Patents

Literature

37results about How to "Satisfy thermal insulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nano modified water-base multifunctional sound-absorbing paint and preparation method thereof

InactiveCN103980771ABasic mechanicsBasic sound-absorbing functionCoatingsWater basedThermal insulation

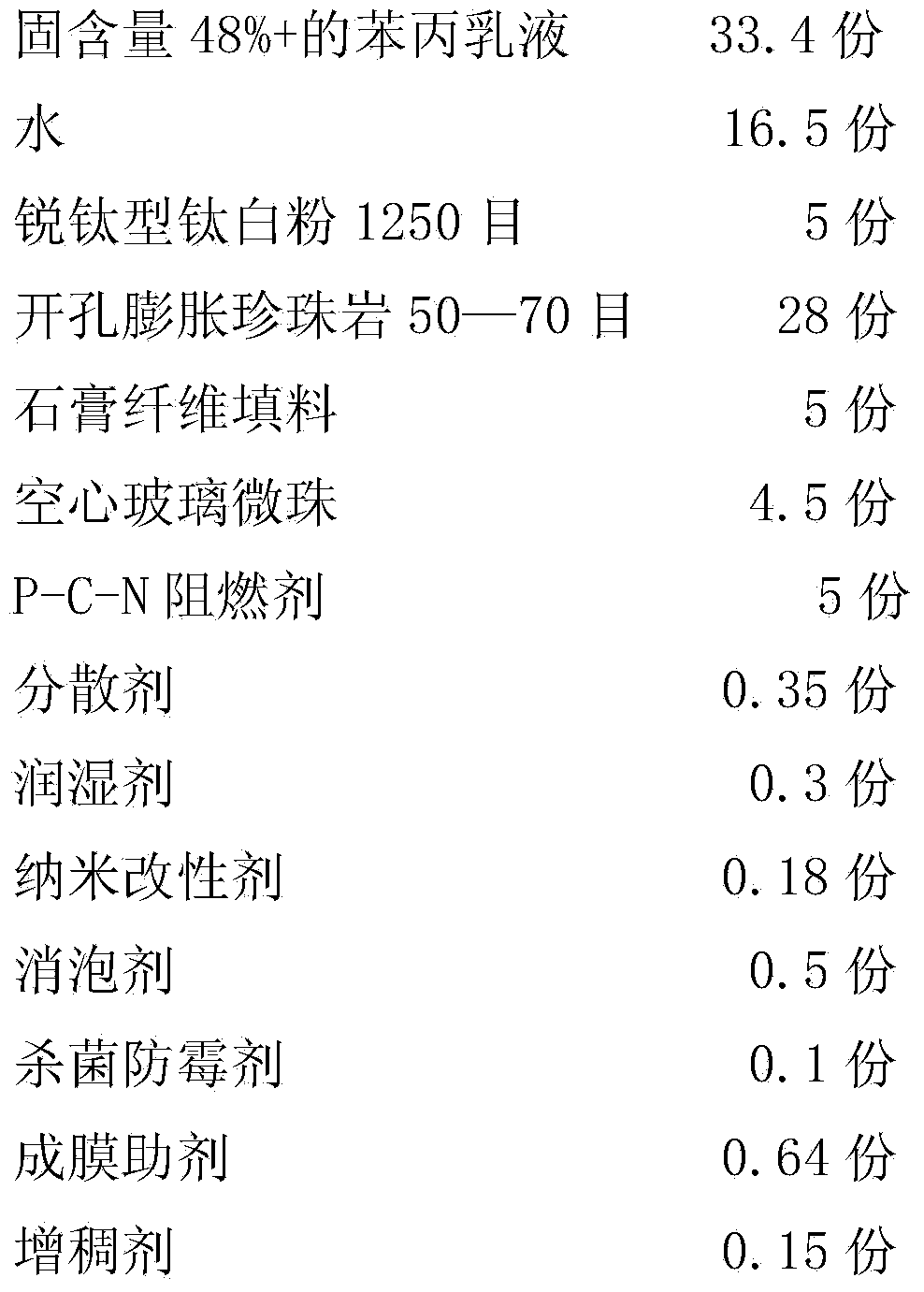

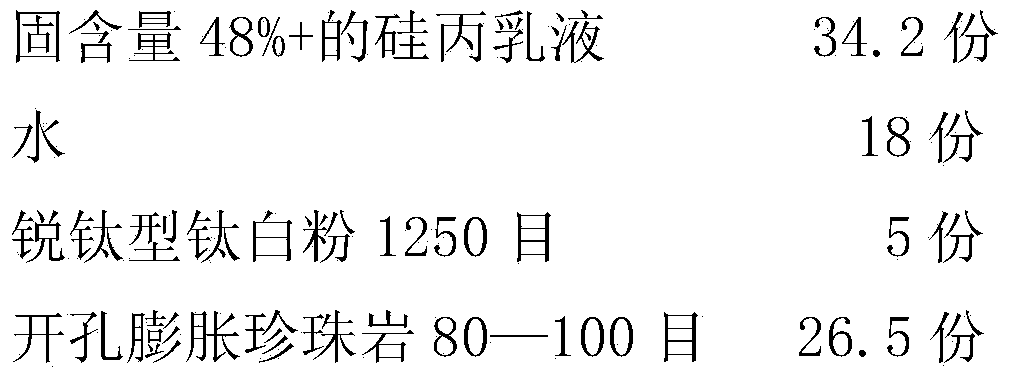

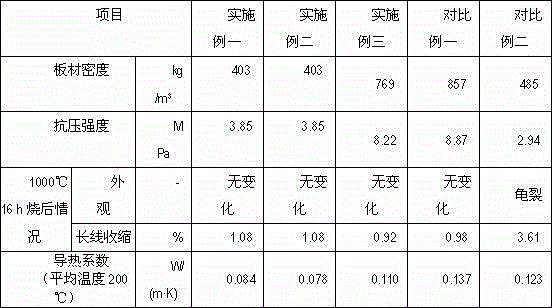

The invention discloses a nano modified water-base multifunctional sound-absorbing paint and a preparation method thereof. The paint is composed of the following components in parts by weight: 28-38 parts of emulsion, 2-10 parts of pigment, 30-45 parts of filler, 15-25 parts of water, 4-8 parts of flame retardant and 2.25-5.43 parts of assistant. By optimizing the paint system structure, the polymer and filler are selected, modified and proportioned to ensure the basic mechanical properties and sound-absorbing function, and the paint has high-value service properties, such as thermal insulation, moisture resistance, fire resistance, aging resistance, fouling resistance, sterilization, air purification and the like, and is especially suitable for rooms and other occasions with higher environmental requirements.

Owner:南京创宁空间新材料科技有限公司

Aluminum silicate fiber refractory felt with good heat insulation performance

ActiveCN107415362AStrong heat insulation abilityAvoid burnsGlass making apparatusLaminationFiberAluminum silicate

The invention specifically discloses an aluminum silicate fiber refractory felt with good heat insulation performance, belonging to the technical field of refractory materials. The aluminum silicate fiber refractory felt is prepared by dipping an aluminum silicate fiber felt in nanometer aerosil slurry, then drying the aluminum silicate fiber felt, separately connecting the two sides of the aluminum silicate fiber felt with refractory layers, then dipping the aluminum silicate fiber felt in the nanometer aerosil slurry again and carrying out drying, wherein the aluminum silicate fiber felt is prepared from modified aluminum silicate fibers through braiding; the modified aluminum silicate fibers are prepared from kaolin powder, alumina, titanium dioxide, a dispersant, nanometer aerosil, polyimide resin, a silane coupling agent, an aluminum phosphate binder and water; and the nanometer aerosil slurry is prepared from diatomite, activated clay, nanometer aerosil and water. The aluminum silicate fiber refractory felt of the invention can form multilayer heat-insulatiing protection, has good heat insulation performance, can meet the demands of equipment for heat preservation and fire resistance and prevents scalding of operators or damage to articles contacting with the felt caused by too high surface temperature of the refractory felt.

Owner:徐州博创建设发展集团有限公司

Method for manufacturing high-strength and energy-saving xonotlite heat-insulation product

InactiveCN103951363AHigh strengthLow densityWater-setting substance layered productHigh densityVolumetric Mass Density

The invention discloses a method for manufacturing a high-strength and energy-saving xonotlite heat-insulation product. On the basis of a high-density plate production process based on a static method, xonotlite slurry synthesized by using a dynamic hydrothermal method is added to reduce the density of a plate so as to obtain the high-strength and energy-saving xonotlite heat-insulation product with moderate density and relatively high strength. Meanwhile, a layer of aluminum foil is coated to ensure that the product has water resistance, the heat insulation effect of materials is enhanced, and the condition of the product is optimized.

Owner:莱州明发隔热材料有限公司

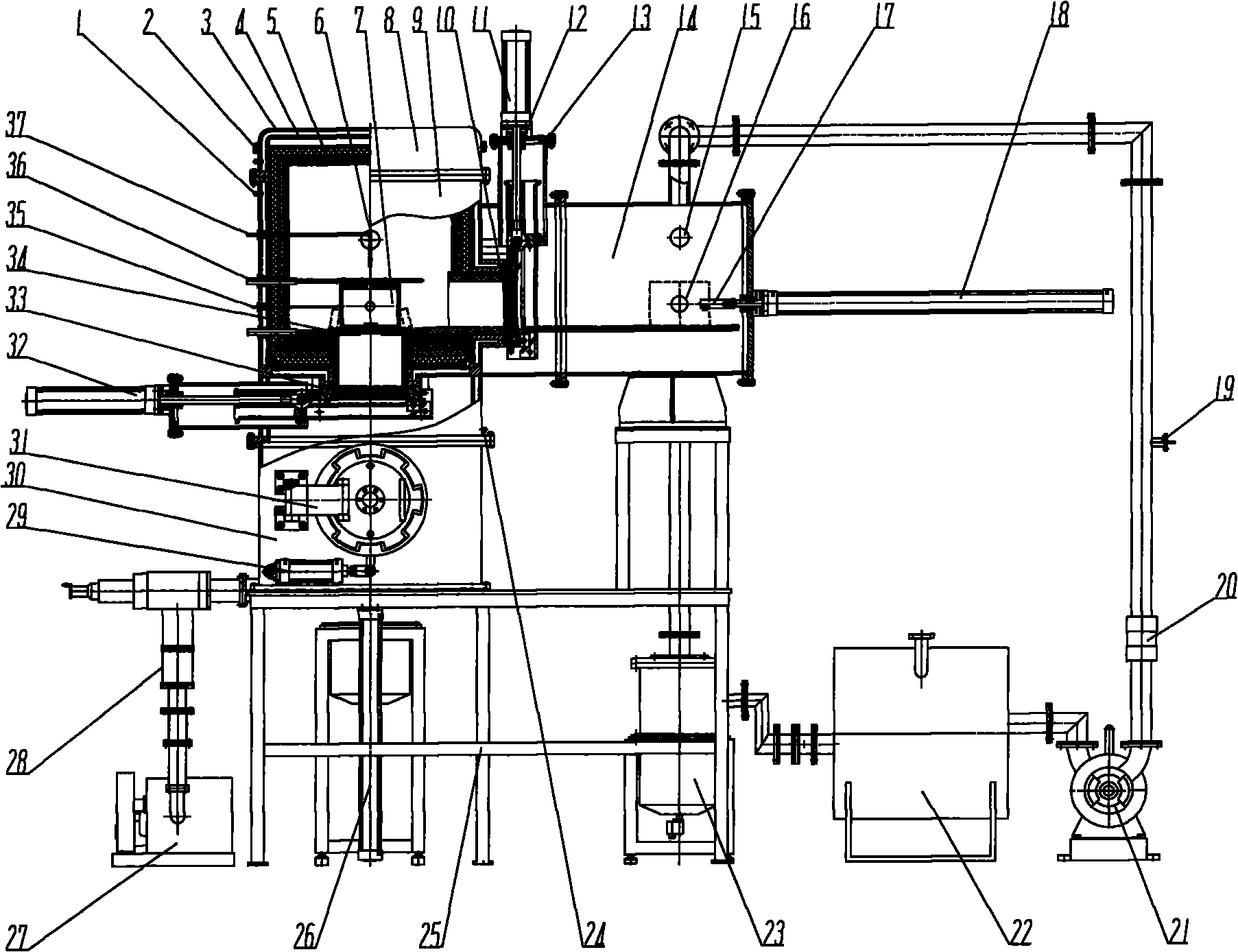

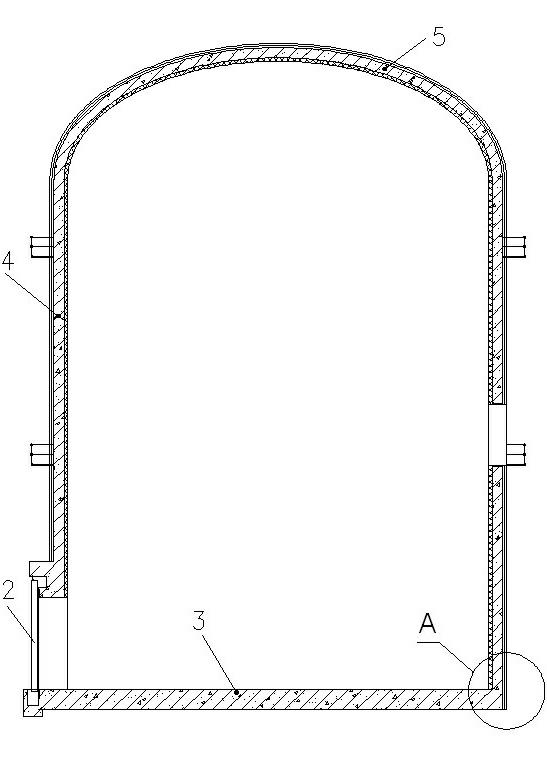

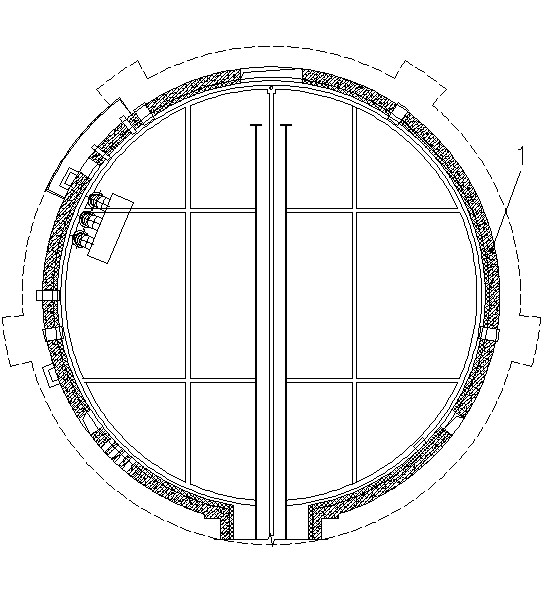

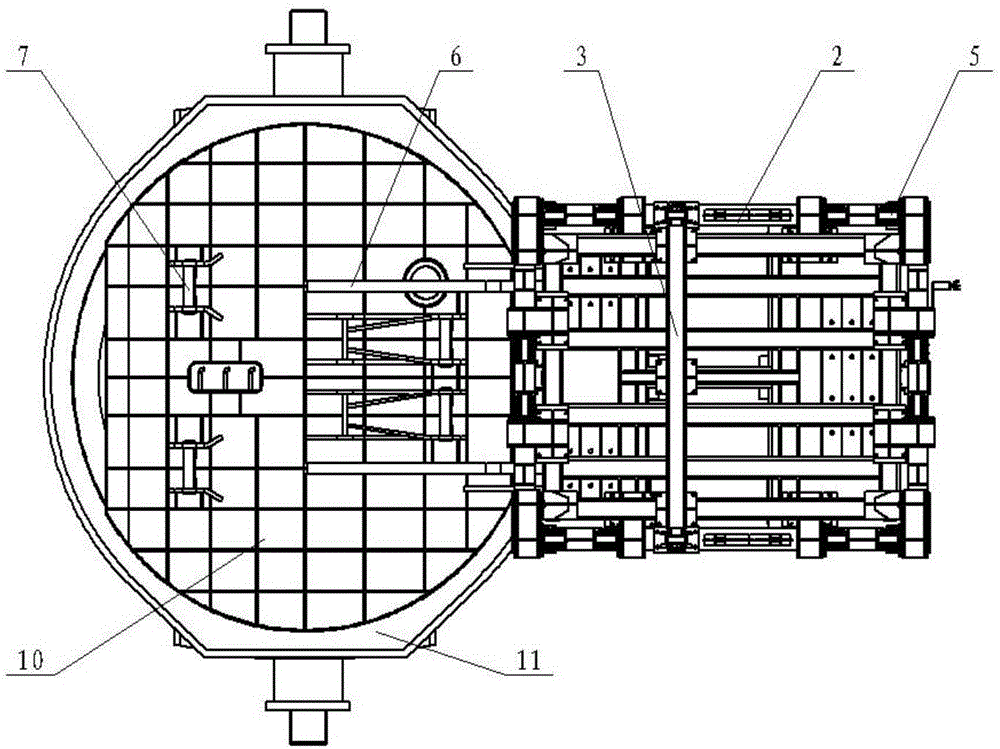

Vertical and horizontal efficient energy-saving vacuum controlled atmosphere furnace for continuous production

The invention aims to provide a vertical and horizontal efficient energy-saving vacuum controlled atmosphere furnace for continuous production with high space utilization rate, high heating speed, high product cooling speed, short production period and avoidance of great energy waste caused by repeated heating and cooling during production. The furnace consists of a feeding chamber, a reaction chamber and a discharge chamber, wherein the feeding chamber is positioned below the reaction chamber, and the feeding chamber and the reaction chamber form a vertical structure; and the discharge chamber is positioned on the lateral surface of the reaction chamber, and the discharge chamber and the reaction chamber form a horizontal structure so as to form a vertical and horizontal structure and improve the space utilization rate. The furnace realizes heat insulation and seal of each chamber by adopting a heat insulation sealing door, and has high heating speed and high energy efficiency by adopting an inductive heating mode; the product is cooled by adopting a circulating air cooling system; and the vertical and horizontal efficient energy-saving vacuum controlled atmosphere furnace for continuous production can perform continuous production only by one-time heating so as to improve the production efficiency, reduce the production cost and save a large amount of energy.

Owner:QINGDAO UNIV OF SCI & TECH +1

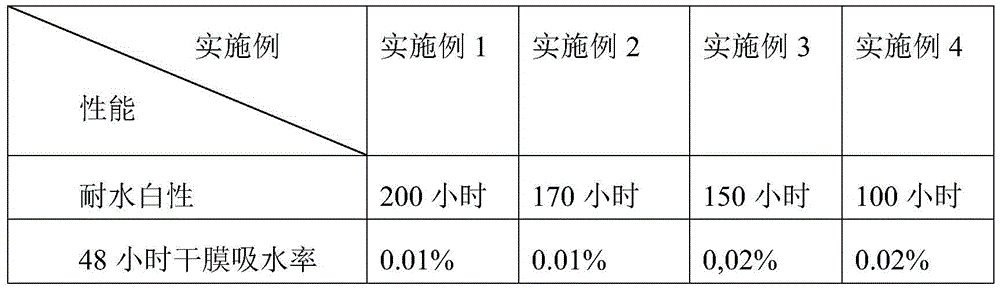

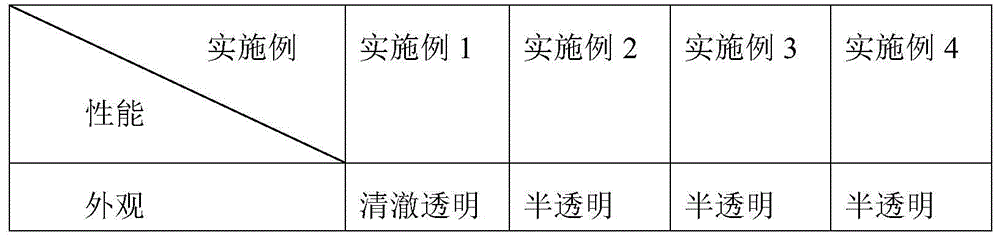

Preparation method of acrylic acid organic silicon soap-free copolymerization emulsion

The invention discloses a preparation method of acrylic acid organic silicon soap-free copolymerization emulsion. Unsaturated monomers, organic silicon, a reactive emulsifier, an initiator and water are adopted as raw materials, temperature of a reaction kettle is controlled by virtue of core-shell polymerization and soap-free polymerization technologies, then treatment is carried out for removing residual monomers, and a neutralizing agent is added for neutralization, so that emulsion is obtained. By virtue of the soap-free polymerization technology, better water white resistance can be realized with less expensive organic silicon monomer, and water absorption of a paint film is reduced. By virtue of the core-shell polymerization technology, a core layer with high glass transition temperature and a shell layer with lower glass transition temperature are obtained, so that synthetic emulsion has lower film formation temperature under the condition that the average glass transition temperature is the same with a homopolymerization technology, usage amount of a coalescing agent is reduced, and influence of solvent volatilization on atmospheric environment is reduced. The acrylic acid organic silicon soap-free copolymerization emulsion product does not contain a free emulsifying agent, so that influence of the acrylic acid organic silicon soap-free copolymerization emulsion product on the environment is greatly reduced, and the acrylic acid organic silicon soap-free copolymerization emulsion product is environmentally friendly; and the acrylic acid organic silicon soap-free copolymerization emulsion has excellent weather resistance, water resistance and pollution resistance.

