Anti-dislocation clamp for book printing

A technology of anti-loosening and books, which is applied in the direction of printing, general parts of printing machinery, printing machines, etc., can solve the problems of easy dislocation and inability to organize and arrange books, and achieve the effect of avoiding dislocation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

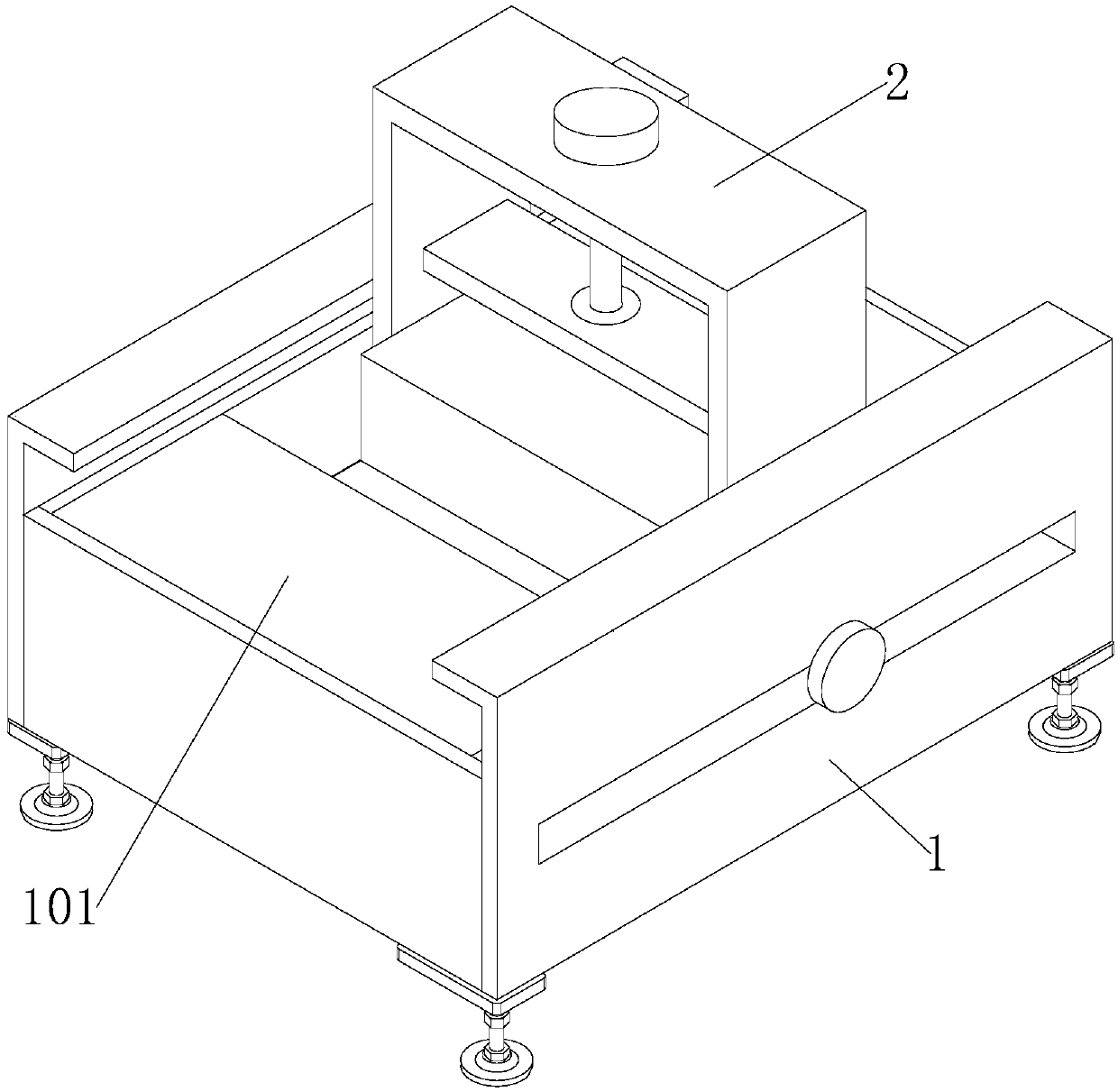

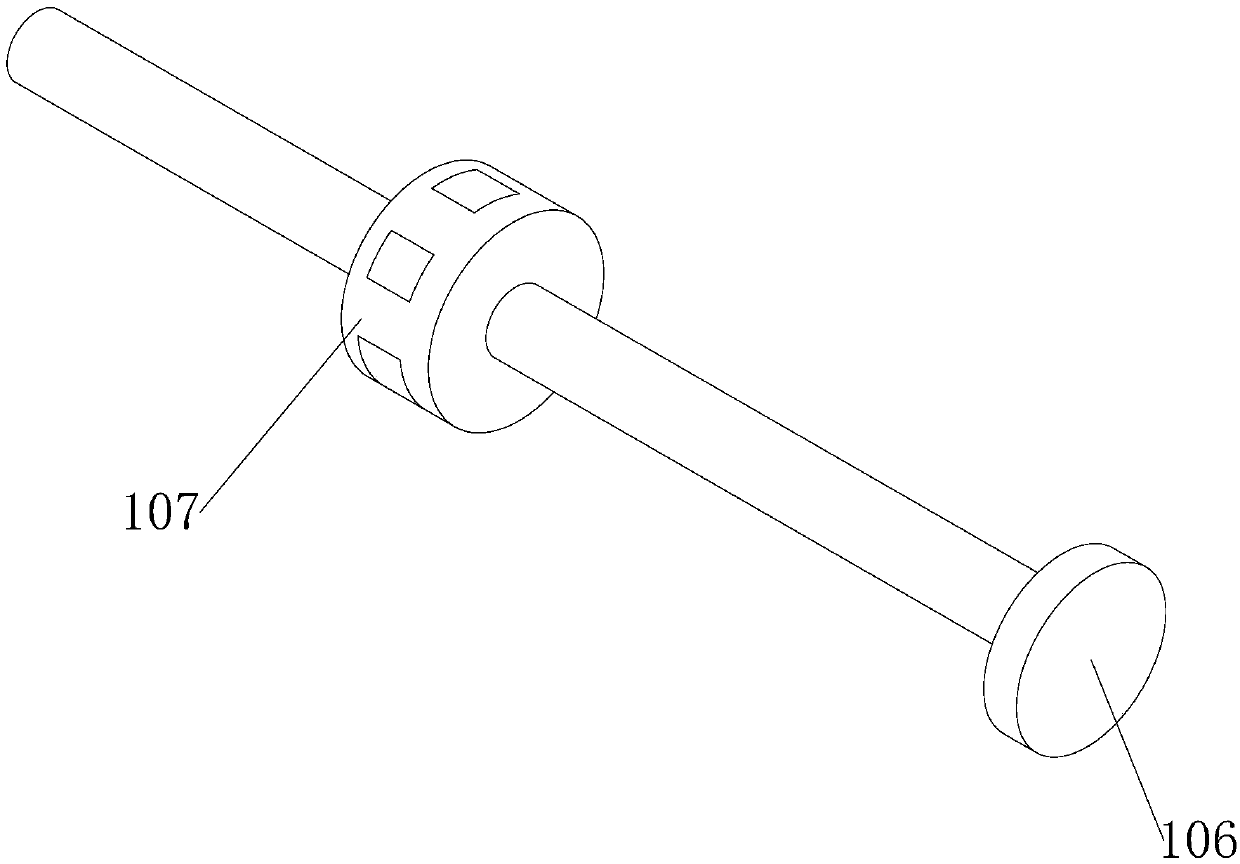

[0023] Reference Figure 1-5 , An anti-dislocation clamp for book printing, comprising a main box body 1, a fixed clamp block 101, a top clamping device 2 and a top clamp block 204. The inner wall of the main box body 1 is fixedly connected with a fixed clamp block 101 and a fixed clamp block The upper end surface of 101 is slidably connected with a movable clamping block 103, and a fastening rotating rod 105 is rotatably connected directly under the movable clamping block 103. The outer wall of the fastening rotating rod 105 is sleeved with a clamping block fixing device 107. The clamping block fixing device 107 includes There are a clamping column 1071 and a driving rod 1072. The clamping column 1071 is engaged with the driving rod 1072. The inner wall of the main box 1 is slidably connected with a top clamping device 2, which is located behind the fixed clamping block 101, and the top clamping The device 2 includes a hemispherical hinge 203 and a top clamping block 204. The ...

