Vertical and horizontal efficient energy-saving vacuum controlled atmosphere furnace for continuous production

A vertical-horizontal, atmosphere furnace technology, used in furnaces, muffle furnaces, cooking furnaces, etc., can solve the problems of low equipment space utilization, long cooling time, and inability to continuous production, and improve space utilization and energy utilization. The effect of high efficiency and improved convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

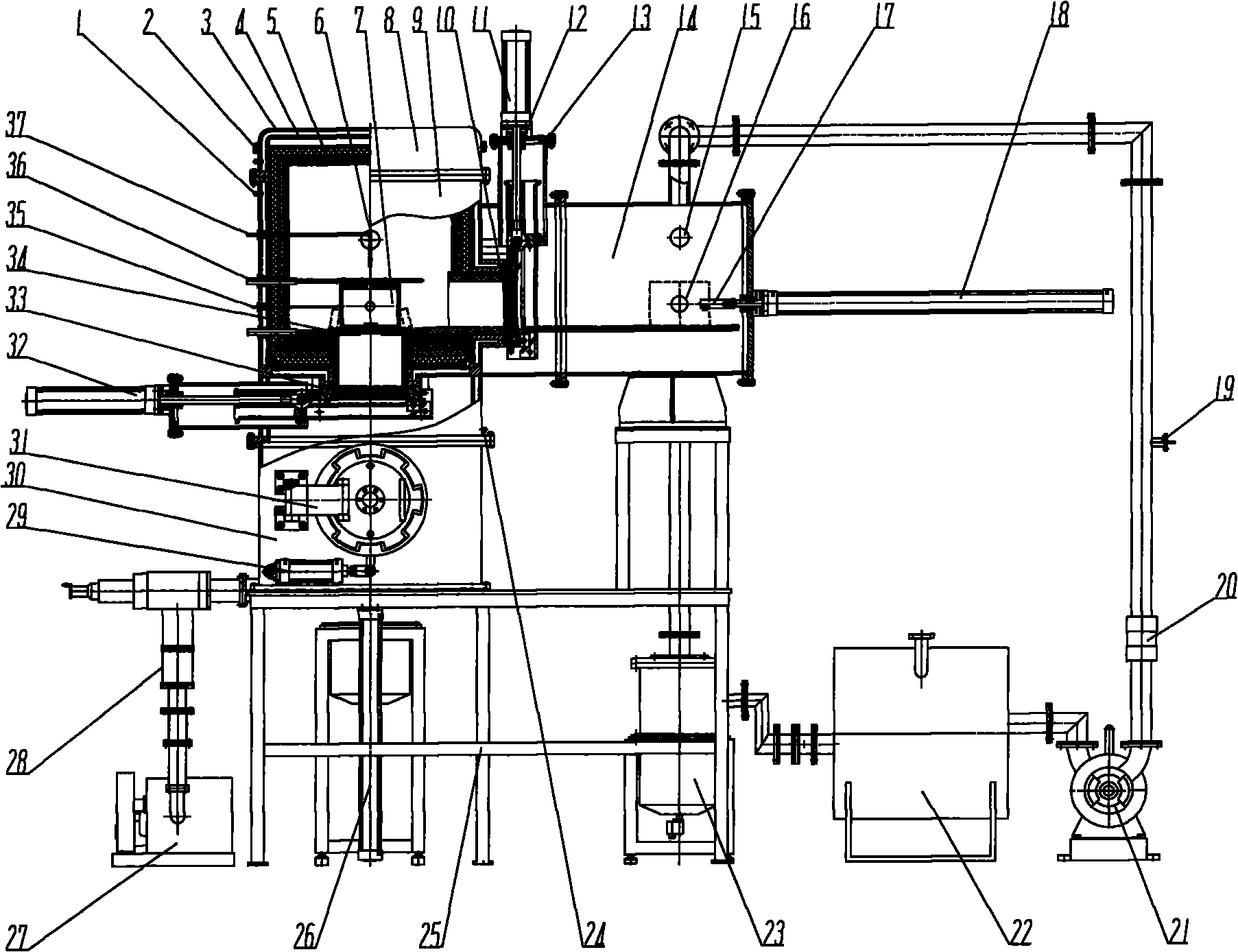

