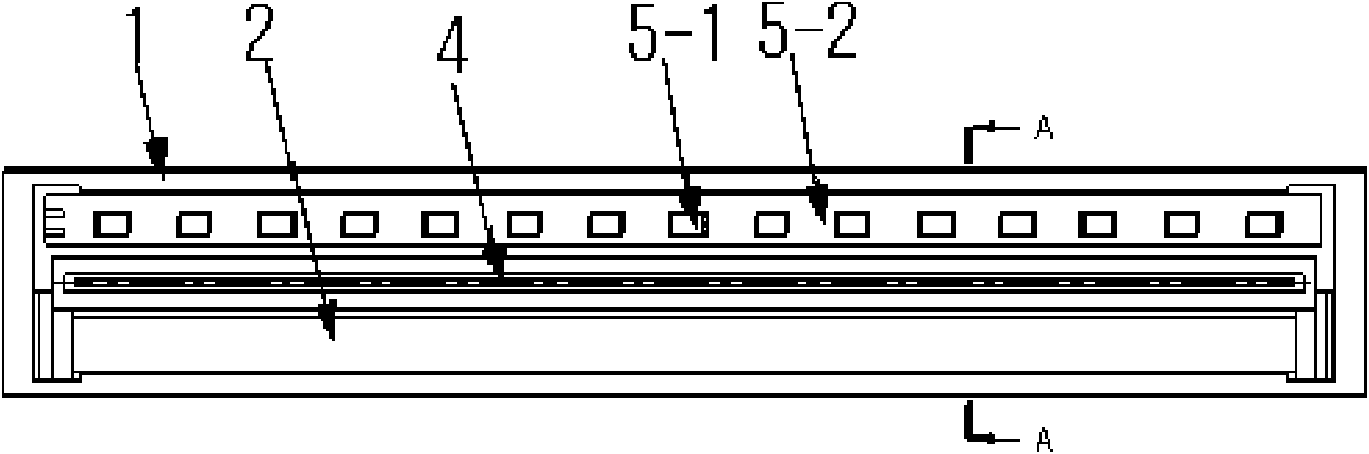

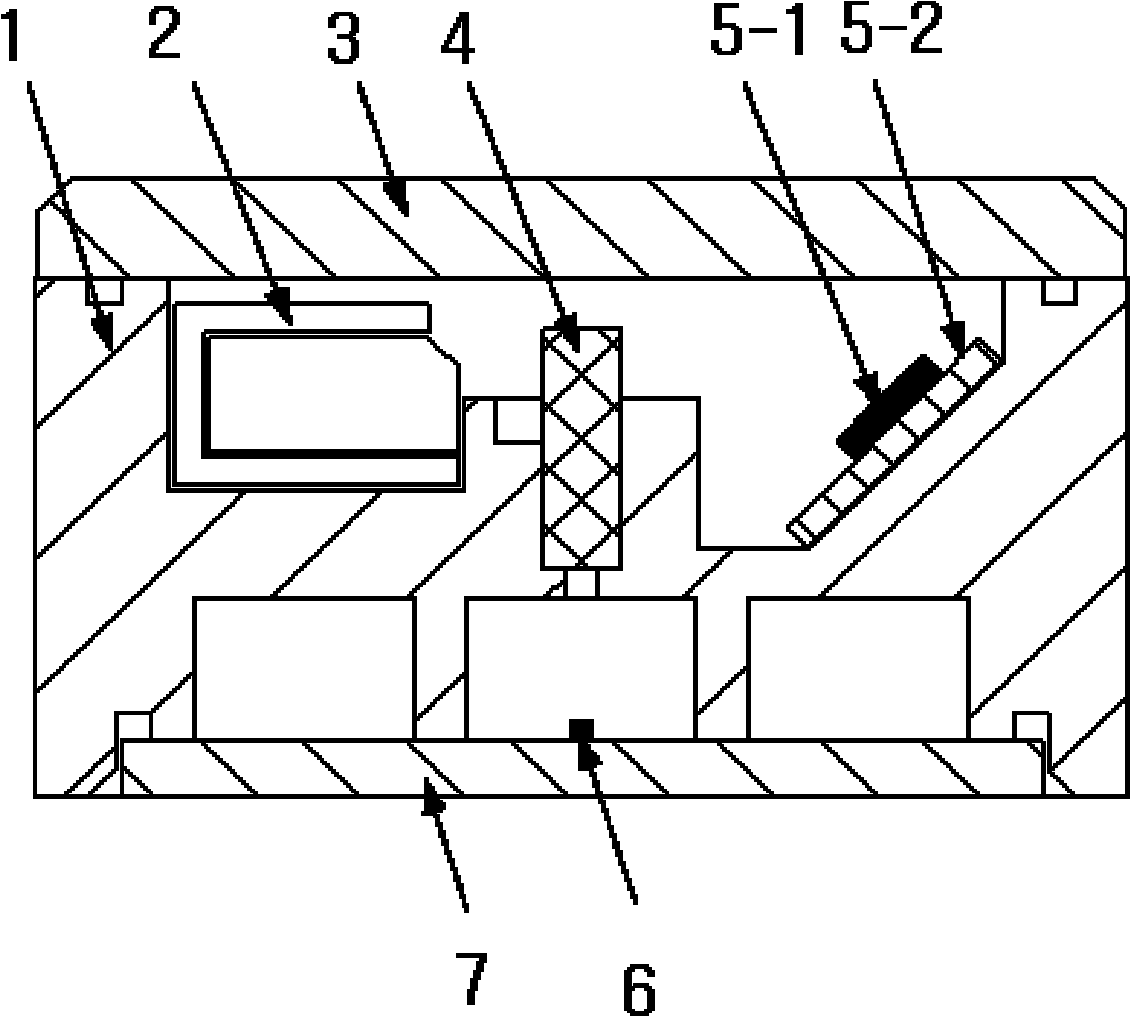

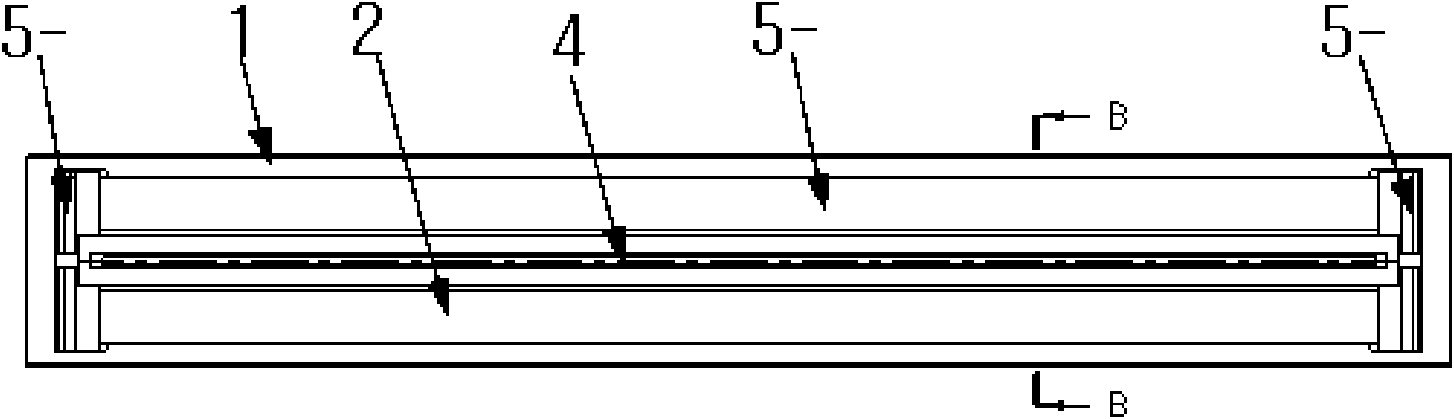

Card edge connector

ActiveCN107546508AImprove structural strengthGood holding effectCoupling device detailsLight guideElectrical and Electronics engineering

A card edge connector includes a longitudinal insulating body, a plurality of conductive terminals received in the insulating body, and a metal member disposed on the insulating body. The insulating body has two side walls extending in the longitudinal direction, end walls connecting the two side walls and a central slot formed by the two side walls and the two end walls, the card edge connector further comprises a light guide plate fixed on the outer side of the metal member, the metal member is located outside the insulating body to enhance product strength, and the light guide plate is placed outside the metal member to enhance the light guiding effect of the product.

Owner:FOXCONN (KUNSHAN) COMPUTER CONNECTOR CO LTD +1

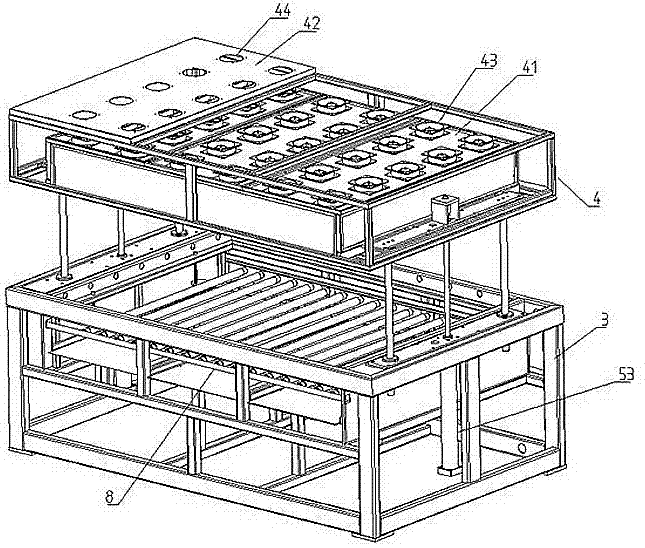

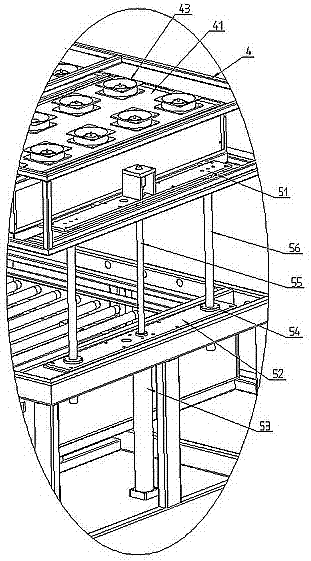

Novel solidifying machine

PendingCN107160848ABright and uniform luminous effectHigh light transmittancePrinting press partsEpoxyUltraviolet lights

A novel solidifying machine comprises a main machine seat and a main electrical cabinet. The main machine seat comprises a main lathe body and an upper frame. The two sides of the main lathe body are provided with sliding guide rod groups. The sliding guide rod groups are connected with the main lathe body and the upper frame. The main lathe body is further provided with a tempered glass platform which is horizontally fixed. The tempered glass platform is used for placement of matrixes. An ultraviolet radiator array is arranged below the temperate glass platform. The upper frame is provided with a lining top plate and an outer top plate. The lining top plate is provided with a cooling fan array. The outer top plate is provided with corresponding through holes corresponding to the cooling fans in position. An auxiliary electrical cabinet is further arranged on one side of the main lathe body. The auxiliary electrical cabinet is electrically connected with the sliding guide rod groups, the ultraviolet lamp array, the cooling fan array and the main electrical cabinet. According to the novel solidifying machine, a light source emitted by the ultraviolet radiator array is fully converted, the manufactured words are high in luminous effect and uniform in luminance, and the light transmittance and light conductivity of the manufactured words are far higher than those of traditional acrylic materials and epoxy resin materials.

Owner:广州市粤雕自动化设备有限公司

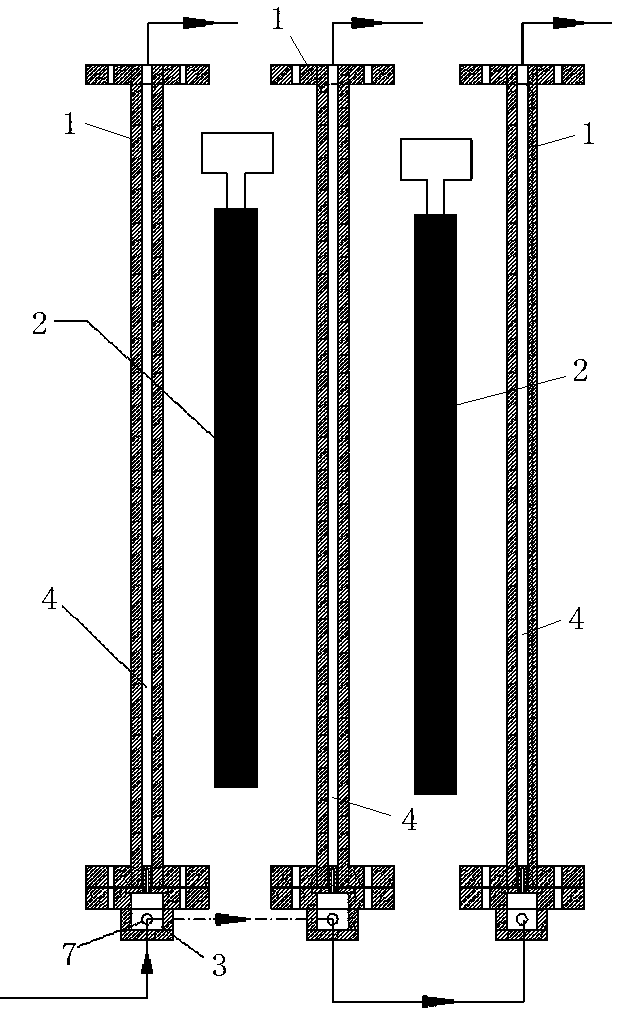

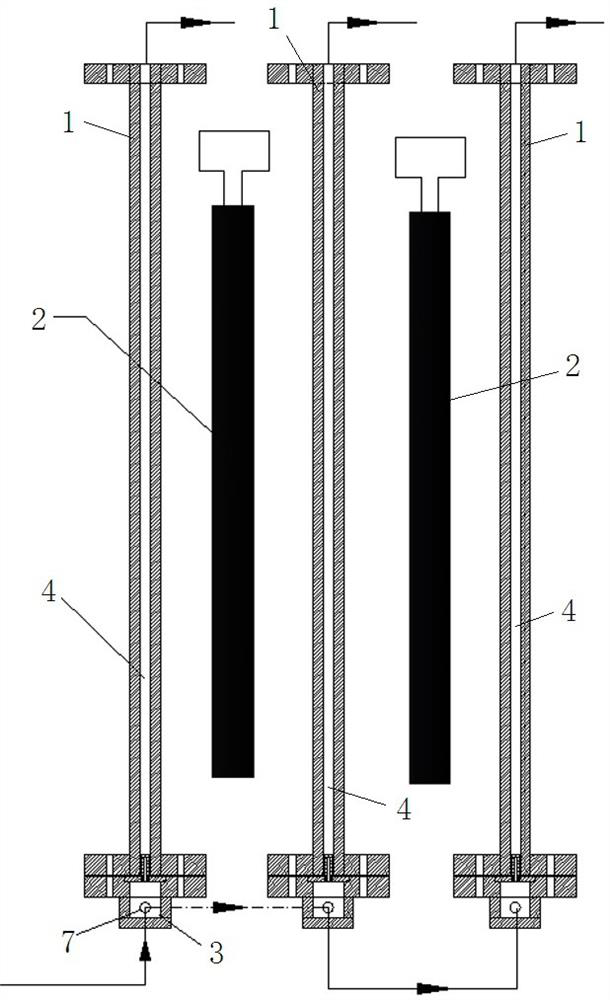

Two-dimensional photo-catalytic fluidized bed device

ActiveCN109745937AIncrease intakeReduce lossesEnergy based chemical/physical/physico-chemical processesPhoto catalyticLight guide

