Patents

Literature

36results about How to "Realize arrangement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

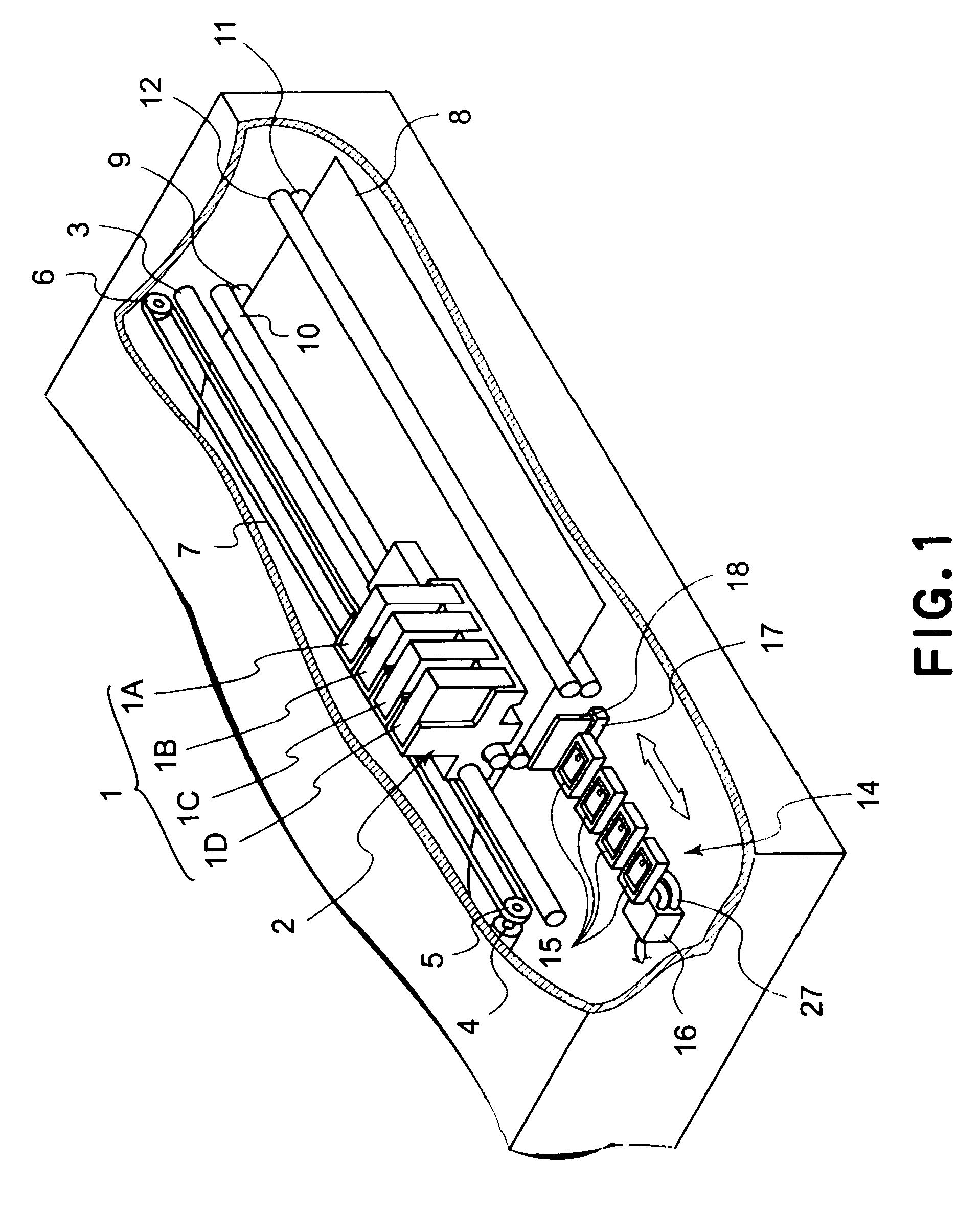

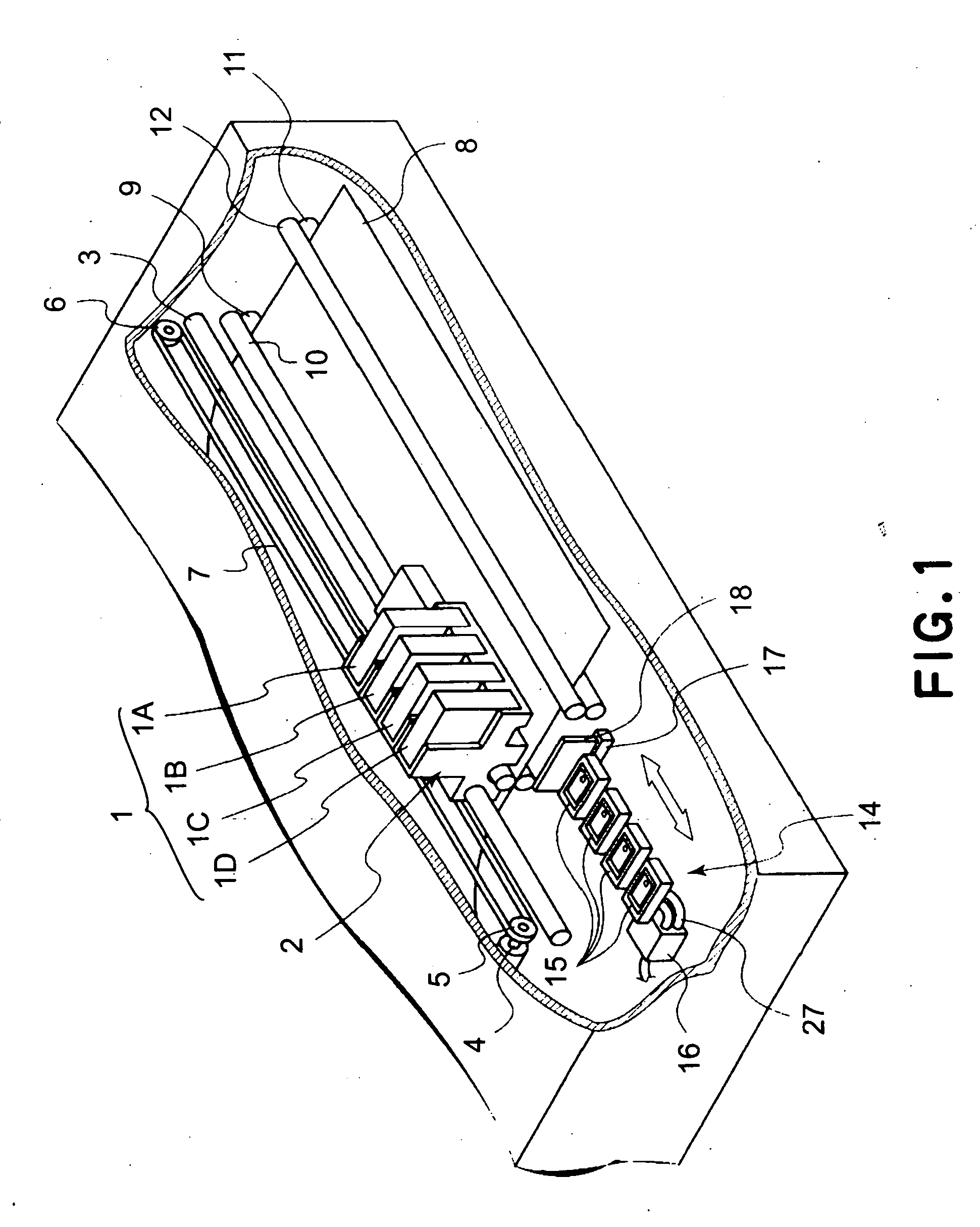

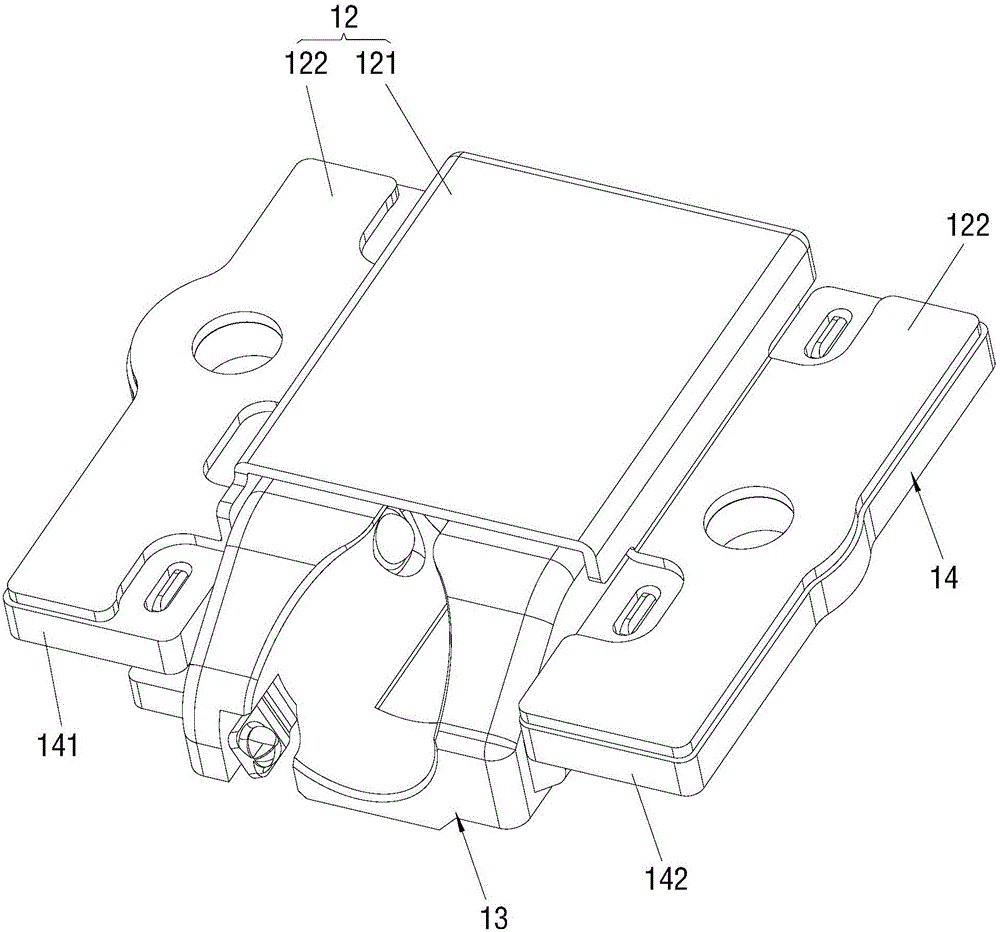

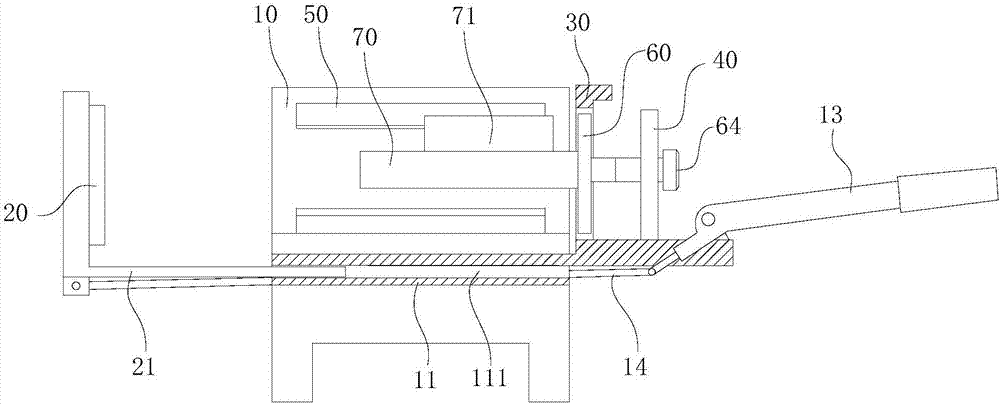

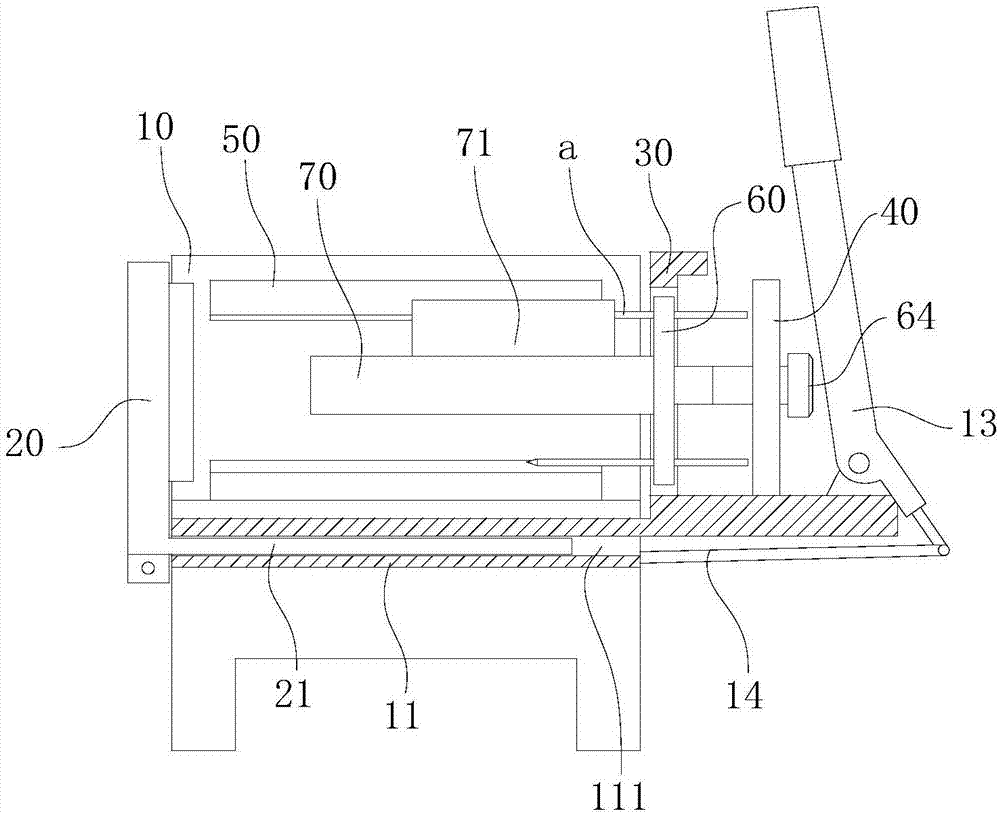

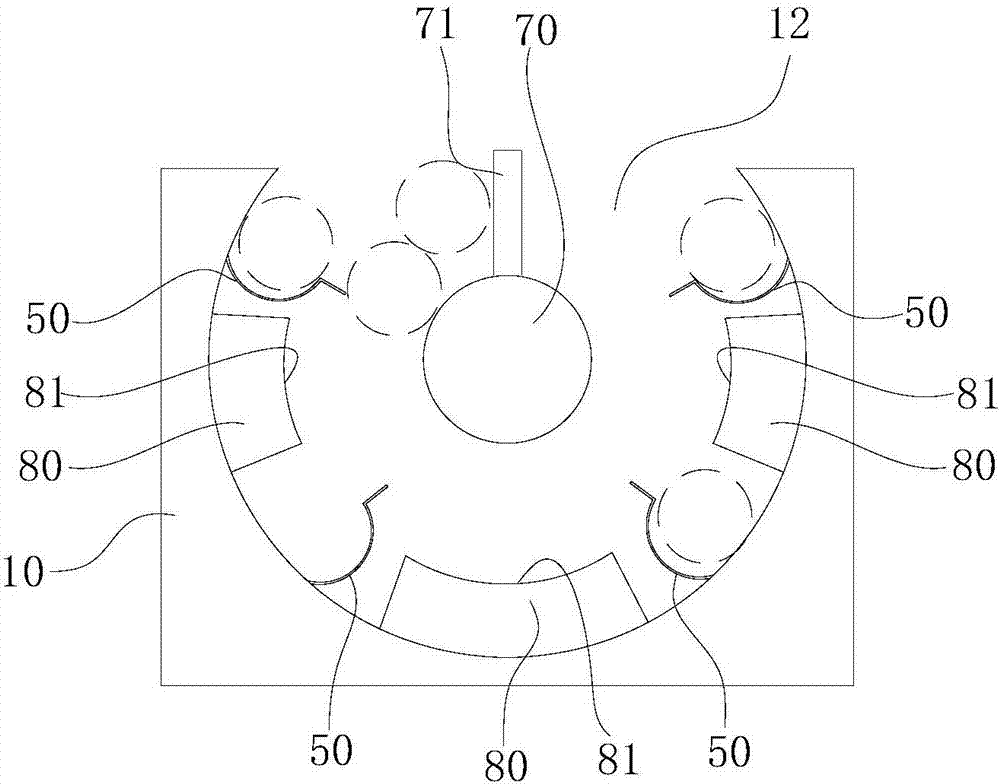

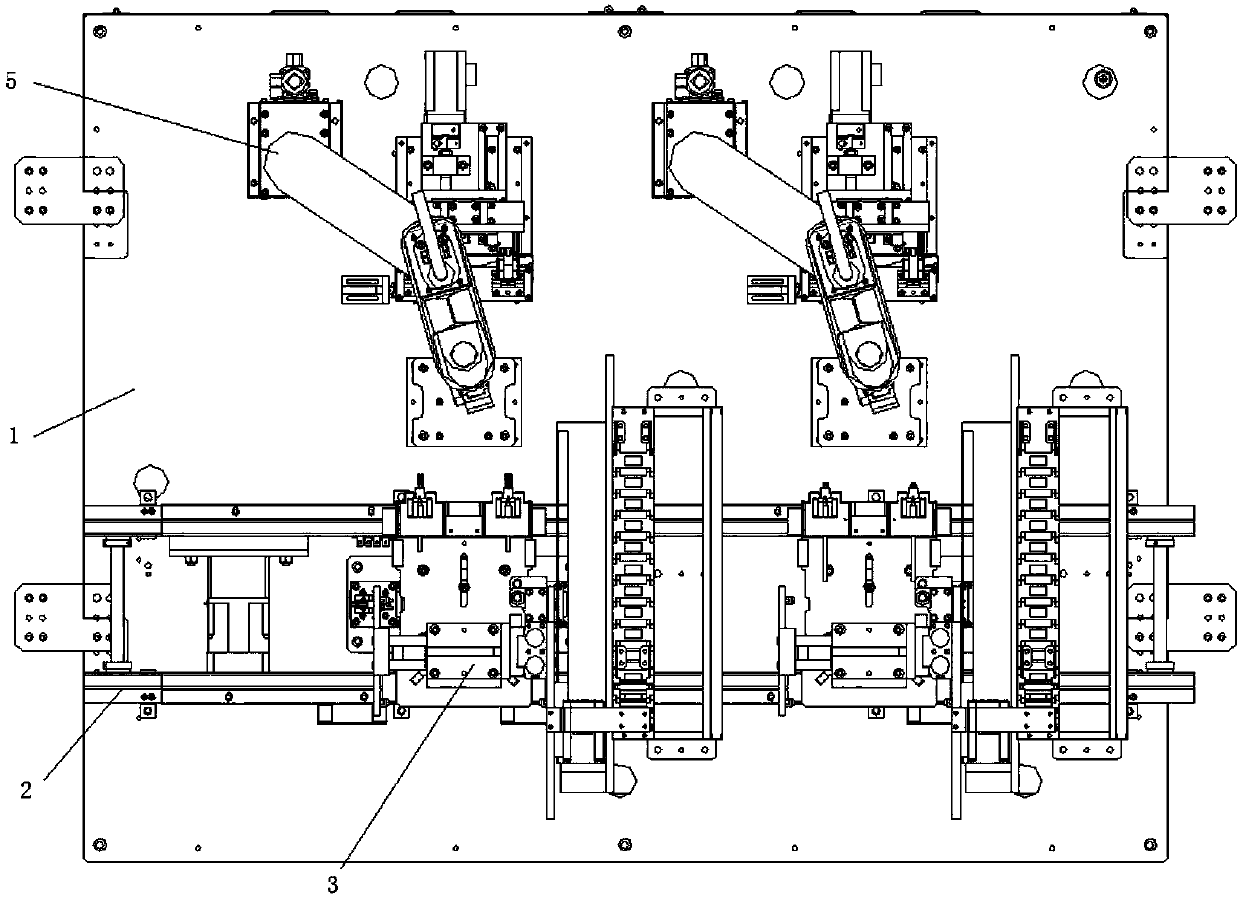

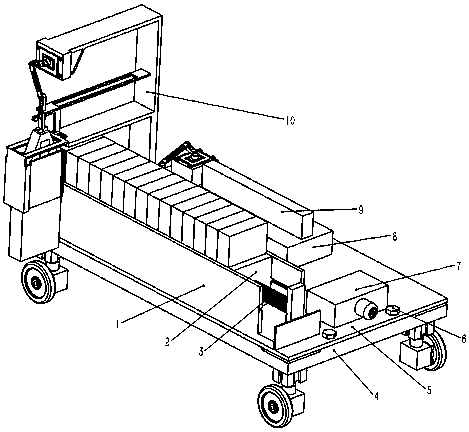

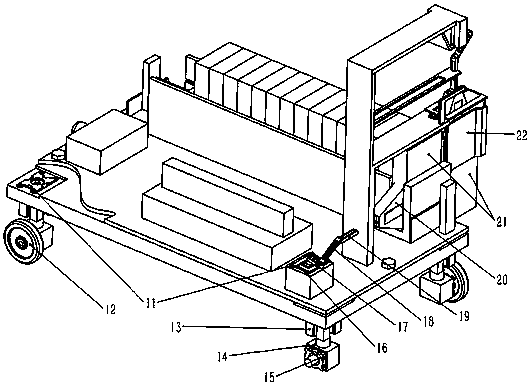

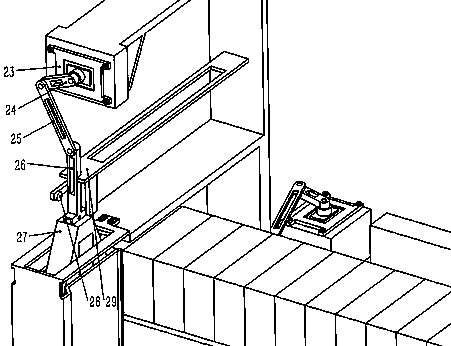

Intelligent sorting equipment for small-batch sheet type scattered devices

InactiveCN109731793ARealize automatic flippingEasy to operate and transferSortingNon destructiveOver treatment