Owner:江苏三瑞生物技术有限公司

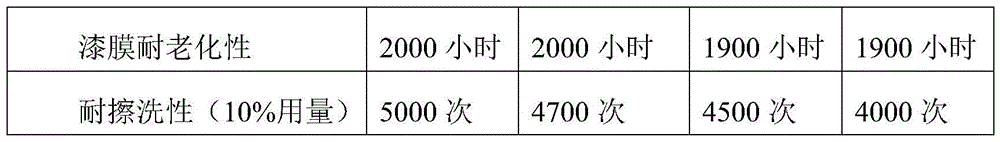

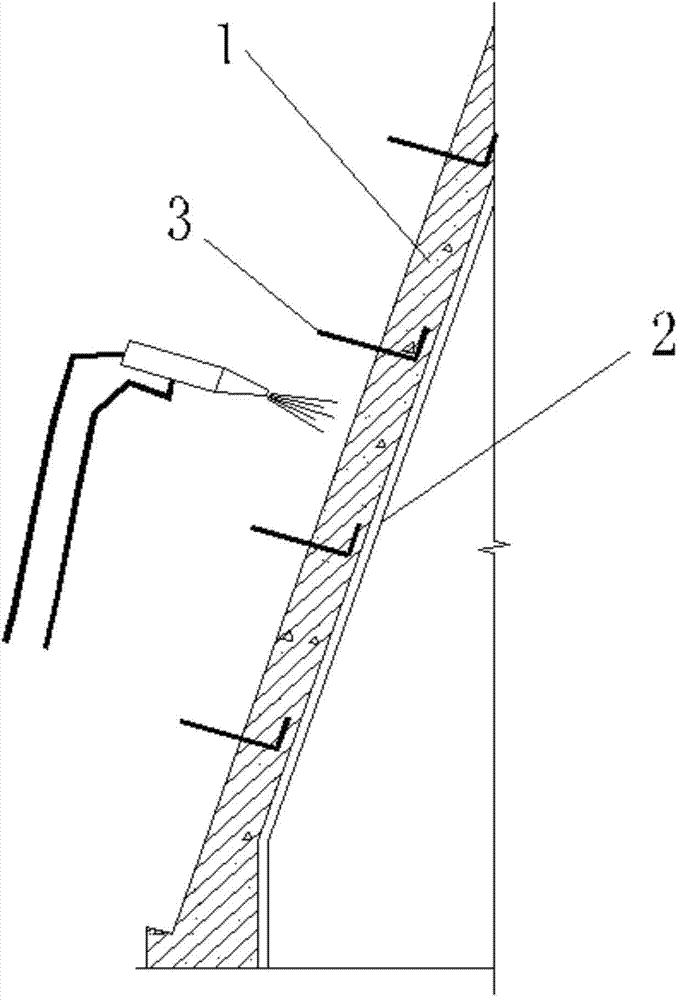

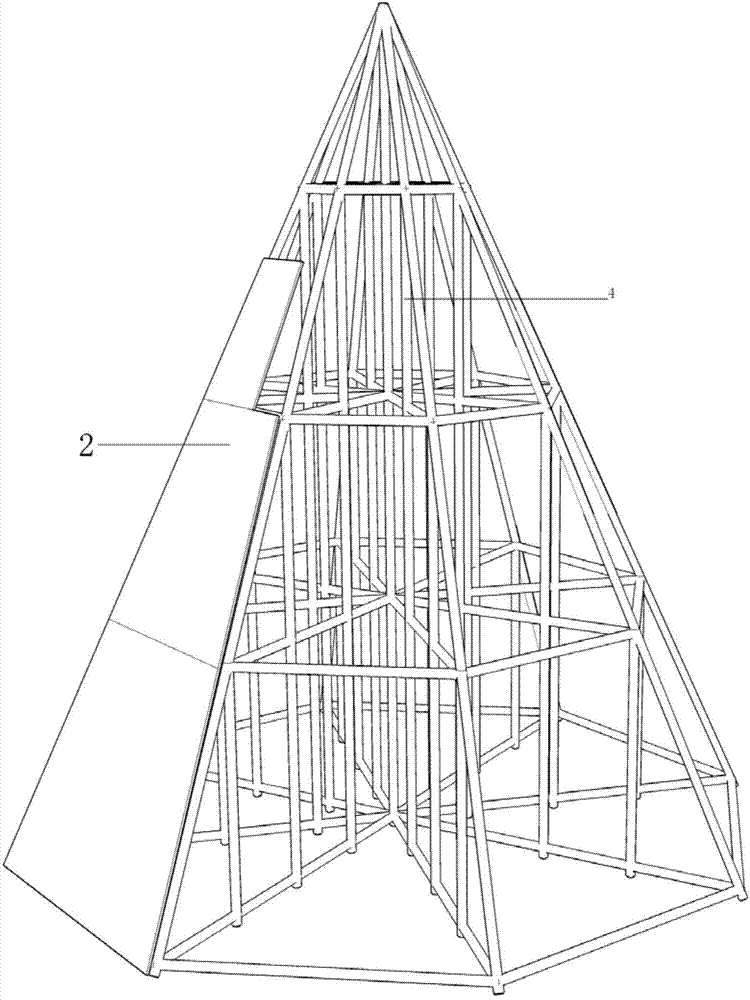

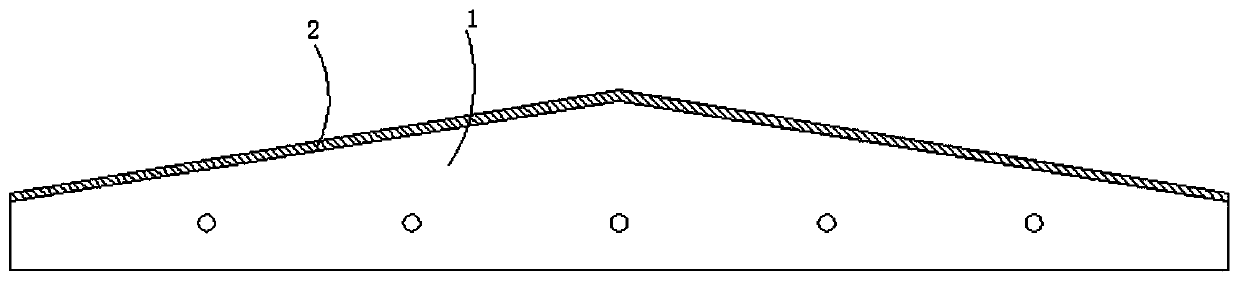

Concrete construction method for big-gradient sloping roof

ActiveCN103615076AShorten the construction periodReduce labor costsRoof covering using sealantsArchitectural engineeringRebar

The invention discloses a concrete construction method for a big-gradient sloping roof. At first, a bottom layer formwork module 2 of the big-gradient sloping roof is installed according to needs, roof panel steel bars are bound according to construction drawings and standard requirements, then sprayed concrete construction is carried out on the big-gradient sloping roof panel 1, the big-gradient sloping roof panel 1 comprises the sloping roof formwork module 2 and pre-buried L-shaped pulling ribs 3, the formwork module 2 is machined in advance to be formed and to be hoisted to a full space bearing frame 4, concrete is continuously sprayed and constructed at one time, construction quality of the concrete can be visually observed, and it is guaranteed that the interior of the concrete is dense; after roof concrete is renovated by means of cement mortar with the same proportion of the roof concrete through cleaning of dross on the surface layer, the concrete is square in appearance size, the exterior of the concrete is flat, and the interior of the concrete is solid.

Owner:CHINA CONSTR 4TH ENG BUREAU 6TH

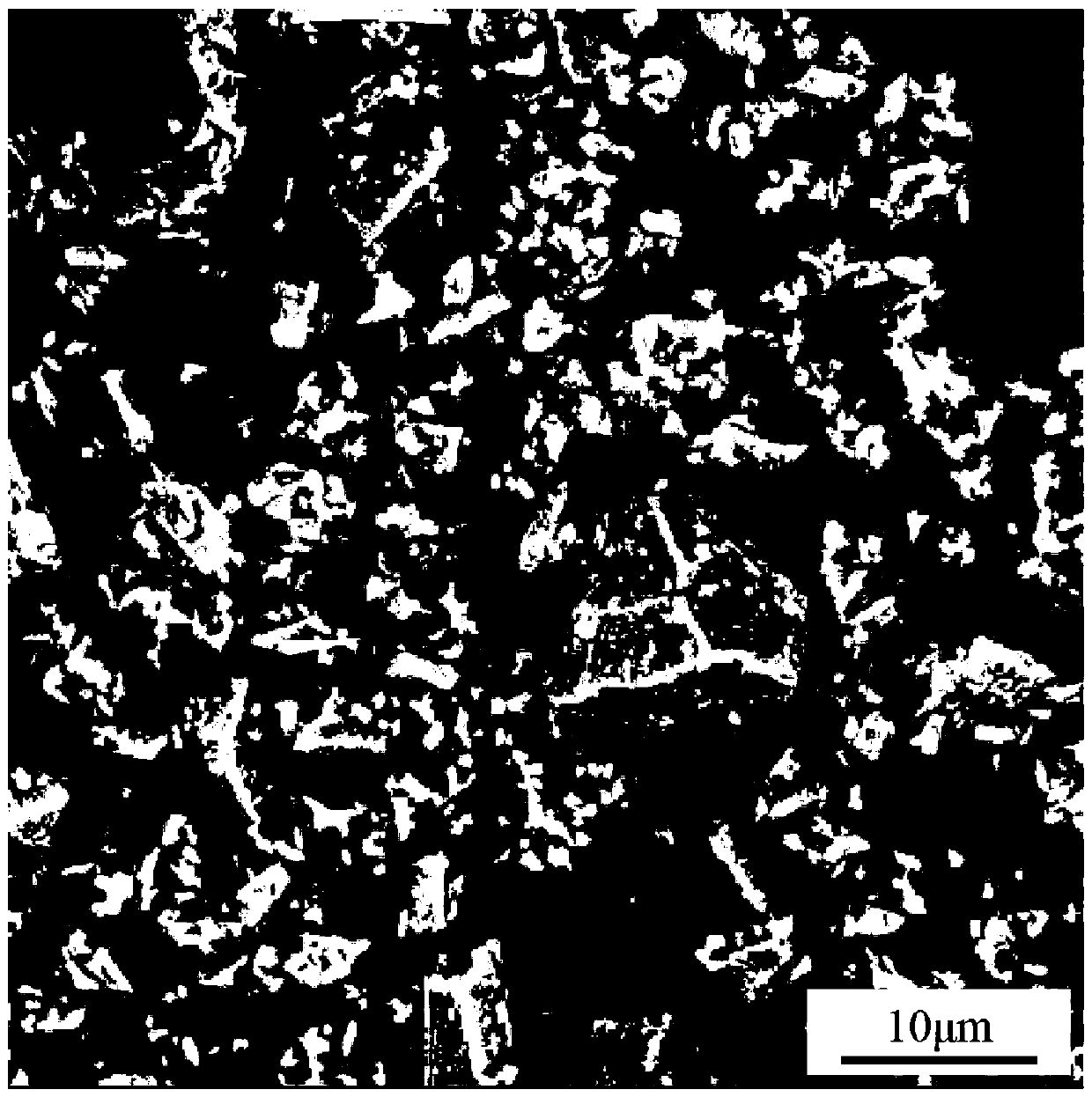

Method for preparing foamed ceramic by microwave sintering of cobalt smelting waste slag

InactiveCN109553393AMass consumptionSolve environmental problemsCeramic materials productionCeramicwareHigh energySlag

The invention belongs to the technical field of resource utilization of solid wastes, and particularly relates to a method for resource utilization of cobalt smelting waste slag. The invention provides the method for preparing foamed ceramic by microwave sintering of the cobalt smelting waste slag. The method comprises the following steps: carrying out proportioning by using the cobalt smelting waste slag, filler, a liquid phase agent, a plasticizer and a foaming agent, carrying out grinding, mixing, granulating, and mold pressing or mold powder accumulation to prepare a green body; and carrying out microwave sintering to prepare the foamed ceramic. The microwave heating method is adopted, and compared with a conventional electric heating or fuel heating mode, the microwave heating methodhas the advantages that the foaming temperature is greatly reduced, the foaming time is shortened, and therefore energy consumption is greatly reduced. According to the method, the problems of high energy consumption in existing formed ceramic industry and high additional value comprehensive utilization of the cobalt smelting waste slag are solved.

Owner:취저우화여우코발트뉴머터리얼컴퍼니리미티드

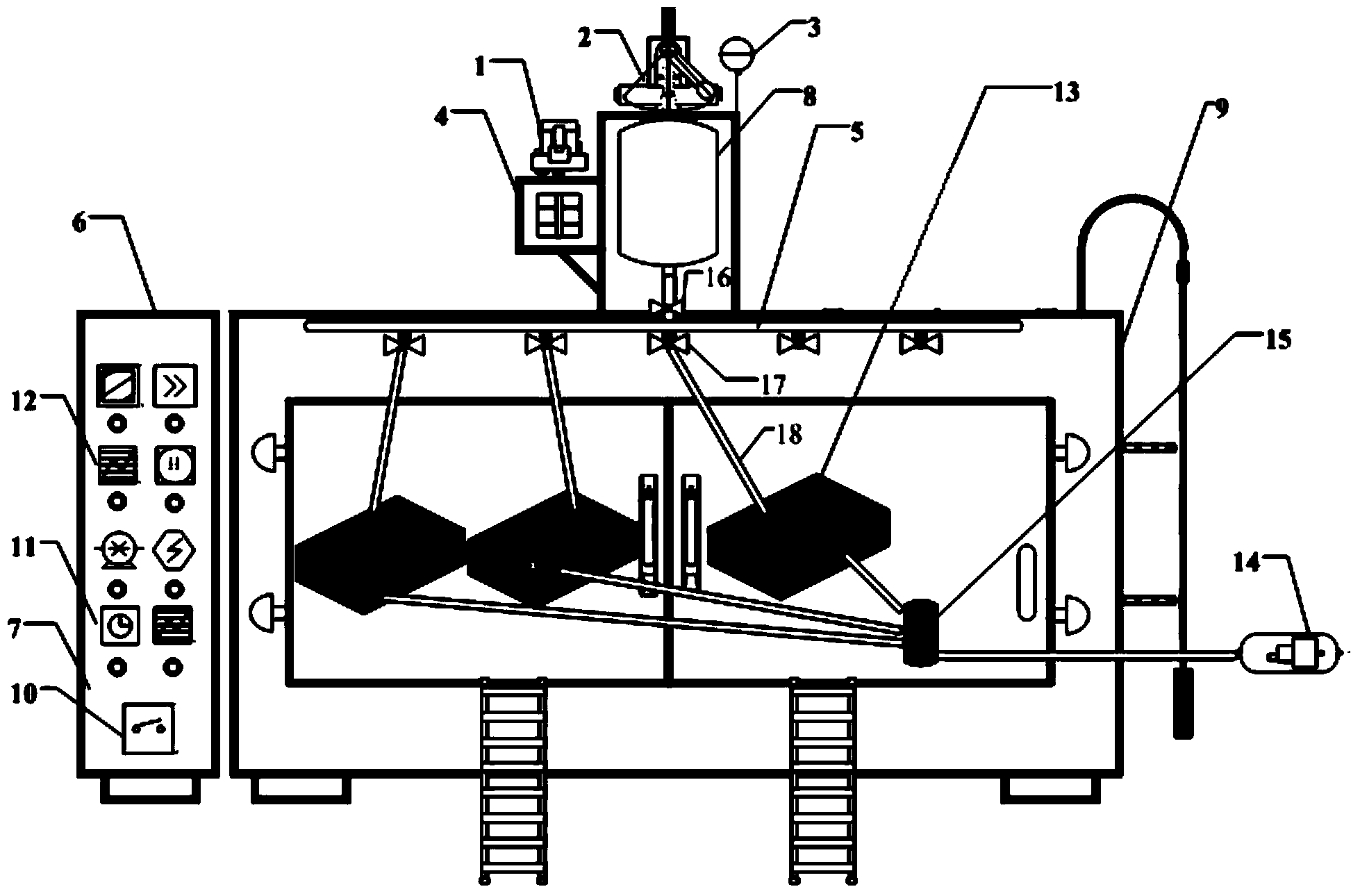

High-temperature RTM (resin transfer molding) integrated molding equipment

The invention provides high-temperature RTM (resin transfer molding) integrated molding equipment. The equipment comprises a resin tank, a high-temperature resin distributing pipeline and a curing tank, wherein the resin tank is arranged at the top of the curing tank in an integrated manner, the high-temperature resin distributing pipeline is arranged at the top part in the curing tank to meet the requirements of heat preservation property of the high-temperature resin distributing pipeline and the flowing property of the rein injection runners, the top part of the curing tank is provided with an opening at a glue outlet of the resin tank, three or more product molds can be placed in the curing tank, a mold vacuum pipeline is arranged outside the curing tank, the glue outlet of the resin tank is connected with the high-temperature resin distributing pipeline by a discharging valve, the high-temperature resin distributing pipeline is provided with three or more outlets, each outlet is connected with one mold through a resin distributing valve and a resin flowing pipeline, and each mold is connected with the mold vacuum pipeline by a liquid storage tank. According to the invention, high-temperature resin can be ensured to be fully poured and fed, the molding operation is convenient and the production efficiency is improved.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

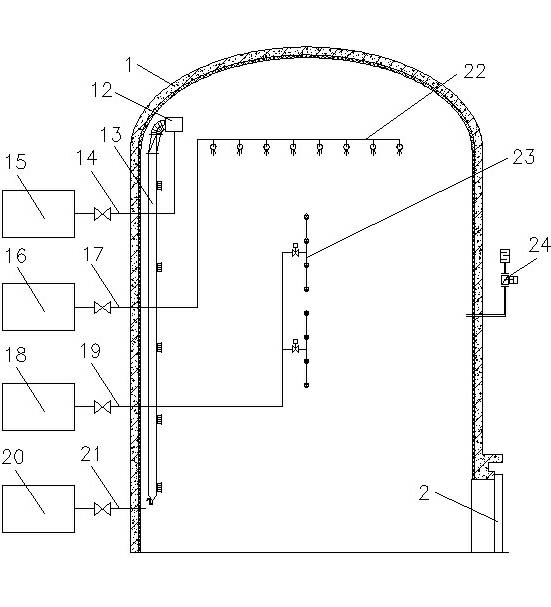

Large-scale experiment device capable of simulating natural environment climate condition

The invention relates to a large-scale experiment device capable of simulating natural environment climate condition, wherein no such device with simple structure, good safety and good sealing property exists at present. The device comprises a tank body, and is characterized in that the bottom of the tank body consists of an epoxy mortar wear-resisting face layer with the thickness of 4-6 mm, a waterproof concrete slope-finding layer with the thickness of 300-500 mm, a 8-12 mm thick lime mortar isolation layer, a thick waterproof layer with the thickness of 1.5-2.5 mm, a thick cement mortar leveling layer with the thickness of 18-22 mm, a thick extrusion molding polystyrene plate with the thickness of 140-160 mm, a thick bottom vapor barrier layer with the thickness of 1.5-2.5 mm and a thick reinforced concrete bottom plate with the thickness of 450-550 mm from top to bottom in sequence; and the wall surface and the top of the tank body consist of a steel plate curtain wall surface layer, a rigid polyurethane insulation layer, an inner vapor barrier layer, a reinforced concrete layer, an outer vapor barrier layer and an outer wall coating material layer from inner side to outer side in sequence. The device has the advantages of reasonable design, good safety and good sealing property, low production cost and convenience for maintenance.