The invention relates to a two-dimensional photo-catalytic fluidized bed device which comprises a plurality of two-dimensional fluidized beds distributed side by side and made of transparent materials; a reaction area of each of the two-dimensional fluidized beds is filled with a light guide part, and a light source is arranged between the adjacent two two-dimensional fluidized beds. The two-dimensional photo-catalytic fluidized bed device provided by the invention has the beneficial effects that by the utilization of the advantage of a thin wall of each of the two-dimensional fluidized beds,the intake of light is facilitated, so that the loss of the light is reduced; as the reaction area of each of the two-dimensional fluidized beds is filled with the light guide part, the light guidingproperty can be greatly enhanced. The two-dimensional photo-catalytic fluidized bed device provided by the invention is simple and reasonable in structure, and solves the problems of low light utilization rate and low catalytic efficiency of a traditional fluidized bed.

Owner:FUZHOU UNIV

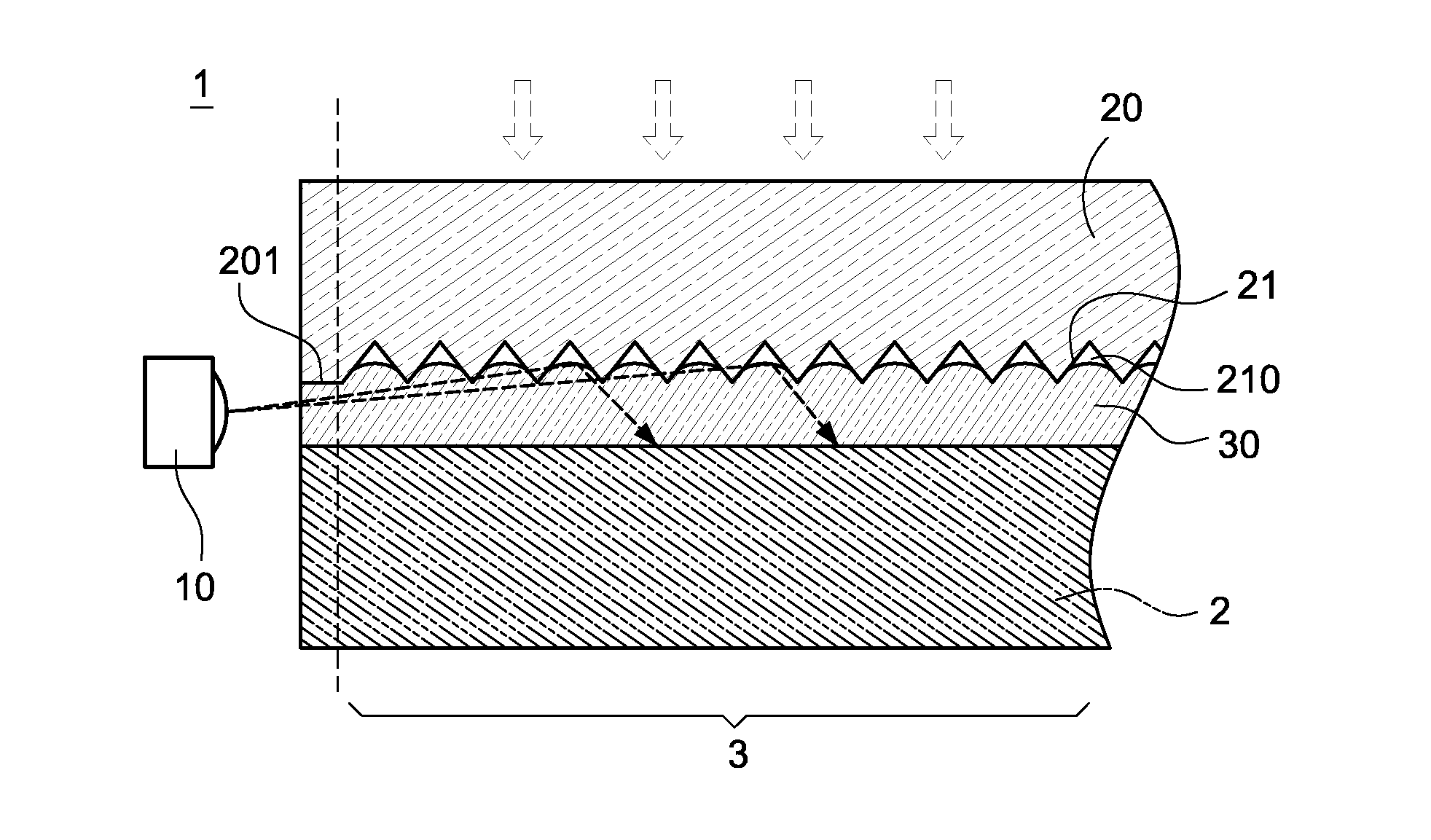

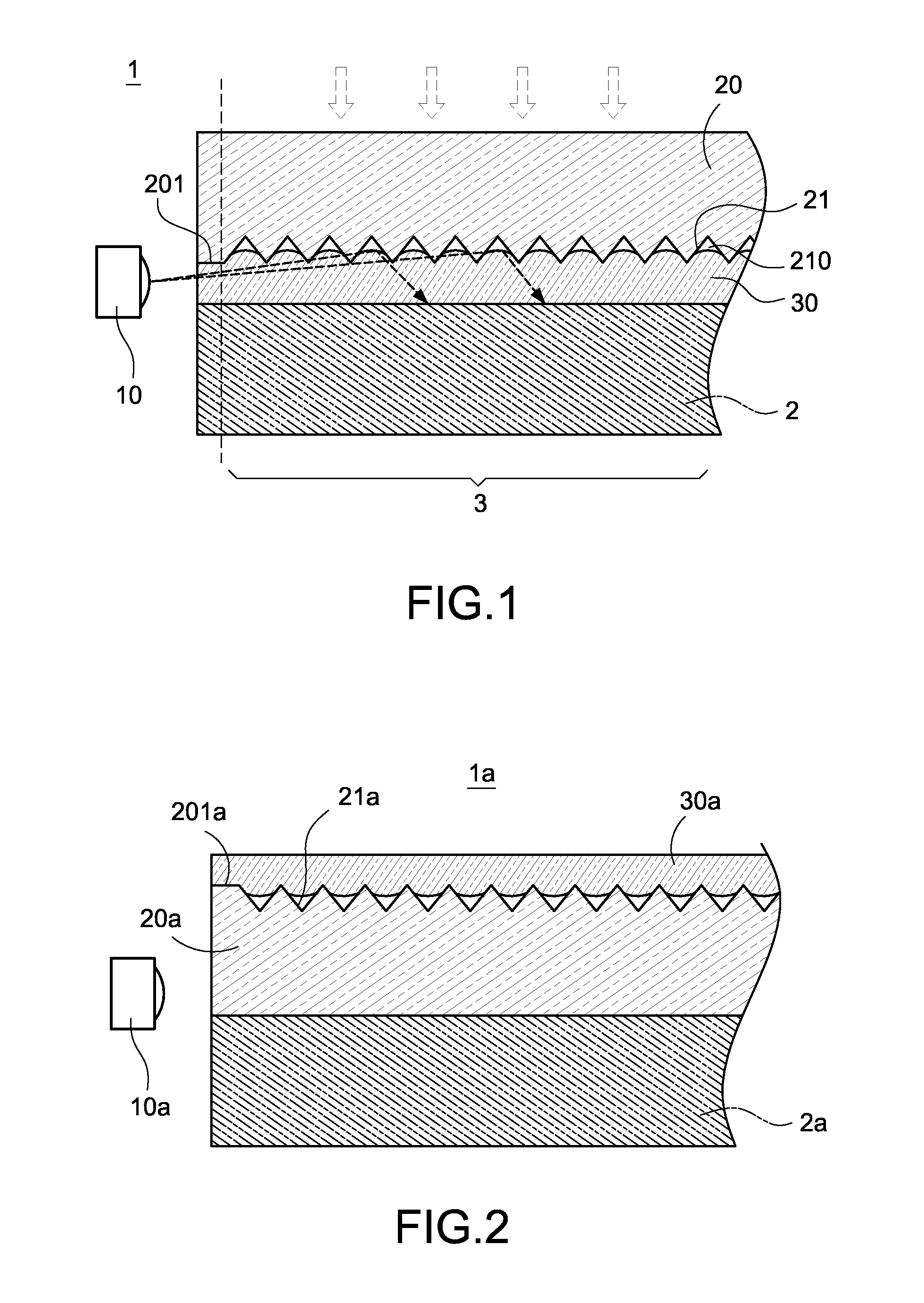

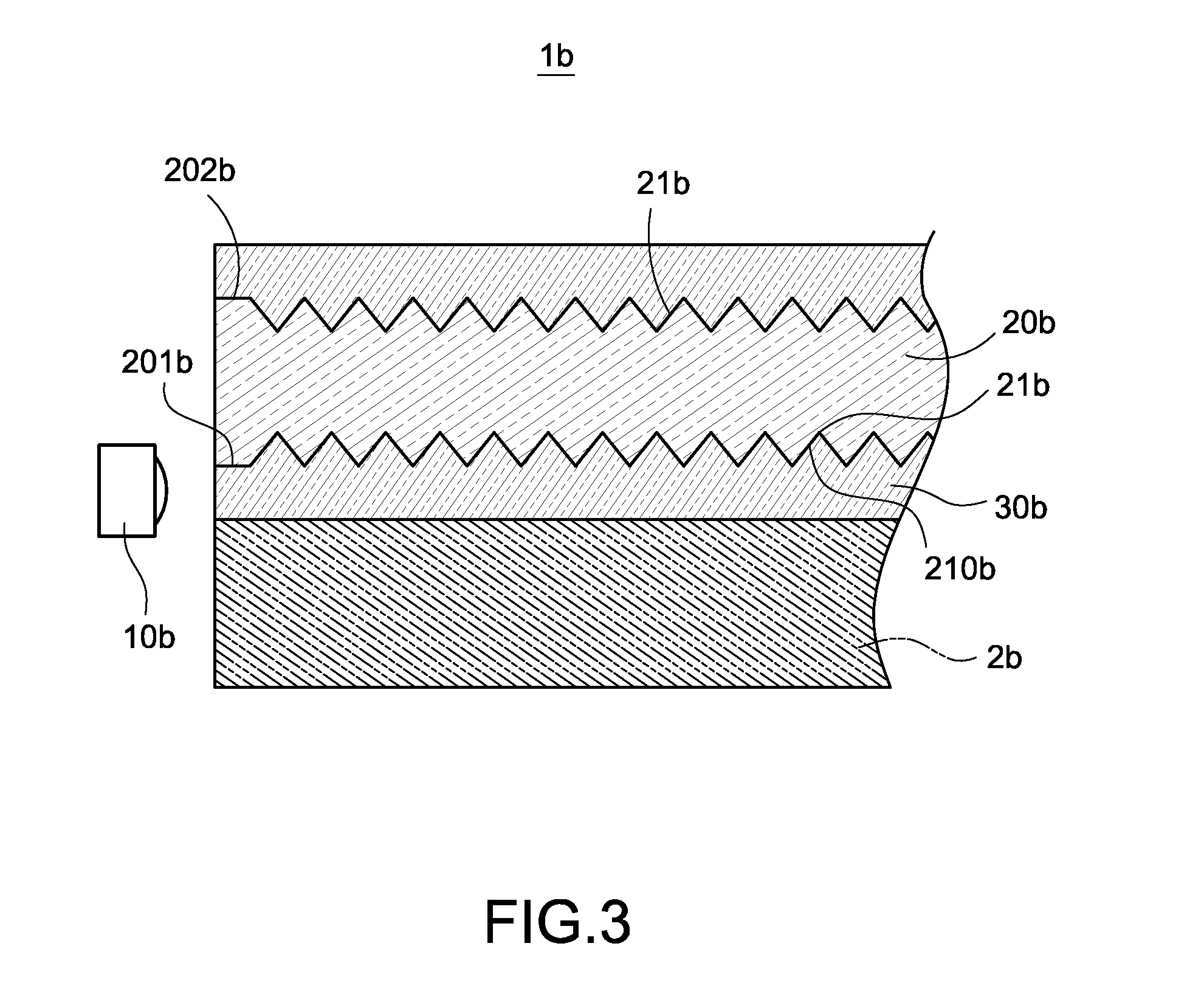

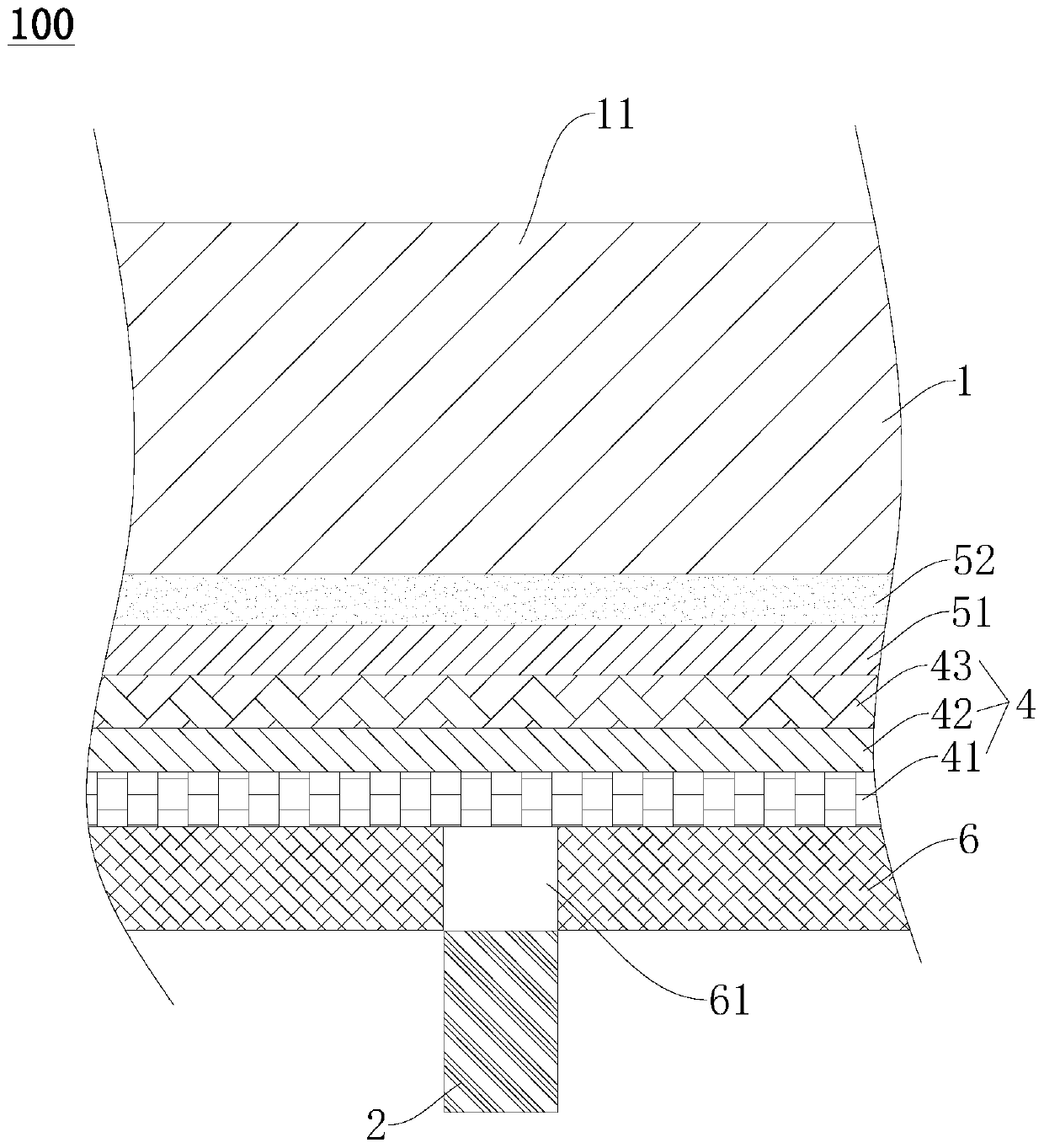

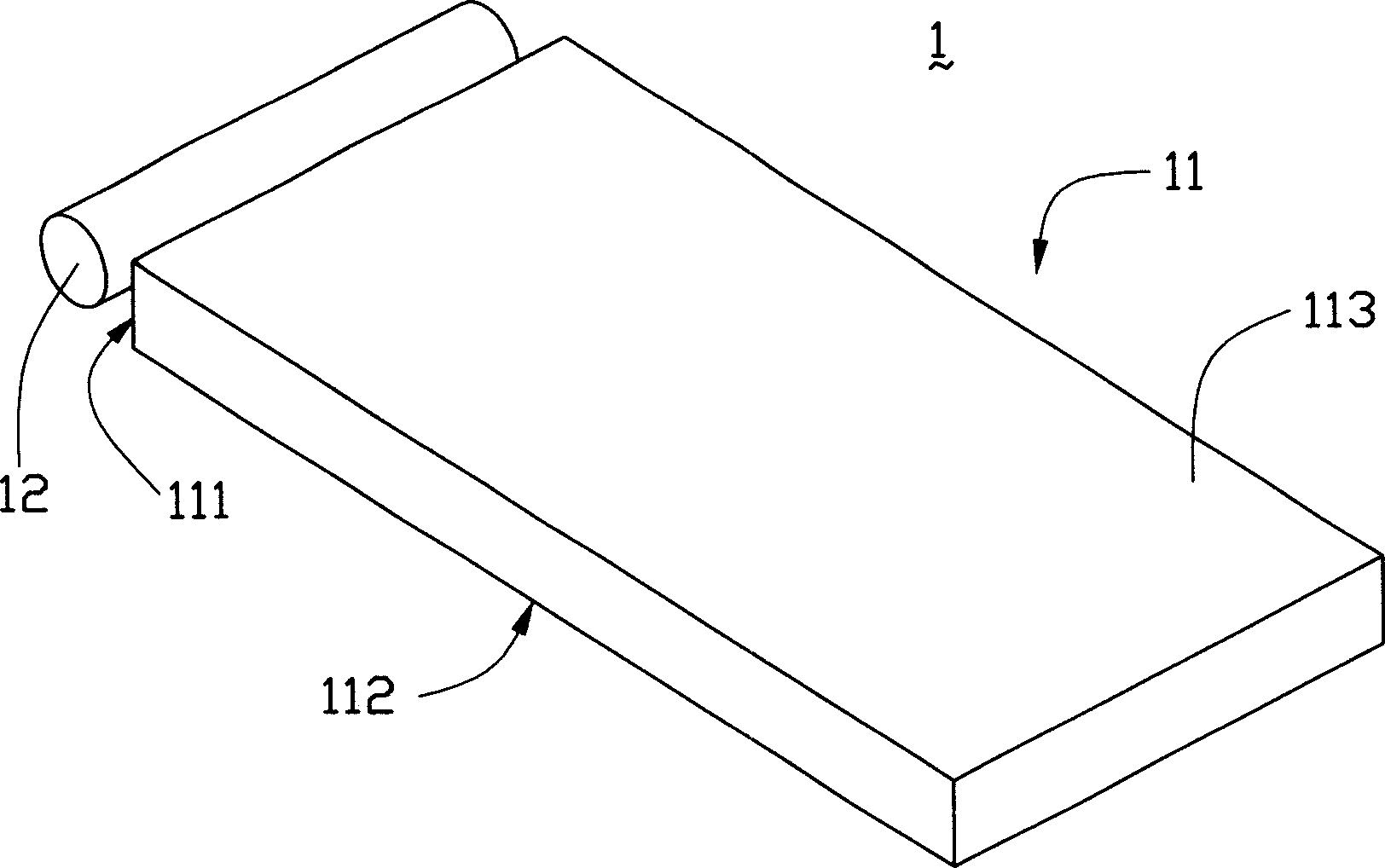

Front light module

InactiveUS20140063841A1Comfortability can be improvedIncrease refractionMechanical apparatusLight guides for lighting systemsOptoelectronicsMicrostructure

A front light module is installed in front of a panel, and the front light module includes a light source, a light guide plate and an intermediate layer disposed on an external side of the panel, and the light guide plate is provided for receiving a light emitted from the