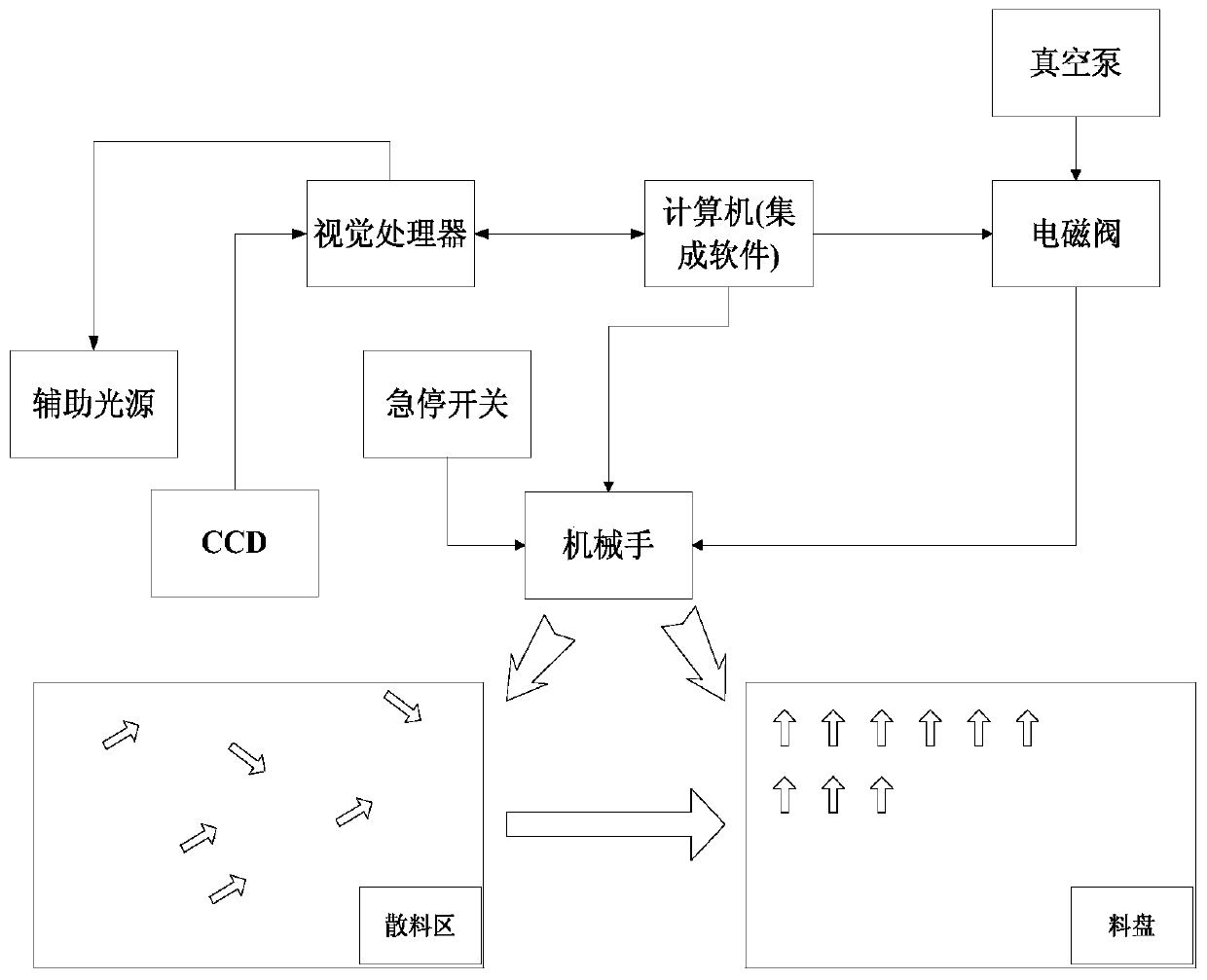

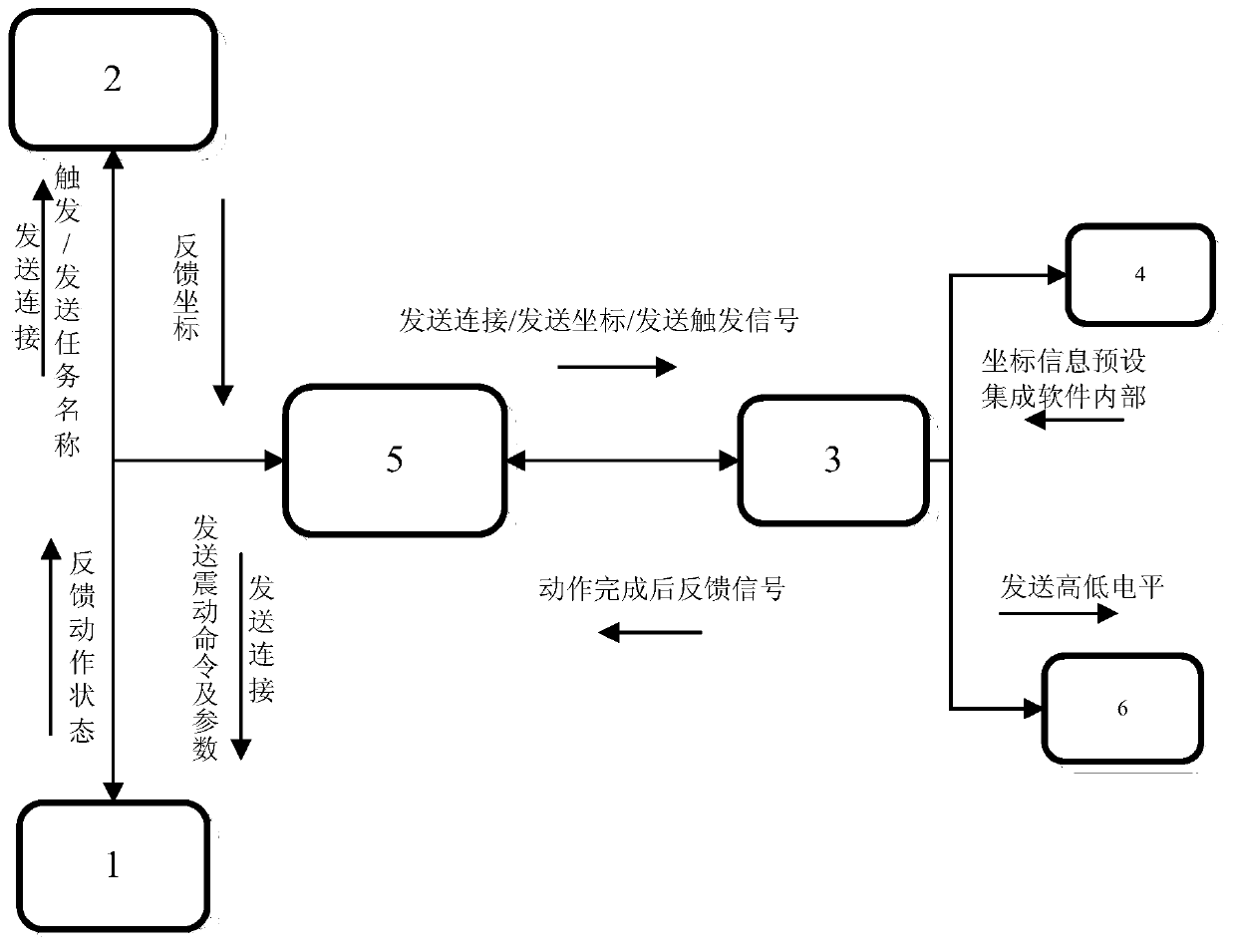

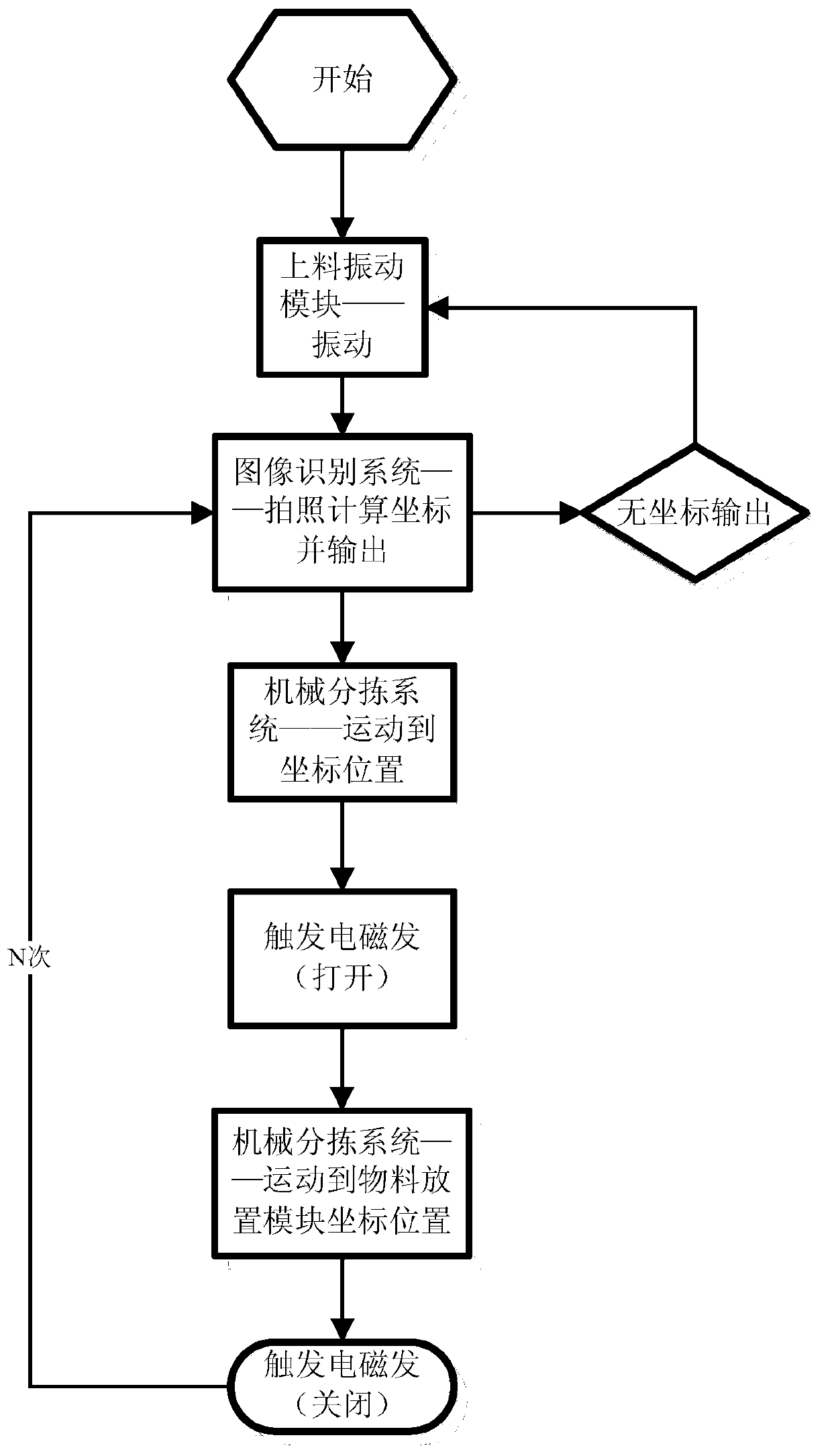

The invention discloses intelligent sorting equipment for small-batch sheet type scattered devices. The equipment aims to solve the problem that small-batch bulk components after secondary screening of electronic components in the military industry cannot be produced by using automatic equipment. The accurate-positioning and non-destructive-picking intelligent sorting equipment for the small-batchsheet type scattered devices are designed through integrated research and development on a feeding vibration module, a mechanical sorting system, an image recognition system, a material placing module, software development and the like. According to the equipment, as a new breakthrough of intelligent manufacturing in the field of electronic assembly, under dragging by software, the feeding vibration module is driven to carry out turning-over treatment on the sheet type scattered devices, the software is switched to drive the image recognition system to realize automatic recognition and framejudgment of the sheet type components, the software commands and drives the mechanical sorting module to intelligently grab the sheet type scattered devices, accurate grabbing of 0402 packaging can beachieved, the software sets material placement to realize the high-precision array sorting and arranging of the sheet type scattered devices, and the sorting quantity and the operation period can further be clearly recorded.

Owner:SHANGHAI AEROSPACE ELECTRONICS CO LTD +1

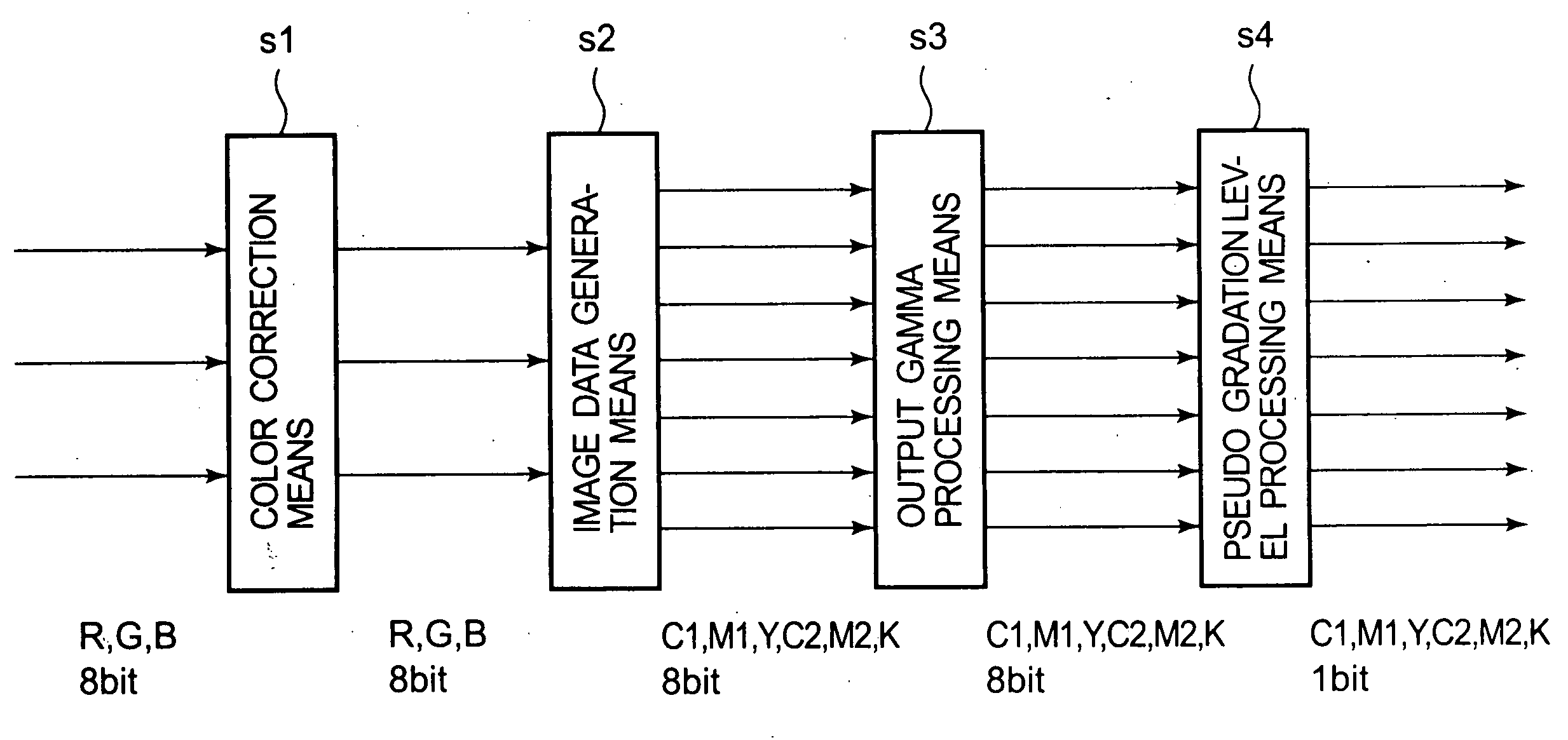

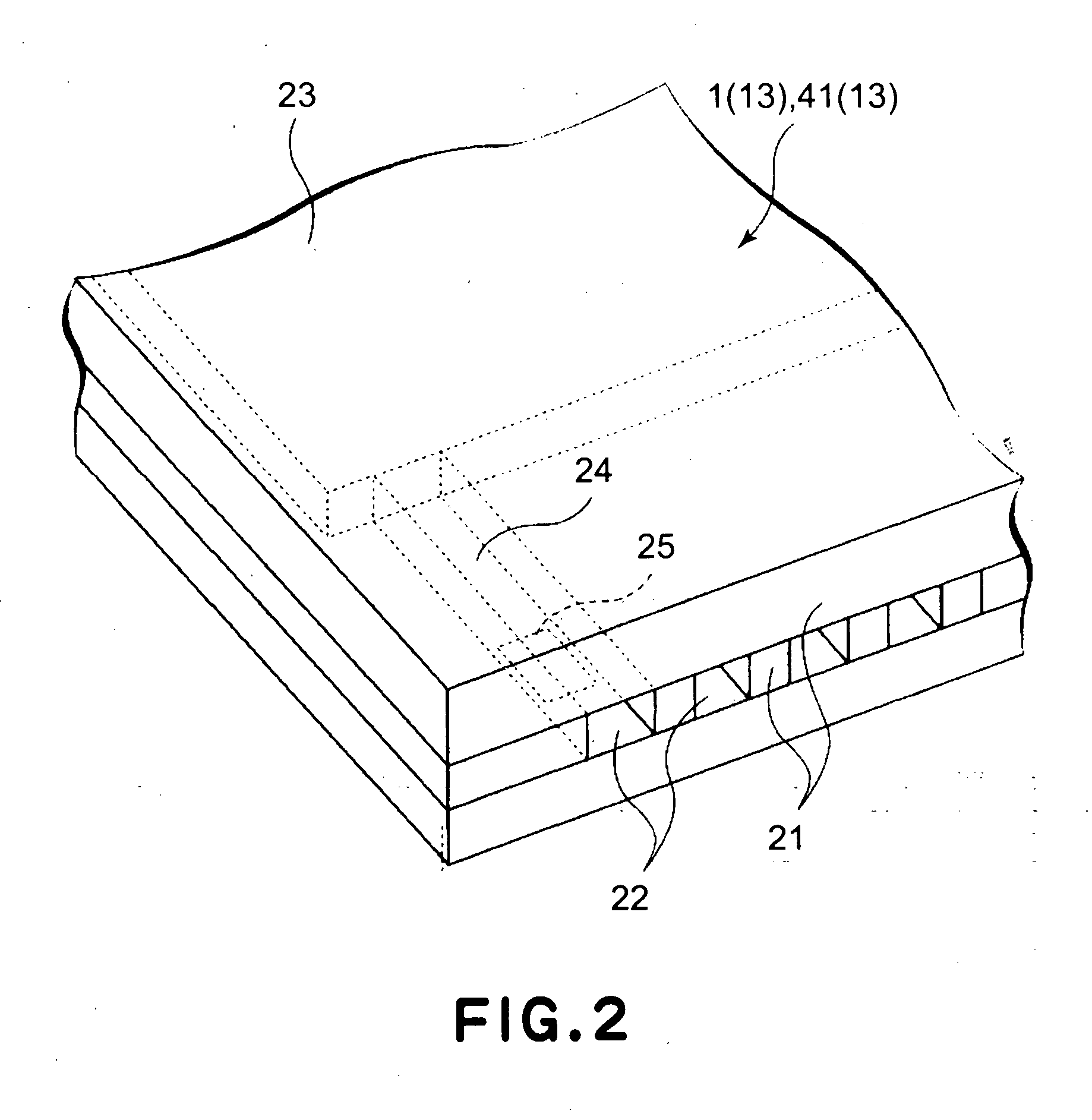

Image processing apparatus, image processing process and program

InactiveUS7515318B2Improve visual propertiesEnsure flexibilityDigitally marking record carriersDigital computer detailsImaging processingHigh density

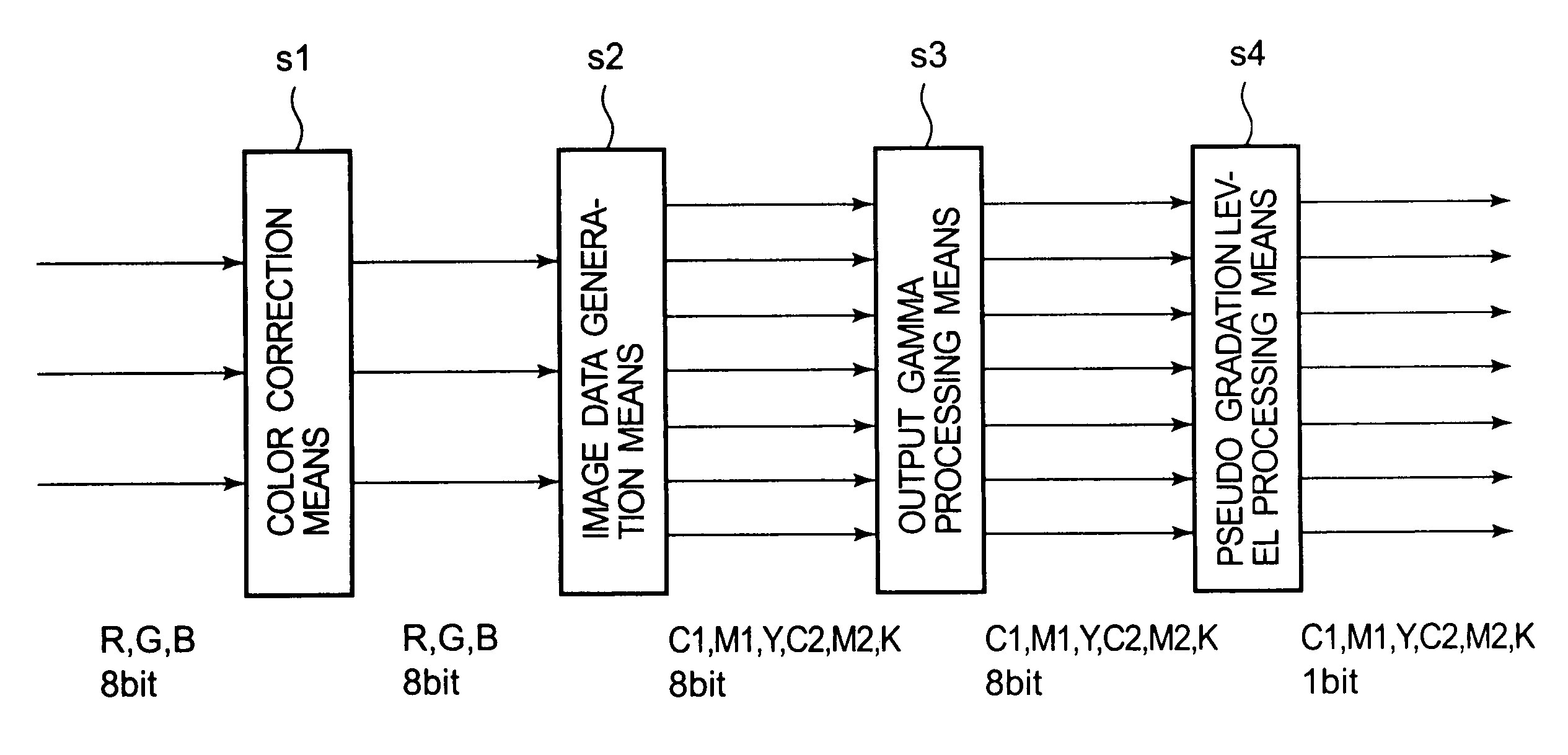

In an image processing method, on the basis of input image data with respect to a target pixel, independent multi-level data (g0, g1) corresponding to respective plural species of dots which are different in at least one of a density and a diameter are generated, and then data (O0, O1) relating to an amount of generation of the dots with respect to the target pixel are generated on the basis of a relationship between the generated independent multi-level data (g0, g1) corresponding to the plural species of dots. The image processing method is effective in performing design having a high degree of flexibility in proper use of a relatively high power dot (high density dot or large dot) and a relatively low power dot (low density dot or small dot) and can realize obviation or alleviation of an occurrence of granulation or an apparent frame caused due to the relatively high power dot.

