Fiber guide pipe with far-infrared heating function

A guide tube, far-infrared technology, applied in the direction of pipeline heating/cooling, protecting pipelines and pipes through thermal insulation, etc., can solve the problems of high energy consumption, fast heat dissipation, and less research on heating equipment, and achieve fast heat exchange speed and heat generation. The effect of uniformity and avoidance of product defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to better understand the present invention, the present invention will be further explained below in conjunction with the accompanying drawings and embodiments, but it should be clear that the scope of protection of the present invention is not limited to the scope indicated by the embodiments.

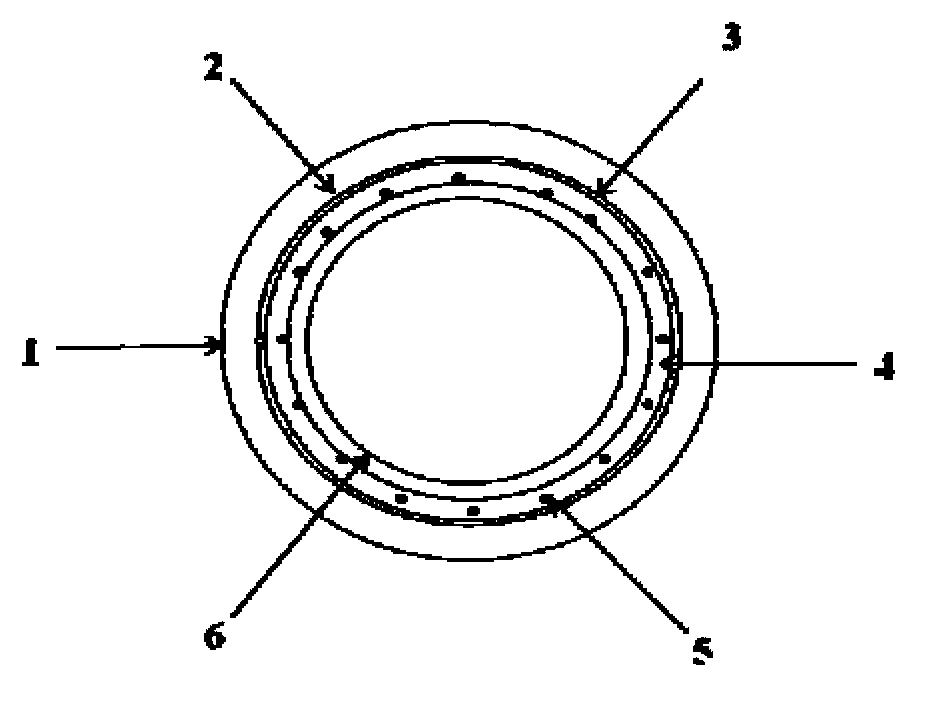

[0016] As shown in the figure, the fiber guide tube with far-infrared heating function of the present invention, from the outside to the inside of the tube wall, is respectively a skin formed by a polyvinyl chloride film and a 100% closed-cell polymethacrylimide (PMI) rigid foam It is composed of an insulation layer, a reflective layer directly calendered from metal aluminum into a thin sheet, an electrothermal conversion heating layer containing carbon fiber heating wires, an inner lining layer formed of self-lubricating polytetrafluoroethylene, and the outer diameter of the fiber guide tube is 3~ 8cm, inner diameter 2~5cm, 3 minutes after power on, the temperature inside...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com