light source and reflecting and refracting the light onto the panel, and the light guide plate has a plurality of microstructures disposed on at least one side parallel to the panel, and the intermediate layer is filled and distributed in the microstructures, so as to avoid glare and enhance the brightness and uniformity of the panel.

Owner:KUO HENG SHENG

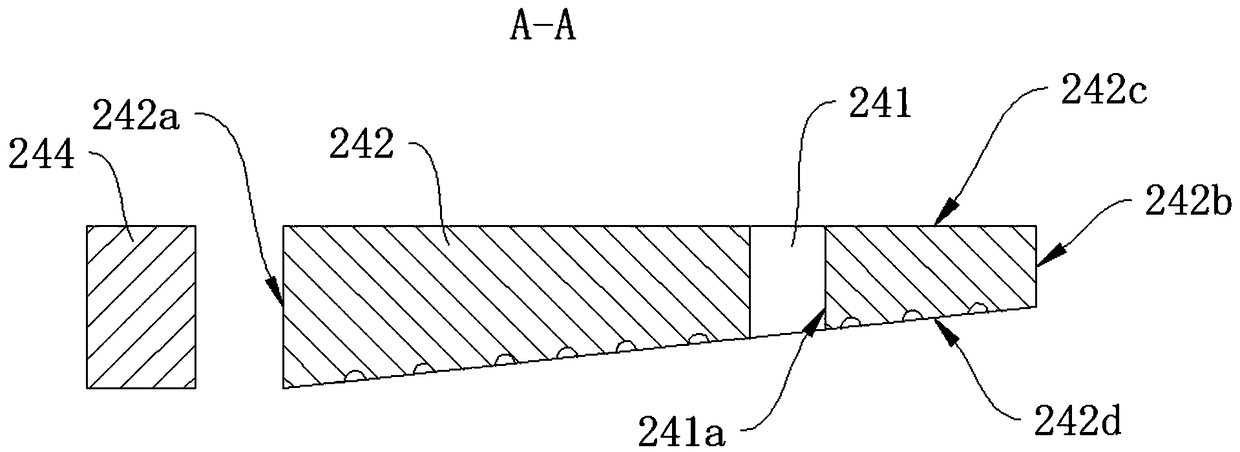

Shell assembly of electronic equipment and electronic equipment

ActiveCN111315165AGood lookingGood coloring effectCasings/cabinets/drawers detailsFibre light guidesLight guideEngineering

The invention discloses a shell assembly of electronic equipment and the electronic equipment. The shell assembly comprises a shell, a light guide module and a light emitting device. The shell is provided with a light transmissive portion, and the light guide module and the light-emitting device are both arranged on the inner side of the shell. The light guide module comprises a light guide column, the light guide column is provided with a light inlet surface and a light outlet surface, the light outlet surface is opposite to the light transmitting part, the part, opposite to the light outletsurface, of the light guide column is a reflecting surface, the reflecting surface protrudes in the direction away from the light transmitting part, the light-emitting device is adjacent to the lightinlet surface, and light generated by the light-emitting device is guided by the light guide module. According to the shell assembly of the electronic equipment, a good color effect can still be shownunder the condition that ambient light is weak, and the effect of well prompting a user can be achieved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

