Patents

Literature

32results about How to "To achieve the effect of clamping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

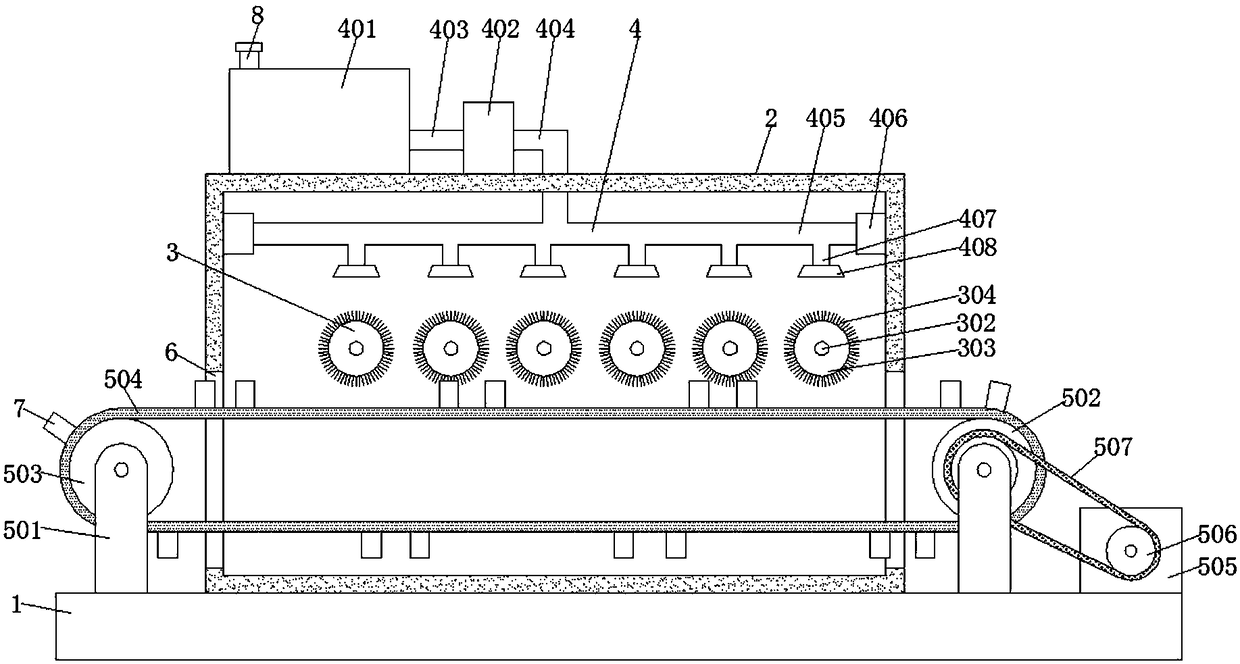

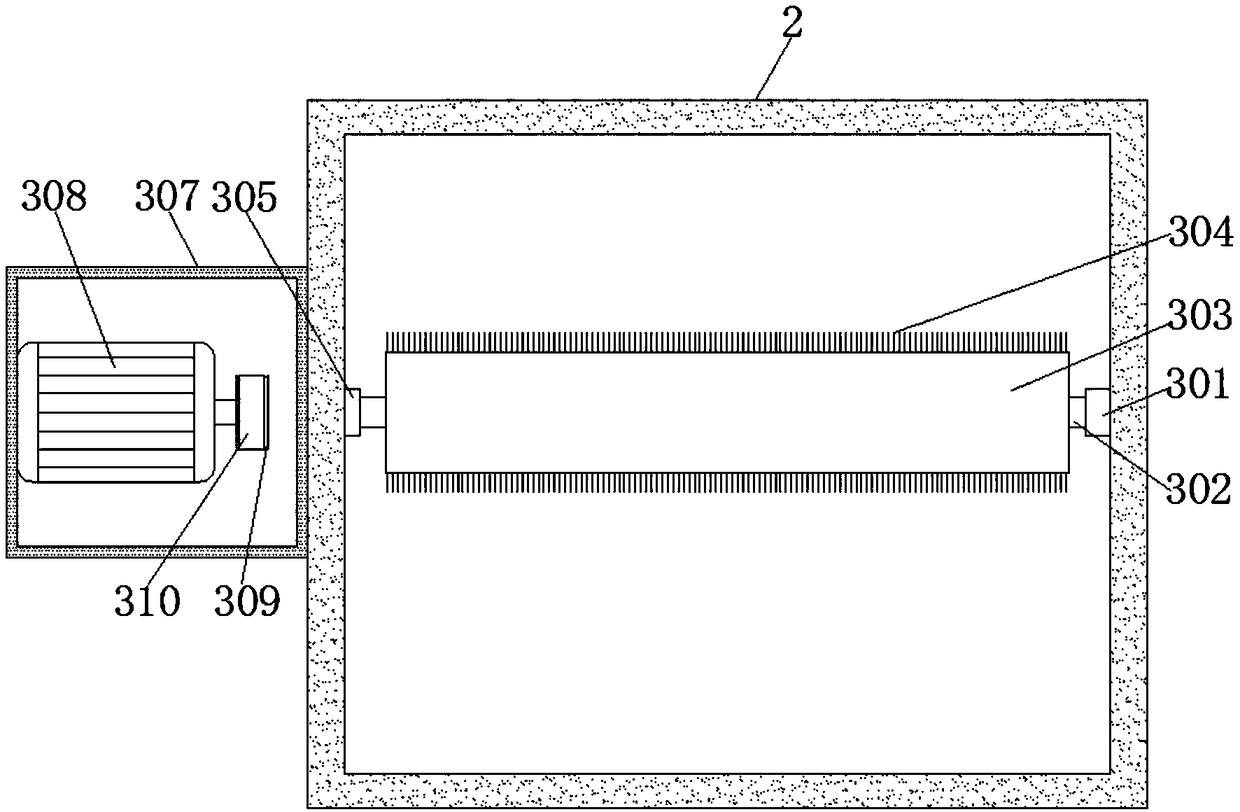

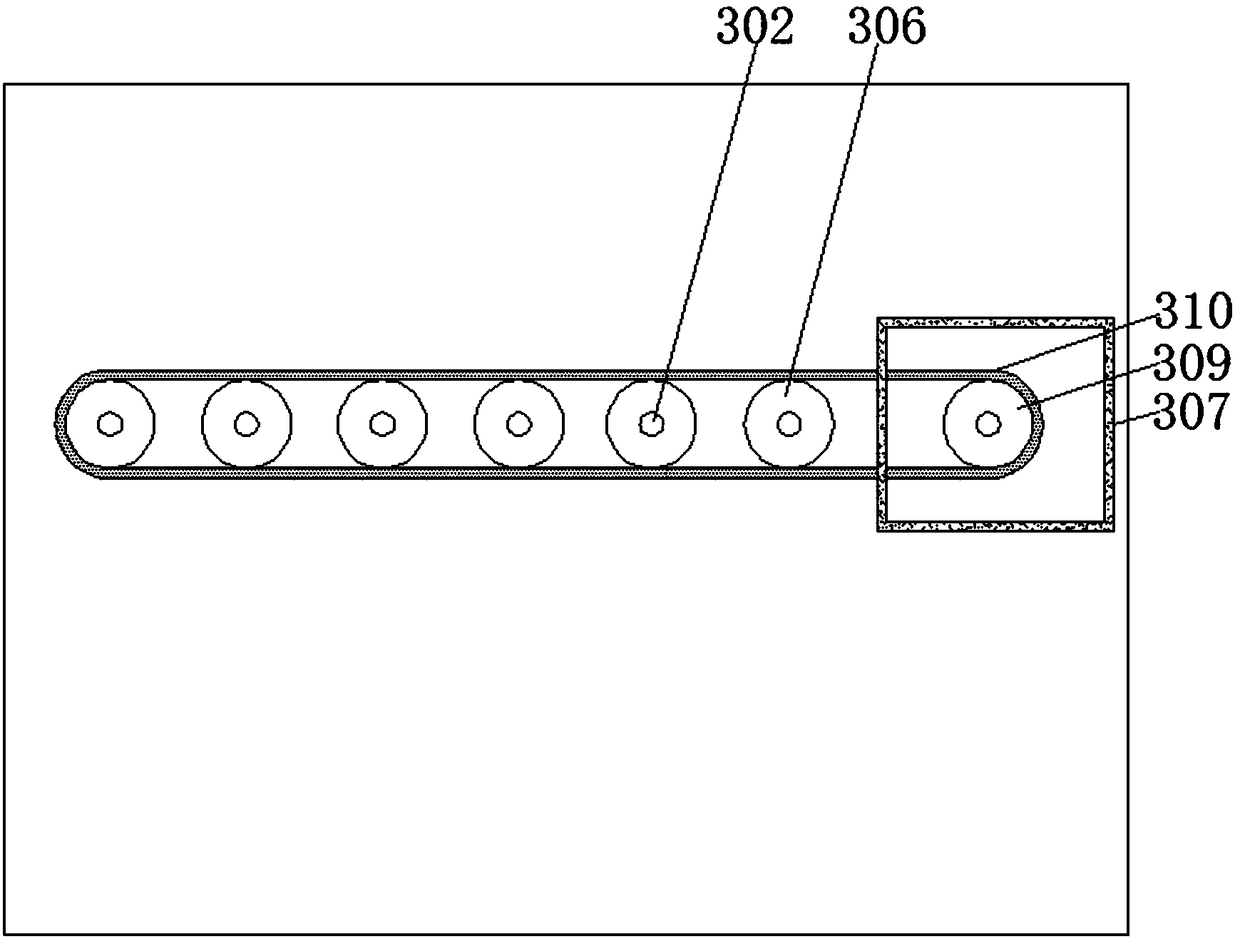

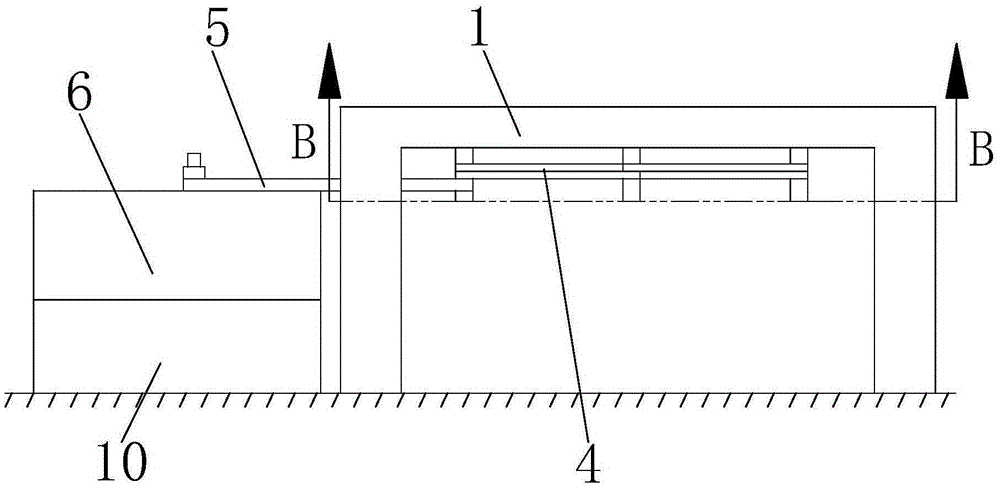

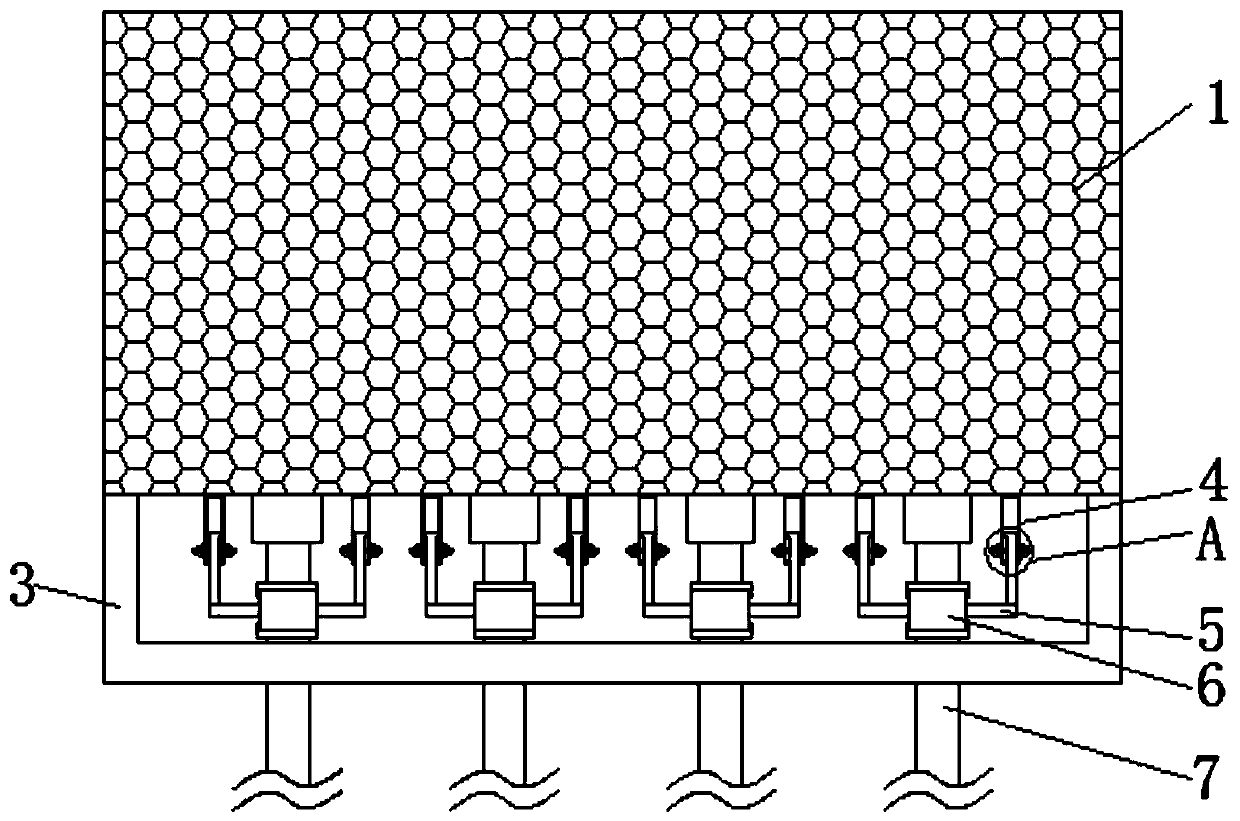

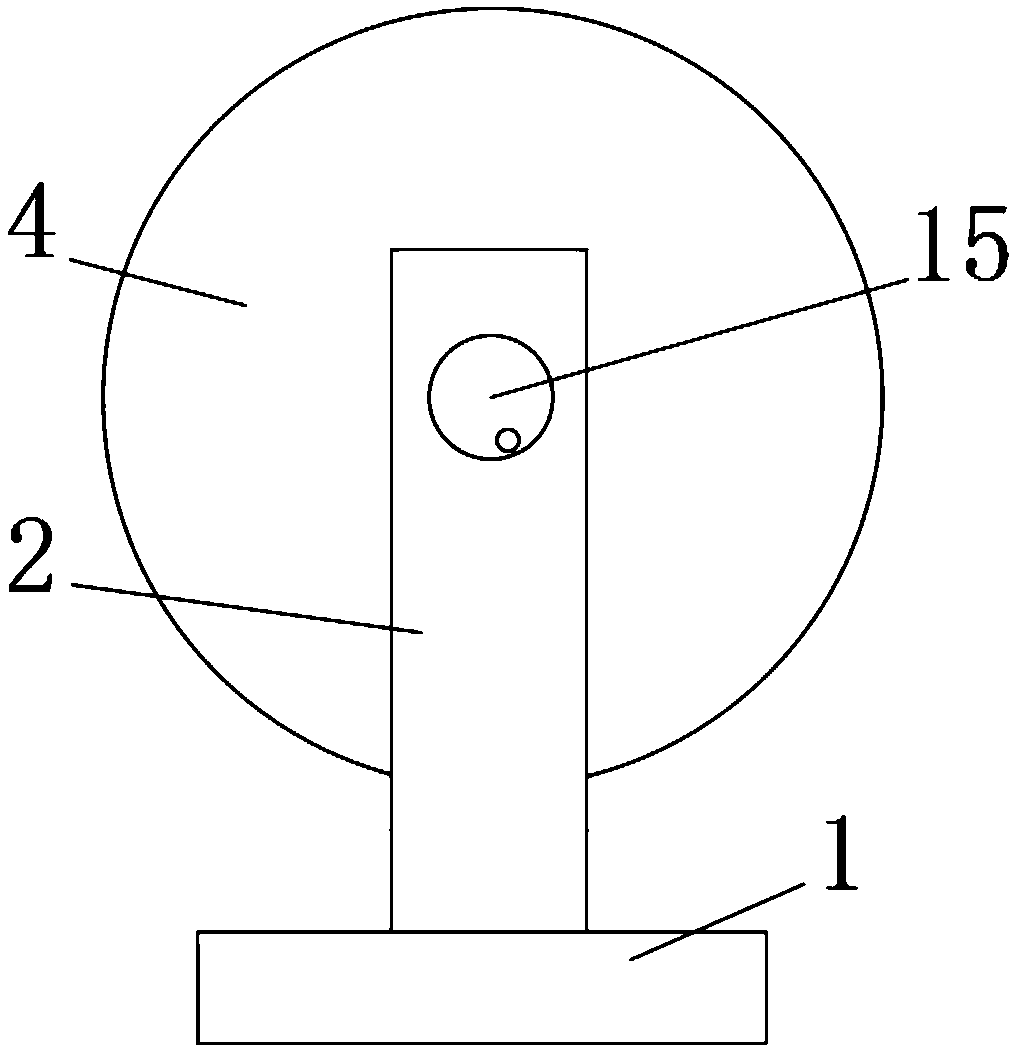

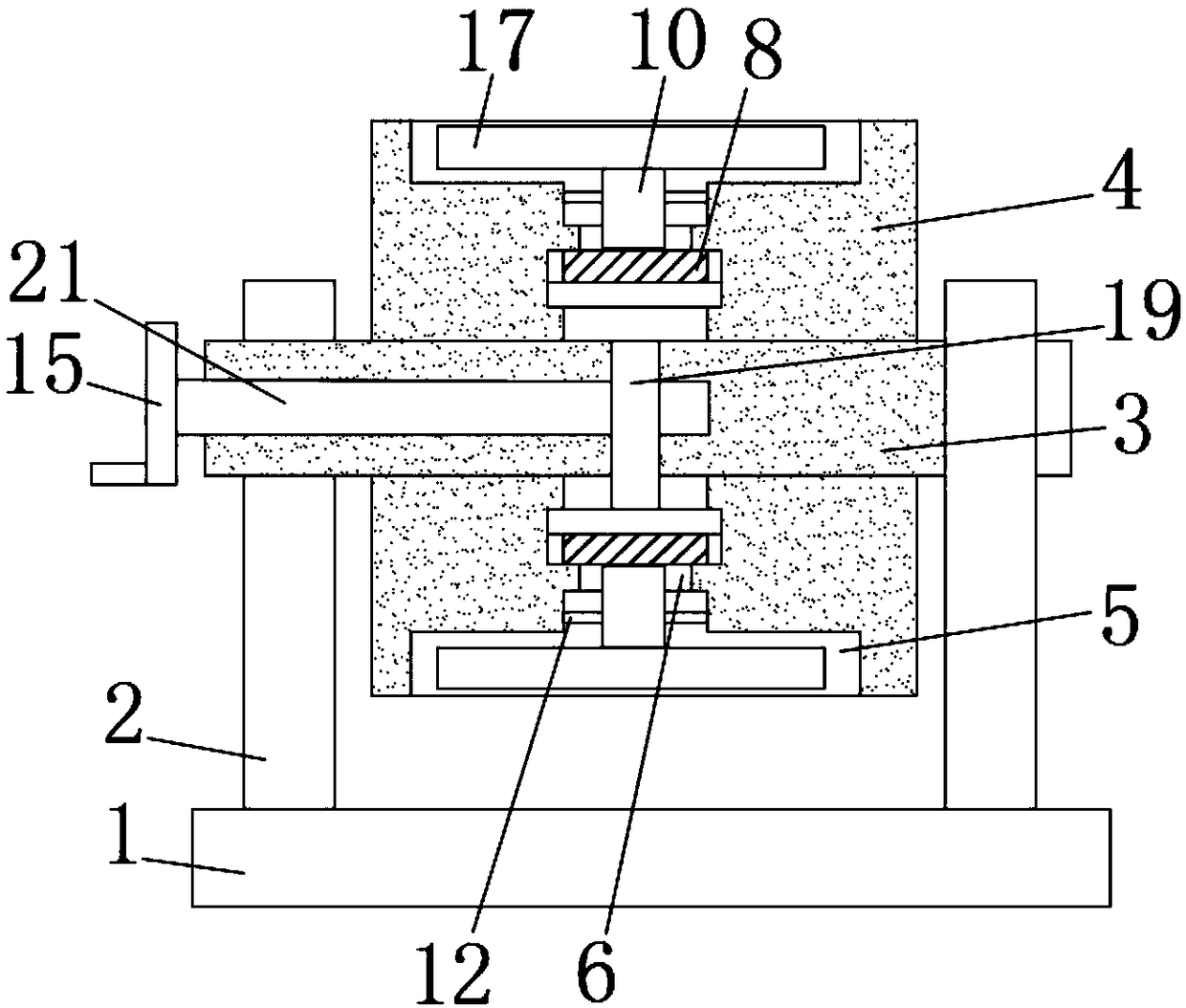

Cleaning device used for solar cell panel

InactiveCN108554859ASolve the use efficiencyClean upPhotovoltaicsCleaning using toolsWater dischargeEngineering

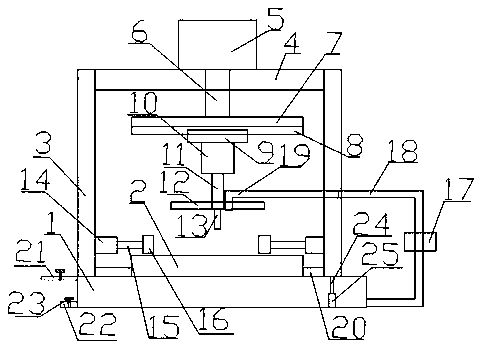

The invention relates to the technical field of solar cell panel cleaning equipment and discloses a cleaning device used for a solar cell panel. The cleaning device comprises a base. The middle of thetop of the base is fixedly connected with a cleaning box. A cleaning mechanism is arranged in the cleaning box. A water discharging mechanism is arranged at the top of the cleaning box. A conveying mechanism is arranged on the left and right sides of the top of the base. Through grooves are formed in the bottoms of the surfaces of the left and right sides of the cleaning box correspondingly. Thecleaning mechanism comprises first sleeves. The first sleeves are fixedly connected with the front side of the inner wall of an inner cavity of the cleaning box. According to the cleaning device, theproblems that since the solar cell panel is held outside for a long time, dust exists on glass, and consequentially, the using efficiency of the solar cell panel is affected are solved, by arranging the cleaning mechanism, the water discharging mechanism, the conveying mechanism and a clamping mechanism, the solar cell panel can be clamped and cleaned, and accordingly, the dust on the glass of thesurface of the solar cell panel can be removed.