Owner:CANON KK

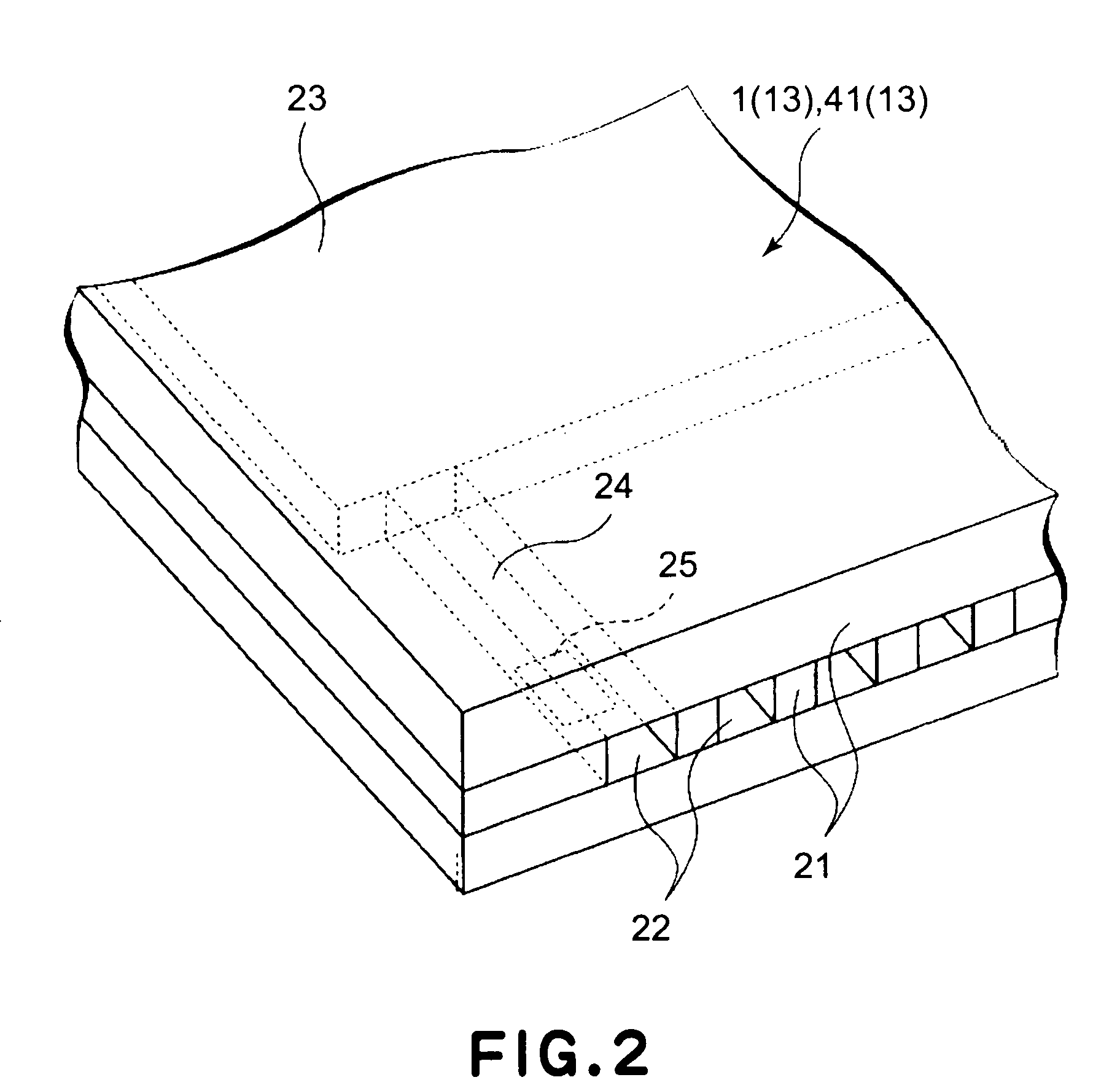

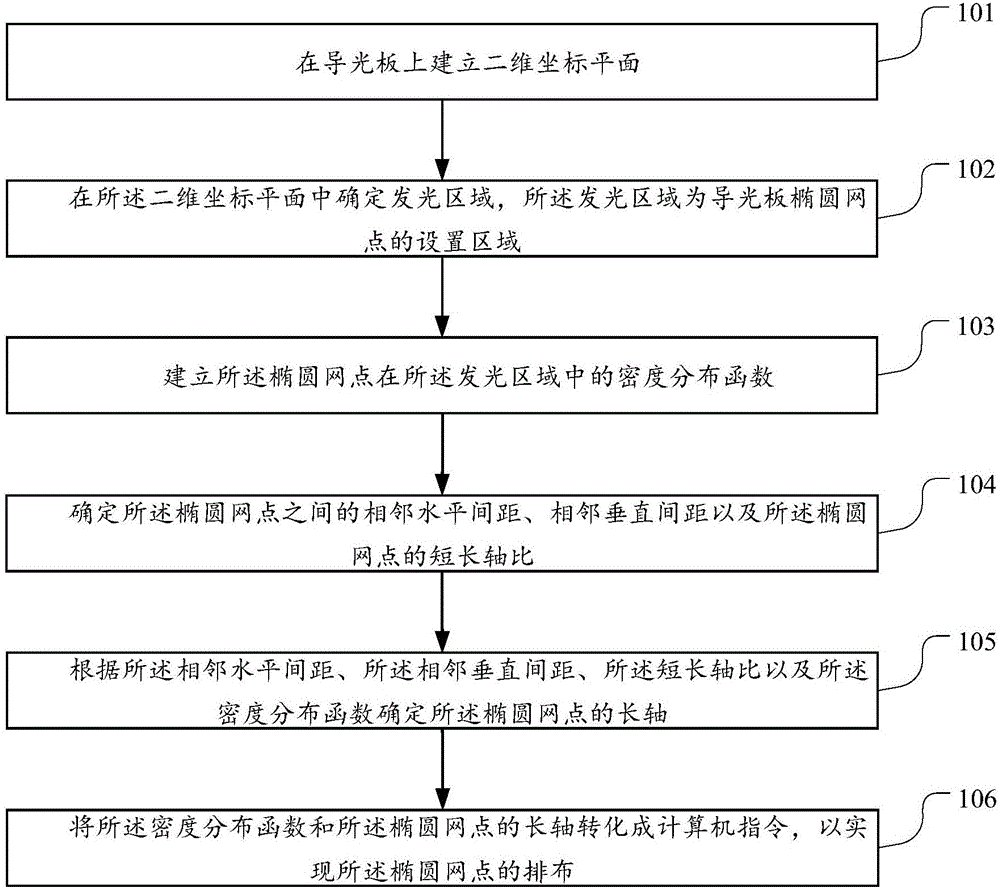

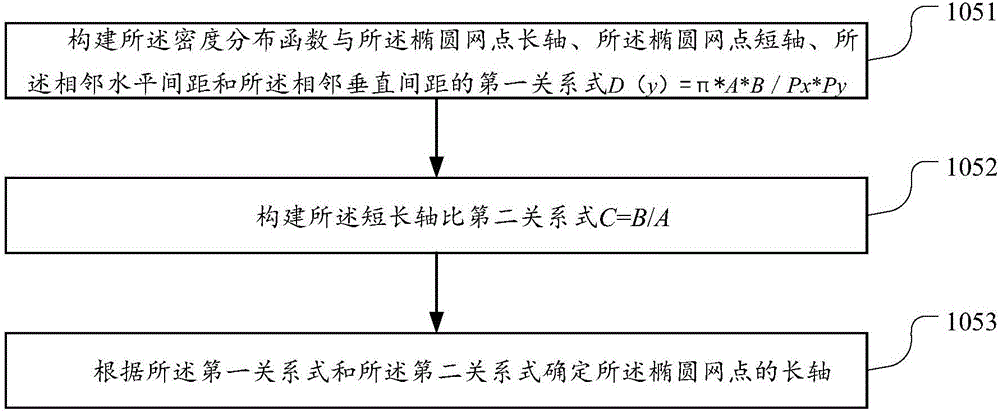

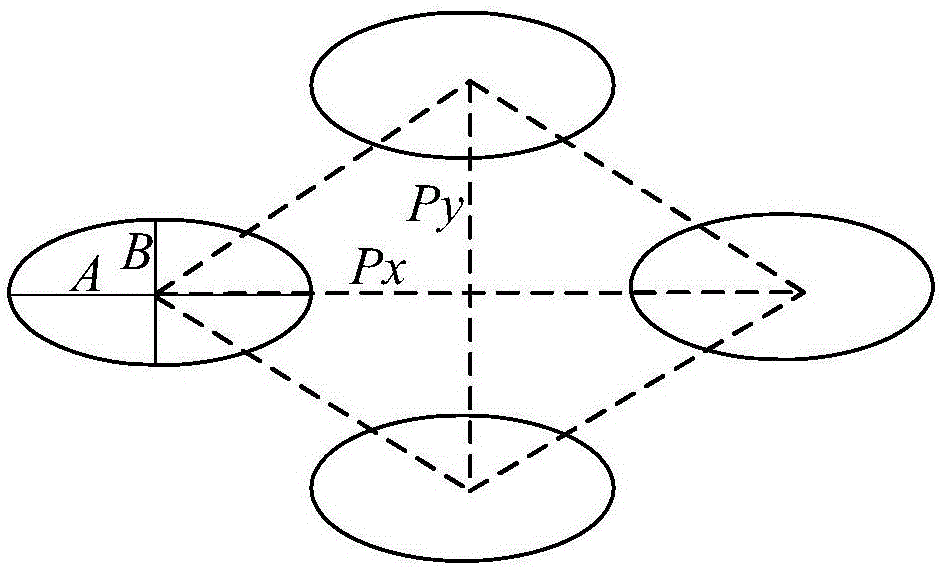

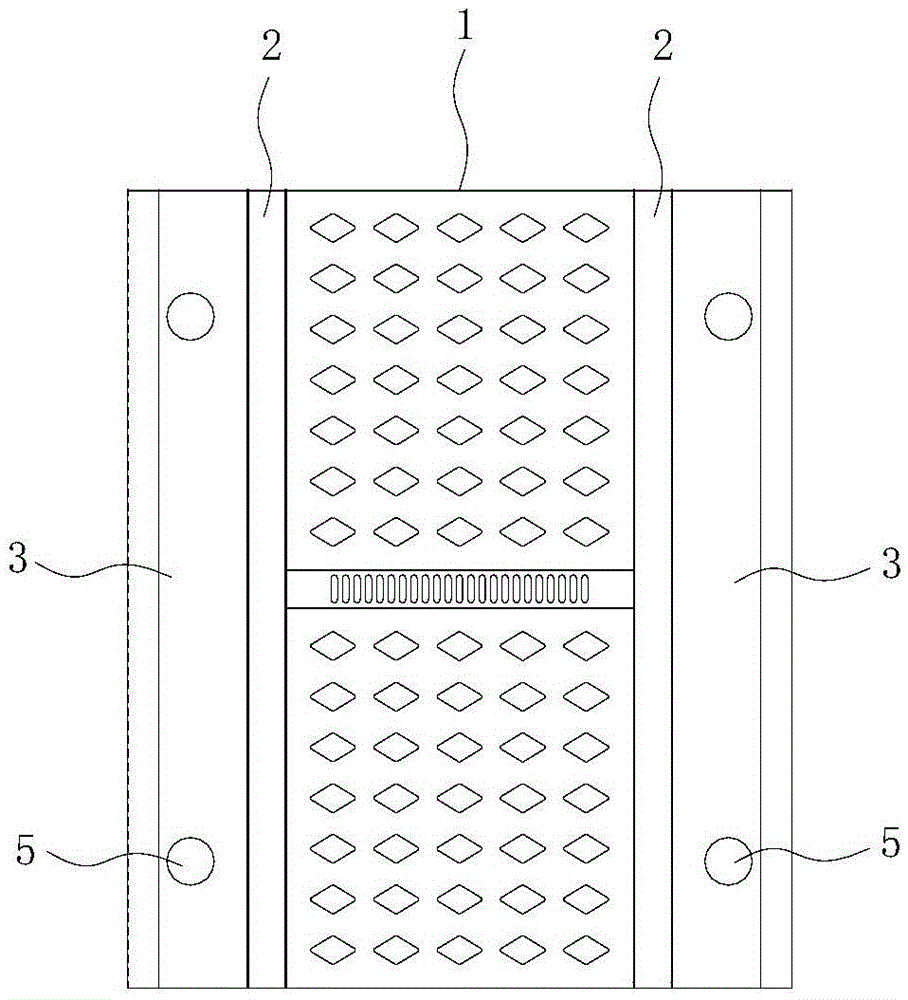

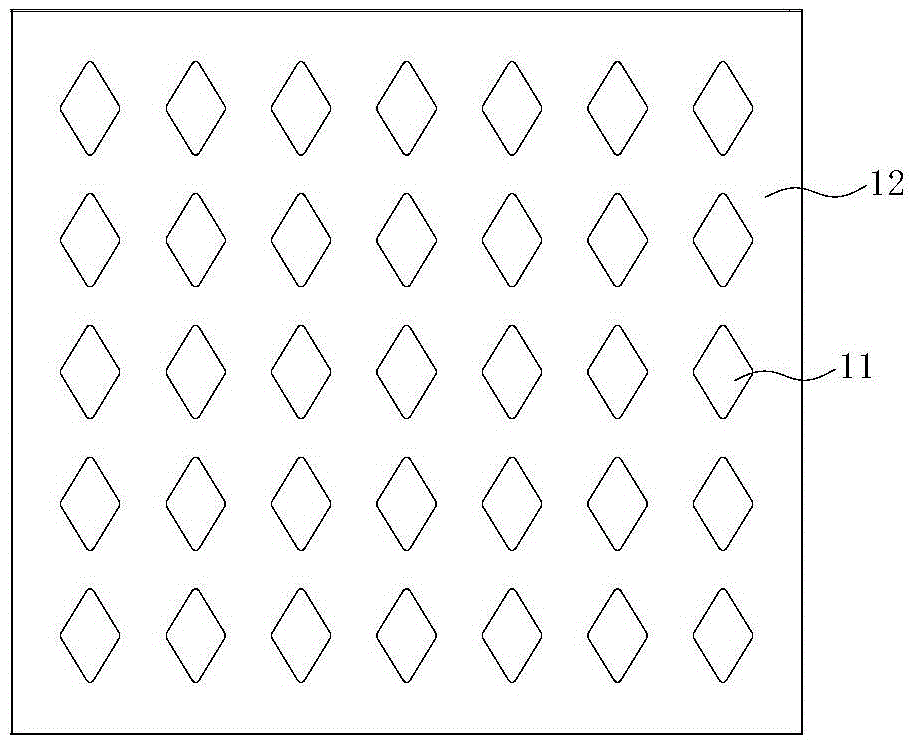

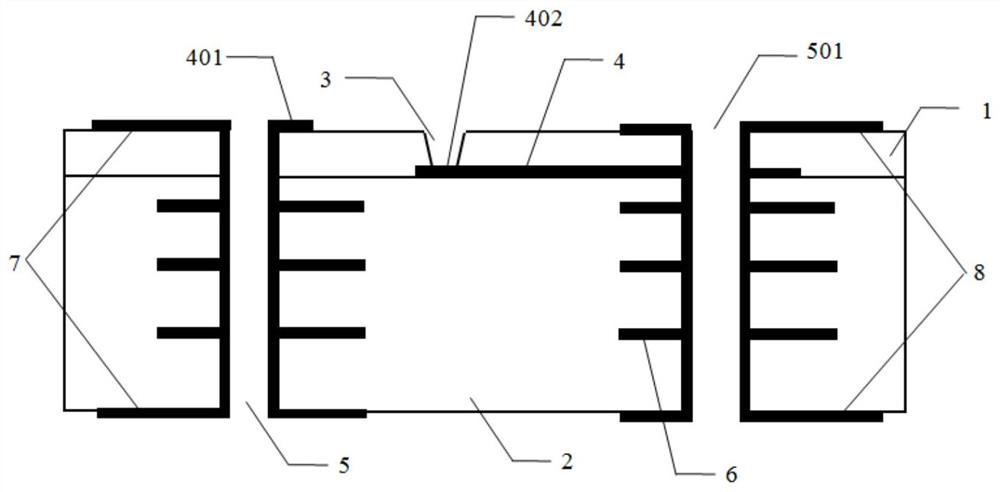

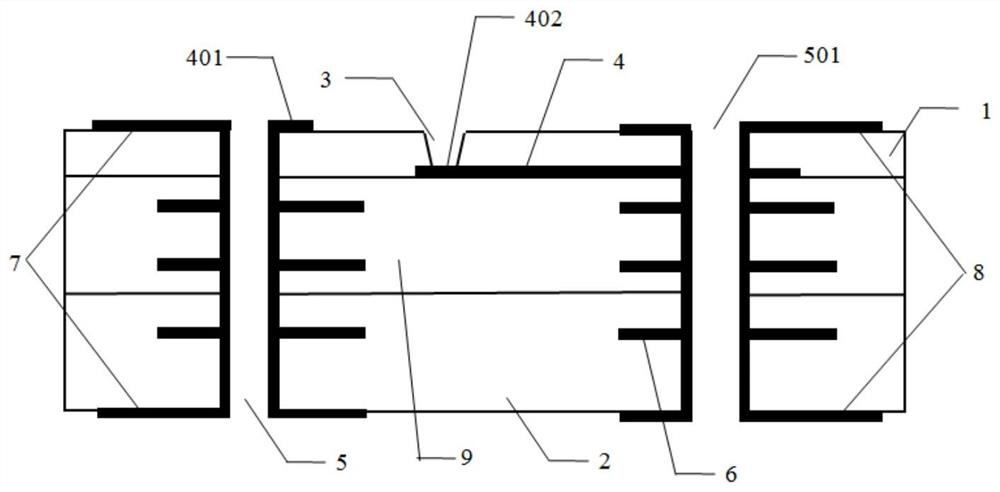

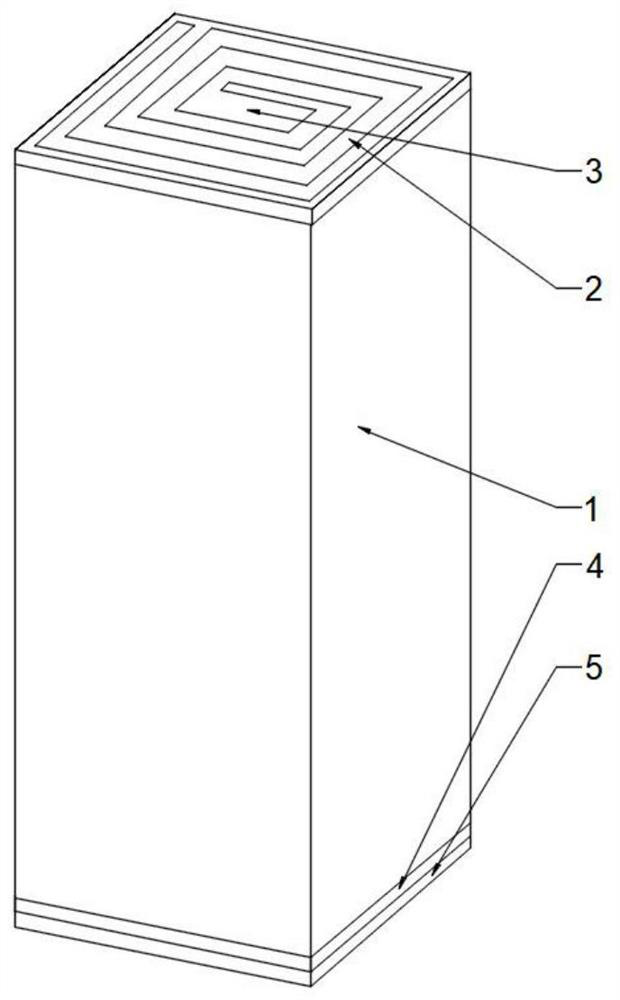

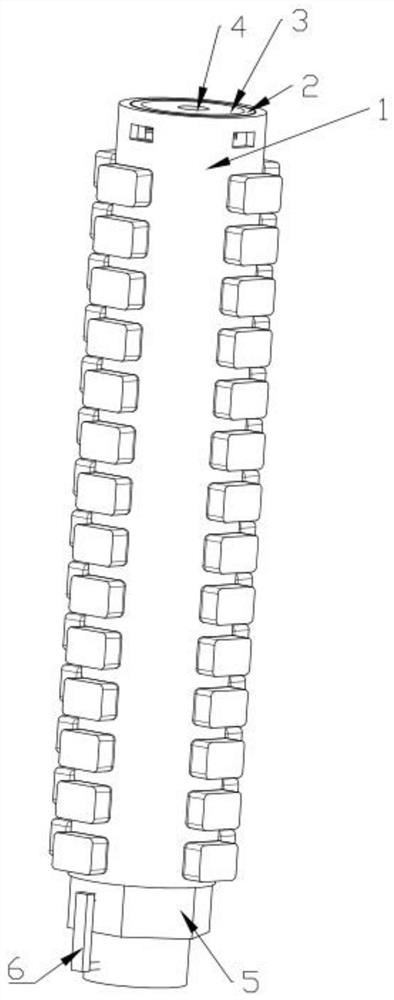

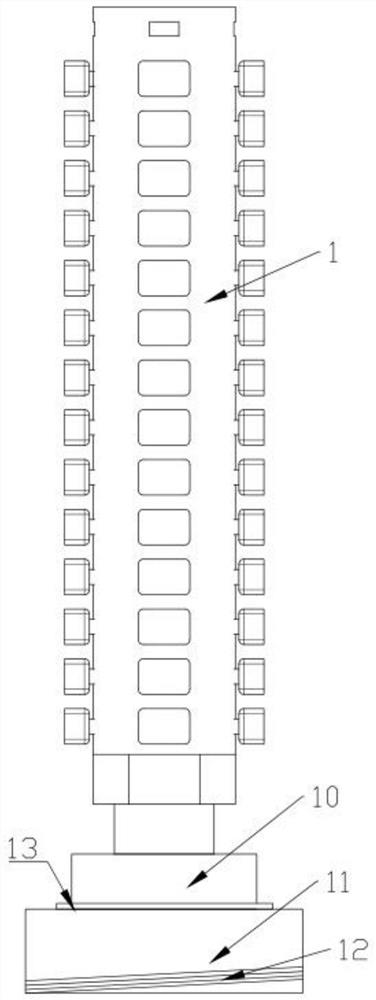

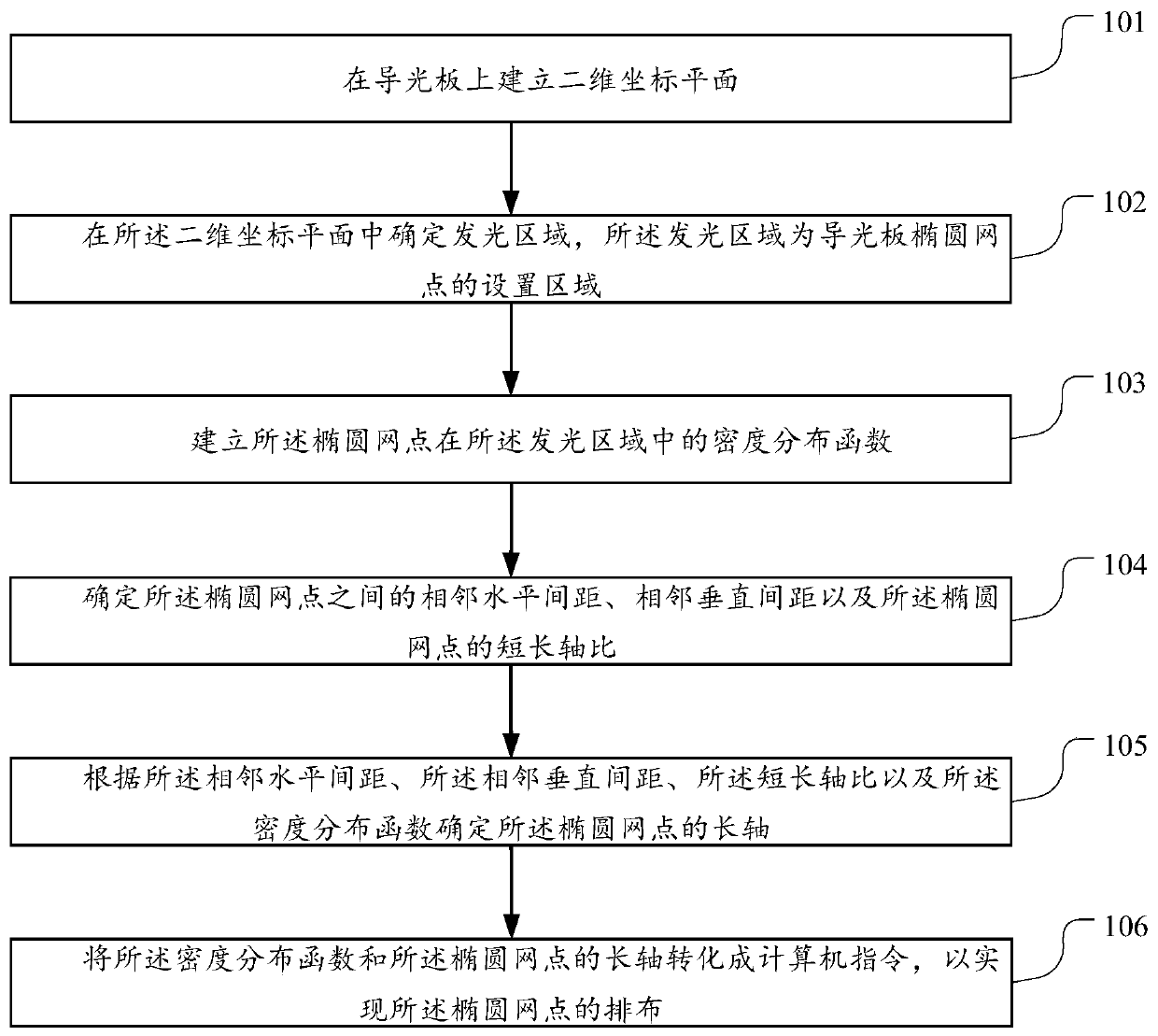

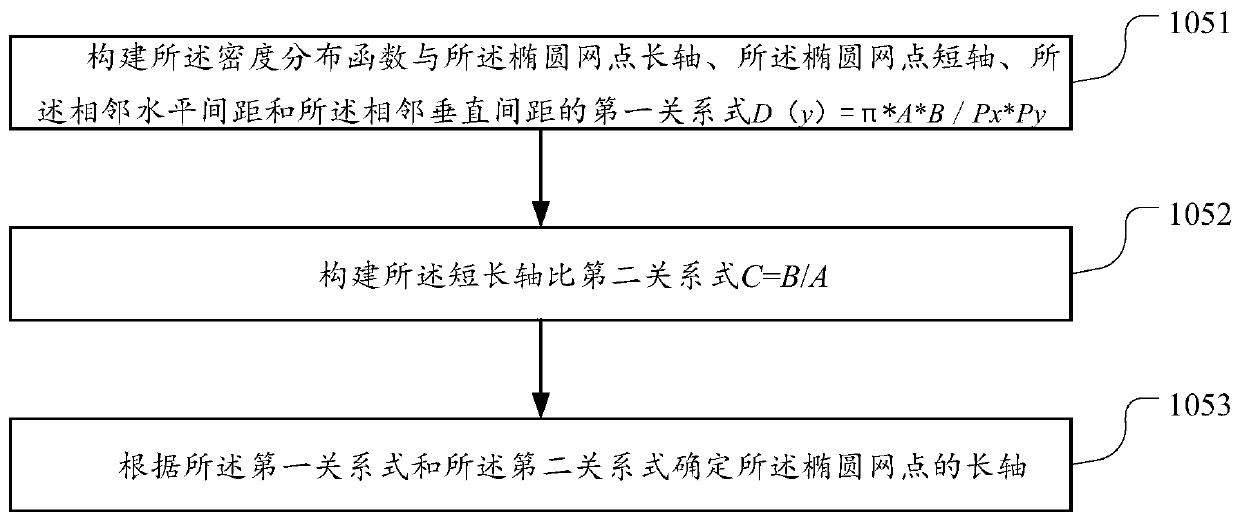

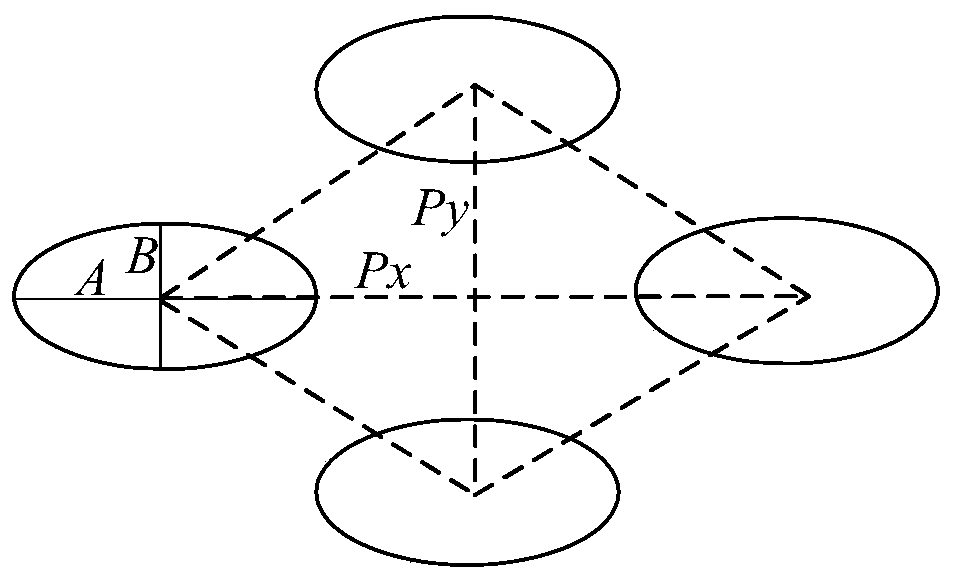

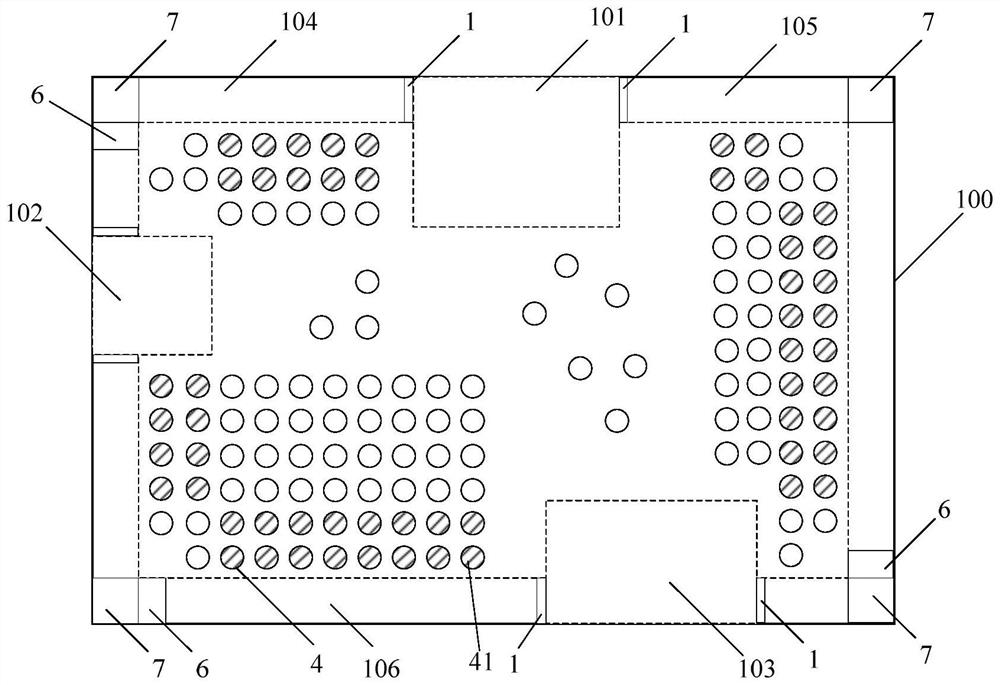

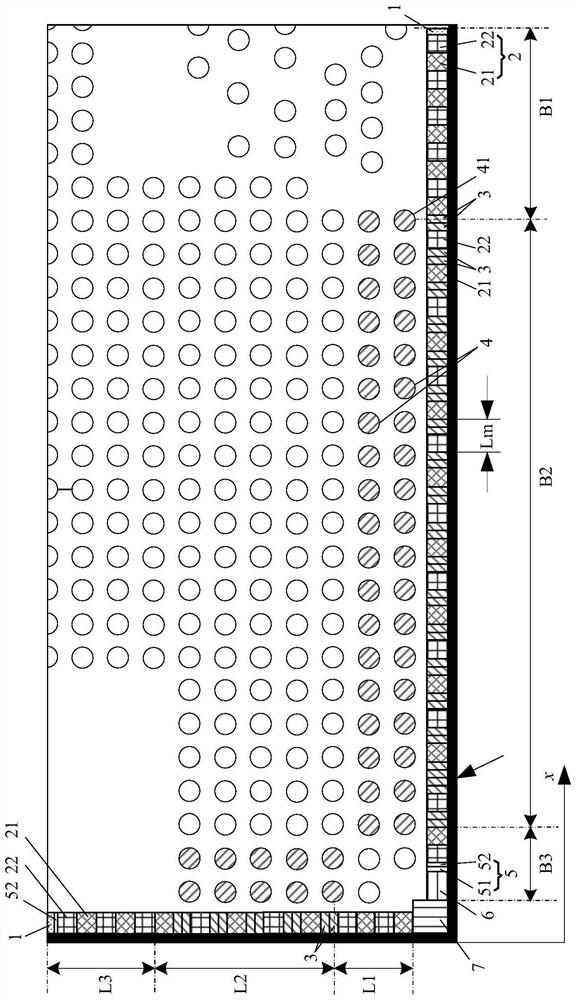

Light guide plate and elliptical dot designing method and device thereof

ActiveCN106646728AImprove light guide effectRealize arrangementOptical light guidesLaser processingAxial ratio

The invention relates to the technical field of light guide plate design and discloses a light guide plate and an elliptical dot designing method and device of the laser-processing light guide plate. The elliptical dot designing method includes: building a two-dimension coordinate plane on the light guide plate; determining a light emitting area in the two-dimension coordinate plane; building a density distribution function of elliptical dots in the light emitting area; determining adjacent horizontal interval and adjacent vertical interval among the elliptical dots and short-long axial ratio of the elliptical dots; determining long axis of the elliptical dots according the the adjacent horizontal interval, the adjacent vertical interval, the short-long axial ratio and the density distribution function; converting the density distribution function and the long axis of the elliptical dots into a computer instruction to realize distribution of the elliptical dots. Length of the long axis of the elliptical dots acquired by calculation is closer to actual distribution of dots compared with conventional linear dots, so that light guide effect of the light guide plate is improved effectively.

Owner:CHUZHOU HKC OPTOELECTRONICS TECH CO LTD

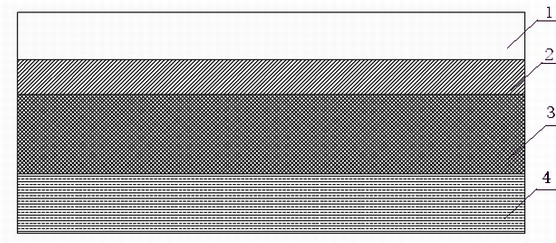

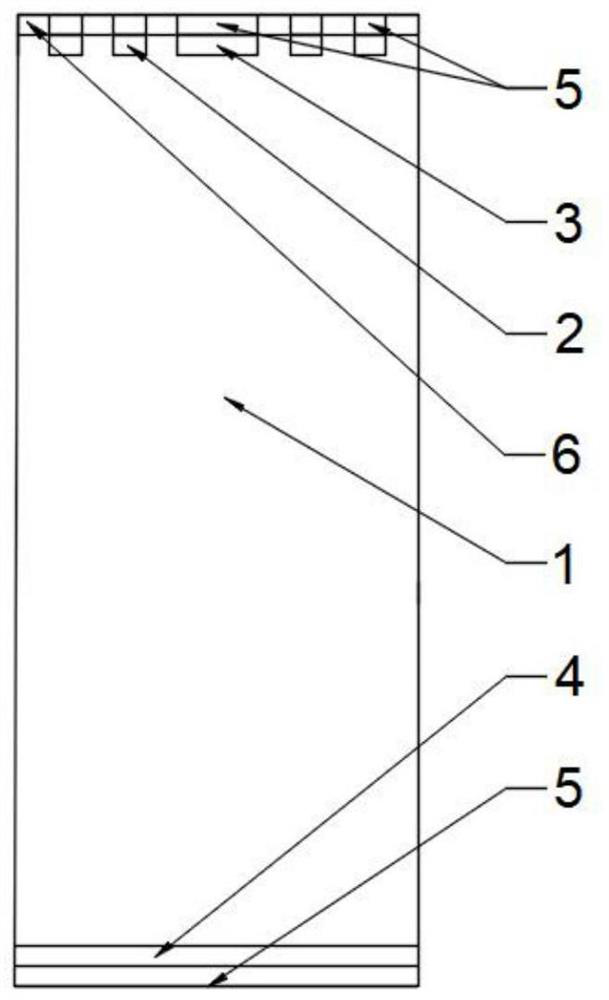

Conductive core plate and manufacturing method

PendingCN111834478ARealize arrangementReduce investment timeFinal product manufacturePhotovoltaicsElectrically conductiveEngineering

The invention discloses a conductive core plate and a manufacturing method. The conductive core plate comprises an insulating material layer, a metal conductive circuit layer, a packaging adhesive film layer and a back plate layer in sequence from top to bottom, wherein all the layers are bonded in a low-temperature heating mode; the metal conductive circuit layer and the packaging adhesive film layer are compounded and bonded, and a conductive circuit diagram is arranged on the metal conductive circuit layer; a plurality of small holes are formed in the insulating material layer, and the positions of the holes correspond to the positions of electrode points on the battery piece; the conductive circuit diagram takes set unit patterns as a basis, and the unit patterns are arranged above thebattery piece in an array manner. According to the invention, the conductive core plate adopts a longitudinal cardinal number column 13*12 half-cut battery arrangement mode, and the cardinal number column battery arrangement is achieved; meanwhile, the number of the batteries connected with the diodes is equal, the installation direction of a junction box is parallel to the short edges of the assembly and is the same as the position of a junction box of a conventional assembly, and if the connection mode is a solder strip assembly, the connection mode is hardly achieved, and the equipment transformation cost can be effectively reduced at the same time.