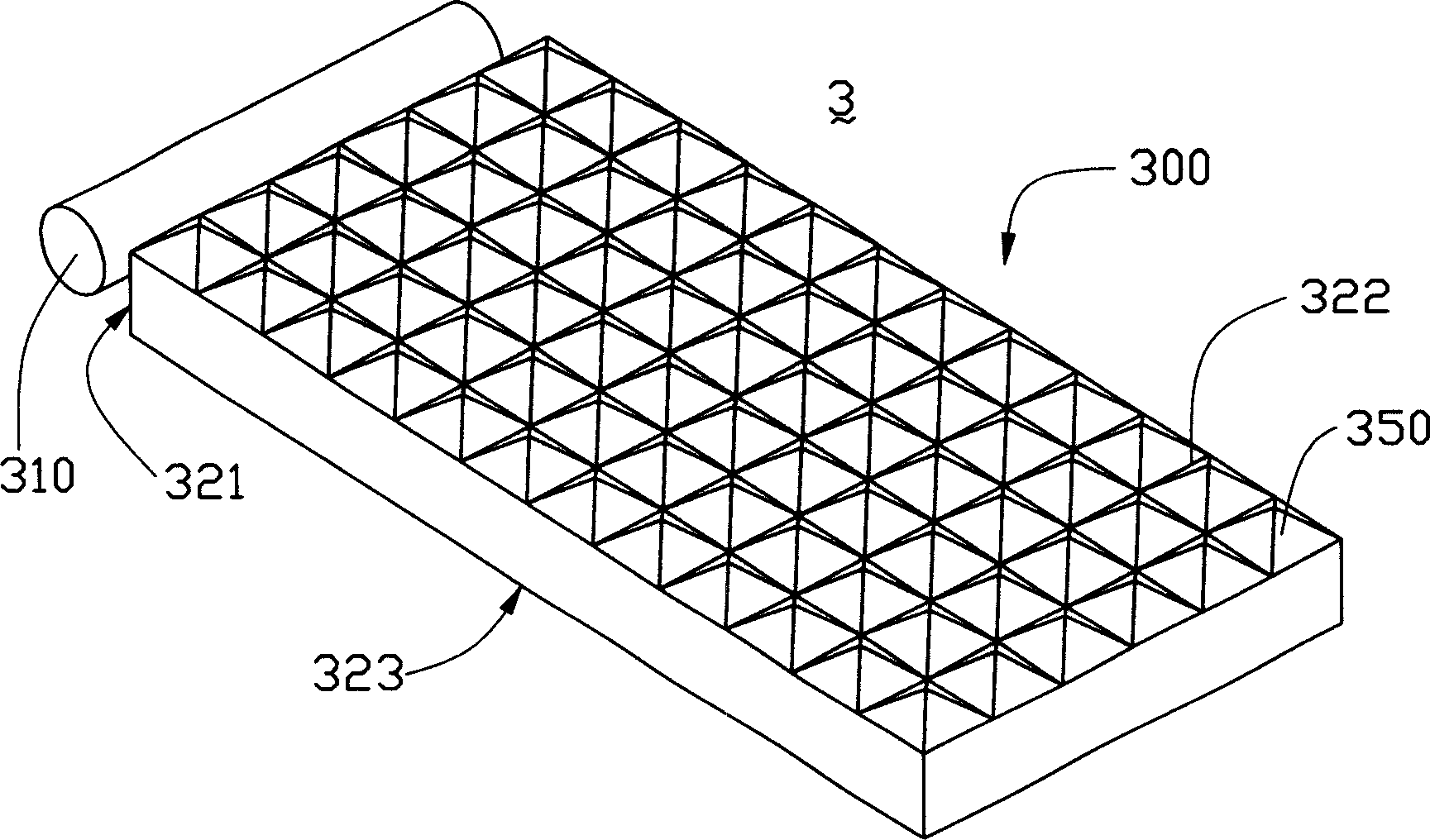

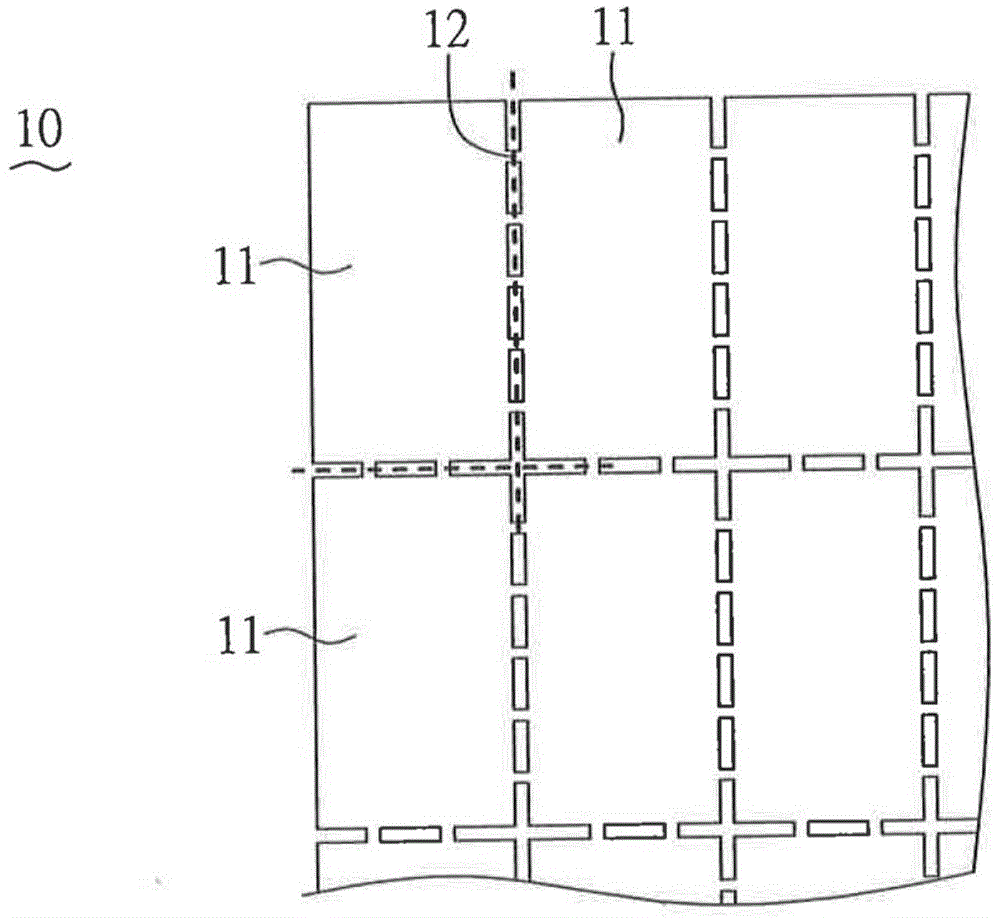

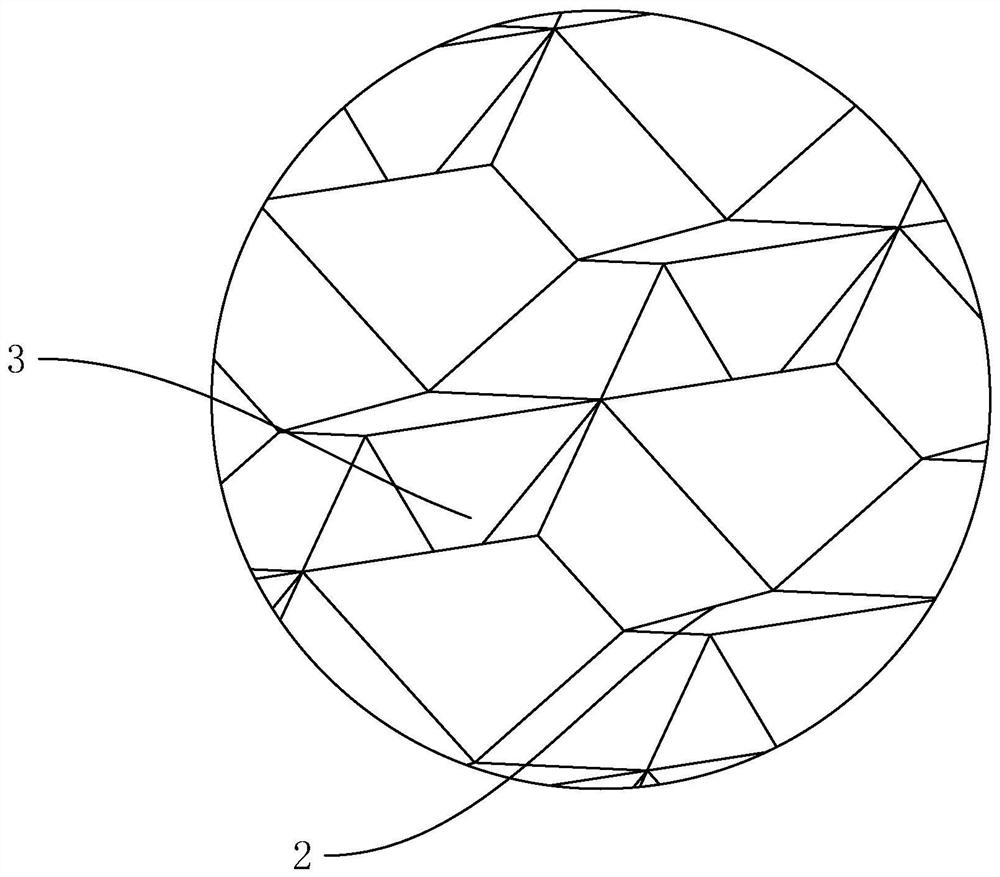

Backlight module and light conducting plate therefor

InactiveCN1690795AImprove light guide effectReduce manufacturing difficultyNon-linear opticsMesh gridOptoelectronics

The invention discloses a backlight mold set, which comprises a light-guide plate and a light source. The light-guide plate comprises an incidence surface opposite to light source, a floor and a reflection surface. Set multiple micro-grids divided evenly underside of light-guide plate, and set grid dots in some micro-grids.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Display equipment

InactiveCN106154392AImprove display qualityImprove light incident efficiencyMechanical apparatusLight guides for lighting systemsLight guideOptoelectronics

The invention relates to the display equipment. The display equipment comprises a display panel, a light guide board arranged at one side of the display panel, and a light emitting unit adjacent to a light incidence surface of the light guide board, wherein the light guide board has the light incidence surface and a light guide board thickness part, at least one rough area is formed on the light incidence surface, and roughness of a surface of the rough area is in a range of 0.18mum-0.7mm.

Owner:INNOLUX CORP

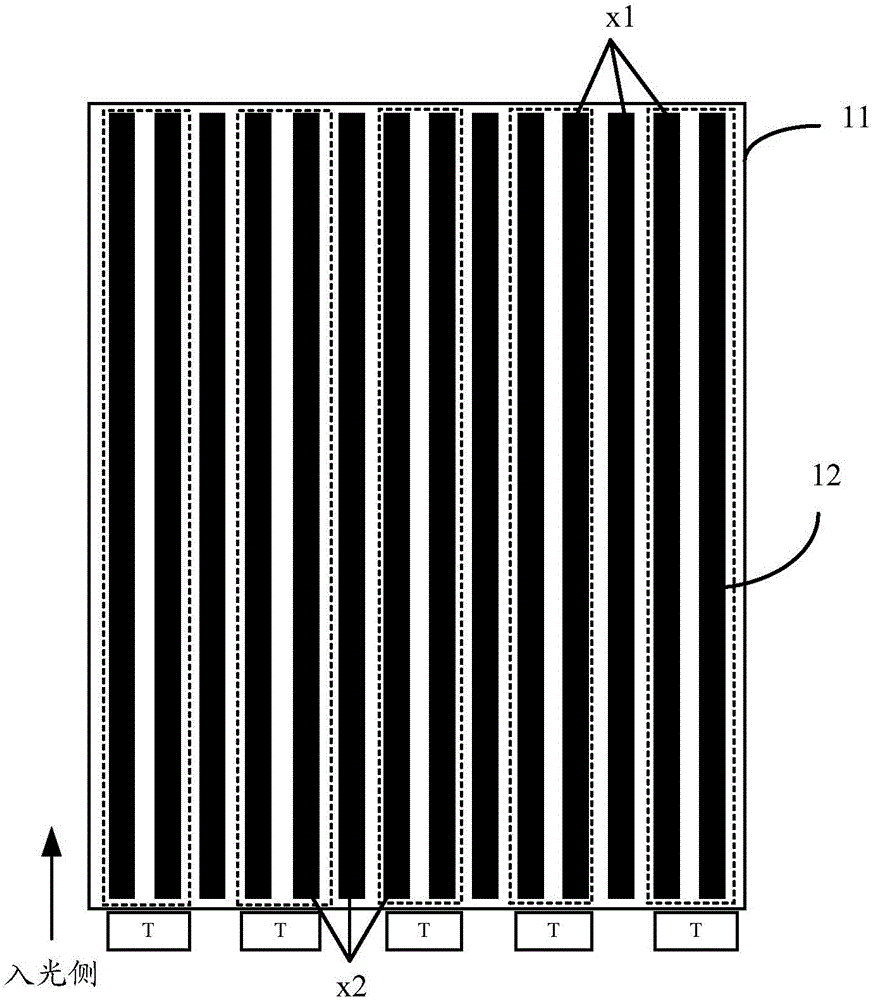

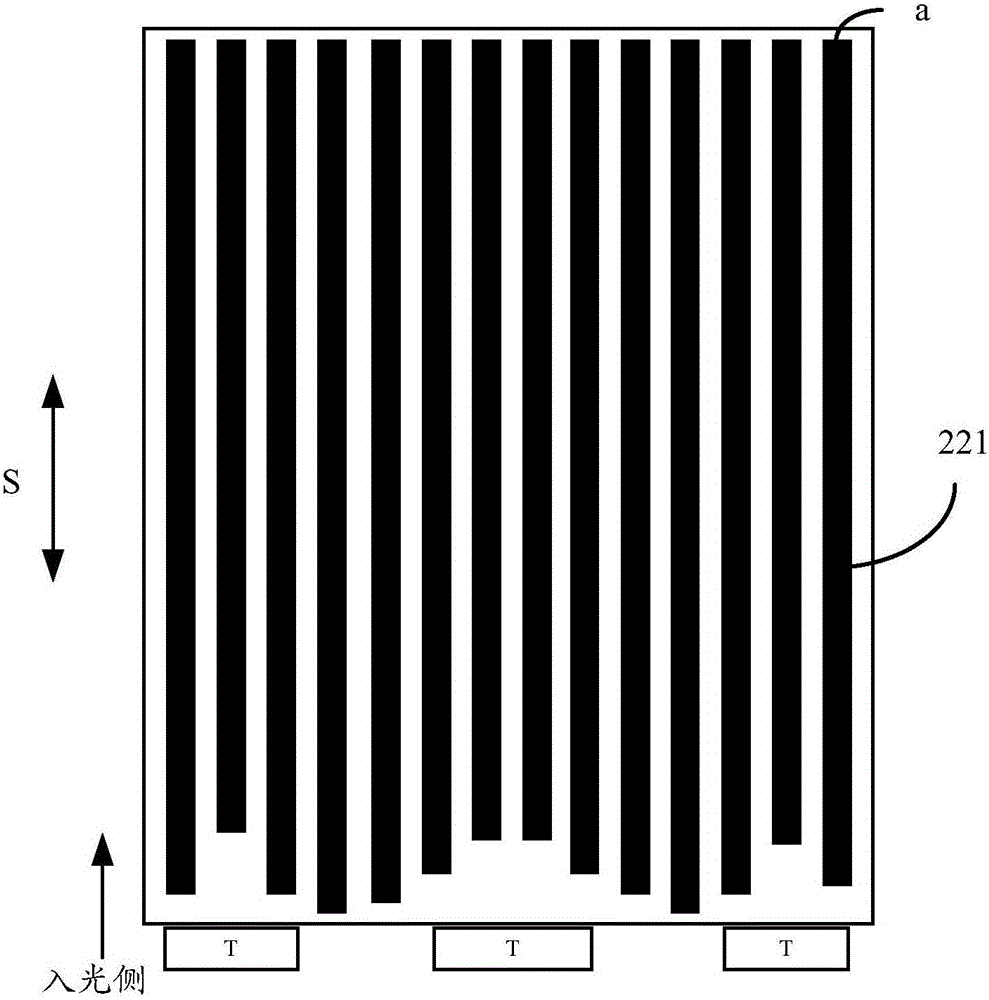

Light guide plate, backlight source module and display device

InactiveCN105891940AEnsure uniformity of lightImprove qualityOptical light guidesLight guideDisplay device

The invention relates to the technical field of backlight, in particular to a light guide plate, a backlight source module and a display device which are used for solving the problem of non-uniform light rays emitted by the conventional light guide plate due to the distribution design of a light emitting strip in the prior art. The light guide plate in the embodiment of the invention comprises a light guide main body part and a light emitting part positioned on one surface of the light guide main body part, wherein the light emitting part comprises a plurality of optical units arranged in the light guide direction; the lengths of the optical units in the light emitting part in the light guiding direction are unequal; each optical unit corresponding to a position where the light emitting strip is designed is shorter than an optical unit corresponding to a position where the light emitting strip is not designed, and one end surfaces, away from the light incident side of the light guide plate, of the optical units are flush with one another. Therefore, the light guide performances of the optical units at the light incident side of the light guide plate are ensured to be nearly consistent, the uniformity of scattering and reflection is improved, the light guide performances are improved, the light emitting uniformity of the light guide plate is ensured, and the quality of the light guide plate is improved.