Owner:SHAOXING UNIVERSITY

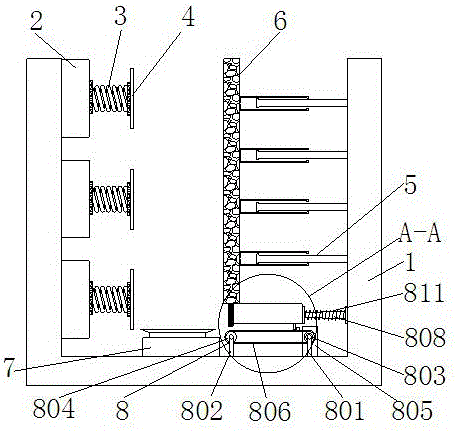

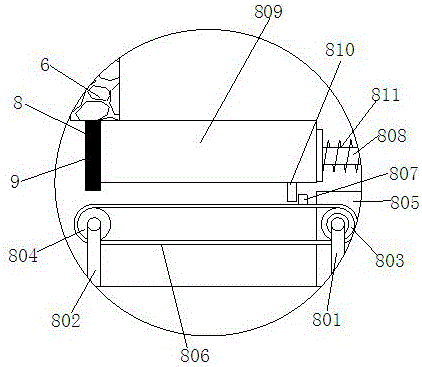

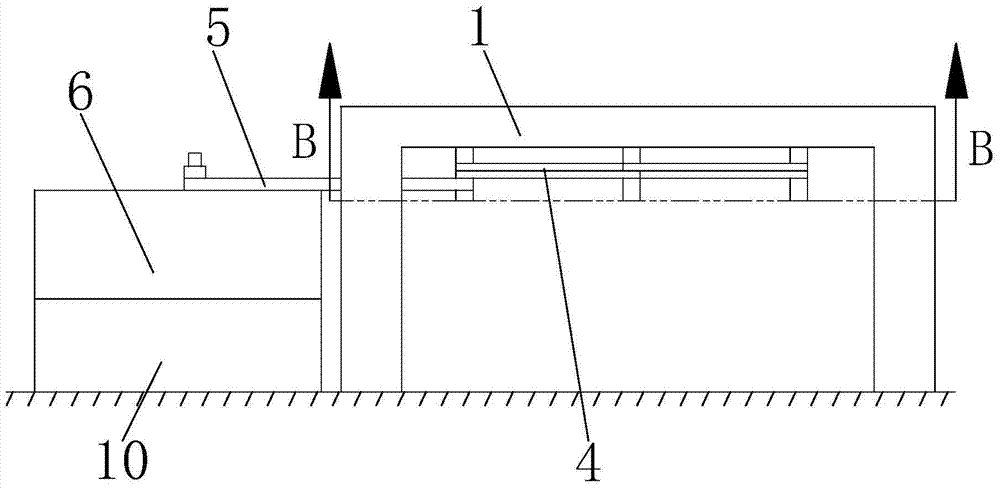

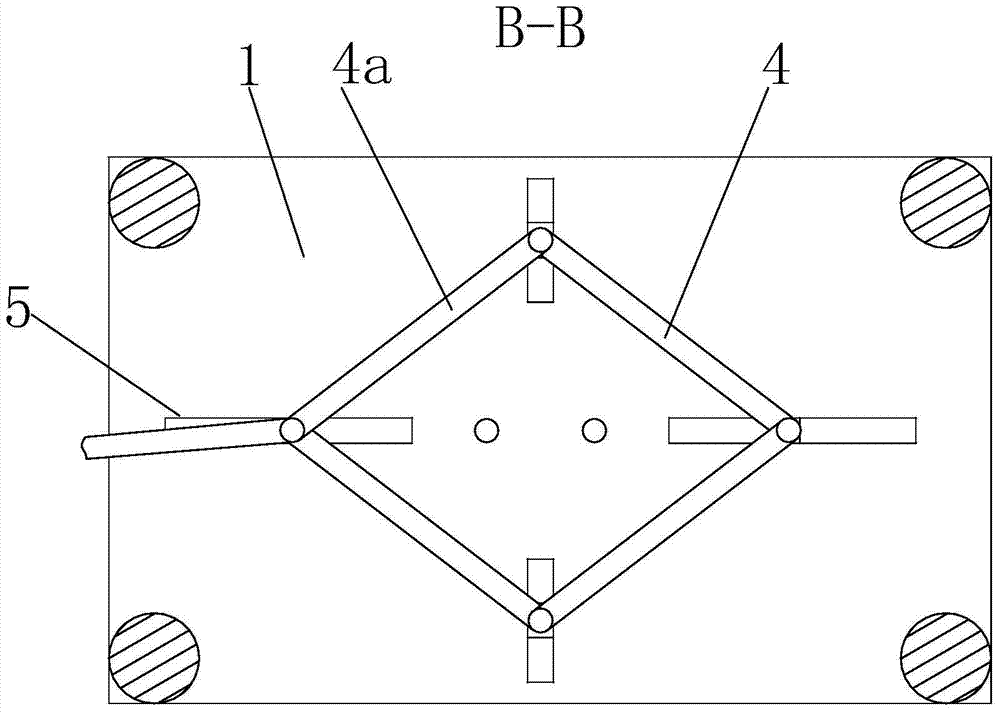

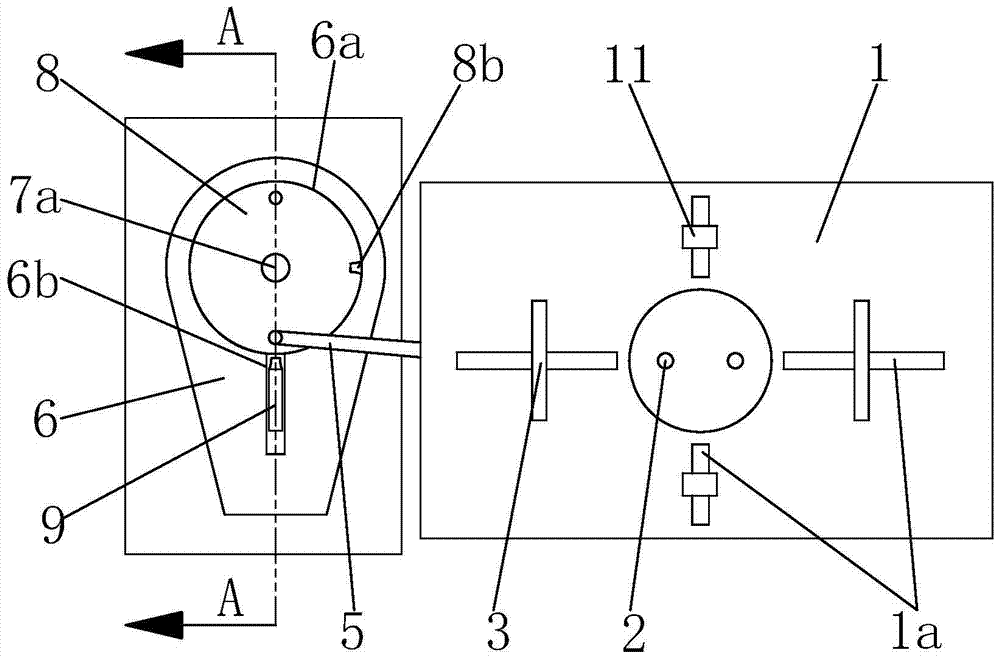

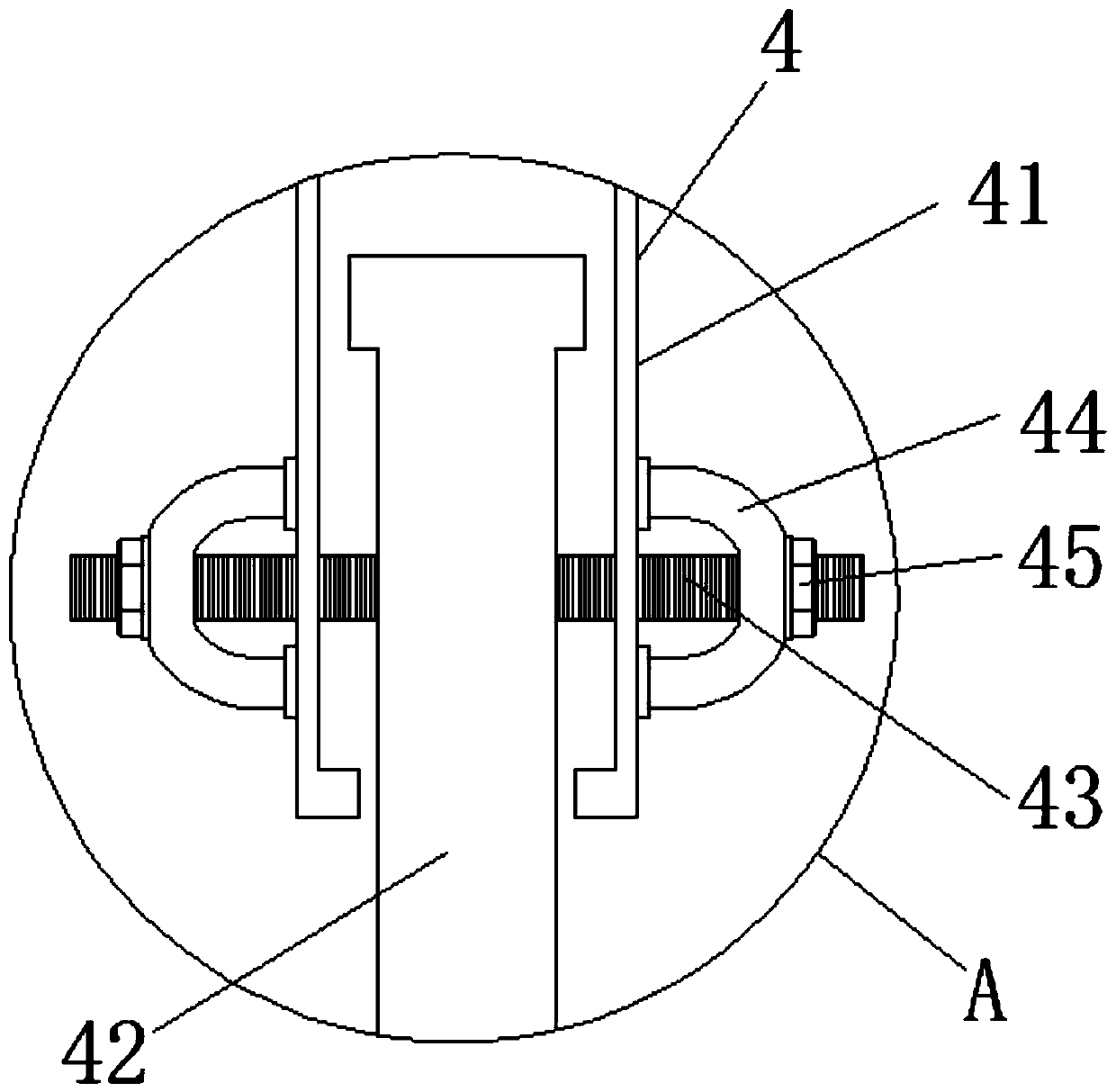

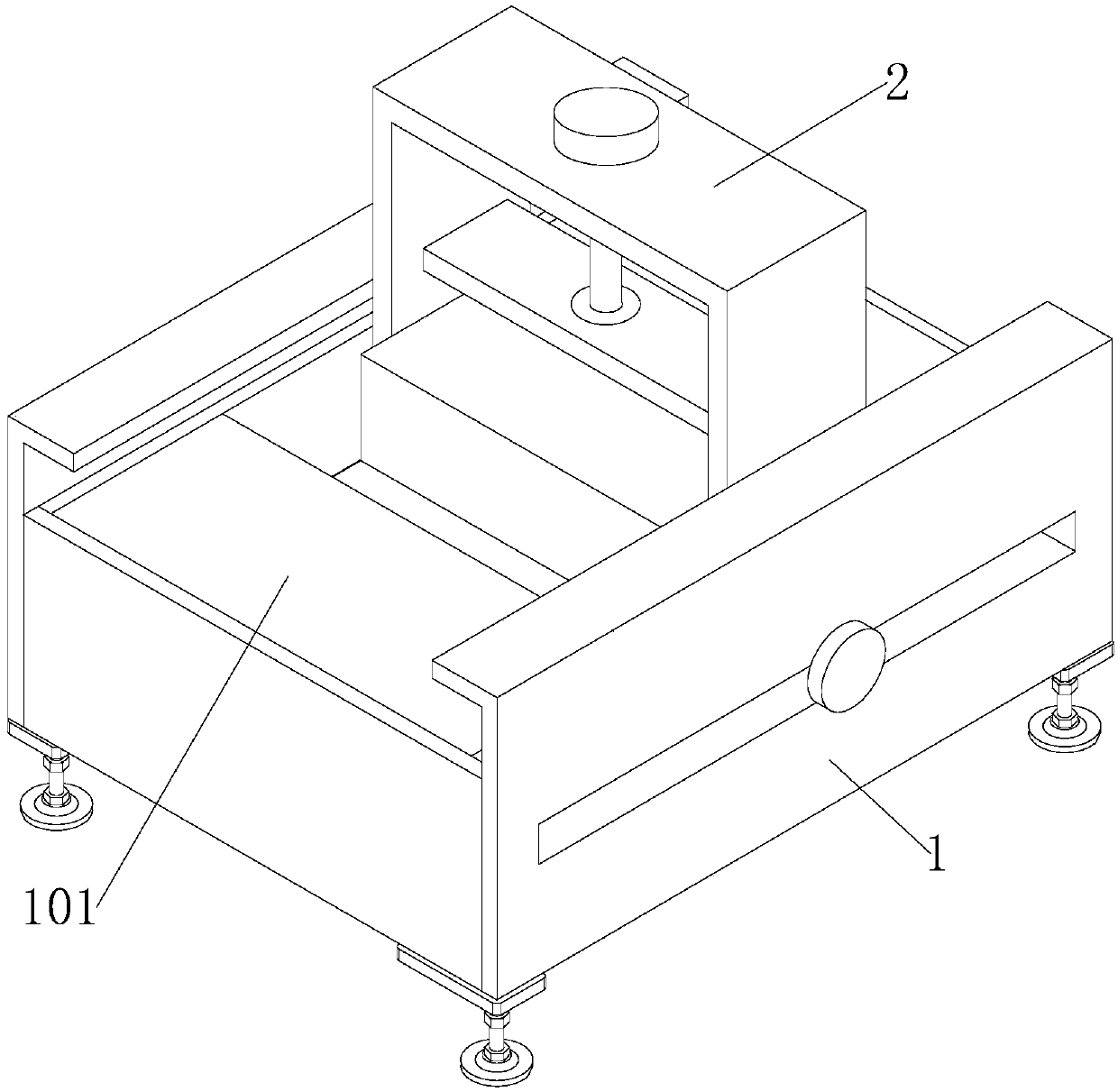

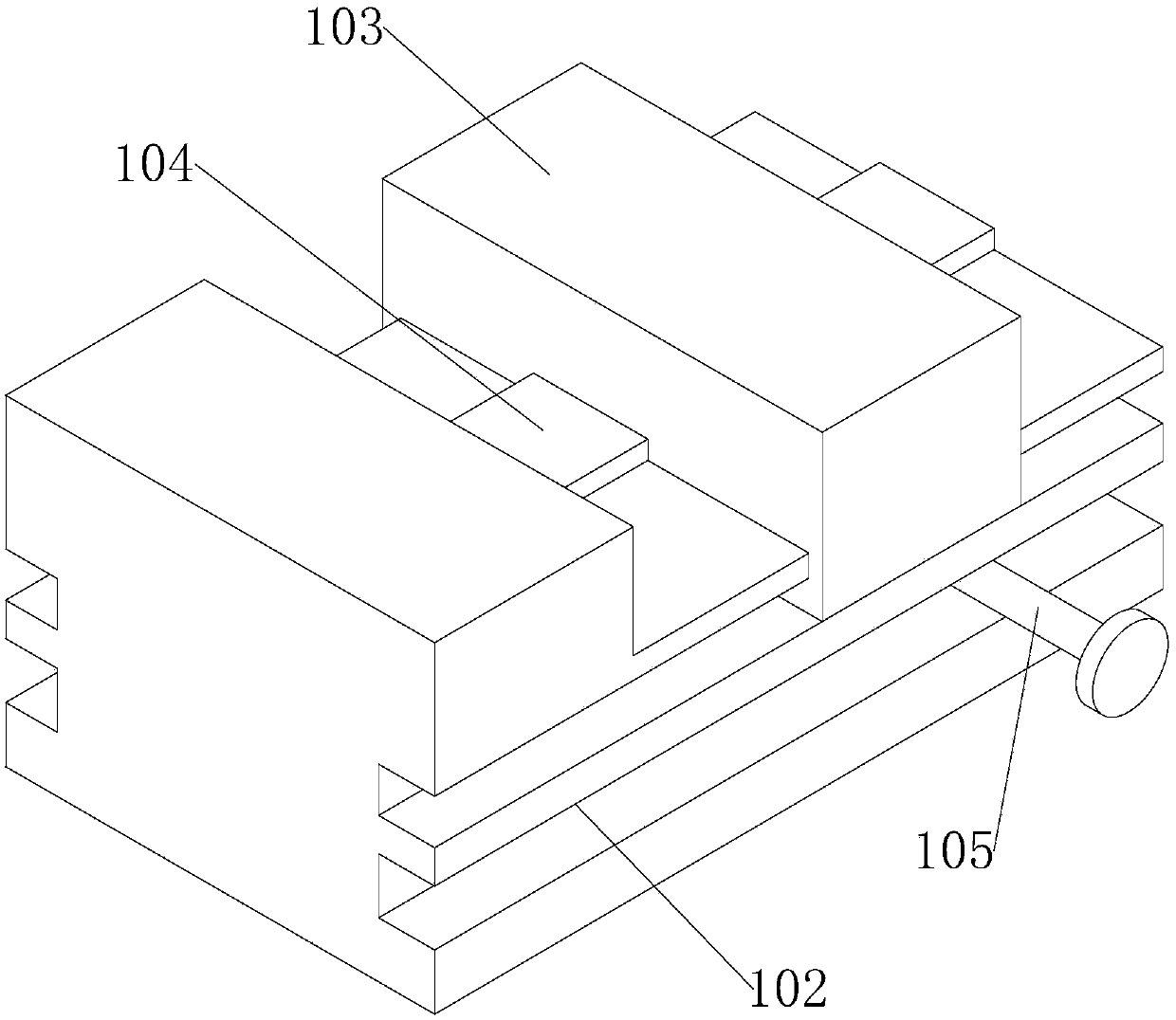

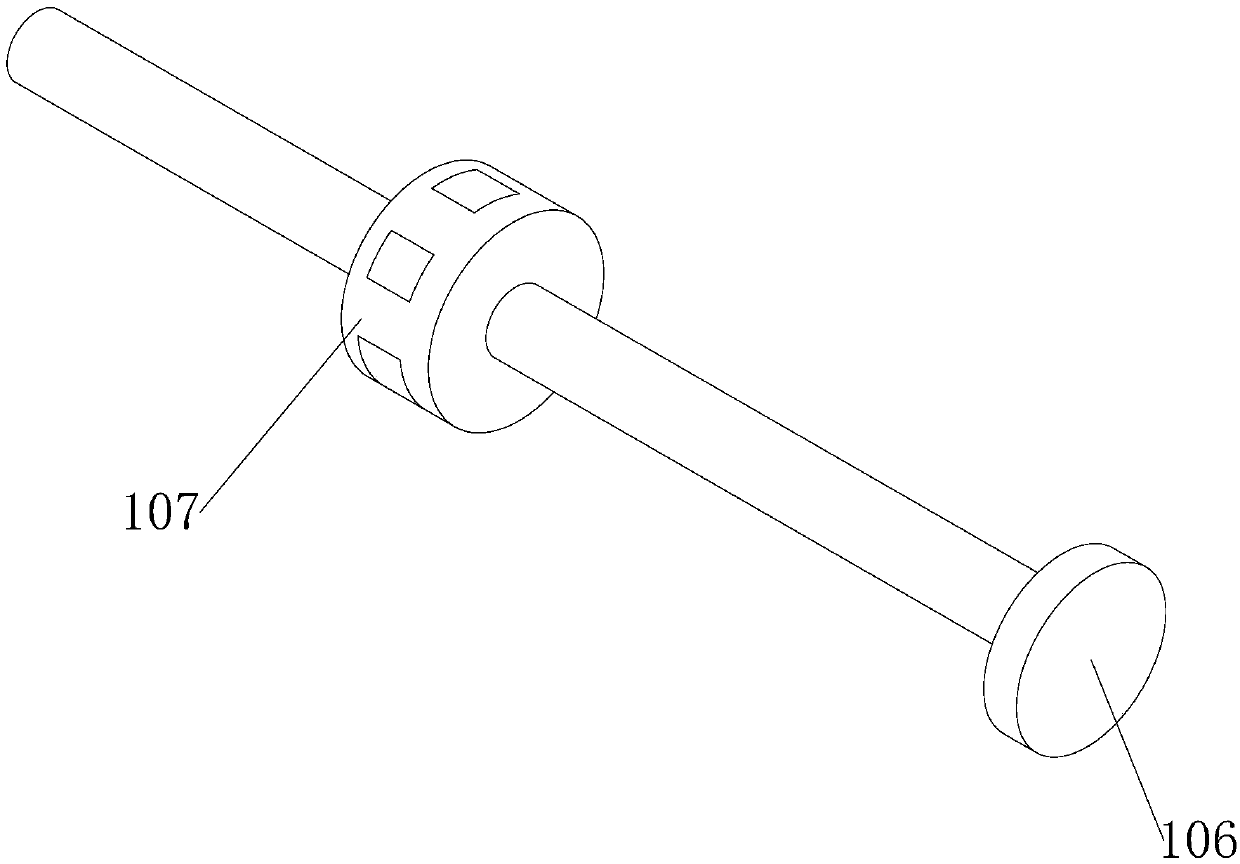

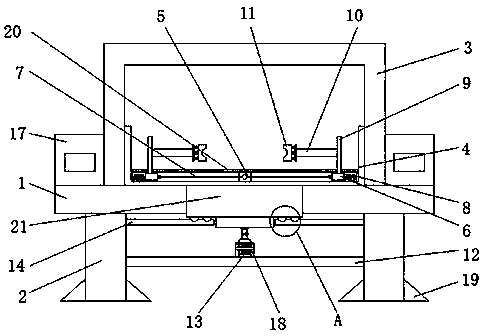

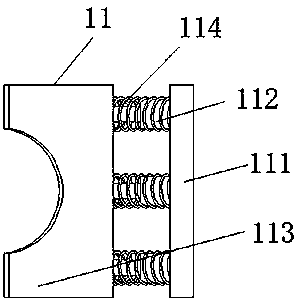

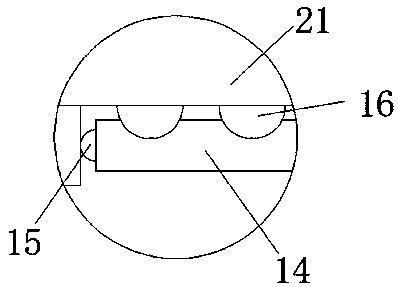

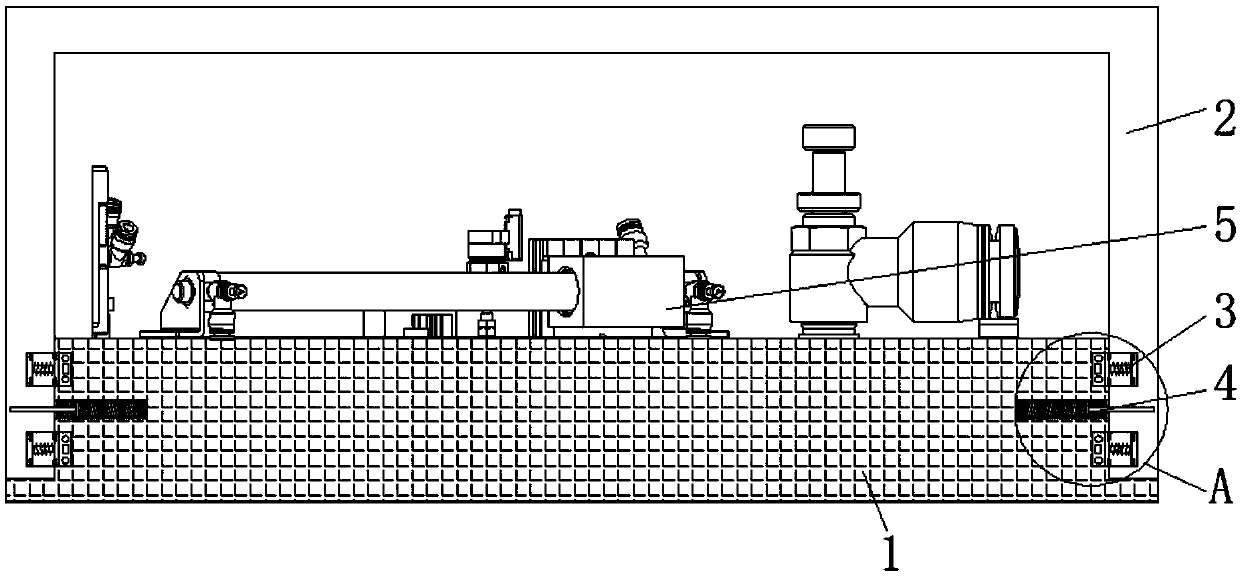

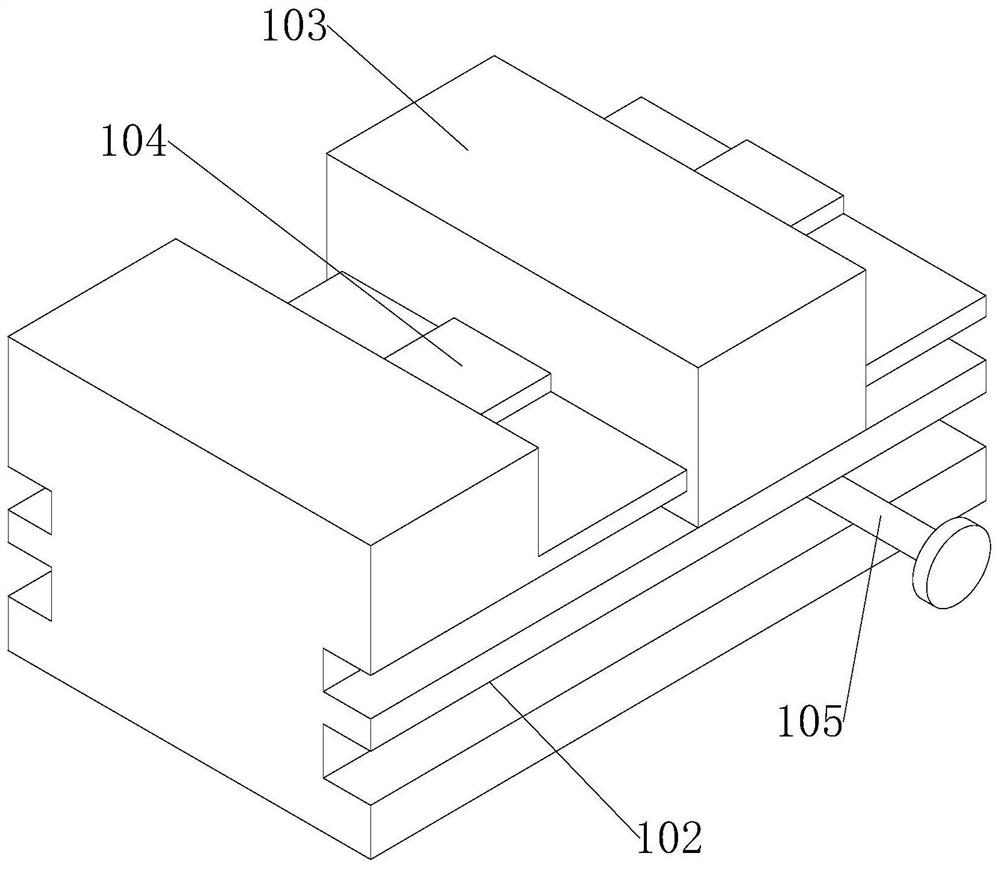

Universal valve body machining fixture

ActiveCN105364563AEasy to useWide range of applicationsPositioning apparatusMetal-working holdersEngineeringMachining

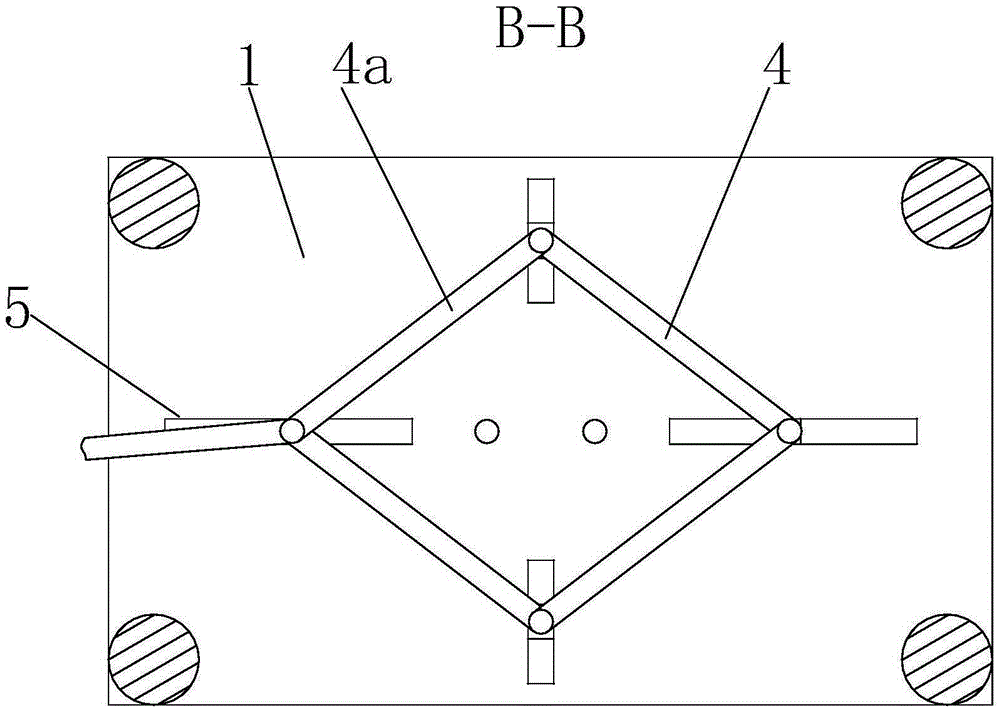

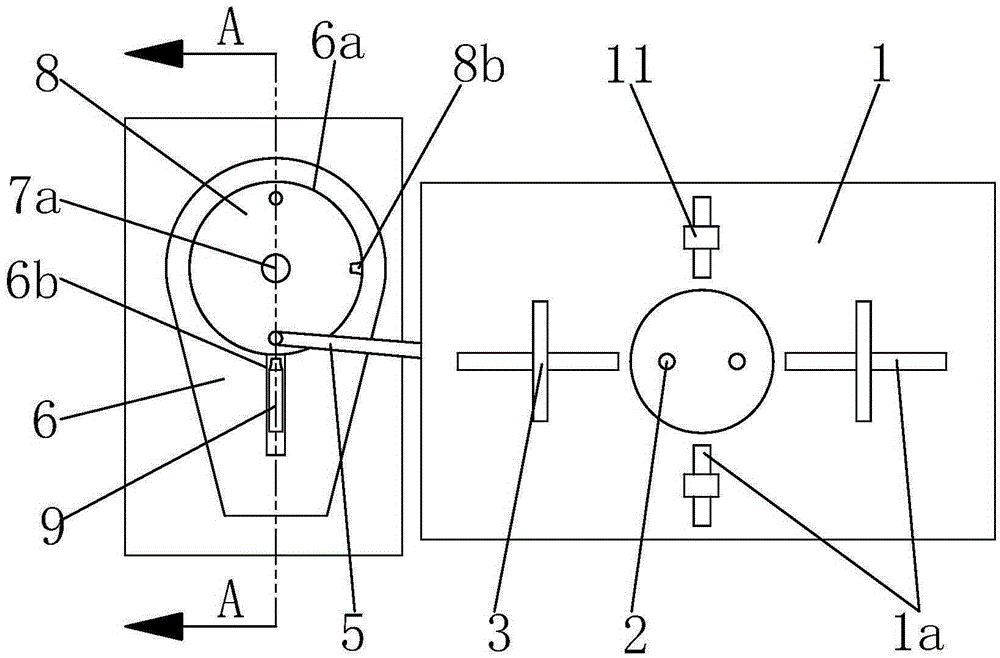

The invention relates to a universal valve body machining fixture. The universal valve body machining fixture comprises a workbench and locating pins, sliding grooves are distributed all around the workbench, and pressing plates and hinged seats are installed in the sliding grooves in a sliding mode; a plane four-bar mechanism is connected between the pressing plates and the hinged seats, a long connecting bar is hinged to the lower end of the left-most pressing plate, the left portion of the long connecting bar is provided with a control rack, the front end of the control rack is provided with a circular groove, a screw is installed in the circular groove in a threaded mode, and an adapting wheel is rotatably installed in the circular groove and hinged to the long connecting rod at any peripheral edge end; an annular groove is formed in the center position of the adapting wheel, the circular arc end of the adapting wheel is provided with a clamping groove, an annular insertion block is fixedly installed on the screw, the front end of the circular groove is communicated with a square groove, an insertion pin is installed in the square groove in a sliding mode, and the center position of the control rack is connected with a supporting rack. According to the universal valve body machining fixture, by means of the connecting mode of the adapting wheel and the control rack, horizontal sliding distance of two pressing plates can be controlled, the effect of clamping valve bodies with different sizes and types can be achieved, and the application range is wide.