Owner:CHINA UNITED ENG

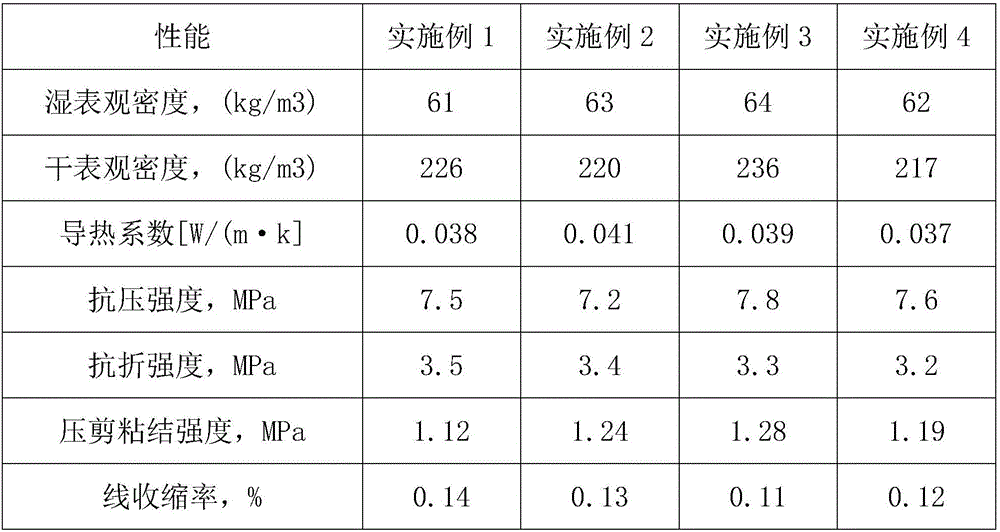

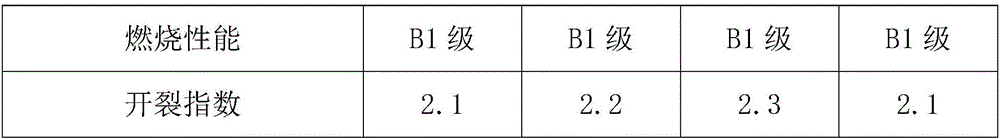

Anti-cracking heat-preserving wall construction material and preparation method thereof

The invention discloses an anti-cracking heat-preserving wall construction material and a preparation method thereof. The anti-cracking heat-preserving wall construction material is prepared from, by weight, 400-600 parts of cement, 40-70 parts of silica powder, 80-220 parts of ash-calcium powder, 80-160 parts of expanded vermiculite, 60-100 parts of sand, 60-100 parts of hollow glass beads, 40-80 parts of rock wool threads, 30-80 parts of modified fly ash, 60-120 parts of polyphenyl particles, 10-20 parts of wood fiber, 5-10 parts of polypropylene fiber, 30-60 parts of polyvinyl alcohol, 40-80 parts of dispersible latex powder and 10-20 parts of cellulose ether. The anti-cracking heat-preserving wall construction material solves the problem that finishing mortar prepared from an existing outer wall heat-preserving material is prone to cracking and poor in durability, and truly achieves heat preservation, heat isolation and high anti-cracking performance.

Owner:MAANSHAN TIANJINYUN PAINT IND

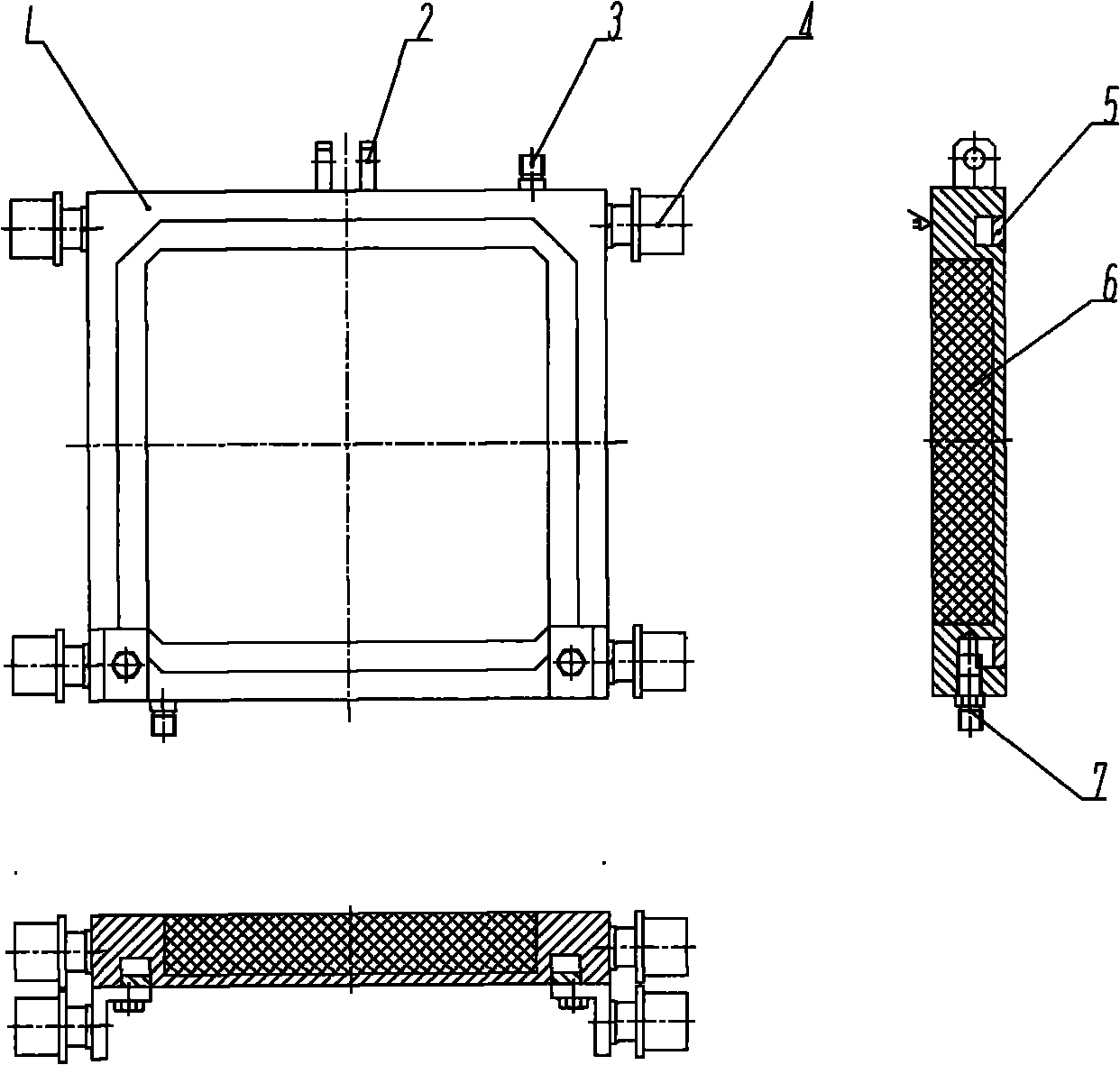

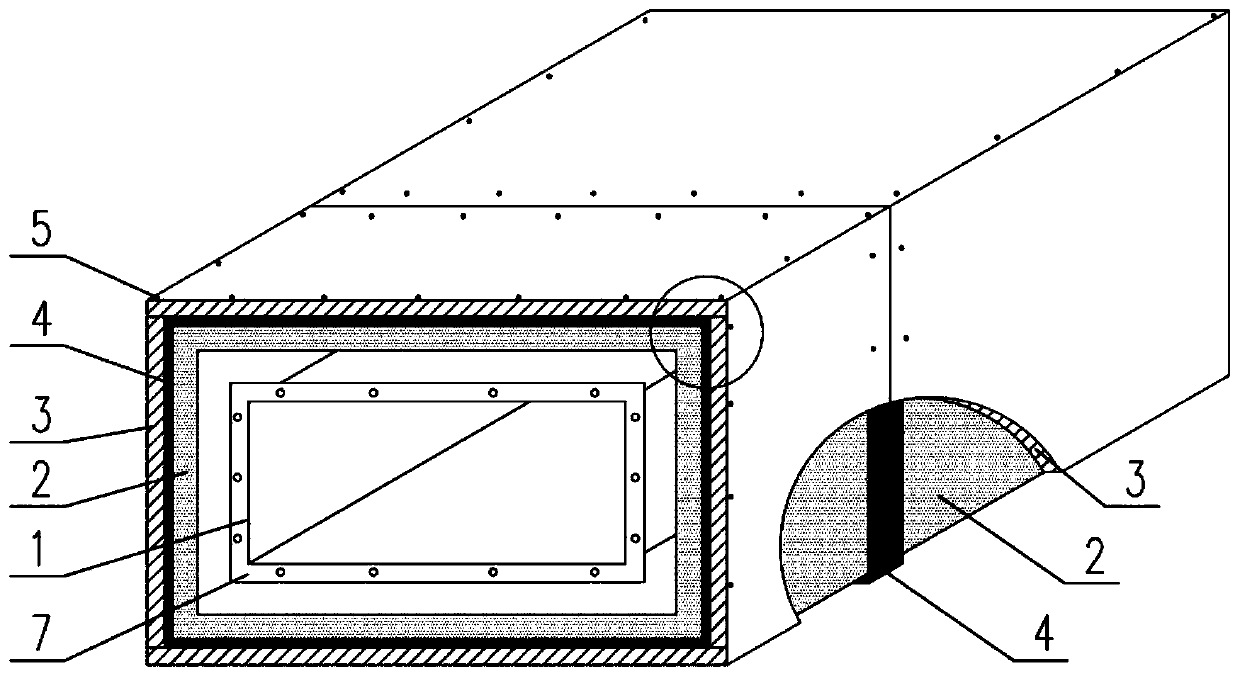

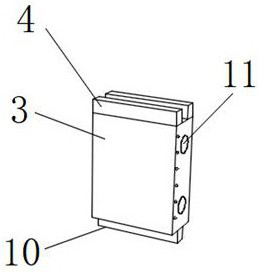

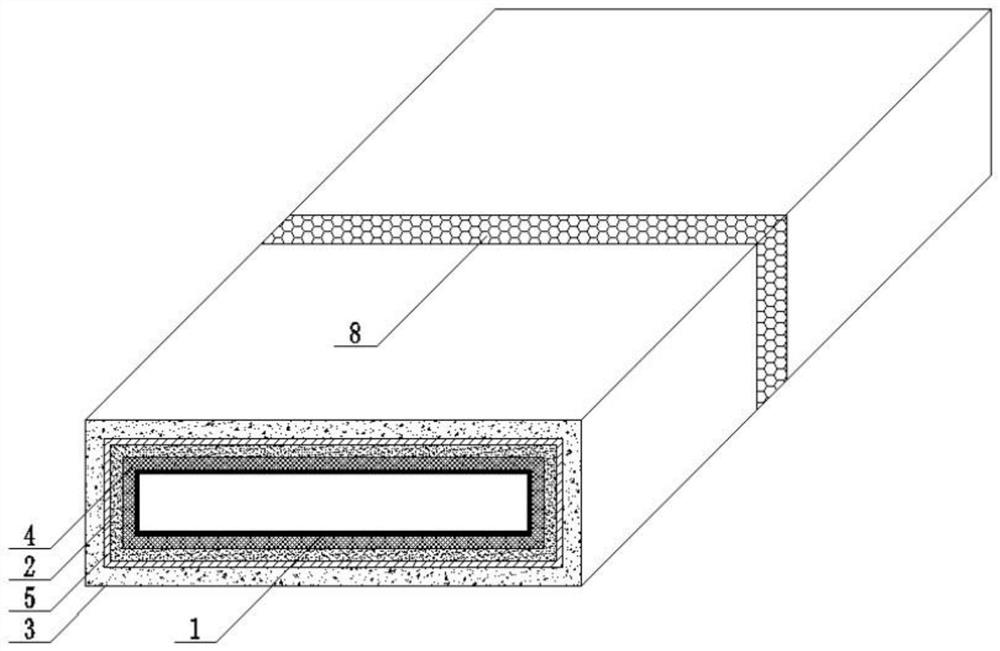

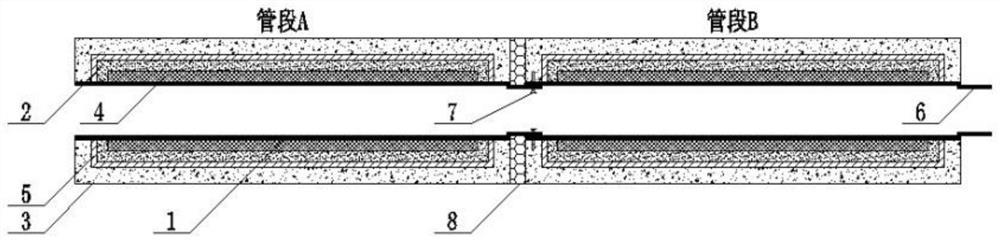

Fireproofing and heat preservation integrated composite air pipe

PendingCN110566726ASatisfy thermal insulationFulfil requirementsThermal insulationPipe protection by thermal insulationInsulation layerFireproofing

The invention discloses a fireproofing and heat preservation integrated composite air pipe. The fireproofing and heat preservation integrated composite air pipe comprises a steel pipeline forming an air pipe main body frame, a heat-preservation and heat-insulation layer covering the outer peripheral surface of the steel pipeline and a fire-resistant layer fixed to the outer peripheral surface of the heat-preservation and heat-insulation layer. The fireproof and heat preservation integrated composite air pipe has the beneficial effects that a steel air pipe, a heat preservation material and a fireproof material are integrated to form the composite air pipe which can simultaneously meet the requirements of air conditioning and smoke prevention and discharge; the composite air pipe meets therequirements of the air conditioning and smoke prevention and discharge on the heat insulation performance and the fireproof performance of the air pipe and effectively solves the problems of complexsite construction procedures, long construction period and difficult later maintenance of an air conditioning and smoke prevention and discharge air pipe can be effectively solved, and the problem ofdamage to the overall performance of a heat insulation layer and a fireproof layer which are wrapped outside the air pipe in the process of installing the air pipe on site.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

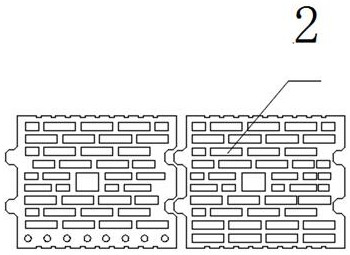

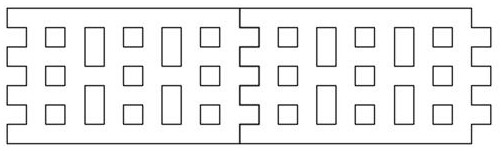

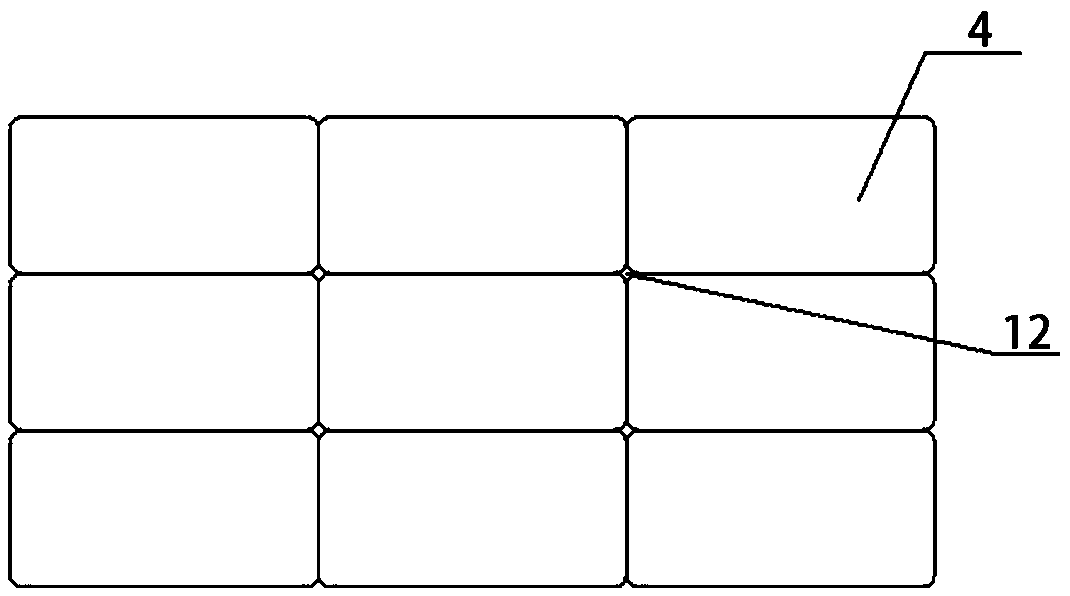

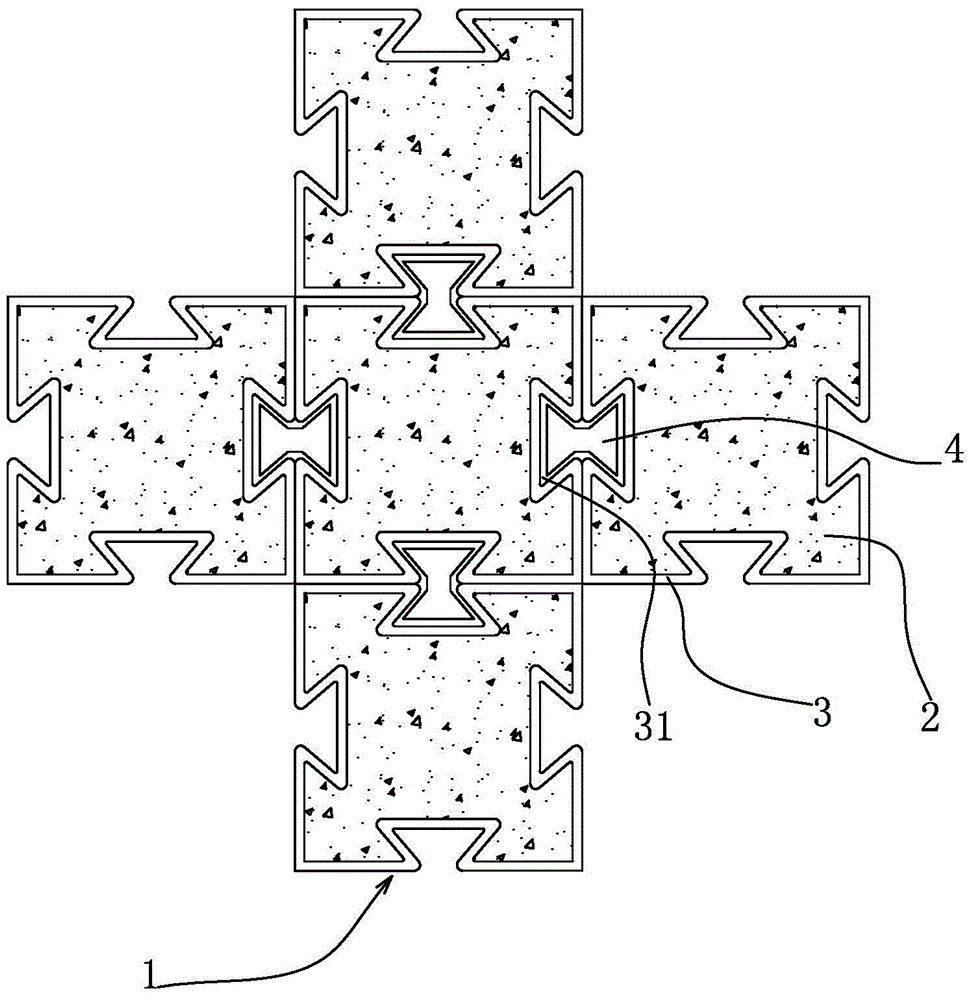

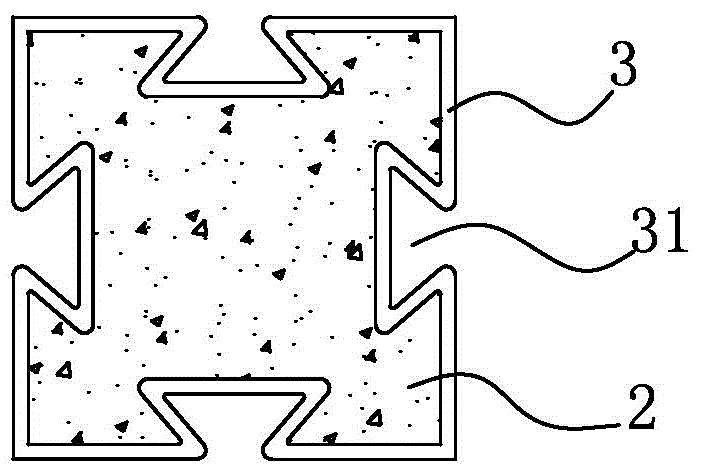

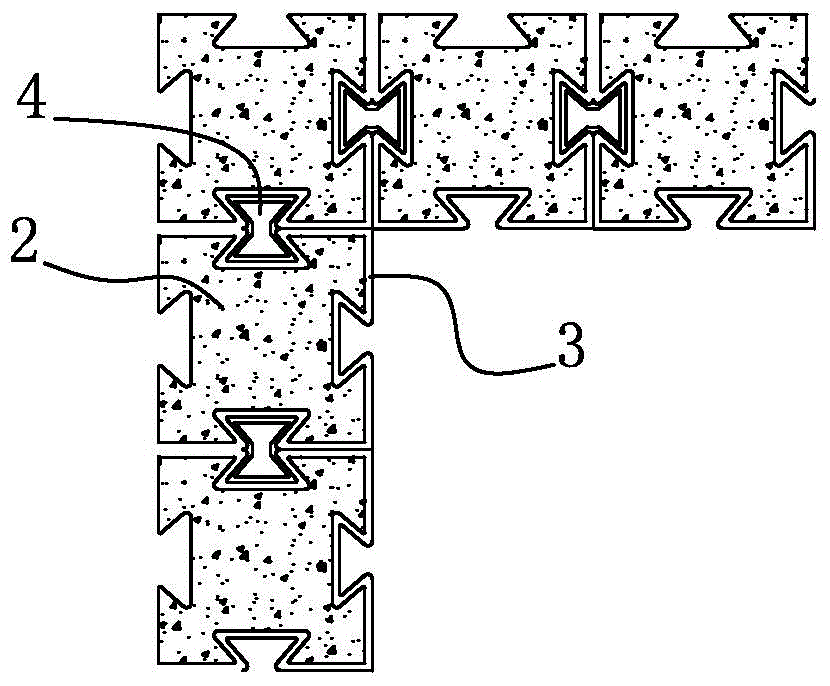

Manufacturing method of shale sintered composite plate for prefabricated building

InactiveCN111663710AImprove construction efficiencyShorten the construction periodWallsHeat proofingBrickThermal insulation

The invention discloses a manufacturing method of a shale sintered composite plate for a prefabricated building. A plurality of thermal insulation holes are formed in a hollow brick body. One or morepenetrating reinforcing steel bar holes for reinforcing steel bars to penetrate through are formed in the direction perpendicular to the direction of the thermal insulation holes. A viscose for connection is sprayed or painted quantitatively between ends of every two adjacent hollow brick bodies, and a reinforcing steel bar penetrates into each overall reinforcing steel bar hole; the viscose fulfills gaps between every two adjacent hollow brick bodies under extrusion; and the ends of the hollow brick bodies are provided with connecting blocks correspondingly, each connecting block is at leastprovided with two connecting holes, one connecting hole is connected with one end of the corresponding reinforcing steel bar, other holes serve as bolt connecting holes for fixing bolts, and the sintered composite plate is formed. Platy wall board structures of various areas are prefabricated in a factory and then transported to a construction site to be overall installed on site, so that construction efficiency is greatly improved, operators for on-site bricklaying construction are greatly reduced, a construction period is shortened, and construction cost is reduced.

