High-strength heat-insulation pipe shell and preparation method

A thermal insulation, high-strength technology, applied in the direction of thermal insulation protection of pipelines, thermal insulation, heat exchange equipment, etc., can solve the problem of poor crack resistance and vibration resistance, low thermal conductivity, vibration and crack resistance, and thermal insulation material strength It can not take into account the problems of thermal insulation performance, etc., to achieve the effect of low cost, improved compressive strength, hardness and temperature resistance, and light weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The specific steps of the preparation method of the high-strength heat-insulating shell are as follows:

[0027] Put vitrified microspheres, lightweight ceramsite, microsilica fume, anti-crack fiber, and aluminate gelling agent into a mixing container in a weight percentage of 20:45:4:3:28; Add 65kg of water to the container for wet mixing; put the mixed mixture into the mold, vibrate with a vibrating rod, and smooth the outer surface; the demoulding time is 12 hours, and after 7 days of stable curing, a high-strength heat-insulating shell will be formed . The thermal conductivity of the material is determined by experiments: 0.17W / (m·K), and the compressive strength is 1.5MPa / cm 2 .

Embodiment 2

[0029] The specific steps of the preparation method of the high-strength heat-insulating shell are as follows:

[0030] Put vitrified microspheres, lightweight ceramsite, microsilica fume, anti-crack fiber, and aluminate gelling agent into a mixing container in a weight percentage of 23:44:4:3:26; Add 55kg of water into the container for wet mixing; put the mixed mixture into the mold, vibrate with a vibrating rod, and smooth the outer surface; the demoulding time is 6 hours, and after 5 days of stable curing, a high-strength heat-insulating shell will be formed . The thermal conductivity of the material is determined by experiments: 0.155W / (m·K), and the compressive strength is 1MPa / cm 2 .

[0031] It is realized by prefabrication during implementation. According to the actual geometric size and performance parameter requirements, it is made into the required shape through the mold, and it can be used after a period of stability and curing.

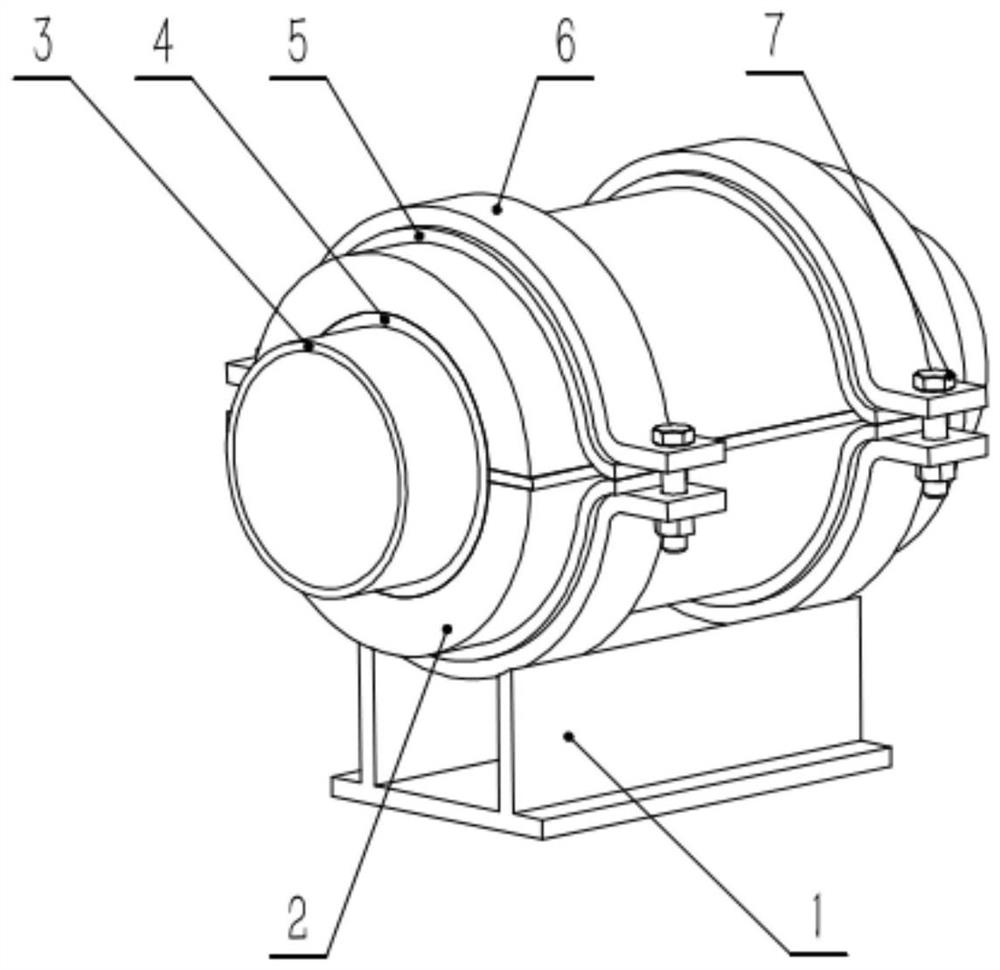

[0032] The typical high-streng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com