Owner:BOE TECH GRP CO LTD +1

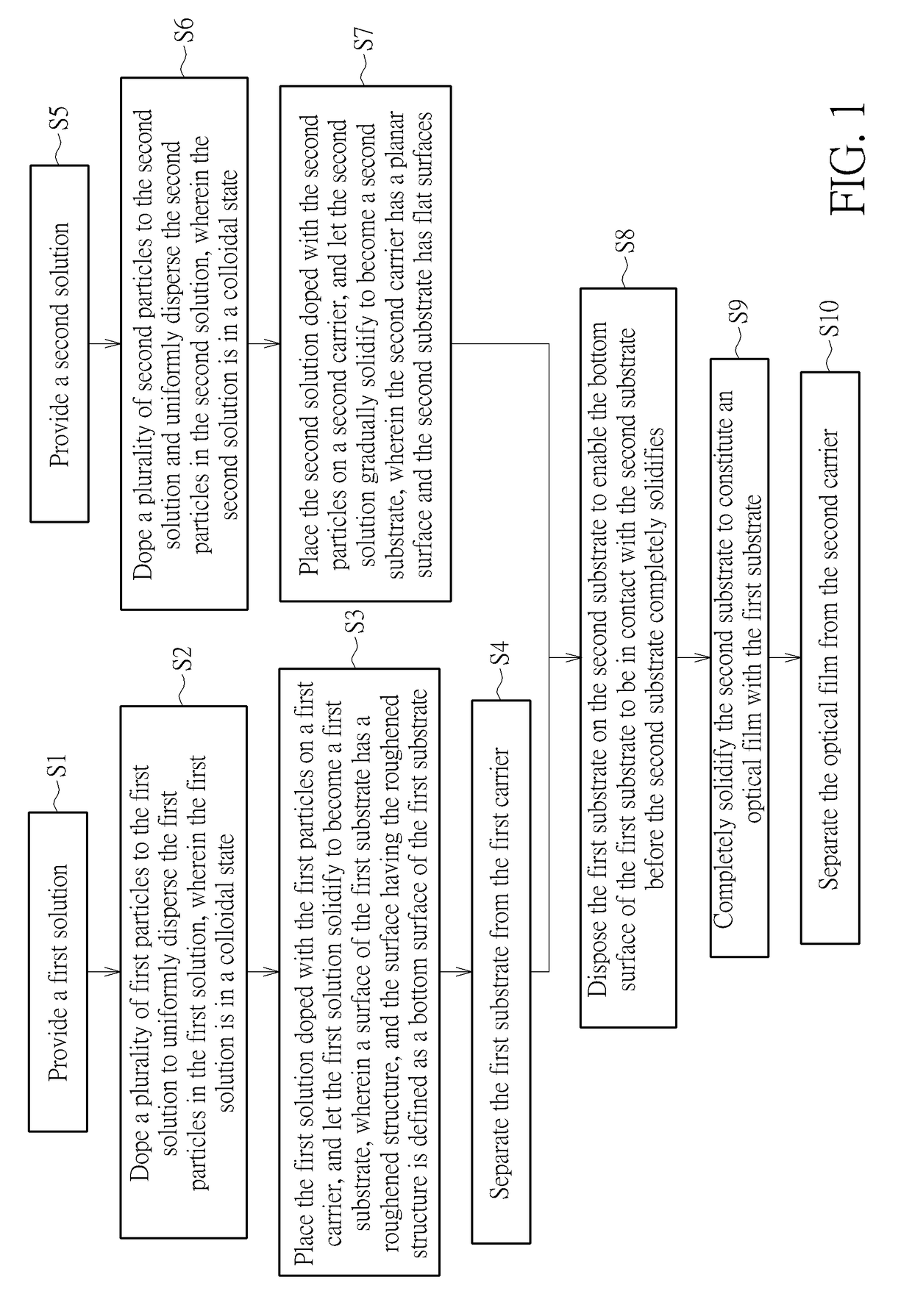

Device and method for manufacturing optical films

InactiveCN103419372AReduce thicknessImprove the thinning degree of optical filmFlat articlesCoatingsEngineeringLight source

The invention relates to a device for manufacturing optical films. The device comprises a material feeding part, a first wheel, a second wheel, and at least one UV light source. The material feeding part is provided with a material discharge pipe extending along a predetermined direction. The central axis of the first wheel and the central axis of the second wheel are in the same horizontal surface and are both perpendicular to the predetermined direction. The first wheel and the second wheel are both under the material discharge pipe, and each wheel comprises a gear-type body and a mold insert surrounding the outer side of the gear-type body. The second wheel is arranged at a predetermined distance away from the first wheel to form a molding channel. Together the first wheel and the second wheel are used to press UV curable resin which flows into the molding channel. The at least one ultraviolet light source is placed inside the gear-type body. The invention also relates to a method for manufacturing optical films.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

