Point-type heat fire detector

A fire detector, point-type technology, applied in the direction of electrical fire alarms, etc., can solve the problems of low light transmission efficiency, assembly production efficiency and maintenance efficiency, reduced manufacturing production efficiency, and failure of fire alarm devices, etc. Light capture rate, improved production efficiency, simple assembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described below with reference to the accompanying drawings.

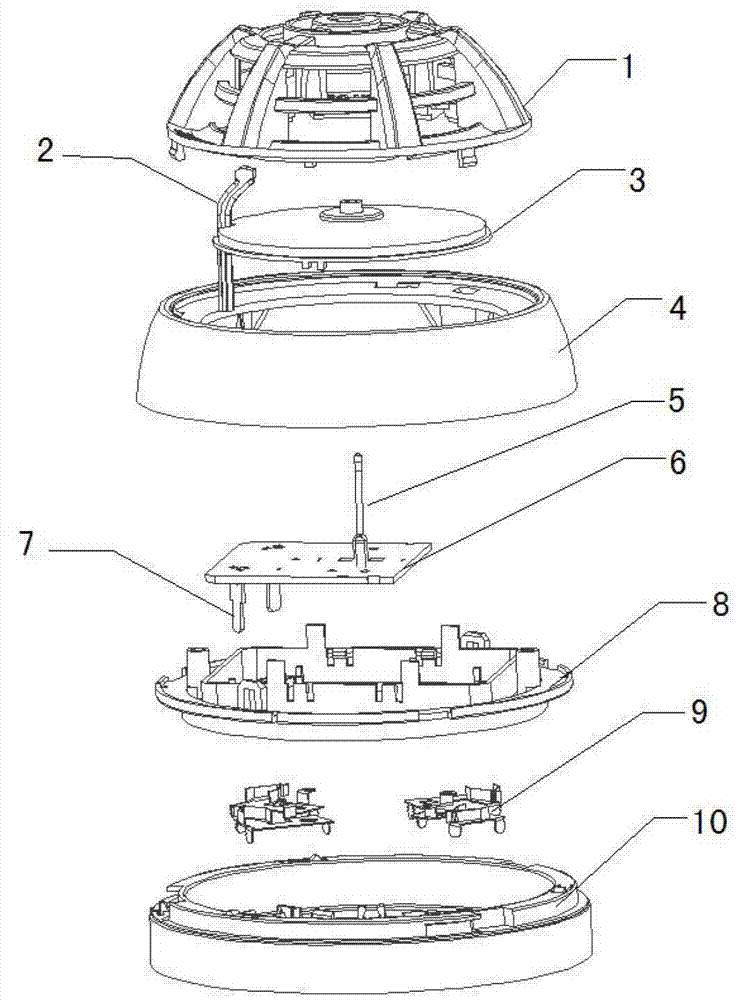

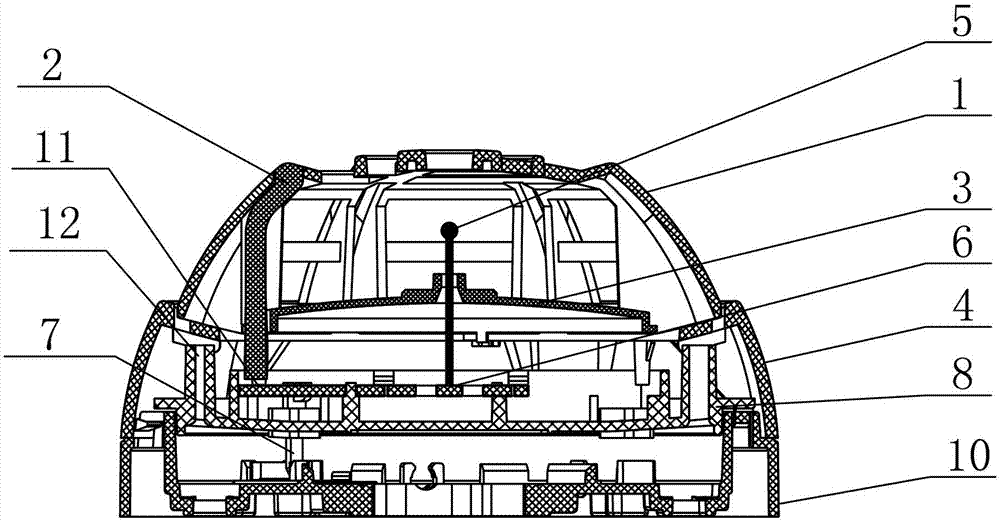

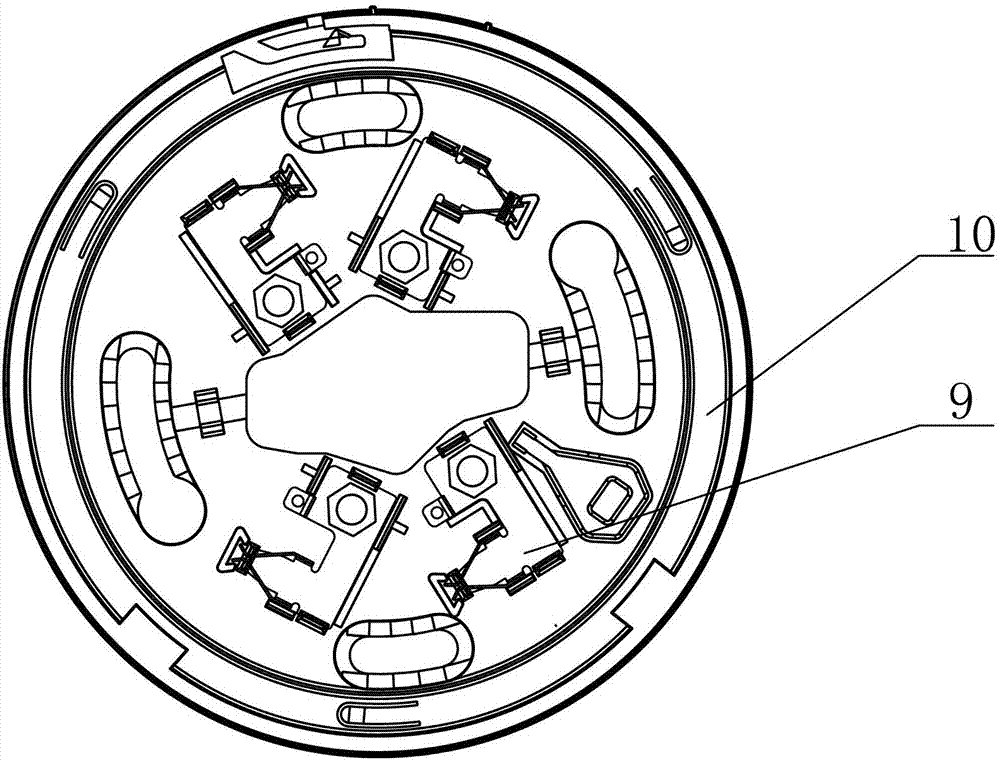

[0048] The present invention relates to a point-type temperature-sensing fire detector, the schematic diagram of the explosion structure and the schematic diagram of the assembled structure are respectively as follows figure 1 and figure 2 As shown, it includes a casing and a circuit board 6 inside the casing, a light guide column 2 and a plate-shaped middle buckle 8. The casing includes a base 10, an annular middle cover 4 and an upper cover 1 connected in sequence, the base 10, the annular middle cover 4 and the upper cover 1. The outer contour formed by the cover 1 is in the shape of a hemispherical table, the upper cover 1 is located at the top of the hemispherical table, the middle button 8 is snap-connected and arranged in the annular middle cover 4, the circuit board 6 is snap-fitted on the middle button 8, and the circuit board 6 is provided with a The thermistor 5 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com