Owner:JIANGSU SUNPORT POWER CORP LTD

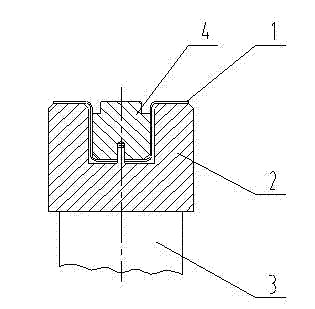

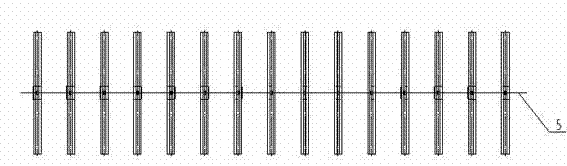

Linear measurement arrangement method for stainless steel vehicle roof cap-shaped curved beams

InactiveCN102818506ARealize arrangementRealize measurementMechanical clearance measurementsStraightedgeMarine engineering

The invention relates to a linear measurement arrangement method for stainless steel vehicle roof cap-shaped curved beams, which is characterized by comprising the following steps of: firstly, placing one stainless steel vehicle roof cap-shaped curved beam with a center hole in a groove body with a center positioning pin, arranging one measuring block of which the center of the bottom is provided with a pinhole on the upper surface of the stainless steel vehicle roof cap-shaped curved beam, enabling the pinhole at the bottom of the measuring block to be coaxially matched with the center positioning pin of the groove body for leading the center of the stainless steel vehicle roof cap-shaped curved beam, which is positioned at the bottom of a groove and cannot be measured, to the top surface and determining the center positioning of the stainless steel vehicle roof cap-shaped curved beam; and then, for a plurality of groups of stainless steel vehicle roof cap-shaped curved beams of a vehicle, aligning center mark points on the upper surfaces of a plurality of measuring blocks, connecting the center mark points into a line and carrying out interval size arrangement and measurement by using a straightedge rule. According to the invention, one measuring block of which the center of the bottom is provided with the pinhole is arranged on the upper surface of one stainless steel vehicle roof cap-shaped curved beam, the pinhole at the bottom of the measuring block is coaxially matched with the center positioning pin of the groove body to lead the center at the bottom of the groove, which cannot be measured, to the top surface, the center mark points of a plurality of measuring blocks are aligned and connected into one line, and the interval size arrangement and measurement are implemented by the center marks on the top surfaces of the measuring blocks through using the straightedge rule.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

Elevator car roof structure

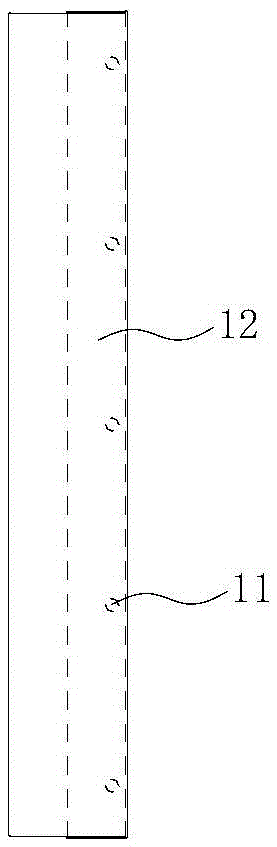

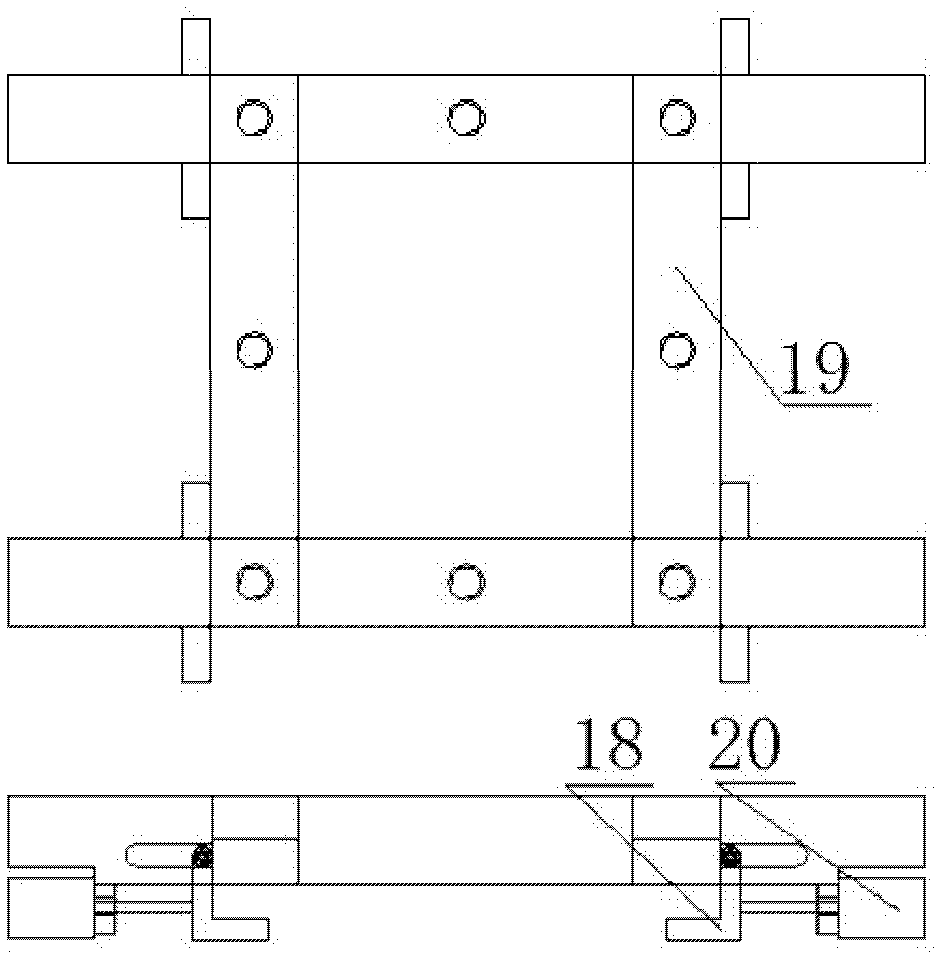

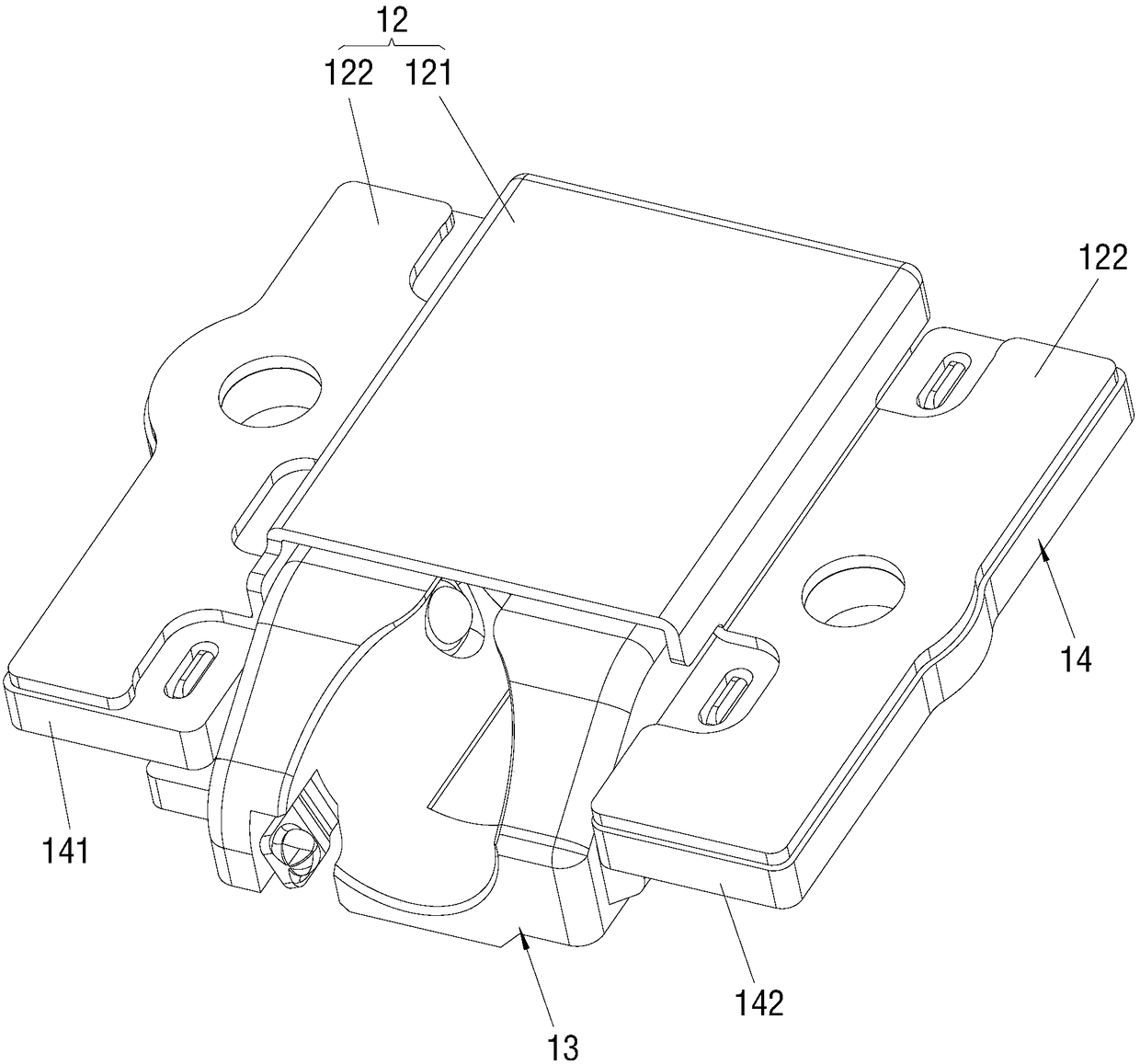

The invention relates to the field of elevators, and discloses an elevator car roof structure. The elevator car roof structure comprises a car roof assembly, first connecting parts are symmetrically connected to the two sides of the car roof assembly, a second connecting part is arranged on the side, far away from the car roof assembly, of each first connecting part, the length of the car roof assembly, the length of the first connecting parts and the length of the second connecting parts are the same, and multiple through holes which are formed in an array mode are formed in the car roof assembly. According to the elevator car roof structure, due to the fact that the first connecting parts are symmetrically arranged on the two sides of the car roof assembly, and the second connecting parts are connected to the outer sides of the first connecting parts respectively, on one hand, an existing car roof structure is simplified; on the other hand, the manufacturing cost is also reduced. Meanwhile, multiple through holes are formed in the car roof assembly in the array mode, ventilation of a car roof and arrangement of decorative lamps in an elevator car can be achieved.

Owner:KUNSHAN FEIPENG METAL IND CO LTD

High-performance network security cabinet that facilitates cable management

PendingCN110868825ARealize arrangementGuaranteed cooling effectCasings/cabinets/drawers detailsFire rescueSolenoid valveEmbedded system

The invention discloses a high-performance network security cabinet that facilitates cable management, and relates to the technical field of network security cabinets in order to solve the problem that connecting wires between various components of a high-performance network security cabinet on the market are scattered inside the cabinet and are prone to knotting, which is not only inconvenient for the maintenance of a circuit, but also affects the appearance inside the cabinet. A control device is fixedly connected to the upper end of the outside of a network security cabinet body. A fire hydrant placing box is fixedly connected to the edge side of the lower end of the network security cabinet body. A control solenoid valve is fixedly connected to the upper end of a dry powder fire hydrant. Universal wheels are fixedly connected to the lower end of the network security cabinet body at the inner side of a support base. One end of a mounting plate is fixedly connected to the inner sideof a movable cabinet door. A temperature sensor and a smoke sensor are fixedly connected to the inner side of a cooling fan at the inner upper end of the network security cabinet body.

Owner:苏州嘉盛科技电讯有限公司

Chip with composite layer and application of chip in biological detection

PendingCN111849735ARealize arrangementLow costBioreactor/fermenter combinationsBiological substance pretreatmentsHemt circuitsEngineering

The invention provides a chip with a composite layer and application of the chip in biological detection. The chip comprises at least a first base layer and a second base layer which are arranged along a vertical direction, wherein at least one first blind hole leading to the second base layer is formed in the first base layer, at least one metallized via hole penetrating through the second base layer is formed in the chip, an electrode is arranged below the first blind hole, the chip is provided with a contact, and the electrode is connected with the contact through a circuit. According to the invention, plastic and metal are combined to develop the chip with the composite layer, the basic functions of the chip are realized through reasonable layout of the base layer, a circuit layer andan internal circuit of the chip, and the chip is simple to manufacture and low in cost.

Owner:QITAN TECH LTD CHENGDU

Image processing apparatus, image processing process and program

InactiveUS20040263883A1Reduce the possibility of overlapImprove featuresDigitally marking record carriersDigital computer detailsPattern recognitionImaging processing

In an image processing method, on the basis of input image data with respect to a target pixel, independent multi-level data (g0, g1) corresponding to respective plural species of dots which are different in at least one of a density and a diameter are generated, and then data (O0, O1) relating to an amount of generation of the dots with respect to the target pixel are generated on the basis of a relationship between the generated independent multi-level data (g0, g1) corresponding to the plural species of dots. The image processing method is effective in performing design having a high degree of flexibility in proper use of a relatively high power dot (high density dot or large dot) and a relatively low power dot (low density dot or small dot) and can realize obviation or alleviation of an occurrence of granulation or an apparent frame caused due to the relatively high power dot.

Owner:CANON KK

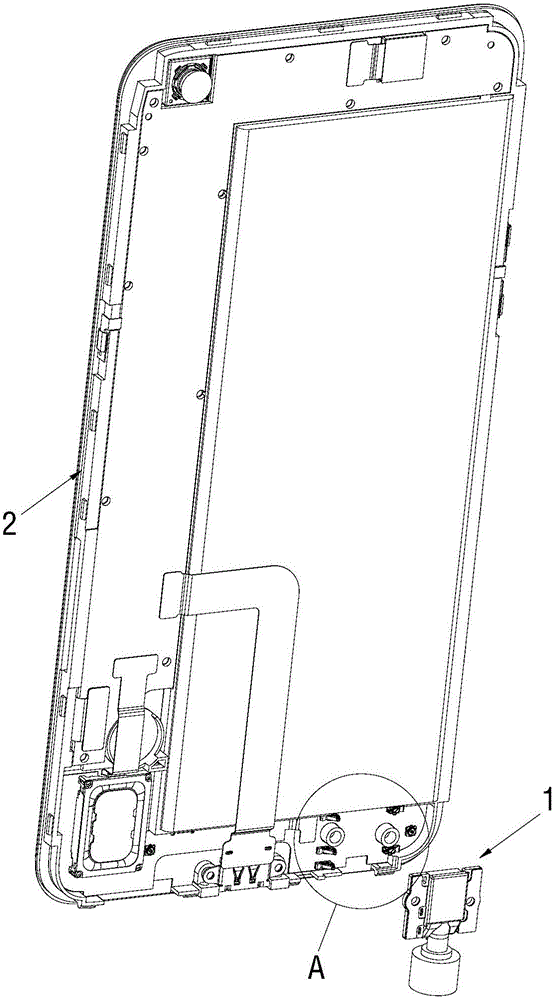

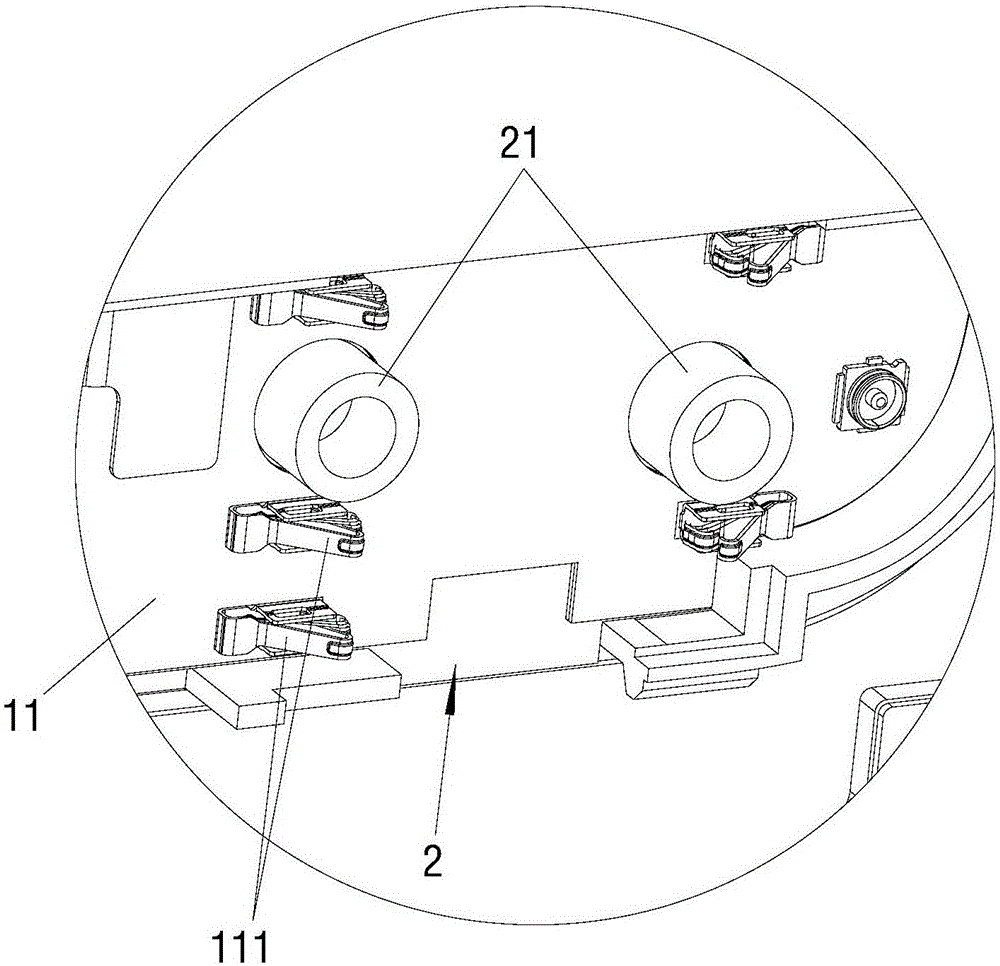

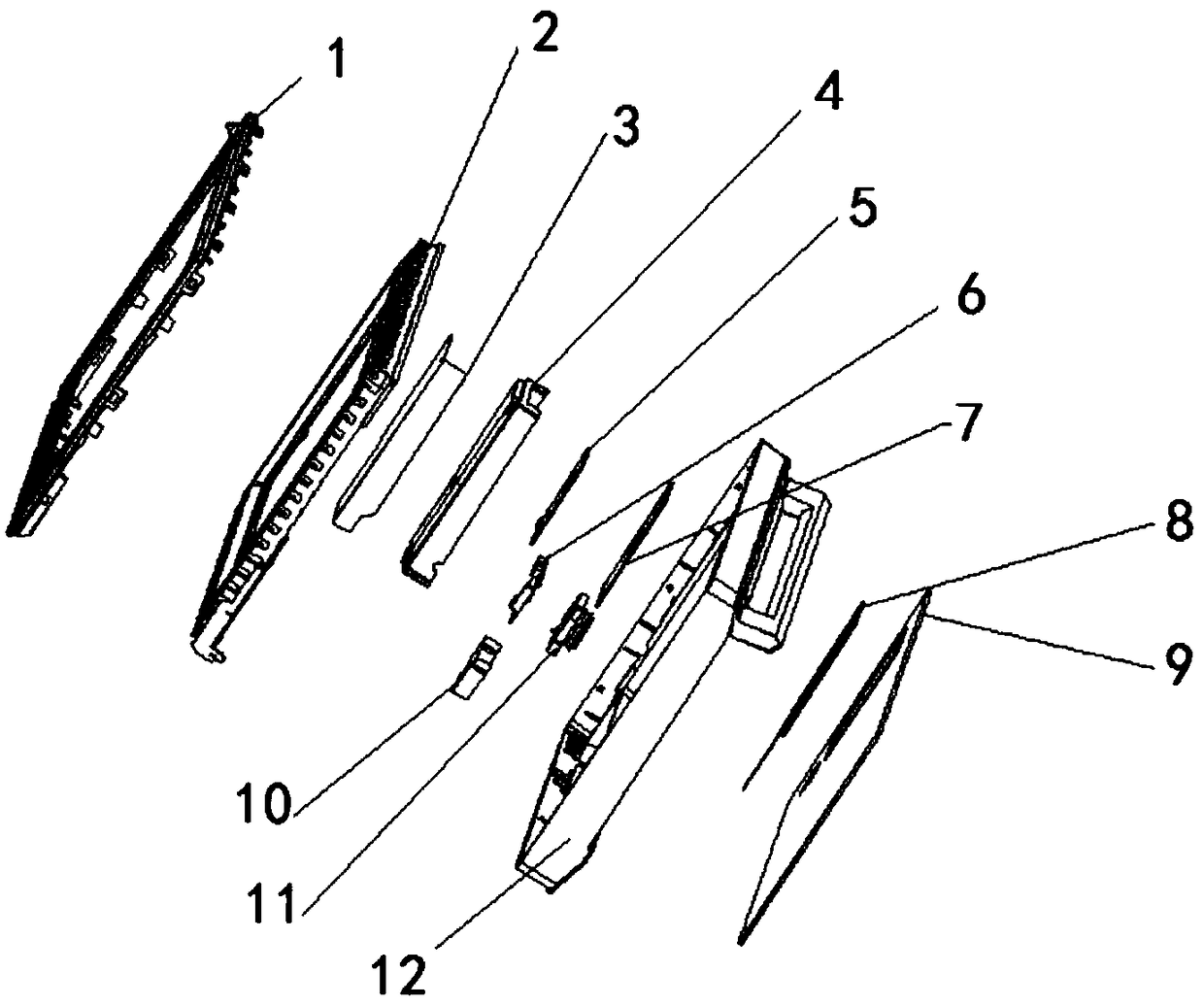

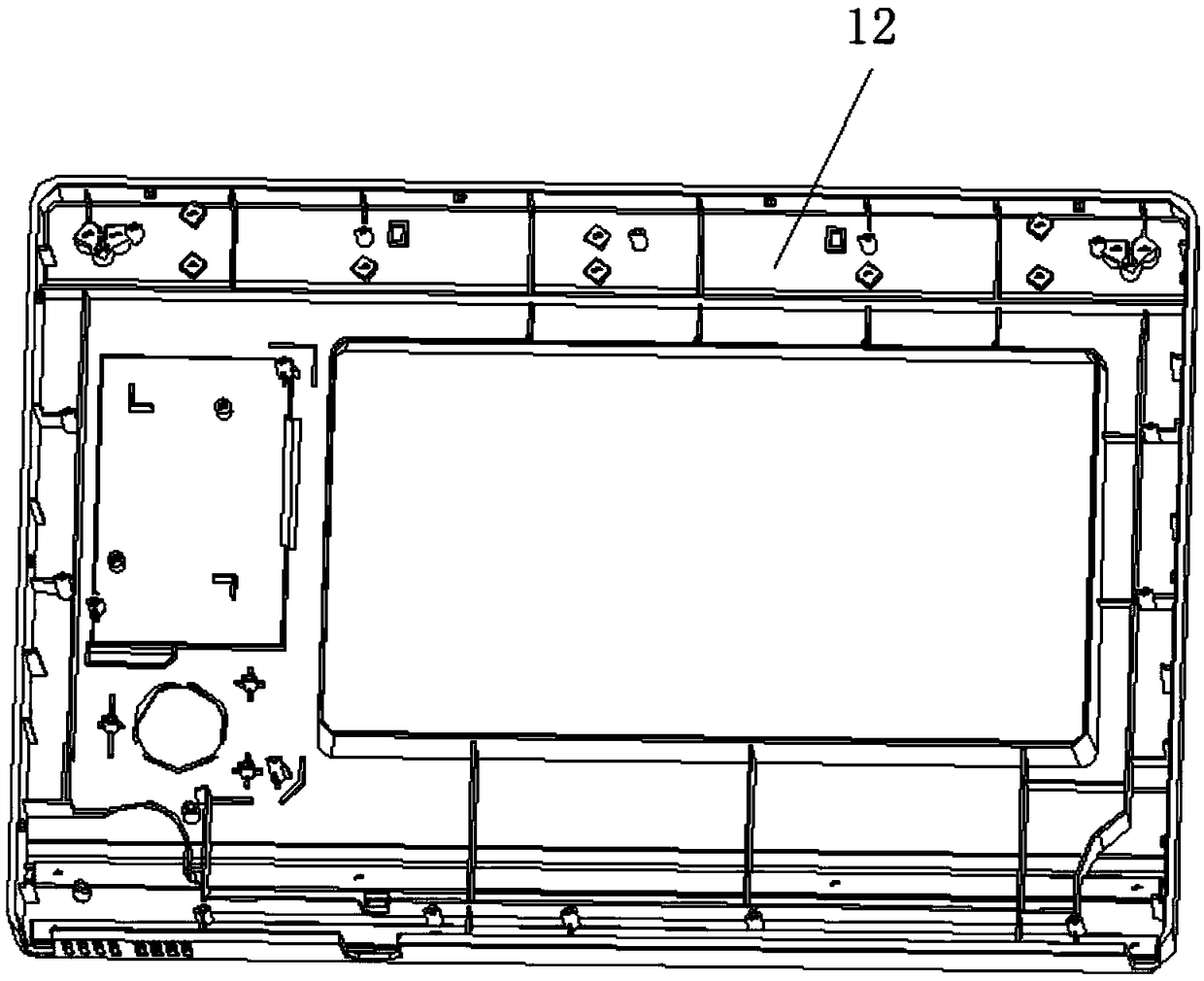

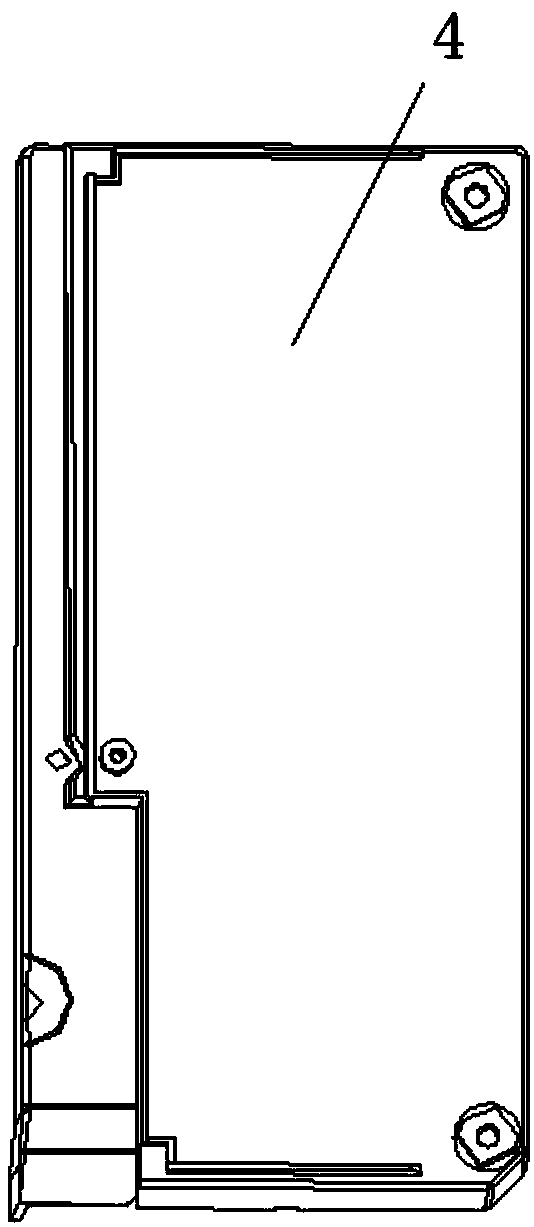

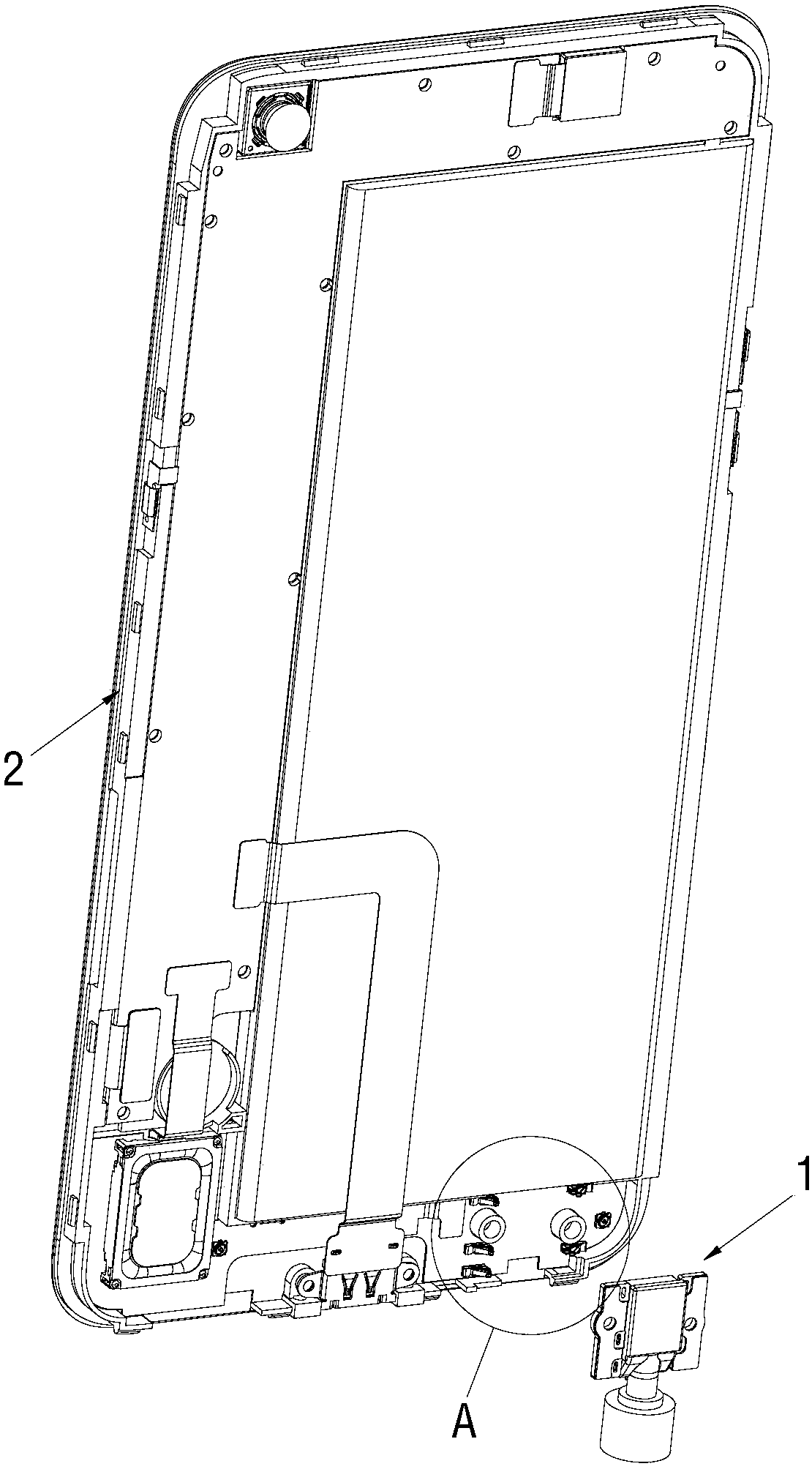

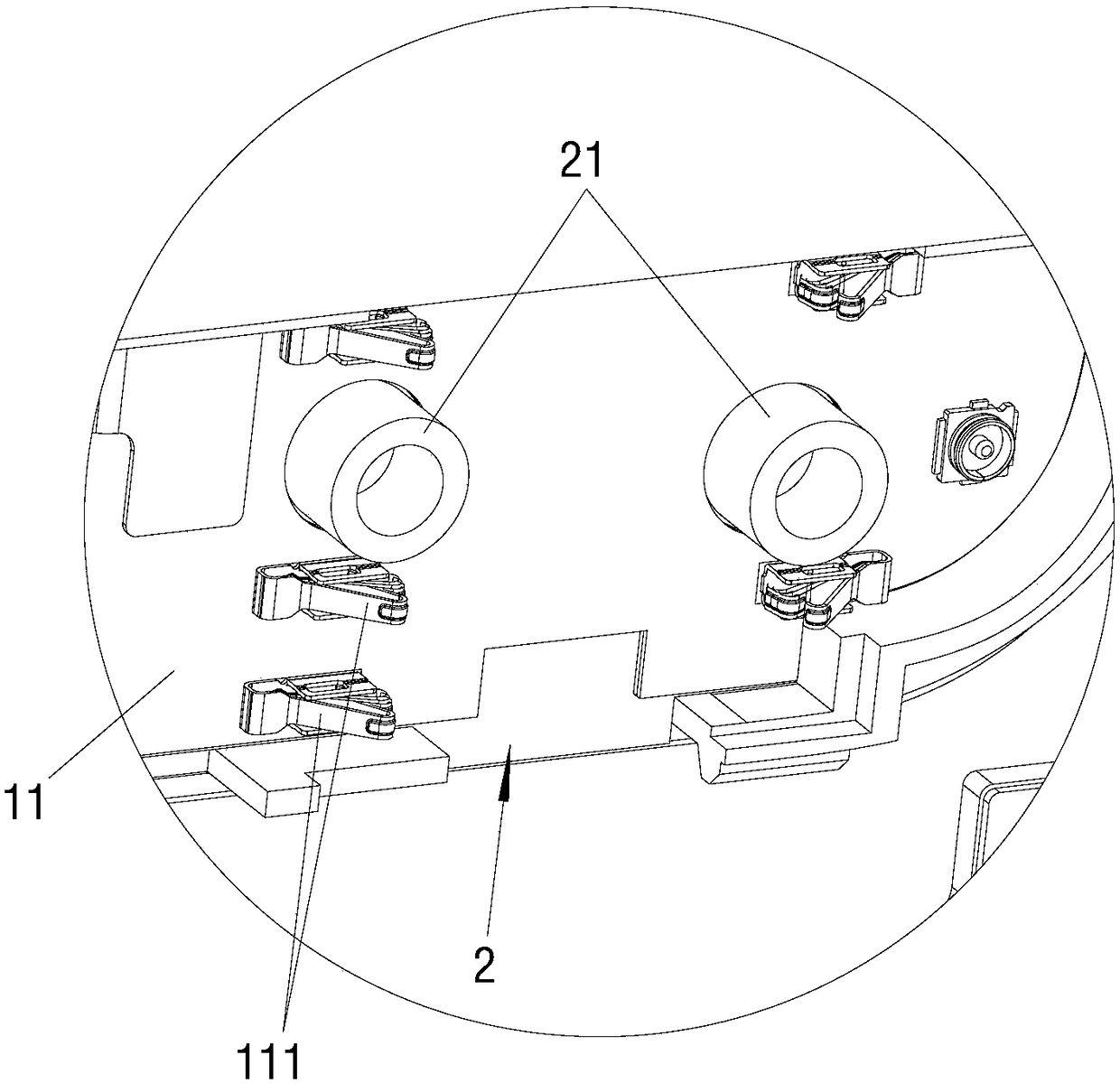

Earphone seat assembly structure and mobile terminal

The invention relates to the technical field of mobile terminals and discloses an earphone seat assembly structure and a mobile terminal. The earphone seat assembly structure comprises a FPC plate which is arranged inside a mobile terminal housing bottom side, a base support which is fixed inside the housing bottom side, an earphone seat and an earphone PCB which is electrically connected with the earphone seat. The earphone seat and the earphone PCB are fixed inside the base support; the earphone PCB and the FPC plate are electrically connected. The mobile terminal comprises a housing and an earphone seat assembly structure which is installed inside the housing. According to the above description, the earphone PCB and the earphone seat are fixed inside the housing bottom side through the seat support and are electrically connected with each other; the earphone seat and the FPC plate are electrically connected through the electrical connection between the earphone PCB and the FPC plate. Therefore, the earphone seat assembly structure can be configured inside the housing bottom side without increasing the thickness of the whole mobile terminal and under the circumstance that there is no space at the earphone seat top side for arranging a PCB.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Machine for enabling stick to penetrate through corn