Owner:临沂罗开投资有限公司

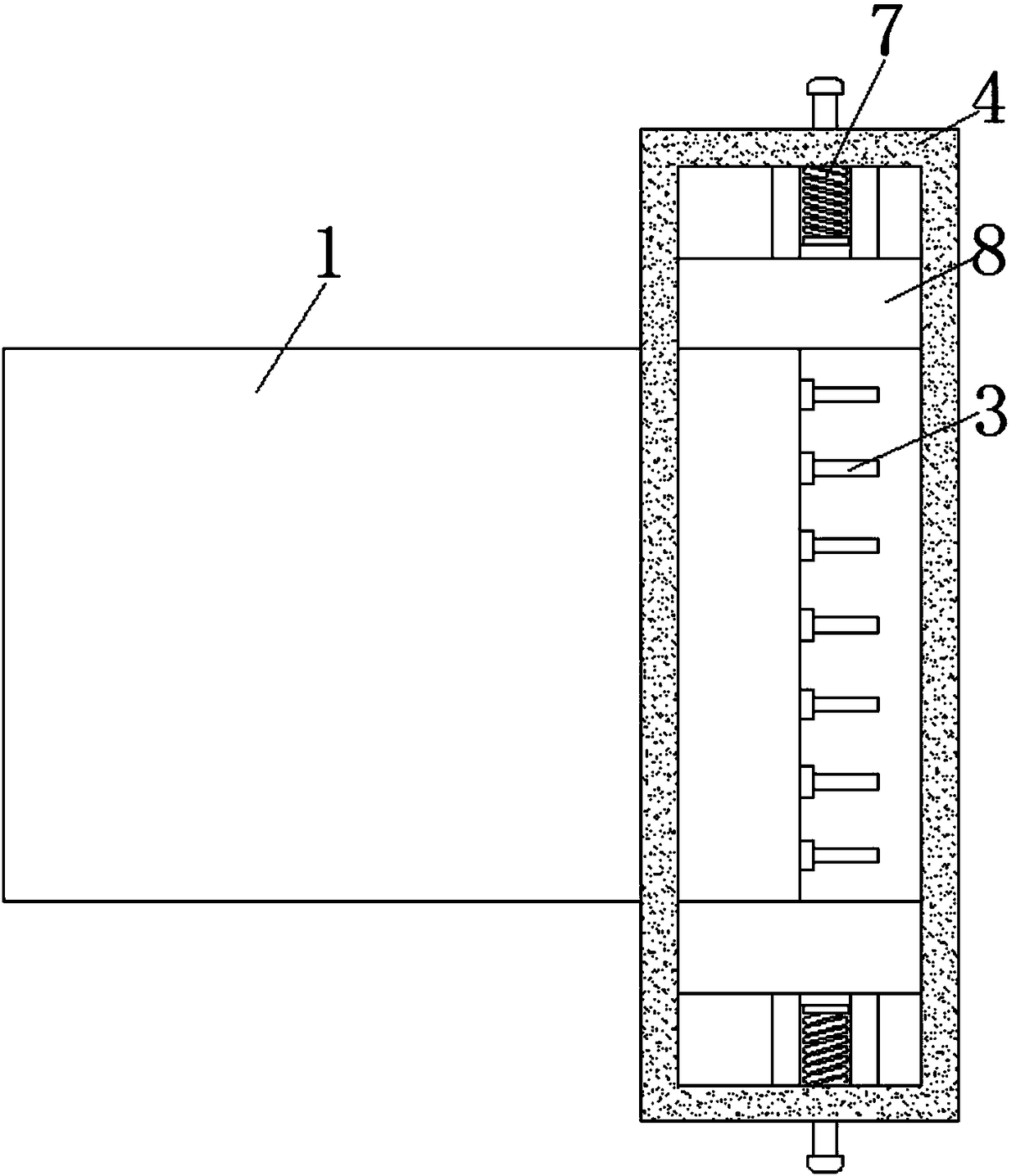

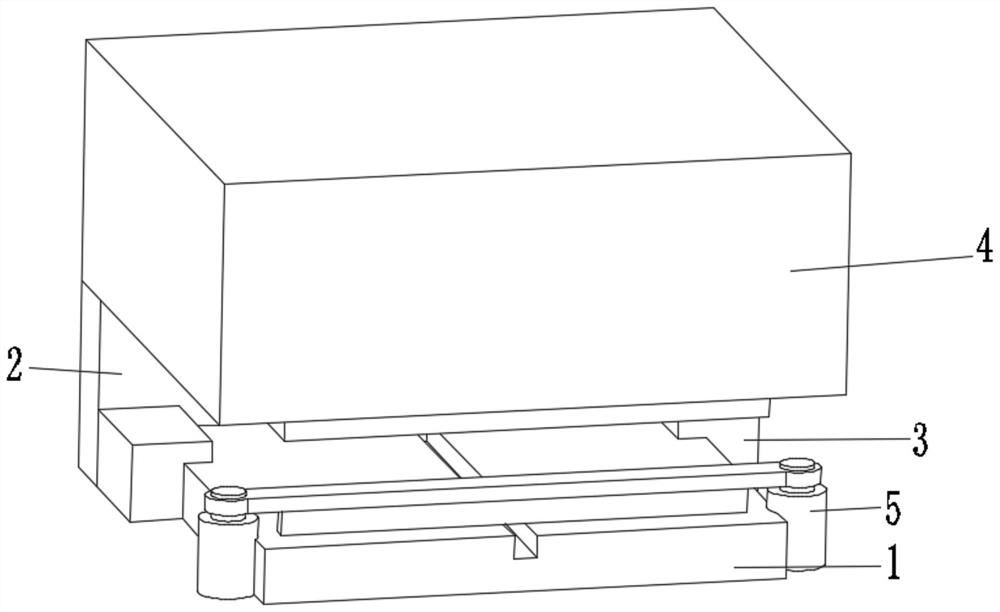

Fixing and clamping device for transformer box

ActiveCN106300080AEffective limitAchieve fixitySubstation/switching arrangement detailsTransformerEngineering

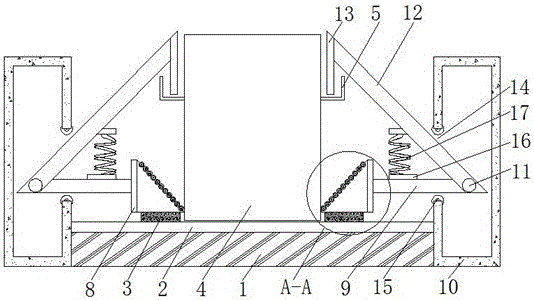

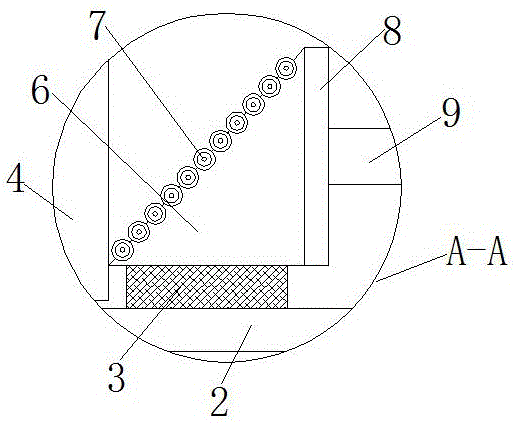

The invention discloses a fixing and clamping device for a transformer box. The fixing and clamping device comprises a base. A sliding rail is fixedly connected to the upper surface of the base. Two sliding blocks are connected to the interior of the sliding rail in a sliding mode. The transformer box is placed between the two sliding blocks. The two sides of the transformer box are provided with L-shaped hooks. The tops of the sliding blocks are fixedly connected with the bottoms of two triangular plates. The inclined faces of the two triangular plates are each provided with a first pulley. The right angle sides of the triangular plates are fixedly connected with one side of a fixing plate. The transformer box is improved, due to cooperation of the sliding rail, the sliding blocks, the triangular plates, the first pulleys and the transformer box, under the pressure of the transformer box, the triangular plates and the first pulleys move back to back, and therefore the sliding blocks are driven to slide left and right inside the sliding rail; due to cooperation of the fixing plate, a through hole and a second pulley, the fixing plate is effectively limited, and therefore the bottom end of the transformer box is fixed and clamped, and the fixing and clamping effects are achieved.

Owner:优尼斯工业服务(徐州)有限公司

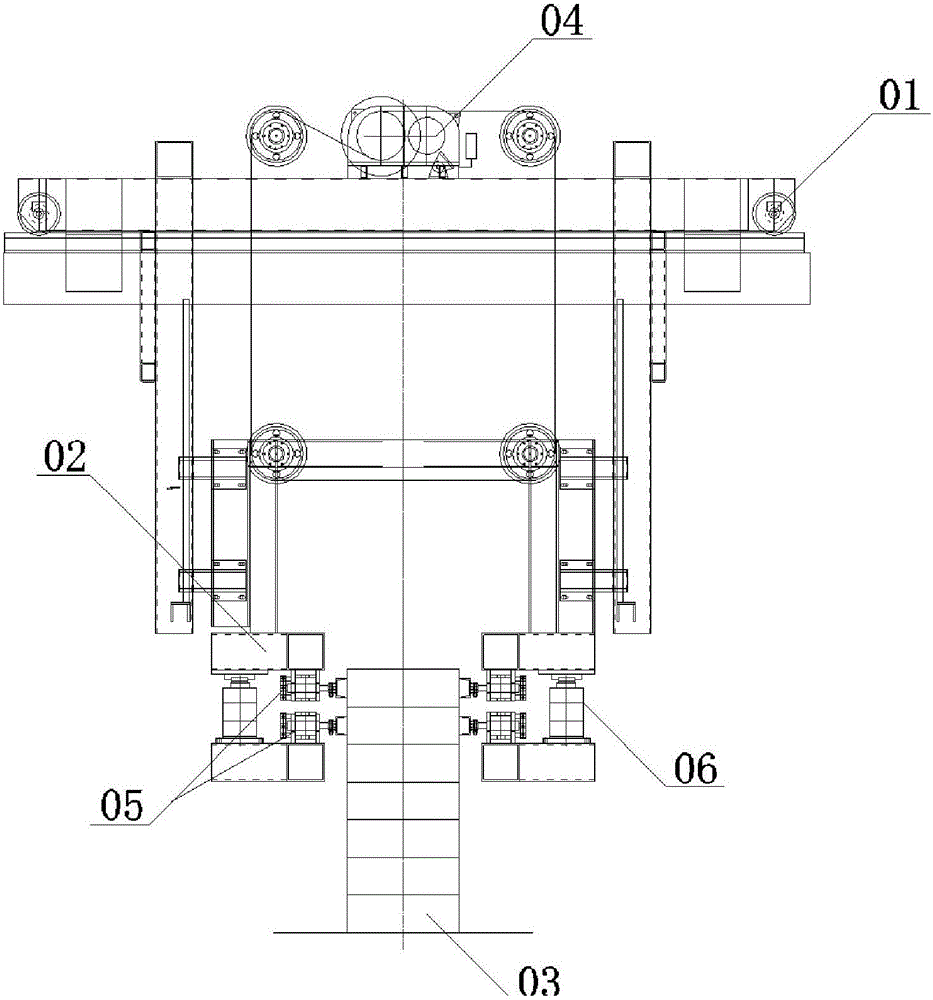

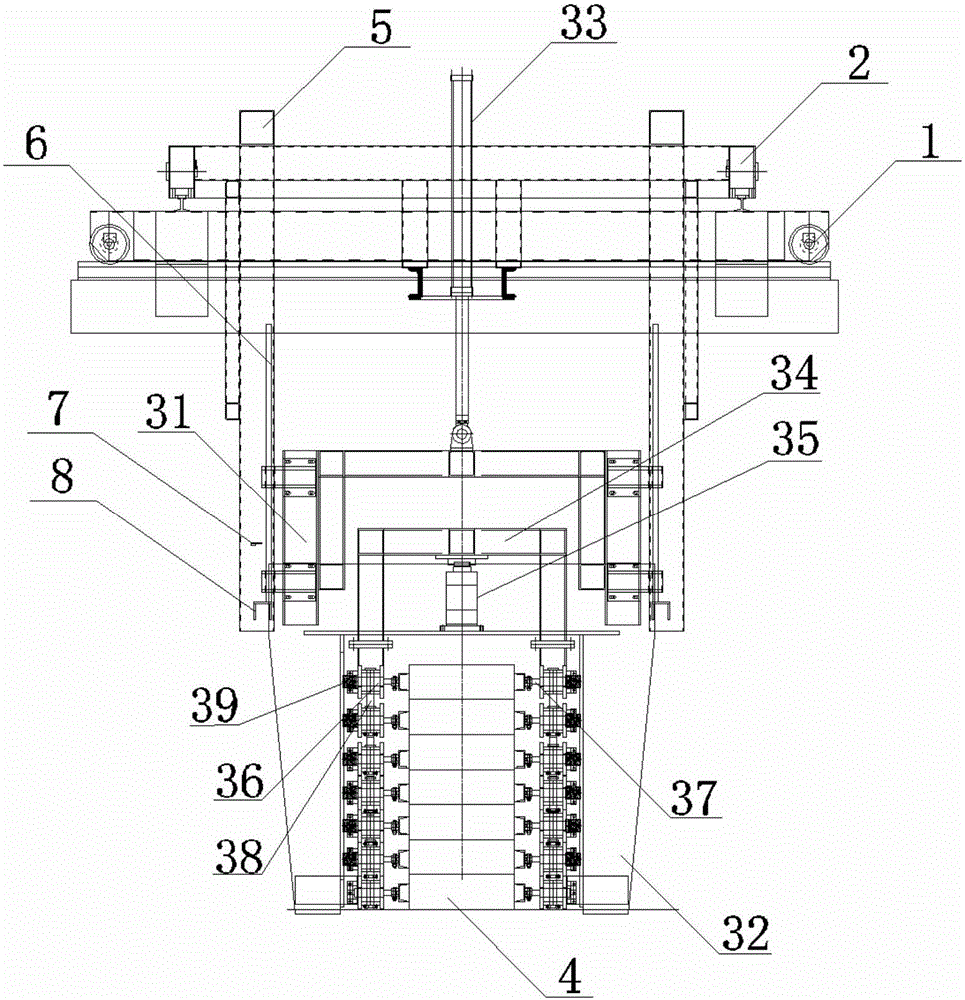

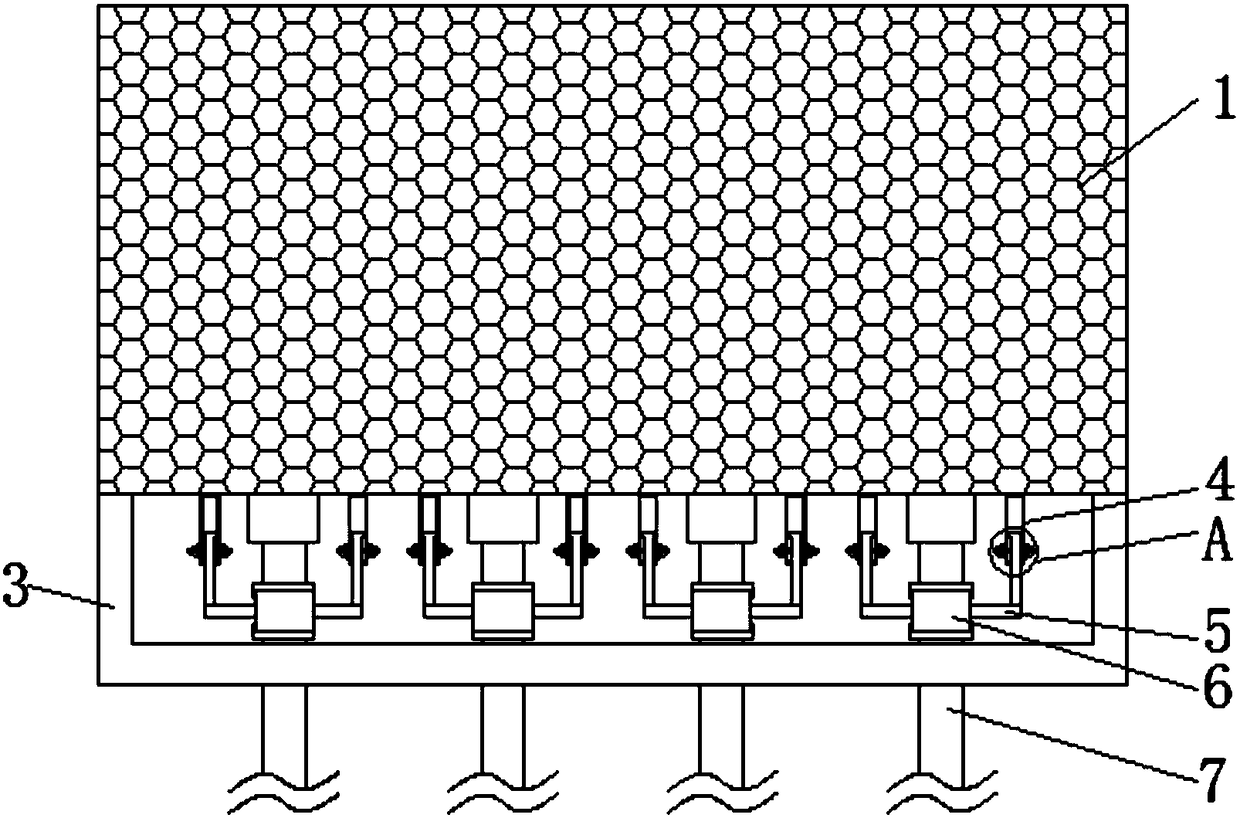

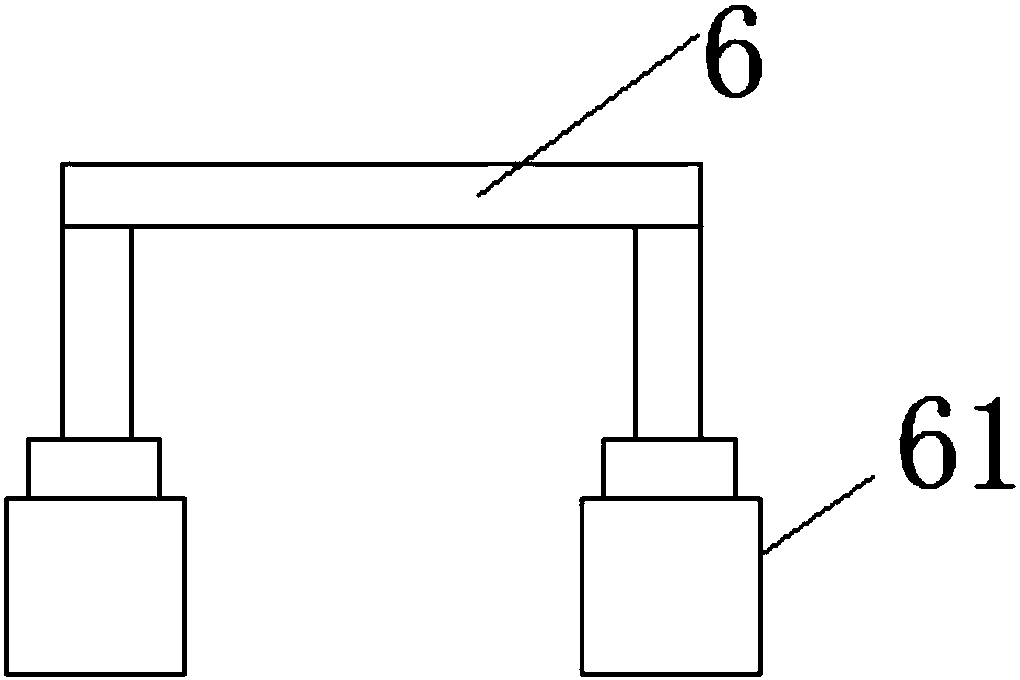

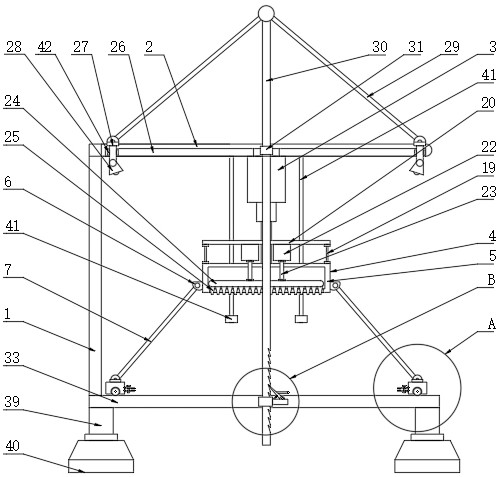

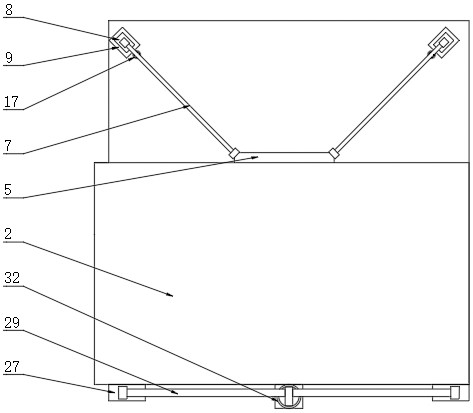

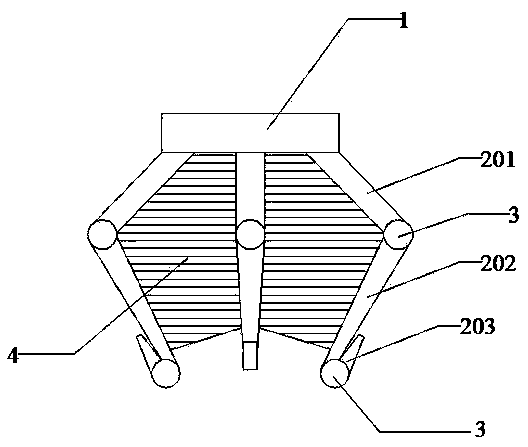

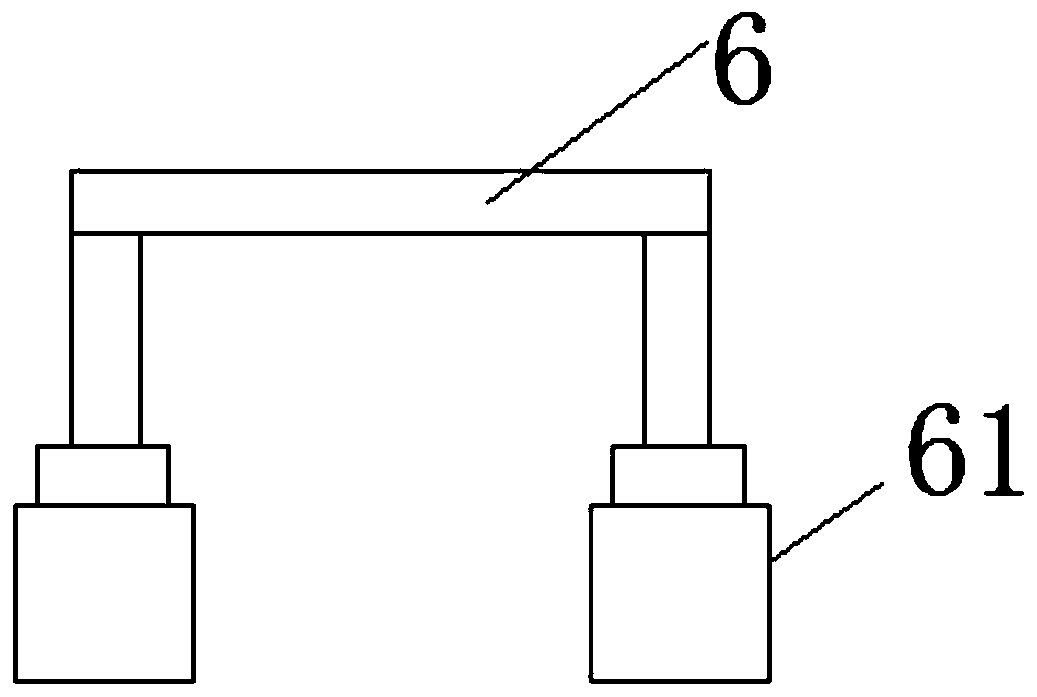

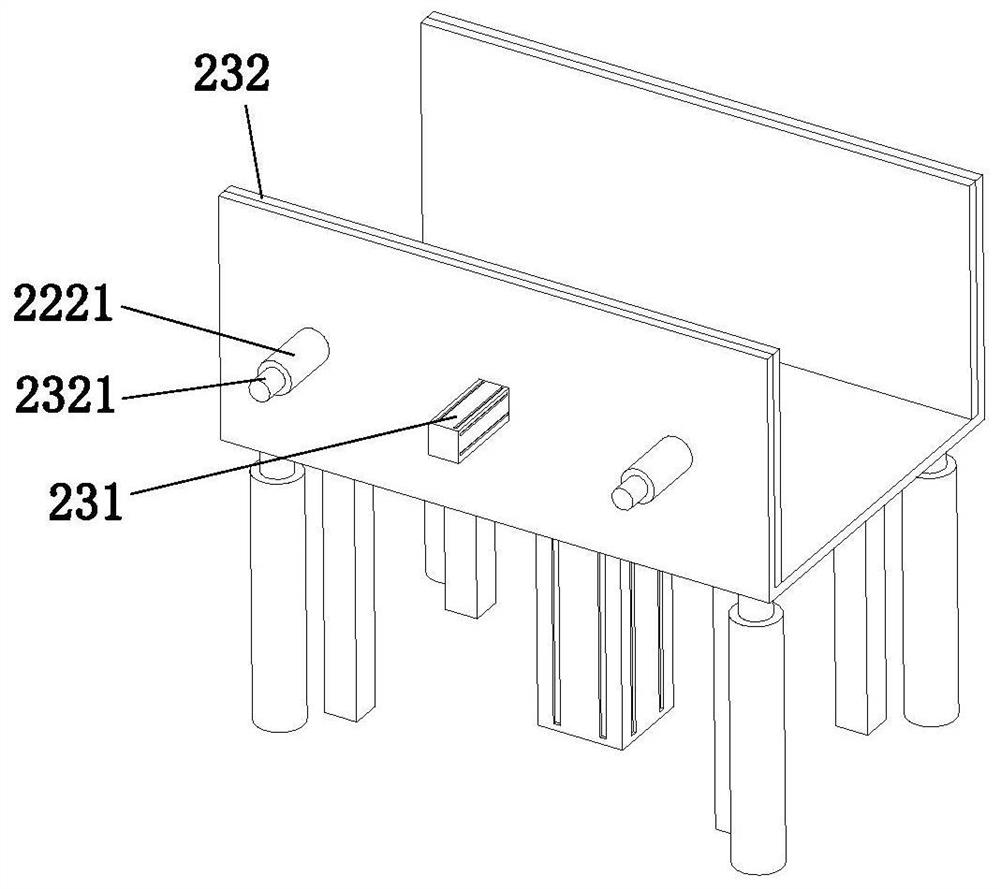

Separator for aerated concrete light bricks

The invention relates to the technical field of brick making mechanical equipment, and discloses a separator for aerated concrete light bricks. The separator comprises a front-back sliding crown block, a left-right sliding crown block fixed to the front-back sliding crown block, and a machine body fixed to the left-right sliding crown block. The machine body comprises a lifting frame, a fixed plate fixed to the lifting frame, a lifting oil cylinder used for driving the lifting frame to move up and down, a brick clamping frame, a brick release oil cylinder connected with the lifting frame and the brick clamping frame, multiple sets of brick clamping bases with the number matched with that of the to-be-separated light bricks, and multiple sets of brick clamping oil cylinders correspondingly arranged on the brick clamping bases. The brick clamping bases include the first set of brick clamping bases fixed to the brick clamping frame, the last set of brick clamping bases fixed to the fixed plate, and at least one set of middle brick clamping bases. Each set of brick clamping bases are sequentially connected through coupling shafts. The first set of brick clamping bases and the middle brick clamping bases are each provided with a slide wheel. The slide wheels are connected with the fixed plate in a sliding manner. The separator is flexible to move, capable of achieving one-time brick release, high in work effect and low in cost.