Owner:重庆金彧新型环保建材有限公司

Construction method and device of reinforced concrete double-layer plates

The invention discloses a construction method and device of reinforced concrete double-layer plates. The device comprises girder side formworks and a girder bottom formwork, a group of batten logs isarranged below the girder bottom formwork, the batten logs are supported through scaffolds, prefabricated reinforced concrete plates are symmetrically arranged on the girder bottom formwork, the girder side formworks are symmetrically mounted on the prefabricated reinforced concrete plates, and composite floor slabs are symmetrically paved on the girder side formworks. The reinforced concrete double-layer plate construction is carried out by adopting the mode of combining the site assembly and cast-in-place, the composite floor slabs and the prefabricated reinforced concrete plates are correspondingly adopted in upper and lower layer plates, the upper-layer composite floor slabs can be used as a formwork of an upper layer plate, the loss of the formworks is reduced, the effects of heat prevention, thermal insulation, waterproof and load bearing can be met, and prefabricated reinforced concrete plays a role of better bearing load due to the fact that the prefabricated reinforced concrete is used as a lower layer plate.

Owner:CHINA CONSTR 4TH ENG BUREAU 6TH

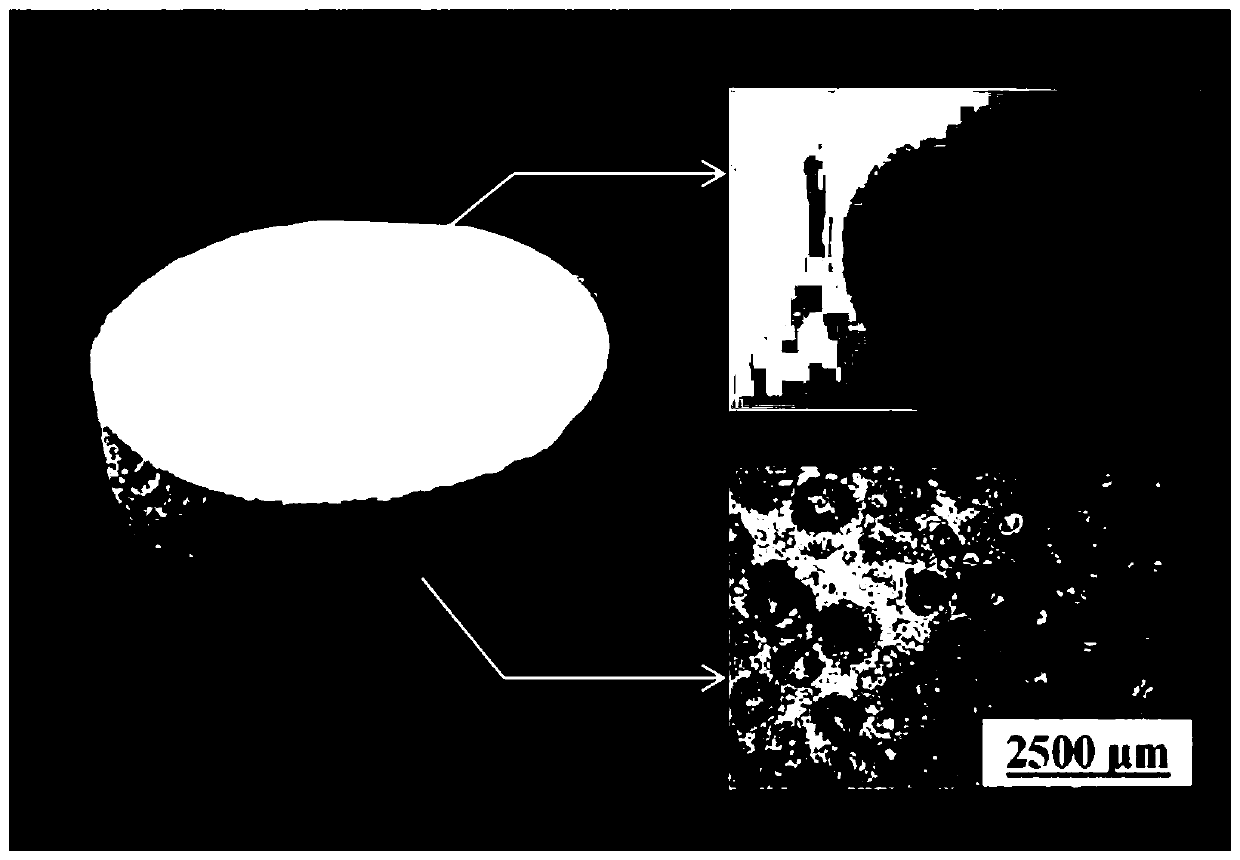

Microcrystal surface porous heat preservation ceramic composite material taking low-grade potassium feldspar as raw material and preparation method of composite material

The invention discloses a microcrystal surface porous heat preservation ceramic composite material taking low-grade potassium feldspar as a main raw material and a preparation method of the compositematerial. The composite material comprises a porous heat preservation ceramic base body and a microcrystal surface layer; the base body takes low-grade potassium feldspar as a main raw material, and the main material of the surface layer comprises perlite, aluminum oxide, magnesium oxide and silicon dioxide; the composite material is prepared by adopting a secondary material distribution and primary high-temperature foaming method, and a foaming agent is silicon carbide. The heat conductivity coefficient of the base body layer is 0.060-0.097 W / (m*K), the base body layer has heat preservation and heat insulation functions, and the surface layer has a decoration effect. The composite material is low in cost, energy-saving and environment-friendly; the microcrystal surface layer greatly improves the mechanical properties of the composite material, can effectively inhibit the fusion and overflow of bubbles in the foaming process, improves the foaming effect, and reduces the consumption ofthe foaming agent. The composite material is formed by primary high-temperature foaming sintering, the process is simple and the preparation cost is low; heat preservation, heat insulation and decoration integration can be achieved in the building field.

Owner:XINYANG NORMAL UNIVERSITY

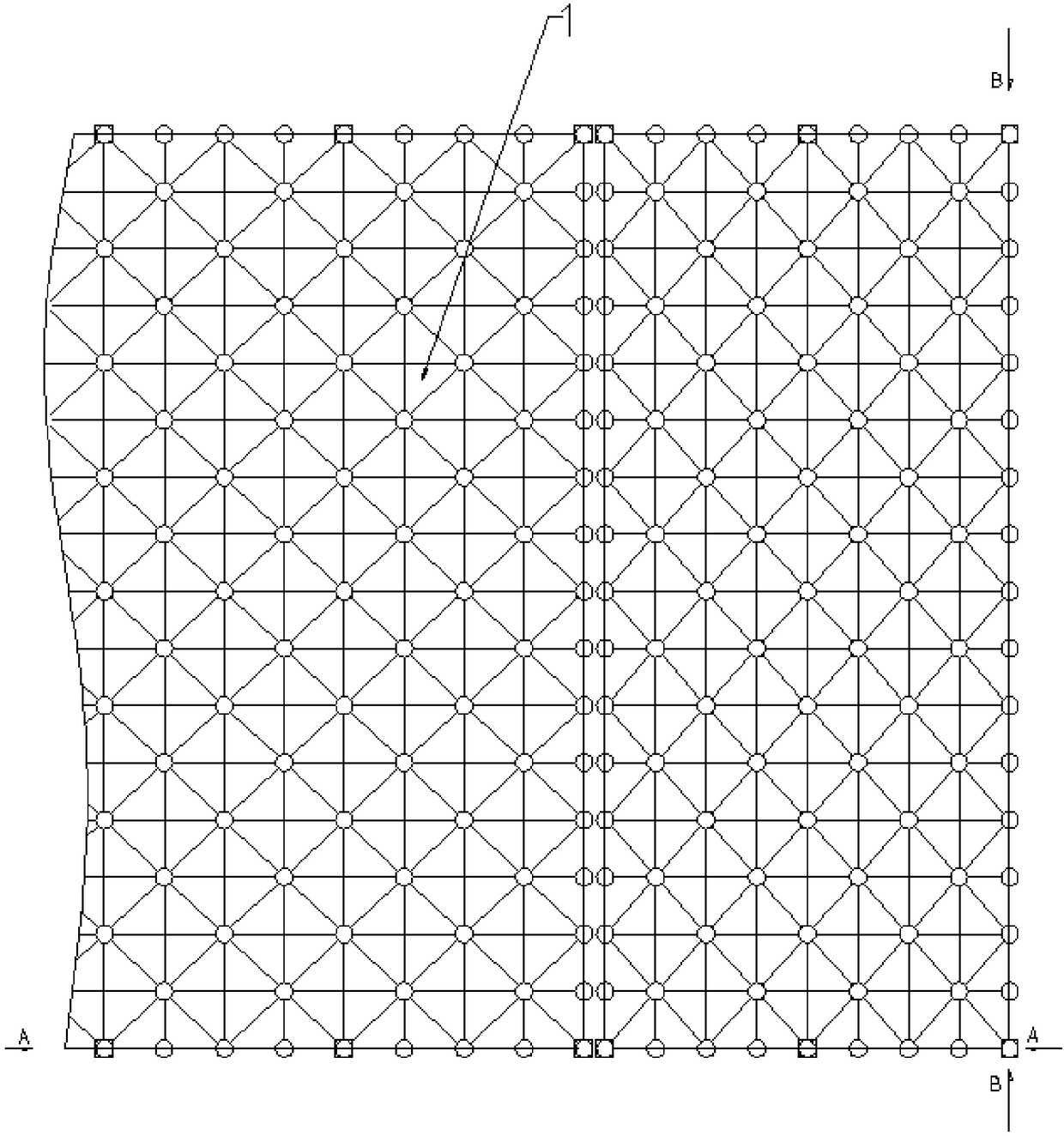

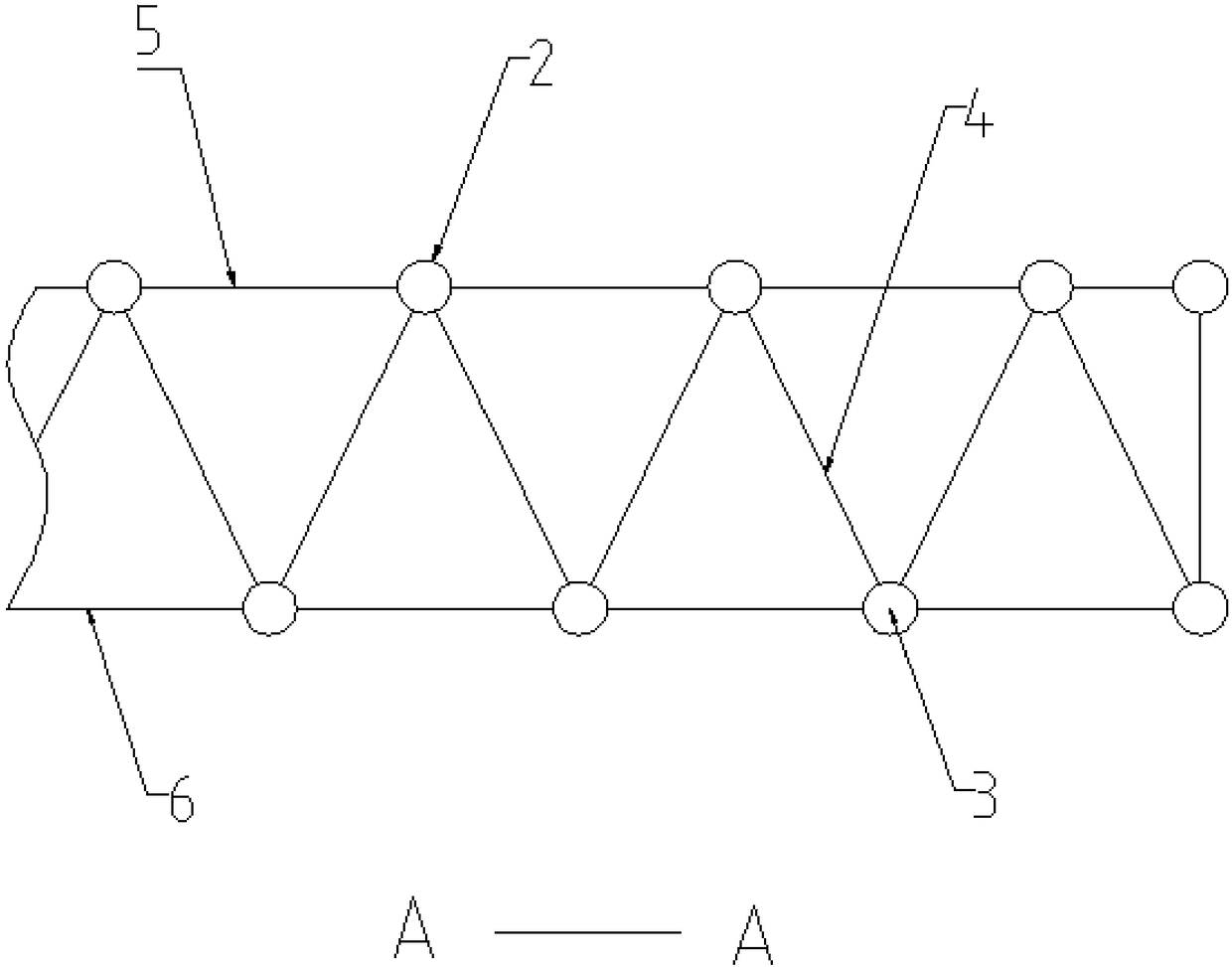

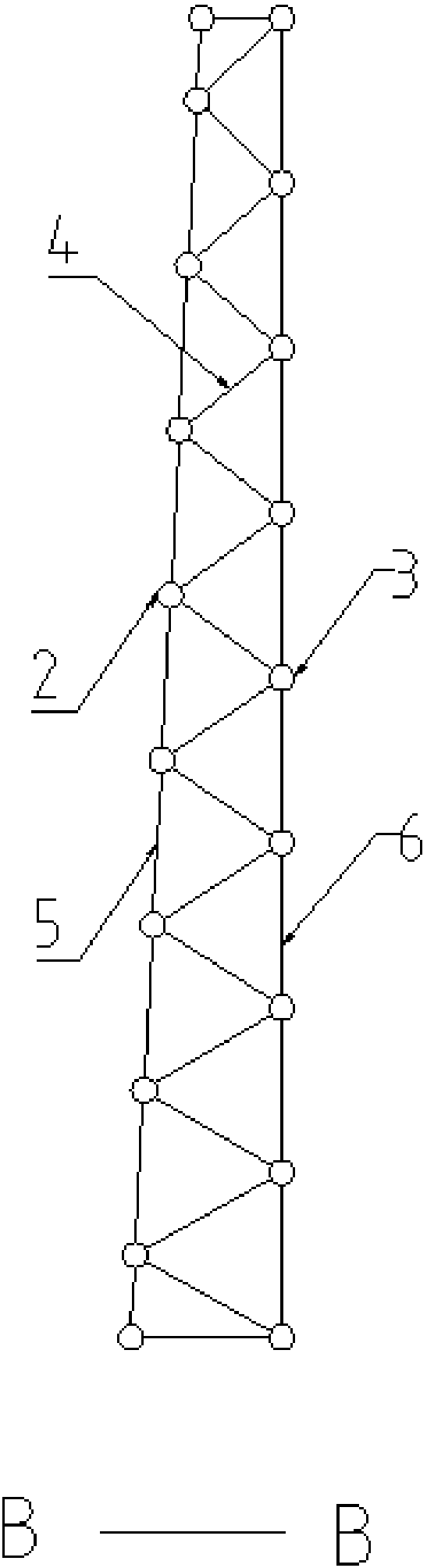

Installation structure of plant roof grid structure project and construction method thereof

PendingCN108590033AImprove structural stabilityGuaranteed stabilityGirdersJoistsReinforced concrete columnPurlin

The invention discloses an installation structure of a plant grid structure project, and belongs to the technical field of building construction. The installation structure comprises a roof frame beam, wherein a roof panel layer is arranged in the roof frame beam, and at least two grid structures are connected to the roof panel layer; the grid structures comprise grid structure upper chord layersand grid structure lower chord layers, wherein upper chord grid structure balls and lower chord grid structure balls are arranged on grid nodes of the grid structure upper chord layers and the grid structure lower chord layers correspondingly; the upper chord grid structure balls and the lower chord grid structure balls are arranged in a staggered mode, and grid structure web members are assembledand connected between the upper chord grid structure balls and the lower chord grid structure balls; a plurality of main purlins are arranged in parallel above the grid structure upper chord layers,a plurality of secondary purlins perpendicular to the main purlins are assembled above the main purlins, and the secondary purlins are connected with the roof panel layer; and the roof frame beam is prefabricated with a plurality of L-shaped reinforced concrete columns, and the two arms of the reinforced concrete columns are correspondingly assembled and connected with the corresponding lower chord grid structure balls so as to achieve the purpose of improving the roof grid structure to improve the water leakage prevention effect and structural strength and simplifying and standardizing the construction process.

Owner:GUODIAN DADU RIVER SHAPING HYDROPOWER CONSTR

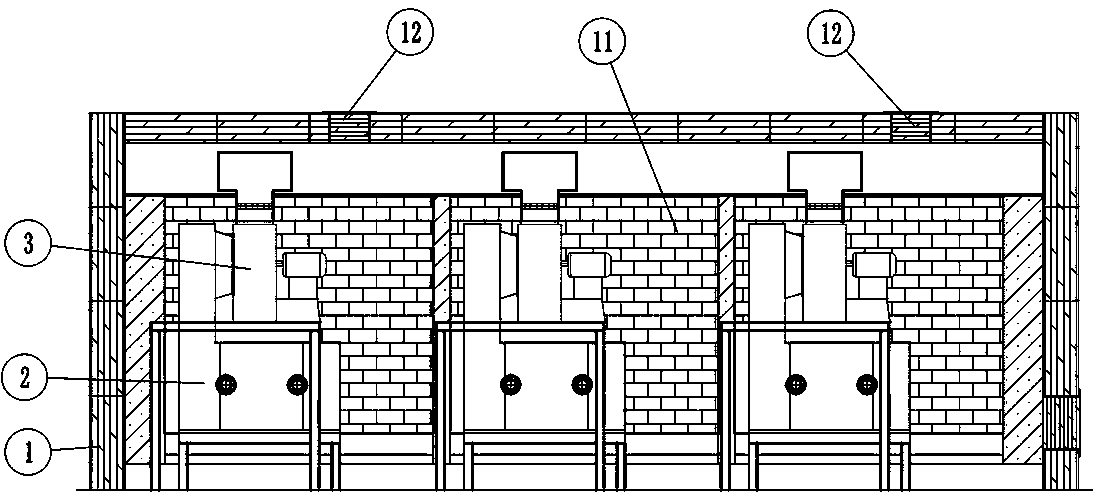

High-voltage solid heat accumulating equipment and heat accumulating control method

ActiveCN107606981AAvoid damageSatisfy thermal insulationHeat storage plantsOhmic-resistance heatingBrickComputer module

The invention discloses high-voltage solid heat accumulating equipment and a heat accumulating control method. The high-voltage solid heat accumulating equipment comprises a heat accumulating module and a heat exchange module; the heat accumulating module comprises a heat accumulator consisting of heat accumulating bricks, a heat insulation layer arranged at the periphery of the heat accumulator,and a heating wire assembly penetrating through the heat accumulator; the heating wire assembly is used for heating the heat accumulator, and comprises heating wire units connected in series; each heating wire unit comprises more than four electric heating wire elements connected in parallel; and the heat accumulating module further comprises an insulation and heat preservation base. The high temperature resistance of the bottom heat insulation layer is improved, the heat accumulating properties of the heat accumulating bricks are fully exerted, precision measurement on the temperature of theheat accumulator and the temperatures of heating wires are realized, the reliability of the high-voltage solid heat accumulating equipment is improved, and the situation that the high-voltage solid heat accumulating equipment has a current leakage failure when the high-voltage solid heat accumulating equipment is not used for a long time can be avoided.