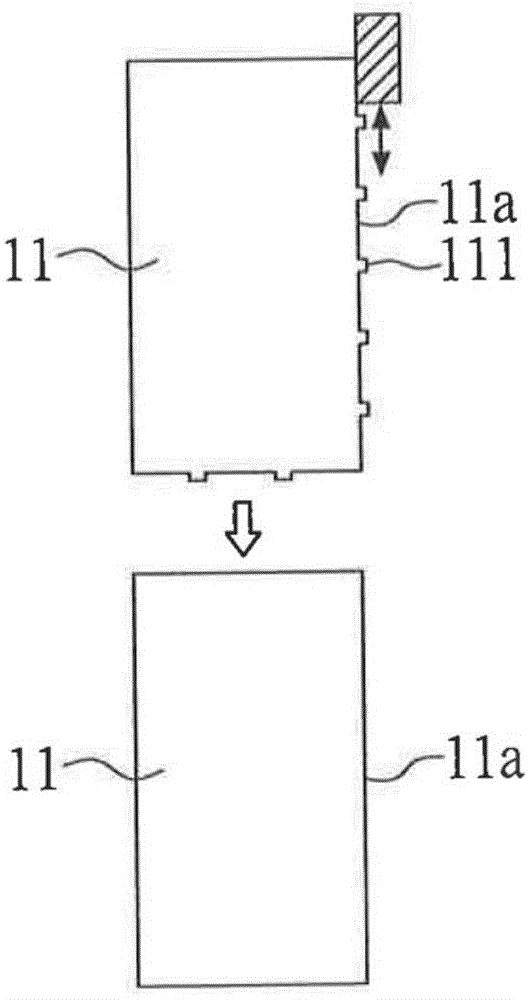

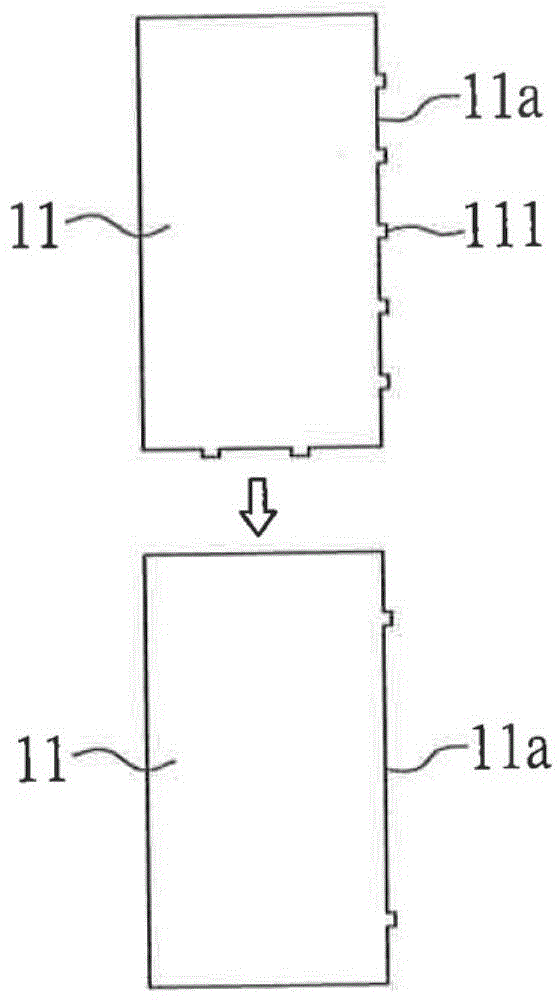

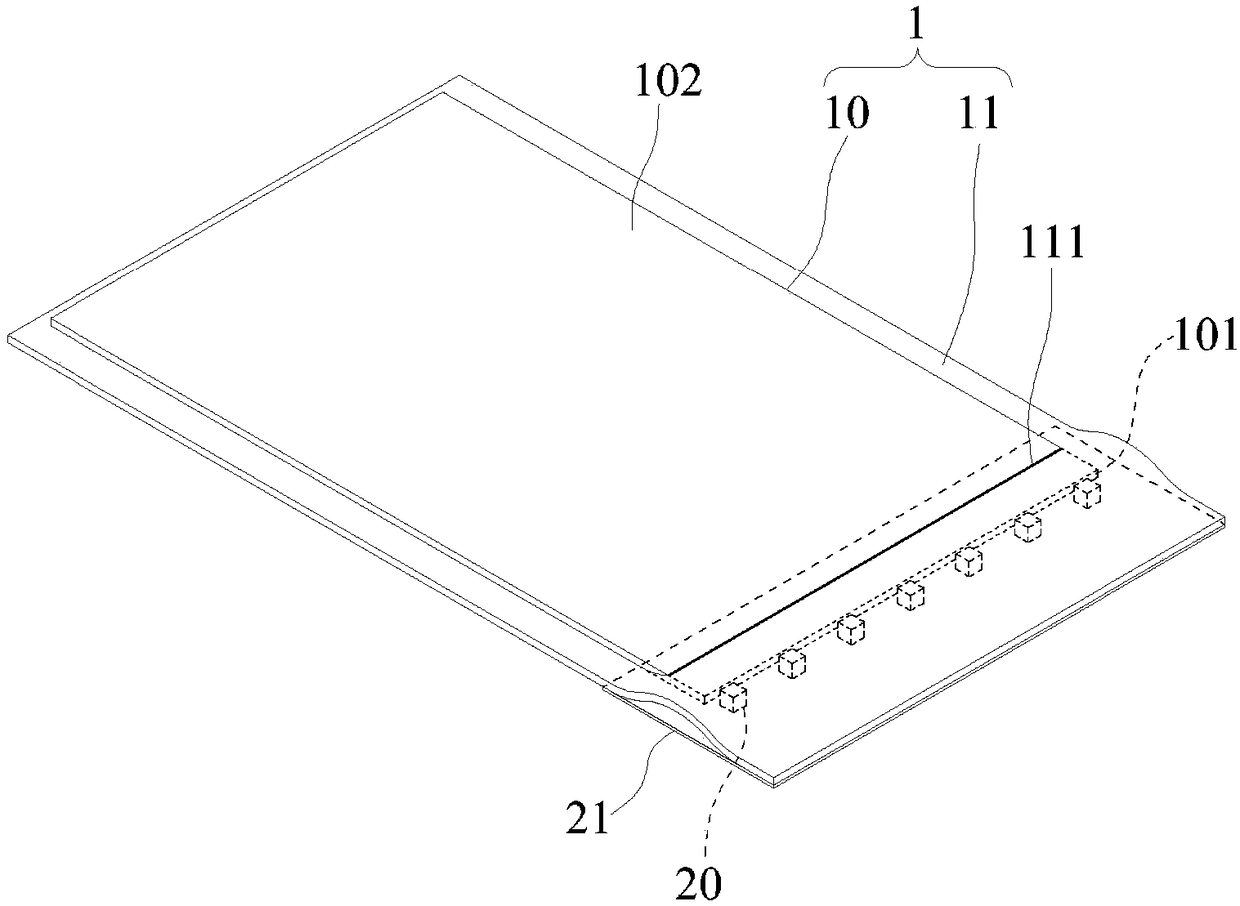

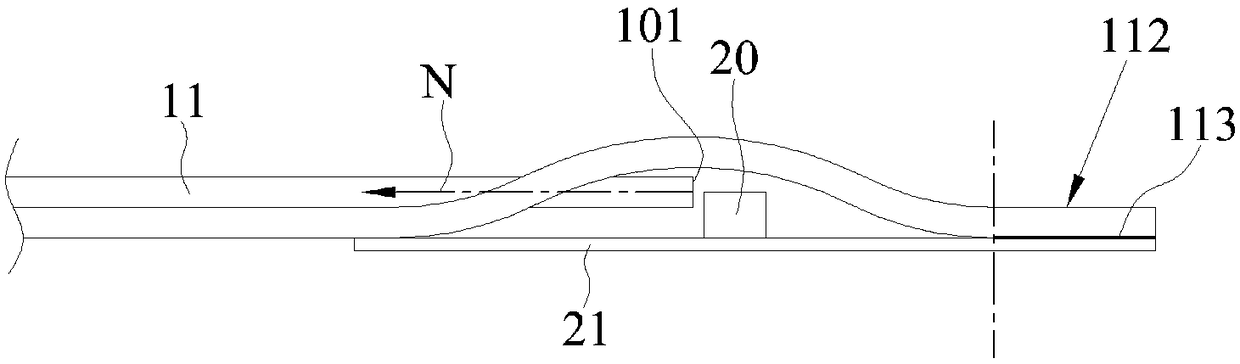

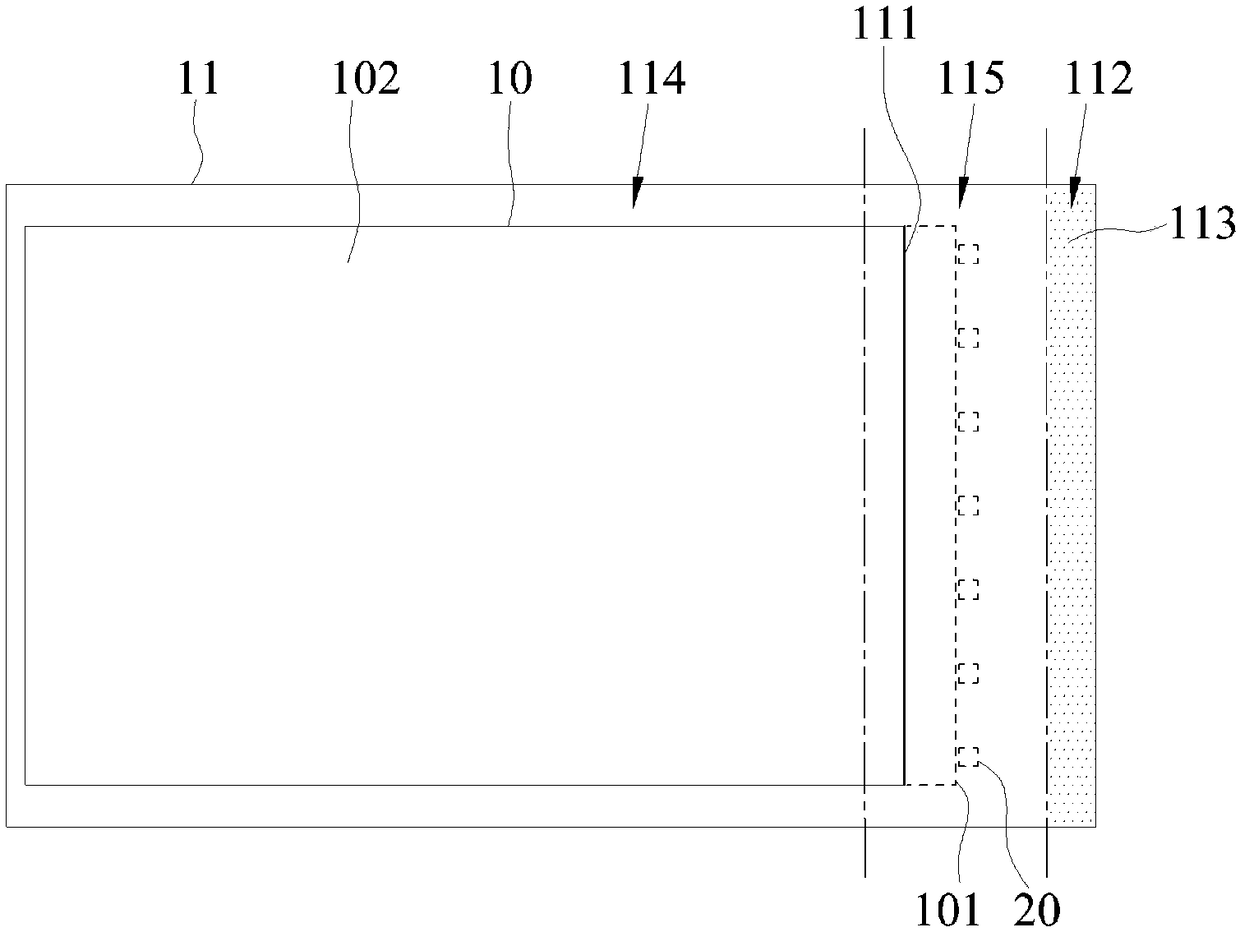

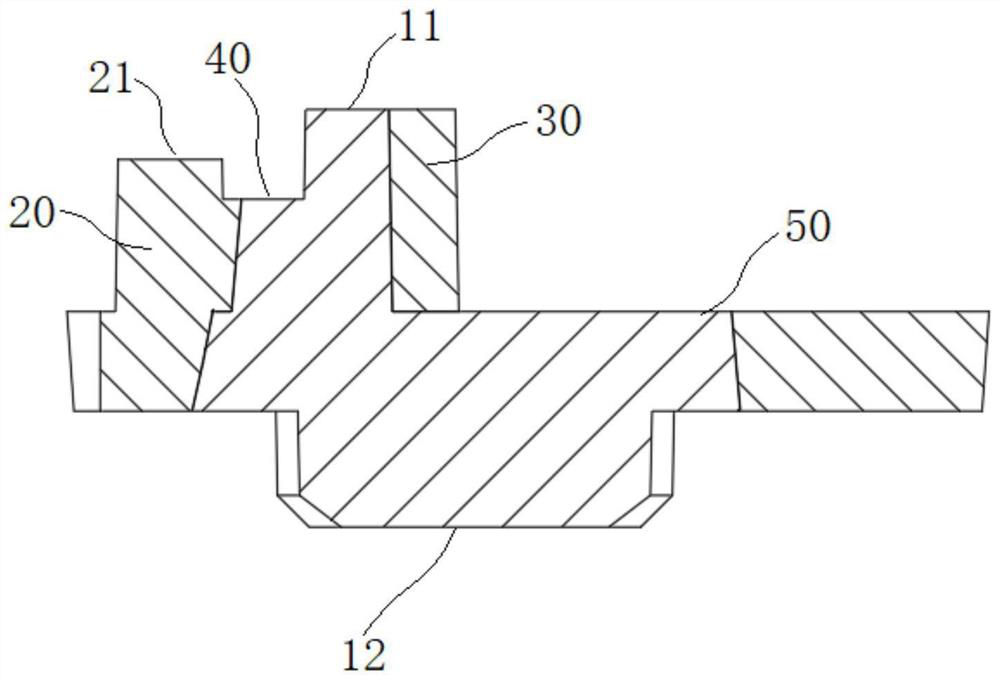

Thin type light guide structure and method for assembling thin type light supply module

InactiveCN108387969AImprove processing speedImprove light guide effectOptical light guidesLight guideOptoelectronics

The invention discloses a thin type light guide structure and a method for assembling a thin type light supply module. The thin type light guide structure includes a light guide plate and a reflectorplate, the light guide plate has a light incidence surface, the reflector plate has a mounting gap and a bonding region, and two opposite surfaces of the reflector plate are reflecting layers. One side of the light guide plate, which has the light incidence surface, penetrates through the mounting gap, and the reflector plate and the light guide plate are arranged in a staggered and laminated manner. The thin type light guide structure is assembled with a light source for use, the bonding region of the reflector plate and a substrate of the light source are combined and fixed, so that an LED on the substrate is arranged corresponding to the light incidence surface, light emitted by the LED can be reflected to the light incidence surface via the reflector plate, lateral incidence light is formed relative to the light guide plate, so that LED light is effectively utilized and an LED of a smaller size can be further carried for use, thereby providing an optical product that better satisfies market demand.

Owner:苏州茂立光电科技有限公司

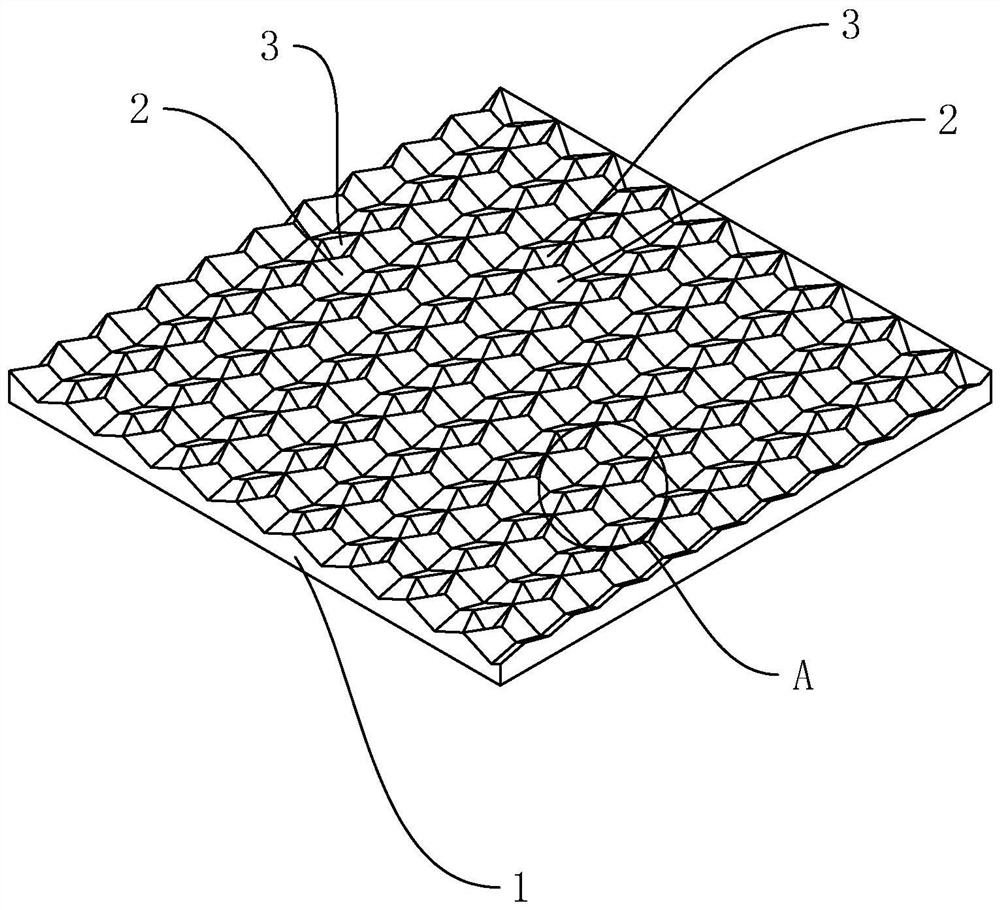

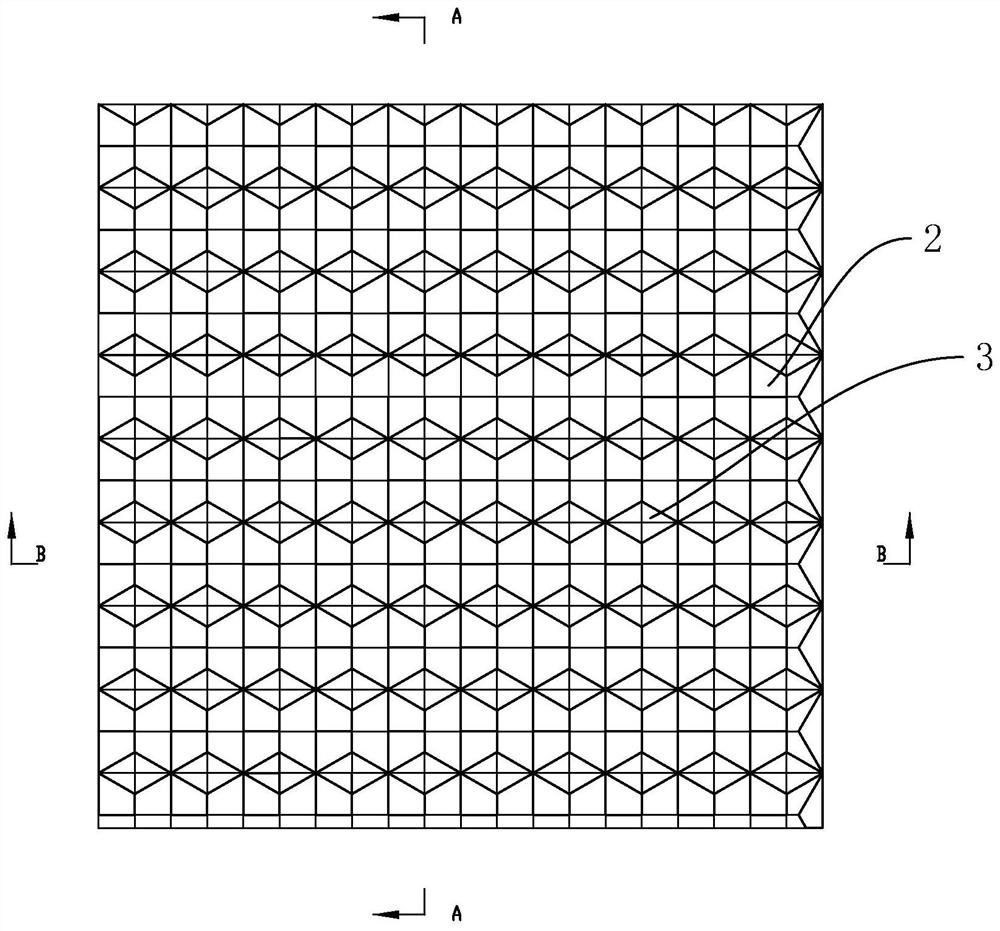

Light guide plate and preparation process thereof

PendingCN113801405AImprove light guide effectReduce brightness differencePlanar/plate-like light guidesLight guidePolystyrene

The invention discloses a light guide plate and a preparation process thereof, relates to an optical conduction technology, and aims to solve the problem that the service life of a product is seriously influenced due to the fact that a PS (polystyrene) material is quickly yellowed in a working environment with higher temperature and stronger oxidizability. The main points of the technical scheme are that the light guide plate comprises a substrate formed through integral extrusion molding, one side of the substrate is sunken to form light guide ridge parts which are distributed in an array and are in a regular polygonal pyramid shape, and diffusion points with rhombic sections are formed between the adjacent light guide ridge parts. The anti-yellowing agent is added into the raw materials of the substrate, so the yellowing condition of the substrate when the substrate is heated for a long time is inhibited, a small amount of coloring agent and light guide powder are added in a matched mode, the light guide effect of the light guide plate can be improved, and light passing through the light guide plate is softer and more uniform; and the hot-melt raw materials are firstly dried, so that the generation of bubbles during hot-melt extrusion can be reduced.