Owner:佛山市南海蓝淇机械设备有限公司

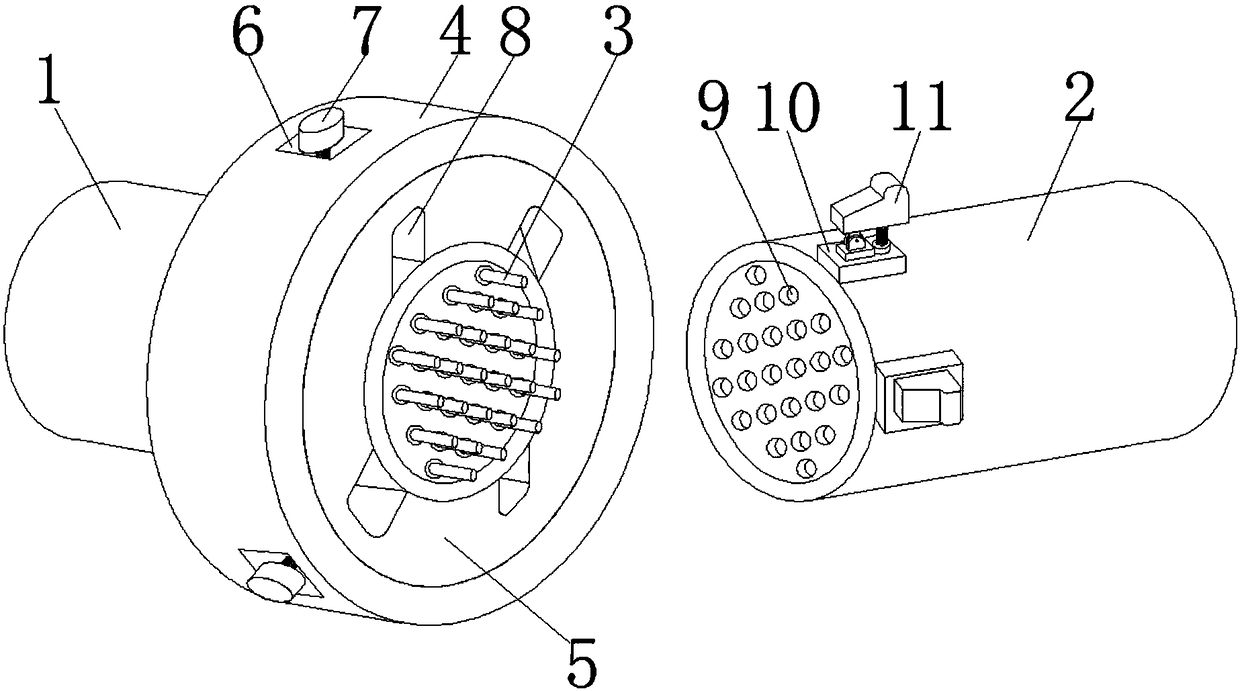

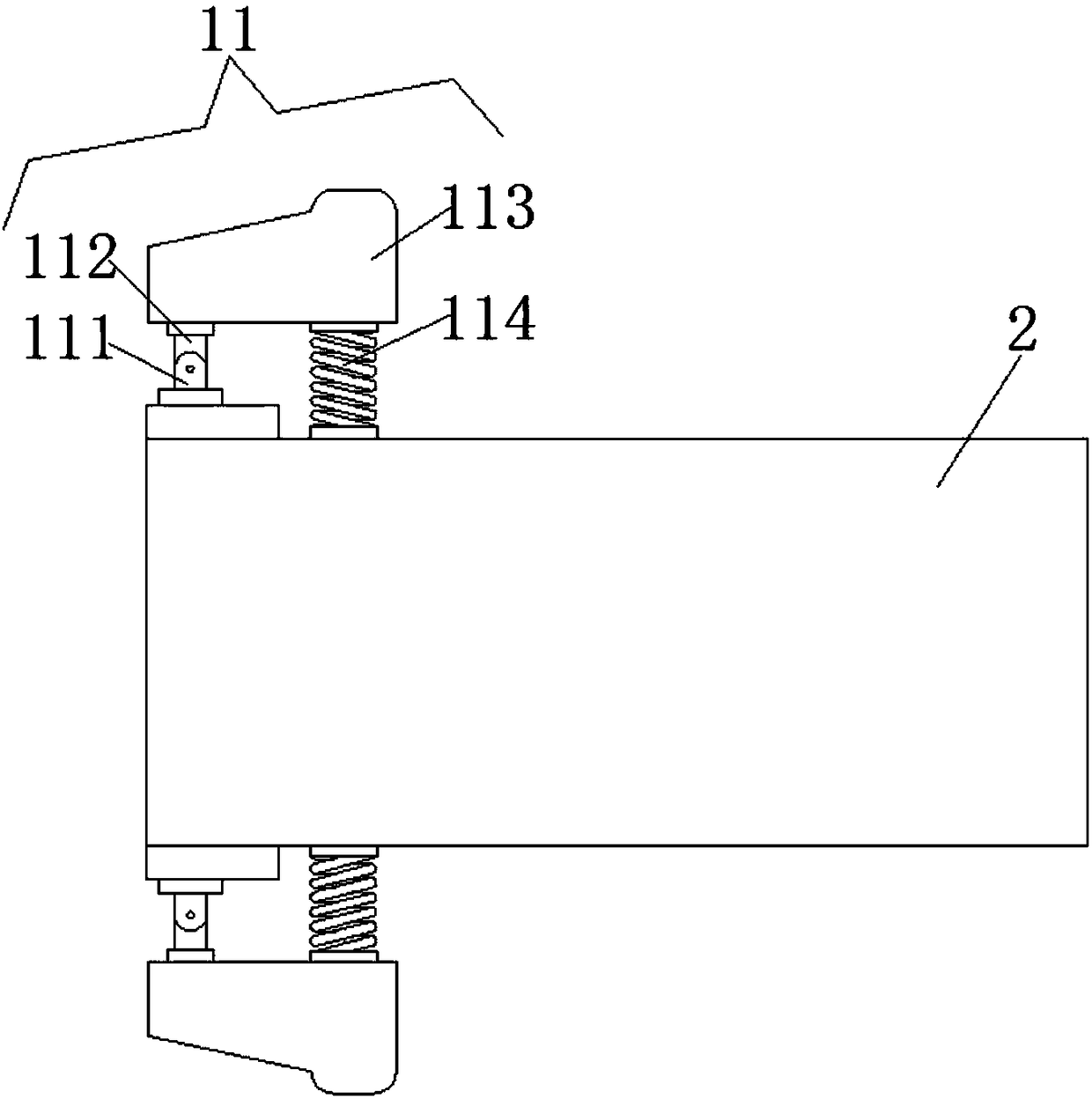

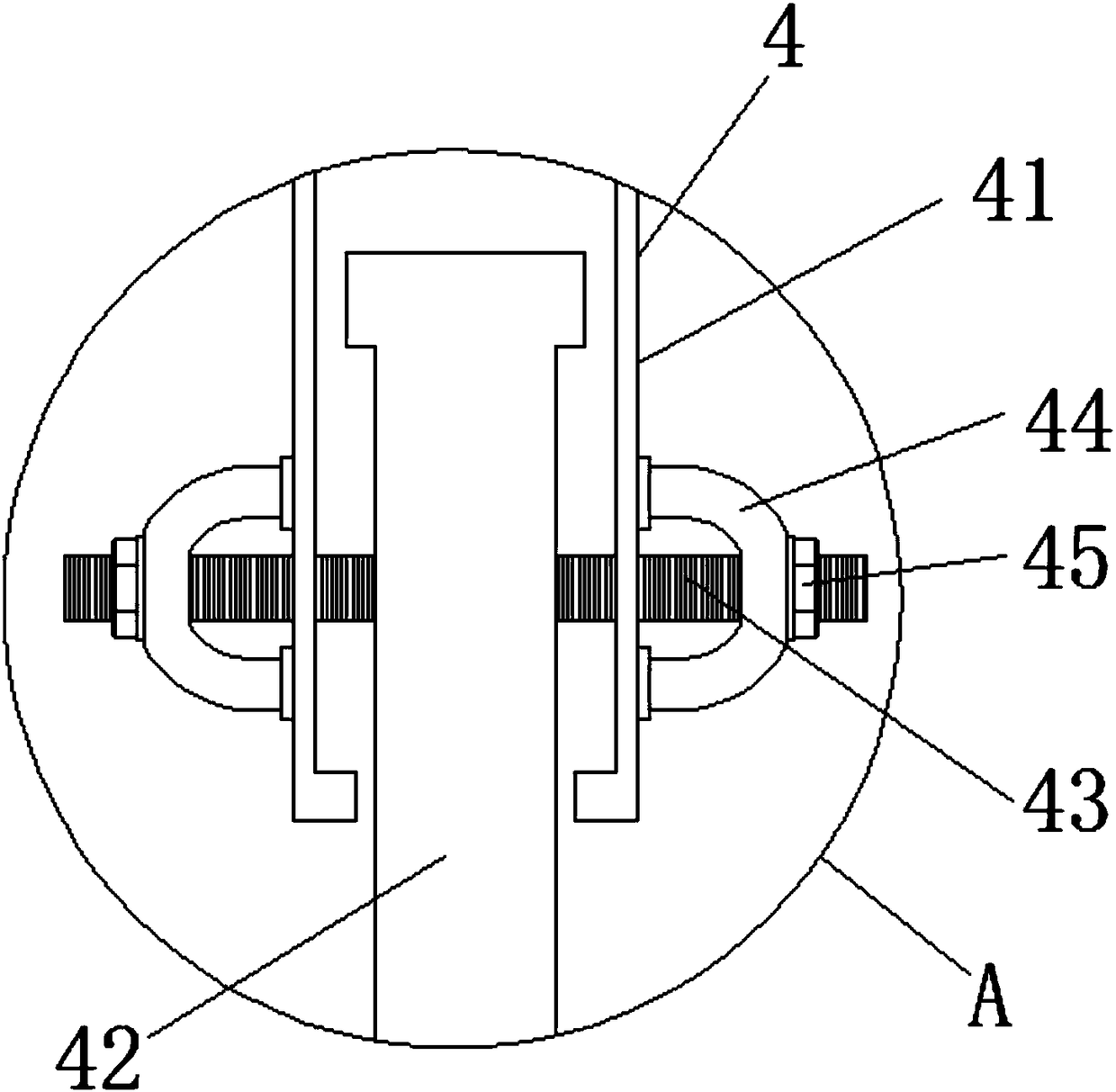

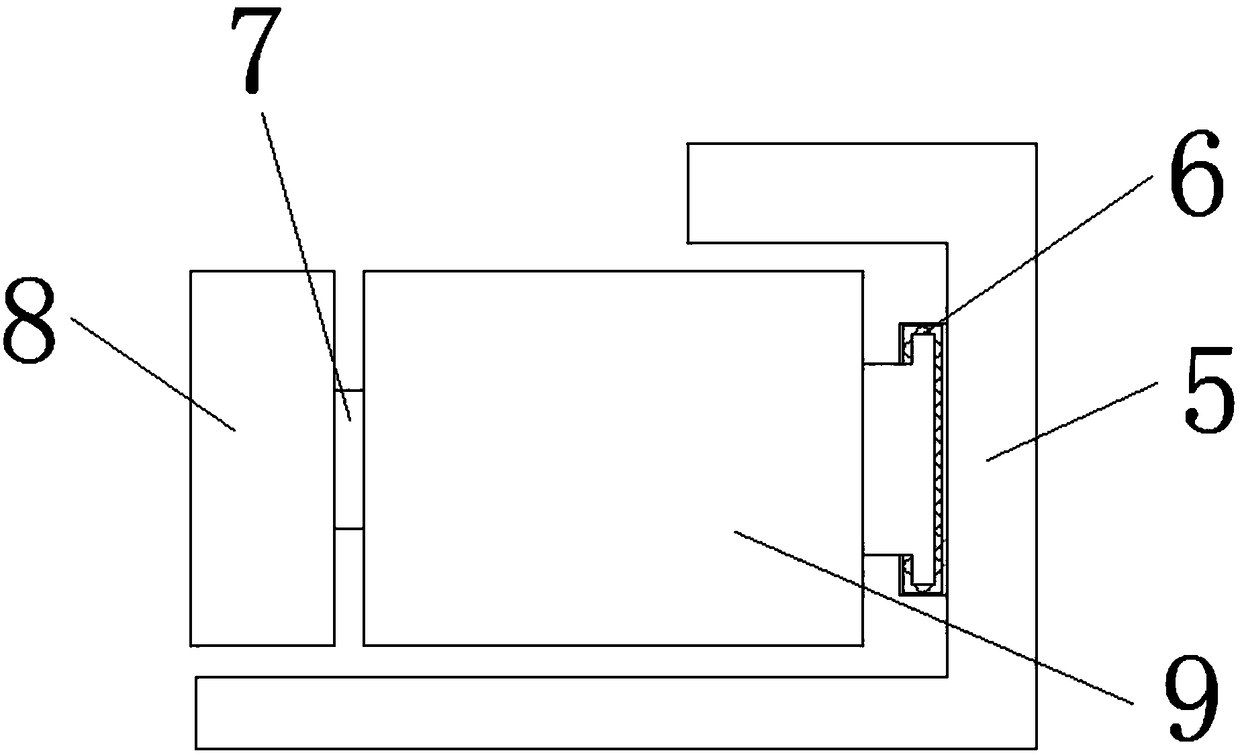

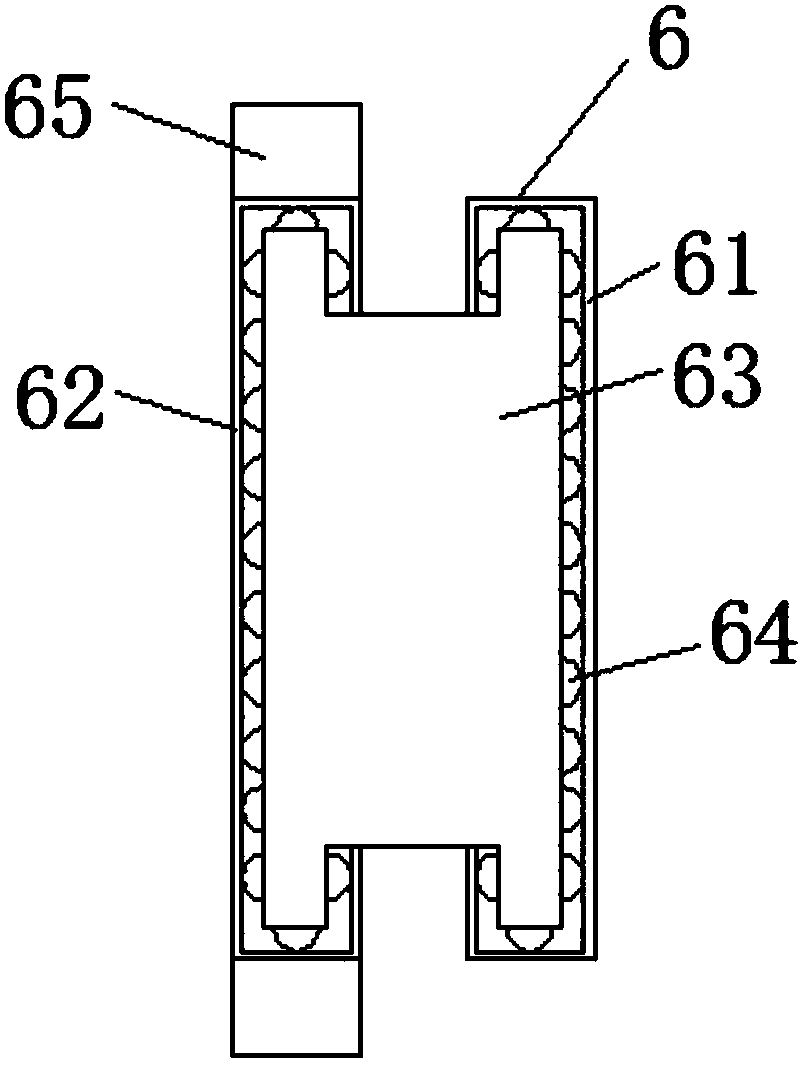

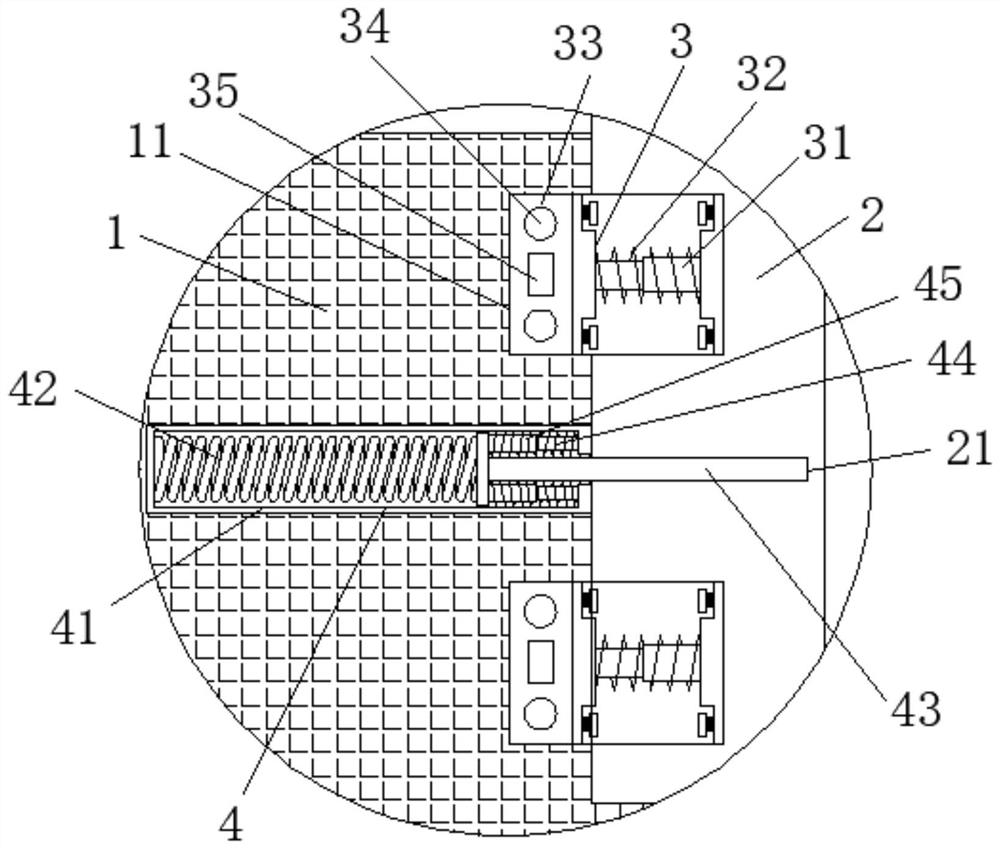

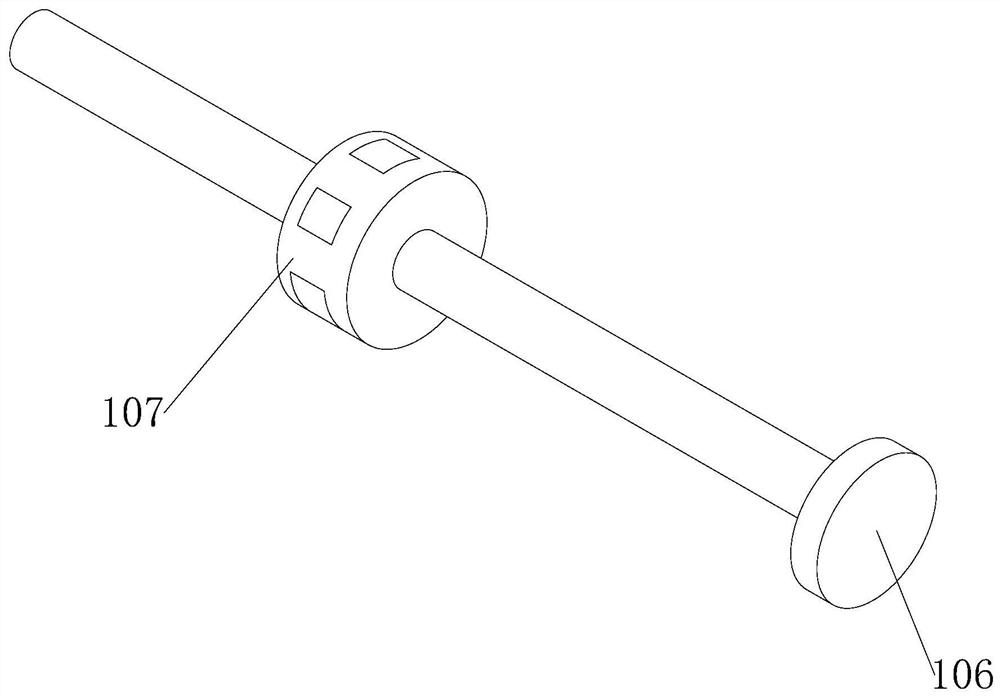

Interface convenient to connect for photovoltaic microgrid

InactiveCN108173068AFirmly connectedTo achieve the effect of clampingCoupling device detailsTwo-part coupling devicesMicrogridElectrical and Electronics engineering

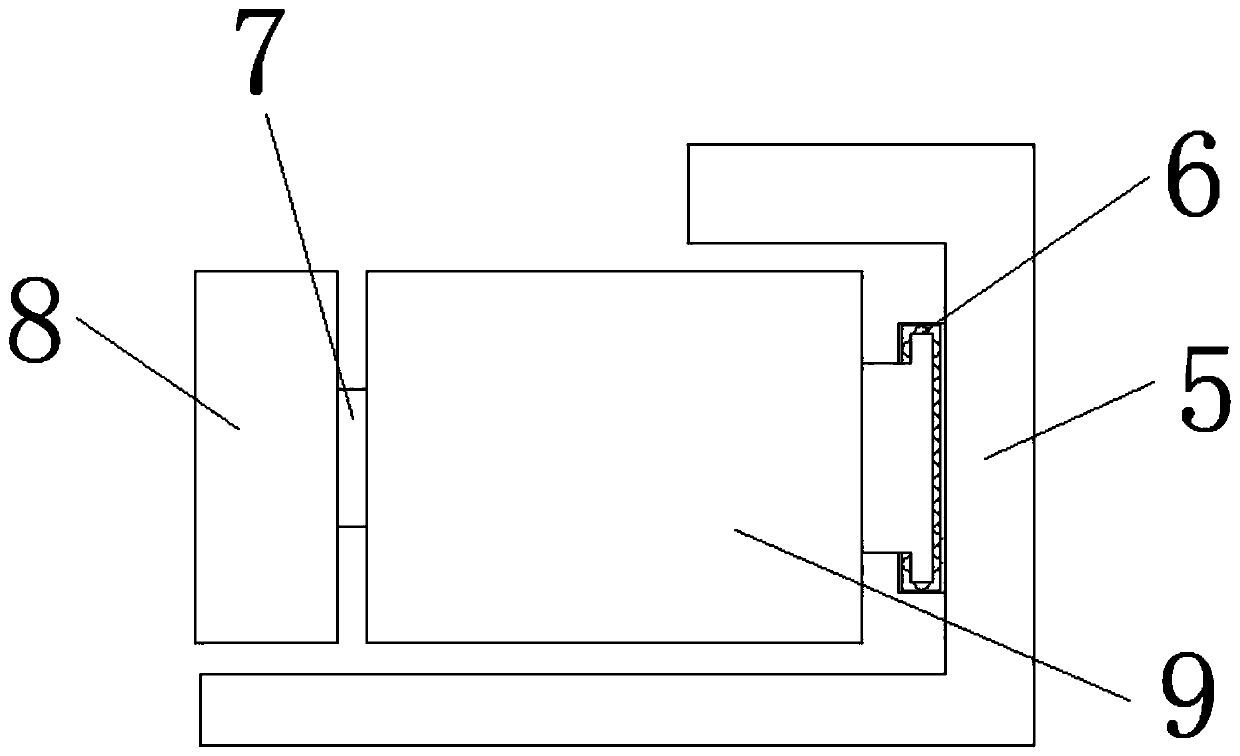

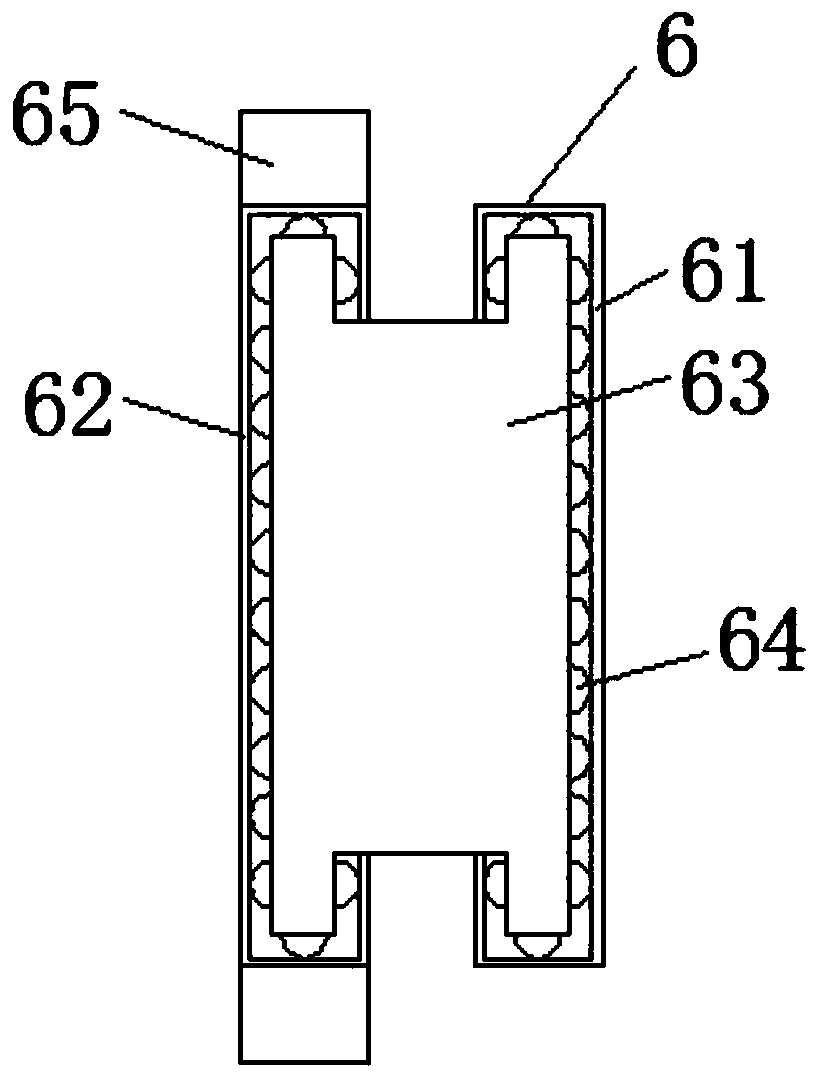

The invention discloses an interface convenient to connect for a photovoltaic microgrid, and relates to the field of photovoltaic microgrids. The interface convenient to connect for the photovoltaic microgrid comprises a first connector and a second connector, wherein one end of the first connector is fixedly connected with an electrical plug, a clamping ring fixedly sleeves a surface of the firstconnector, a through hole is formed in a surface of the clamping ring, a first groove is formed in a surface of the clamping ring, a tensioning device is arranged in the first groove, and a second groove is formed in a side surface of the clamping ring. In the interface convenient to connect for the photovoltaic microgrid, the first connector and the second connector can be plugged to each otherby arranging the first connector, the second connector, the electrical plug and a jack; the first connector and the second connector can be fixed by arranging the tensioning device and a clamping device, so that the interface for the whole photovoltaic microgrid is convenient to connect; and by arranging a first reset spring, the clamping device can be clamped into the first groove.