Owner:YANTAI ZHUOYUE NEW ENERGY TECH

High-density hard flame-retardant polyimide foam material and preparation method thereof

ActiveCN112126106AReduce usageChange the interfacial tensionChemical industryPolymer sciencePtru catalyst

The invention belongs to the technical field of high polymer materials, and relates to a preparation method of a high-density hard flame-retardant polyimide foam material. The preparation method comprises the following steps of: 1) uniformly mixing anhydride, low-molecular-weight alcohol and a surfactant I to obtain a precursor A material; uniformly mixing a catalyst and a foaming agent to obtaina precursor B; 2) mixing and stirring the precursor A and the precursor B to obtain a foaming white material; 3) mixing and stirring isocyanate, a flame retardant and a surfactant II to obtain a foamed black material; 4) mixing a foamed white material and the foamed black material in proportion, stirring the mixture at a high speed, pouring the mixture into a plastic mold, making the mixture standstill, carrying out microwave curing treatment on the product and the mold to obtain a foamed precursor, taking out the foamed precursor from the mold, and curing and shaping the foamed precursor inan oven to obtain a final foam material; According to the high-density hard flame-retardant polyimide foam material and the preparation method, organic solvent is used; and the prepared polyimide foammaterial has the characteristics of high density and tensile strength and excellent flame retardancy.

Owner:GUIZHOU AEROSPACE TIANMA ELECTRICAL TECH

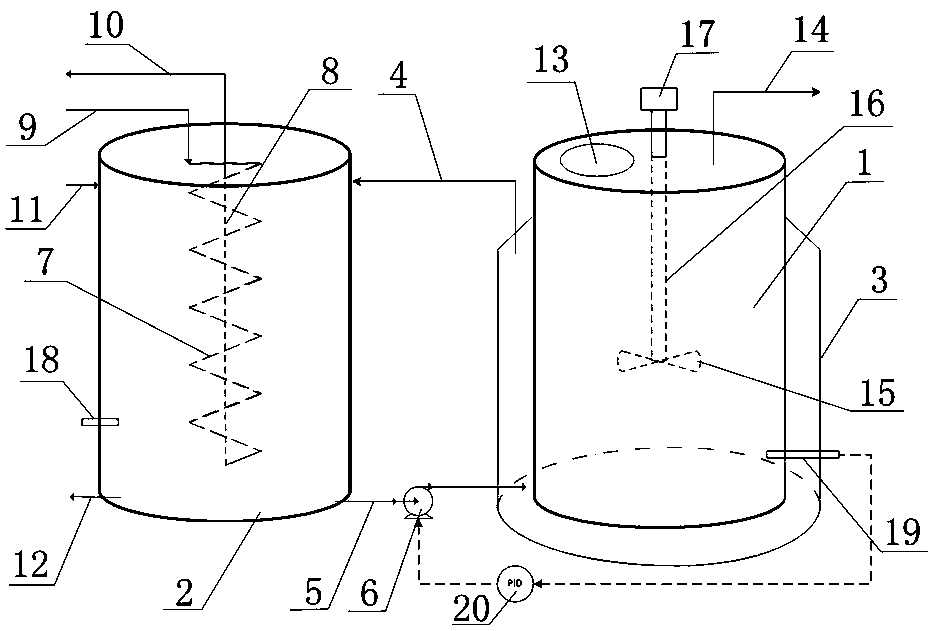

Electrolytic copper foil additive heating insulation system

InactiveCN109224899ASatisfy heatingSatisfy thermal insulationCellsTransportation and packagingElectrolysisSystem stability

The invention discloses an electrolytic copper foil additive heating insulation system which comprises an additive tank and a heating tank, wherein a heating jacket is arranged on the outer side of the additive tank; the heating jacket is an uncovered cylinder, and the inner diameter of the heating jacket is greater than the outer diameter of the additive tank; the heating jacket is sleeved on theouter side of the additive tank from the lower end of the additive tank; the upper end of the heating jacket inclines and extends toward inner side and is fixedly sealed on the outer side surface ofthe additive tank; a gap between the inner wall of the heating jacket and the outer wall of the additive tank is a closed heating water cavity; the upper end side surface of the heating jacket is communicated with the upper end side surface of the heating tank through a return water pipe; the lower end side surface of the heating jacket is communicated with the lower end side surface of the heating tank through a delivery pipe, and a delivery pump is arranged on the delivery pipe; a heating disc is arranged in the heating tank. According to the system disclosed by the invention, since a heat source does not directly contact with an additive, the safety of the additive is improved, and the system stability is high.

Owner:JIANGDONG ELECTRONIC MATERIALS CO LTD

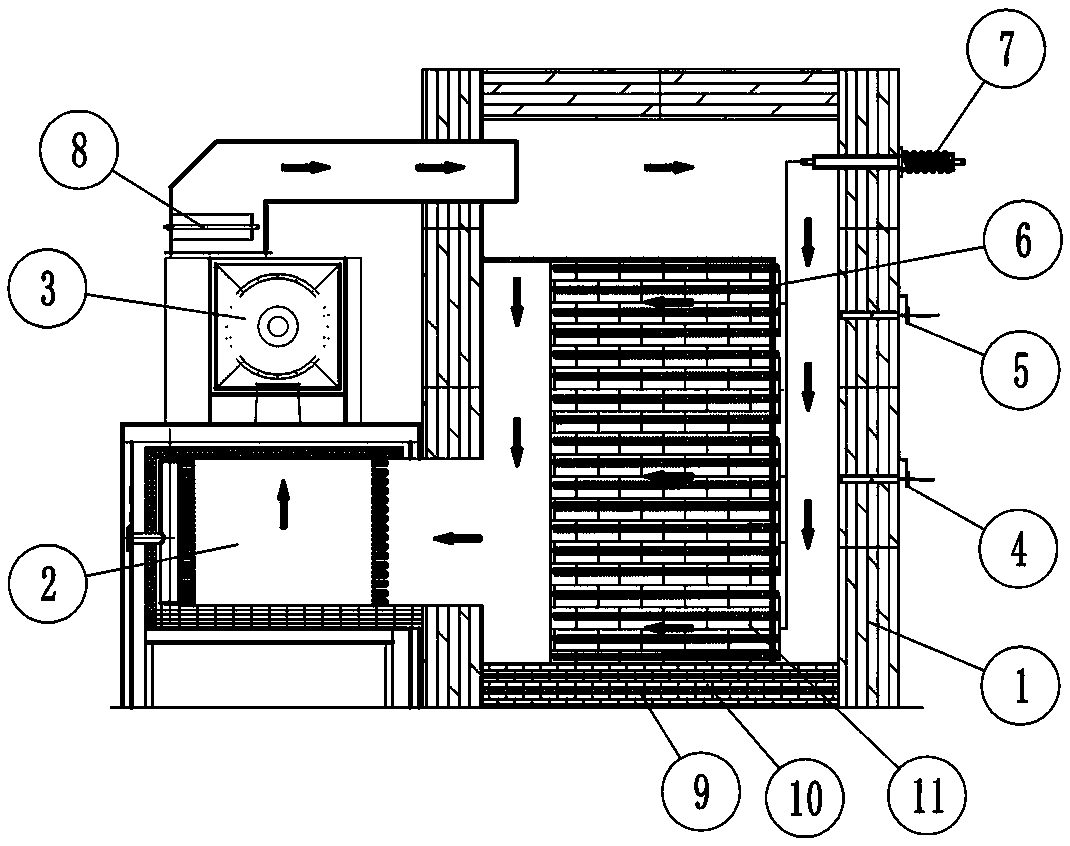

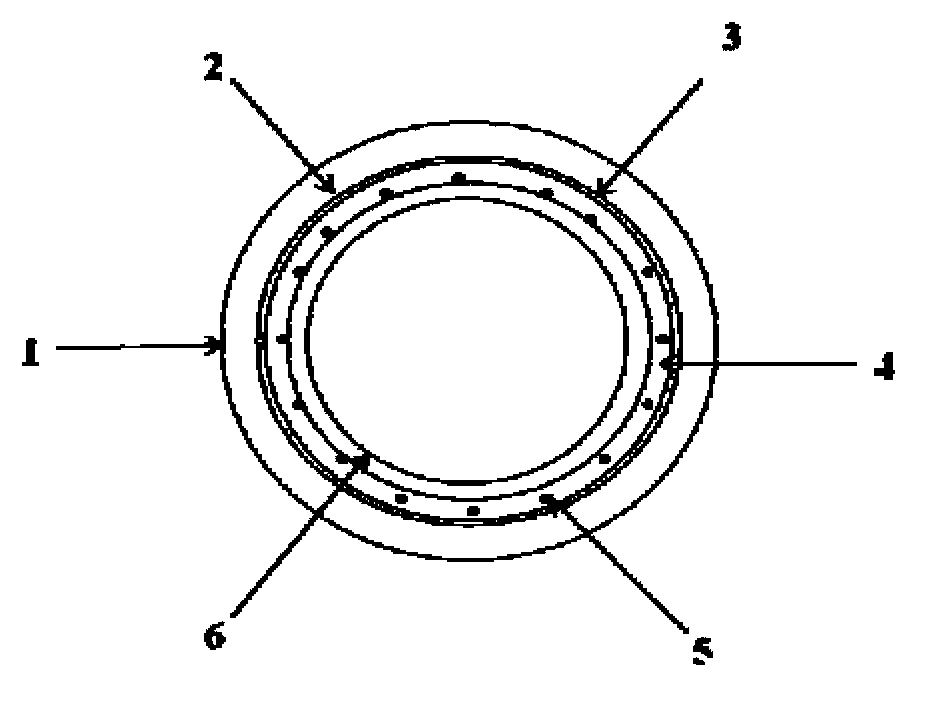

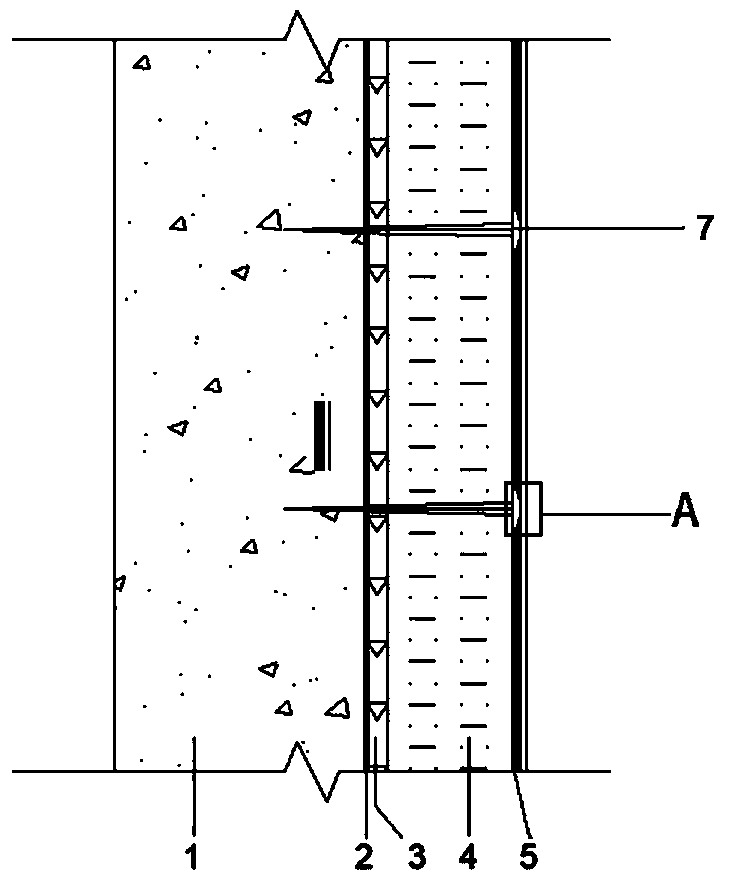

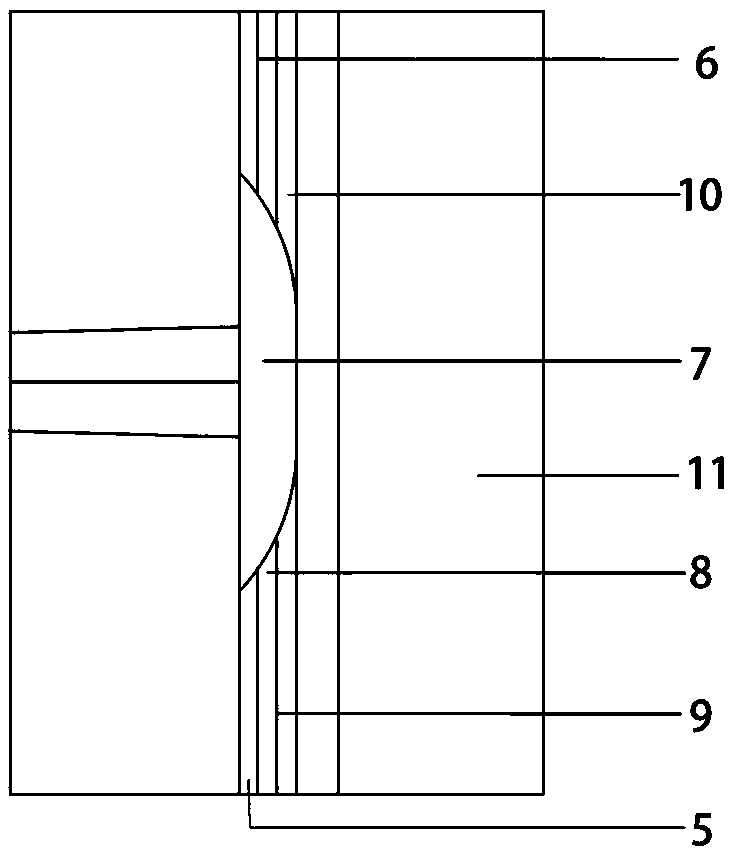

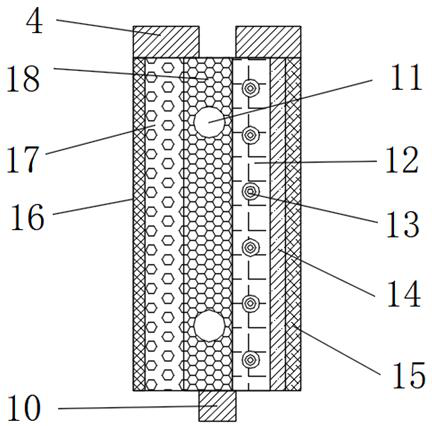

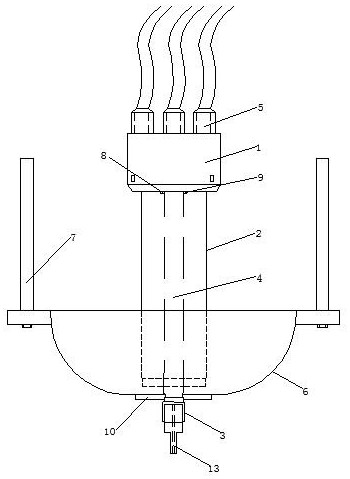

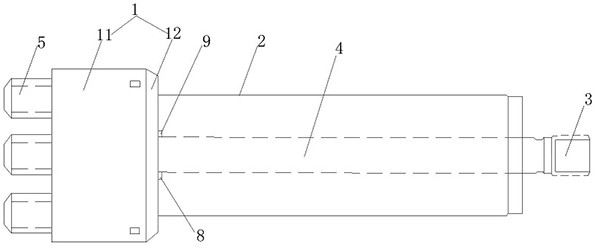

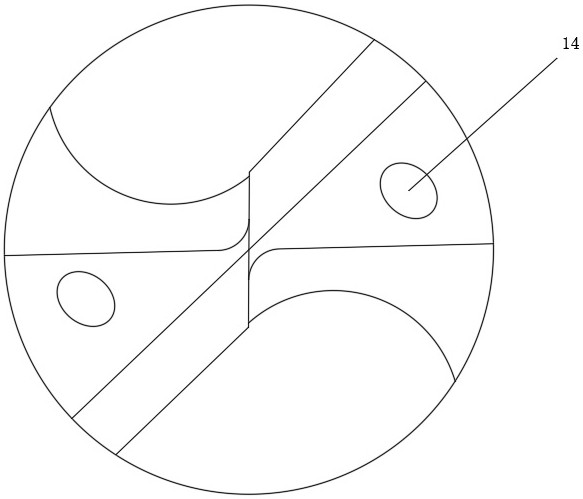

Fiber guide pipe with far-infrared heating function

InactiveCN103527863ASatisfy thermal insulationSatisfy the thermal insulationThermal insulationPipe heating/coolingHeat deflection temperatureFiber

The invention provides a fiber guide pipe with a far-infrared heating function. The pipe wall is composed of a cover 1, a heat-insulation layer 2, a reflection layer 3, a heating layer 4 and a lining layer 6 from outside to inside, wherein the heating layer 4 comprises carbon fiber heating wires 5, the heat-insulation layer is made of 100% hole-sealed PMI rigid foam, the heat deformation temperature is 180-240 DEG C, the specific strength and specific rigidity are high, and the heat-insulation layer plays a role in heat insulation, heat preservation and support of the fiber guide pipe. The heating layer is an electric heat conversion layer containing pure black material carbon fiber heating wires, and the lining layer is a macromolecule layer with a self-lubricating function and mainly plays a role in reducing friction between conveyed fibers and the guide pipe. The fiber guide pipe with the far-infrared heating function has the advantages of being fast in temperature rise, uniform in heat radiation, long in service life and the like, the temperature can be raised to 135 DEG C within 3 minutes, and the requirement for rapid heating of on-line formation continuously fed fibers of light-weight high-strength composite materials.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +1

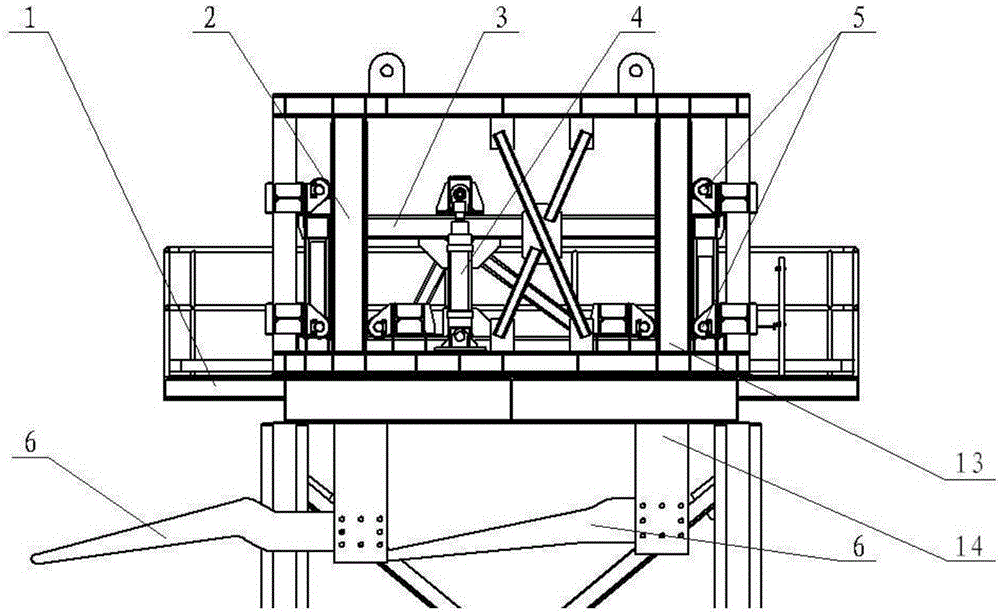

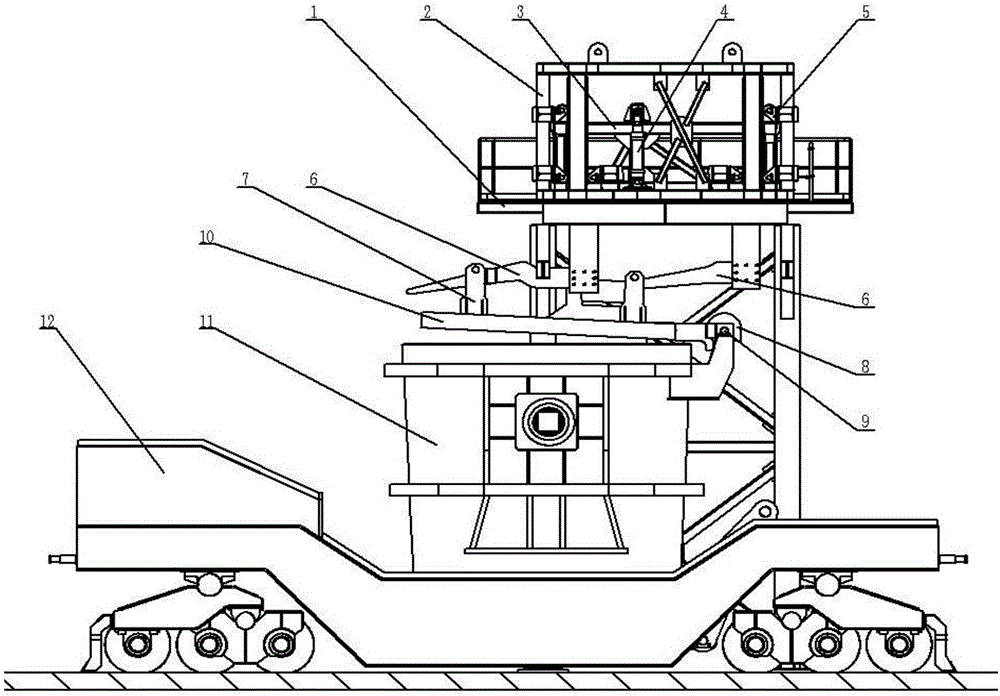

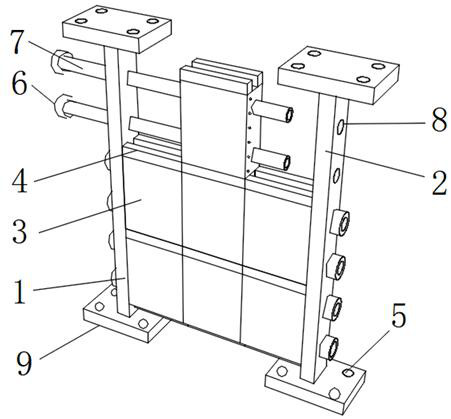

Automatic steel ladle covering and uncovering device

InactiveCN106041039ASatisfy thermal insulationFulfil requirementsMelt-holding vesselsHydraulic cylinderEngineering

The invention discloses an automatic steel ladle covering and uncovering device, and belongs to the technical field of steel making equipment. The automatic steel ladle covering and uncovering device comprises a mechanism fixed table, a fixed bracket, a lifting bracket, a lifting hydraulic cylinder, a guide wheel, insertion teeth, a steel ladle cover rotary lifting point, a steel ladle cover limiting hook, a limiting hook stop rod, a steel ladle cover, a steel ladle, a steel ladle car, a guide rail, a vertical connecting piece and a limiting groove; the fixed bracket is mounted on the mechanism fixed table through the connecting piece; the lifting bracket is connected with the fixed bracket through the lifting hydraulic cylinder; four insertion teeth are arranged in front of and behind the lifting bracket; the steel ladle cover is provided with the steel ladle cover limiting hook and the steel ladle cover rotary lifting point; the steel ladle is provided with the limiting hook stop rod; and the steel ladle is on the steel ladle car. The automatic steel ladle covering and uncovering device has such advantages as simple structure, reliable operation, high practicability, convenience for maintenance and replacement and few occupied labor-hours.