Owner:绍兴明优光电科技有限公司

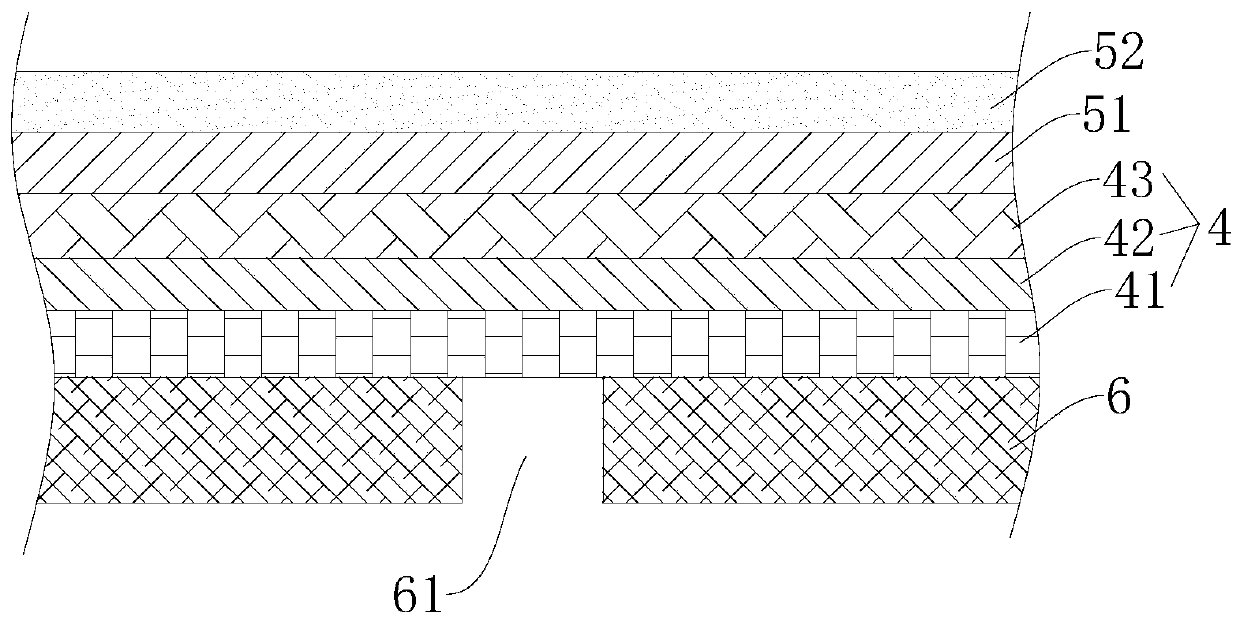

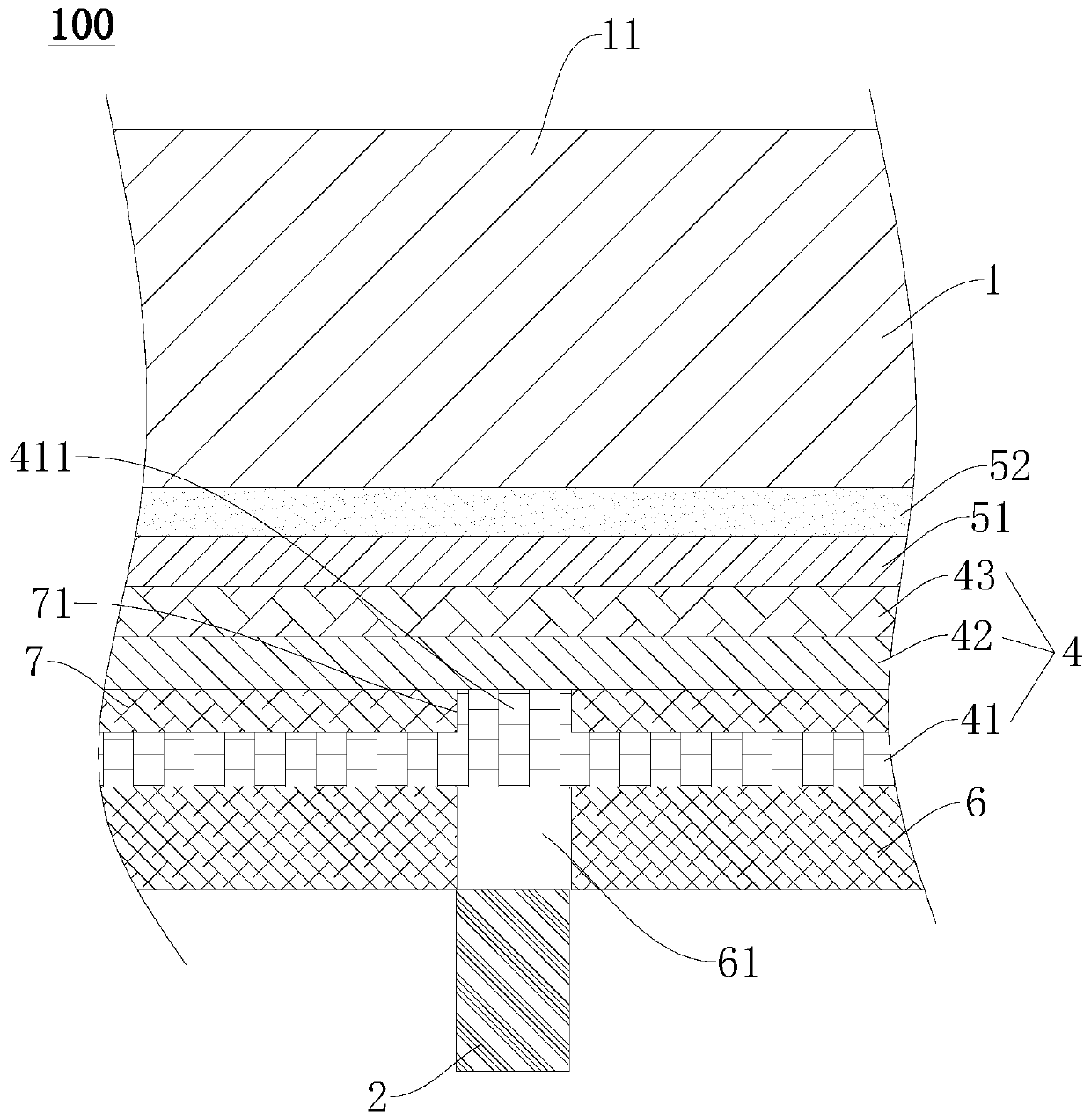

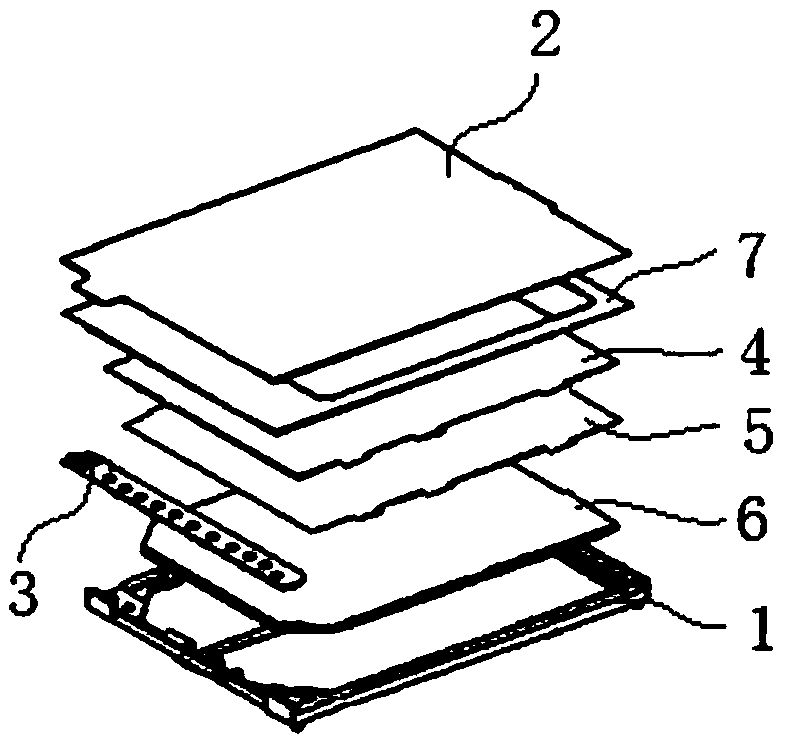

LCM backlight source

PendingCN108761915AReduce thicknessThe overall thickness is thinNon-linear opticsDiffusionLight guide

The invention relates to an LCM backlight source. The backlight source comprises an aluminum alloy protective frame, a light transmitting glass protective plate, an LED backlight FPC, a light guidingplate, a diffusion plate, a diffusion intensifying plate and a light blockage glue frame, the light transmitting glass protective plate, the diffusion plate, the diffusion intensifying plate and the lifht guiding plate are sequentially bonded together from top to bottom, the light guiding plate is wrapped with the aluminum alloy protective plate, the LED backlight FPC tightly adheres to the side wall of one end of the light guiding plate and is fixed to the end part of the aluminum alloy protective frame, the light blockage glue frame is arranged between the light transmitting glass protectiveplate and the diffusion plate, protrusions are arranged on the diffusion plate and a pair of the long side edges of the diffusion intensifying plate, grooves which can clamp the protrusions togetherare formed in a pair of long side edges of the aluminum alloy protective frame, the LED backlight FPC comprises an FPC body and LED light beads, the end part of the FPC body is provided with a leadingend, and the LED light beads are welded to the FPC body by adopting a connection manner of two series connection and N parallel connection and are connected with the leading end through a guiding wire. According to the LCM backlight source, the structure is simple and stable, the heat dissipation performance is good, and the backlight effect is excellent.

Owner:JIANGSU JUTAI TECH CO LTD

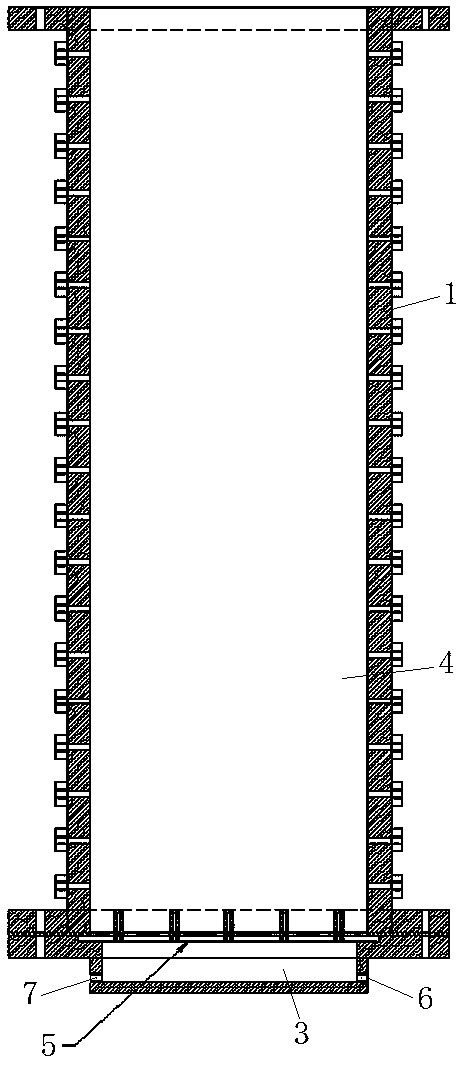

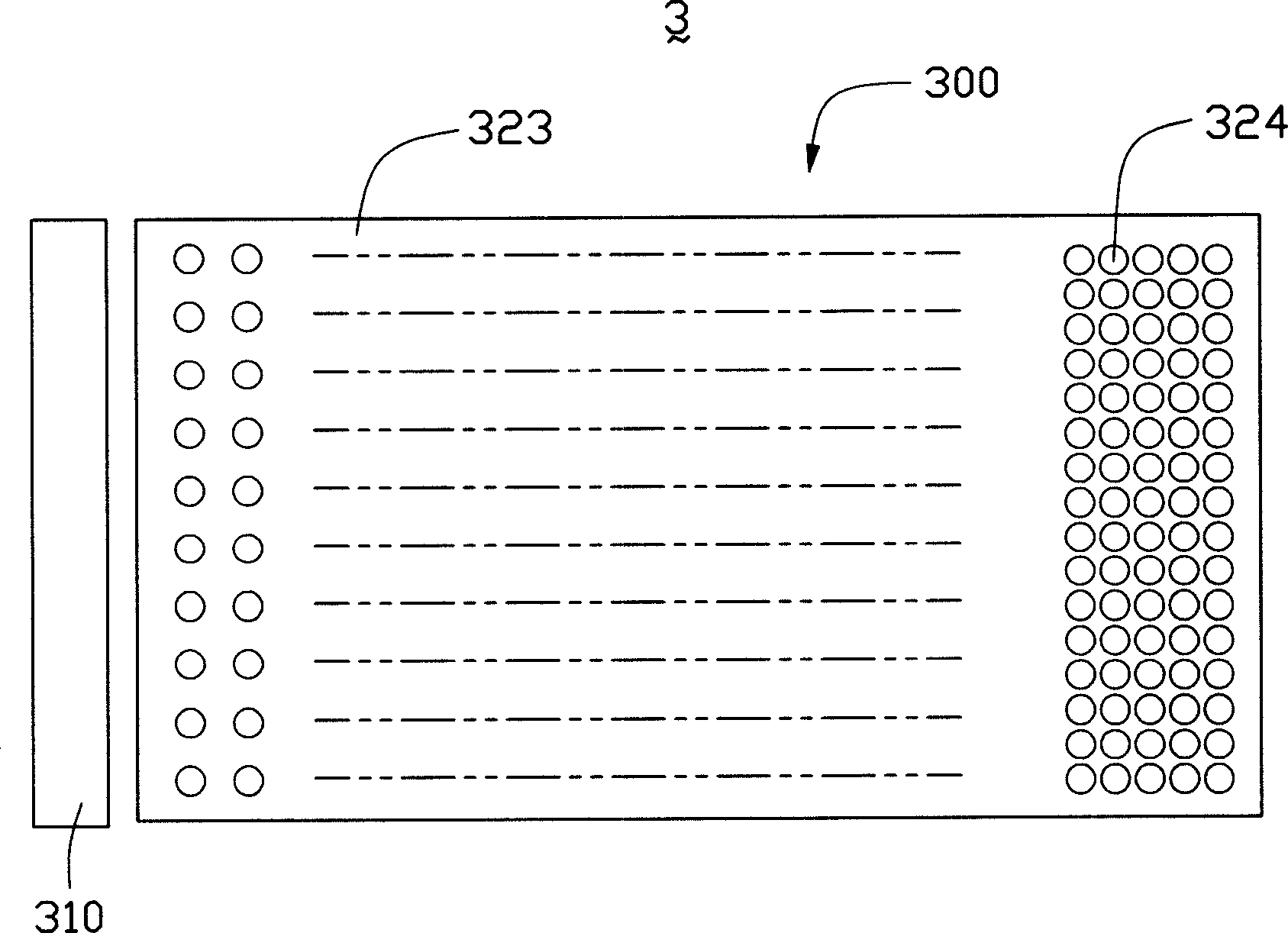

Contact type image sensor

ActiveCN102034295AGuaranteed uniformity and strengthSolve serious attenuation phenomenonPaper-money testing devicesPictoral communicationPhysicsOpto electronic

The invention relates to an image reading device, in particular to a contact type image sensor in which an ultraviolet linear light source is in a light conductor type. The contact type image sensor comprises a frame, wherein a circuit board is arranged below the frame, and a photoelectric conversion chip is arranged on the circuit board; a lens is arranged above the photoelectric conversion chip, and the light source is arranged at the side face of the lens; and a glass plate is arranged above the frame. The contact type image sensor is characterized in that the linear light source consisting of an ultraviolet light-emitting diode (LED), a light conductor and an LED circuit board is arranged at the side face of the lens, and the ultraviolet LED is arranged at the end of the light conductor. The contact type image sensor provided by the invention has the advantages of low cost, low power consumption, high uniformity, high sensitivity of ultraviolet information identification and the like.