Owner:浙江中正新能源科技有限公司

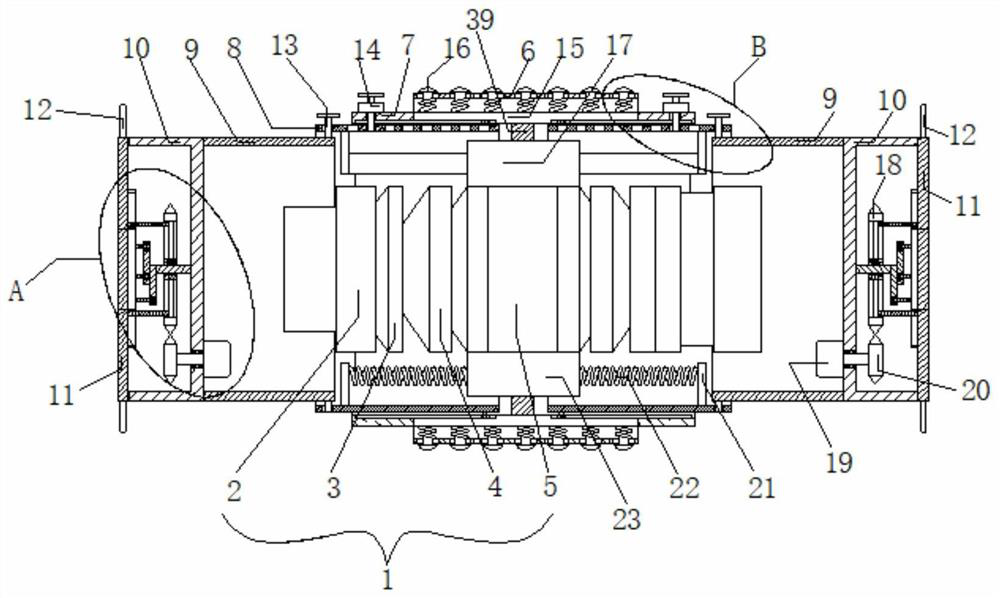

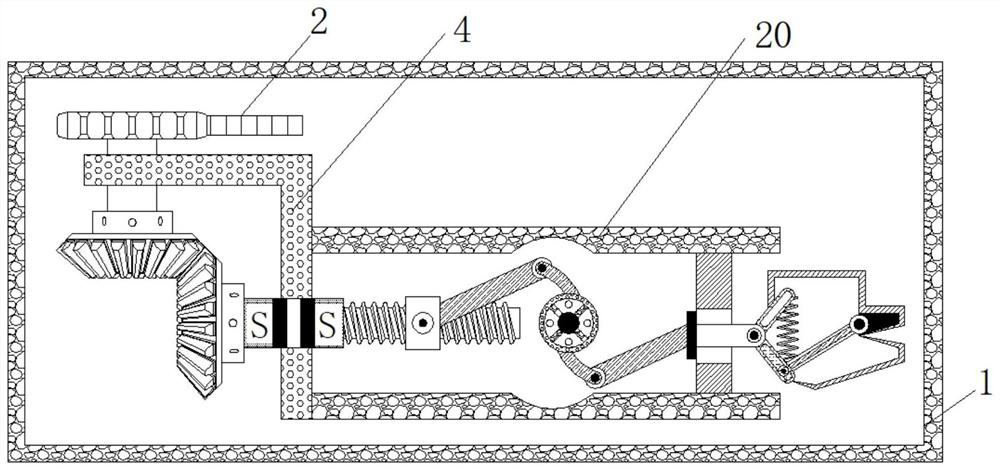

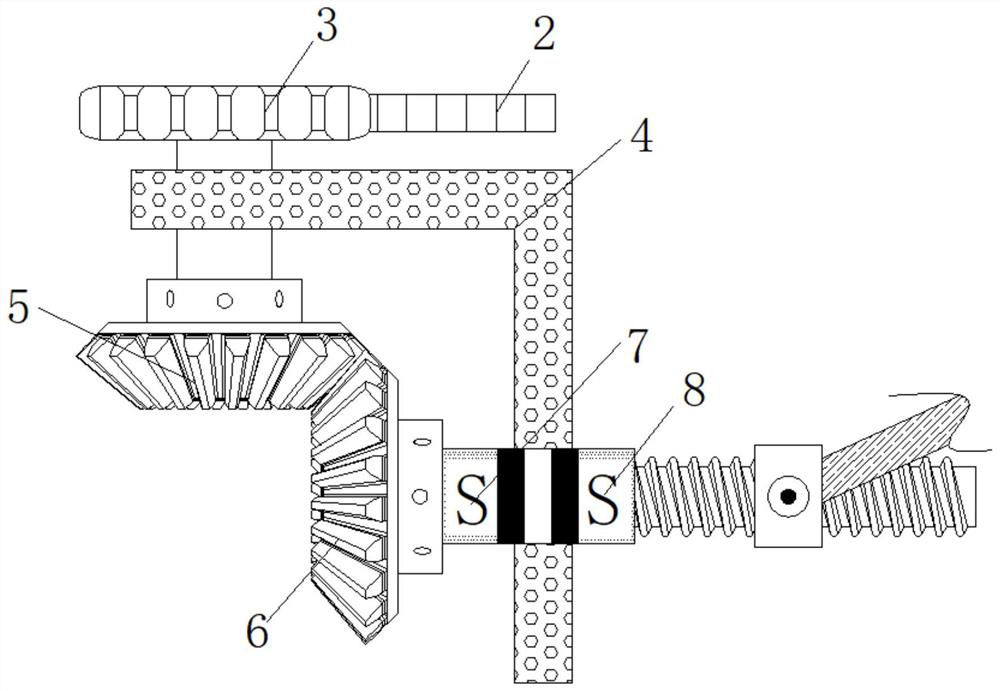

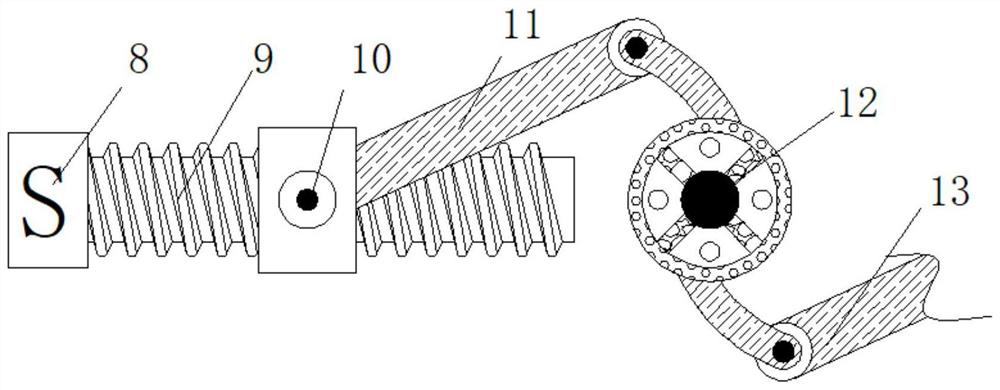

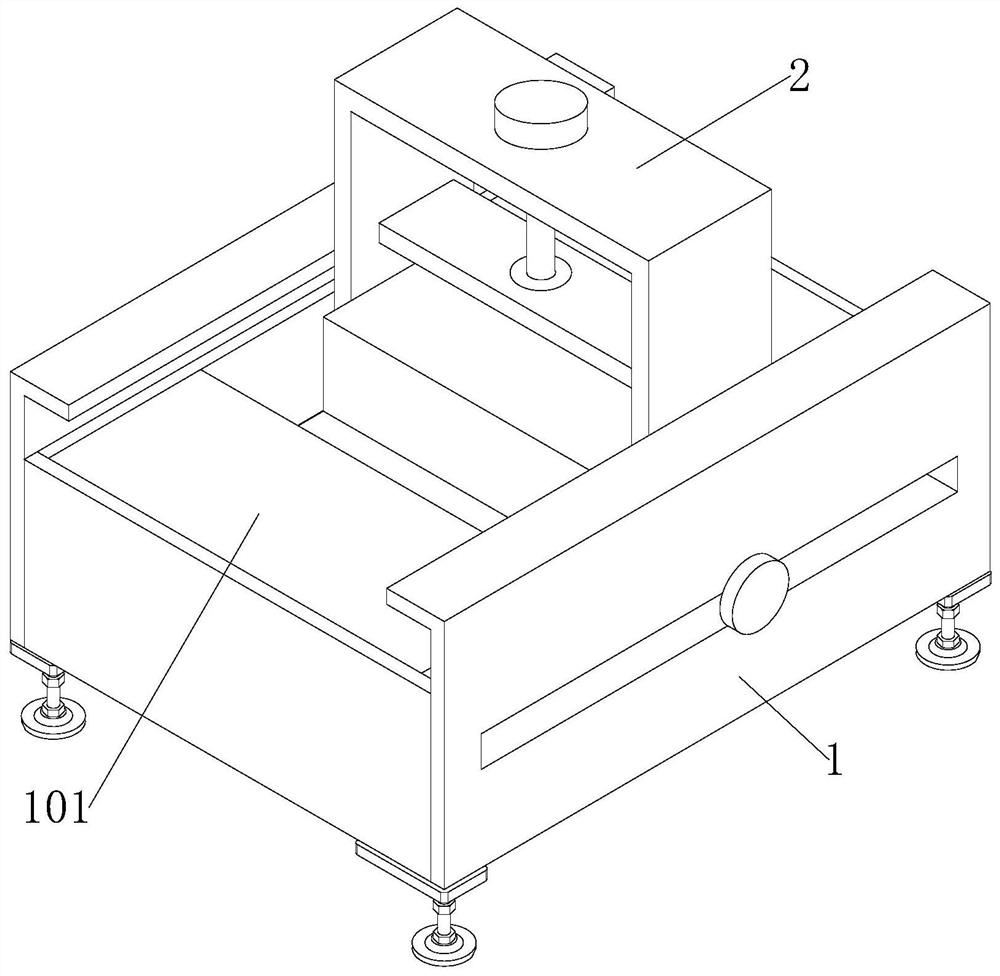

Bridge plug provided with mounting anchoring mechanism and using method thereof

InactiveCN113338854ALeft and right position adjustmentIncrease the scope of applicationSealing/packingGear wheelElectric machinery

The invention discloses a bridge plug provided with a mounting anchoring mechanism and a using method thereof. The bridge plug comprises a horizontally arranged bridge plug body, wherein the bridge plug body is composed of a drillable slip, a composite cone, a composite sheet and a combined rubber cylinder; the bridge plug body is sleeved with a fixed pipe body; connecting plates are fixedly connected to the top and the bottom of an inner cavity of the fixed pipe body; the other ends of the connecting plates are fixedly connected with the bridge plug body; a movable pipe body is sleeved with the fixed pipe body; a connecting pipe body is sleeved with the movable pipe body; and the bridge plug body is located in the connecting pipe body. Through mutual cooperation of a micro motor, a pinion, a large gear, a rectangular frame body, a round rod, a connecting rod, a rotating rod and other components, a fan-shaped plate can be unfolded, so that an anchoring rod can anchor and reinforce the fan-shaped plate, the falling of the fan-shaped plate caused by infirm mounting can be effectively prevented, and the working efficiency of the fan-shaped plate can be effectively improved.

Owner:宋玉峰

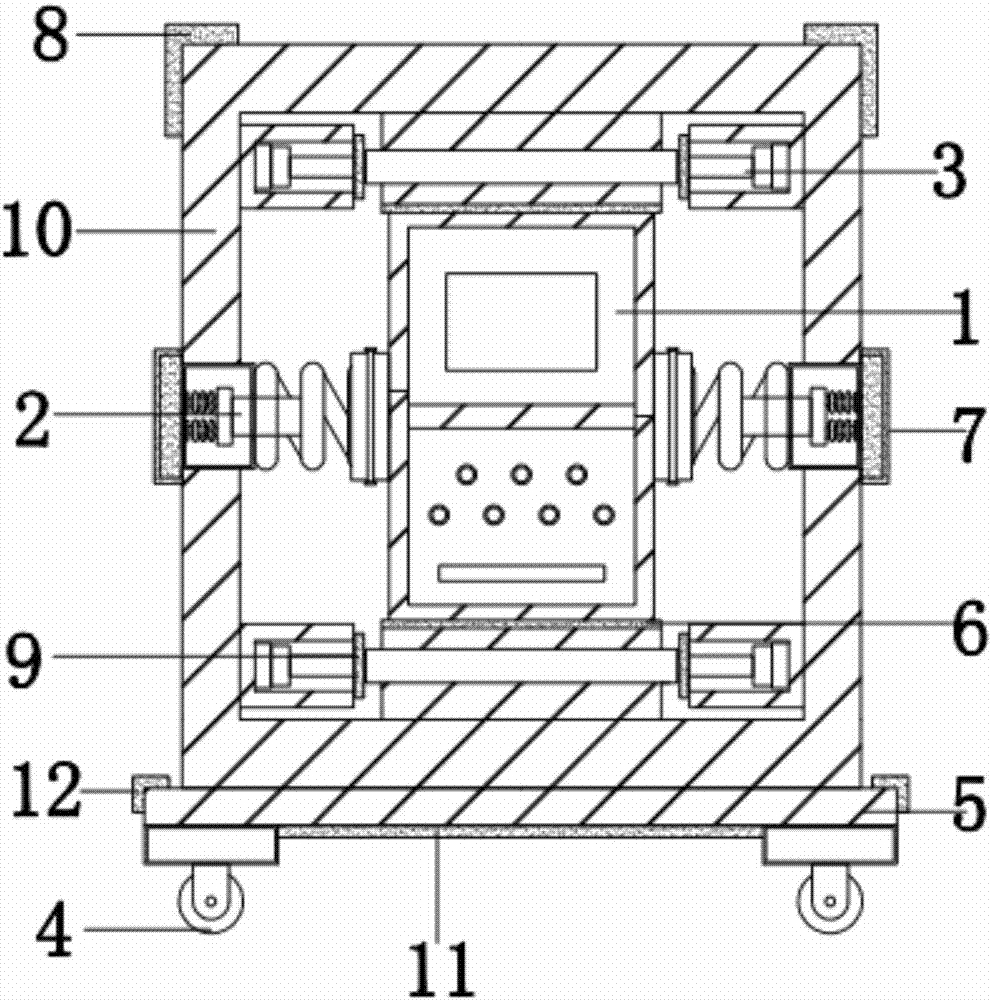

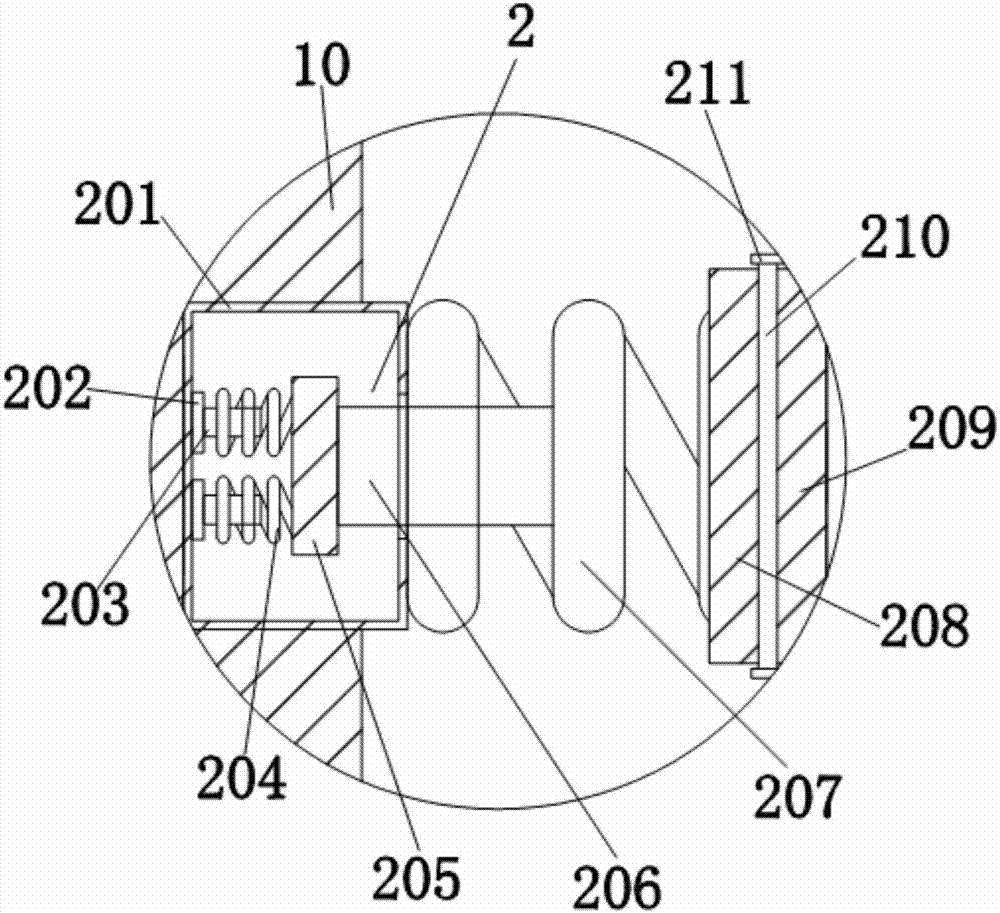

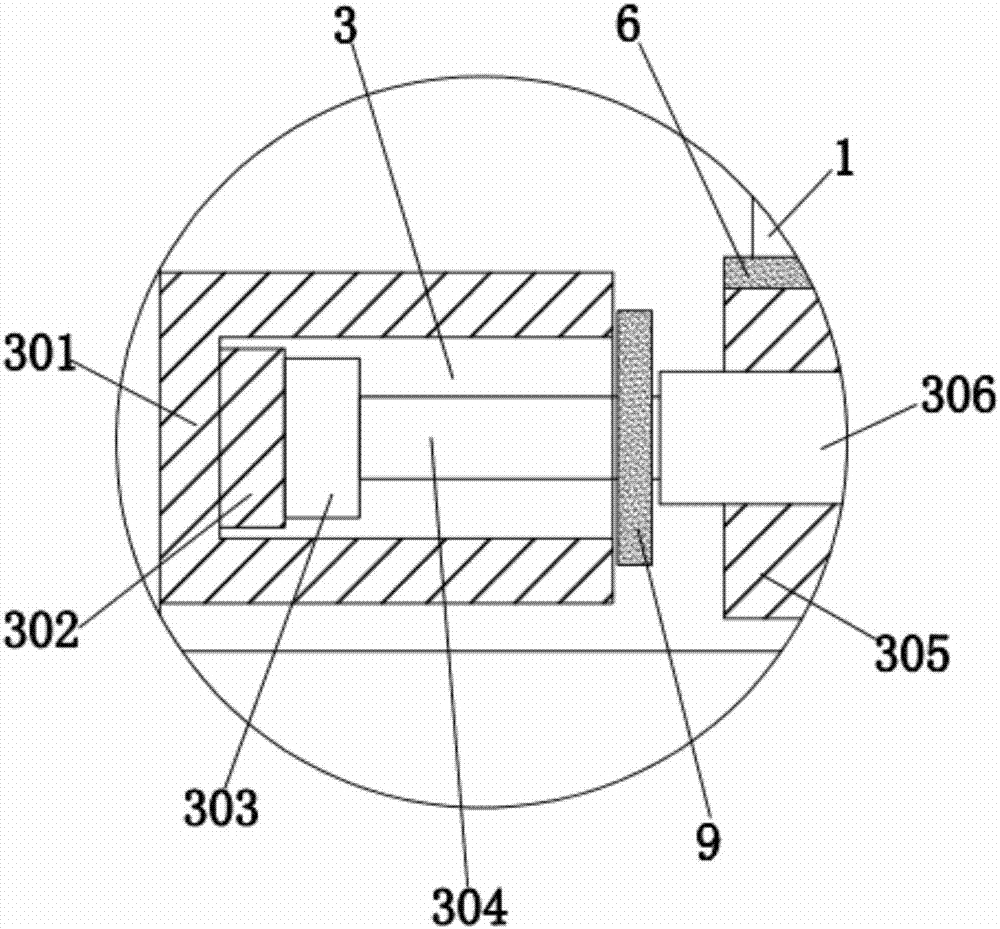

Protecting device for computer mobile internet

InactiveCN108001500ATo achieve the effect of clampingBe fixedHand carts with multiple axesHand cart accessoriesEngineeringMobile internet

The invention discloses a protecting device used for the computer mobile internet. The protecting device comprises a computer, fixing devices are arranged at both the left side and the right side of the computer, each fixing device comprises a first connecting pillar, a first cushion plate is installed at the inner side of an inner cavity of each first connecting pillar, a first supporting rod isinstalled at the inner side of each first cushion plate, a third spring is installed at the inner side of each first fixed block, a first rotary shaft is installed at the inner side of each first spring, a second connecting shaft is installed at the inner side of each first rotary shaft, third cushion plates are installed at both the upper side and the lower side of each second connecting shaft and are clamped with the computer, and a base is installed at the bottom of a second fixed groove. By means of the protecting device for the computer mobile internet, through the first connecting shaftswhich are installed at the cushion plates and second baffles which are installed at the right sides of the first connecting shafts, and thus the computer can be clamped and fixed.