InactiveCN107997221ARealize stick operationRealize arrangementFood shapingMechanical engineeringEngineering

The invention relates to a machine for enabling a stick to penetrate through corn. The machine comprises a material storing cylinder which is horizontally arranged, wherein a pressing plate is arranged at one end of the material storing cylinder; the plate surface of the pressing plate is vertical and is perpendicular to the length direction of the material storing cylinder, and a material distributing plate is arranged at the other end of the material storing cylinder; a stick clamping groove for clamping inserting sticks is formed in the vertical plate surface of the material distributing plate; the length direction of the stick clamping groove is parallel to the length direction of the material storing cylinder; an inserting stick distributing mechanism is arranged on the material distributing plate, and is interlocked with each inserting stick, so that each inserting stick is clamped in the stick clamping groove; a positioning plate is arranged on the side of the material distributing plate; the plate surface of the positioning plate is parallel to the material distributing plate; a driving mechanism is used for diving the pressing plate to be close to or away from one end of the material storing cylinder; the driving mechanism is started, and the pressing plate is close to the cylinder opening of the material storing cylinder, so that each corn is interlocked to move in the length direction of the material storing cylinder until the end part of each corn cob core is abutted to the end part of the corresponding inserting stick, and the operation of inserting the sticksin the corn is realized. Through the adoption of the machine for enabling a stick to penetrate through corn disclosed by the invention, the operation of enabling a stick to penetrate through a corn cob core can be convenient, and the efficiency of enabling a stick to penetrate through a corn cob core is improved.

Owner:李翠平

Display control assembly for microwave oven door, microwave oven door and microwave oven

InactiveCN109028175ASolve the fragileImprove assembly efficiencyDomestic stoves or rangesDoors for stoves/rangesProduction lineMicrowave oven

The invention relates to a display control assembly for a microwave oven door, a microwave oven door and a microwave oven. The display control assembly for the microwave oven door comprises a shell, atouch panel, a display panel and a computer board, wherein the touch panel, the display panel and the computer board are arranged in the shell; and the touch panel and the display panel are electrically connected with the computer board. According to the microwave oven door structure with a touch display function provided by the invention, the touch panel, the display panel and the computer boardare integrated into one module so as to be installed, so that a split type installation mode is changed into an integrated installation mode, the assembling efficiency of a production line is greatlyimproved, and meanwhile, the problem that the display panel and the touch panel are easy to damage during the installation process is solved; and once if a touch display function is failed, only thedisplay control assembly needs to be replaced in time, so that the convenience in repair is improved.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

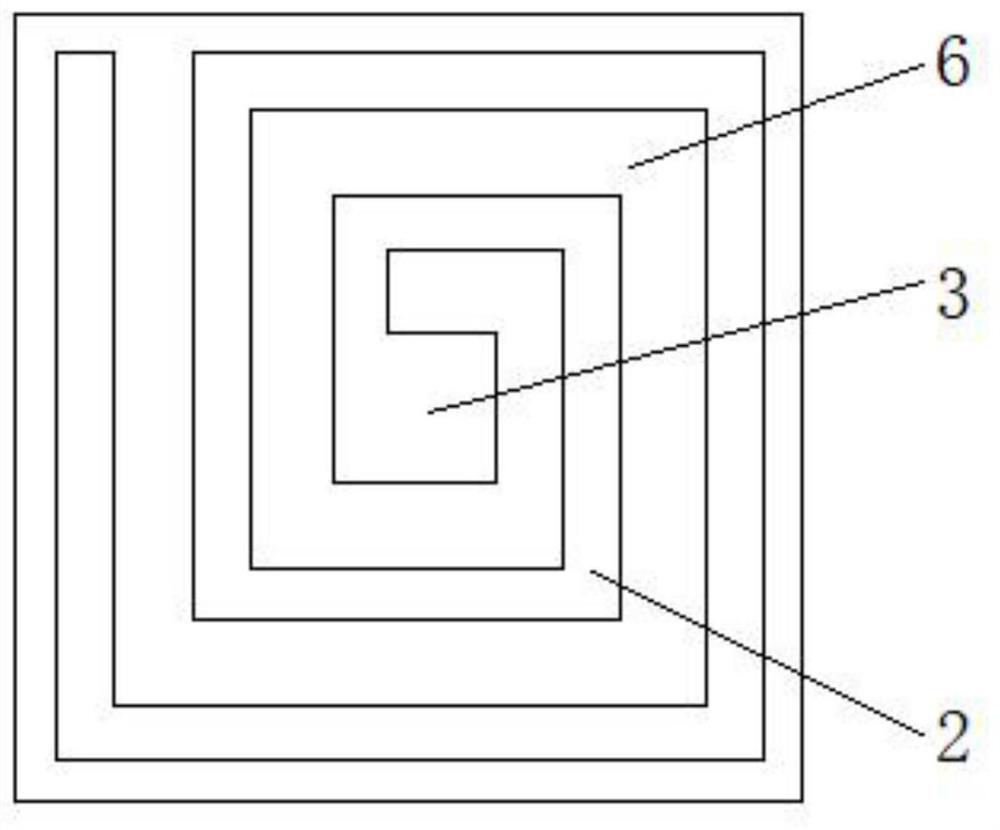

Spiral ring electrode silicon array detector

PendingCN112071945ALeakage current and capacitance are smallReduce noiseSemiconductor devicesSurface electrodeCapacitance

The invention discloses a spiral ring electrode silicon array detector, and relates to the technical field of radiation detection. The area of a spiral ring electrode of the detector is far smaller than that of a traditional whole-surface electrode, the leakage current and capacitance are smaller, the noise is small, and the energy resolution is high. According to existing processes, the pixel canbe in a micro-nano level, and the position resolution is very high; the detector can flexibly set a pressurization mode, the design of the spiral ring enables the electrode to have enough space to serve as a reading electrode or apply bias voltage. The detector comprises a cylindrical substrate, the top surface of the substrate is provided with a cathode jointly formed by a spiral ring electrodeformed by doping and a central electrode, and the central electrode is located in the center of the spiral ring electrode. The spiral ring electrode surrounds the central electrode, the number of spiral rings of the spiral ring electrode is K, K is a positive integer, and the bottom surface of the substrate is an anode formed by doping; and an electrode contact layer is arranged on the electrode on the top surface of the substrate, SiO2 covers the part without the electrode contact layer, and an electrode contact layer is arranged on the whole electrode on the bottom surface of the substrate.

Owner:LUDONG UNIVERSITY

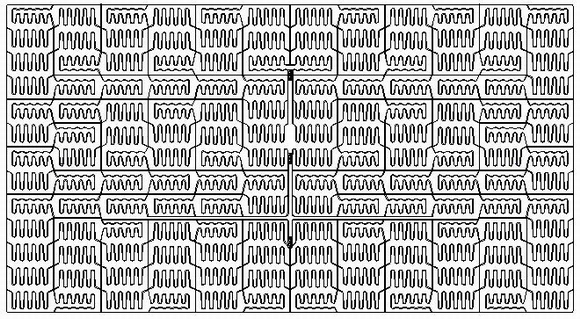

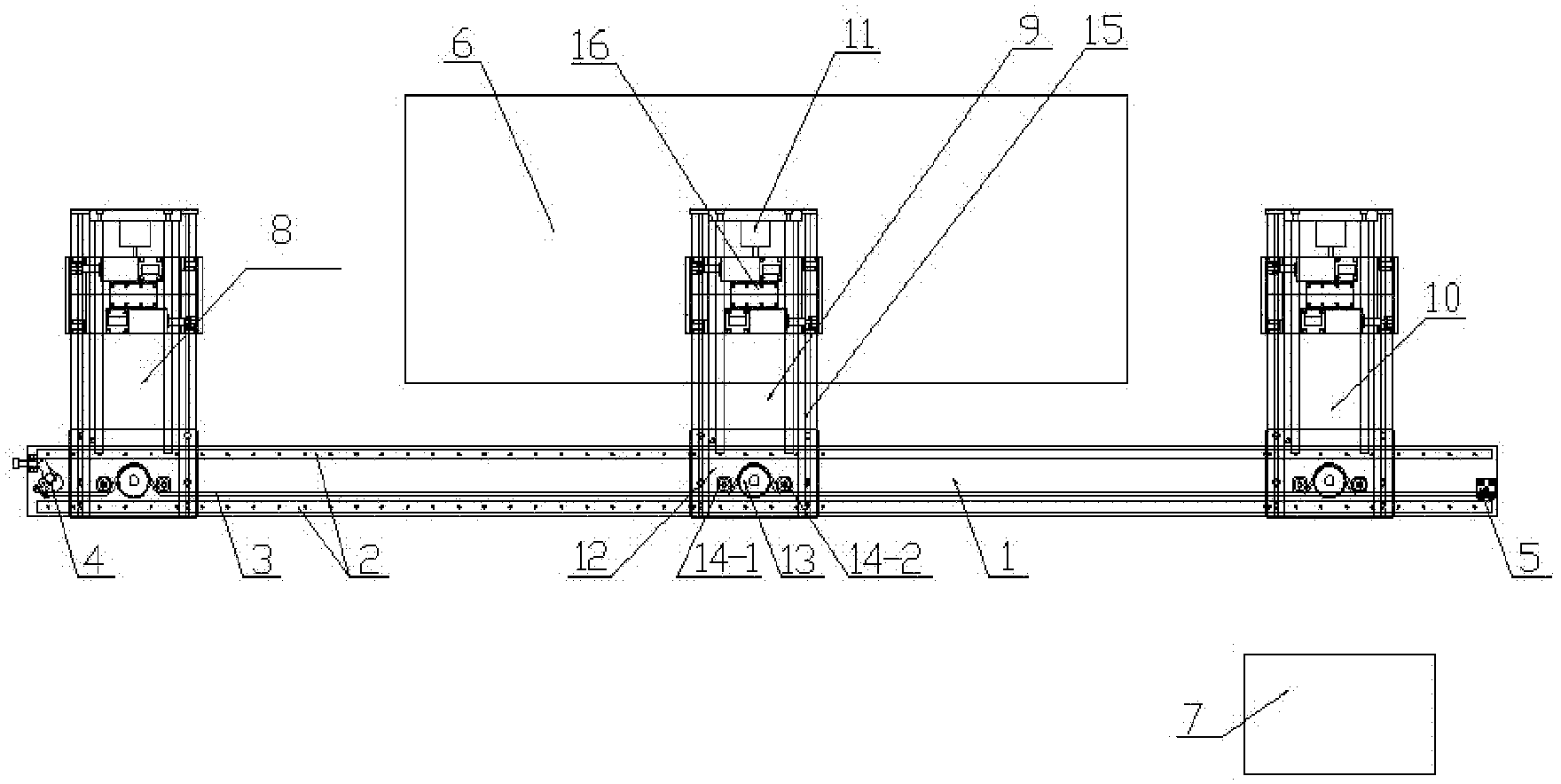

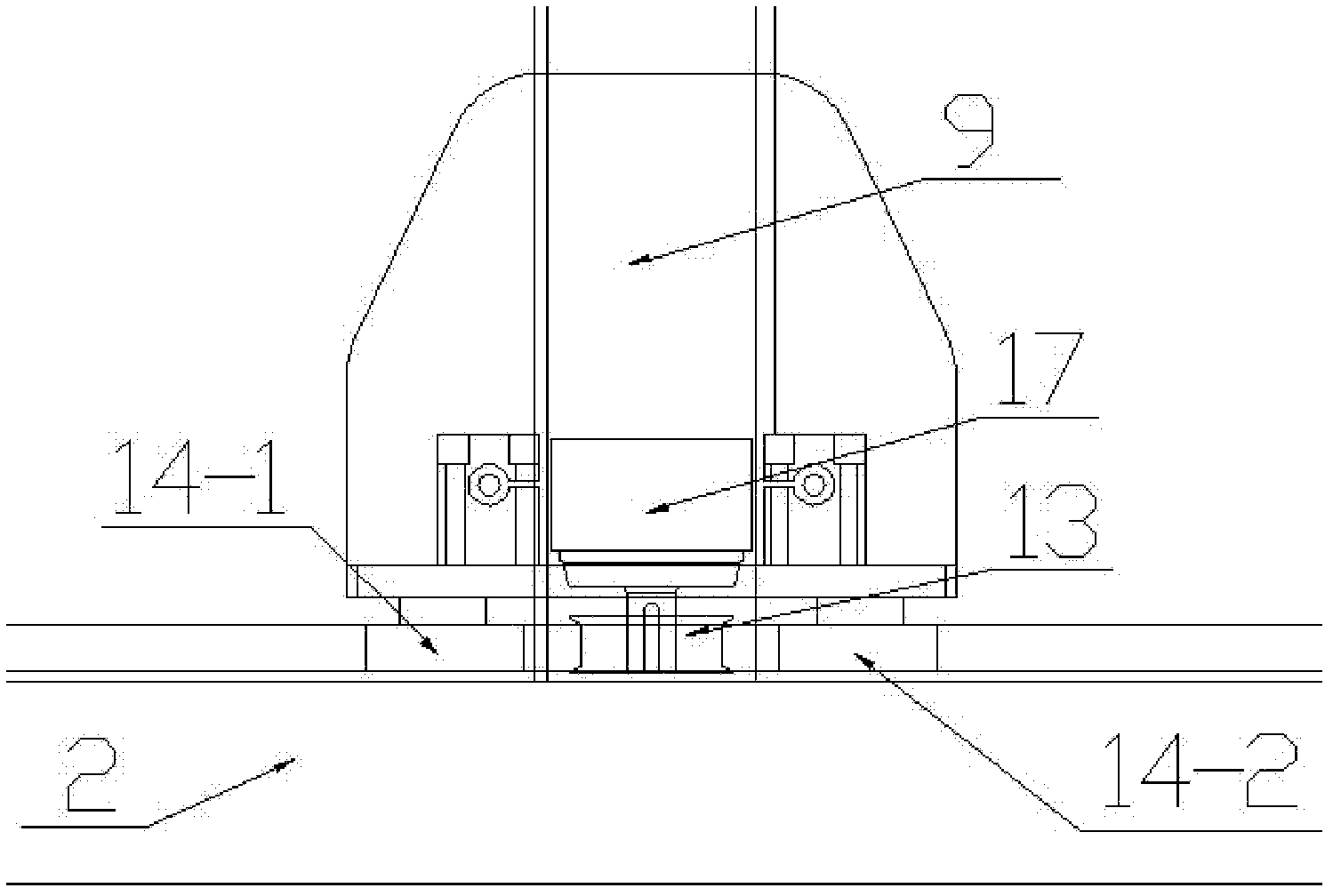

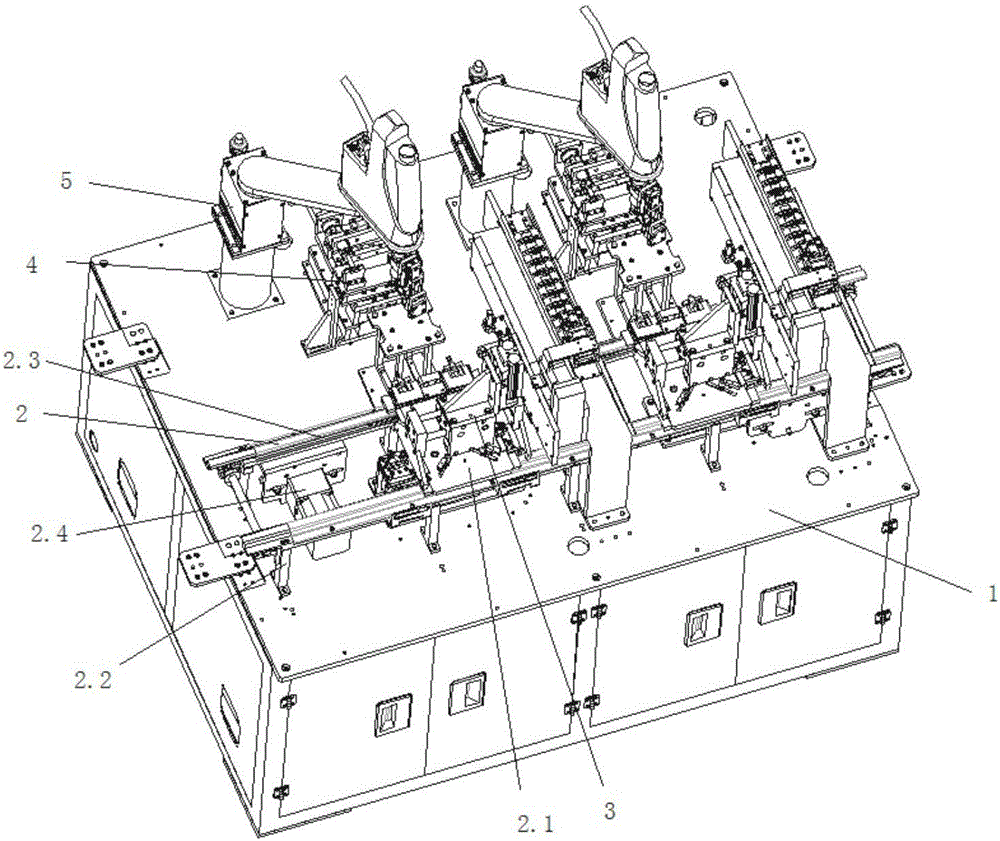

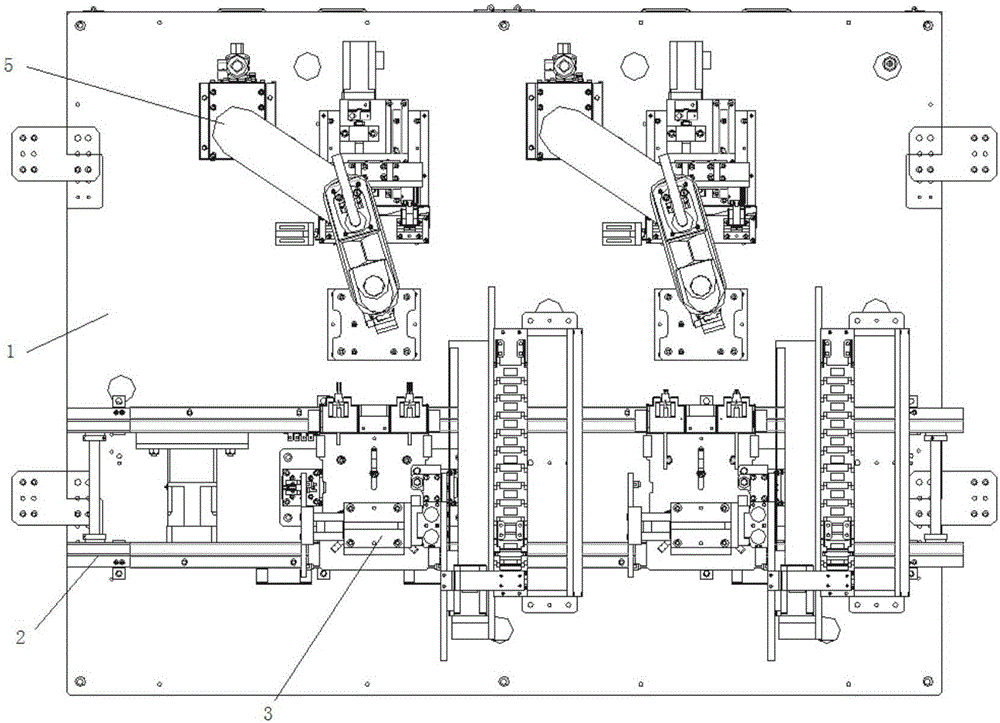

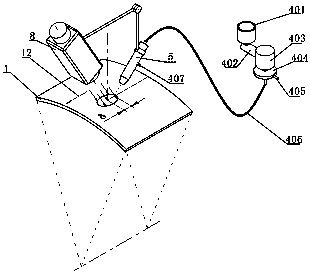

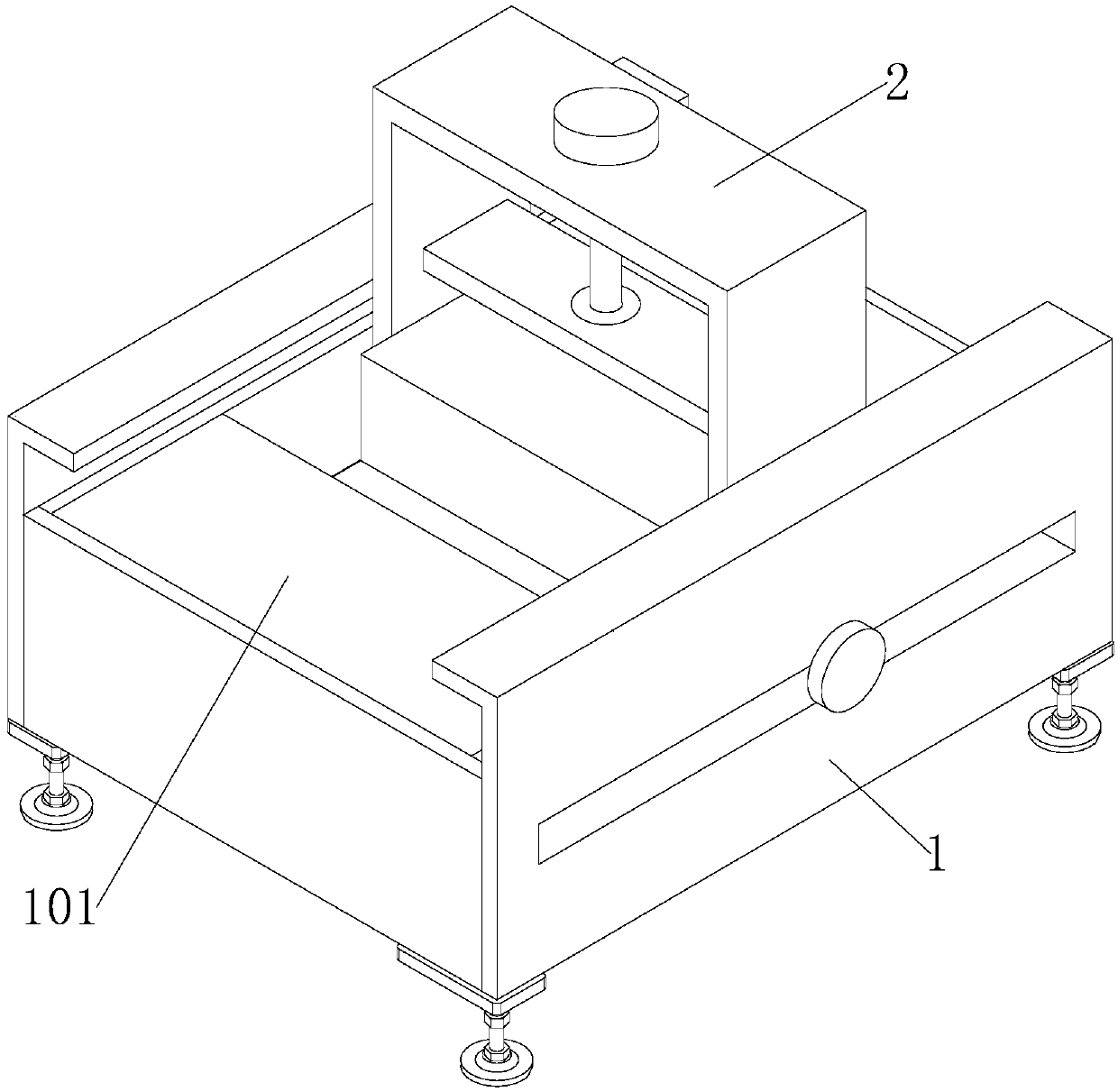

Industrial manipulator applicable to automatic arrangement and welding of solar photovoltaic cell

ActiveCN102528355ARealize fully automated handlingRealize arrangementProgramme-controlled manipulatorWelding/cutting auxillary devicesRobotic armEngineering

The invention discloses an industrial manipulator applicable to automatic arrangement and welding of a solar photovoltaic cell. The industrial manipulator comprises a pedestal, a sliding rail, a sliding platform, three mechanical arms, a servo motor, a synchronous pulley, a synchronous belt, a welding gun, a cylinder, a control cabinet, a fixture 1 and a fixture 2, wherein the sliding rail is arranged on the pedestal; the three manipulators are arranged on the sliding rail; the servo motor is arranged in each manipulator shell; a motor main shaft is connected with the synchronous pulley; the synchronous belt is engaged with the synchronous pulley, and the two ends of the belt are fixed inside the sliding rail and are tightened; the side face of a slide block is provided with a pulling device; and the pulling device is connected with one cylinder and is provided with the cylinder. The industrial manipulator has the advantages of simple structure, reliable control, accurate positioning and the like; the work of two workers for clamping and handling the photovoltaic cell during charging and discharging is substituted; the welding stability is guaranteed; the cost is greatly reduced; and the efficiency and the safety are improved.