Owner:WEIHAI HUALING OPTO ELECTRONICS CO LTD

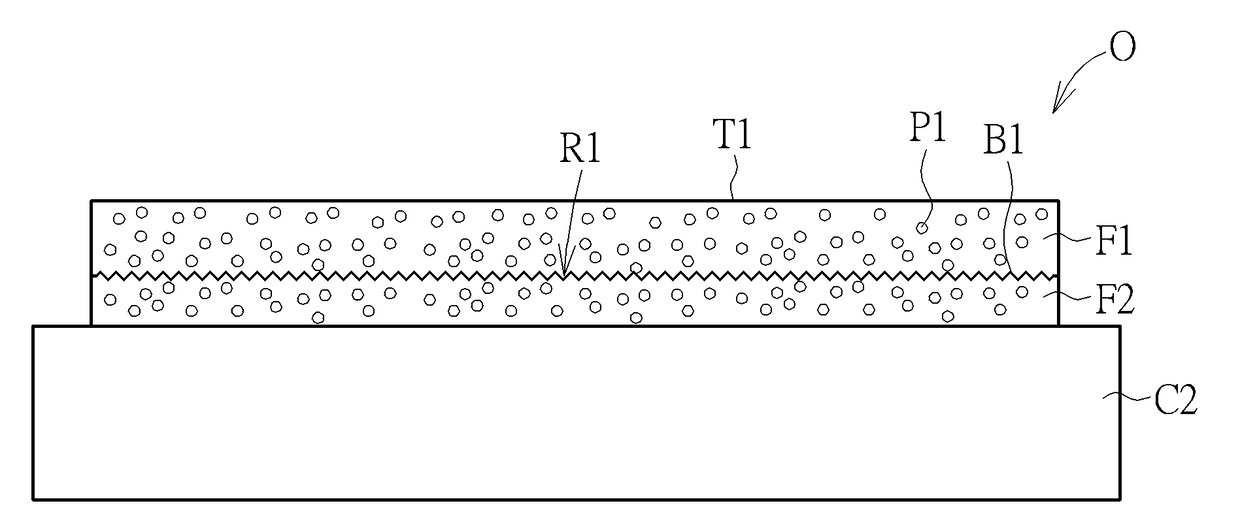

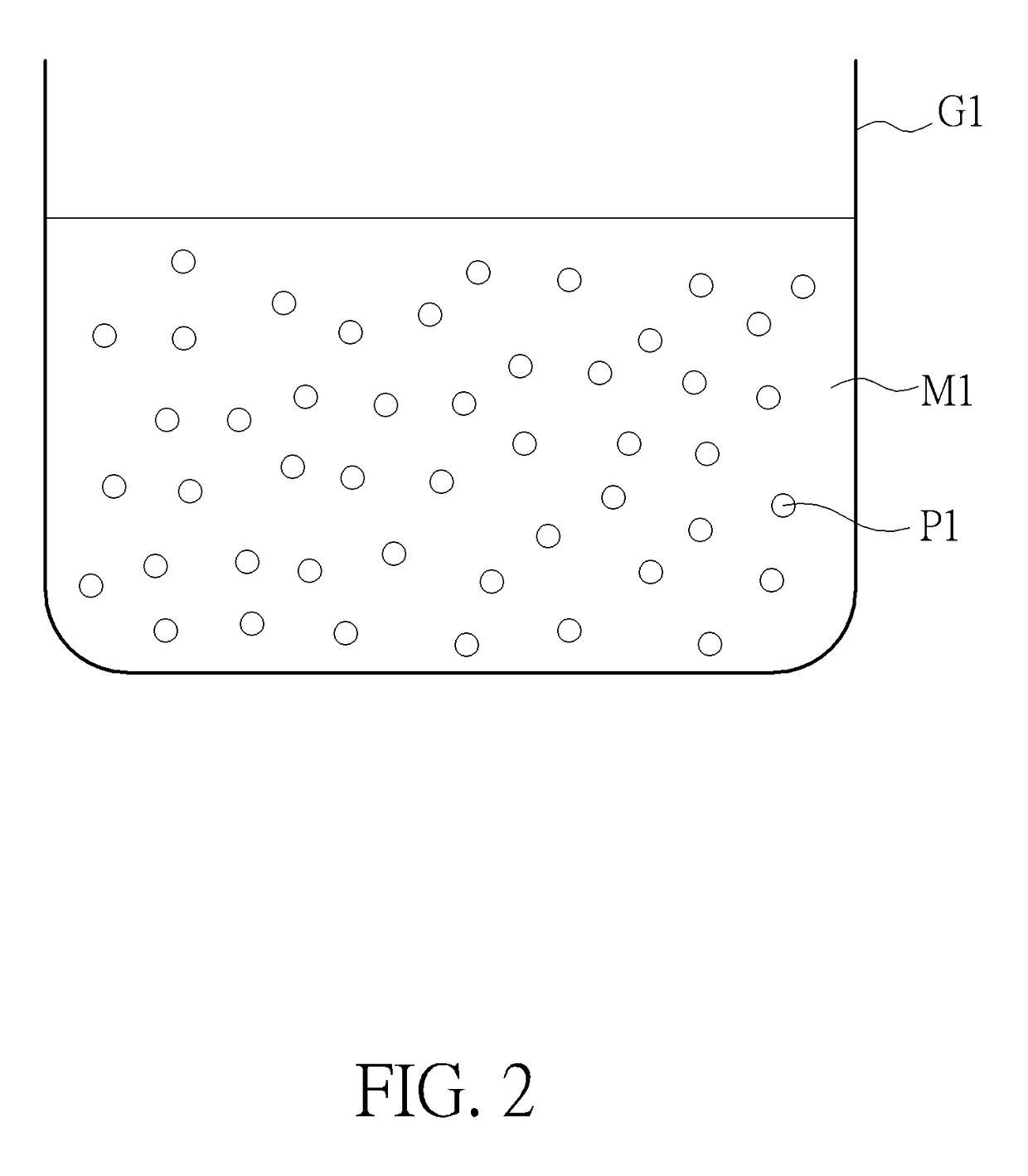

Optical film and manufacturing method thereof

InactiveUS20170160445A1High transparencyIncrease volumeDiffusing elementsNon-linear opticsRough surfaceOptical film

An optical film includes a first substrate and a second substrate. A plurality of first particles are doped and dispersed in the first substrate, and a plurality of second particles are doped and dispersed in the second substrate. The first substrate has a top surface and a bottom surface, wherein the top surface is a flat surface and the bottom surface is a rough surface. The second substrate is attached to the bottom surface of the first substrate and the second substrate has flat surfaces.

Owner:CHUNGHWA PICTURE TUBES LTD +1

Light guide column and electronic equipment

PendingCN113709277AImprove light guide effectGuaranteed normal transmissionTelephone set constructionsAmbilightFirst light

The invention discloses a light guide column and electronic equipment, and the light guide column comprises a light guide body, wherein the light guide body comprises a light incident surface and a light emergent surface, the light incident surface and the light emergent surface are located at the two opposite sides of the light guide body, and light is guided into the light guide body from the light incident surface and guided out from the light emergent surface; and a first light shielding body which is arranged on the first side of the light guide body, and a glue overflowing groove is defined between the first light shielding body and the light guide body in a matched mode. By arranging the first light shielding body on the light guide body, ambient light can be effectively prevented from entering the light guide column from the first side of the light guide body, and it is guaranteed that light is transmitted on the light inlet face and the light outlet face of the light guide column. Meanwhile, the glue overflowing groove is formed between the first light shielding body and the light guide body, it is guaranteed that glue overflows into the glue overflowing groove in the glue dispensing process and does not overflow into the light inlet face, the glue is prevented from shielding the light inlet face, and the light guide effect of the light guide column is improved.

Owner:VIVO MOBILE COMM CO LTD

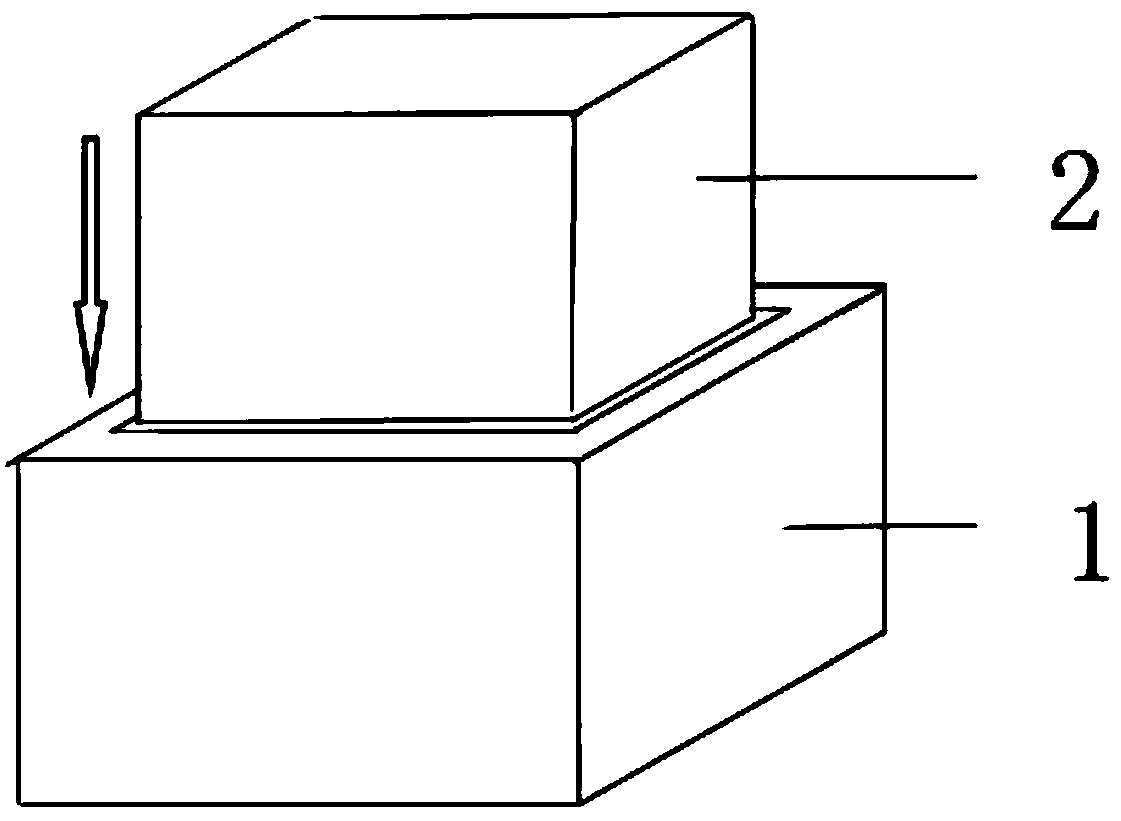

Concrete block with lightweight, thermal insulation and light transmission and manufacturing method of concrete block

PendingCN107558652ALow densityImprove light guide effectConstruction materialCeramic shaping apparatusThermal insulationLight guide

The invention discloses a concrete block with lightweight, thermal insulation and light transmission. The concrete block comprises a substrate and a light guide medium, wherein the substrate is arranged around the light guide medium; the light guide medium is fixedly connected with the substrate; the substrate is made of composite materials, wherein the composite materials comprise cement concreteand a filler and the density of the filler is lower than that of the cement concrete. The light guide medium is added into the block, so that the light guiding performance of the block is enhanced; meanwhile, the filler with lower density is added in the composite materials, so that the average thermal conductivity of the block is reduced, the thermal insulation property of the block is improvedand further the mass of the block is reduced. The invention also provides two manufacturing methods of the concrete block with lightweight, thermal insulation and light transmission; in addition, themanufacturing methods are simple and convenient to operate and are suitable for popularization and application.

Owner:BEIJING MUNICIPAL ENG RES INST

A two-dimensional photocatalytic fluidized bed device

ActiveCN109745937BIncrease intakeReduce lossesEnergy based chemical/physical/physico-chemical processesChemical physicsLight guide

The invention relates to a two-dimensional photocatalytic fluidized bed device, comprising several two-dimensional fluidized beds distributed side by side and made of transparent materials, the reaction zone of the two-dimensional fluidized bed is filled with light guides, There is a light source between two adjacent two-dimensional fluidized beds; the two-dimensional fluidized bed has the advantages of thin walls, which is conducive to the intake of light and reduces light loss, and the two-dimensional fluidized bed is filled in the reaction zone The light guide can greatly enhance the light guide. The invention has a simple and reasonable structure, and solves the problems of low light utilization rate and low catalytic efficiency of the traditional fluidized bed.

Owner:FUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com