Owner:BEIJING SHOUGANG INT ENG TECH

High-rise ultralow-energy-consumption residence outer wall composite external thermal insulation system and construction method thereof

ActiveCN109750760AReduce thicknessReduce weightClimate change adaptationPassive housesGlass fiberResidence

The invention discloses a high-rise ultralow-energy-consumption residence outer wall composite external thermal insulation system and a construction method thereof. The system sequentially comprises afoundation wall body, a vacuum thermal insulation and preservation plate and a rock wool thermal preservation plate from inside to outside. the vacuum thermal insulation and preservation plate and the foundation wall body are bonded and fixed through a bonding layer, and the rock wool thermal preservation plate and the vacuum thermal insulation and preservation plate as well as the foundation wall body are bonded, anchored, combined and fixedly connected through auxiliary connecting pieces and a bonding layer; a protective layer is arranged on the outer surface of the rock wool thermal preservation plate, and two reinforcing material layers are arranged in the protective layer. The inner layer adopts the vacuum thermal insulation and preservation plate, and the outer layer adopts the rockwool thermal preservation plate, so that the thermal preservation performance and the fireproof requirement are met, and meanwhile, the thickness and the weight of an outer thermal insulation systemare reduced; a fixing mode of combining sticking and anchoring, and mainly using anchoring is adopted, the number of rock wool plate anchor bolts is 12-14 / m<2> in, so that the connection is reliable,and the construction is convenient; the overall anchoring force of section thermal bridge anchor bolts is enhanced through double-layer glass fiber gridding cloth, and the crack resistance of a surface layer and the durability of an overall system are improved.

Owner:北京城乡建设集团有限责任公司

High strength combination column

The invention provides a high strength combination column, includes high strength fossil fragments and filling material that metal material made, its characterized in that: fossil fragments are formed by the concatenation of a plurality of bare bones, said bare bones is cavity cylindricality structure, and is adjacent the bare bones links together, fill in the cavity of bare bones said filling material. The high strength combination column has the advantages of light weight, flexible installation, fire prevention and warm insulation, and low cost.

Owner:黄通

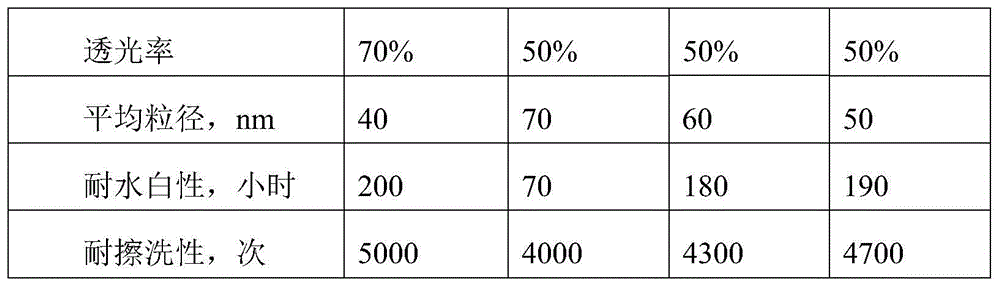

Preparation method of acrylic acid organic silicon soap-free copolymer nano-emulsion

The invention discloses a preparation method of an acrylic acid organic silicon soap-free copolymer nano-emulsion. The method is characterized by using an unsaturated monomer, organic silicon, a reaction type emulsifier, a co-emulsifier, an initiator and water as raw materials, utilizing soap-free polymerization and micro-emulsion polymerization processes, using the reaction type emulsifier containing olefin bonds, and introducing long C-chain alcohol as the co-emulsifier to prepare the acrylic acid organic silicon soap-free copolymer nano-emulsion. Through the adoption of the micro-emulsion polymerization process, the introduction of long C-chain alcohol and the adoption of high-speed emulsifying mode, latex particles form ultra-fine micelles, and the polymerization is performed in the micelles under the effect of the initiator to finally obtain a nano-scale and isotropic emulsion finished product which is clear and transparent. Through the adoption of the soap-free polymerization process and the long C-chain emulsifier containing olefin bonds, the olefin bonds directly participate in the polymerization to be one part of the final latex particles, so that the final emulsion finished product does not contain free emulsifier, and the purity degree of the film after final film formation of the emulsion is guaranteed.

Owner:江苏三瑞生物技术有限公司

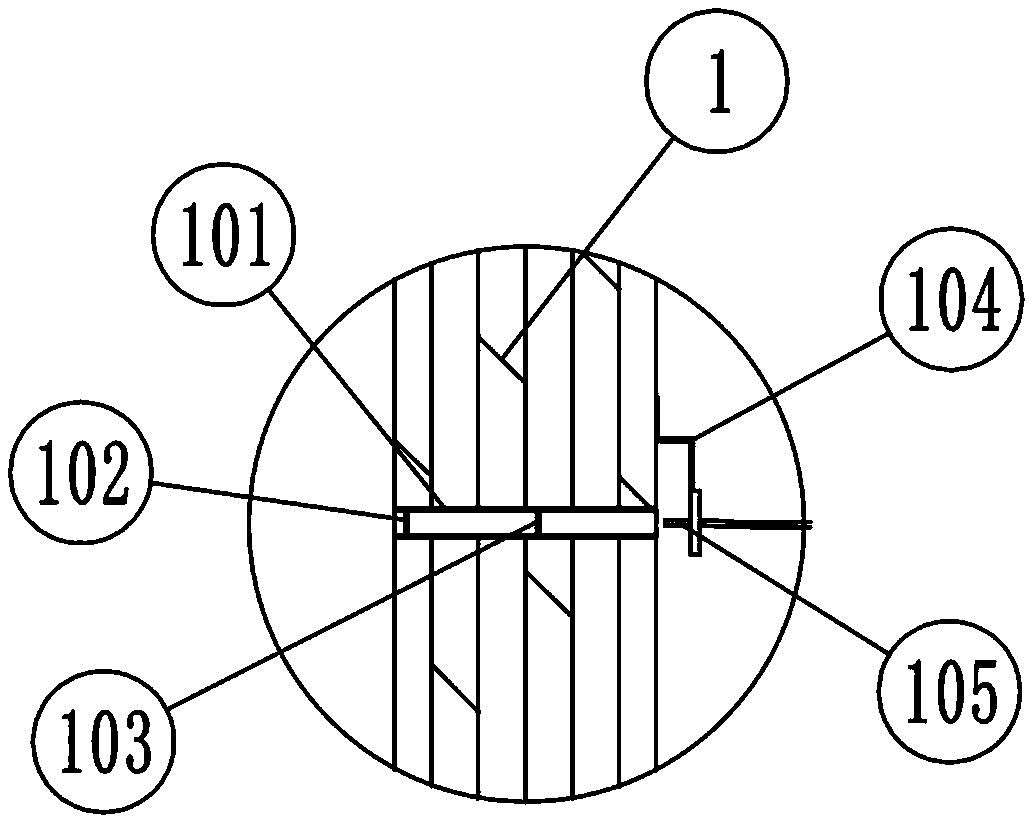

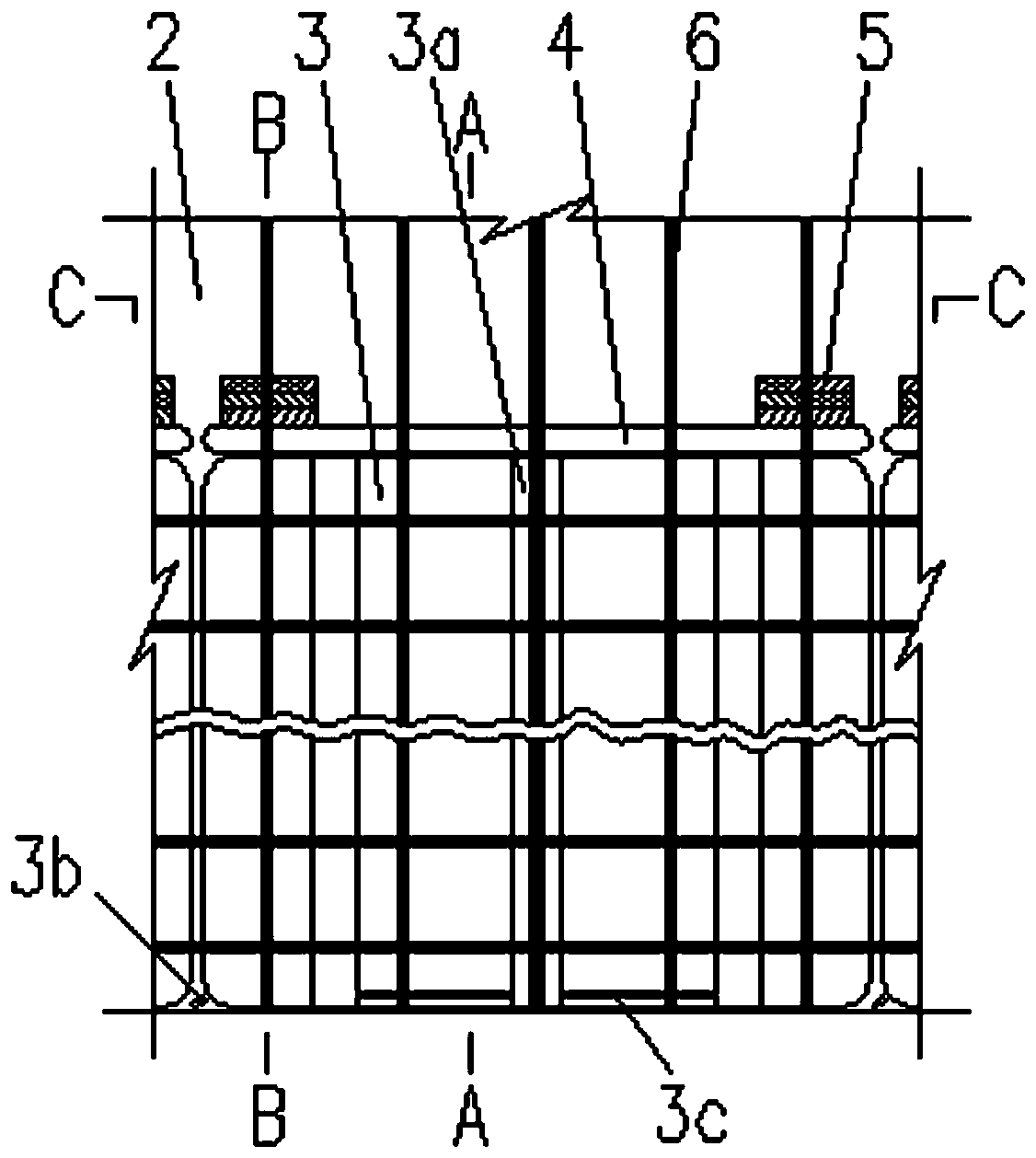

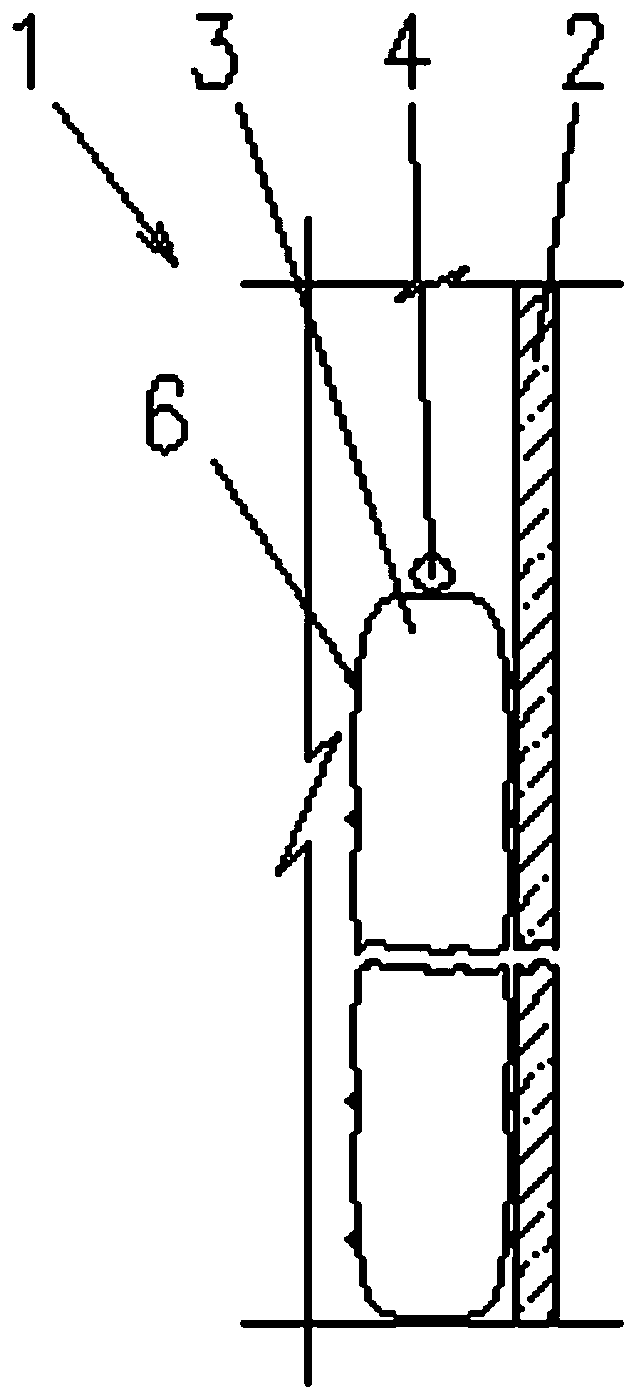

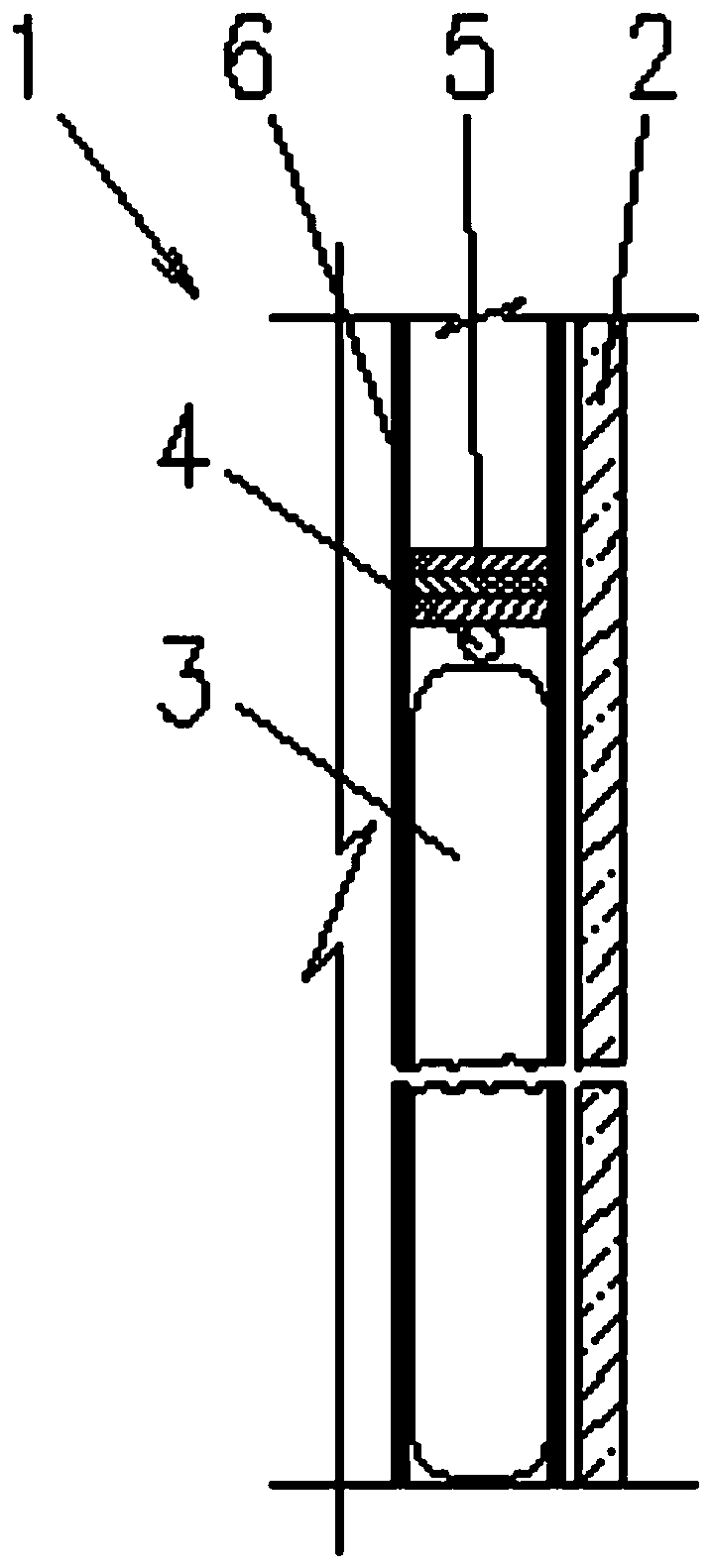

Secondary air inflation thermal insulation device for agricultural greenhouse glass wall

PendingCN109952890AControl altitudeEasy accessClimate change adaptationGreenhouse cultivationThermal insulationGreenhouse

The invention relates to a secondary air inflation thermal insulation device for an agricultural greenhouse glass wall. The secondary air inflation thermal insulation device comprises a greenhouse (1), and the greenhouse (1) is provided with the glass wall (2). The secondary air inflation thermal insulation device is characterized in that a group of air cushions (3) are arranged on the inner sideof the glass wall (2), each of the two sides, parallel to the glass wall (2), of each air cushion (3) is provided with a group of guy ropes (6), a pressing rod (4) is arranged above each air cushion (3), each of the two ends of each pressing rod (4) is connected to a group of saddle weights (5), a group of vertical gas columns (3a) connected to external air inflation equipment are arranged in a cavity of each air cushion (3), an air faucet (3b) connected to the air inflation equipment is also arranged at the bottom of each air cushion (3), and the bottom of each air column (3a) is connected tothe external air inflation equipment through an air supply pipe (3c). The secondary air inflation thermal insulation device has the advantage of being low in cost, capable of being applied to large-scale implementation and capable of meeting the illumination intensity in the daytime and the heat preservation property at night.