Owner:宁波贝达新能源科技有限公司

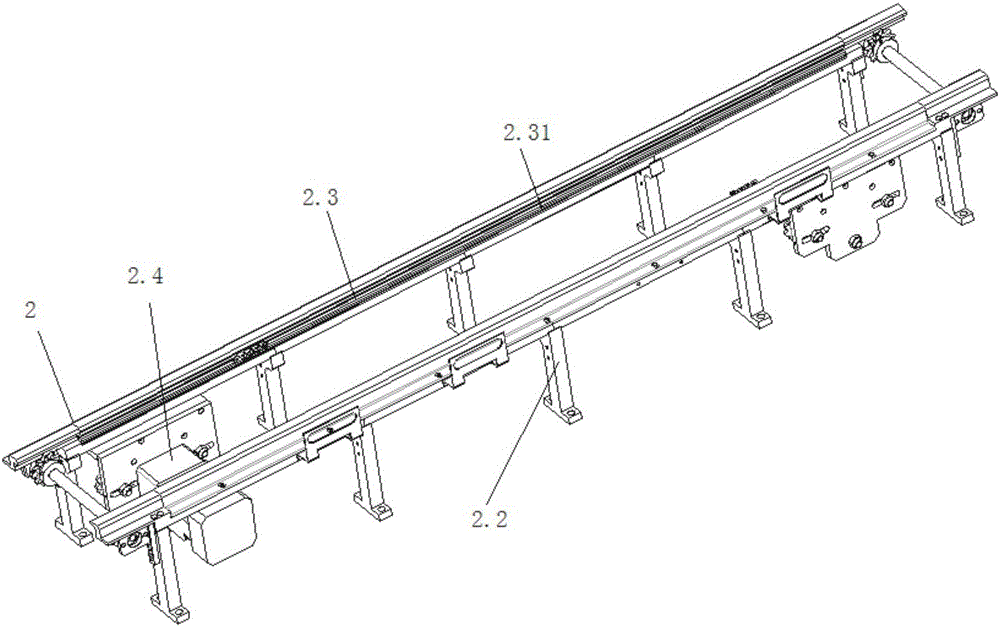

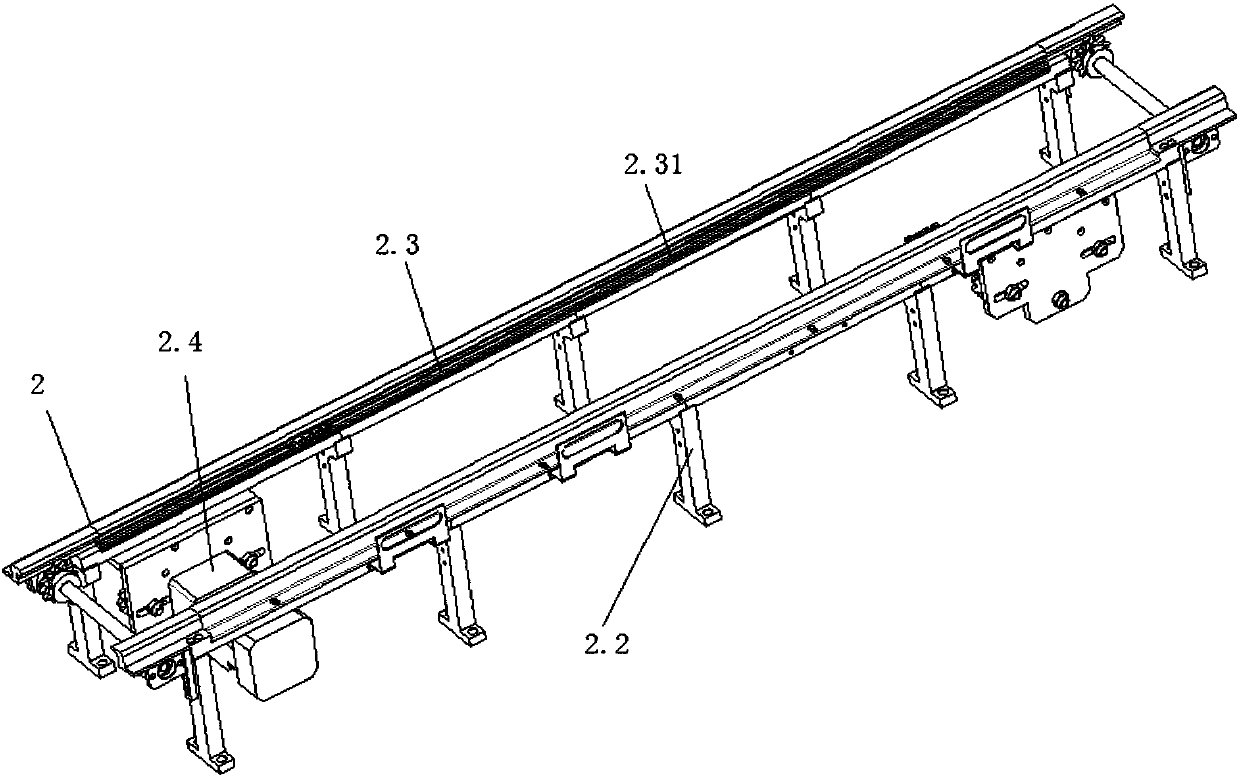

Automatic wire arranging system

ActiveCN106067648AImprove work efficiencyPrecise positioningLine/current collector detailsIndustrial engineering

The invention provides an automatic wire arranging system comprising a work table board and at least one wire arranging work group arranged on the work table board; the wire arranging work group comprises a conveying device, a jacking and shifting module group, an insulating layer detaching module group and a wire arranging and cutting module group; the specific number of the wire arranging work group is decided according to actual production requirements; the following modes of configuration are feasible for satisfying different requirements: only one wire arranging work group is put in place, a plurality of wire arranging work groups are connected in series, and a plurality of wire arranging work groups are connected in parallel; wire material is conveyed onto a work position to be jacked via the conveying device, the wire material is shifted to a work position to be processed via the jacking and shifting module group, part of an insulating layer on the wire material is detached via the insulating layer detaching module group in such a way that a wire core of certain length is exposed, the wire core of the wire material is subjected to wire arranging and cutting operation via the wire arranging and cutting module group, whole processes are finished via machines without manual labor, and work efficiency can be greatly improved.

Owner:CHANGSHA KINAL AUTOMATION TECH CO LTD

A typesetting device used in the process of graphic design

The invention relates to the field of outdoor equipment used in design tools, in particular to a typesetting device used in the process of graphic design. The invention aims to solve the problem in the prior art that there is no installation and work of graphic page manual typesetting equipment in a non-design environment. The present invention includes a sliding sleeve in the middle of the outer sleeve and an inner rotating column that are fitted together. Nuts are welded on the bottom of the outer sleeve, and the nuts are threaded with the rotating column. At least two sets of lamp block installation holes are arranged in a row in the direction of the main shaft. After the lamp block passes through the sleeve, it is connected with the middle slider. There is a corresponding groove in the middle slider. The top of the slide tube is also provided with a light control device corresponding to the mounting holes of each row of light blocks. The light control device is connected to the control circuit, and the push switches are connected in parallel on the control circuit. The advantages are: - easy to carry, various projects, various deformations, convenient for practical operation, and adaptable to various occasions.

Owner:HENAN INST OF SCI & TECH

Design method and device of elliptical dots of light guide plate and light guide plate

ActiveCN106646728BImprove light guide effectRealize arrangementOptical light guidesAxial ratioLaser processing

The invention relates to the technical field of light guide plate design and discloses a light guide plate and an elliptical dot designing method and device of the laser-processing light guide plate. The elliptical dot designing method includes: building a two-dimension coordinate plane on the light guide plate; determining a light emitting area in the two-dimension coordinate plane; building a density distribution function of elliptical dots in the light emitting area; determining adjacent horizontal interval and adjacent vertical interval among the elliptical dots and short-long axial ratio of the elliptical dots; determining long axis of the elliptical dots according the the adjacent horizontal interval, the adjacent vertical interval, the short-long axial ratio and the density distribution function; converting the density distribution function and the long axis of the elliptical dots into a computer instruction to realize distribution of the elliptical dots. Length of the long axis of the elliptical dots acquired by calculation is closer to actual distribution of dots compared with conventional linear dots, so that light guide effect of the light guide plate is improved effectively.

Owner:CHUZHOU HKC OPTOELECTRONICS TECH CO LTD

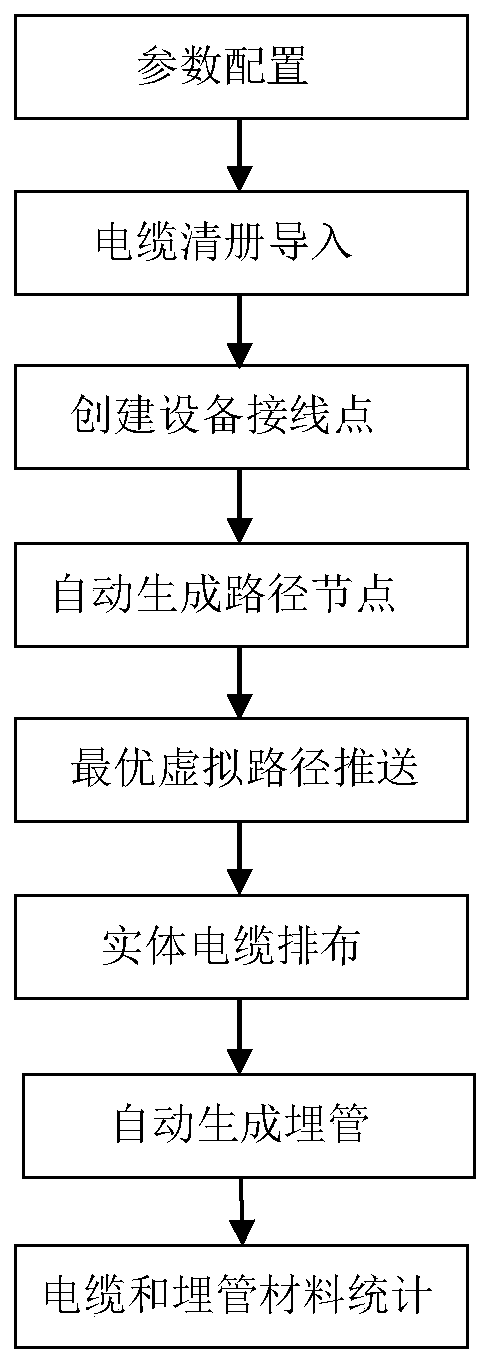

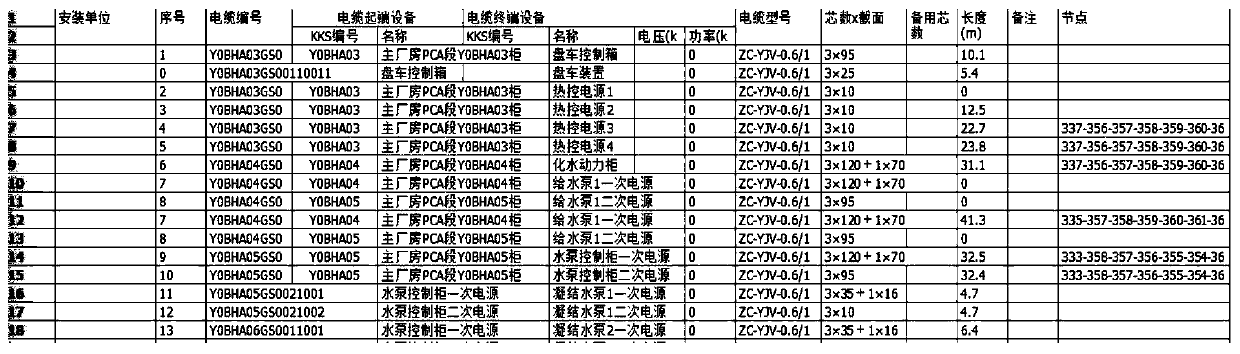

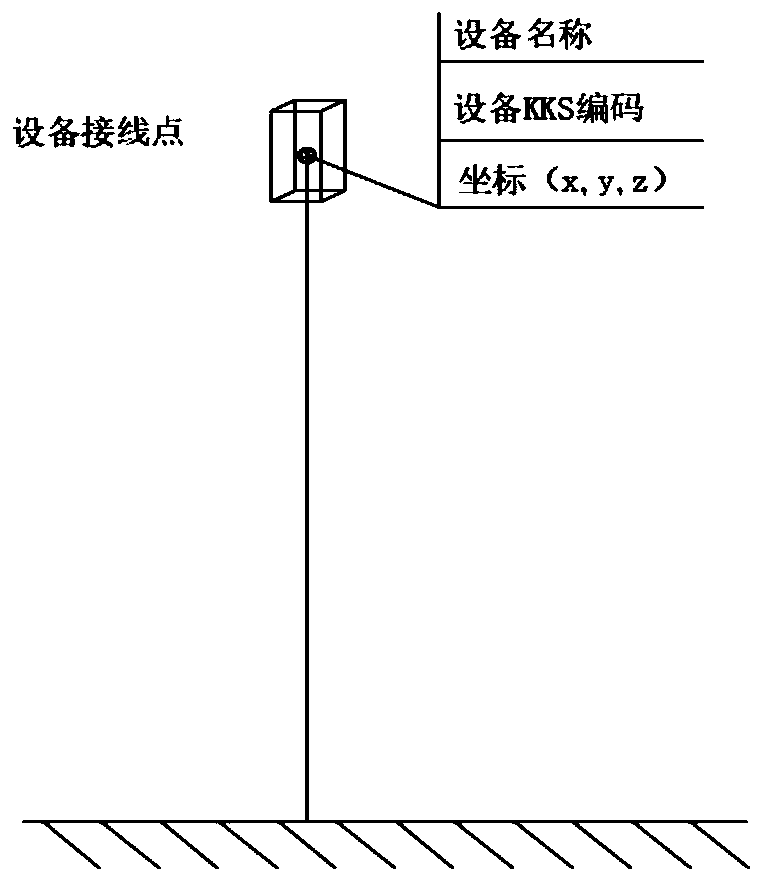

A method for intelligent laying of physical cables based on pdms platform

ActiveCN110442996BAchieving Digital Forward DesignHelp with general contracting projectsDesign optimisation/simulation3D modellingTerminal equipmentStructural engineering

The invention relates to the field of electrical entity cable design, and discloses a PDMS platform-based entity cable intelligent laying method. Automatic laying of a cable virtual path, optimal pathpushing and entity cable arrangement are realized, so that the design efficiency and the design quality are improved, and the utilization rate of materials is improved by performing accurate statistics on the materials. The method comprises the following steps: reading parameters required by laying of an entity cable from a parameter configuration library; importing the cable inventory into a PDMS platform to form a cable list of all inventory data; for each cable in the cable list, creating a three-dimensional model of wiring points of the starting end of the cable and the terminal device; selecting a space range of cable laying, and generating a cable path node; calculating an inflection point path and a node path, and pushing an optimal virtual path based on the inflection point path and the node path; performing entity cable arrangement in a PDMS platform according to the optimal virtual sequence; automatically generating a buried pipe for the cable on which the solid cable is laid; and finally, performing cable and buried pipe material statistics.

Owner:四川电力设计咨询有限责任公司

Typesetting device used in graphic design process

ActiveCN111137050APrevent typographical errorsReduce memory difficultyWriting aidsGraphic designDesign tool

The invention relates to the field of outdoor use equipment in design tools, in particular to a typesetting device used in a graphic design process. The problem that in the prior art, manual graphic page typesetting equipment has no place to install and work in a non-design environment is solved. The device comprises an external sleeve, a middle sliding barrel and an internal rotating column whichare sleeved with each other, a nut is welded to the bottom of the external sleeve, the nut is in threaded fit with the rotating column, the sliding barrel is in threaded fit with the rotating column,at least two sets of lamp block mounting holes are formed in the sleeve in a row in the direction parallel to a main shaft, lamp blocks penetrate through the sleeve and then are connected with the middle sliding barrel, corresponding grooves are formed in the middle sliding barrel, push type switches are arranged at the bottoms of the grooves, lamp control devices are further arranged at the tops, correspond to all the columns of mounting holes, of the middle sliding barrel, the lamp control devices are connected with a control circuit, and all the push type switches are connected to the control circuit in parallel. The device has the advantages of being convenient to carry, diverse in engineering, capable of deforming, convenient to operate practically and capable of adapting to variousoccasions.

Owner:HENAN INST OF SCI & TECH

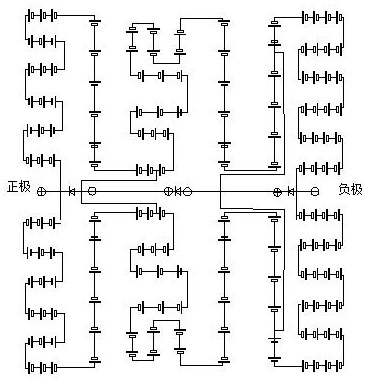

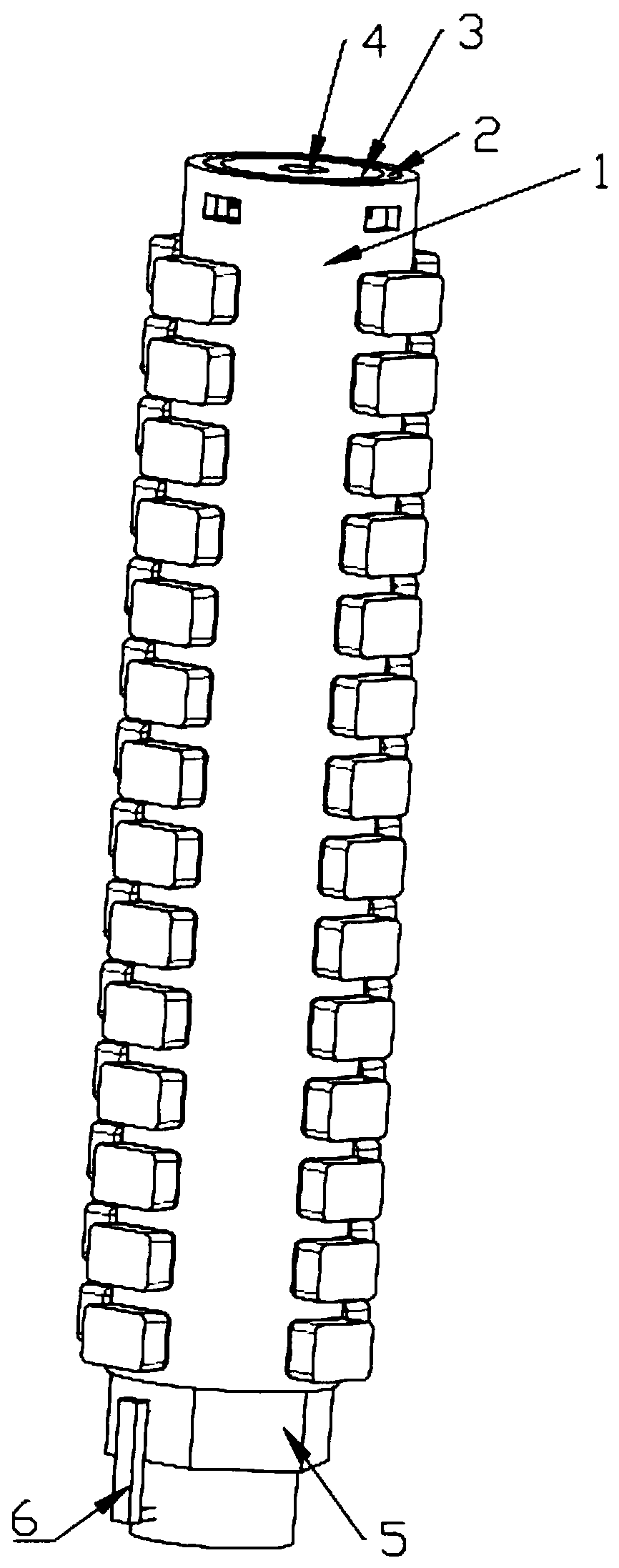

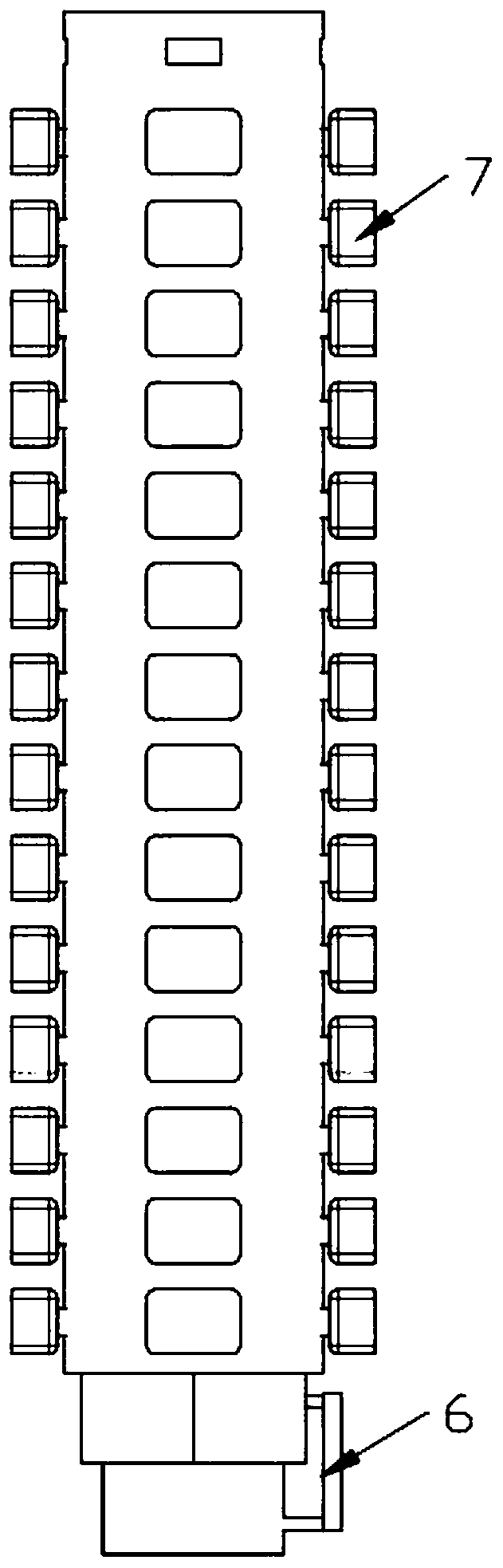

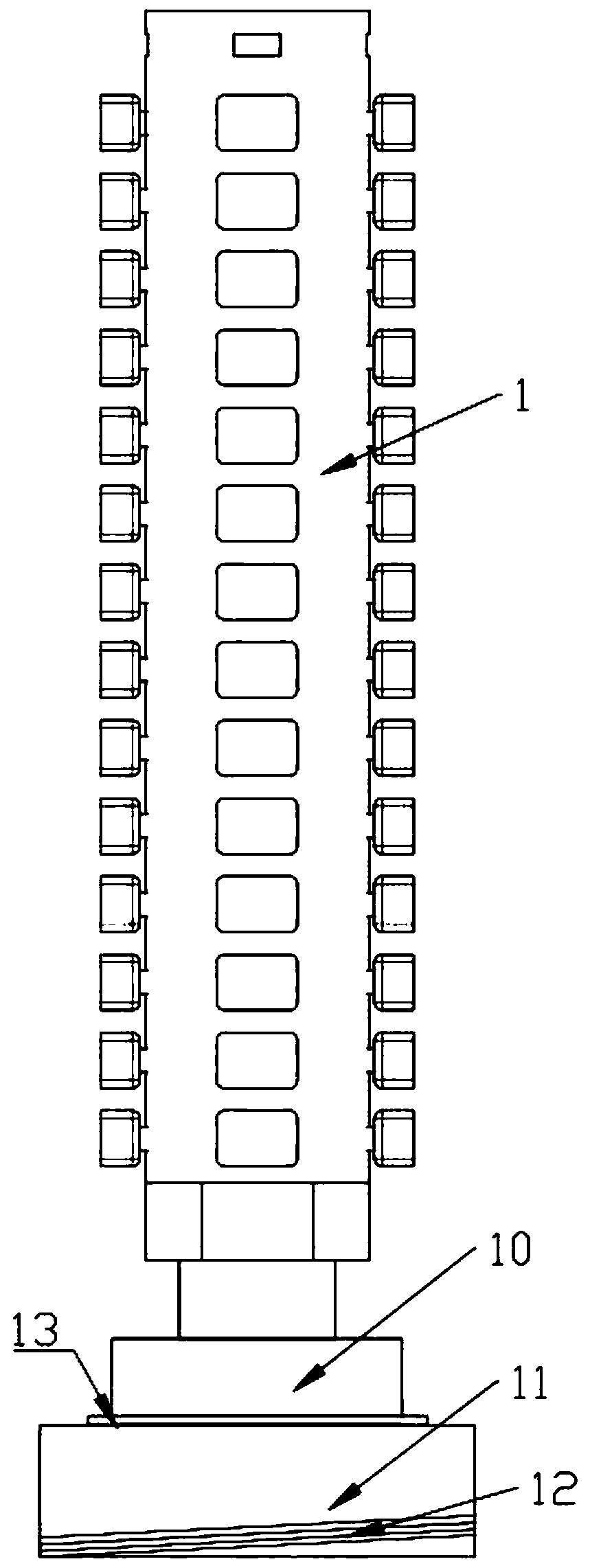

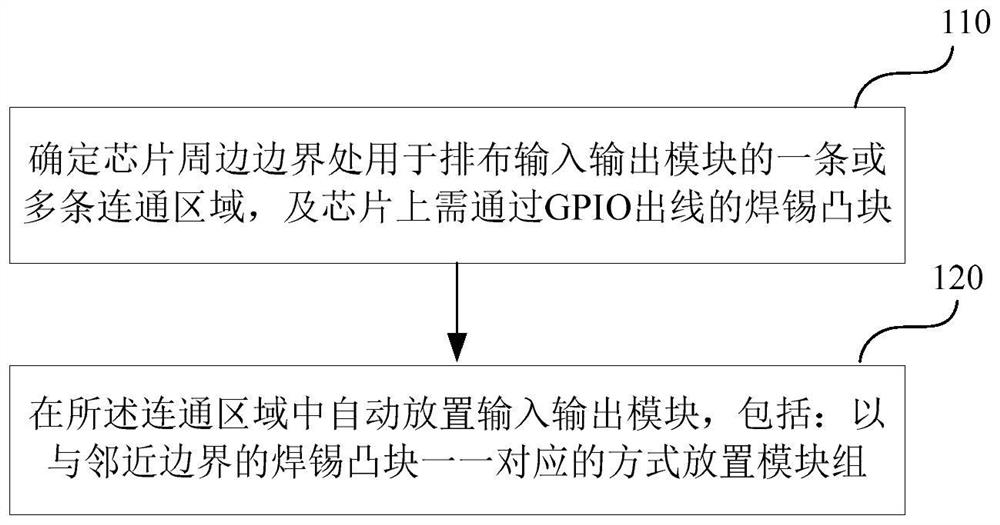

Chip input and output module arrangement method and device and storage medium

PendingCN114692555ARealize arrangementImprove layout efficiencyComputer aided designSpecial data processing applicationsSignal integrityInput/output

The invention discloses a chip input and output module arrangement method and device and a storage medium. The method comprises the following steps: firstly, determining one or more communication regions for arranging input and output modules at the peripheral boundary of a chip, and a soldering tin bump needing to pass through a GPIO (General Purpose Input / Output) outgoing line on the chip; and automatically placing an input / output module in the communication area, wherein module groups are placed in a one-to-one correspondence manner with the soldering tin bumps adjacent to the boundary. The embodiment of the invention further provides a device for implementing the method. According to the embodiment of the invention, automatic arrangement of the input and output modules of the chip can be adaptively realized, so that the input and output modules of the chip meet the requirements of wire outgoing rationality and signal integrity, and the arrangement efficiency is greatly improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Assembly structure of earphone holder and mobile terminal

The invention relates to the technical field of mobile terminals and discloses an earphone seat assembly structure and a mobile terminal. The earphone seat assembly structure comprises a FPC plate which is arranged inside a mobile terminal housing bottom side, a base support which is fixed inside the housing bottom side, an earphone seat and an earphone PCB which is electrically connected with the earphone seat. The earphone seat and the earphone PCB are fixed inside the base support; the earphone PCB and the FPC plate are electrically connected. The mobile terminal comprises a housing and an earphone seat assembly structure which is installed inside the housing. According to the above description, the earphone PCB and the earphone seat are fixed inside the housing bottom side through the seat support and are electrically connected with each other; the earphone seat and the FPC plate are electrically connected through the electrical connection between the earphone PCB and the FPC plate. Therefore, the earphone seat assembly structure can be configured inside the housing bottom side without increasing the thickness of the whole mobile terminal and under the circumstance that there is no space at the earphone seat top side for arranging a PCB.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

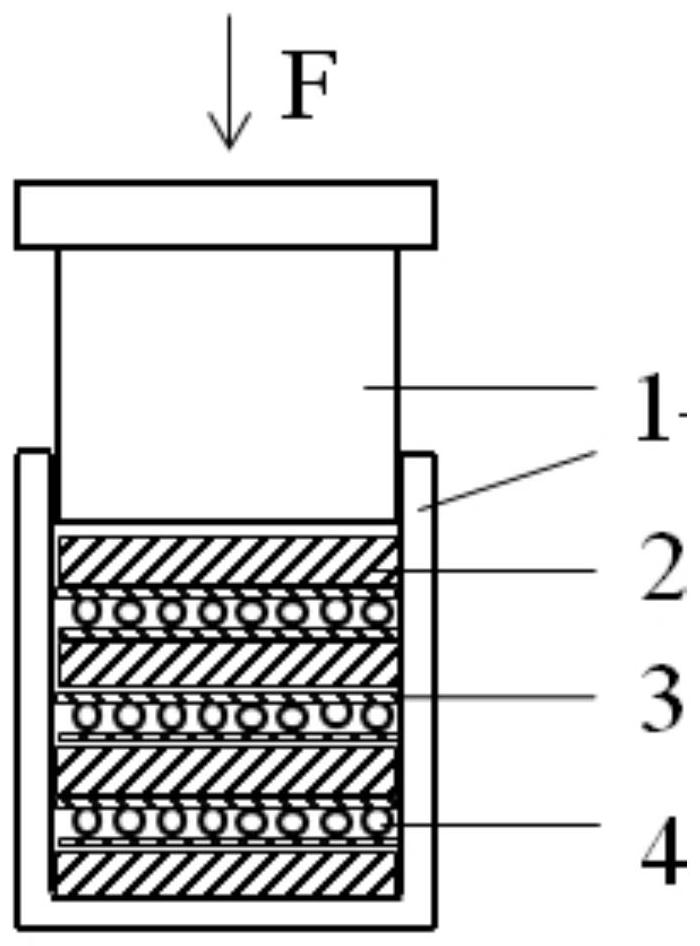

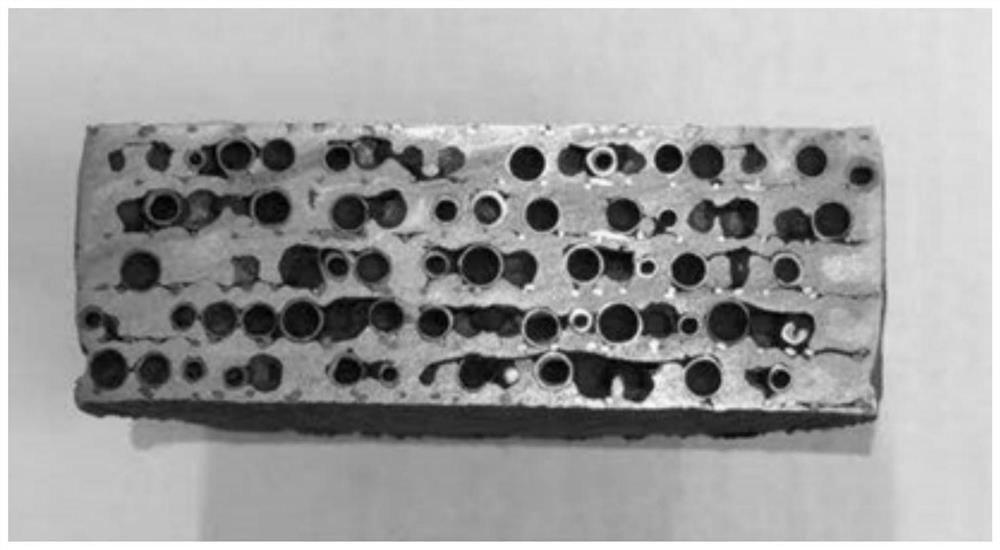

Preparation method of metal hollow sphere composite with grid-reinforced structure

The invention discloses a method for preparing a metal hollow sphere composite material with a grid-reinforced structure. The grid structure and metal hollow spheres are combined to form an arrangement structural unit with a structural design, and the matrix and the structural units are stacked in a mold in a stacking manner Complete stacking within 0.9~1.1T m Keep warm for 0.5-2 hours, apply a certain pressure, and after the heat preservation is over, put it at a low temperature of 0.5-0.8T m Insulate for 1 to 6 hours, and take out the sample after cooling with the furnace. The technical method provided by the invention has a simple process, can shorten the production cycle, and has fewer defects such as internal cracks in the obtained composite material, and has a well-bonded interface inside the obtained composite material, and the hollow spheres are basically arranged according to the structurally designed structure , can realize the performance designability of the metal hollow sphere composite material, and can improve the mechanical properties, and the introduction of the interface can improve the energy absorption performance of the composite material.