Owner:惠水县凡趣创意科技有限公司

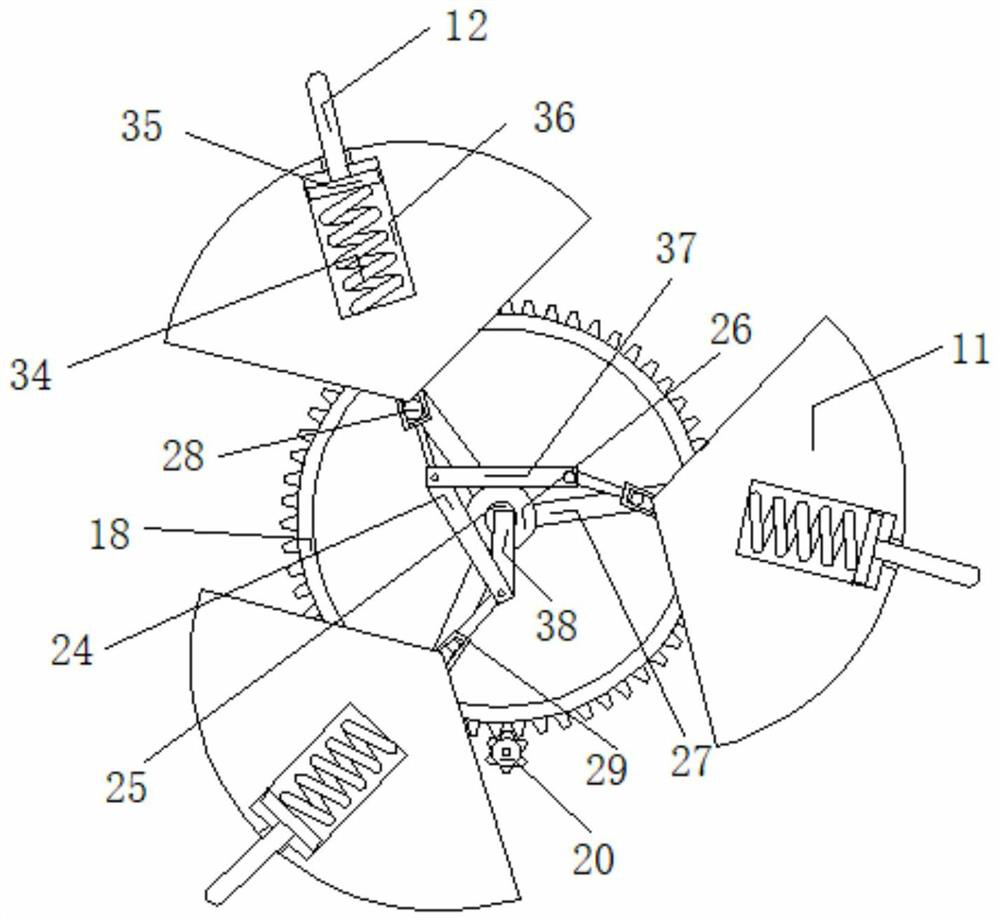

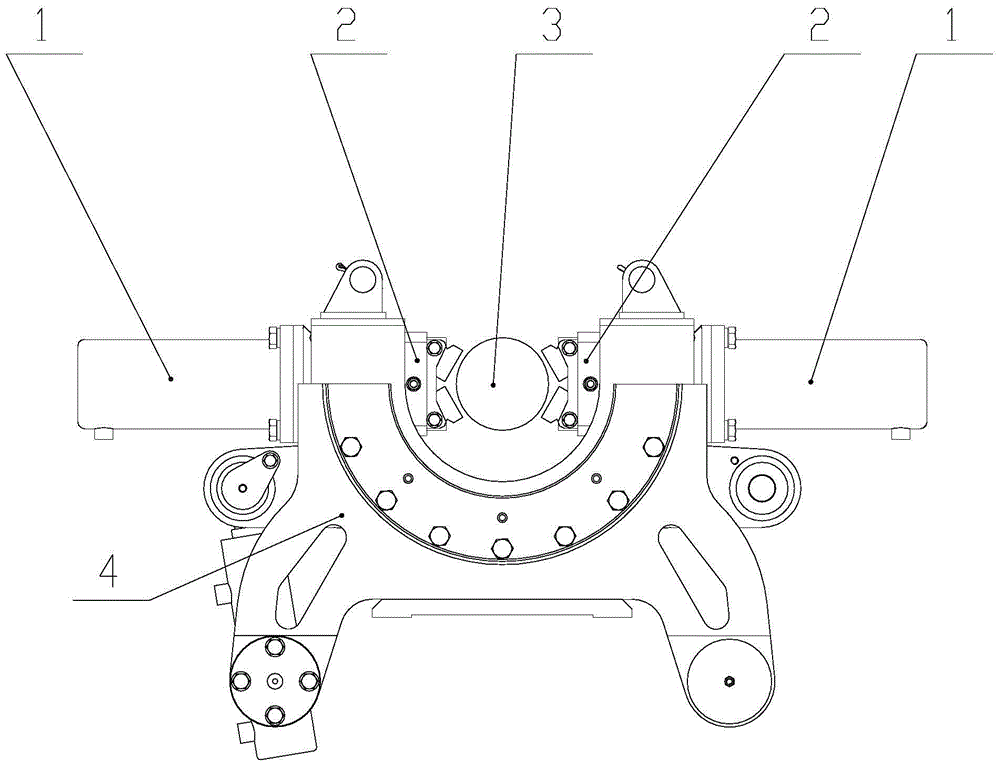

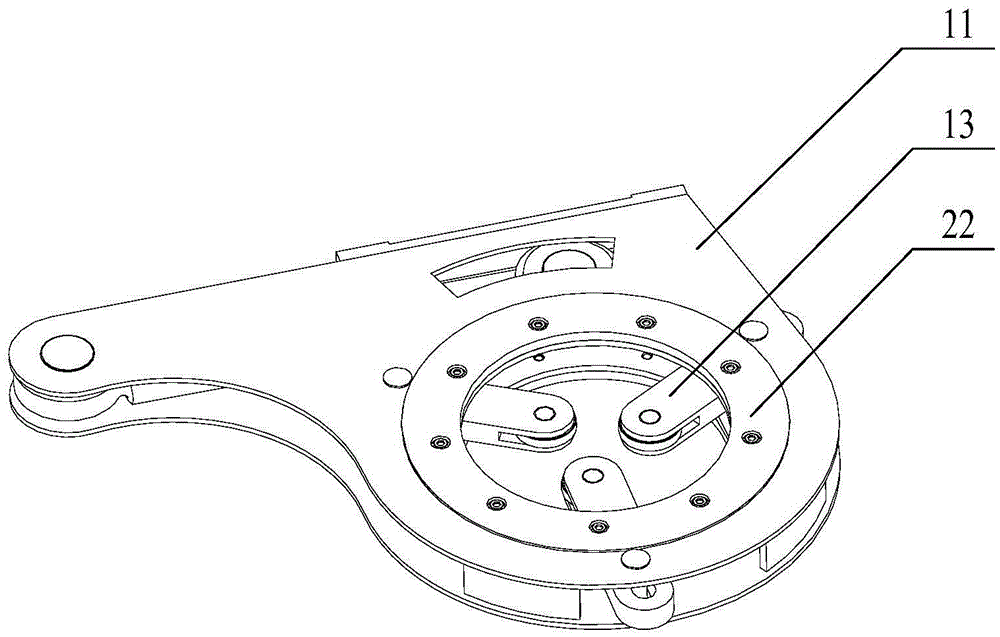

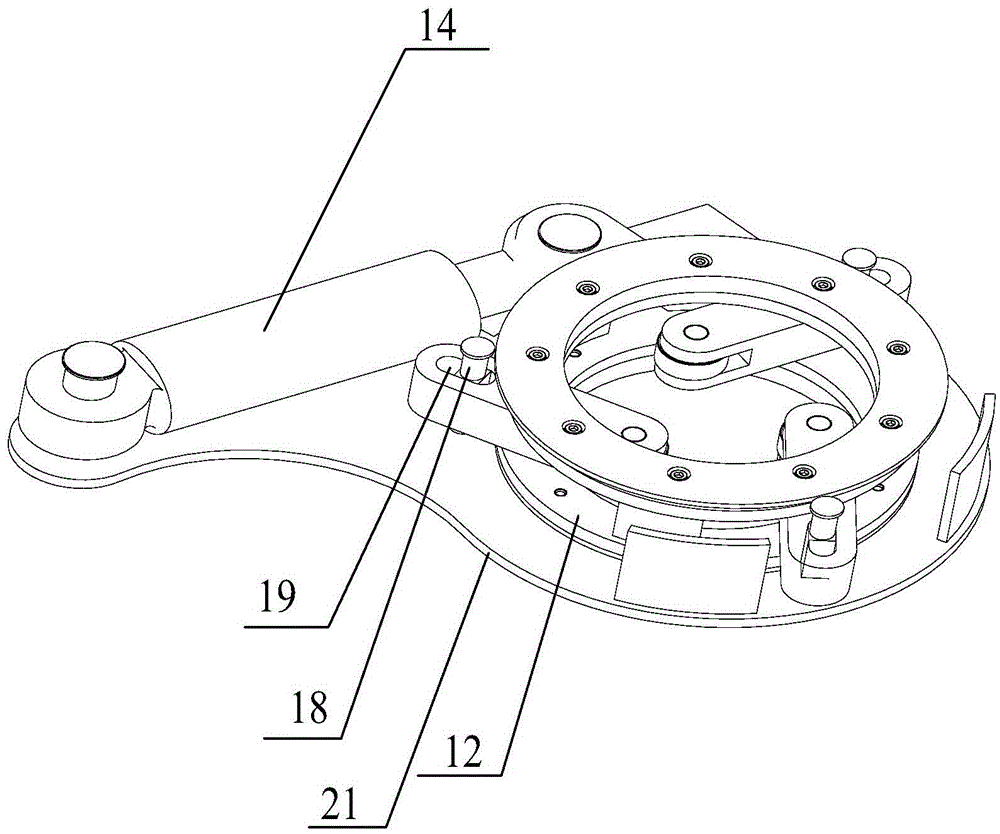

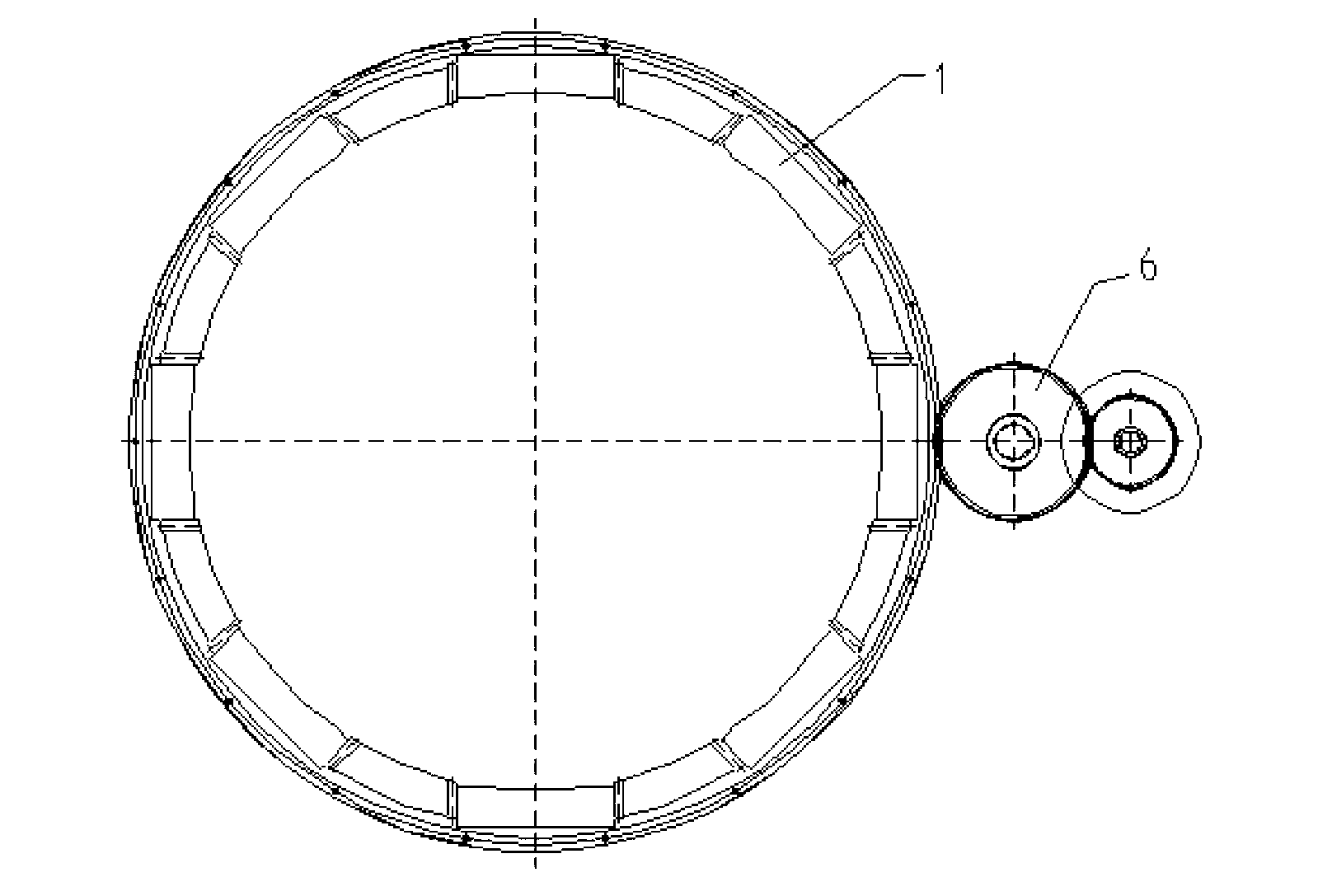

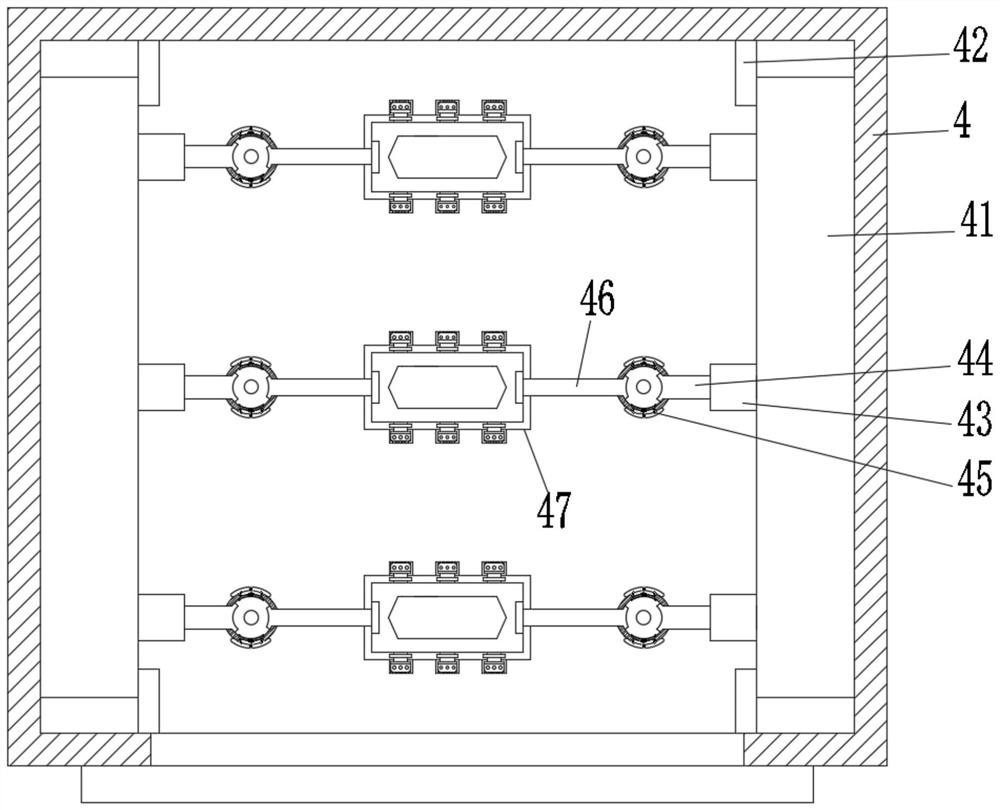

Roofbolter and gripper thereof

The invention discloses a roofbolter and a gripper thereof. The gripper comprises a fixed support, a slide block support, at least three slide blocks and a drive device. The fixed support is provided with a hollow part. The slide block support is arranged on the fixed support in a rotatable mode. The slide blocks are all hinged to the slide block support and the fixed support. Wheels extending into the hollow part are arranged at the inner ends of the slide blocks respectively. The wheels of the slide blocks have an external common tangent circle. The drive device is used for driving the slide block support to rotate. In this way, according to the gripper of the roofbolter, a drill stem is located in the circle surrounded by the slide blocks of the gripper in the whole working process all the time, and when the drill stem inclines, because of the constraint of the slide block on the drill stem, the drill stem can return to the central position.

Owner:BEIJING CSR TIMES LOCOMOTIVE & ROLLING STOCK MECHANICS

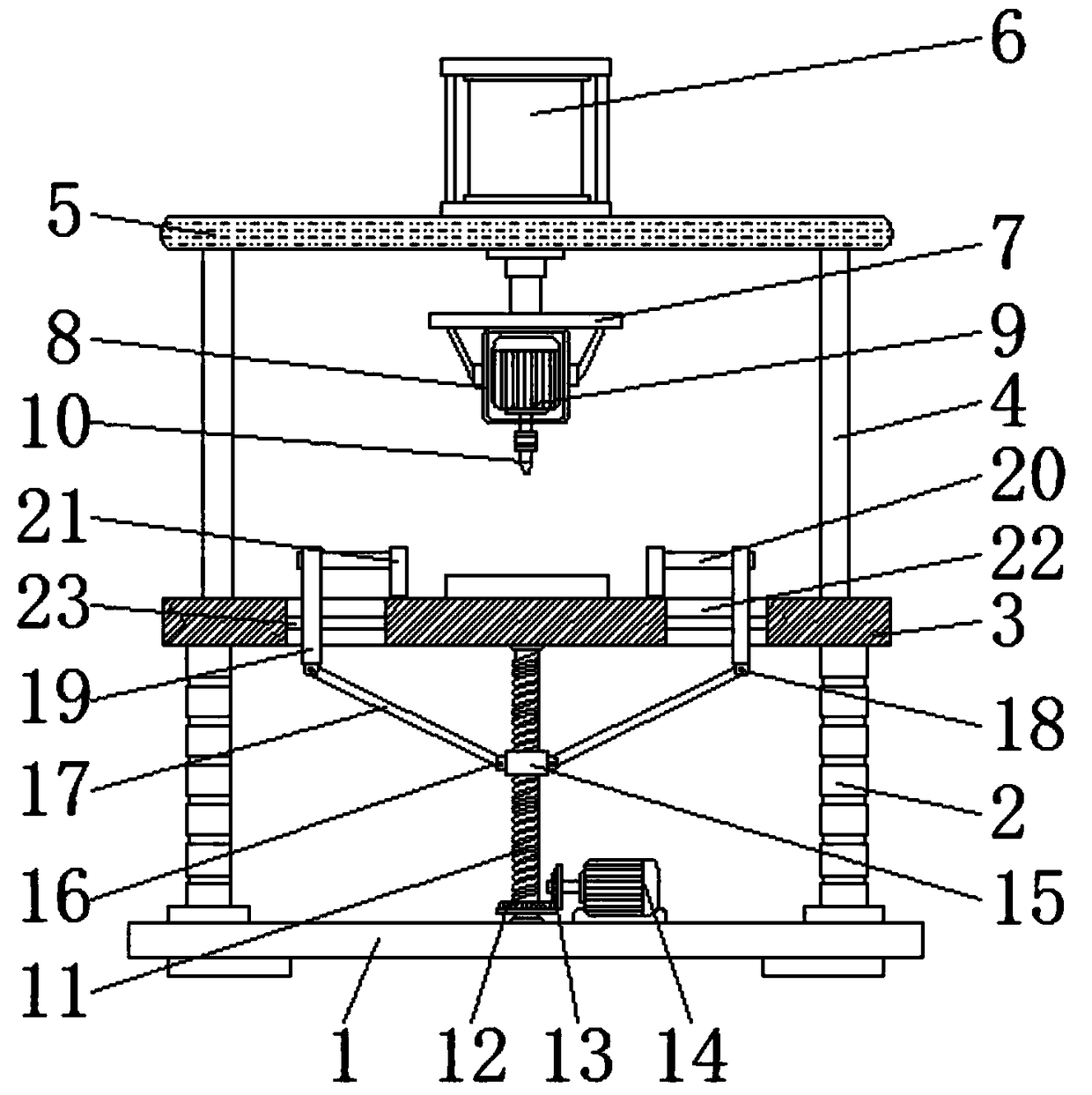

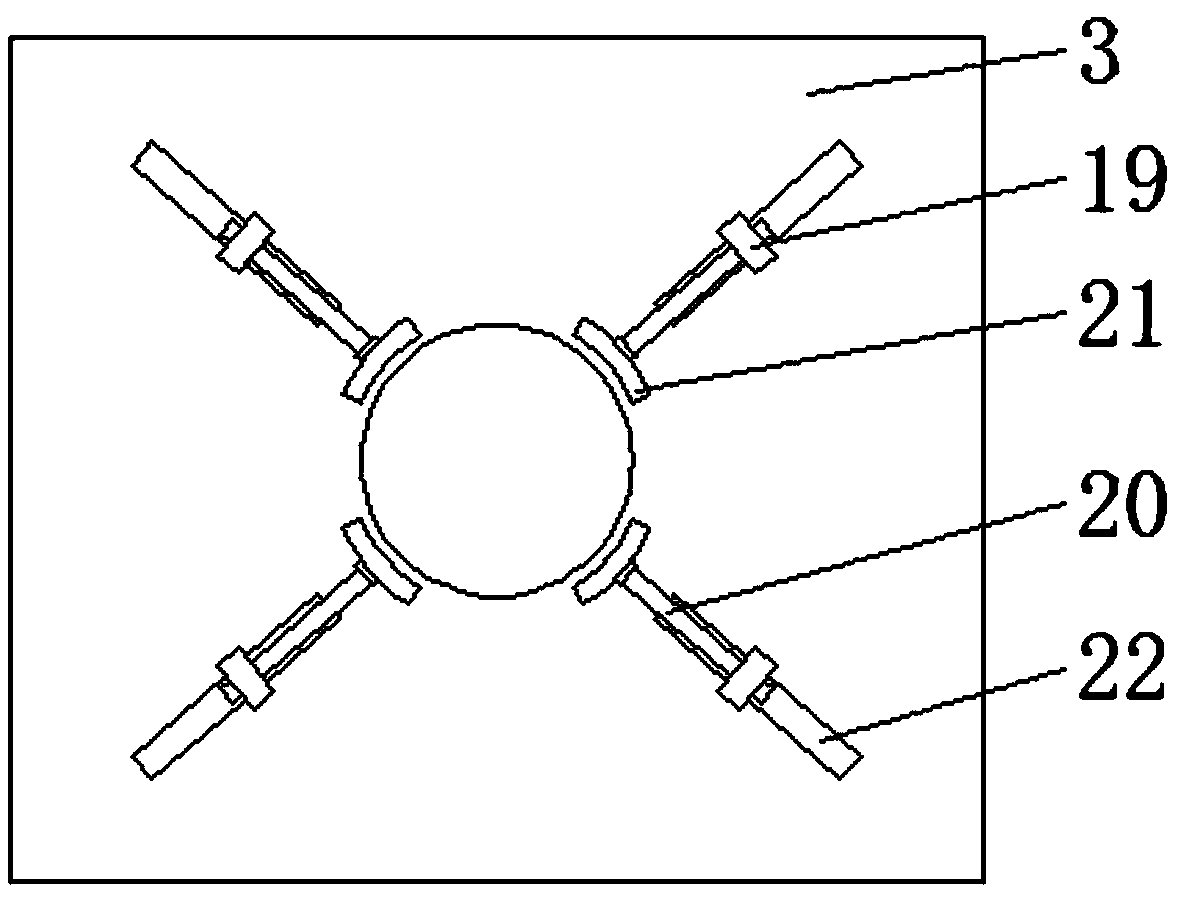

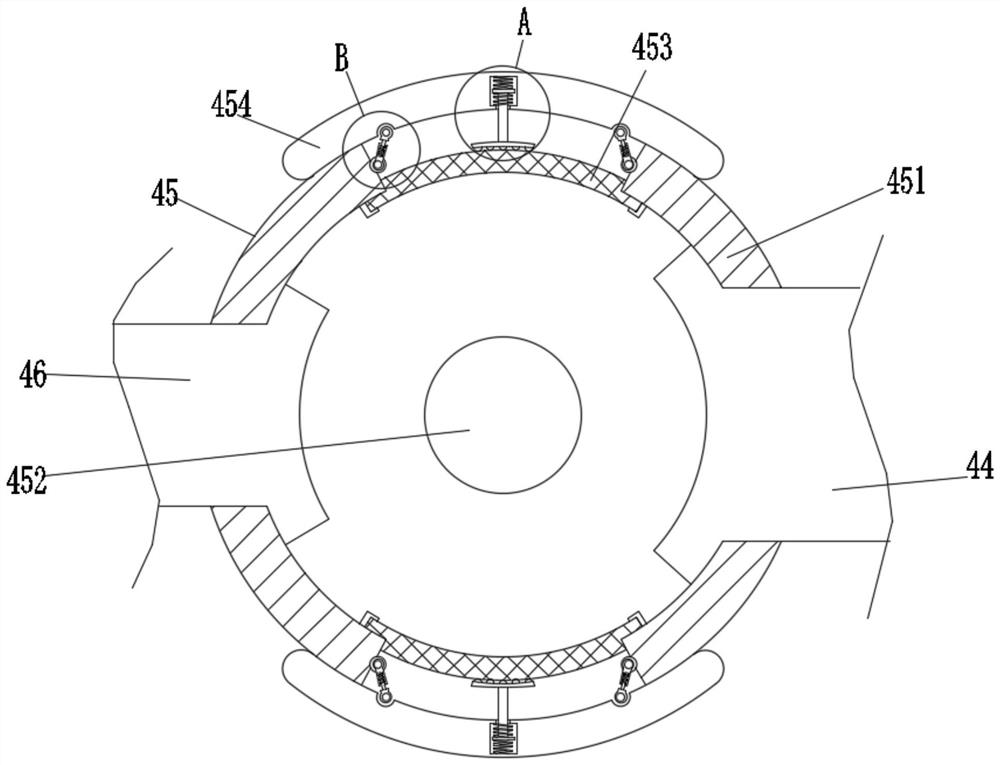

Drilling machine for bearing machining and with clamping function

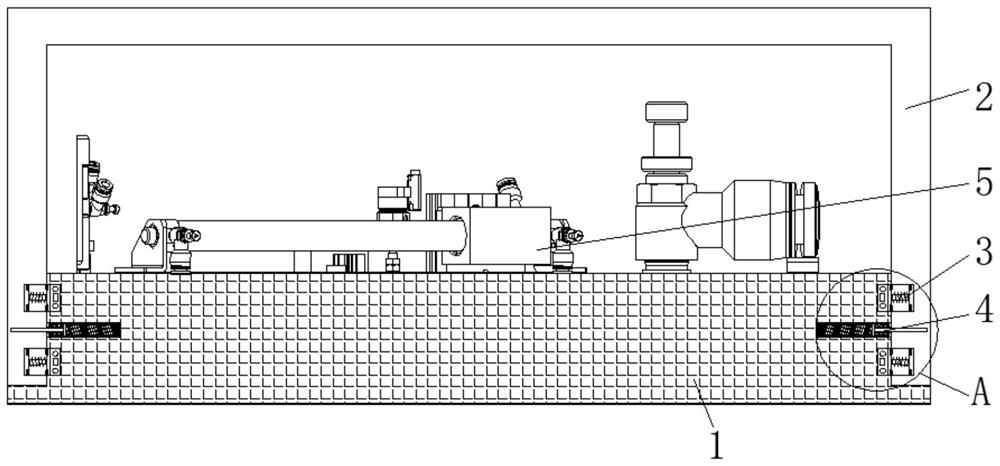

InactiveCN109158650ARealize moving up and downWith clamping functionPositioning apparatusMetal-working holdersEngineeringMechanical engineering

The invention relates to the technical field of bearing machining, and discloses a drilling machine for bearing machining and with a clamping function. The drilling machine comprises a base. Supporting rods are fixedly mounted at the four corners of the top of the base. A fixed plate is fixedly mounted at the tops of the four supporting rods. Fixed rods are fixedly mounted at the four corners of the top of the fixed plate. A top plate is fixedly mounted at the tops of the four fixed rods. A hydraulic air rod is fixedly mounted at the top of the top plate. A connecting plate is fixedly mountedon a power shaft of the hydraulic air rod. A fixed box is fixedly mounted at the bottom of the connecting plate. According to the drilling machine for bearing machining and with the clamping function,connecting rods drive moving rods in a cooperation manner, the moving rods can move in communicating openings, and therefore a bearing is clamped by four arc plates; and sliding rods are used for limiting the moving tracks of the moving rods, the moving tracks of the four moving rods keep synchronous, and therefore the bearing is clamped, and the clamping function is achieved.

Owner:罗刚

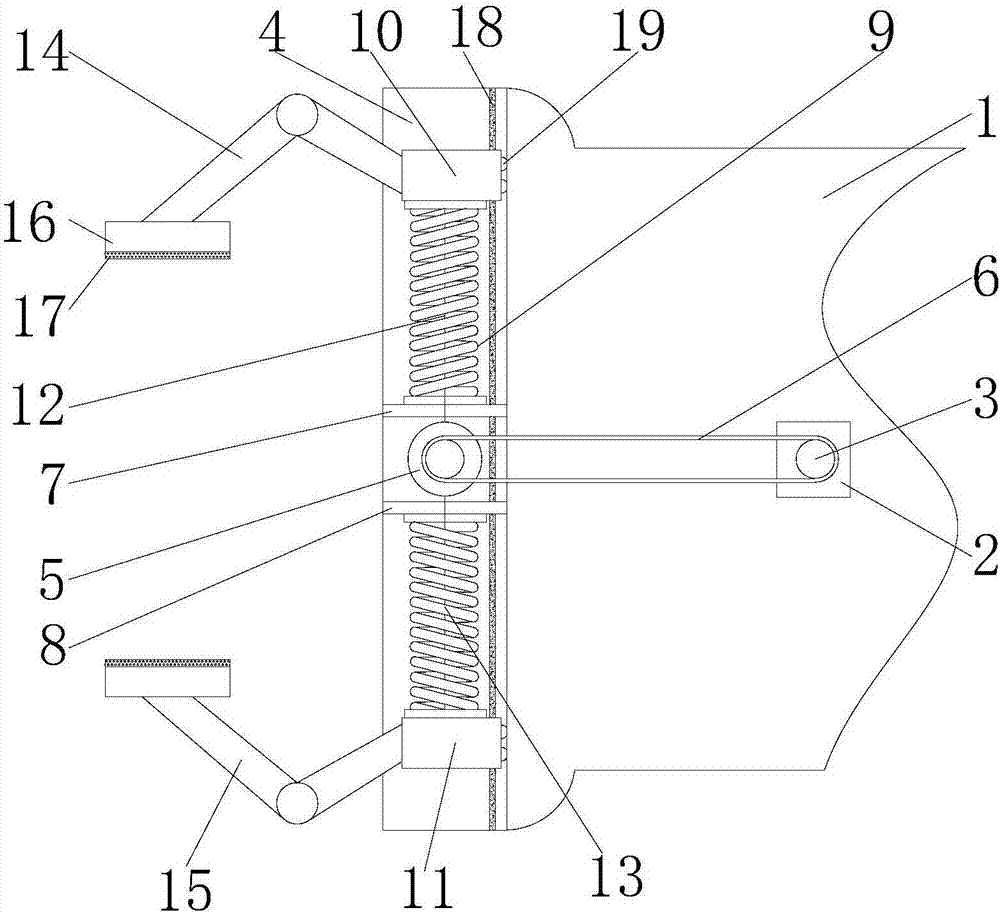

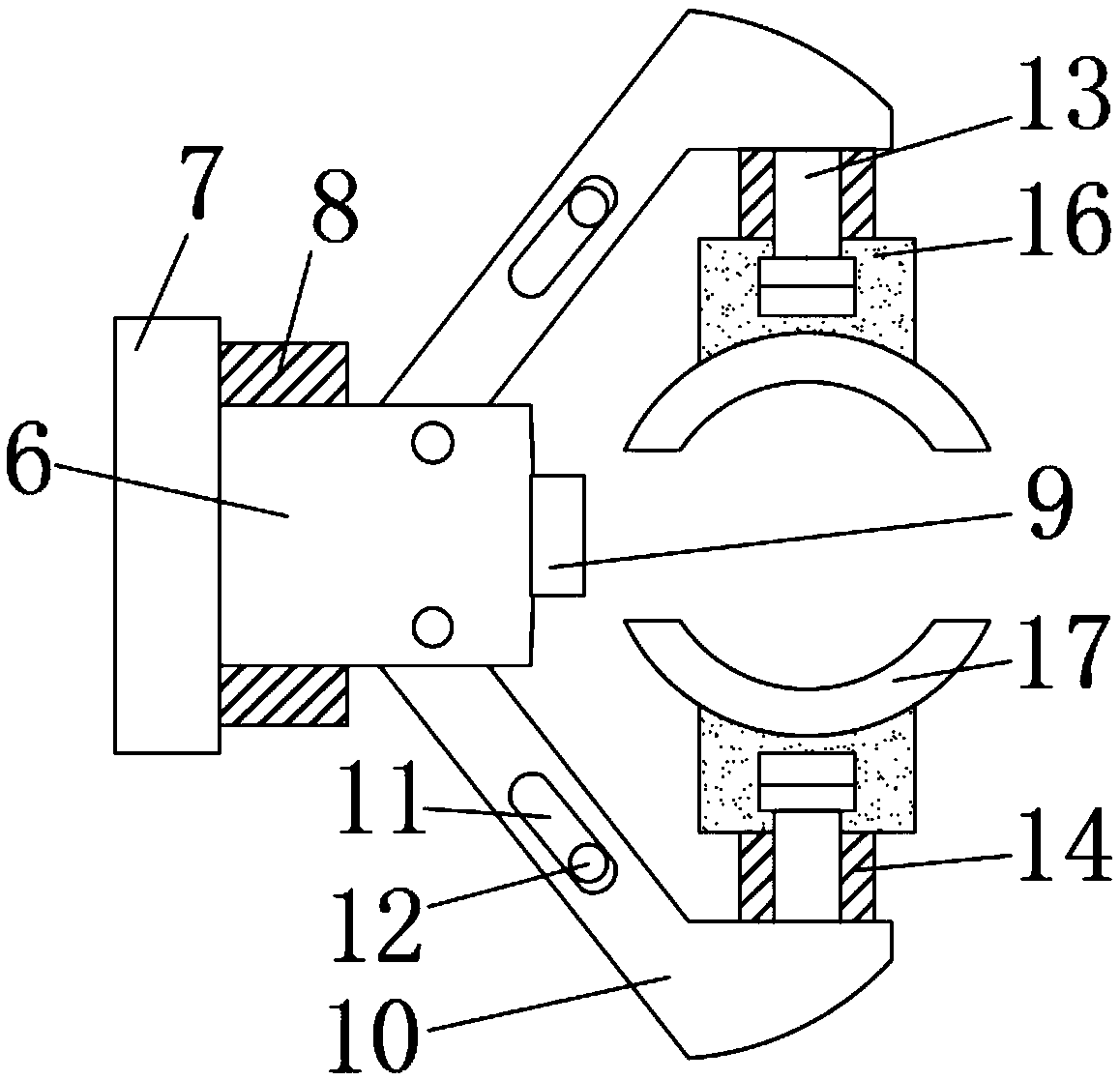

Gas cylinder transportation device with firm fixing and clamping effects

PendingCN106764422AClamp firmlyTo achieve the effect of clampingVessel mounting detailsContainer filling methodsVertical barGas cylinder

The invention discloses a gas cylinder transportation device with the firm fixing and clamping effects. The gas cylinder transportation device comprises a shell; one side of the inner wall of the shell is fixedly connected to one ends of extrusion springs through extrusion blocks; the other ends of the extrusion springs are fixedly connected with abutting plates; the other side of the inner wall of the shell is fixedly connected to the fixed ends of telescopic tubes; the movable ends of the telescopic tubes are fixedly connected to one side of compressed foam; a bearing plate and an abutting device are sequentially arranged at the bottom of an inner cavity of the shell from left to right; and the abutting device comprises a first vertical bar and a second vertical bar, wherein the first vertical bar is positioned on the right side of the second vertical bar, and a driving gear and a driven gear are movably connected on the first vertical bar and the second vertical bar respectively. According to the gas cylinder transportation device with the firm fixing and clamping effects, the clamping effect is achieved, moreover, the clamping is firm, the effects of buffering and damping are achieved, and existence of potential safety hazards of gas cylinders in the transportation process is avoided; and the gas cylinder transportation device with the firm fixing and clamping effects is compact in structure, reasonable in design, high in applicability and convenient to popularize and use.

