Internal cooling device for PCB processing and processing method

A processing method and cooling medium technology, applied in electrical components, printed circuit manufacturing, printed circuits, etc., can solve the problems of blockage of internal cooling conveying channels, inability to circulate coolant, high temperature operation of drill bits, etc., to avoid tool wear and meet PCB requirements. Machining requirements, the effect of reducing cutting heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to facilitate those skilled in the art to understand the present invention, the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

[0033] The present application is further described in conjunction with the following examples.

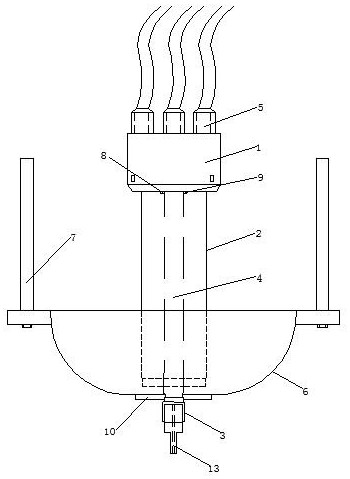

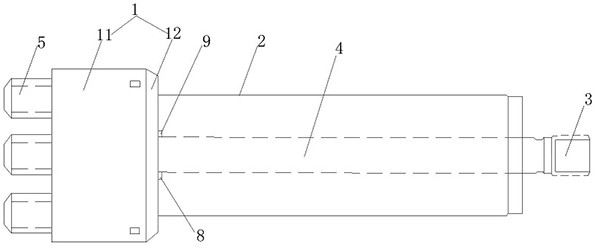

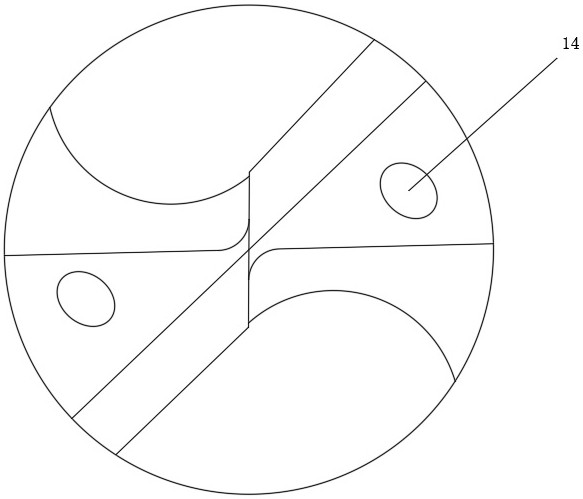

[0034] Such as Figure 1 to Figure 4 , an internal cooling device for PCB processing, including a pressure rotary joint 1, a main shaft 2 and a tool holder 3, the main shaft 2 is located between the tool holder 3 and the pressure rotary joint 1; the PCB processing The internal cooling device also includes an internal cooling delivery pipe 4 and a cooling medium multi-way interface 5 . Wherein, the internal cooling delivery pipe 4 is arranged in the pressure rotary joint 1, the main shaft 2 and the tool holder 3 and extends from the pressure rotary joint 1 tool holder 3 to the tool holder 3; the cooling medium multi-way interface 5 are arranged on the pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com