Owner:HARBIN ENG UNIV

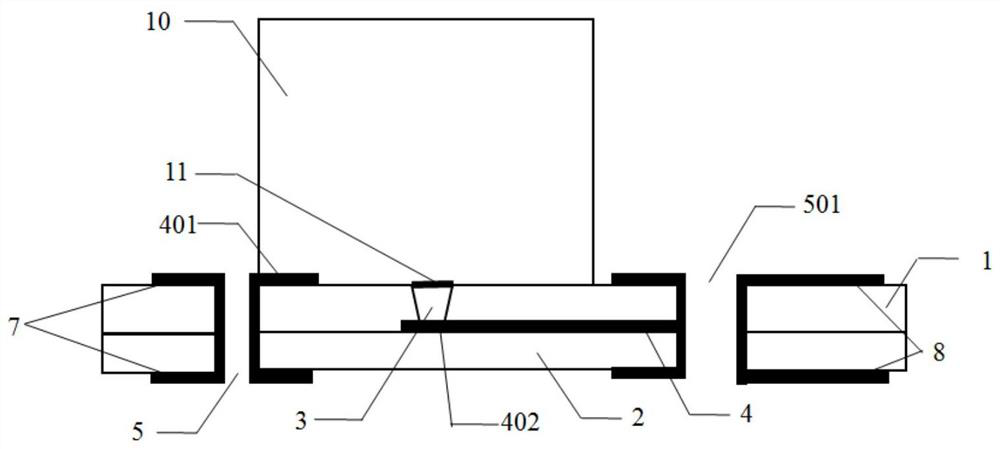

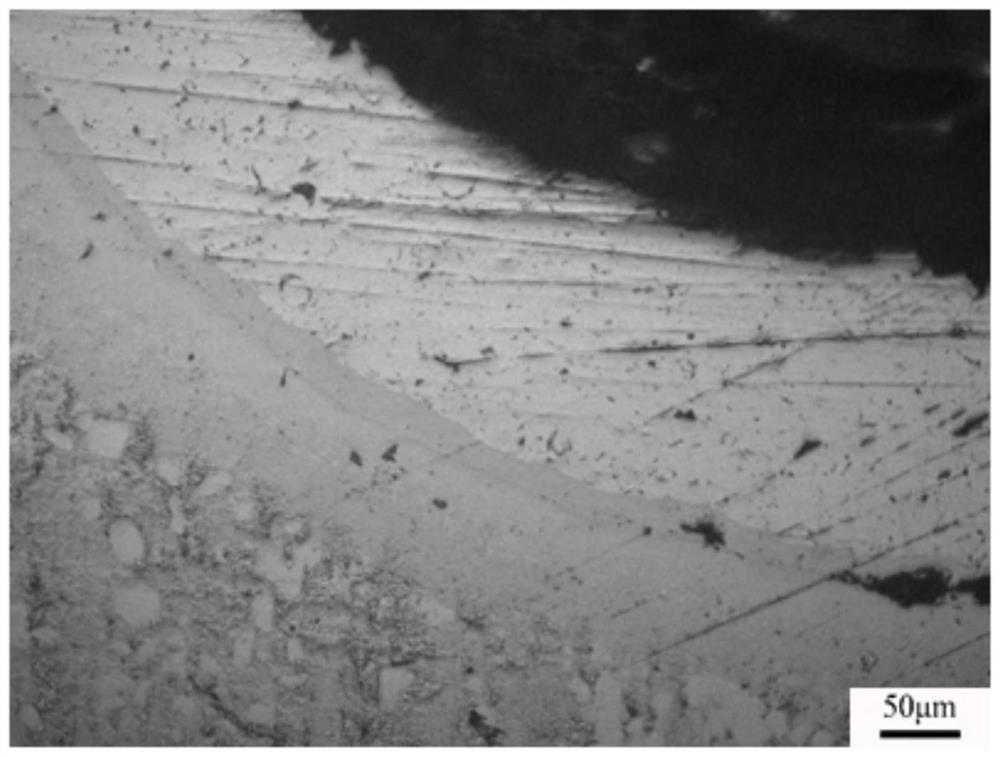

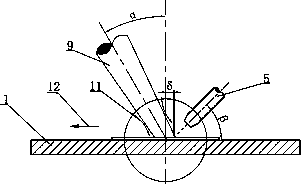

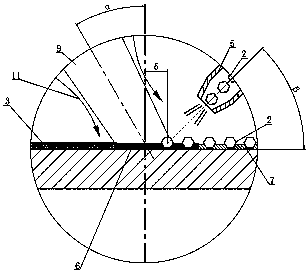

A method of laser brazing single-layer cubic boron nitride tool

ActiveCN107030344BAvoid severe burning and oxidationHigh bonding strengthSoldering apparatusLaser beam welding apparatusOptoelectronicsBoron nitride

The invention relates to a method for laser brazing of a single-layer cubic boron nitride (CBN) tool. The method comprises the following steps: providing a base body of a CBN tool; coating the surface of the base body of the CBN tool with a solder to manufacture a CBN tool blank; providing an injection system, wherein the injection system comprises a hopper and a spray gun connected with the hopper; providing CBN abrasive particles and placing the CBN abrasive particles in the hopper; providing a laser brazing system, wherein the laser brazing system comprises a laser generator and a laser brazing work head; aligning the laser brazing work head and the spray gun to the surface of the tool blank; and starting up the laser brazing system and the injection system, and simultaneously moving the laser brazing work head and the spray gun, so that a focused laser beam generated by the laser brazing work head is directly irradiated onto the surface of the prearranged solder in front to melt the solder, and the CBN abrasive particles are sprayed into a brazing weld pool behind laser spots by use of the spray gun. According to the method, paraxial spraying of the CBN abrasive particles is adopted to perform laser brazing, so that the CBN abrasive particles are prevented from burning loss and oxidation during brazing.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Linear measurement arrangement method for stainless steel vehicle roof cap-shaped curved beams

InactiveCN102818506BRealize arrangementRealize measurementMechanical clearance measurementsStraightedgeMarine engineering

The invention relates to a linear measurement arrangement method for stainless steel vehicle roof cap-shaped curved beams, which is characterized by comprising the following steps of: firstly, placing one stainless steel vehicle roof cap-shaped curved beam with a center hole in a groove body with a center positioning pin, arranging one measuring block of which the center of the bottom is provided with a pinhole on the upper surface of the stainless steel vehicle roof cap-shaped curved beam, enabling the pinhole at the bottom of the measuring block to be coaxially matched with the center positioning pin of the groove body for leading the center of the stainless steel vehicle roof cap-shaped curved beam, which is positioned at the bottom of a groove and cannot be measured, to the top surface and determining the center positioning of the stainless steel vehicle roof cap-shaped curved beam; and then, for a plurality of groups of stainless steel vehicle roof cap-shaped curved beams of a vehicle, aligning center mark points on the upper surfaces of a plurality of measuring blocks, connecting the center mark points into a line and carrying out interval size arrangement and measurement by using a straightedge rule. According to the invention, one measuring block of which the center of the bottom is provided with the pinhole is arranged on the upper surface of one stainless steel vehicle roof cap-shaped curved beam, the pinhole at the bottom of the measuring block is coaxially matched with the center positioning pin of the groove body to lead the center at the bottom of the groove, which cannot be measured, to the top surface, the center mark points of a plurality of measuring blocks are aligned and connected into one line, and the interval size arrangement and measurement are implemented by the center marks on the top surfaces of the measuring blocks through using the straightedge rule.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

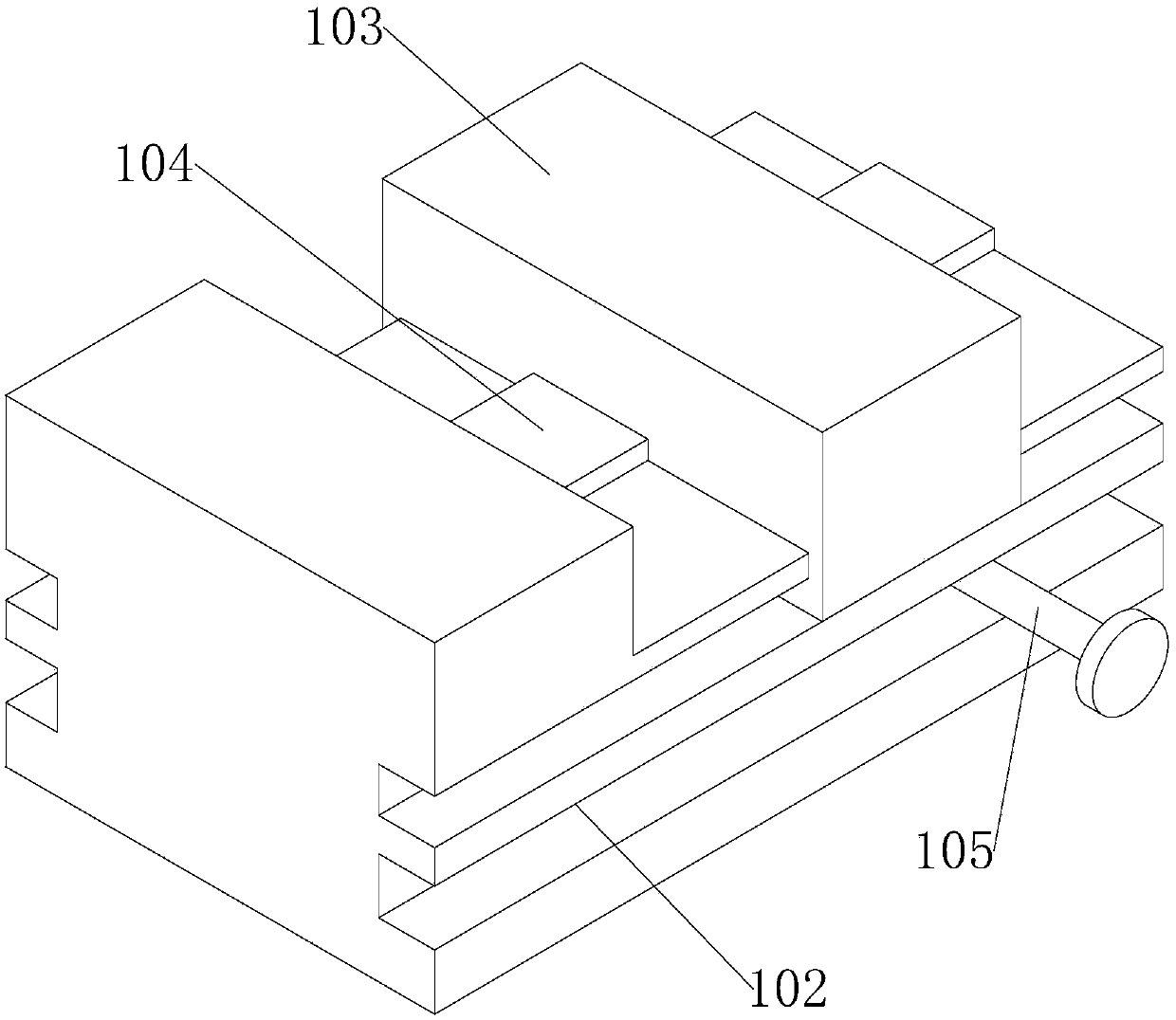

Anti-dislocation clamp for book printing

ActiveCN109624498APrevent dislocationTo achieve the effect of clampingPrinting press partsDislocationEngineering

The invention discloses an anti-dislocation clamp for book printing. The anti-dislocation clamp comprises a main box body, a fixed clamping block, a top clamping device and a top clamping block. The inner wall of the main box body is fixedly connected with the fixed clamping block. The upper end surface of the fixed clamping block is slidably connected with a movable clamping block. A fastening rotating rod is rotationally connected directly below the movable clamping block. The outer wall of the fastening rotating rod is sleeved with a clamping block fixing device. The clamping block fixing device comprises a clamping column and a driving rod. The clamping column is engaged with the driving rod. The inner wall of the main box body is slidably connected with the top clamping device. The top clamping device is positioned behind the fixed clamping block. The top clamping device comprises a hemispherical hinge and a top clamping block. According to the anti-dislocation clamp, the clampingcolumn is abutted against the lower end surface of the movable clamping block, so that the clamping effect is achieved, dislocation of the movable clamping block and books is avoided, and the angle of the top clamping block is adjusted through the hemispherical hinge, so that books which are not arranged in an orderly way are arranged.

