Self-heat-preservation double-formwork composite wall structure and composite wall comprising same

A technology of laminated walls and self-insulation, applied in the direction of insulation, building structure, walls, etc., can solve the problems of overall thickness increase, building volume ratio, building actual usable area, cost impact, and complex construction procedures, etc., to reduce the overall Thickness, is conducive to effective application and promotion, and optimizes the effect of prefabrication process and construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

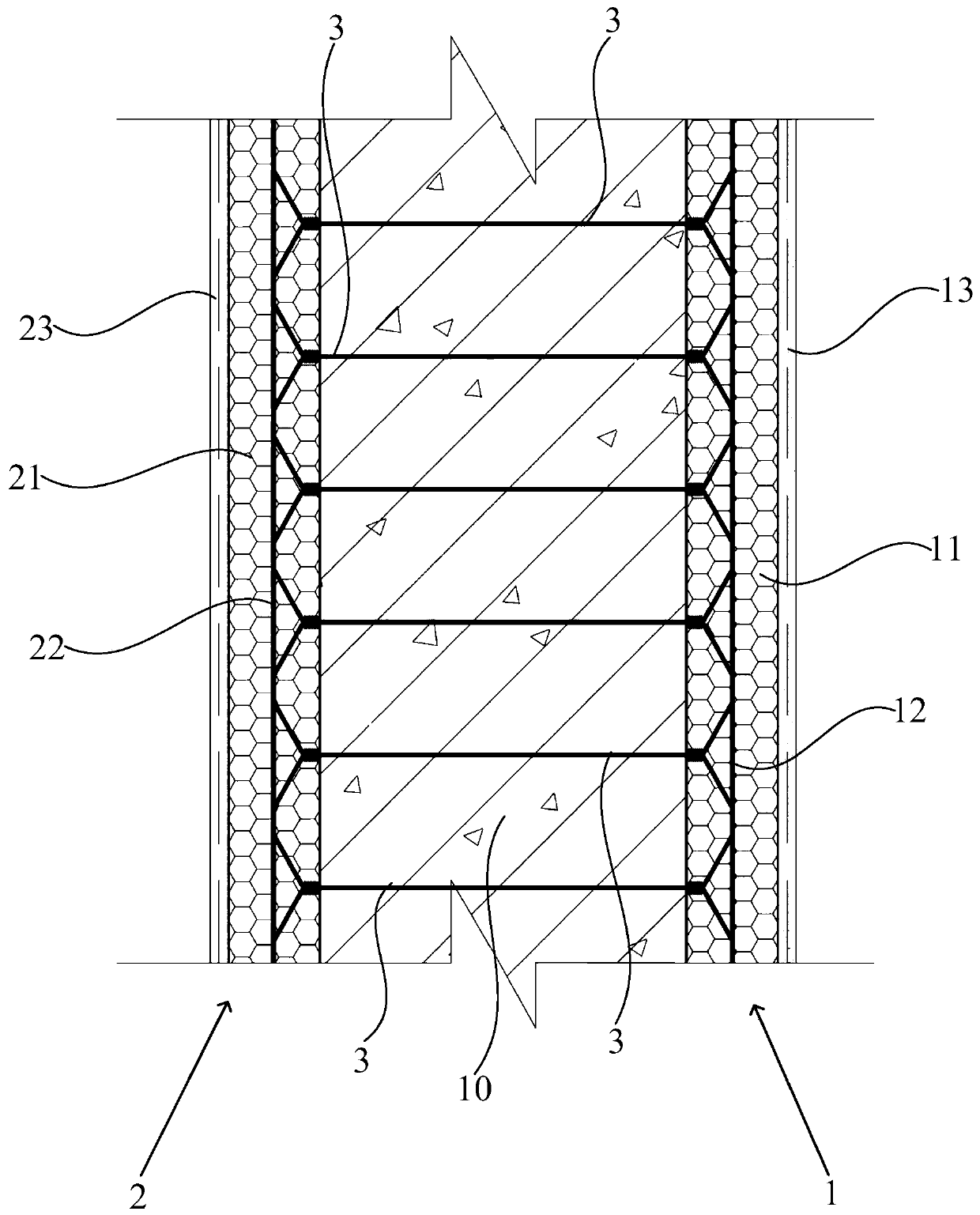

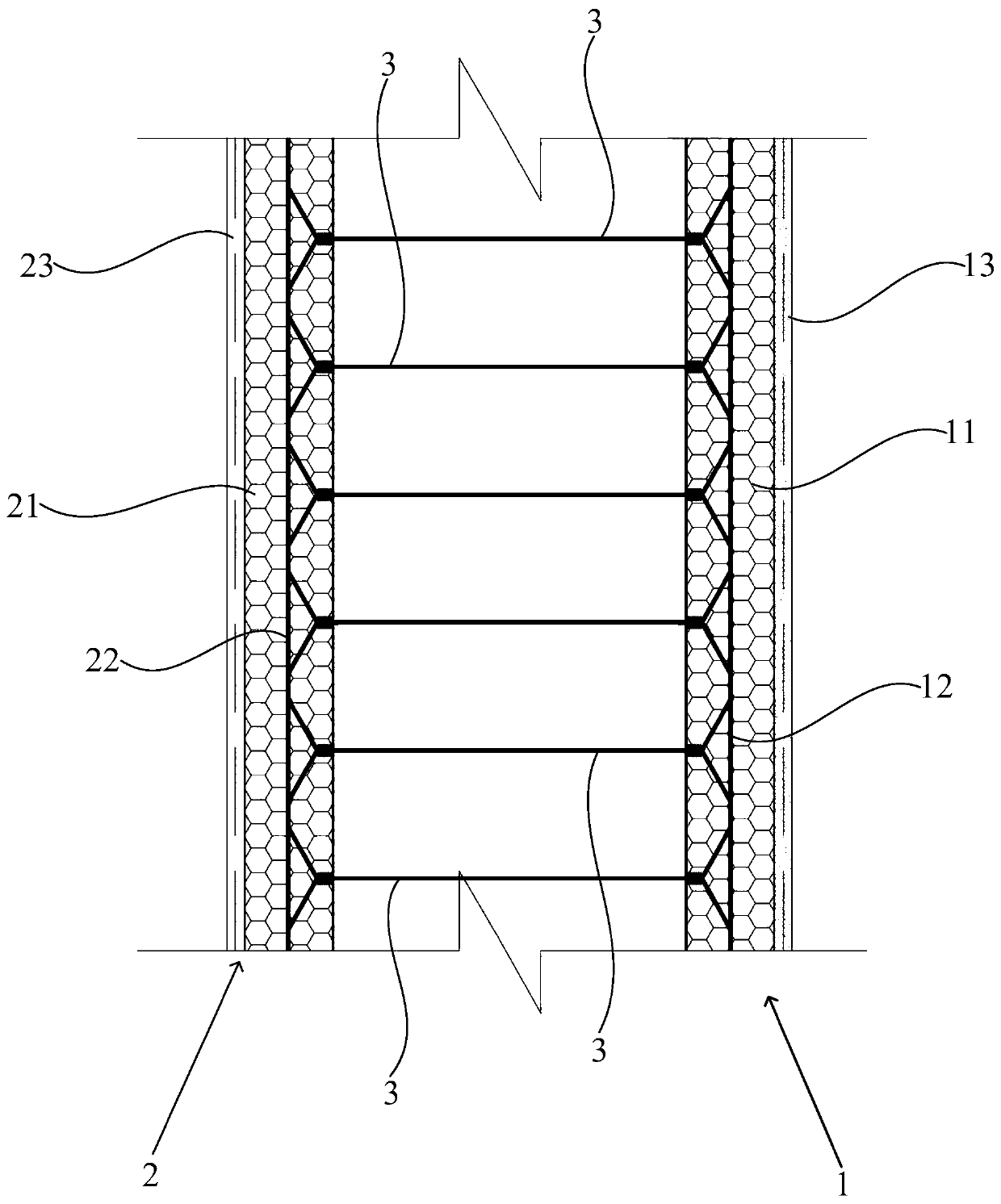

[0036] Such as figure 1 and figure 2 As shown, this embodiment discloses a laminated wall, which includes a concrete layer 10 and a self-insulating double-form shell laminated wall structure. The self-insulating double-form shell laminated wall structure includes an inner formwork shell 2, an outer formwork shell 1 and several connecting ribs 3, and the outer formwork shell 1 includes a first armor layer 13, a first class A fireproof insulation material layer 11 and a first Reinforce the grid frame 12, the first A-level fire-proof and heat-insulating material layer 11 and the inner mold shell 2 are spaced apart, and the first armor layer 13 is connected to one of the first A-level fire-proof and heat-insulating material layers 11 that faces away from the inner mold shell 2 On the side, the first reinforced grid frame 12 is set in the first A-level fire-proof and heat-insulating material layer 11, and several first connecting ribs 3 are located between the first A-level fire-...