Owner:WUXI DONGHE METAL PROD

A universal processing fixture for a valve body

ActiveCN105364563BTo achieve the effect of clampingEasy to usePositioning apparatusMetal-working holdersEngineeringScrew thread

The invention relates to a universal valve body machining fixture. The universal valve body machining fixture comprises a workbench and locating pins, sliding grooves are distributed all around the workbench, and pressing plates and hinged seats are installed in the sliding grooves in a sliding mode; a plane four-bar mechanism is connected between the pressing plates and the hinged seats, a long connecting bar is hinged to the lower end of the left-most pressing plate, the left portion of the long connecting bar is provided with a control rack, the front end of the control rack is provided with a circular groove, a screw is installed in the circular groove in a threaded mode, and an adapting wheel is rotatably installed in the circular groove and hinged to the long connecting rod at any peripheral edge end; an annular groove is formed in the center position of the adapting wheel, the circular arc end of the adapting wheel is provided with a clamping groove, an annular insertion block is fixedly installed on the screw, the front end of the circular groove is communicated with a square groove, an insertion pin is installed in the square groove in a sliding mode, and the center position of the control rack is connected with a supporting rack. According to the universal valve body machining fixture, by means of the connecting mode of the adapting wheel and the control rack, horizontal sliding distance of two pressing plates can be controlled, the effect of clamping valve bodies with different sizes and types can be achieved, and the application range is wide.

Owner:临沂罗开投资有限公司

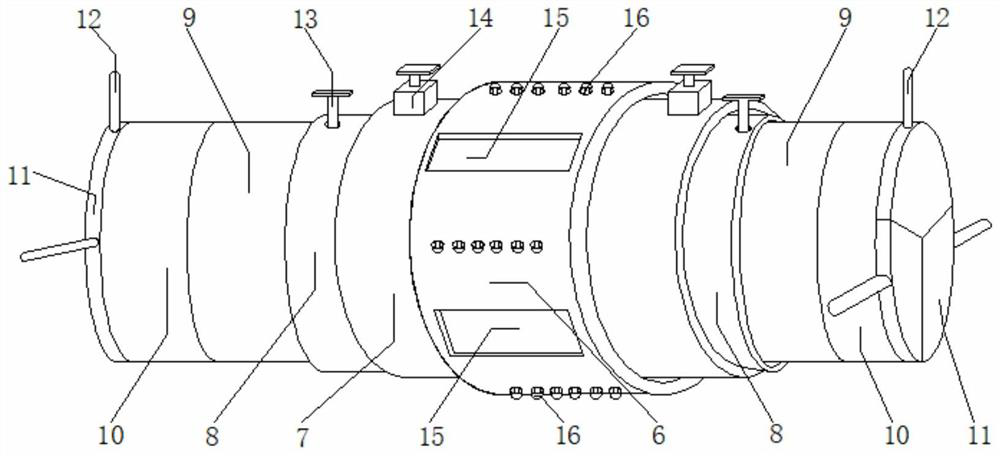

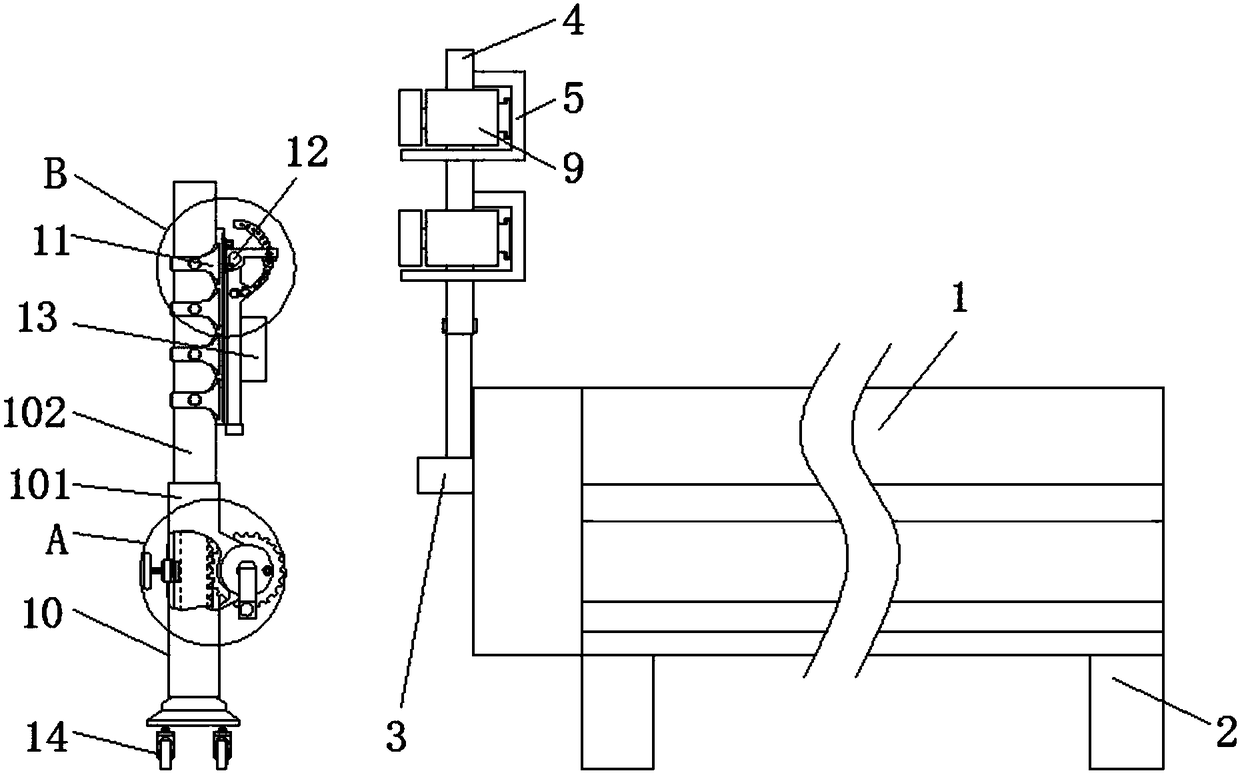

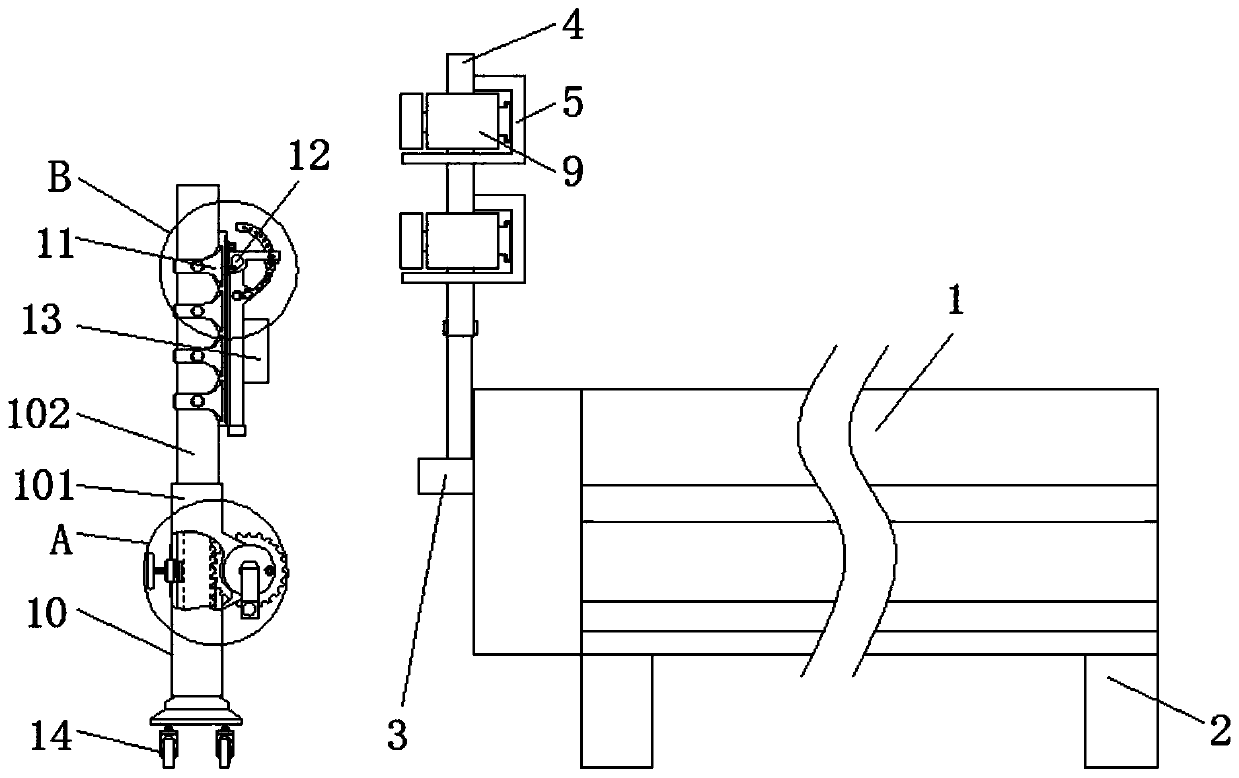

Pipeline robot with clamping and placing function

InactiveCN107972037AAchieve the effect of turningTo achieve the effect of clampingGripping headsDrive wheelEngineering

The invention discloses a pipeline robot with a clamping and placing function. The pipeline robot comprises a body, a positive and negative rotation motor is arranged inside an arm of the body, an output shaft of the positive and negative rotation motor is fixedly connected with the back face of a driving wheel, one side of the arm is provided with a placing box, a winding wheel is movably connected to the interior of the placing box, a rotating shaft of the winding wheel is in driving connection with the surface of the driving wheel through a conveying belt, an upper vertical plate and a lower vertical plate are sequentially arranged inside the placing box from top to bottom, and the winding wheel is located between the upper vertical plate and the lower vertical plate. The pipeline robotwith the clamping and placing function achieves a clamping effect, a buffer and damping effect is achieved through cooperated usage of a damping block, an upper sleeve, a lower sleeve, a connection rod, a reset spring and an extrusion spring, the arm of the robot is prevented from damaging clamped objects in the clamping process, and the pipeline robot with the clamping and placing function is compact in structure, reasonable in design, high in applicability and convenient to use and popularize.

Owner:XIANGTAN HONGYUAN ELECTRONICS SCI & TECH CO LTD

Drilling device for automobile parts

InactiveCN108994327ATo achieve the effect of clampingAvoid wastingMaintainance and safety accessoriesBoring/drilling machinesSlide platePiston rod

The invention provides a drilling device for automobile parts. The drilling device for the automobile parts comprises a base. A water purification mechanism is arranged in the base, a placing plate isarranged above the base, stand columns are arranged on the left and right sides of the placing plate, a first cross beam is arranged between the stand columns, a first air cylinder is arranged at theupper end of the middle portion of the first cross beam, a first piston rod is arranged at the lower end of the first air cylinder, a second cross beam is arranged at the lower end of the first piston rod, the length of the second cross beam is the same as that of the placing plate, and a slide rail is arranged in the second cross beam. The sliding rail is provided with a sliding plate, a motor is arranged at the lower end of the sliding plate, a motor rod is arranged at the lower end of the motor, the motor rod is provided with a closing plate, a drill bit is arranged at the lower end of themotor rod, the drill bit is detachable, the closing plate is provided with a water adding mechanism, the stand columns are provided with a second air cylinder, the second air cylinder is provided with a second piston rod, and the second piston rod is provided with a pushing block, so that waste of resources is prevented, the operation is simple, and the quality is improved.

Owner:芜湖鸣人汽车维修服务有限公司

Time synchronization device with data line fastening function

ActiveCN108156774AWith fastening functionAvoid churnCasings/cabinets/drawers detailsData connectionData loss

The invention discloses a time synchronization device with a data line fastening function. The device comprises a time synchronization device body with the data line fastening function. A data line jack is arranged in the back of the time synchronization device body with the data line fastening function. A protection frame is fixedly arranged on the back of the time synchronization device body with the data line fastening function. Adjusting rods are arranged on both sides of the data line jack on the back of the time synchronization device body with the data line fastening function. The telescopic ends of two adjusting rods are fixedly connected through a connecting cross plate. A line clamp plate is fixedly arranged at the top of the connecting cross plate. A line clamp buckle is fixedlyarranged at the bottom of the line clamp plate. A data connection line is inserted into a line insertion slot on the surface of the protection frame. The line clamp plate is in clamp connection withthe surface of the data connection line. One end of the data connection line is inserted into the data line jack. According to the time synchronization device with the data line fastening function, the data connection line is not loosened; normal operation of the time synchronization device with the data line fastening function is ensured; the time synchronization device with the data line fastening function is prevented from data loss caused by the loose data connection line; and the device facilitates the work of people.

Owner:湖北中科亿能科技有限公司

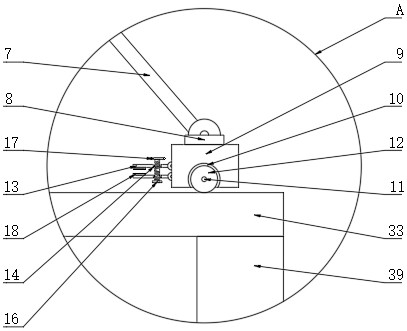

Water jet loom waste selvage yarn bobbin creel

The invention discloses a water jet loom waste selvage yarn bobbin creel which comprises a water jet loom body; supporting legs are fixedly mounted on the bottom of the water jet loom body; a horizontal plate is fixedly mounted on one side of the water jet loom body; an adjusting rod is fixedly mounted on the top of the horizontal plate; connecting frames are fixedly mounted on the adjusting rod;movable connecting members are fixedly mounted on the inner walls of the connecting frames; connecting rods are fixedly mounted on ends of the movable connecting members; outer parts of the connectingrods are sleeved with textile threads; an adjusting frame is disposed on one side of the water jet loom body; a fixing frame is fixedly mounted on one side of the top end of the adjusting frame; andan angle adjuster is disposed on one side of the fixing frame. By adopting the water jet loom waste selvage yarn bobbin creel, the height of the textile threads can be adjusted according to on-site requirements; the angle and the height of an object placement box can be adjusted as required on-site; and the water jet loom waste selvage yarn bobbin creel has the function of clamping the textile threads, is convenient to adjust, easy to use and reasonable in design, and improves the work efficiency.

Owner:青岛世纪海佳机械有限公司

A water-jet loom waste edge yarn creel

The invention discloses a water jet loom waste selvage yarn bobbin creel which comprises a water jet loom body; supporting legs are fixedly mounted on the bottom of the water jet loom body; a horizontal plate is fixedly mounted on one side of the water jet loom body; an adjusting rod is fixedly mounted on the top of the horizontal plate; connecting frames are fixedly mounted on the adjusting rod;movable connecting members are fixedly mounted on the inner walls of the connecting frames; connecting rods are fixedly mounted on ends of the movable connecting members; outer parts of the connectingrods are sleeved with textile threads; an adjusting frame is disposed on one side of the water jet loom body; a fixing frame is fixedly mounted on one side of the top end of the adjusting frame; andan angle adjuster is disposed on one side of the fixing frame. By adopting the water jet loom waste selvage yarn bobbin creel, the height of the textile threads can be adjusted according to on-site requirements; the angle and the height of an object placement box can be adjusted as required on-site; and the water jet loom waste selvage yarn bobbin creel has the function of clamping the textile threads, is convenient to adjust, easy to use and reasonable in design, and improves the work efficiency.

Owner:青岛世纪海佳机械有限公司

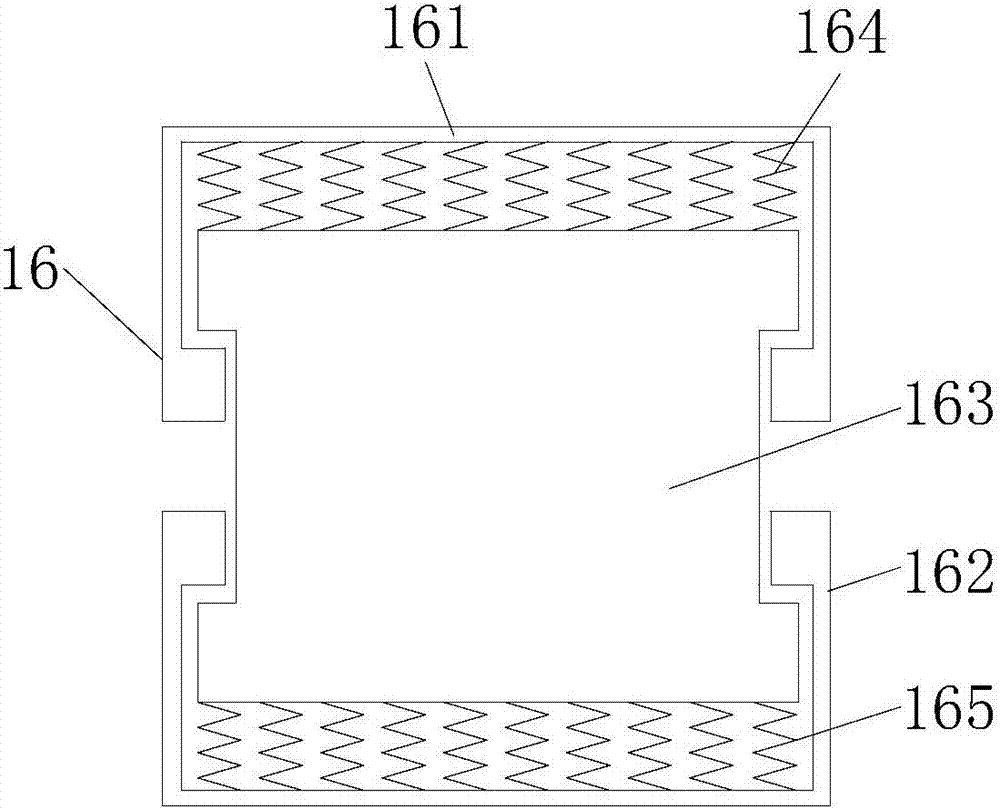

Silk quilt processing equipment special for silk quilt

InactiveCN112281299ATo achieve the effect of clampingAchieve the effect of pullingNon-woven fabricsStretchingRubber materialPolymer science

The invention discloses silk quilt processing equipment special for a silk quilt, and particularly relates to the field of silk processing. The silk quilt processing equipment comprises a vertical plate, a top plate is fixedly arranged at the top of the vertical plate, two sliding rods are fixedly arranged at the bottom of the top plate, and a lifting rod is fixedly arranged at the bottom of the top plate; and a wadding pulling mechanism is fixedly arranged at the bottom of the lifting rod and comprises a sliding box, and a fixing column is fixedly arranged on the outer side of the sliding box. Compared with the prior art, by arranging the wadding pulling mechanism, a silk blank is placed between clamping plates, a rotary disc is rotated, a double-end silk bolt rotates to drive the clamping plates to be gathered inwards, through clamping pads on the clamping plates, the clamping pads are made of rubber materials, so that the effect of not damaging silk is achieved, and the effect of clamping the silk blank is also achieved; and the lifting rod pushes the sliding box, the sliding box slides downwards along the sliding rods, a first supporting and pulling rod pushes a first fixing block, the first fixing block drives idler wheels to slide, and therefore the effect of pulling the silk blank open is achieved.

Owner:湖州韵峰丝绸有限公司

Manipulator with jibs

The invention discloses a manipulator with jibs. The manipulator with the jibs comprises an end portion and a plurality of manipulator arms and is characterized by further comprising connecting components for connecting the neighboring manipulator arms and the jibs arranged at the top of every manipulator arm; every manipulator arm at least comprises two supporting arms. The manipulator with the jibs has the advantages that by means of the design of the connecting components, the manipulator can play a certain supporting and lifting role when gripping a soft object to avoid damaging the shape structure of the object and to also achieve a gripping effect reasonably and effectively. Besides, the arrangement of the jibs can guarantee that the jibs can timely rotate below the object when the soft object is supported and lifted, the effect that the middle portion of the object has a certain supporting and lifting force can be guaranteed, and the gripping effect can be achieved effectively and reasonably.

Owner:SUZHOU SUPERLIGHT MICROELECTRONICS

A controller box for an electric vehicle

ActiveCN108684164BEasy to installEasy to disassembleElectrical apparatus casings/cabinets/drawersStructural engineeringElectric cars

The invention discloses a controller box for an electric vehicle, which comprises a bottom plate, the upper surface of the bottom plate is provided with electrical components, and a cover body is sleeved on the outside of the bottom plate, and a locking hole is opened on one side of the cover body. The surface of the cover is provided with a second screw hole and a sliding hole, a cavity is provided on the side wall of the inner cavity of the cover, a first clamping member is provided inside the cavity, and a side wall of the bottom plate is provided with There is a clamping slot, one end of the first clamping part is clamped inside the clamping groove, a second clamping part is arranged inside the bottom plate, and one end of the second clamping part is clamped on the side wall of the cover body into the hole provided on the The electric vehicle controller box body is convenient for replacing electrical components. The electric vehicle controller is convenient for cleaning and maintaining the electrical components after a long period of use, which is convenient for maintenance and testing, and the electric vehicle controller box body is easy to install and disassemble. The installation and removal process is simple, time-saving and efficient.

Owner:徐州科悦电子科技有限公司

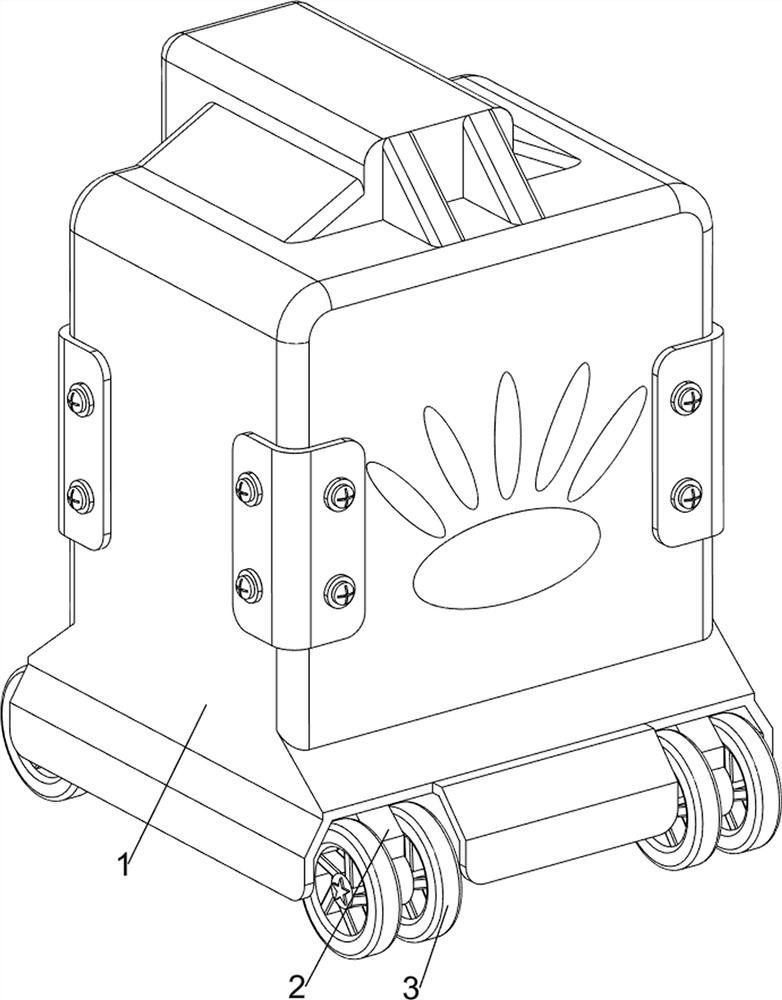

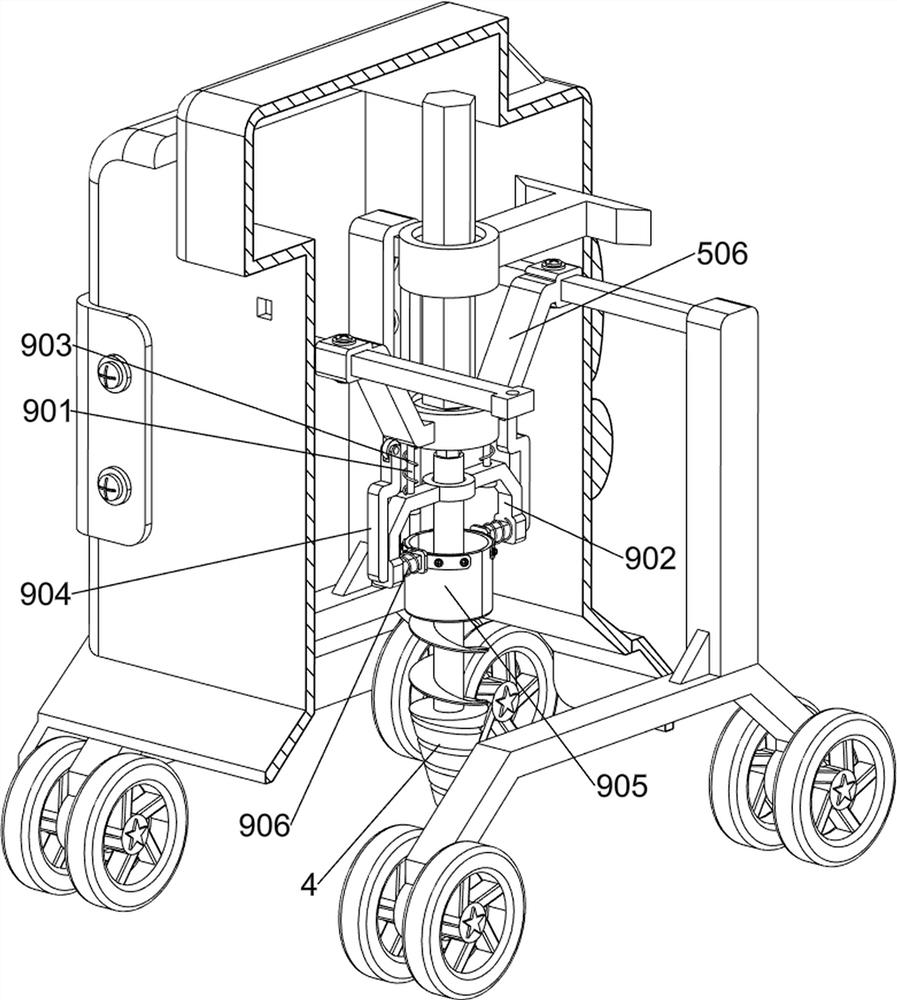

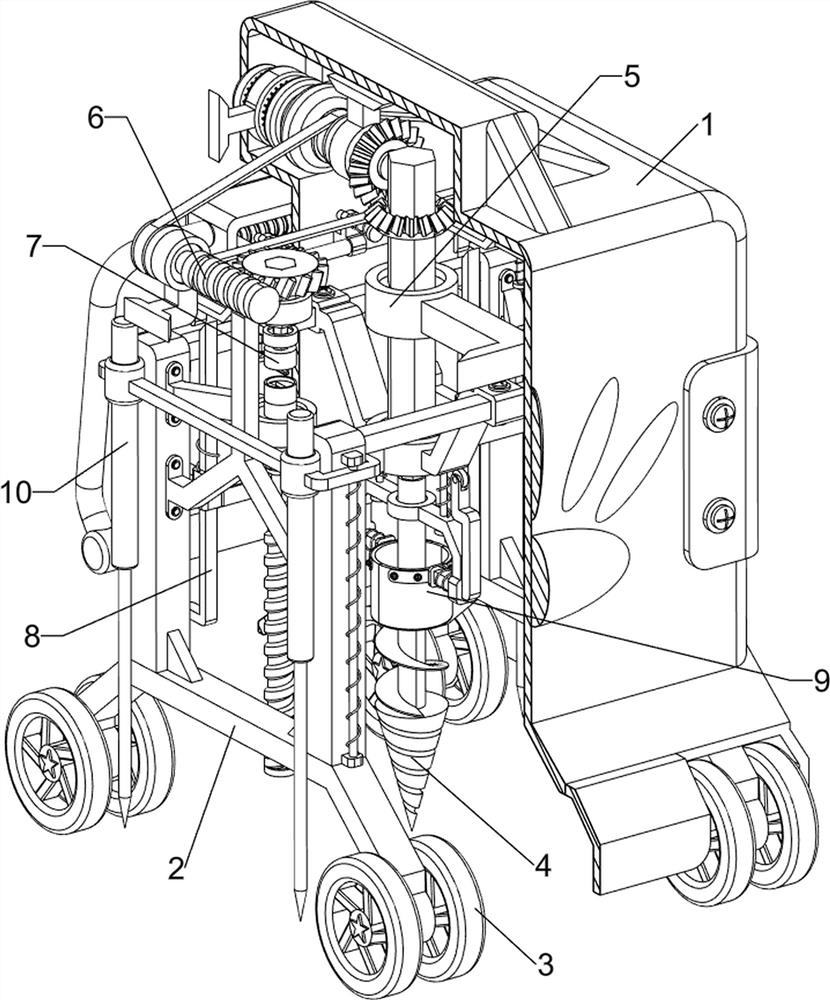

Small blast hole dumping equipment for mining blasting

PendingCN114135235AImprove work efficiencyTo achieve the effect of clampingEarth drilling toolsConstructionsDrill bitEnvironmental geology

The invention relates to dumping equipment, in particular to small blast hole dumping equipment for mining blasting. The technical problem is to provide the small blast hole dumping equipment for mining blasting, which is high in stability and has an automatic bulldozing function. According to the technical scheme, the small blast hole dumping equipment for mining blasting comprises a shell and supporting frames, and the supporting frames are arranged on the two sides of the interior of the shell; the wheels are rotationally and symmetrically arranged on the two sides of the bottom of the supporting frame; the soil discharging assembly is arranged in the middle of the interior of the shell; the drill bit is arranged on the lower side of the soil discharging assembly. After a check block moves rightwards and passes through a first sliding rod, the first sliding rod is driven to move upwards under the action of a fifth spring, and at the moment, the first sliding rod blocks the check block, so that the working efficiency of dumping of the equipment can be improved, and the clamping effect is achieved.