Owner:深圳市红标点科技有限公司

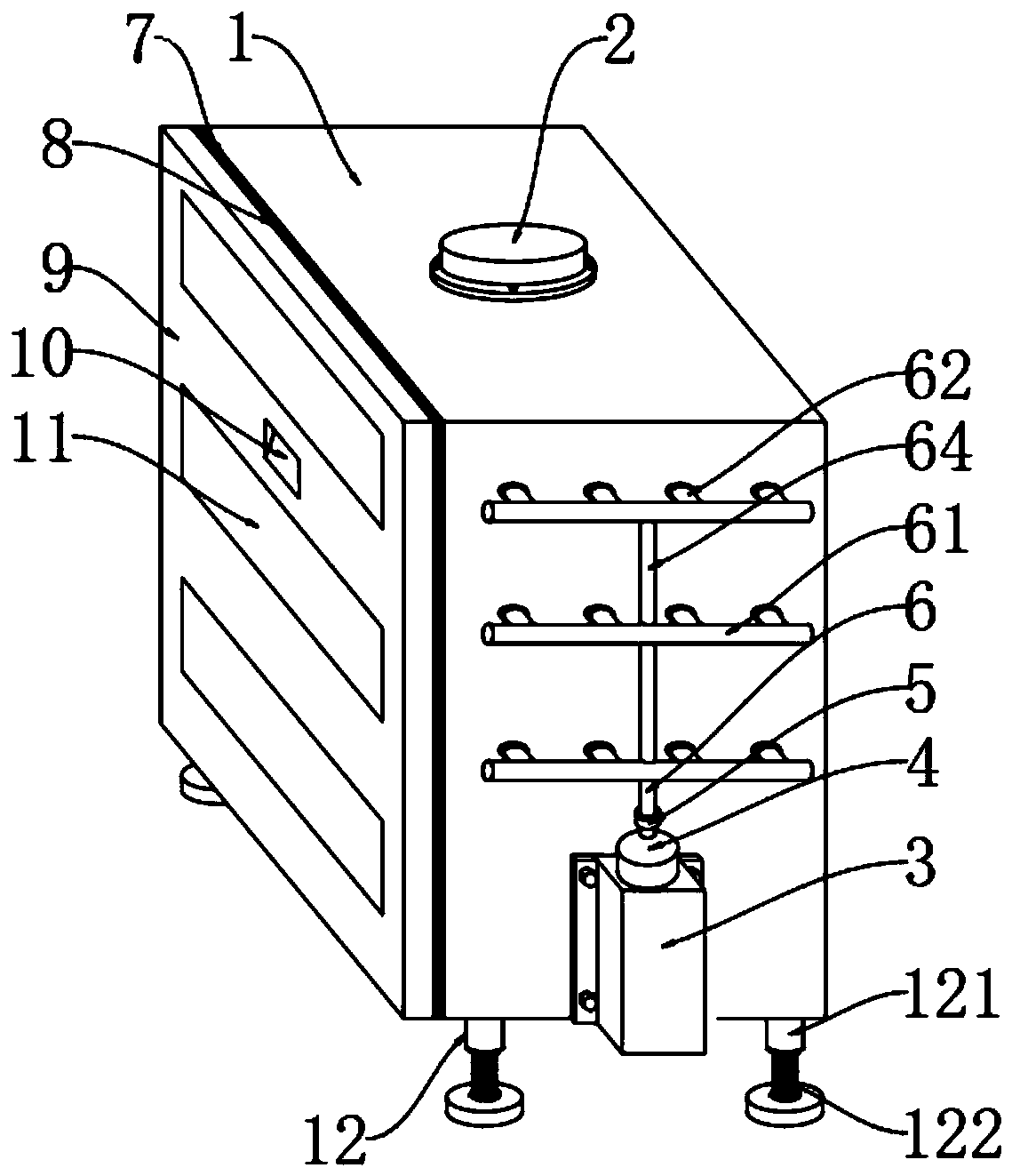

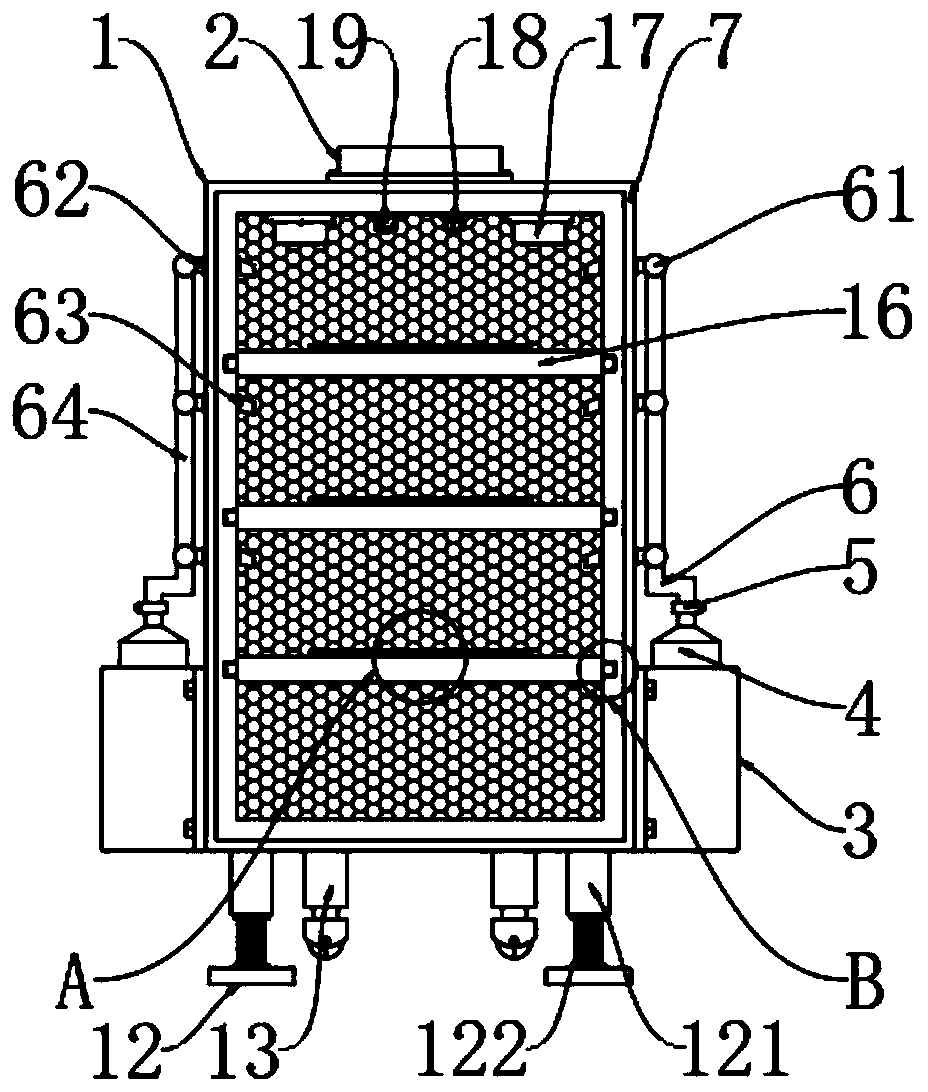

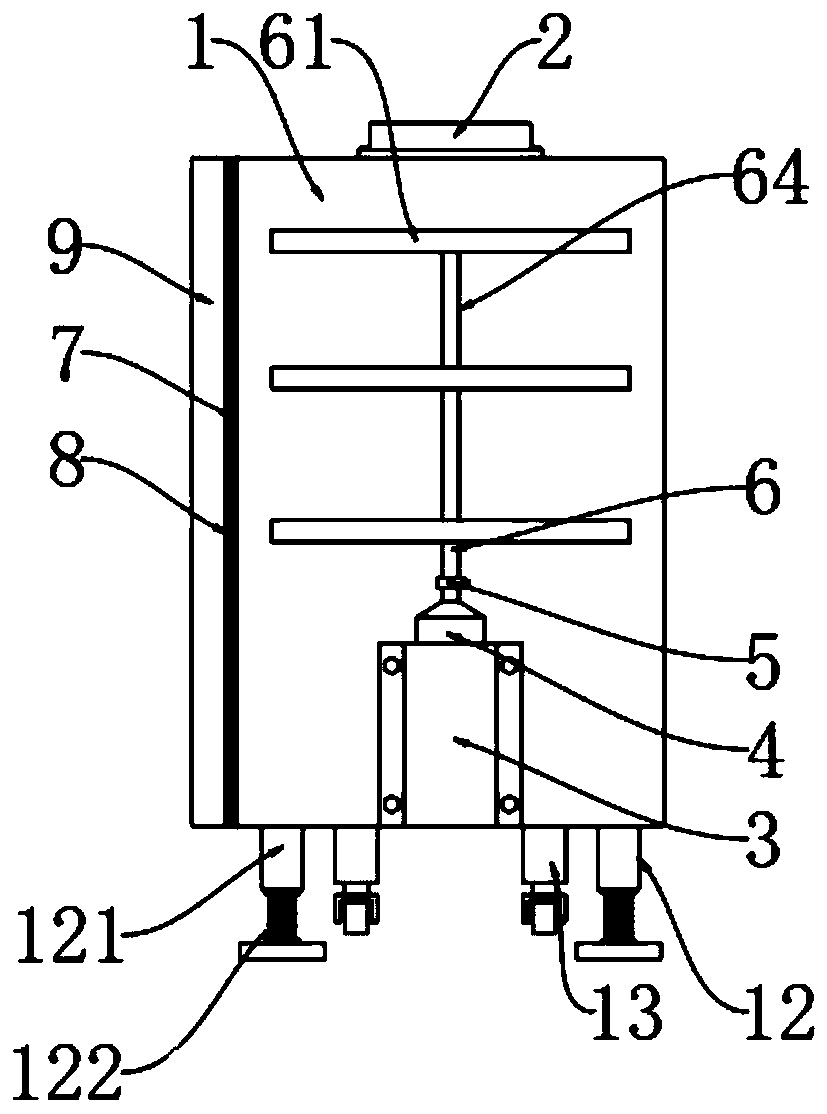

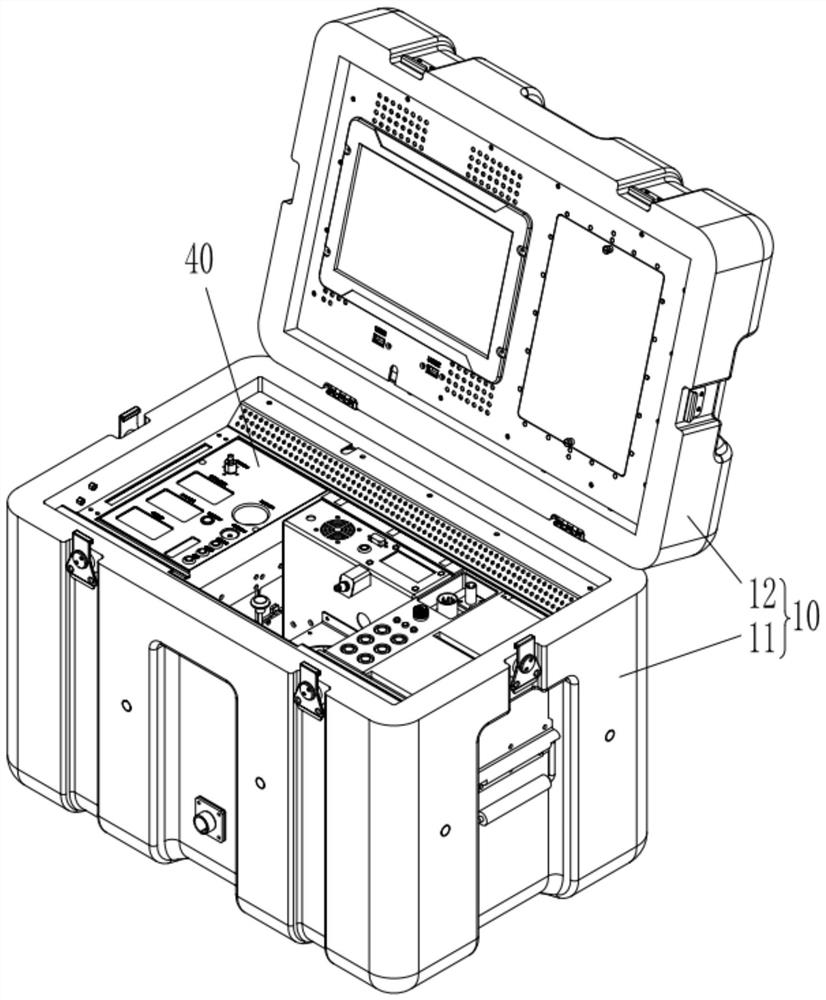

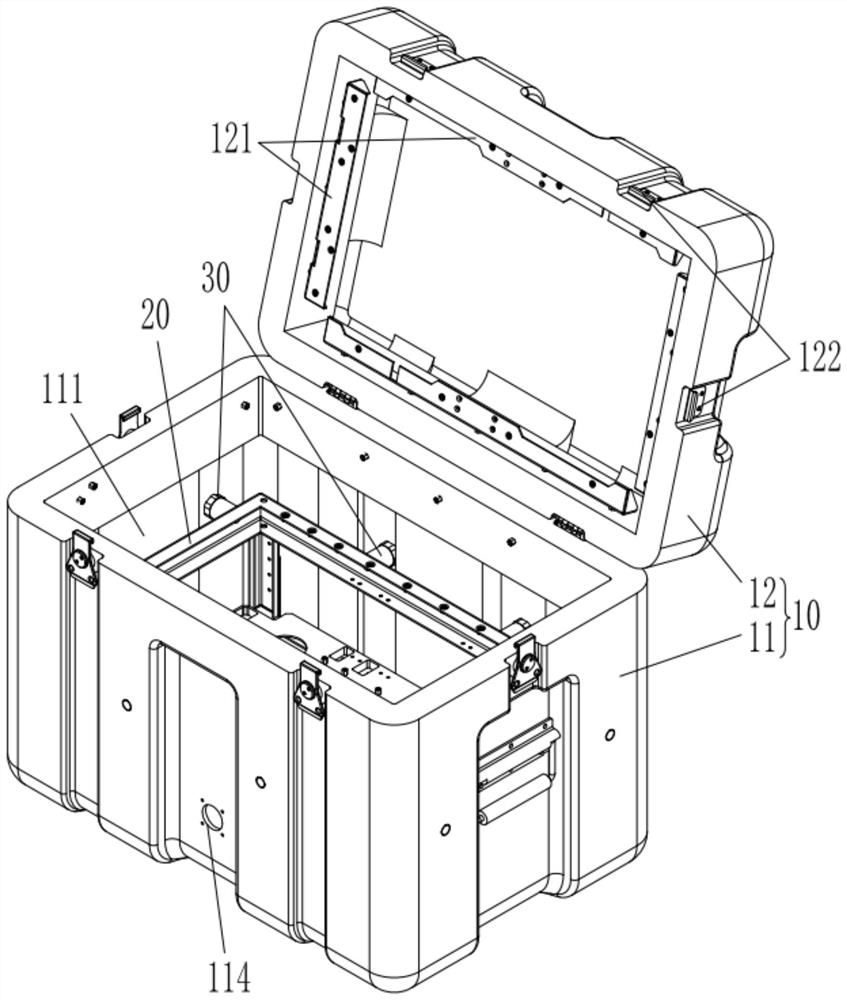

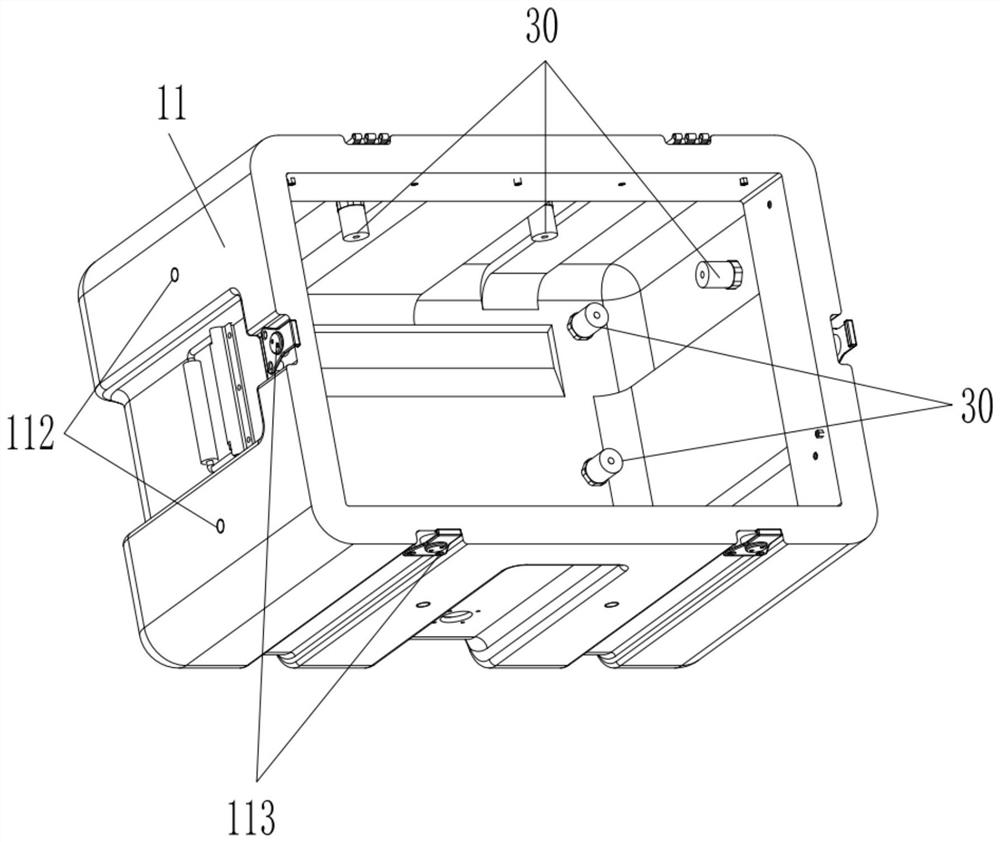

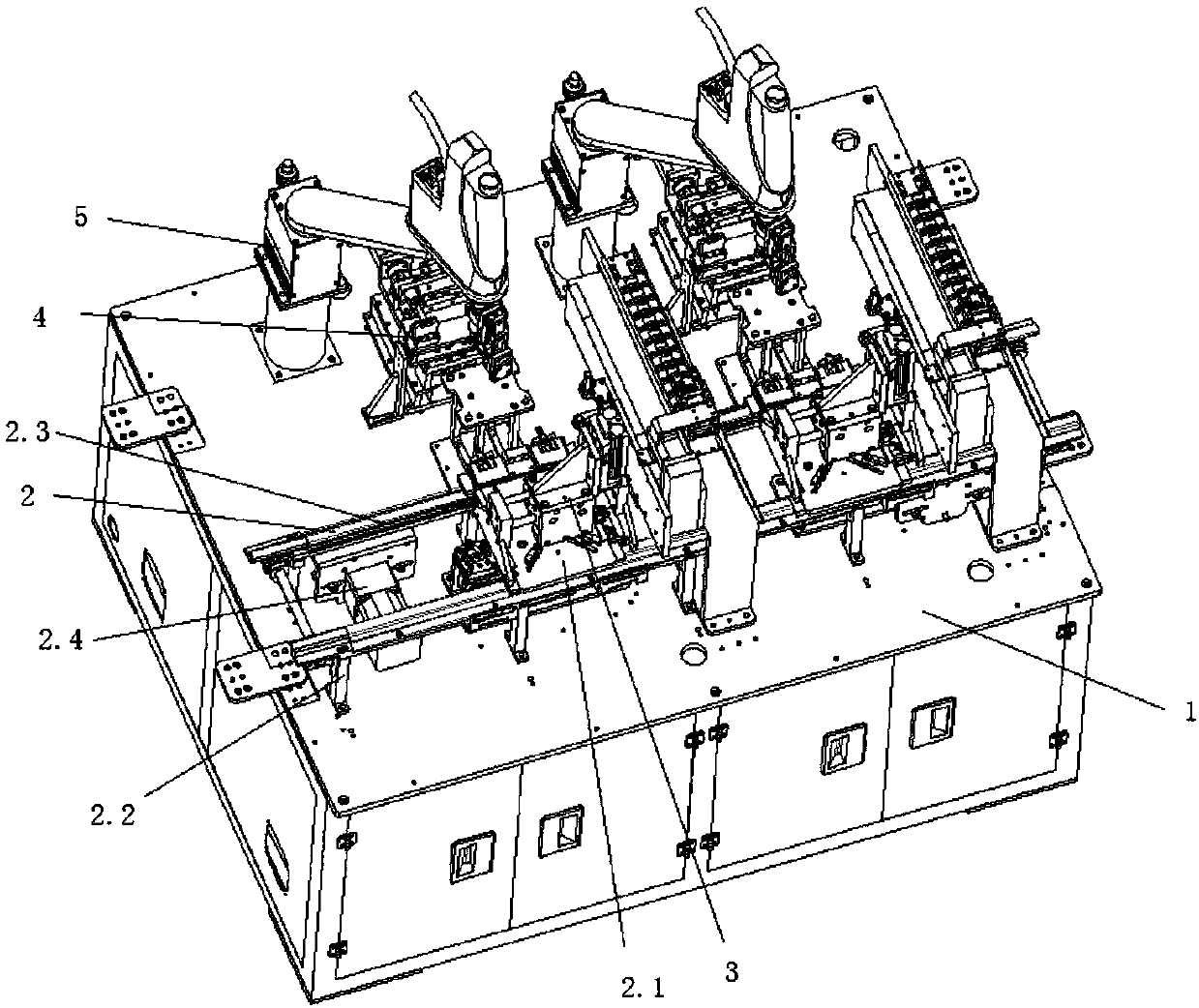

Multifunctional module integrated oil test box

PendingCN113917117AFirmly connectedEasy to maintainNon-rotating vibration suppressionMaterial testing goodsProcess engineeringElectrical and Electronics engineering

The invention provides a multifunctional module integrated oil test box, comprising: a box body assembly comprising a box body and a box cover connected with the box body; a mounting rack which is arranged in the box body and is connected with the box body through a plurality of damping components arranged in the box body; and a module assembly which comprises a plurality of test modules and a power supply module used for supplying power to each test module, wherein at least two test parts are integrated in each test module, and the test modules and the power supply modules are connected with the mounting rack through plugging structures. According to the invention, all modules in the box body can be damped and protected in multiple directions; the operation convenience of the whole structure is improved through a modular plugging mode, the maintenance is convenient, the time is saved, and the cable-free connection among the internal modules is realized; and through integrated installation of a plurality of test components, multi-index detection of oil performance is realized, and the test modules can be deleted, added or replaced according to functional requirements.

Owner:重庆赛宝工业技术研究院有限公司

An automatic line management system

ActiveCN106067648BRealize continuous deliveryAchieve separationLine/current collector detailsIndustrial engineeringCable management

Owner:CHANGSHA KINAL AUTOMATION TECH CO LTD

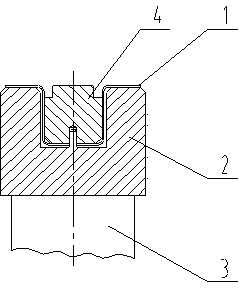

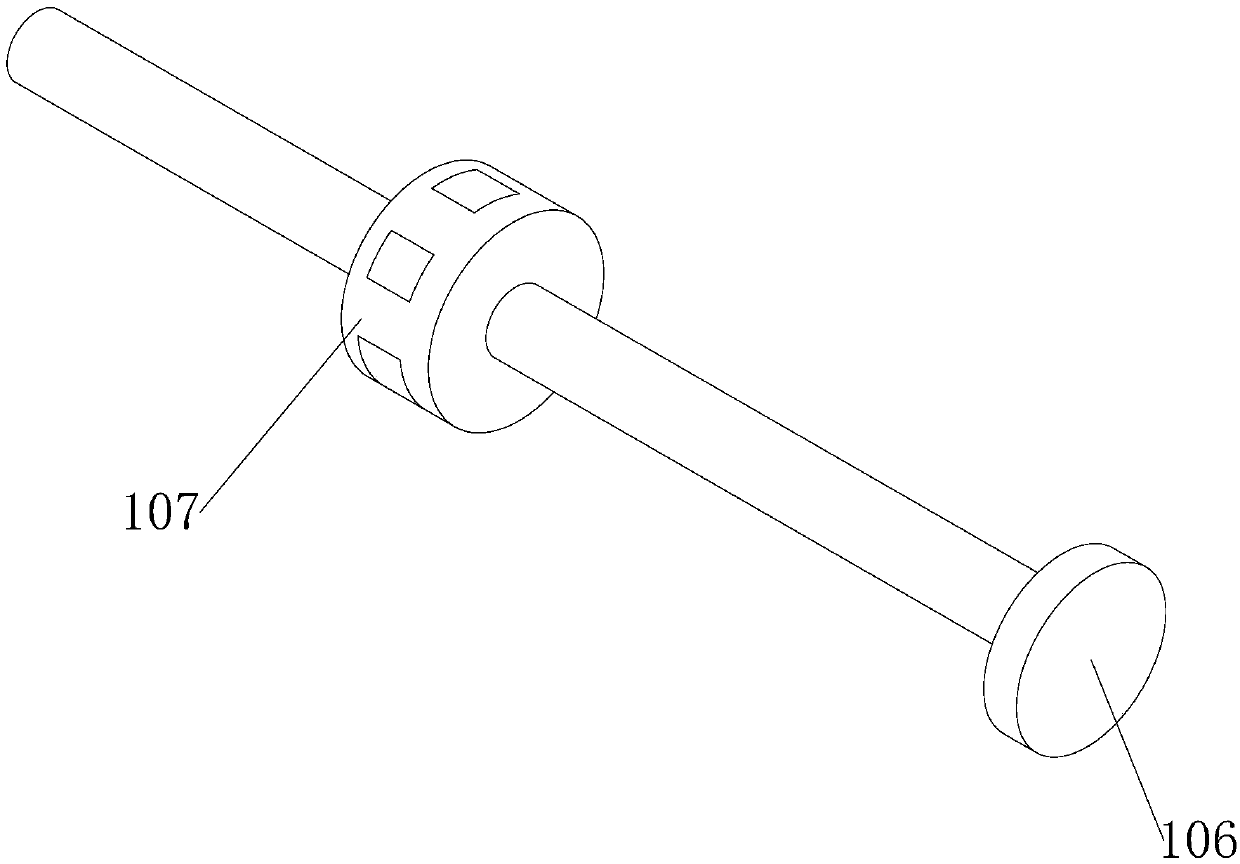

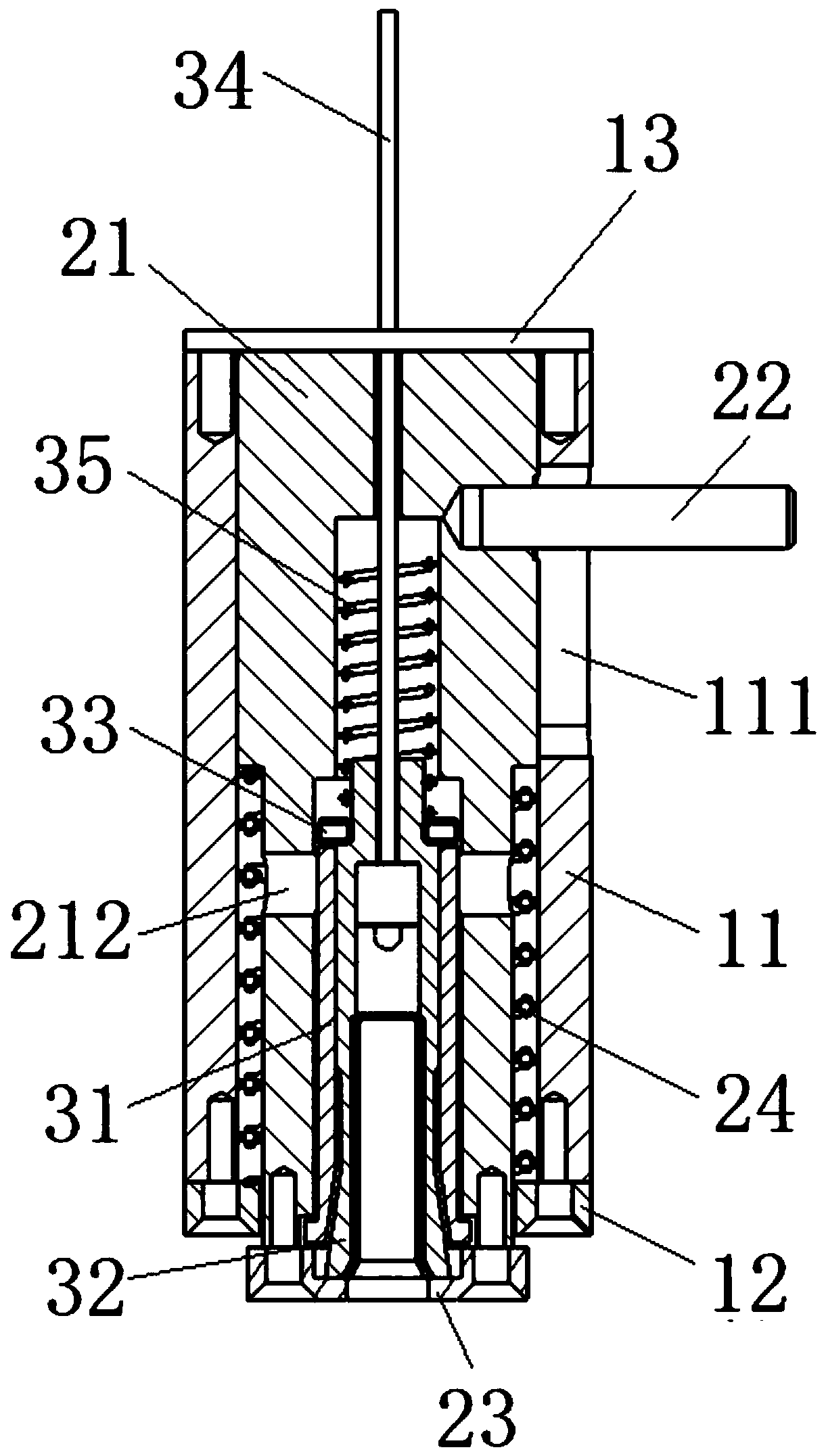

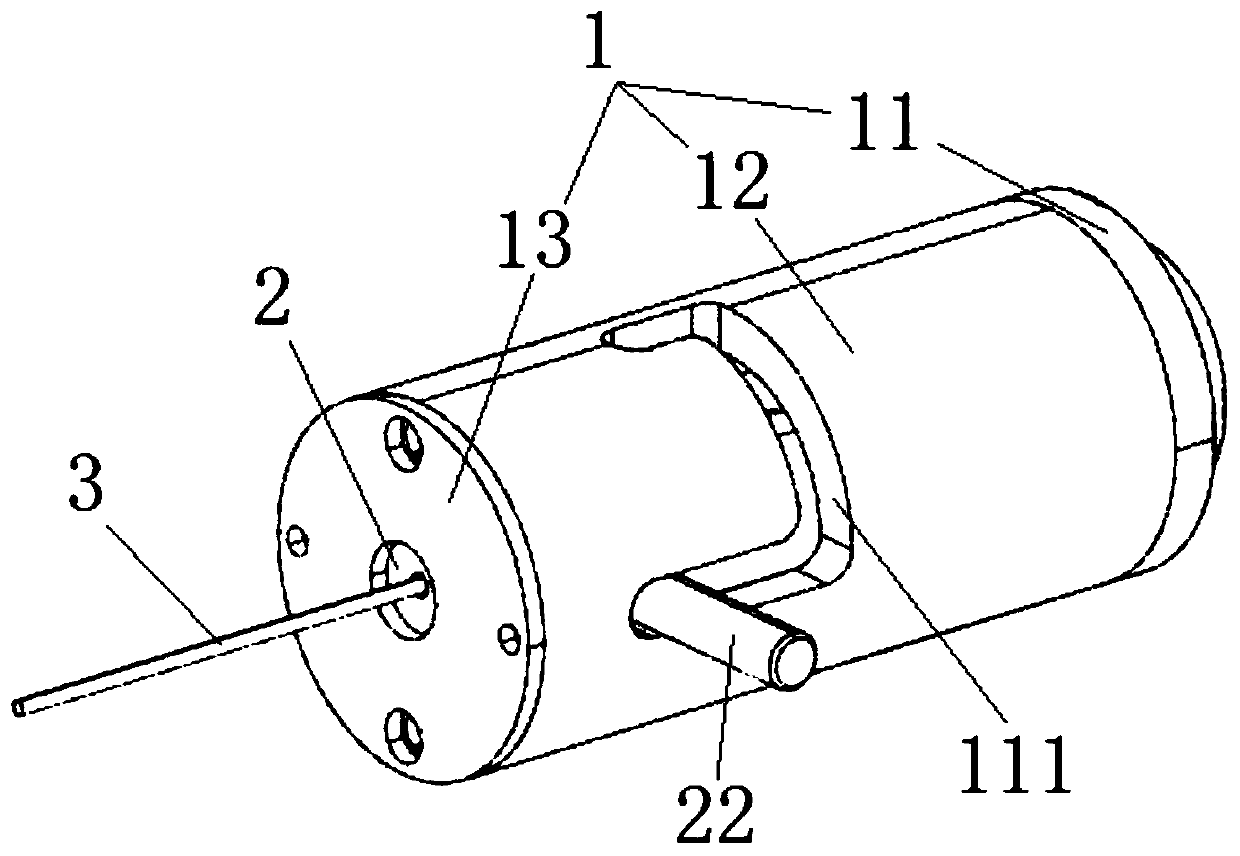

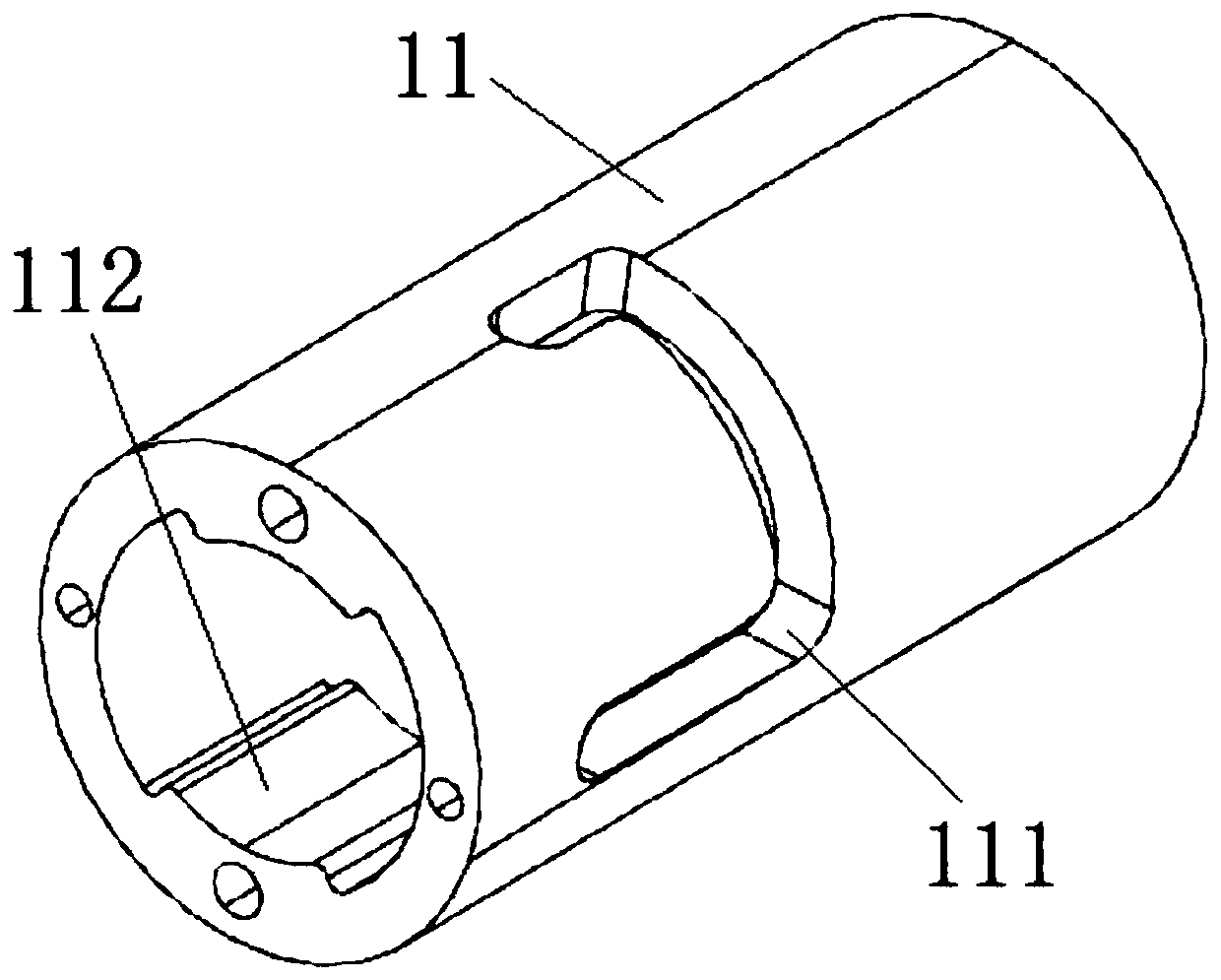

High precision self-centering external contracting type tensioning positioning mechanism

PendingCN110238773AQuick positioning installationTo achieve the integration effectWork holdersEngineering

The invention belongs to the technical field of clamping tools, and relates to a high precision self-centering external contracting type tensioning positioning mechanism. The high precision self-centering external contracting type tensioning positioning mechanism comprises an axial hollow housing assembly, a compression assembly which can axially contract in the housing assembly and a tensioning assembly which can axially contract in the compression assembly. The high precision self-centering external contracting type tensioning positioning mechanism can achieve rapid installation and positioning, achieves integration effects, is compact and beautiful in structure, low in cost, and capable of automatically releasing, can perform autonomous centering, and meanwhile can achieve flexible or long-distance locking operation, can achieve optimization for a testing space, and can achieve humanized design and arrangement for locking operation actions.

Owner:巨硕精密机械(常熟)有限公司

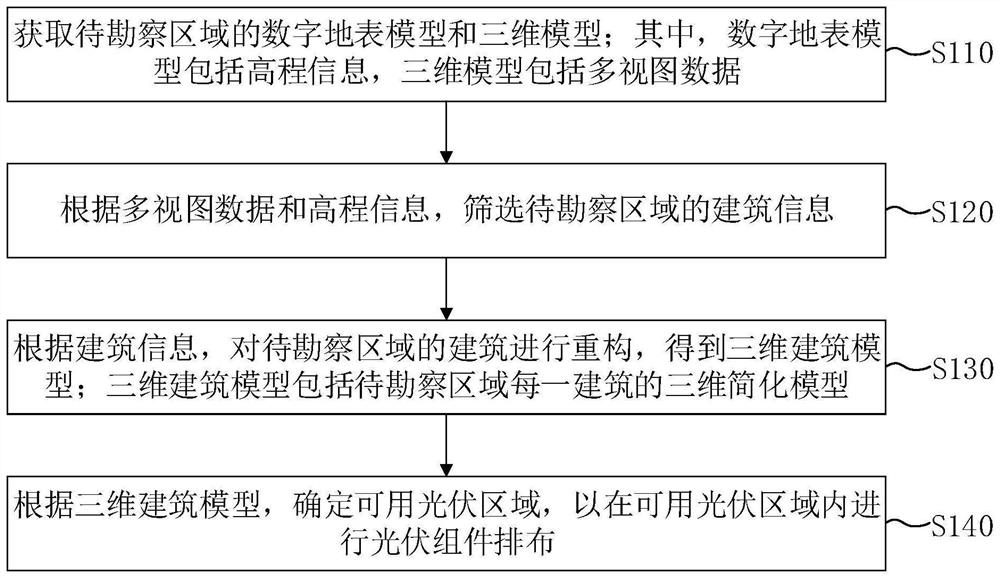

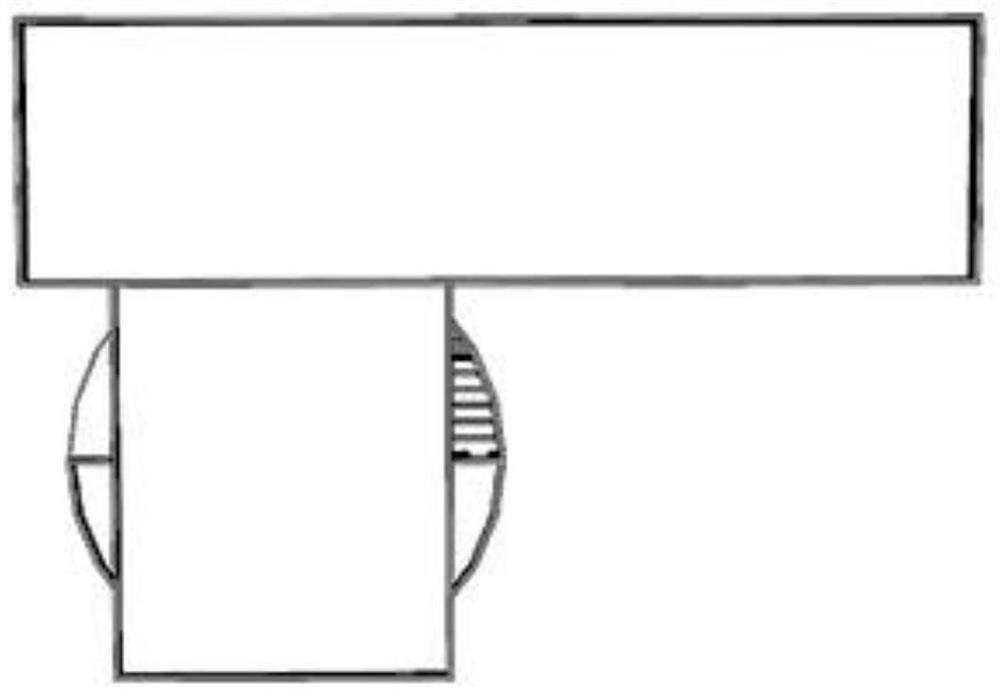

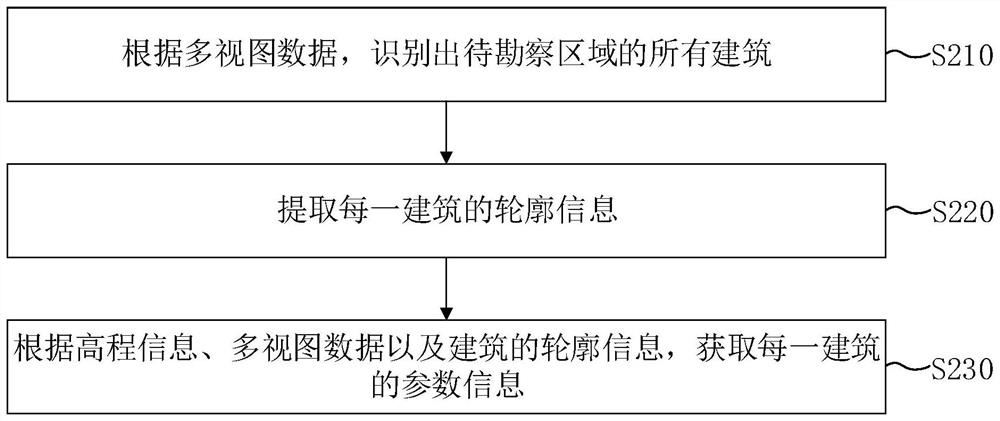

Photovoltaic power station area determination method and device suitable for roof

PendingCN114861278AProcessing speedQuick fixGeometric CADSpecial data processing applicationsTelecommunicationsDigital Earth

The embodiment of the invention discloses a photovoltaic power station area determination method and device suitable for a roof. The photovoltaic power station area determination method suitable for the roof comprises the following steps: acquiring a digital earth surface model and a three-dimensional model of an area to be surveyed; wherein the digital earth surface model comprises elevation information, and the three-dimensional model comprises multi-view data; screening building information of the to-be-surveyed area according to the multi-view data and the elevation information; according to the building information, reconstructing a building in the to-be-surveyed area to obtain a three-dimensional building model; the three-dimensional building model comprises a three-dimensional simplified model of each building in the to-be-surveyed area; and according to the three-dimensional building model, determining an available photovoltaic area so as to carry out photovoltaic module arrangement in the available photovoltaic area. Compared with the prior art, the scheme can quickly and accurately realize the determination of the photovoltaic power station area.

Owner:HEFEI SUNGROW RENEWABLE ENERGY SCI & TECH CO LTD

A device for automatically arranging dominoes

ActiveCN105107197BRealize arrangementReduce premature collapseIndoor gamesToysSingle chipMINOS complex

Owner:江苏朗彤建设工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com