Manufacturing method of shale sintered composite plate for prefabricated building

A manufacturing method and technology of composite panels, which are applied in construction, building components, building structures, etc., can solve the problem of uneven thermal insulation or thermal insulation effects of thermal insulation partition panels, hollow bricks that are prone to loosening, dislocation, and no open thermal insulation partition walls. Decorative board and other problems, to improve the thermal conductivity, improve the effect of heat insulation and shorten the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

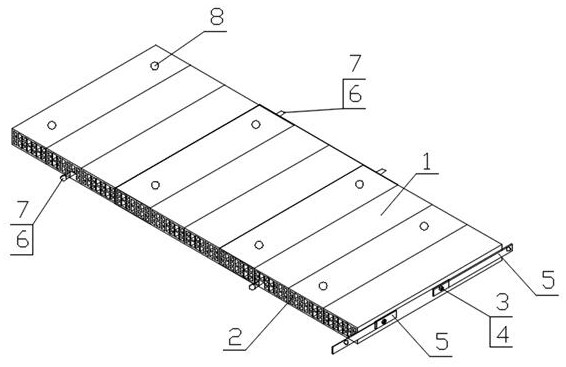

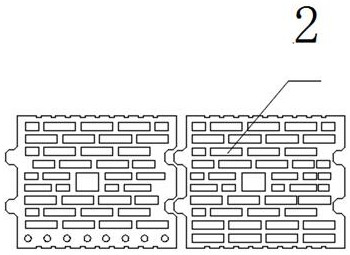

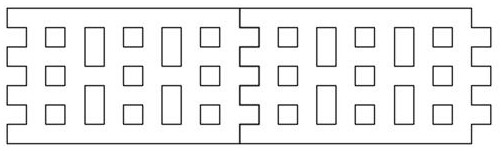

[0044] Such as figure 1 , 2 , 3, the manufacturing method of the shale sintered composite panel for prefabricated buildings provided by Embodiment 1 of the present invention comprises the following steps: 1. According to the process requirements, a hollow brick body 1 is made, and several heat-insulating panels are formed in the hollow brick body 1. Hole 2; 2. Before heating and sintering the hollow brick body 1 or during the heating and sintering process, set one or more penetrating steel bar holes 3 on the hollow brick body 1 perpendicular to the direction of the heat insulation hole 2 for piercing Reinforcing bar; on part or all of the hollow brick body, a non-penetrating panel connecting hole 6 is arranged perpendicular to the reinforcing bar hole to set the panel connecting piece 7; the reinforcing bar hole 3 is perpendicular to the heat insulation hole 2, and the panel is connected The hole 6 is usually parallel to the heat insulation hole 2, and the direction is the sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com