Segmental prefabricated heat preservation and insulation type fabricated structure air duct and construction method thereof

A technology of thermal insulation and thermal insulation layer, applied in the field of air ducts, can solve the problems of difficult maintenance in the later stage, cumbersome construction procedures, long construction period, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

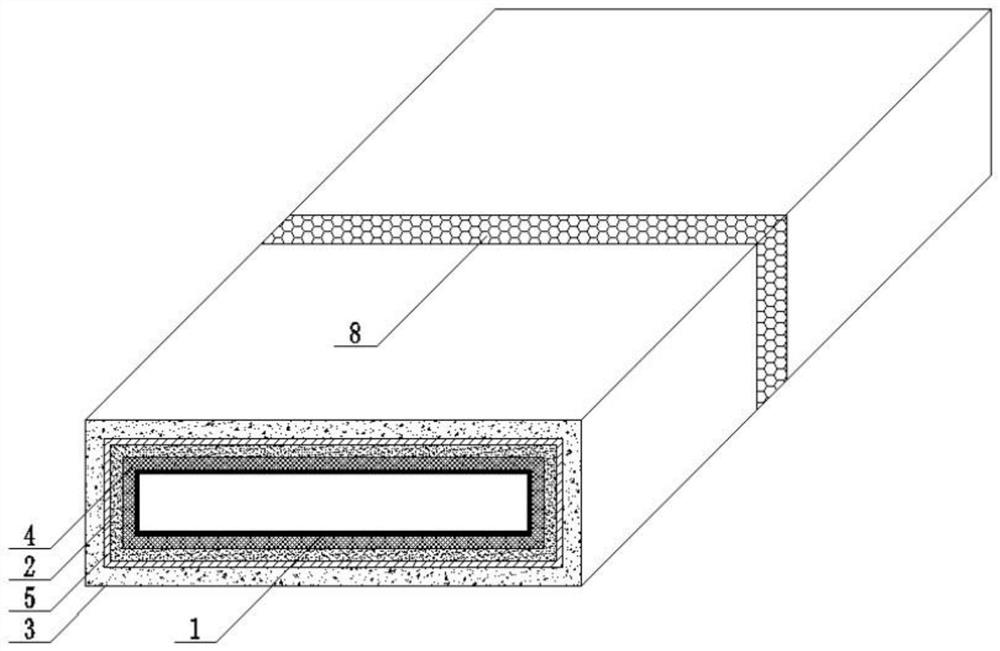

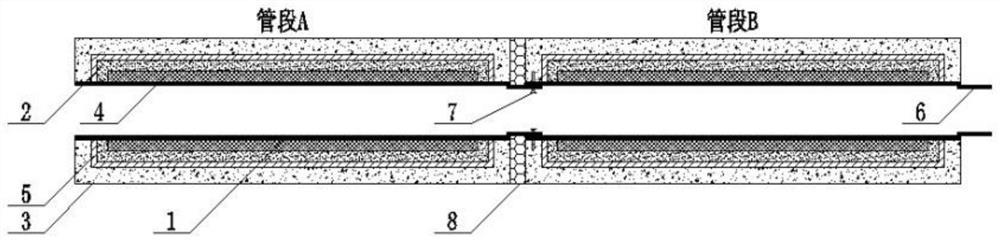

[0030] A segmental prefabricated thermal insulation type assembled structural air duct, which is formed by connecting and matching the main sections of several air ducts sequentially. The main sections of the air duct include a stainless steel lining 1 for forming the main frame of the air duct 1. The thermal insulation layer 2 coated on the outer peripheral surface of the stainless steel lining 1 and the structural layer 3 coated on the outer peripheral surface of the thermal insulation layer 2, and the adjacent air duct main sections are connected by a lap joint structure.

[0031] In this example, if Figure 1-2 As shown, the main sections of several air ducts are connected end to end in turn to form a complete structural air duct. The main section of the air duct includes stainless steel lining 1, thermal insulation layer 2 and structural layer 3, which has the characteristics of integral molding, simultaneous implementation, and easy installation. , Durable, maintenance-f...

Embodiment 2

[0041] Embodiment 2 of the present invention is further improved on the basis of Embodiment 1, so as to fully exert the technical advantages of the present invention, which will be illustrated below.

[0042] For example: the expansion node 6 is an integral board or a segmented board. When the expansion node 6 is an integral plate, it is a closed structure, and its cross-sectional shape is similar to that of the stainless steel lining 1 and its size is slightly smaller. It is used to connect the main sections of two adjacent air ducts to ensure that the adjacent The stability of the connection between the main sections of the two air ducts and the airtightness of the connection ensure the overall fire resistance of the air duct after the connection. When the expansion node 6 is a segmented plate, the expansion node 6 is a plurality of stainless steel plates distributed between the main sections of the two air ducts.

[0043] Furthermore, it can also be considered in Embodimen...

Embodiment 3

[0046] A construction method for segmental prefabricated thermal insulation type assembled structural air duct, comprising the following steps:

[0047] Step 1: Prefabricate the main section of the air duct in the prefabrication yard according to the design requirements;

[0048] Step 2: The main section of the air duct is composed of a stainless steel lining 1, a thermal insulation layer 2 coated on the outer peripheral surface of the stainless steel inner lining 1, and a structural layer 3 coated on the outer peripheral surface of the thermal insulation layer 2;

[0049] Step 3: During the on-site installation of the air duct, the main sections of several air ducts are sequentially connected through the end-to-end connection of the overlapping structure;

[0050] Step 4: Seal the concrete sealant at the joints of the concrete structure to form a complete segmental prefabricated thermal insulation type prefabricated structural air duct, which adopts segmental prefabrication a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com