Rotary cone for all-casing full-rotating drilling machine

A full-rotary drilling rig and full-casing technology, which is applied to the driving device for drilling in the borehole, drilling equipment, earthwork drilling and production, etc., can solve the loosening of the ring gear and the cone, the influence of machine transmission and clamping, and the loosening of bolts, etc. problem, to achieve good transmission and clamping, easy disassembly and assembly, time-saving and labor-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

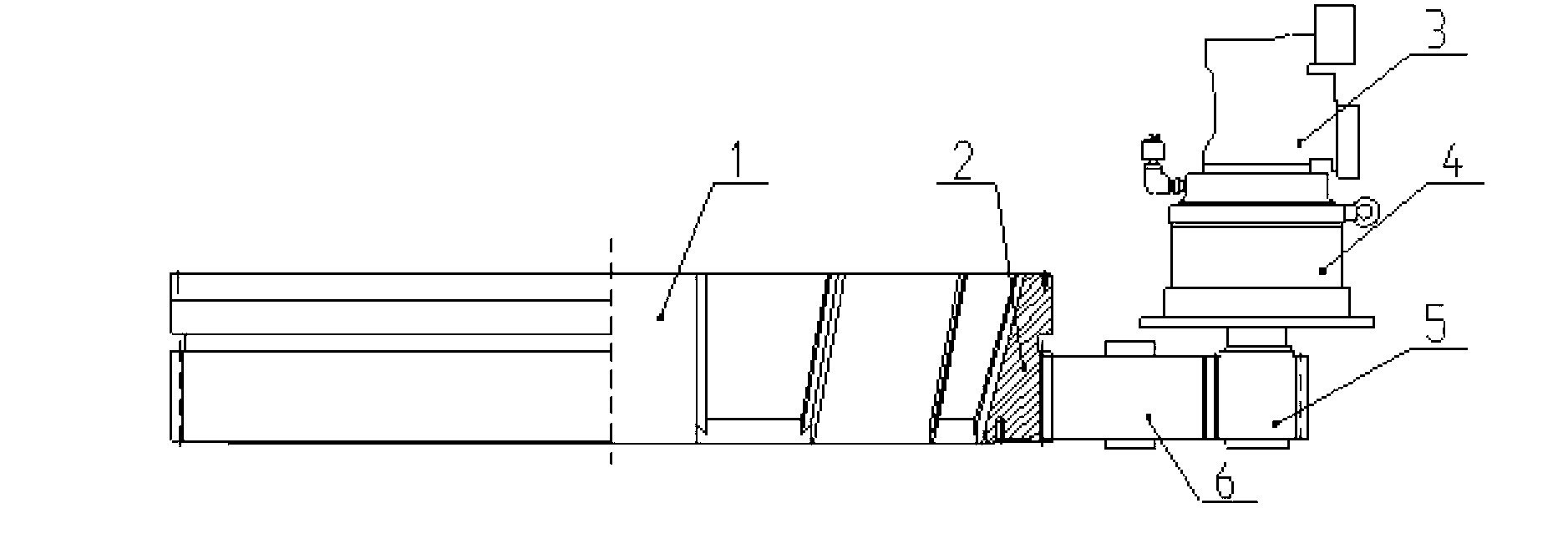

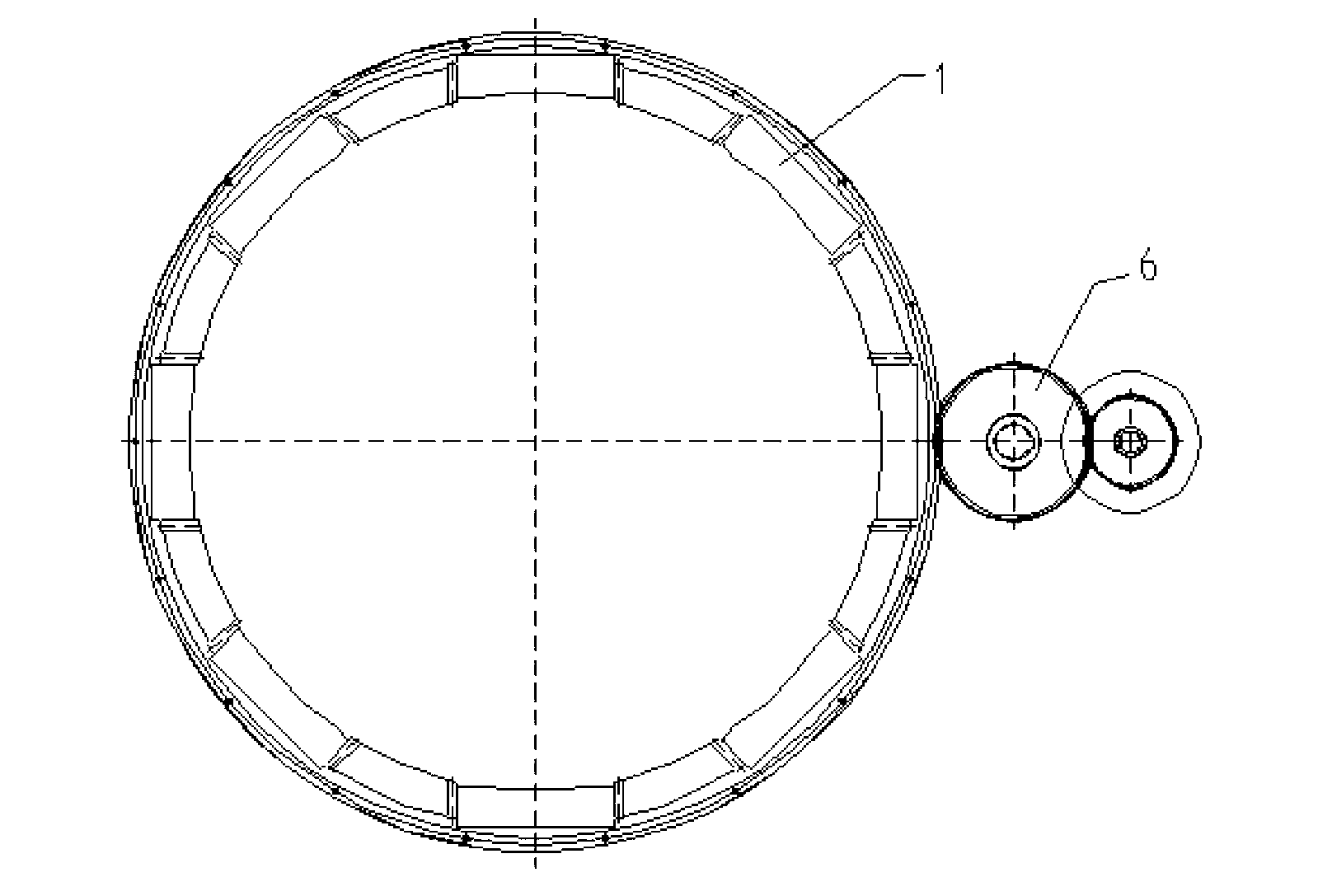

[0013] A rotary cone for a full-casing full-rotary drilling machine includes a rotating part 1 and a gear part 2 . The rotating part 1 and the gear part 2 are integrated. The rotating part 1 is roughly ring-shaped. The gear part 2 is formed on the outside of the rotating part 2 and is a ring gear made by processing, which is used to mesh with the external gear to drive the rotating part 1 to rotate. When working, the hydraulic motor 3 starts to drive the reducer 4 to rotate. The reducer 4 drives the driving gear 5 to rotate through the output shaft. The driving gear 5 meshes with the idler 6 to drive the idler 6 to rotate. It drives the entire rotary cone to rotate, and then clamps the casing rotation operation of the full-casing full-rotary drilling rig.

[0014] The rotary cone of the present invention is processed outside the rotating part 1 to form the gear part 2 of the ring gear structure. Structurally, the rotating part 1 and the gear part 2 are integrated without any c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com