Vacuum thermal-insulation module

A technology of vacuum heat preservation and heat preservation layer, applied in the field of heat preservation and sound insulation materials, can solve the problems of fragile use range, inability to meet the requirements of anti-atmospheric pressure, resource consumption, etc., to reduce the possibility of abnormal use and damage to the cavity, maintenance And the effect of convenient replacement and reuse, and improved sound insulation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but it should not be understood that the scope of the subject matter of the present invention is limited to the following embodiments. Without departing from the above-mentioned technical idea of the present invention, various replacements and changes made according to common technical knowledge and conventional means in this field shall be included in the scope of the present invention.

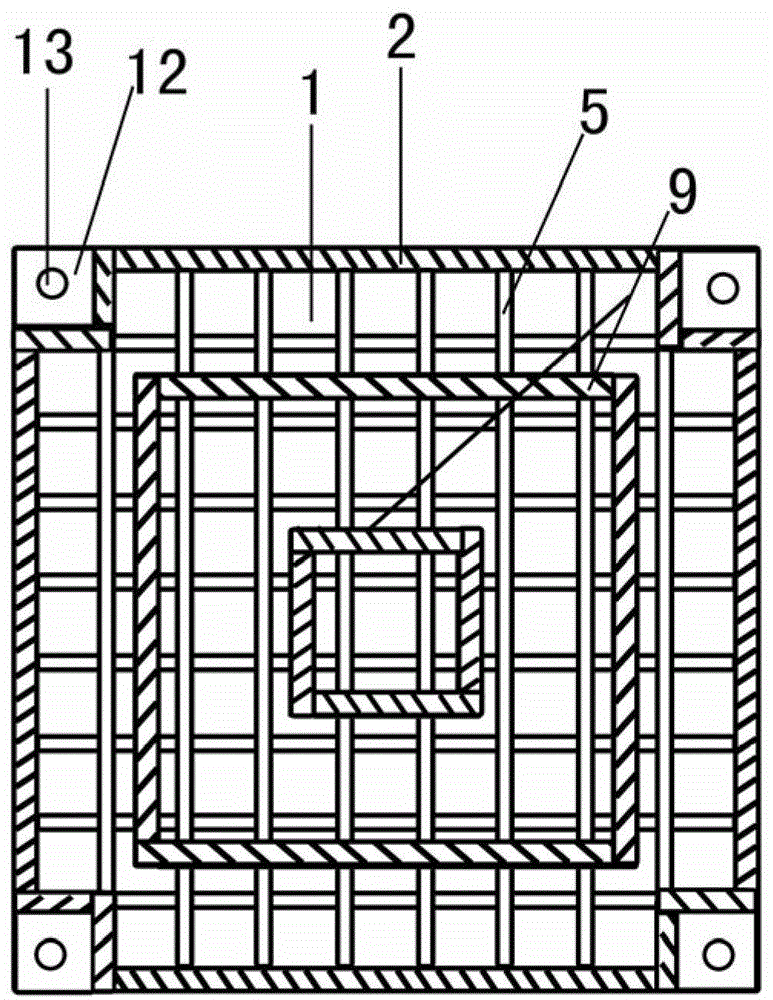

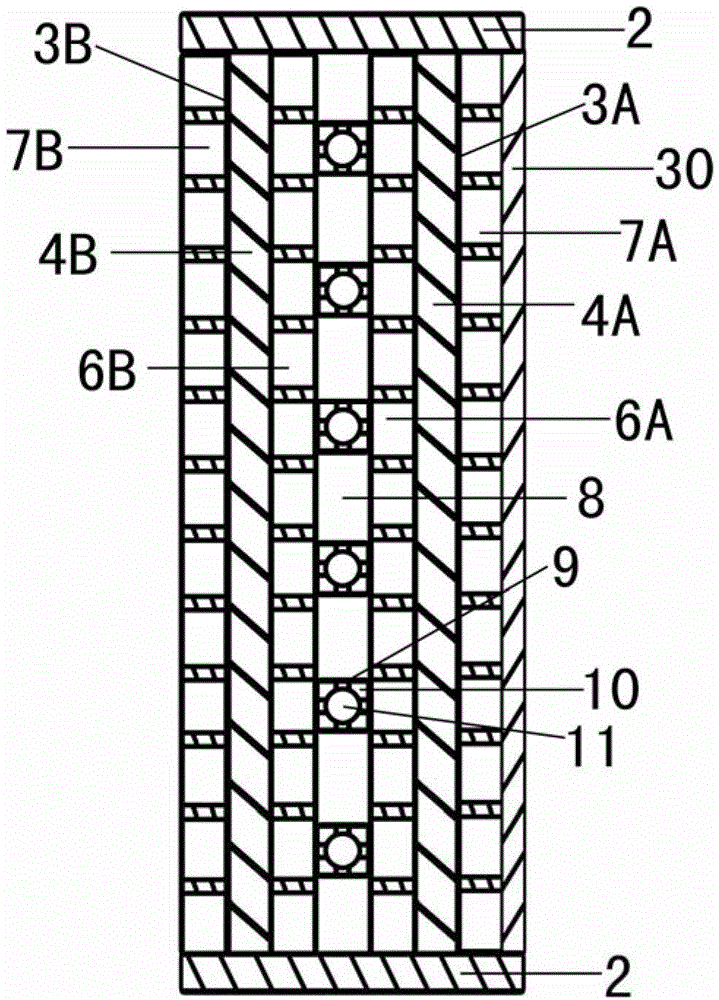

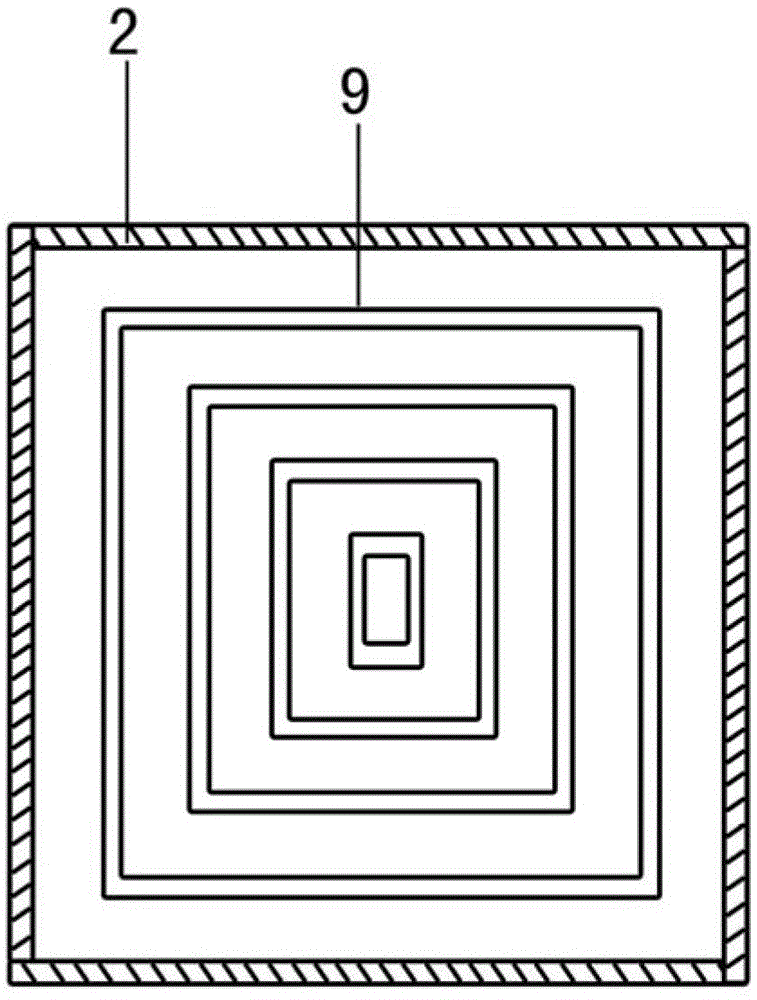

[0040] as attached figure 1 , 2 Shown in and 10: the vacuum insulation module in the figure, comprises the front 3A of module 1, back 3B, side wall 2 and cavity 8, and pad frame 9, wherein, described front 3A and back 3B comprise skeleton 6A and 6B, sealing layers 4A and 4B and extracavity skeletons 7A and 7B, the front 3A and back 3B are respectively connected to the side wall 2 as a whole, the skeleton is a netted grid support skeleton, the intracavity skeleton 6A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com