Building nonbearing wall body and forming method thereof

A molding method and non-load-bearing technology, which can be used in buildings, building components, building materials, etc., can solve the problems of poor thermal insulation effect and sound insulation effect of non-load-bearing walls, increase the scope of use and practicability, and improve sound insulation and heat insulation. Performance and surface mechanical properties, the effect of improving the effect of sound insulation and thermal insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

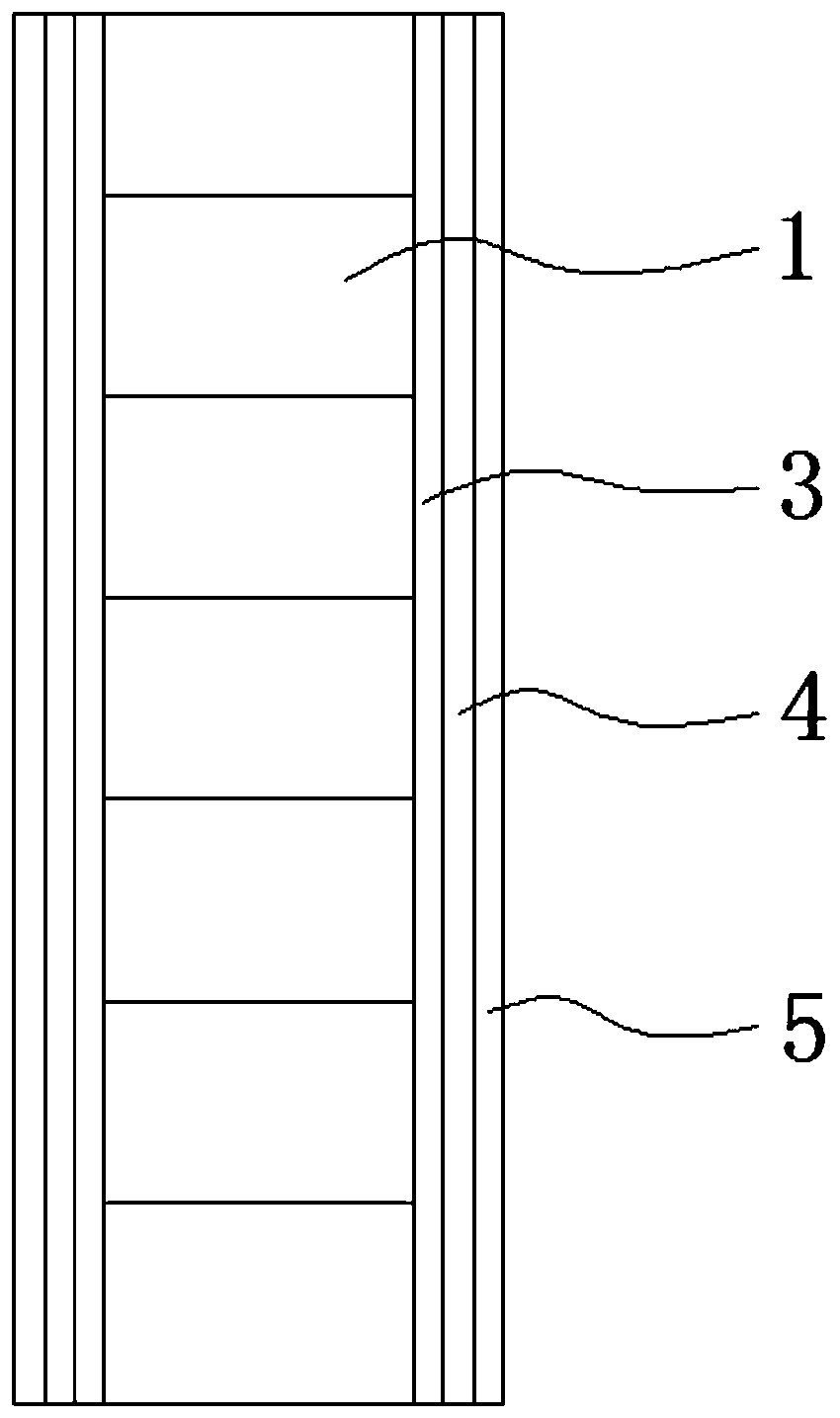

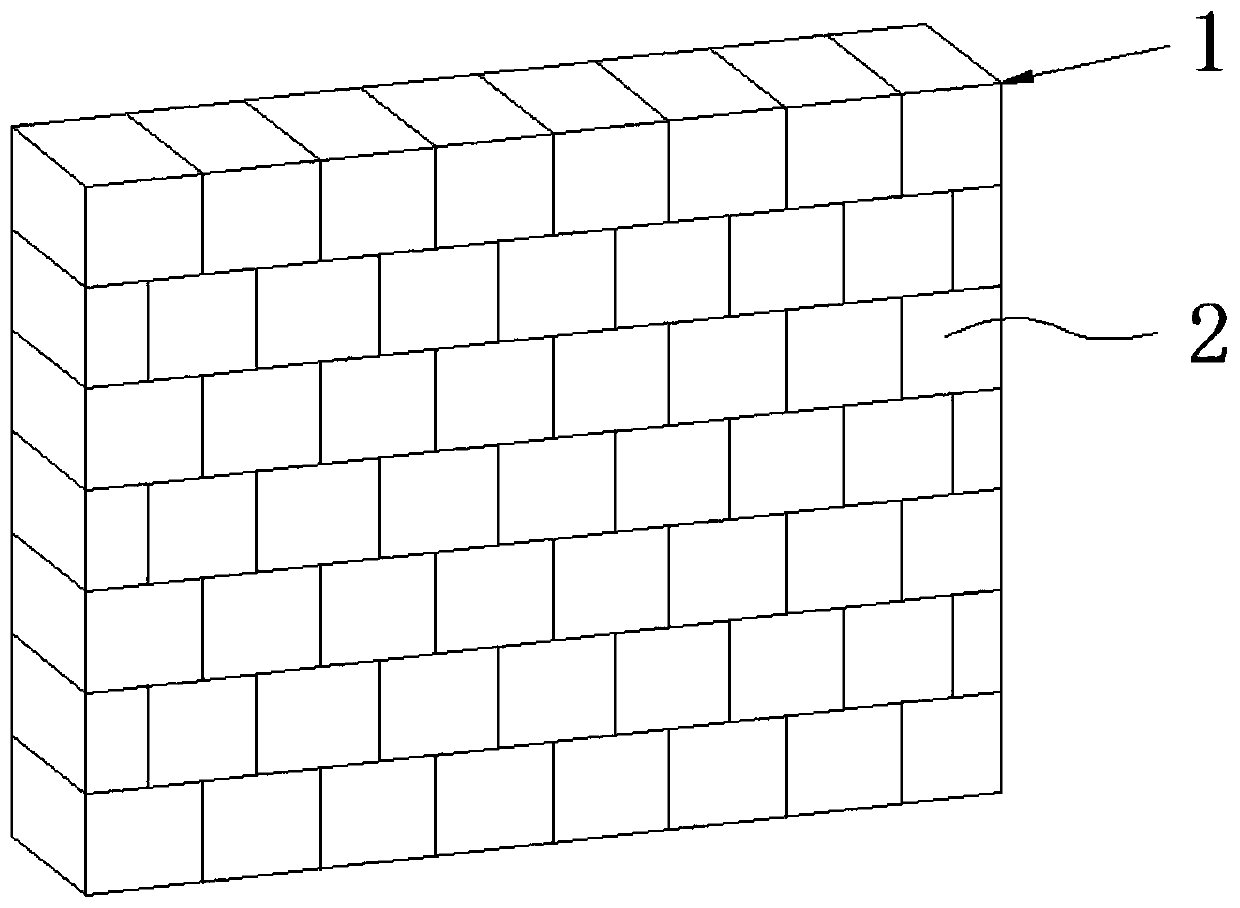

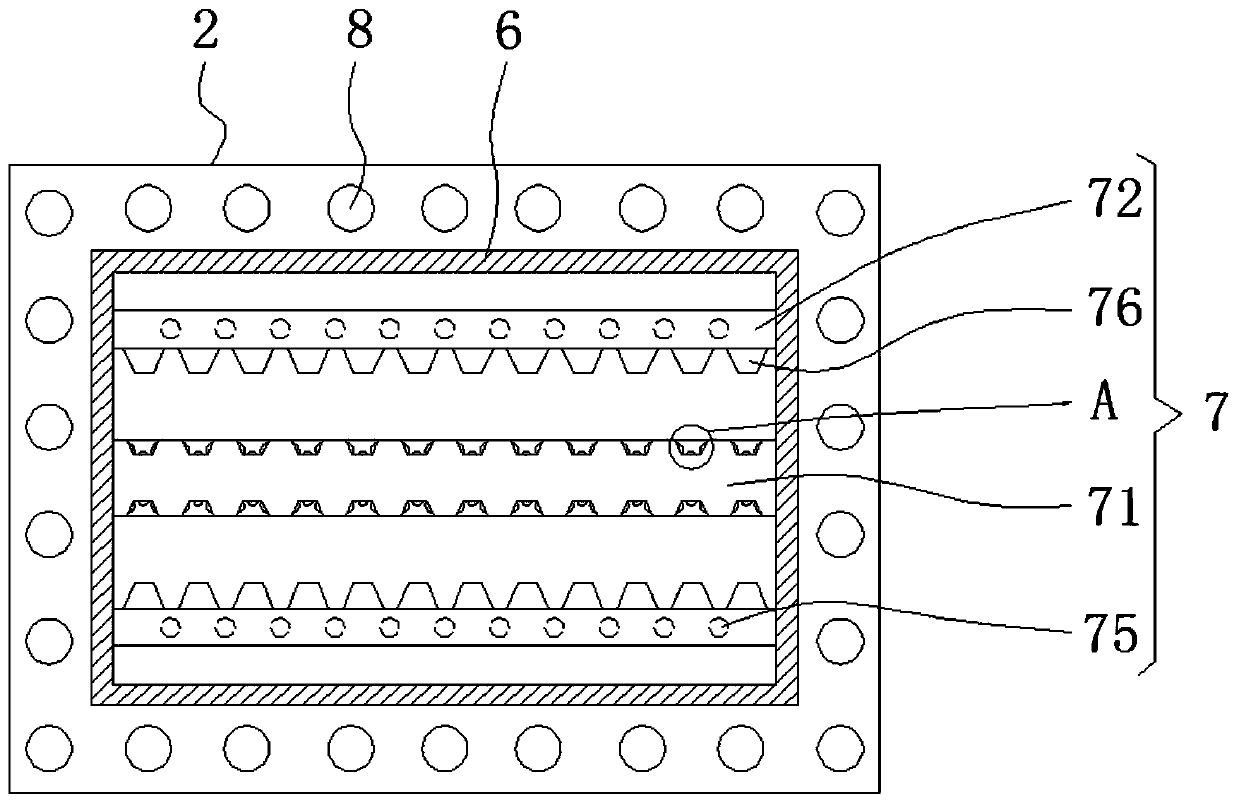

[0059] Please refer to figure 1 , figure 2 , image 3 and Figure 4 ,in, figure 1 A structural schematic diagram of a preferred embodiment of the building non-load-bearing wall body provided by the present invention; figure 