Embodiment 2

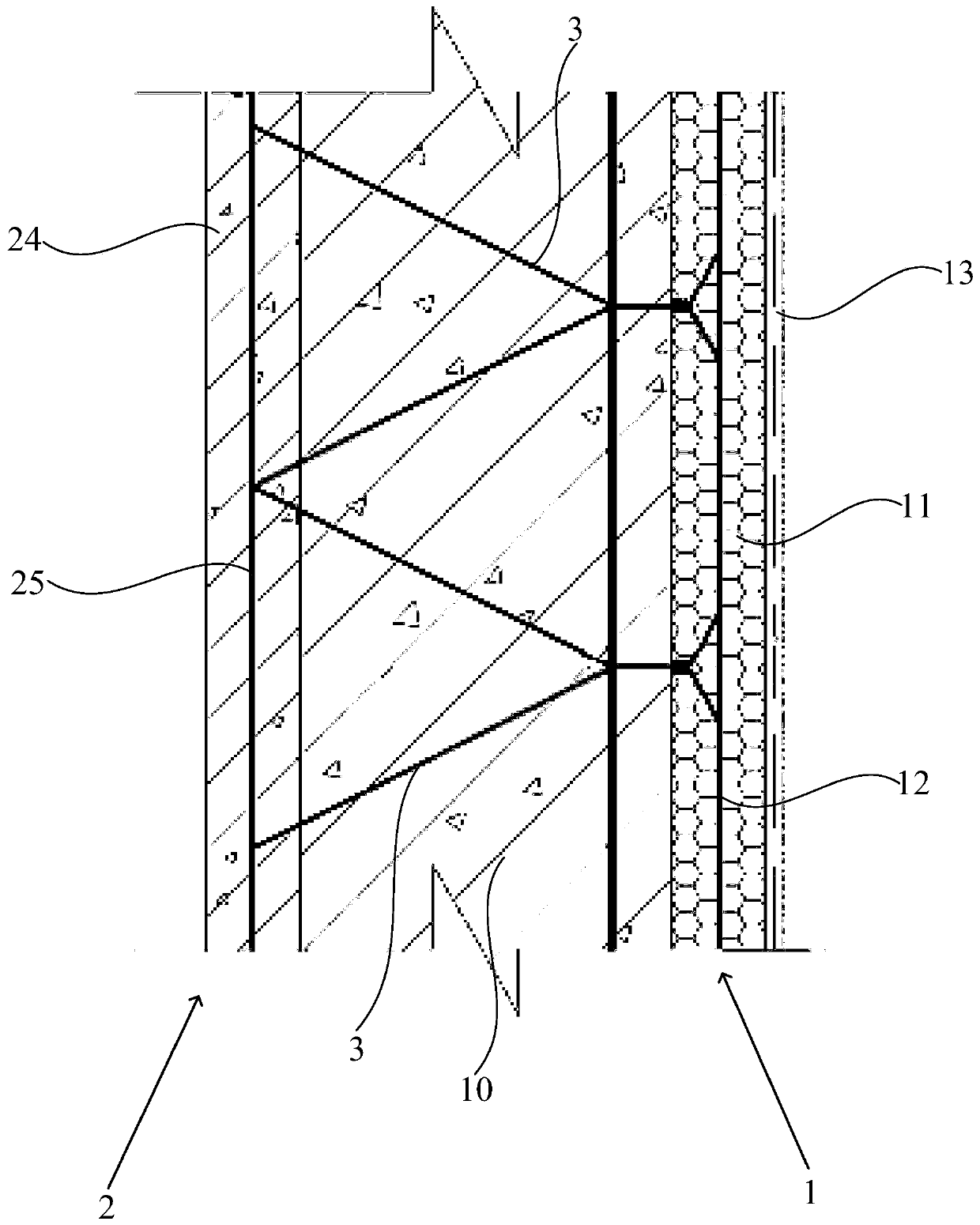

[0047] The parts of the second embodiment that are the same as those of the first embodiment will not be repeated, and only the different parts will be described. Such as image 3 and Figure 4 As shown, as shown, in this embodiment 2, the inner formwork 2 includes an ultra-high performance concrete layer 24 and a reinforcement part 25, the ultrahigh performance concrete layer 24 and the outer formwork 1 are arranged at intervals, and the reinforcement part 25 is located at In the ultra-high performance concrete layer 24 , the connecting rib 3 is connected to the reinforcement part 25 . The ultra-high-performance concrete layer 24 is formed by pouring ultra-high-performance concrete, which has high strength, excellent wear resistance and explosion resistance; the reinforcement part 25 is arranged in the ultra-high-performance concrete layer 24 to further strengthen the self-insulating double-form shell The overall structural strength of the laminated wall structure, so as to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com