Owner:CHINA TRIUMPH INT ENG

Thermal insulation wallboard

InactiveCN113718980AImprove fire performanceFunctionalLighting and heating apparatusWallsInsulation layerThermal insulation

The invention provides a thermal insulation wallboard, and relates to the technical field of wallboards. The thermal insulation wallboard comprises a thermal insulation module, the thermal insulation module comprises a thermal insulation layer, a sound insulation layer and a heat conduction layer, graphite polystyrene particles are arranged in the thermal insulation layer, a fireproof layer is fixedly connected to the other side of the heat conduction layer, a heating assembly is arranged in the heat conduction layer, mounting pipes are arranged on the inner sides of two mounting holes, a second supporting plate is arranged at the other end of the outer sides of the mounting pipes, and fixing pieces are fixedly connected to the two ends of a first supporting plate and the two ends of the second supporting plate correspondingly. The thermal insulation layers, the sound insulation layers and the heat conduction layers are arranged in the thermal insulation modules, the sound insulation layers and the heat conduction layers enrich the functions of the graphite polystyrene board, the requirements for thermal insulation, sound insulation and heating of a building are met, functionality is high, the two mounting pipes penetrate through the multiple thermal insulation modules at the same time, the thermal insulation modules can be assembled into a thermal insulation wall, mounting is convenient and rapid, and time and labor are saved.

Owner:赵跃

High-strength heat-insulation pipe shell and preparation method

PendingCN112608116AImprove crack resistanceImprove good performanceThermal insulationPipe protection by thermal insulationFiberAluminate

The invention relates to an accessory matched with a pipeline, in particular to a high-strength heat insulation pipe shell and a preparation method. The high-strength heat insulation pipe shell is mainly formed by mixing vitrified micro bubbles, light ceramsite, silica fume, anti-cracking fibers and an aluminate gelling agent according to the weight percentage of 20-24: 40-45: 3-5: 3-4: 26-30 and then performing curing. The preparation method comprises the following steps: (1) uniformly mixing the vitrified micro bubbles, the light ceramsite, the silica fume, the anti-cracking fibers and the aluminate gelling agent according to a ratio in a dry manner; 2) adding water for wet mixing to obtain a mixture; (3) placing the mixture in a mold, enabling a vibrating bar to vibrate, and enabling the outer surface to be flattened; 4) performing demolding and then performing stable curing to obtain the product. The composite material has the advantages of light weight, higher strength, lower heat conductivity coefficient and better vibration resistance and crack resistance. The cost is low, the process is simple, and industrial production is easy. The heat preservation and insulation support is used for heat distribution pipelines and gravity thermal equipment of petrochemical engineering, thermal power plants, pharmacy and heating engineering.

Owner:山东佳能科技股份有限公司

Internal cooling device for PCB processing and processing method

PendingCN112087865AReduce lossAvoid wear and tearPrinted circuit manufactureThermodynamicsCooling effect

The invention relates to the technical field of PCB processing and particularly relates to an internal cooling device for PCB processing and a processing method. The internal cooling device for PCB processing comprises a pressure rotating joint, a main shaft, a cutter chuck, a cutter, an internal cooling conveying pipe and a cooling medium multi-way interface, wherein the main shaft is located between the cutter chuck and the pressure rotating joint; the inner cooling conveying pipe is arranged in the pressure rotary joint, the main shaft and the tool chuck, and the cooling medium multi-way connector is arranged on the pressure rotary joint and communicated with the inner cooling conveying pipe. According to the inner cooling device for PCB machining, the same or different cooling media can be directly conveyed to the position between a tool and a machined PCB through the cooling medium multi-way connector, heat generated in the machining process is reduced, the effect of reducing cutting heat is achieved through the most direct method, and the machining efficiency is improved; a problem that cutting heat generated between a cutter and a machined PCB is difficult to directly reducein other external cooling modes is solved, the cooling effect is optimal, and the influence of the cutting heat in PCB machining is greatly reduced.