2 for figure 1 Schematic diagram of the structure of the wall shown; image 3 for figure 2 The schematic diagram of the structure of the adobe shown; Figure 4 for image 3 A partial enlarged view of A is shown. Architectural non-load bearing walls include:

[0060] Wall body 1, described wall body 1 is built by brick adobe 2 and mortar;

[0061] Two insulation layers 3, the two insulation layers 3 are arranged on both sides of the wall 1 through mortar;

[0062] Two sound-insulating layers 4, the two sound-insulating layers 4 are arranged on the sides of the two heat-insulating layers 3 separated by mortar;

[0063] Two anti-corrosion layers 5, the two anti-corrosion layers 5 are arranged on the side away from the two sound-insulating layers...

no. 2 example

[0109] Please refer to Figure 6 , based on the non-load-bearing building wall and its forming method provided in the first embodiment of the present application, the second embodiment of the present application proposes another non-bearing building wall and its forming method. The second embodiment is only a preferred mode of the first embodiment, and the implementation of the second embodiment will not affect the independent implementation of the first embodiment.

[0110] Specifically, the difference between the non-load-bearing building wall and its forming method provided in the second embodiment of the present application is that the non-bearing building wall and its forming method further include the following steps:

[0111] S1. Material selection: Select production raw materials: 30-40 parts of waste building stones, 15-25 parts of clay, 5-15 parts of coal gangue, 2-5 parts of feldspar tailings, 5-10 parts of vitrified microbeads, ceramsite 2-6 parts, 5-7 parts of to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com