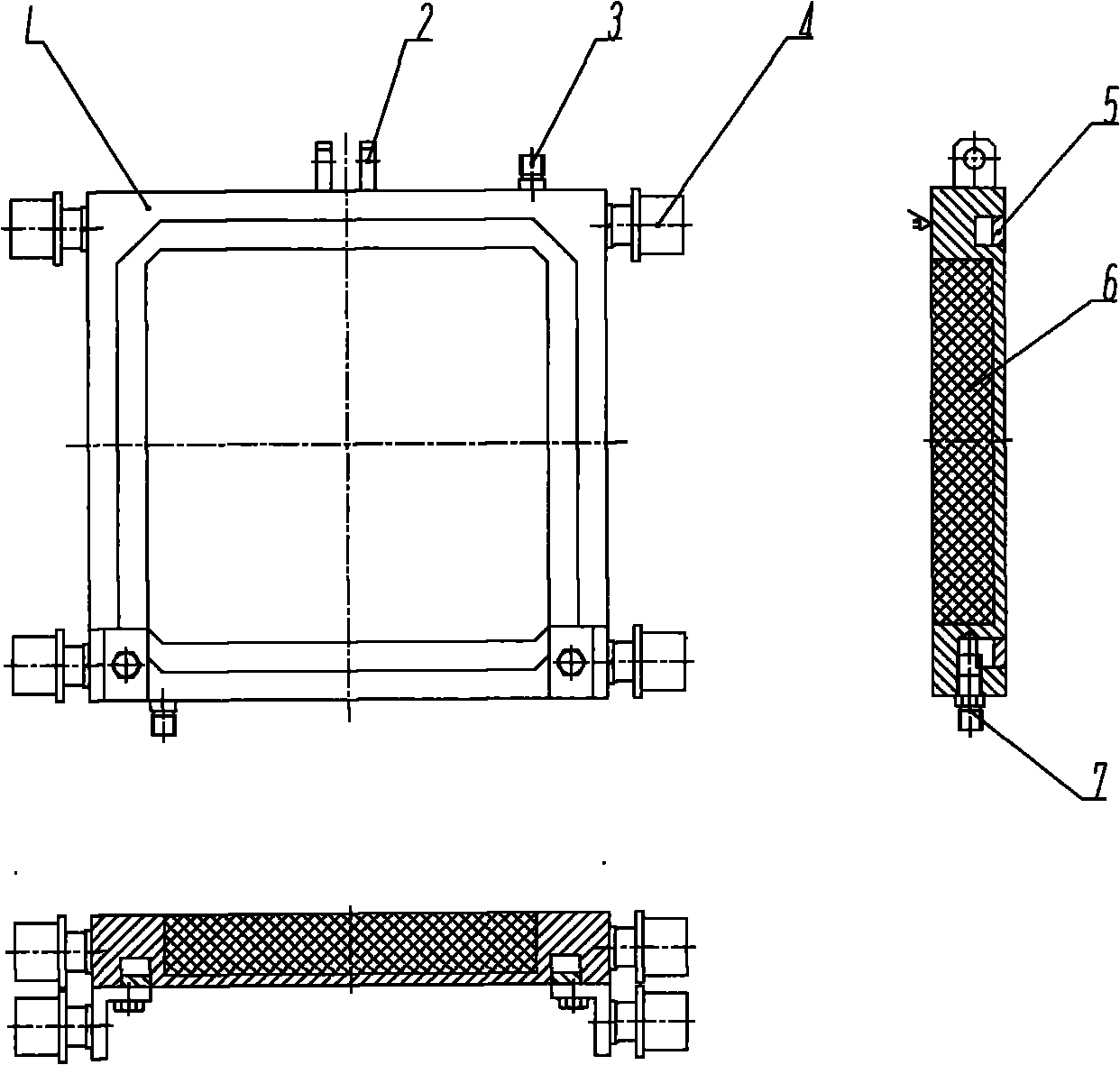

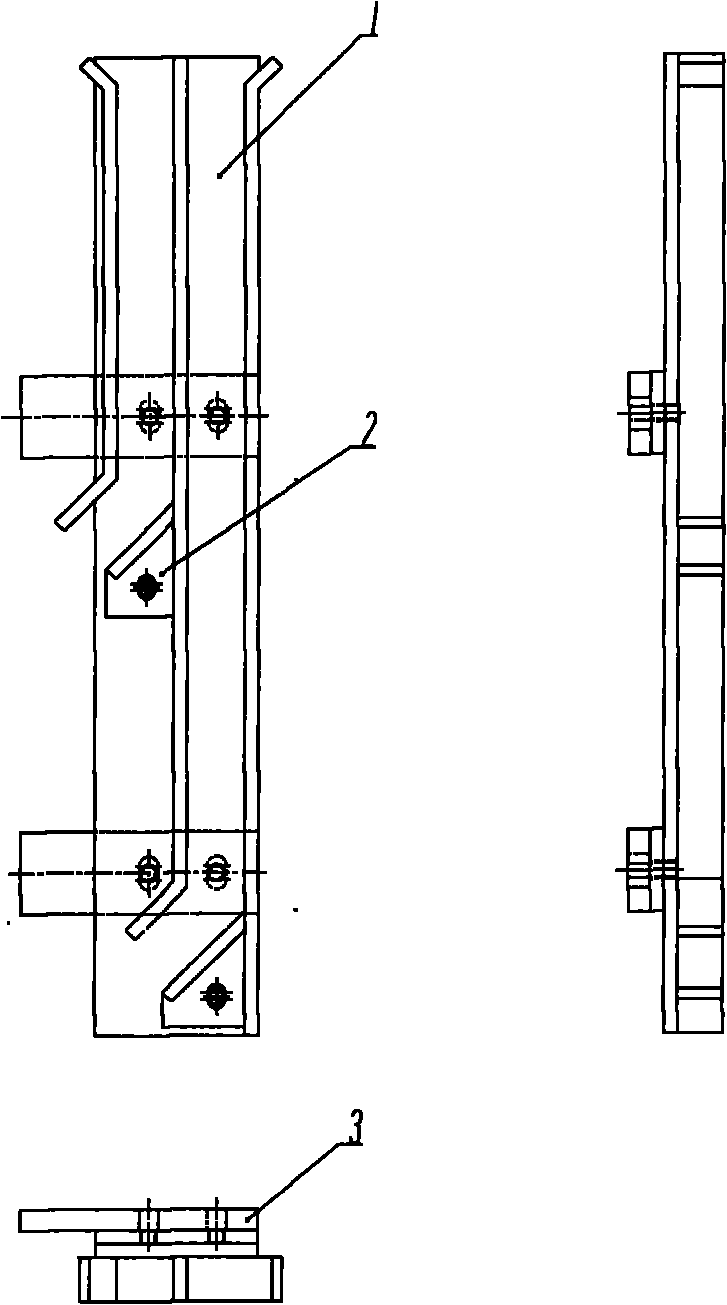

[0027] The present invention will be described in detail below in conjunction with implementation example and accompanying drawing: The vertical and horizontal design in this implementation example is efficient, energy-saving vacuum controllable atmosphere furnace that can be produced continuously, and its structure schematic diagram sees the specification attached figure 1, mainly by water outlet 1, lifting lug 2, outer wall of furnace 3, inner wall of furnace 4, heat insulation layer 5, vacuum pipe 6, 15, carrying box 7, maintenance furnace cover 8, reaction chamber 9, heat preservation sealing door 1 (feeding chamber side) 33, thermal insulation sealing door I gas (hydraulic) pressure cylinder 32, thermal insulation sealing door II (discharging chamber side) 10, thermal insulation sealing door II cylinder 11, oil seal sealing ring 12, "O" type sealing ring 13. Discharge chamber 14, inflatable pipe 16, material pulling rod grab head 17, material pulling cylinder 18, air charg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com