Owner:张杏杏

A time synchronization device with data line fastening function

ActiveCN108156774BWith fastening functionAvoid churnCasings/cabinets/drawers detailsData connectionData stream

The invention discloses a time synchronization device with a data line fastening function. The device comprises a time synchronization device body with the data line fastening function. A data line jack is arranged in the back of the time synchronization device body with the data line fastening function. A protection frame is fixedly arranged on the back of the time synchronization device body with the data line fastening function. Adjusting rods are arranged on both sides of the data line jack on the back of the time synchronization device body with the data line fastening function. The telescopic ends of two adjusting rods are fixedly connected through a connecting cross plate. A line clamp plate is fixedly arranged at the top of the connecting cross plate. A line clamp buckle is fixedlyarranged at the bottom of the line clamp plate. A data connection line is inserted into a line insertion slot on the surface of the protection frame. The line clamp plate is in clamp connection withthe surface of the data connection line. One end of the data connection line is inserted into the data line jack. According to the time synchronization device with the data line fastening function, the data connection line is not loosened; normal operation of the time synchronization device with the data line fastening function is ensured; the time synchronization device with the data line fastening function is prevented from data loss caused by the loose data connection line; and the device facilitates the work of people.

Owner:湖北中科亿能科技有限公司

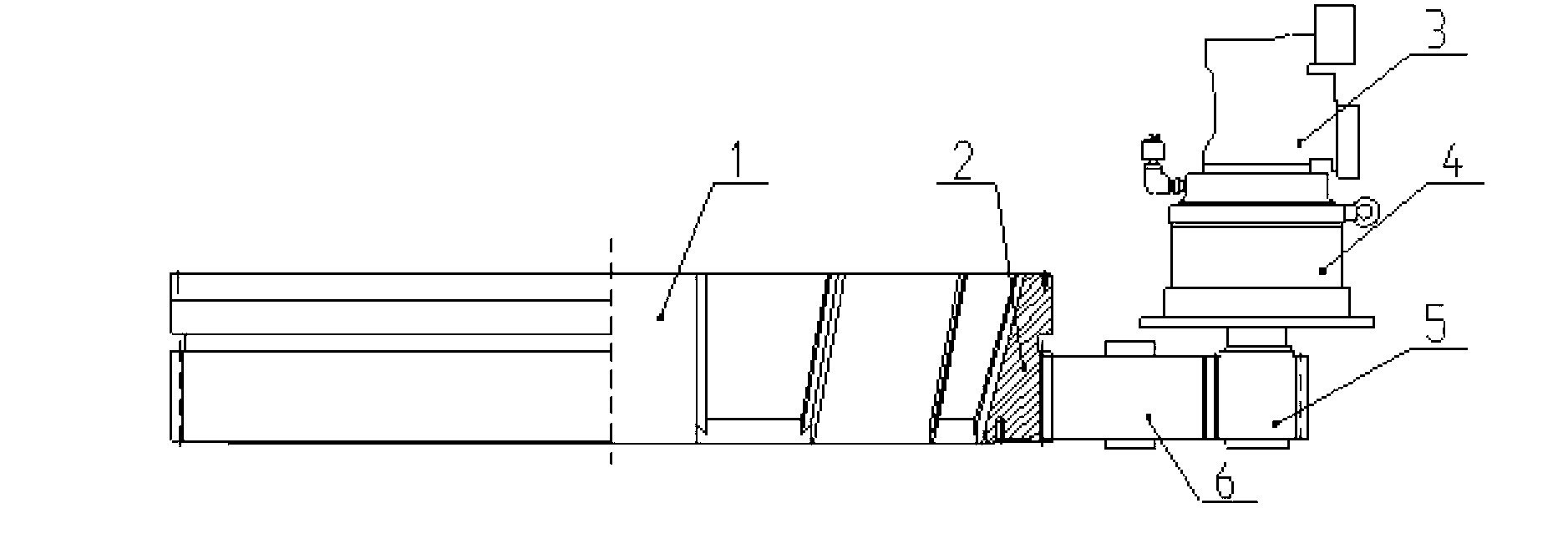

Rotary cone for all-casing full-rotating drilling machine

InactiveCN103206169ANo loosenessHigh working reliabilityBorehole drivesDrilling machinesOperational reliability

Disclosed is a rotary cone for an all-casing full-rotating drilling machine. The rotary cone comprises a rotary portion and a gear portion disposed on the outer wall of the rotary portion. The rotary portion and the gear portion are in an integral structure, and the gear portion is used for being meshed with an external gear to drive the rotary portion to rotate. According to the rotary cone for the all-casing full-rotating drilling machine, the rotary portion and the gear portion are in the integral structure, so that loosing of the rotary cone between the rotary portion and the gear portion due to loosing or damage of bolts of a separated structure connected through the bolts can be prevented, and the operational reliability is high.

Owner:徐州盾安重工机械制造有限公司

Anti-dislocation clamp for book printing

ActiveCN109624498APrevent dislocationTo achieve the effect of clampingPrinting press partsDislocationEngineering

The invention discloses an anti-dislocation clamp for book printing. The anti-dislocation clamp comprises a main box body, a fixed clamping block, a top clamping device and a top clamping block. The inner wall of the main box body is fixedly connected with the fixed clamping block. The upper end surface of the fixed clamping block is slidably connected with a movable clamping block. A fastening rotating rod is rotationally connected directly below the movable clamping block. The outer wall of the fastening rotating rod is sleeved with a clamping block fixing device. The clamping block fixing device comprises a clamping column and a driving rod. The clamping column is engaged with the driving rod. The inner wall of the main box body is slidably connected with the top clamping device. The top clamping device is positioned behind the fixed clamping block. The top clamping device comprises a hemispherical hinge and a top clamping block. According to the anti-dislocation clamp, the clampingcolumn is abutted against the lower end surface of the movable clamping block, so that the clamping effect is achieved, dislocation of the movable clamping block and books is avoided, and the angle of the top clamping block is adjusted through the hemispherical hinge, so that books which are not arranged in an orderly way are arranged.

Owner:深圳市红标点科技有限公司

Corner machining device of brush pen product

InactiveCN108656786ATo achieve the effect of clampingAchieve the effect of rotationPen repairingEngineeringMachining

The invention discloses a corner machining device of a brush pen product. The device comprises a connecting transverse plate; two support legs are fixedly mounted at the bottom of the connecting transverse plate; a frame is fixedly mounted at the top of the connecting transverse plate; a frame body is arranged on the upper surface of the connecting transverse plate, and is positioned in the frame;the bottom of the frame body is contacted with the upper surface of the connecting transverse plate; a separation plate is fixedly mounted in the frame body; a first motor is fixedly mounted at the bottom of an inner cavity of the frame body, and is positioned under the separation plate; two movable blocks are arranged under the separation plate and positioned on the frame body; and one ends of the two movable blocks are fixedly connected with the surface of a wire winding disc, fixedly mounted on an output shaft of the first motor, through cotton ropes. The corner machining device of the brush pen product is convenient to clamp and fix a pen container in the brush pen corner machining, achieves the rotating effect, improves the working efficiency, saves the time, and achieves conveniencefor people work.

Owner:临泉县龙笔笔业有限公司

Electric vehicle controller box body

ActiveCN108684164AEasy to installEasy to disassembleElectrical apparatus casings/cabinets/drawersEngineeringElectric vehicle

The invention discloses an electric vehicle controller box body, which comprises a bottom plate. An electrical element is arranged on the upper surface of the bottom plate, a cover body is sleeved outside the bottom plate, and a clamping hole is formed in one side of the cover body. A second screw hole and a sliding hole are formed in the surface of the cover body, and a cavity is formed in the side wall of the inner cavity of the cover body. A first clamping piece is arranged in the cavity, and a clamping groove is formed in the side wall of the bottom plate. One end of the first clamping piece is clamped in the clamping groove, and a second clamping piece is arranged in the bottom plate. One end of the second clamping piece is clamped in a clamping hole formed in the side wall of the cover body. The electric vehicle controller box body is advantageous in that the replacing of electrical elements is convenient; the electric vehicle controller can conveniently clean and maintain the electric appliance element after long-time use, so that maintenance and detection are facilitated; the electric vehicle controller box body is convenient to mount and dismount, and the mounting and dismounting processes is simple and convenient; the time is saved, and the efficiency is high.

Owner:徐州科悦电子科技有限公司

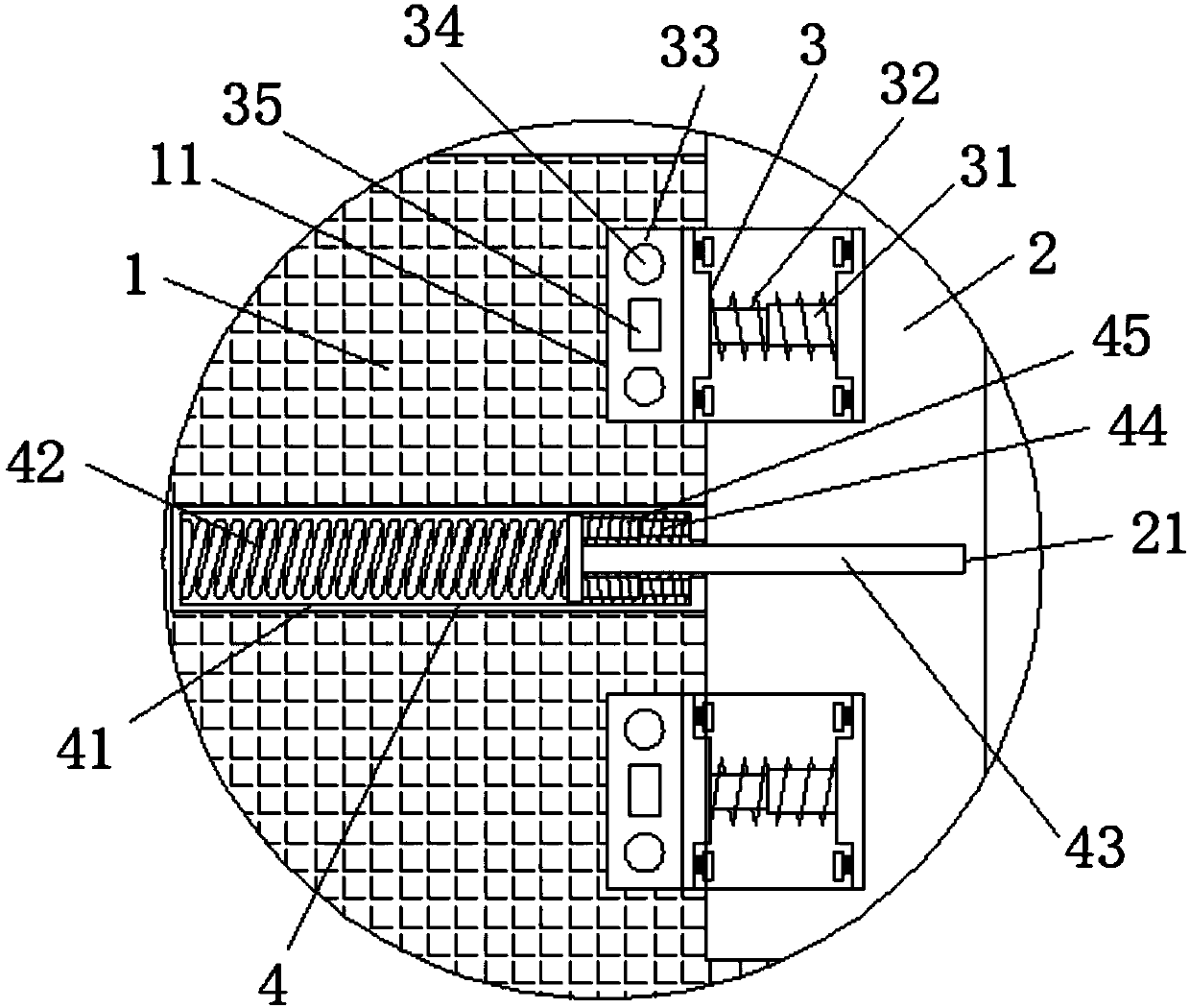

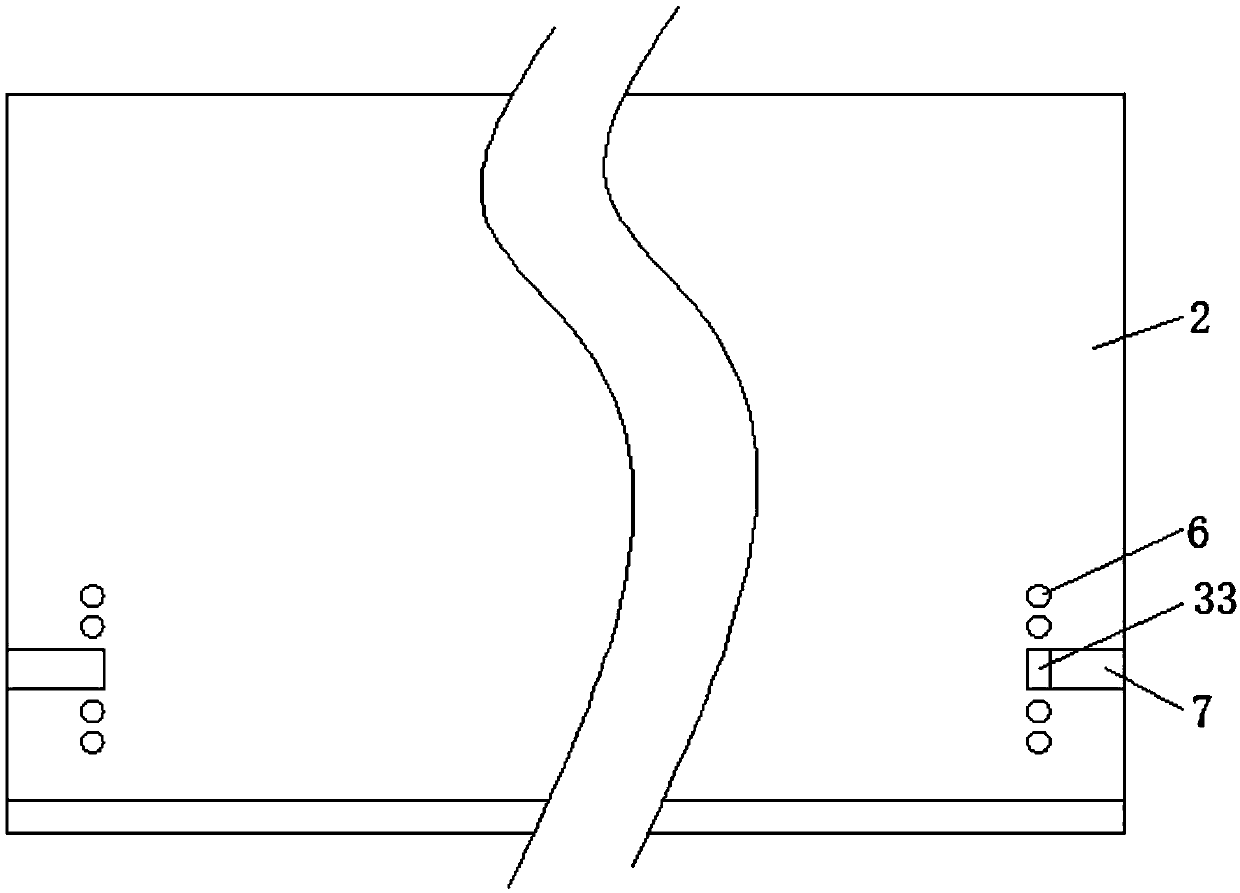

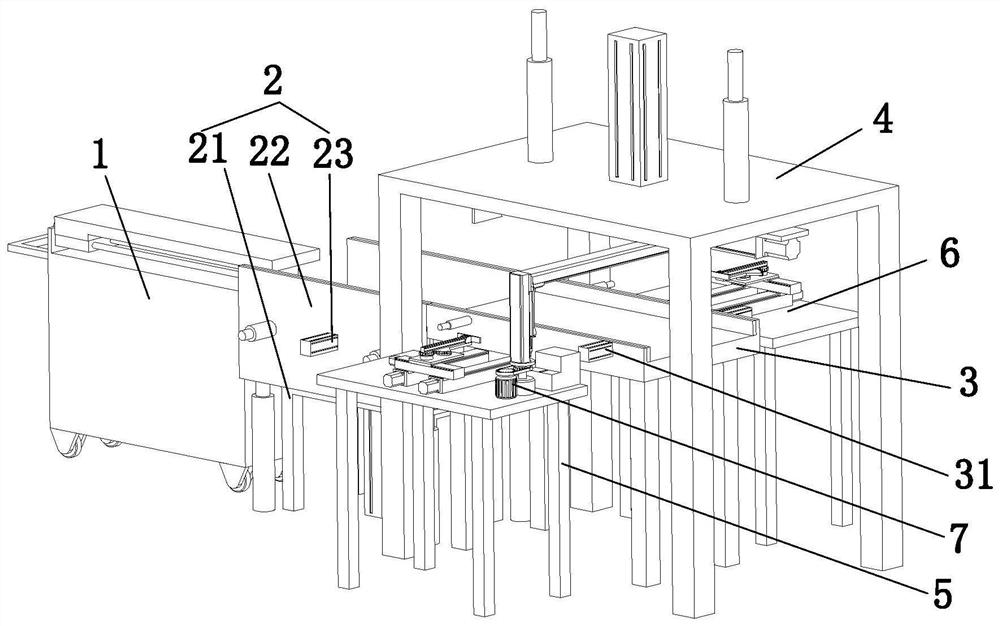

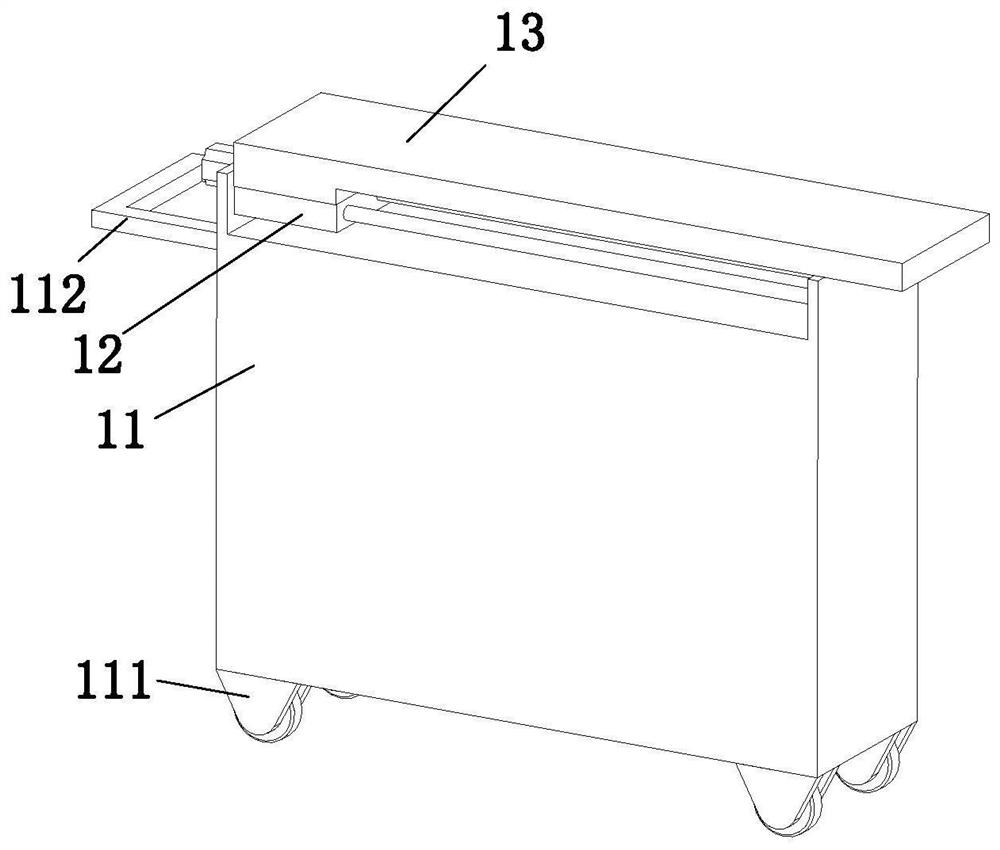

A wooden door handle automatic installation equipment

ActiveCN110802705BTo achieve the effect of clampingConsistent processing surfaceWood working apparatusRaw materialSupport plane

The present invention relates to the field of wooden door processing equipment, in particular to an automatic installation equipment for wooden door handles, including a raw material pushing device, a raw material carrying device, a raw material processing platform, a material pulling device, a left positioning device, a right positioning device and a screw mounting device. The raw material pushing device, the raw material carrying device and the raw material processing platform are arranged along a straight line, the raw material processing platform is located directly below the material shifting device, and the left positioning device and the right positioning device are respectively located on both sides of the raw material processing platform. The screw installation device is fixed on the left positioning device, and the raw material carrying device includes a first support frame, a lifting assembly and two first limit assemblies, the lifting assembly is installed on the first support frame, and the two second limit assemblies A limiting component is installed symmetrically on the lifting component, and two second limiting components are arranged symmetrically on the raw material processing platform. The invention realizes the automatic installation of the handle on the wooden door, improves the installation efficiency, and is suitable for mass production.

Owner:王建民

Chinese international education sentence difficulty level intelligent measuring equipment

PendingCN114867286AImprove uniformityAvoid heat dissipationEnergy efficient computingCooling/ventilation/heating modificationsCold airThermodynamics

The invention discloses Chinese international education sentence difficulty level intelligent measuring equipment, and relates to the technical field of Chinese international education. Through a cold dissipation assembly, when the cold air flow is small, the cold dissipation assembly can serve as a transfer station for transmitting cold air, and meanwhile, the cold dissipation assembly can release a small amount of cold air; according to the cooling device, the cooling uniformity of the cold air is improved, when the flow of the cold air is large, the situation that the cold air can only pass through a certain fixed position for cooling is avoided, and the effect of increasing the cooling and cooling effect in the first fixed block is achieved, and when the flow of the cold air in the first round block is large, the cooling effect is improved. According to the cooling device, cold air can be blocked so that the cold air can move towards the two sides of a circular block, the effect of dispersing the cold air is achieved, an arc-shaped plate can be subjected to more cold air pressure, and through a first filter screen, the cold air can be filtered to a certain degree, and meanwhile the cold air can be dispersed so that the cold air can flow into a first fixing block in a dispersed mode.

Owner:YUNNAN COLLEGE OF BUSINESS MANAGEMENT

Supercharged vice transverse clamping equipment

The invention relates to the technical field of supercharged vises, and discloses a supercharged vise transverse clamping equipment which comprises an equipment body. A transverse tooth is fixedly installed in the equipment body, a main gear meshes with the inner part of the periphery of the transverse tooth, a fixing rod is rotatably connected to the bottom of the main gear, the bottom of the fixing rod is rotatably connected with a transmission gear, the periphery of the transmission gear meshes with a driving gear, the right side of the driving gear is rotatably connected with a fixed magnetic block, and the end, away from the main gear, of the fixing rod is fixedly connected with a sliding magnetic block. The driving gear continuously rotates on the periphery of the transmission gear to drive the fixed magnetic block on the right side to move back and forth, meanwhile, the sliding magnetic block on the fixing rod further moves along with the sliding magnetic block, so that the effect of continuously and transversely moving and clamping is achieved, an extension rod pulls a rotating upper tightening block to move downwards on a fixing lower tightening block, and therefore the clamping effect is achieved.

Owner:桂文明

An anti-dislocation clamp for book printing

ActiveCN109624498BPrevent dislocationTo achieve the effect of clampingPrinting press partsEngineeringMechanical engineering

Owner:深圳市红标点科技有限公司

Spinning roller frame device

InactiveCN108789336ATo achieve the purpose of opening and closingTo achieve the effect of clampingWork tools storageEngineeringMechanical engineering

The invention discloses a spinning roller frame device and relates to the technical field of spinning. The spinning roller frame device comprises a base. The two sides of the top end of the base are each fixedly connected with a support column. A first rotary shaft is movably connected to the top ends of the support columns. A rotary roller is movably connected in the axial direction of the firstrotary shaft. A first groove is formed in the rotary roller. An adjusting rod is arranged in the first groove. A limiting block is fixedly connected to one end of the adjusting rod. A return spring isarranged in the middle of the adjusting rod circumferentially. One end of the return spring is fixedly connected with the limiting block. The other end of the return spring is fixedly connected withthe rotary roller. The spinning roller frame device is provided with the rotary roller, and thus spinning rollers can be placed annularly, needed spinning rollers can be selected more easily during taking and placing. The adjusting rod is arranged, thus a force arm can be driven to achieve a clamp opening and closing purpose, and a clamping effect is achieved. The return spring is arranged, thus the adjusting rod can be driven to pull the force arm backwards, and an automatic clamping purpose is achieved. A push block is arranged so that the spinning rollers can be pushed out.

Owner:湖州新爱品纺织有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com