Owner:GUANGDONG UNIV OF TECH

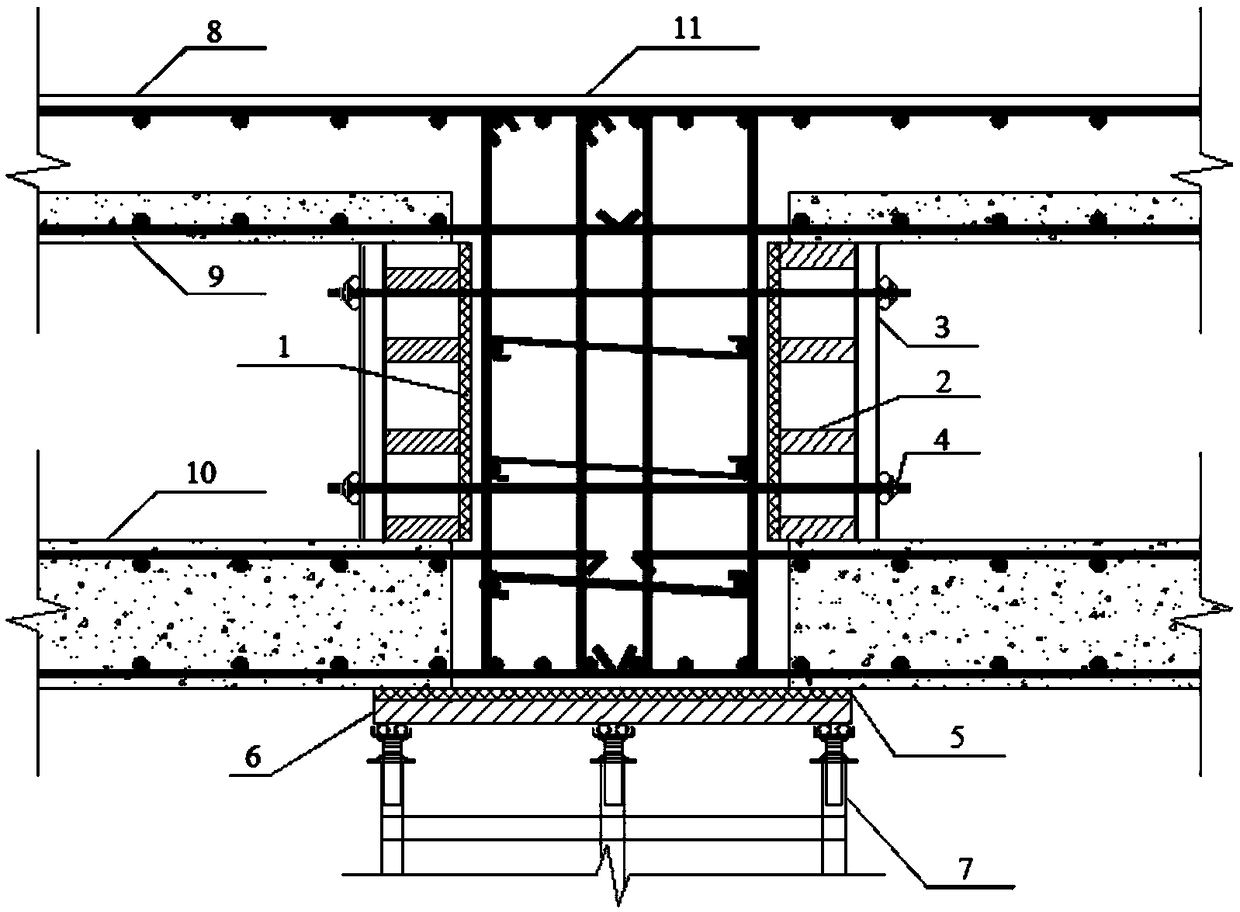

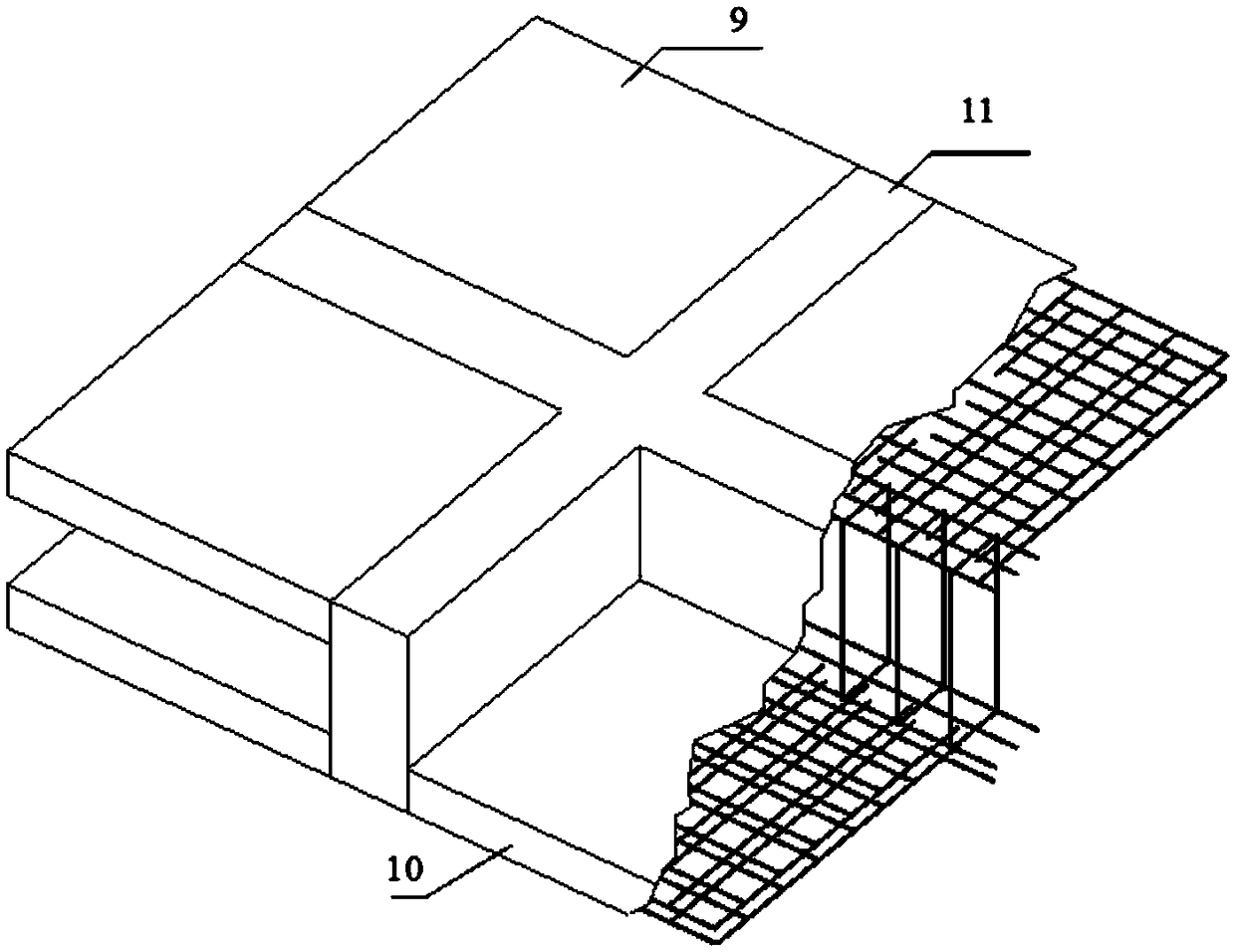

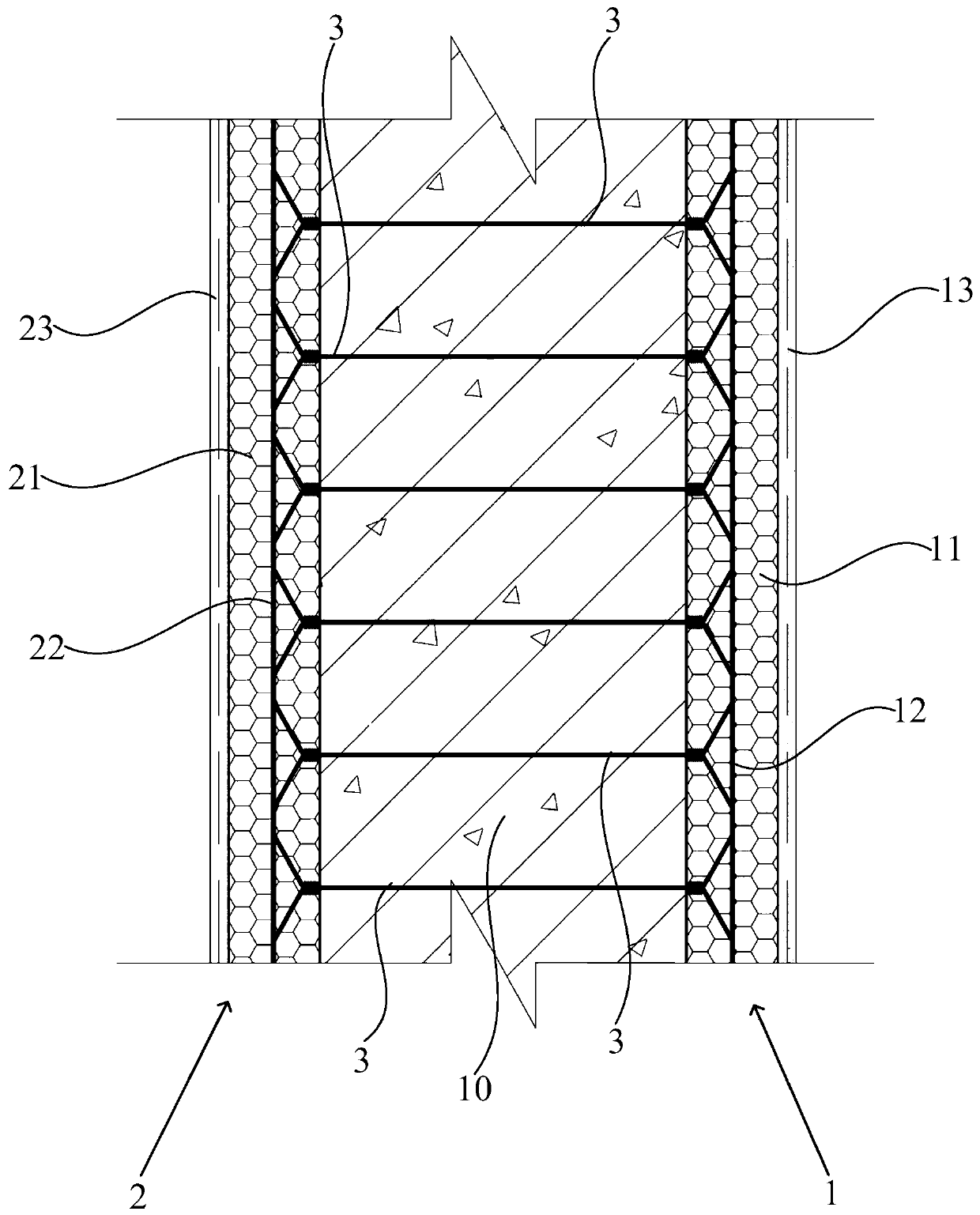

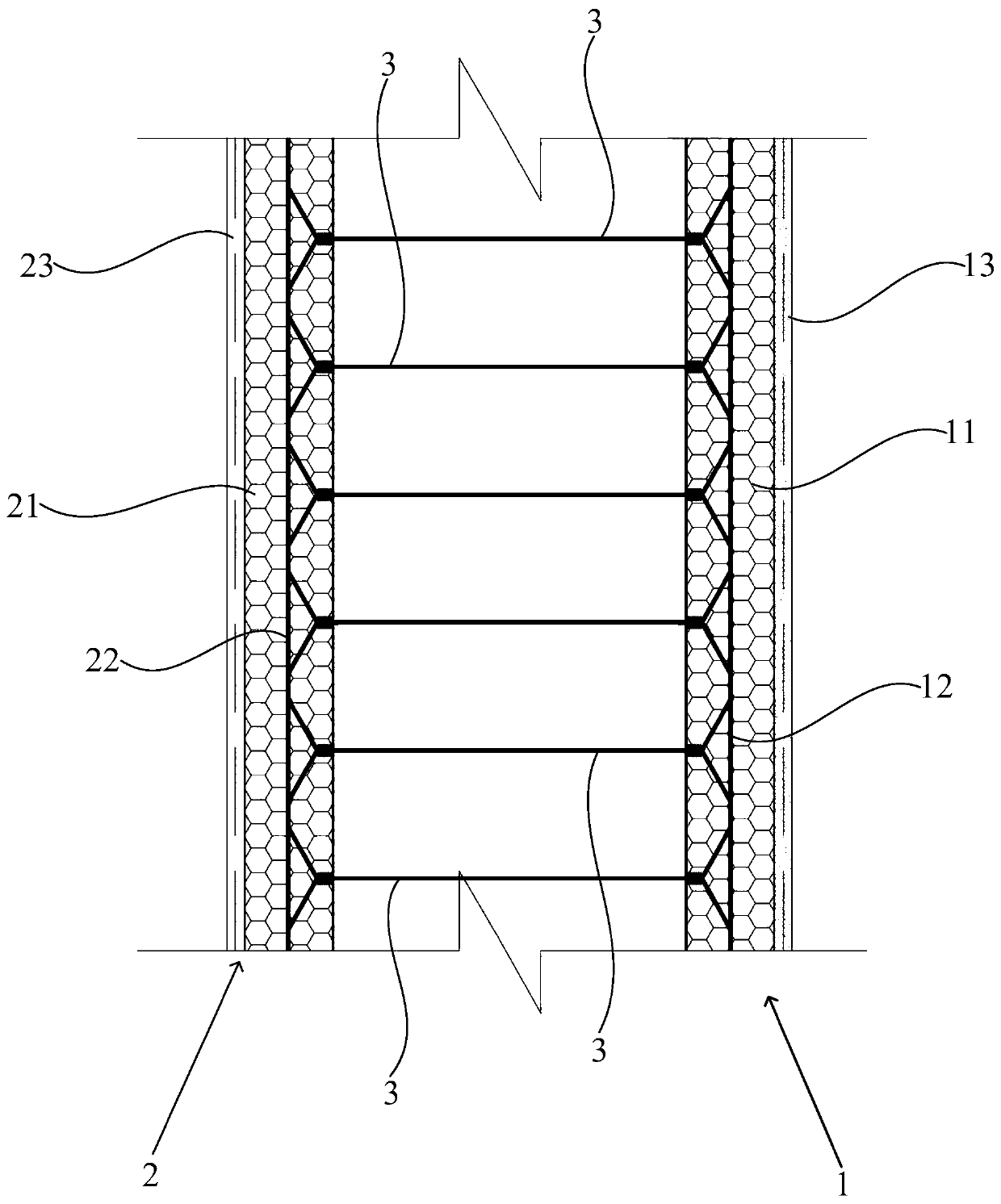

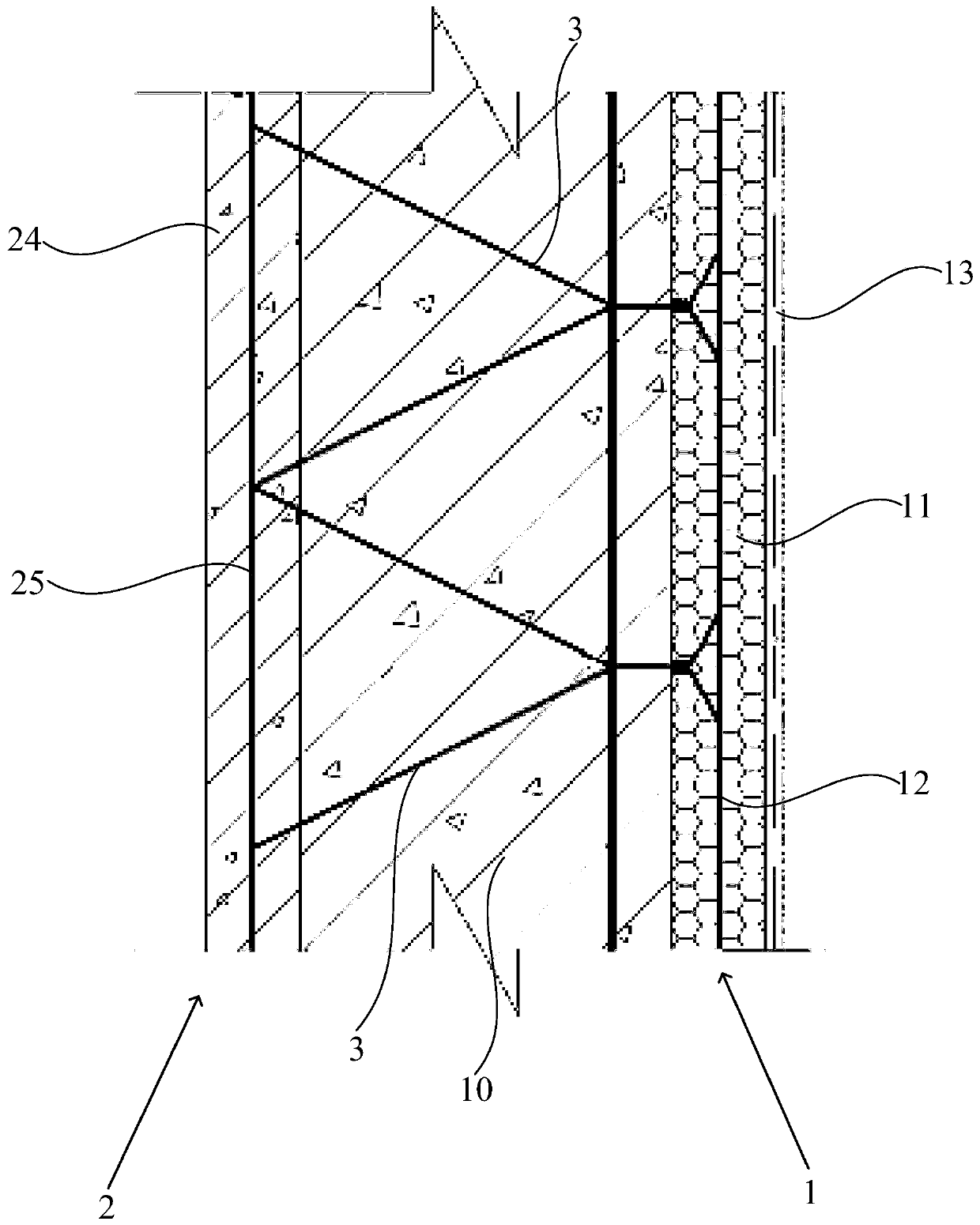

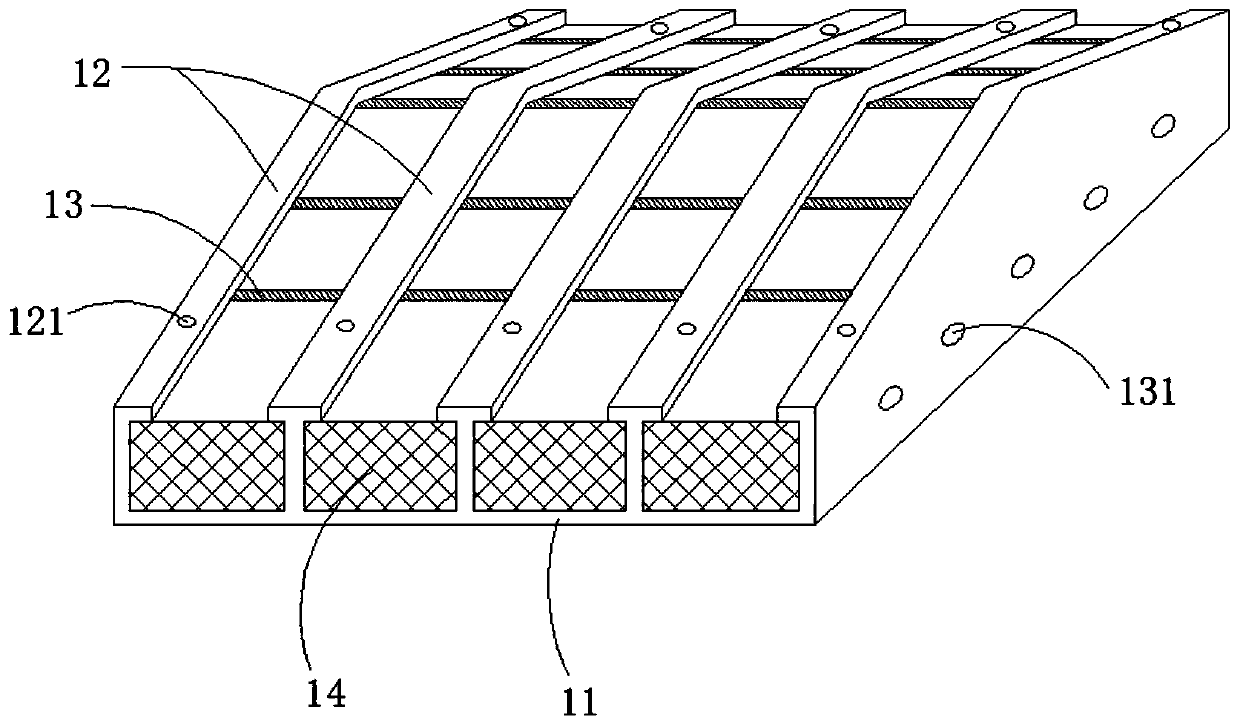

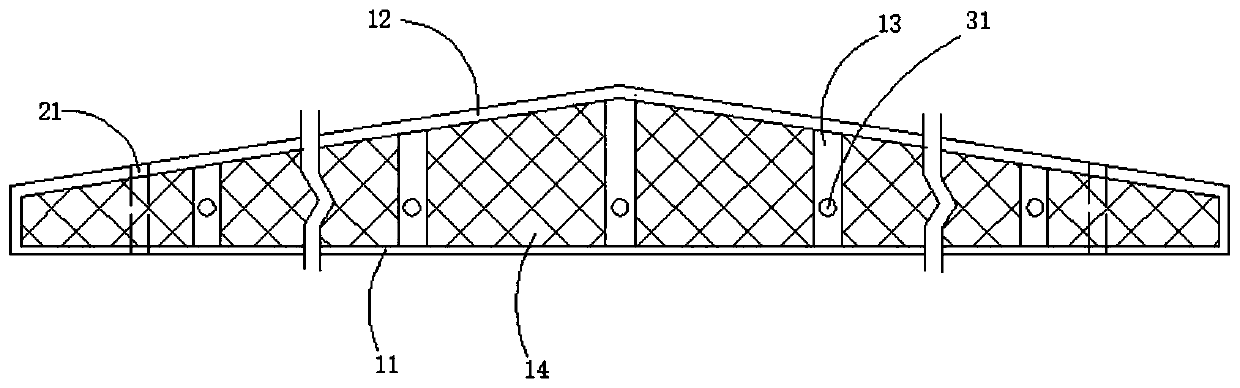

Self-heat-preservation double-formwork composite wall structure and composite wall comprising same

PendingCN111502086AMeet structural strength requirementsSatisfy thermal insulationWallsHeat proofingSupporting systemConstruction engineering

Owner:SHANGHAI SHENGKUI PLASTIC IND

Large-span prefabricated multi-rib sandwich panel and corrugated tile combined roofing

InactiveCN110847470AMeet anti-corrosion requirementsReduce construction costsBuilding roofsMechanical engineeringSandwich panel

The invention discloses a large-span prefabricated multi-rib sandwich panel and corrugated tile combined roofing. The roofing comprises a panel body and corrugated tiles, wherein the corrugated tilescover the panel body; the longitudinal section of the top surface of the panel body is in a pyramid shape; the panel body comprises a bottom plate, longitudinal ribbed beams, transverse ribbed beams and sandwich blocks; each longitudinal ribbed beam comprises L-shaped ribbed beams positioned on two sides of the bottom plate and a T-shaped ribbed beam positioned in the middle of the bottom plate; the longitudinal ribbed beams are perpendicular to the transverse ribbed beams; the sandwich blocks are positioned in cavities formed by the bottom plate, the longitudinal ribbed beams and the transverse ribbed beams; vertical reserved holes penetrating through the panel body are formed in the longitudinal ribbed beams and used for connecting front and rear wall boards; transverse through holes areformed in the transverse ribbed beams and used for connecting and hoisting panel bodies. The large-span prefabricated multi-rib sandwich panel and corrugated tile combined roofing is large in span and good in bearing property, has the advantages of low weight, high corrosion resistance, heat preservation and insulation, low manufacturing cost and the like, and has a wide market prospect.

Owner:HUNAN CHENGYOU GREEN BUILDING MATERIAL TECH CO LTD

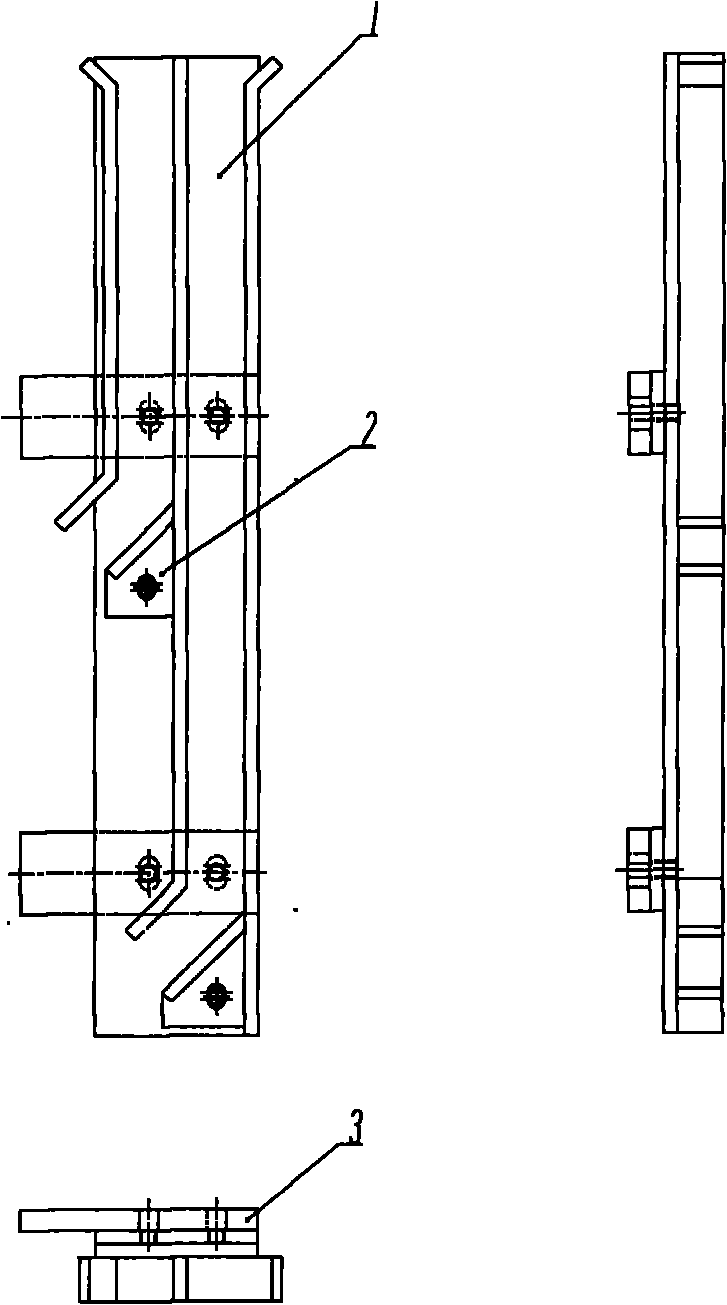

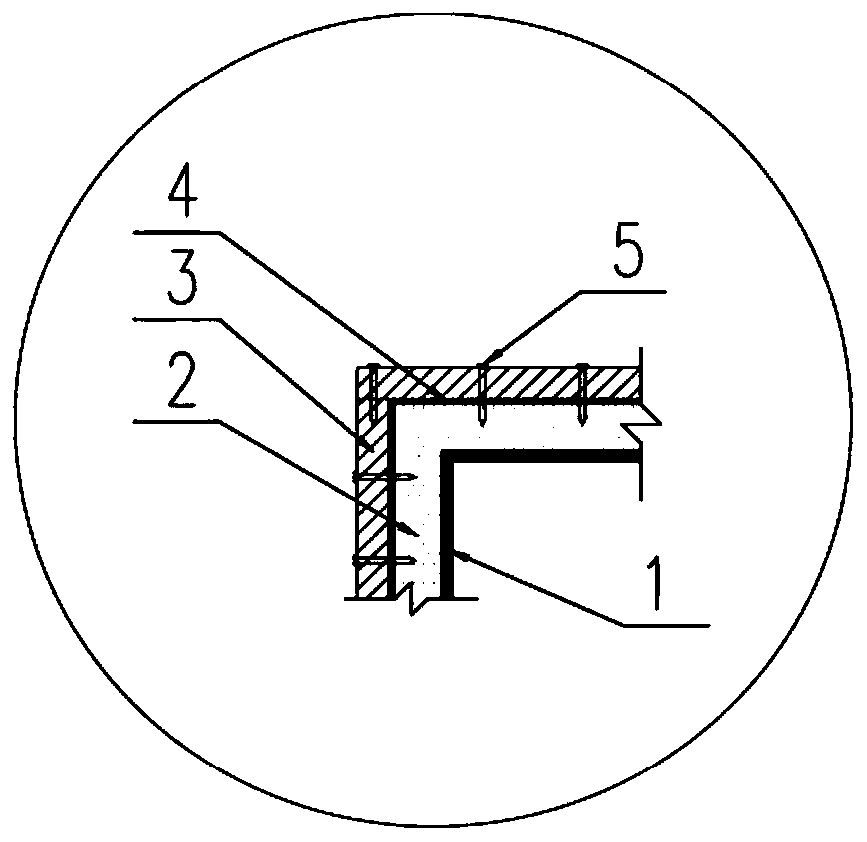

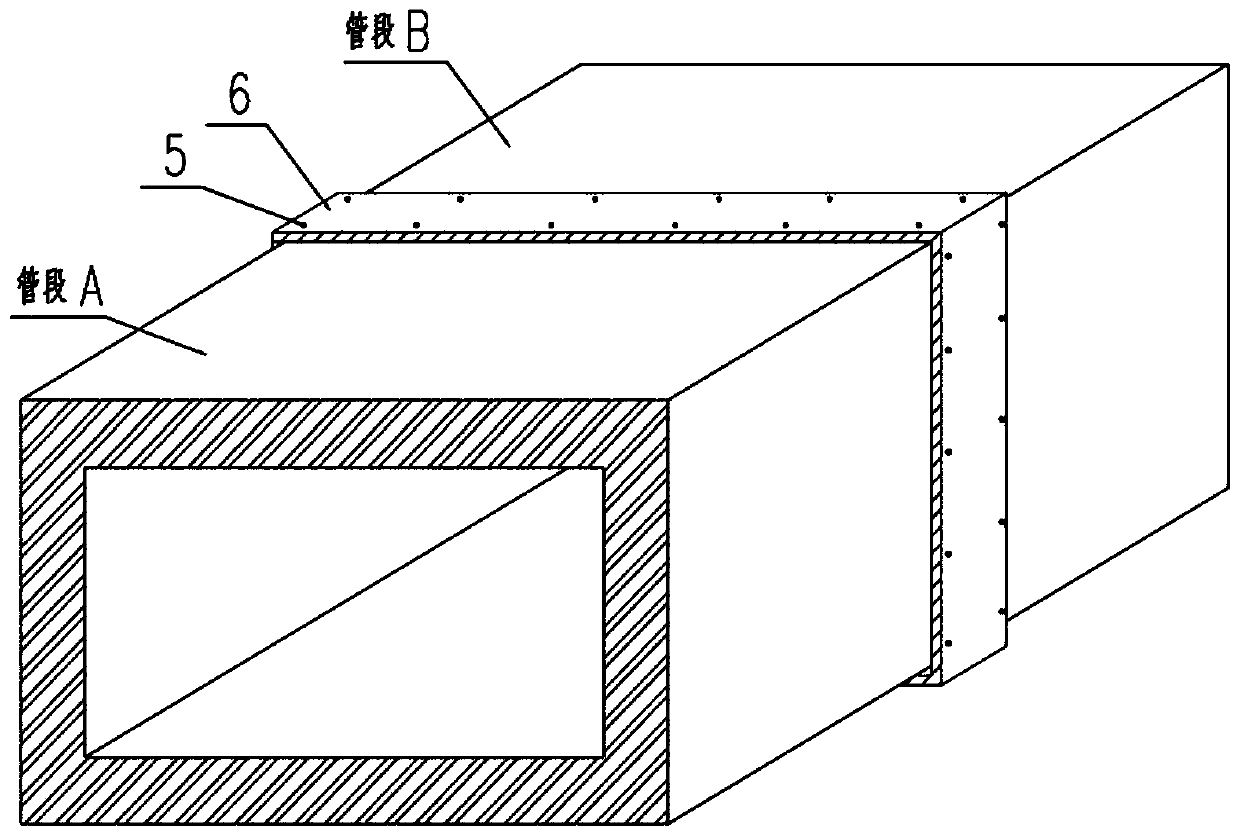

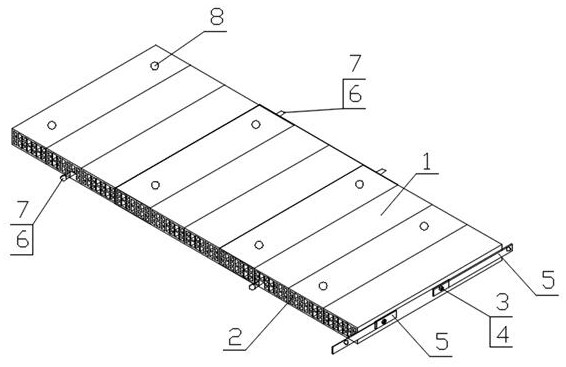

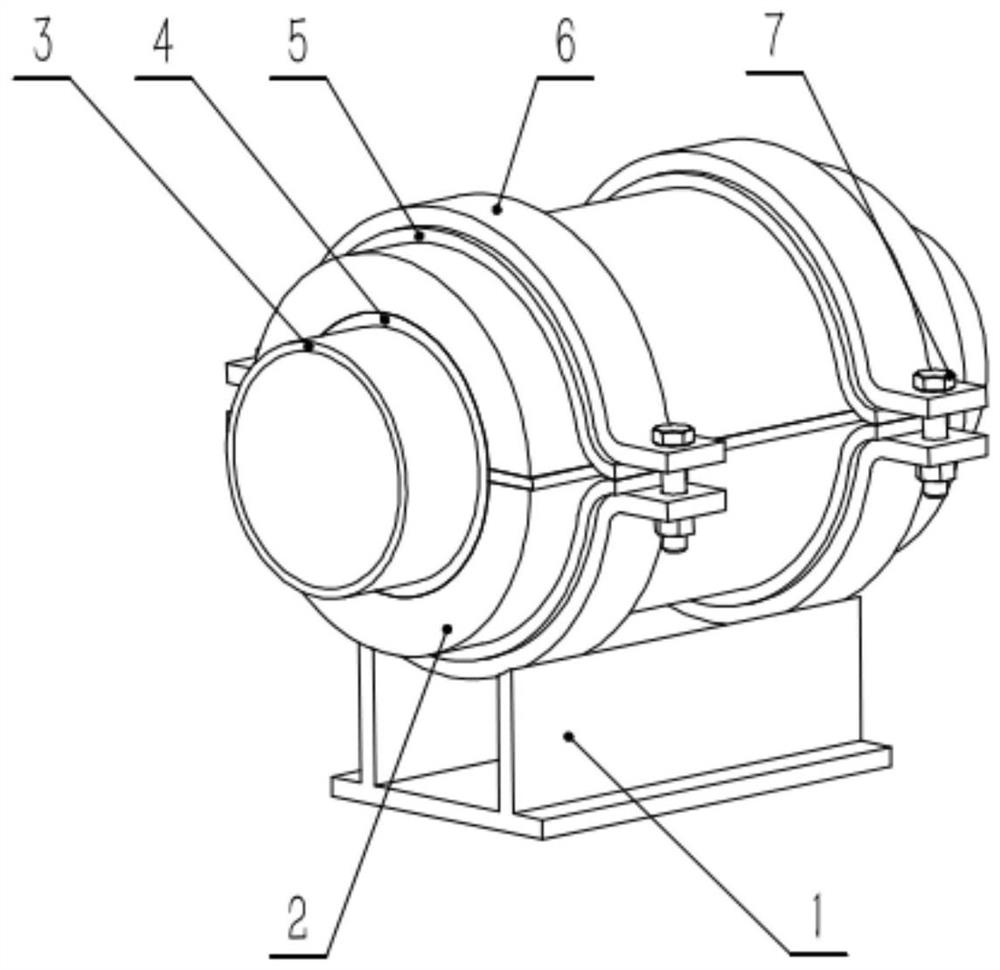

Segmental prefabricated heat preservation and insulation type fabricated structure air duct and construction method thereof

PendingCN114278050ASatisfy thermal insulationMeet fire resistanceDucting arrangementsThermal insulationThermal insulationLap joint

The invention belongs to the technical field of air ducts, and particularly relates to a segment prefabricated assembly type structure air duct and a construction method. The segment prefabricated assembly type structure air duct is formed by sequentially connecting and matching a plurality of air pipe main body segments end to end; each air pipe main body section comprises a stainless steel lining used for forming an air pipe main body frame, a heat preservation and insulation layer wrapping the peripheral face of the stainless steel lining and a structural layer wrapping the peripheral face of the heat preservation and insulation layer, and the adjacent air pipe main body sections are connected through lap joint structures. According to the invention, the requirements of ventilation, air conditioning and smoke prevention and exhaust are simultaneously met, the requirements of thermal insulation performance, fireproof performance and assembly type installation performance are met, and the problems of many air pipe installation procedures, long installation period, large occupied underground space, poor durability, inconvenience in maintenance and the like can be effectively solved; and the problem of damage to the overall performance of a heat preservation layer and a fireproof layer wrapped outside the air pipe in the field installation process of the air pipe is also avoided.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com