Embodiment 2

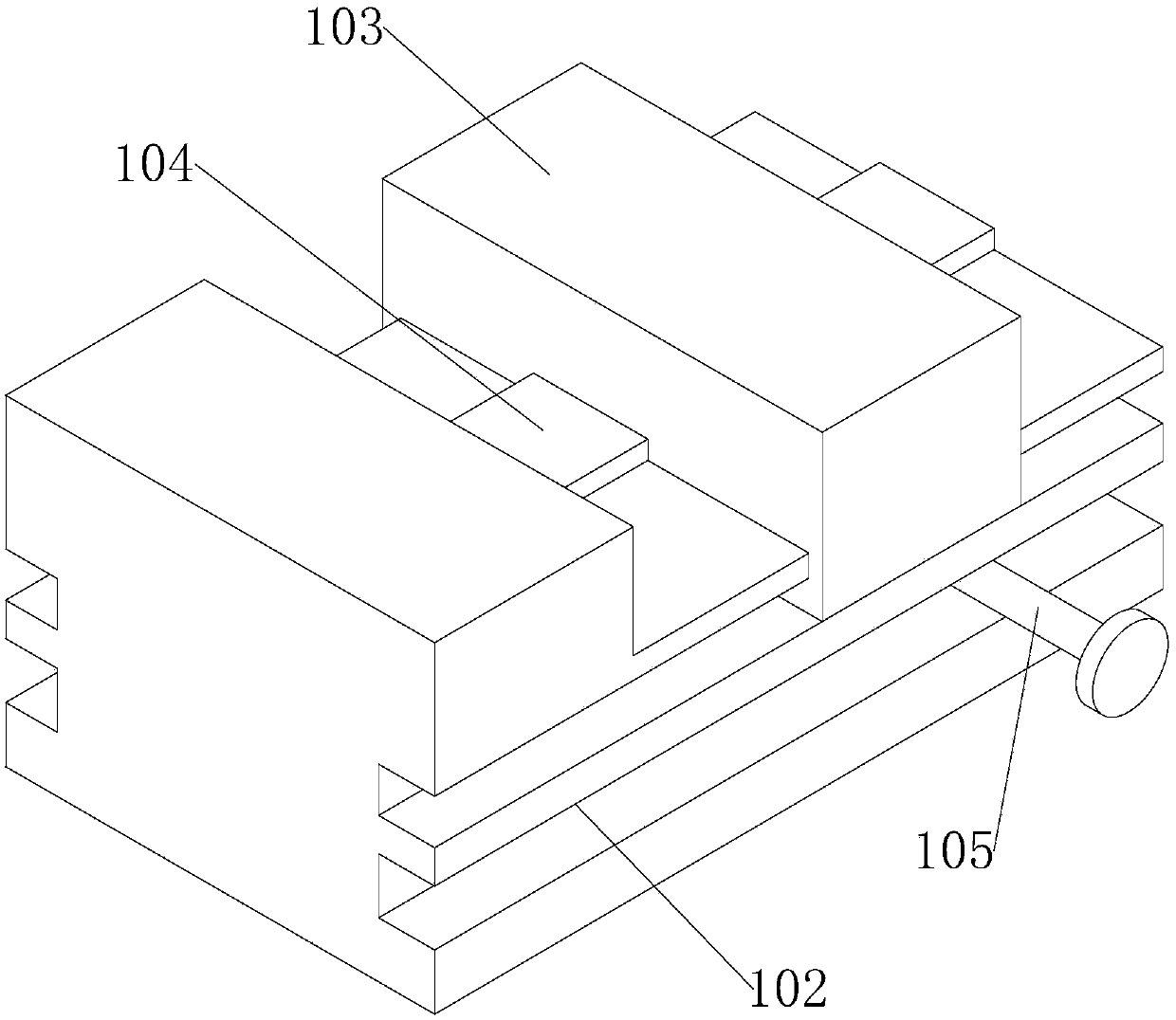

[0025] Reference figure 2 with image 3 , An anti-dislocation clamp for book printing, which is basically the same as embodiment 1. Furthermore, the lower end surface of the fixed clamp block 101 is fixedly connected with a slide rail 102, the slide rail 102 and the movable clamp block 103 are arranged in parallel, and the slide rail The upper end surface of 102 is in contact with the movable clamp block 103. The upper end surface of the fixed clamp block 101 is fixedly connected with a positioning strip 104. The inside of the movable clamp block 103 is provided with a rectangular through hole, and the positioning strip 104 penetrates the inside of the rectangular through hole. The movable clamping block 103 slides along the positioning bar 104 toward the fixed clamping block 101, so that the fixed clamping block 101 and the movable clamping block 103 are closely attached to the book, and the top clamping device 2 is slid along the slide rail 102 to the book The book is clamped...

Embodiment 3

[0028] Reference Figure 5 , An anti-dislocation clamp for book printing, which is basically the same as embodiment 1. Furthermore, the upper end surface of the top clamping device 2 is provided with a circular through hole, and the inside of the circular through hole is connected with a lifting column 201 for lifting The column 201 is composed of a casing and a telescopic tube. The casing and the telescopic tube are collinear with the axis of the telescopic tube. The telescopic tube can slide along the casing to realize the lifting adjustment of the lifting column 201. The lower end surface of the lifting column 201 is fixedly connected with The connecting rod 202 is fixedly connected to the lower end surface of the connecting rod 202 with a hemispherical hinge 203, and the connecting rod 202 can move with the lifting column 201. The connecting rod 202 is used to connect the lifting column 201 with the hemispherical hinge 203, so that the lifting column 201 can be connected. Ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com